Page 25

4

Analysis of the Current Situation

The previous chapters have described the nature and extent of the aging avionics problem, as well as ongoing efforts to address it. The problem, which significantly affects the readiness of Air Force assets, is manifested most severely in the maintenance and modernization of the current fleet. However, the obsolescence of avionics systems in new aircraft will also have to be managed. New approaches to avionics design, such as MOSA, can mitigate the aging problem in future aircraft, and MOSA precepts can also be incorporated into programs to modify and upgrade legacy avionics systems—especially if the added short-term expense is justified by long-term savings in TOC. However, the path to better management of the aging avionics problem is strewn with many obstacles, of which the technical obstacles may be the easiest to overcome. A comprehensive solution will require that more challenging obstacles, such as fragmented management responsibilities within the Air Force, budget/funding restrictions in aircraft modernization programs, and ensuring the maintenance of a healthy and dynamic industrial base of avionics suppliers, will also have to be addressed.

This chapter presents the committee's analyses of major challenges to solving the problem of aging avionics in the four most important issue areas: Air Force enterprise-management processes; budget/funding management processes; technical issues; and business issues.

GOVERNMENT ENTERPRISE-MANAGEMENT PROCESSES

The coordinated management of the aging avionics problem in a complex organization like the Air Force and a rapidly changing technological environment raises several concerns: fragmented responsibilities in DoD for managing the problem and activities that cut across all of the services; attracting and retaining support personnel for new and upgraded weapon systems; training air crews and support personnel for new systems; and keeping track—and control—of constantly changing avionics configurations in the fleet.

Fragmented Responsibilities

The committee determined that no enterprise (DoD-wide or even Air Force-wide) strategy has been developed for dealing with the aging/obsolescent avionics problem. The committee found little evidence of effective cross-program, cross-platform, or cross-service coordination in the planning, funding, or implementing of actions to maintain the existing fleet or to define/ design maintainable, extensible avionics systems for

Page 26

the future. In fact, the lack of coordinated management is evident even in activities dealing with multiple versions of the same platform.

Evolution of the Air Force Weapon-System Management Structure

Fragmented management is the result of recent reorganizations within the Air Force. The Goldwater Nichols Act of 1986 (P.L. 99-433) required that all Acquisition Category I (ACAT I) programs1 be assigned to program managers who report directly to a program executive officer, who reports in turn directly to the service acquisition executive. ACAT I programs are considered major defense acquisition programs (MDAPs) and generally entail total expenditures of more than $365 million on R&D, testing, and evaluation in FY00 constant dollars or more than $2.19 billion for procurement. Managers of lower cost acquisition programs (ACAT II, III, or IV), including acquisition programs for most avionics systems, report to a product center commander or an air logistics commander, both of whom report to the commander of Air Force Materiel Command (AFMC). Although one way to reduce TOC would be to establish a common avionics system for multiple aircraft, the program manager of an avionics system and the program manager of an MDAP (who controls very large procurement funds) are each concerned about management of their own programs (stove-pipe management) and have different reporting chains of command.

At the same time the Air Force was reorganized to comply with the Goldwater Nichols Act, it was also in the process of combining the Air Force Systems Command and the Air Force Logistics Command into the AFMC. In response to concerns that management of programs for aircraft acquisition and support would become too fragmented, the AFMC created the concept of integrated weapon-system management (IWSM) to coordinate the acquisition and support of all Air Force programs in the AFMC. Although IWSM provides an effective approach to coordinating management for the total life cycle of a single weapon system or aircraft platform, it does not have a mechanism for addressing problems that affect multiple aircraft platforms. The management structure of operational logistics for fleet avionics is similar. Therefore, maintenance is largely reactive to crises. The current management structure does serve the basic purpose of providing integrated management for each weapon system. However, stronger horizontal management authority for issues like aging/obsolescent avionics will require some form of matrix management. Integrated product and process teams or special program offices are examples of management techniques that could be used.

Importance of Avionics Modernization Road Maps

A practical, affordable approach to assessing and managing the problem in terms of a single platform must begin with the preparation of avionics modernization road maps for each platform, emphasizing planned, periodic upgrades. If supported by a concurrent budgeting plan, a series of cost-effective, systematic, periodic (every two to three years) upgrades could then be planned to upgrade system performance incrementally and/or to mitigate future obsolescence problems and ensure a ready, highly capable fleet.

The Air Force is now (and should continue) creating and implementing road maps for each platform (Raggio, 2000). The test of success of these road maps will be how well they are coordinated with the budgeting process—especially out-year commitments. These road maps must become real plans, rather than “wish lists” that never make it above the funding cut line.

Comprehensive road maps for individual platforms can also provide an effective framework for cross-platform and, eventually, cross-service coordination. The road maps could also be used as a basis for total-enterprise planning and management, which could reduce redundant expenditures and improve schedule efficiencies. The sharing of best practices among different weapon-system programs would be an added benefit. In fact, from a process viewpoint, the coordinated management of the activities identified in Chapter 3 of this report could reduce redundancies and increase efficiencies for all current activities addressing the aging avionics issue.

Coordinating MOSAManagement with the Joint Technical Architecture

The platform-to-platform interoperability requirements for new and legacy weapon systems are imposed by the Joint Technical Architecture (JTA) Development Group and the Global Information Grid (GIG).

1 Aircraft platform programs, such as a fighter, bomber, or transport aircraft, are categorized as ACAT I because of their large total acquisition cost.

Page 27

The development of the JTA is implemented under a council managed jointly by the Office of the Assistant Secretary of Defense (Command, Control, Communications and Intelligence (OASD[C3I]), the Office of the Under Secretary of Defense for Acquisition, Technology and Logistics (OUSD[AT&L]), and the Office of the Joint Chiefs of Staff (OJCS). The GIG is managed by the Chief Information Office of DoD, currently headed by ASD (C3I).

However, the JTA Development Group was established to address interplatform interoperability issues. The latest version of the JTA (3.0) designates architectural standards that extend beyond the interoperability domains of weapons systems—imposing standards that apply to intraplatform architectures (DoD, 1999a).This extension went beyond the JTA's initial charter (DoD, 1999b). This leads to the potential for generating inconsistent and/or conflicting approaches to the modular open-system design of avionics systems that is being guided by the Open Systems Joint Task Force (Logan, 2000).

The committee is quite concerned that the 359 mandatory standards being imposed on avionics systems by JTA (along with another 228 standards being evaluated for mandatory designation) could be counter-productive because they could inhibit design innovation and minimize the achievement of MOSA goals. In addition, they would have little or no real effect on platform-to-platform interoperability.

In the committee's opinion, JTA requirements should be limited to interplatform interoperability standards and should not include intraplatform architectures and standards. In addition, tightly coordinated management for DoD architectural standards is necessary, rather than the loosely integrated leadership of JTA, coupled with the somewhat disconnected management of the JTA, GIG, and MOSA.

Need for New, Innovative Contracting Approaches

Current DoD contracting approaches generally do not provide positive incentives to either government contracting offices or defense contractors for reducing product cost to the government. Production programs frequently use firm fixed price contracts, which do put a cost cap on the government's obligation; the contractor benefits from any savings (or pays for overruns), but there is no reduction in cost to the government. Any postcontract change in requirements generally results in as large a bill as the contractor can justify. On subsequent contracts, the government strives to reduce the price based on previous actual costs, and the contractor attempts to justify the highest price traffic will bear. This often leads to adversarial relationships that undermine joint attempts to reduce costs. The recent use of award fees is a step in the right direction, but the most successful approaches are based on positive incentives through shared savings (Ebersole, 2000).

Contracts that involve generous shared savings of any cost to the government would create a “win-win” environment for all participants. With the advent of MOSA, cost reductions will be more likely, and both government and industry will be motivated to seek innovative ways to improve their performance. A mutually agreed upon TOC model can also provide incentives for reductions in TOC.

Management Focal Point

The committee received extensive briefings on the aging avionics problem from the Aeronautical Systems Center headed by Lt. Gen. Robert Raggio of AFMC. With its Affordable Avionics Initiative, the Aeronautical Systems Center has already become a strong focal point in the Air Force for addressing the aging avionics problem. Recently, the Affordable Avionics Initiative was placed under the authority of the newly created Aging Aircraft System Program Office, which will be led by a general officer and will include all aspects of aging, with an emphasis on aging avionics. This new office could become the starting point for the development of an Air Force-wide enterprise strategy for addressing the aging avionics problem. However, this office will need significantly more funding to halt the upward spiral of avionics support costs.

Each service has its own management processes for making budgetary decisions and overseeing programs. In the past, the Air Force used Quarterly Acquisition Program Reviews (QAPRs) to evaluate the potential of modular open avionics designs to reduce avionics TOC. The committee believes the Air Force should continue to use QAPRs as a tool for periodic top-level Air Force oversight and management of the problem of aging avionics.

Education and Retention of Qualified Personnel

As advances in computer technology have been incorporated into modern avionics systems, the software content in these systems has increased dramatically;

Page 28

thus, more software engineers must be hired and trained to accommodate this trend. Recent studies have shown that the technical competency of maintenance personnel is eroding, particularly in the software technology area, in both the government and the defense industry (NRC, 1997). The maintenance workforce is aging and falling further and further behind the continuing technology surge. Workforce turnover is a related problem, as younger, high-potential personnel are leaving for jobs in nondefense industries where pay scales are higher and perceived opportunities are more abundant.

The committee was in general agreement that this software environment will continue to degrade in the future. The growing disparity between the supply and demand of software engineers, the mismatch between old and new design methodologies faced by an aging workforce, the tug of war between government and industry for skilled personnel, and the increasing complexity of software system, will create an even more serious problem for avionics maintenance in the future.

Education and training of software-proficient system engineers, along with an efficient design environment (e.g., tools and processes) is, and will be, essential. The Air Force should consider ways to identify and share best practices in software design/maintenance and explore ways to consolidate software support activities that will result in a critical mass of technical talent. To attract new technical personnel, the Air Force should expand its hiring incentives to potential employees that could help narrow the gap between government and industry opportunities.

The committee members had different opinions about joint actions by the Air Force and industry to deal with this problem. Much of the debate centered around the degree to which the Air Force should contract out to industry a substantial portion of avionics software maintenance, especially for legacy systems currently supported by in-house (organic) capability. In some cases, only government depots have the detailed data and experienced personnel familiar with legacy equipment, making it difficult for industry to assume maintenance responsibility. However, in industry, personnel are increasingly being used by government depots as on-site workers to compensate for the diminishing in-house capability.

Because most of the major upgrade and new avionics software (in a MOSA environment) will be designed by avionics suppliers and platform prime contractors, both industry and government will have to work together adjusting continually to achieve a balance in the future. Therefore, the committee decided not to offer an all-encompassing recommendation regarding software outsourcing at this time. However, this issue deserves continuing attention.

Training

The effects of aging avionics on the training of Air Force personnel are not currently being measured, managed, or included in aging avionics models. Relevant activities include: training logisticians to develop and execute plans across platforms to solve aging avionics problems; training configuration management specialists to keep track of all changes and their downstream effects; and training mission planners to consider the effects of changes in avionics on sortie rate and mission performance.

The acquisition of systems for all of the active and reserve services is performed by two groups of personnel: (1) program managers and engineers in system program offices (SPOs) for systems under development; (2) item managers at depots for systems in production or operation. For MOSA to be effective for the acquisition of upgraded or new systems, both groups must be trained in defining MOSA requirements, writing subsequent specifications for systems, evaluating bids, and developing and administering contracts.

SPO personnel receive their training at the Defense Systems Management College or the Industrial College of the Armed Forces. Curricula at both institutions should be reviewed to ensure that courses are consistent with MOSA. Depot personnel at the Air Force's three logistics centers (Oklahoma City, Ogden, and Warner Robins) may attend either institution and may receive additional in-house training on special topics. Depot personnel involved in acquiring, developing, defining, or specifying software requirements should receive in-house training in MOSA.

BUDGETARY ISSUES

The AFMC estimates that $250 million to $275 million per year in additional funding will be necessary to address the aging avionics issue (personal communication with Lt. Gen. Robert Raggio, Commander, Aeronautical Systems Center, October 6, 2000). By any measure, this is a large amount of money; however, even with this amount, government constraints on allocations and expenditures could preclude its being spent

Page 29

in the most efficient way. The committee noted four budgetary issues that need attention:

-

Long acquisition and upgrade cycles virtually require that avionics technology-refresh cycles be built into program plans during the engineering, manufacturing, and development phases prior to initial fielding.

-

Budgets are compartmentalized into rigid accounts (“colors of money”), which makes it difficult for managers to address problems as they arise.

-

Many system-capability upgrades could be opportunities to solve avionics obsolescence issues if a combined approach were used. However, certain mandated flight-safety upgrades have little impact on solving the problems caused by high-TOC avionics subsystems.

-

Obtaining front-end funding to reduce TOC is difficult.

Long Acquisition and Upgrade Cycles

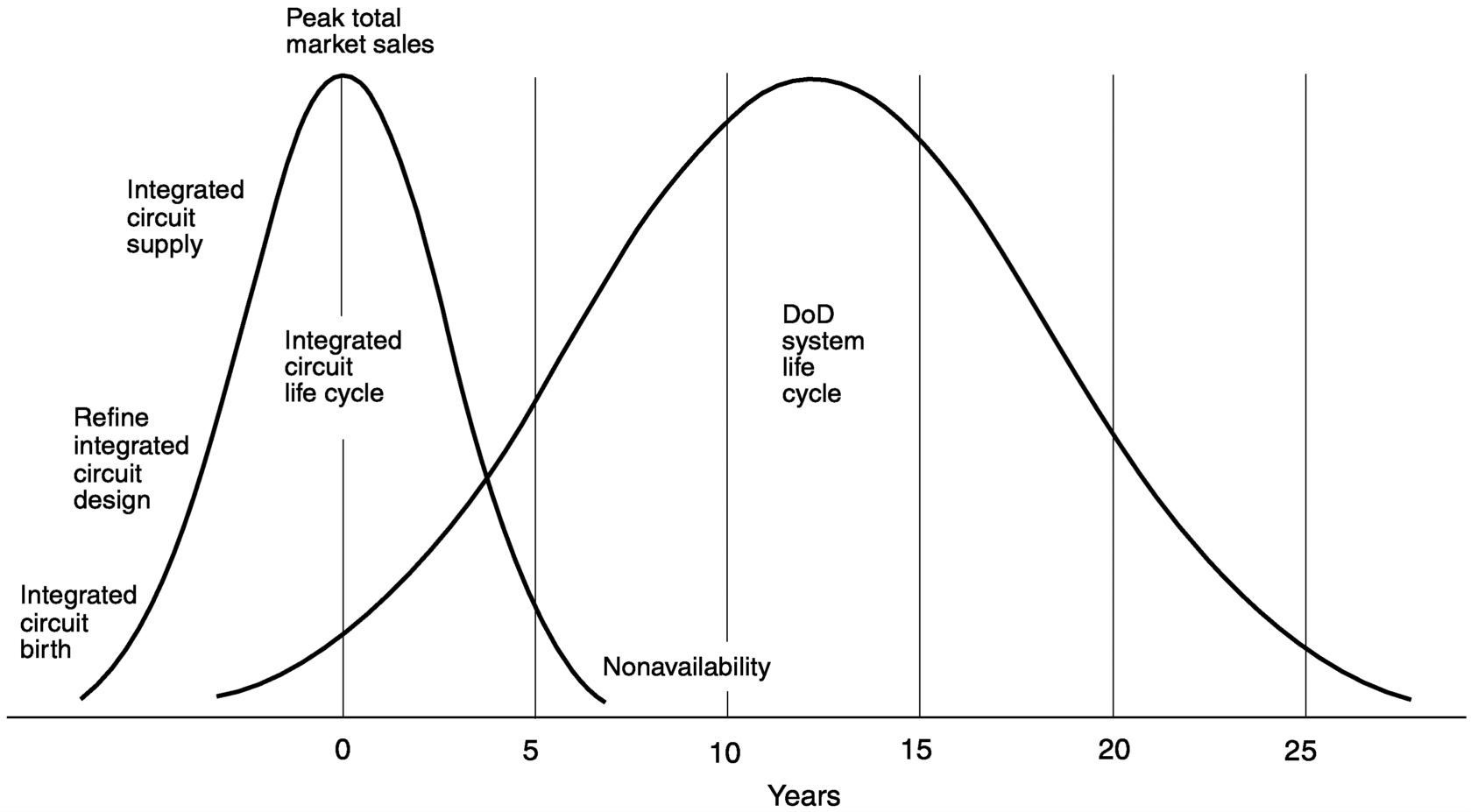

Avionics technology is advancing at a much faster pace than DoD acquisition cycles ( Figure 4-1 ) because avionics product cycles are driven by the commercial market, whereas DoD acquisition cycles are complex and often delayed by funding constraints (DSB, 1999). Perhaps the best example is the F-22, which will have undergone four avionics technology-refresh cycles before the first production airplane rolls off the line. Another example is the F-15 APG-63 radar modification. The contract was awarded in FY97, and the first unit was delivered in FY99. Because of funding constraints, production will cease in FY04 and FY05 and resume in FY06 (Donatelli, 2000). As a result, unless funds are reprogrammed in future budgets, the modification will not be fully installed until FY09. Unless the manufacturer is funded to procure all parts during the initial years of production, the interval of 11 years from first to final installation almost guarantees that the parts will be obsolete in future years. Unfortunately, MOSA was not incorporated into this redesign, so the cost of changes will be higher than they might have been.

In areas like avionics in which technologies are evolving rapidly, it makes little sense for design and implementation cycles to stretch out for many years. New designs or retrofitting modifications must be planned and implemented when relevant technologies are available. Therefore, at all levels of the system, parts/functional updates must be planned that minimize impacts on the unchanged hardware/software. In most cases, the window of availability is about five years, or at most ten years. To complete avionics modification

~ enlarge ~

FIGURE 4-1 Life-cycle mismatch. Source: Wasson, 2000.

Page 30

programs within this time window, DoD will have to change the current planning and implementation cycle in several ways.

In Directive 5000.1, DoD defined principles for acquisition reform to reduce cycle times (DoD, 2000b). These “evolutionary acquisition” principles are based on a recognition that firm requirements for the entire life cycle of a weapon system cannot be specified realistically from the beginning; instead, the requirements must be developed interactively, based on the experience of warfighters using the system. Under this doctrine, delivery of the first unit would not be delayed until all mission requirements were met; the first unit would be a functional, but basic, system that would be upgraded at regular intervals through “block upgrades” of hardware and software until all requirements were satisfied. Each block upgrade would provide an opportunity to capture the most up-to-date technology. Periodic upgrades, which would be specified in evolving platform road maps, could be an effective strategy for addressing the aging avionics problem, especially if it were combined with MOSA architectures that emphasize ease of change.

Colors of Money

To ensure that appropriated funds are used for their intended purpose, Congress has placed a number of legal restrictions on funds available to address the aging avionics problem:

-

Project requirements of a specific fiscal year must be funded only with appropriations enacted for obligation in that fiscal year.

-

The purpose of the expenditure must be authorized in the appropriation.

-

Amounts appropriated for general or specific purposes may not be exceeded even if changing priorities dictate otherwise.

The major budget categories associated with aging avionics are: research, development, testing, and evaluation (RDT&E, designated as 3600 funds); procurement (designated 3010, 3011, 3020, or 3080 funds); and O&M (designated 3400 funds). Although in practice the lines between these categories are somewhat blurred, managers cannot use funds appropriated in one account to solve a problem associated with another account. For example, even though funds may be available to procure an avionics system in a given year, they cannot be used to solve a lingering RDT&E problem with that system. Commercial corporations make such decisions on a routine basis for the benefit of the enterprise, but DoD program managers are denied this flexibility. As a result, program managers spend a great deal of time trying to manage these “color of money” issues. In some cases (e.g., the fiscally constrained F-15 program), the amount of money in the various budget categories actually determines what can be done toward meeting avionics requirements, rather than the reverse (Durante, 2000).

In each budget category, there are many competing demands, some of which take priority over reducing the TOC of avionics systems. For example, many of the avionics modifications that are funded, such as the installation of TCAS and the reduced vertical separation minimum (RVSM), are capability improvements required by the Federal Aviation Administration (FAA) for all aircraft that fly in the new global air traffic control system. Few of these modifications will affect avionics with high TOCs. The Air Force needs a systematic funding that addresses both aging avionics components and capability improvements.

All of the funds available for avionics modernization combined still leave a shortfall that will continue to increase unless the budget is increased to provide funds to support the flying-hour program and to meet the following needs:

-

safety-mandated avionics upgrades

-

avionics upgrades necessary to fly in the air traffic control system

-

replacements of high-TOC avionics with new avionics, with the goal of achieving economic, consistent solutions throughout the fleet

-

periodic, systematic upgrades that address the issues of performance and obsolescence

Front-End Funding

From the point of view of a program manager concerned with allocating the current year's budget, the least expensive approach to fixing an avionics problem is a customized, point solution for that problem. The likelihood that this short-term solution will be difficult to maintain or upgrade and will, therefore, cost more over the life of the aircraft is not an immediate concern. A more comprehensive solution, such as the

Page 31

application of MOSA to replace obsolete hardware and software, generally requires more expensive redesigning and requalification. In many instances, this solution will cost more in the short run but will reduce TOC in the long run. Unfortunately, in the current budget environment, it is difficult for the program manager to justify spending money now to save money later, especially when savings may occur in a different budget category.

Since 1995, the Air Force has kept track of high-TOC avionics components in its AFTOC database (U.S. Air Force, 2000a), and since 1998 a small amount of funding has been made available for the front-end funding of projects designed to reduce TOC. The committee supports these efforts, but additional funding should be made available to support well documented opportunities to reduce avionics TOC. Revolving funds, such as the Working Capital Fund, to which all of the services contribute, may provide a possible mechanism for providing these funds.

Funding for initiatives to solve the issues related to DMS and to reduce TOC will remain a challenge for all of the services. The best solution would be to budget for and fund modernization modifications that incorporate modular open-systems architectures. This would not only solve immediate DMS problems but would also reduce the cost of solving future DMS problems.

The second-best solution would be for each service to create a budget line item that would be funded each year and used to solve DMS problems as they are identified. This line item would also fund other TOC cost-reduction initiatives. A rigorous cost analysis comparing the TOC for continued system operation with and without the change or initiative would have to be done to determine the comparative cost/benefit of competing proposals or initiatives.

The next best way to ensure that funds are available for solving DMS issues would be to use a revolving fund, such as the Working Capital Fund. However, the SPO director, the Air Logistics Command supply-chain manager for the commodity group, and the Major Command would all have to agree on the need for funding and for the surcharge increase the weapon system would incur by using the Working Capital Fund. The Air Force has already established a parts-obsolescence funding line as part of the Working Capital Fund overhead. However, this line item, which was only established in FY00, is relatively small.

TECHNICAL ISSUES

The concept of MOSA for avionics design has evolved in DoD and industry over the past several years. Generally patterned after the architecture of modern commercial information systems, the purpose of MOSA is to provide scalable, extendable, modular avionics systems that can be upgraded affordably by the replacement of modules.

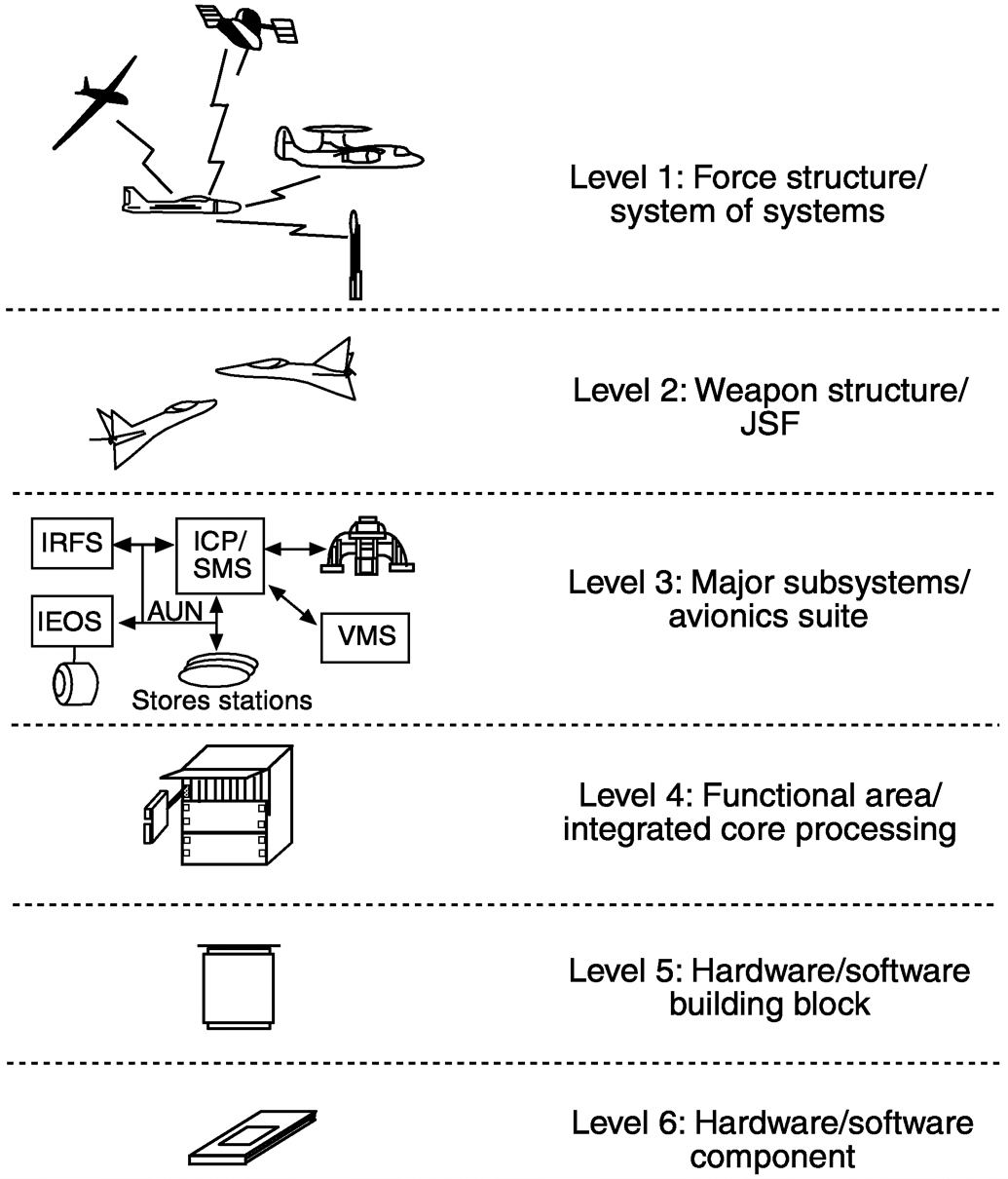

Figure 4-2 shows the hierarchical structure associated with the Joint Strike Fighter; levels three through six represent the avionics suite. Various levels of modules, or building blocks, are shown in a hierarchy, with defined functional/electrical/physical interfaces at the horizontal and vertical “flanges” where these units interconnect.

Military avionics systems have had traditionally “federated” structures: that is, assemblages of largely independent, single-function subsystems (“black boxes”) that collectively met the overall performance requirements. Internal interfaces in a subsystem were owned and controlled by the designer/supplier (a

~ enlarge ~

FIGURE 4-2 JSF architectural hierarchy. Source: Logan, 2000.

Page 32

“closed” system); external interfaces (e.g., communication interfaces) were specified by the government.

As avionics have become more digitized, and as affordable computing power has increased, the trend has been to develop integrated avionics systems. In these systems, more functionality is embodied in software that could be integrated into one or more general-purpose processors. Hardware and software from multiple suppliers operate in an integrated environment. Thus, many internal interfaces have to be shared by the suppliers (less “closed” more “open”). A modular approach to the architecture would simplify the definition and control of these interfaces, leading DoD and industry to define and develop a MOSA environment for avionics system design.

Modular systems are commonly defined in terms of the portability of applications software and the implementation of widely supported standards for key system interfaces. In avionics architectures, technology independence is important, but modular partitioning is even more important. The primary goal is for systems to be affordable, as well as easily upgradable, expandable, and scalable.

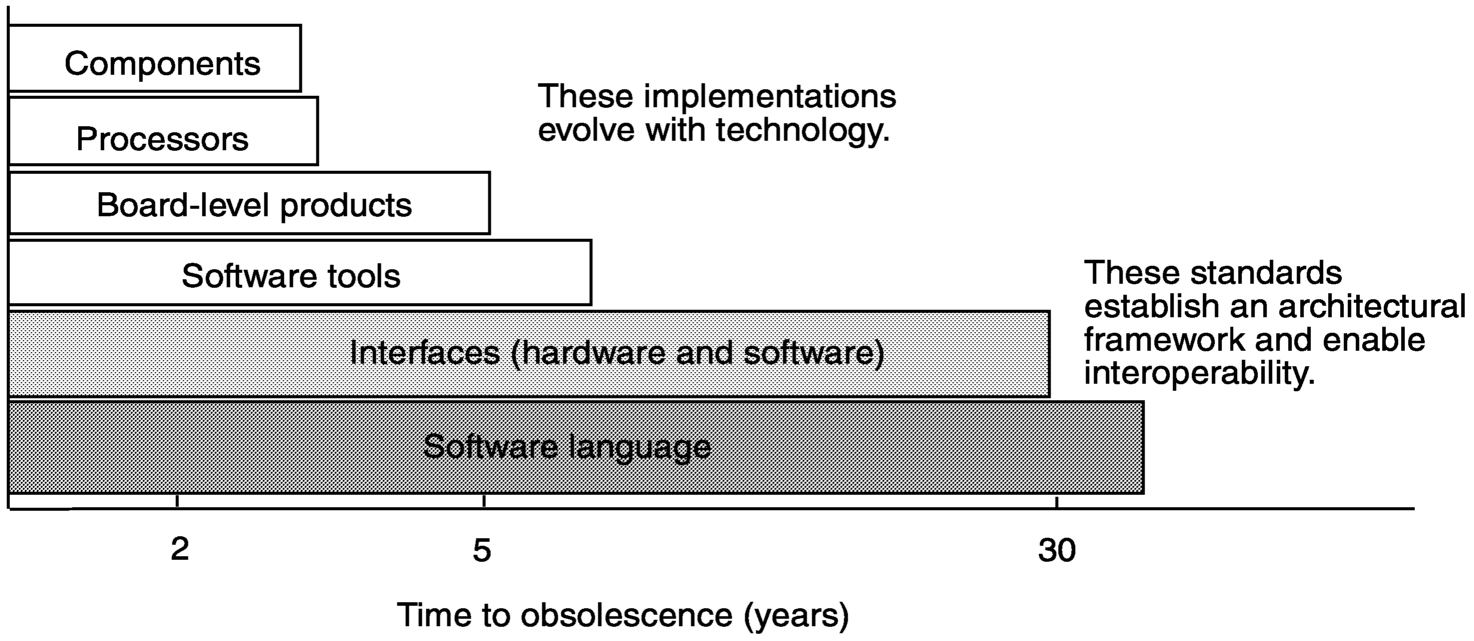

Common Understanding of MOSA

To meet evolving military requirements for better sensors, countering an increasing variety of threats, and increasing mission capability, future avionics systems will have to be flexible and easy to modify and upgrade. The Air Force has endorsed a MOSA approach as a strategy for managing the problem of avionics obsolescence in both new systems and legacy aircraft systems. Office of the Under Secretary of Defense for Acquisition, Technology and Logistics has chartered the Open Systems Joint Task Force to coordinate and motivate DoD MOSA activities and to solicit inputs from industry. The task force has characterized an open system as “a design based on nonproprietary interface standards broadly accepted and used throughout industry” (Logan, 2000). The architectural framework adopted by the task force is shown in Figure 4-3 .

A more definitive characterization of an “open system” is described in Architectures for Next Generation Military Avionics Systems (Borky et al., 1998). Open systems are also generally modular, but with additional attributes. A modular system has the following attributes:

-

The system is designed to maintain external hardware/software interface compatibility of a module independent of changes made internal to the module.

-

Both hardware and software (physical and functional/logical) aspects of architectural interfaces are included in the system.

-

The system can be scaled in capability by incrementally adding or deleting modules of functionality.

~ enlarge ~

FIGURE 4-3 Architectural framework adopted by the Open System Joint Task Force. Source: Logan, 2000.

Page 33

The system can be maintained or upgraded by selective replacement of elements without impacting other elements.

The system can reuse existing elements and provide reusable elements to other systems.

An open system has the following attributes:

-

All of the attributes of a modular system are also included in an open system.

-

The system can be integrated from elements supplied by multiple sources.

-

Choice/application of standards represent a design decision that follows open system partitioning and functional interface definition.

Subsequent to modular/open architecture definition, the requirements for interoperability, communications protocols, data formats, and logical functionality can lead to the definition and selection of proper open standards.

The committee generally agrees that a transition to MOSA for avionics system designs would significantly improve the aging/obsolescence/upgrade environment. However, perceptions of MOSA vary considerably throughout DoD and industry, especially concerning the definition of “open.” Definitions range from truly open architectures with standard and/or publicly available interfaces at most hardware and software levels of the structure to architectures with proprietary (“locally open”) interfaces at the modular (line-replacement unit/ building block) level and open interfaces at the higher functional, subsystem, and intersystem levels.

Although the words “modular” and “open” are almost always used together—as in the acronym MOSA—the committee wishes to stress that they are, in fact, separate concepts. Although open systems would in principle provide great benefits to the Air Force, the associated business complications could make their wide-scale application problematic. Purely “modular” but “closed” or only partially open systems (i.e., systems available from only one vendor) in most cases can provide most of the benefits of MOSA without the complications and thus may be more easily applied in a variety of situations.

Complicating the issue is that—for various reasons (e.g., technology, cost, size/weight, legacy systems)— avionics architectures will continue to be a mix of federated systems (“black box” functionality) and integrated systems (common processing and/or sensors for multiple functions) for the foreseeable future. The degree of hardware/software independence/decoupling will vary, and the disciplines for defining subsystems, modules, and components will also vary. In all likelihood, the perception of openness will continue to be fuzzy. Therefore, the degree of openness will necessarily vary from system to system, and the emphasis on mitigating the problems of aging/obsolescent avionics and planned avionics upgrades should be on the modular (rather than the open) aspect of avionics architectures.

The modular approach should be extended to include nondigital functions, such as sensors, communication, and navigation systems which often dominate the cost of an avionics system. Openness should be required at the intersystem level to ensure interoperability and should be specified at interfunctional communications interfaces for which standard protocols provide the best technical and cost approach.

Although the MOSA concept will generally be used in designing new avionics systems, it can also be applied to the modernization of older, legacy systems. Obsolete and/or underperforming subsystems can and should (where practical and affordable) be replaced with newer, modularly structured subsystems. In addition to meeting current needs, MOSA, especially when compounded or repeated, could reduce the cost, time, and complexity of upgrades. Considering the long life cycle of a platform, and the short life cycle of avionics/ electronics, future savings could be significant.

MOSA Design Tools

The committee found a critical need for further development and ensured availability of MOSA design tools that will support the disciplined design process for implementing avionics system architectures. These design tools include modeling and simulation tools and selected, high-level design languages (hardware and software) with related compilers.

A crucial enabler for the design and implementation of MOSA-driven avionics architectures is a set of “building codes” that govern system interfaces, module/functional definition processes, software languages, interconnect characteristics, and other global system parameters. Rigorous definition of modules, preferably through executable simulation objects, will be particularly important. The concept of building codes is known in software engineering as the use of “architectural patterns,” which originate from the architectural domain (Alexander, 1977). A pattern is

Page 34

defined as an abstraction from a concrete form that can recur in a specific context. A pattern constitutes a template for problem-solving documentation, that describes the proven solution in a given context or problem. Rigorous definitions of modules representing established solutions to specific tasks necessary. To ensure the safety and reliability of avionics systems, formal verification methods and executable models will have to be used. According to a white paper, Architectures for Next Generation Military Avionics Systems (Borky et al., 1998):

Object oriented design has emerged as the current leading methodology for managing complexity and ensuring correctness in system development. It seeks to improve on traditional approaches to functional decomposition and structured design through, among other things, better encapsulation of functionality, strict definition of interactions among entities, and traceability of requirements up and down a system hierarchy. This may well prove to be a powerful technique for achieving the open system characteristics needed in next-generation avionics suites.

The standards profile of a system emerges from the system-engineering process based on the most effective implementation at a given point in time. An evolving (but limited) set of standard interfaces could be considered for the development of new avionics systems to ensure the interoperability of subtier suppliers' equipment. Examples include commercial standards (e.g., ARINC, etc.) that enable dual-use applications. For fully integrated applications, commercial hardware and software standards should be considered to ensure interoperability among system components.

The Air Force and other services must recognize that developing a new modular design for a single platform will be costly. However, if a modular approach were adopted for several platforms, the savings could be significant. The modular approach would also provide design flexibility for addressing unique platform requirements through a common software language. To maximize the savings, the whole spectrum of tools including design tools, system enablers, building codes, and system modeling and simulation, could be addressed jointly by DoD and industry. The Air Force has already taken a step in this direction by working with the SEI (see Appendix A ) on a system design and a maturity model of system engineering capability.

Database for the Reuse of Designs

An integral part of the MOSA design strategy will be providing easy access to reusable design fragments, including examples from which pieces can be extracted and examples of applied interface standards illustrating how they can be applied to solve difficult problems (especially the incorporation of advanced technology that might easily be considered incompatible or in conflict with the standards).

Reuse libraries should be indexed/accessible so a competent user can easily find relevant cases. Whether organized by case-based reasoning or some other method, they must engage a user in a dialogue that results in valuable suggestions that can be applied to real designs. Rather than a universal database accessible to all, reuse libraries should be developed by industry and should remain in their domain.

Configuration Management

Addressing DMS/OP and modernizing avionics systems in an era of constrained budgets raises a serious problem of configuration management. Because of reduced production buys and cyclical updates, aircraft fleets are not all in the same configuration. Program extensions often cause the same problem, especially at the component level where parts can become obsolete even before the retrofitting is complete.

Currently, the Air Force has no institutionalized configuration-management processes, tools, or requirements. In fact, configuration management is not even integrated with logistics, maintenance, training, testing, and operations processes. This issue will have to be addressed by a top-down management approach.

Streamlining Requalification/Recertification Testing

When avionics systems are modified or old components are replaced with new ones, the new system must be tested to prove its functional compatibility with existing hardware/software, to demonstrate the new performance, and to ensure flight safety. Testing represents an increasing percentage of costs for both DMS fixes and for system upgrades (e.g., certification testing has traditionally represented nearly 40 percent of software development costs). The lack of a practical, efficient (in time and cost) strategy for requalification and recertification testing of avionics systems and subsystems subsequent to modifications and/or upgrades is a major problem. The proper application of MOSA allows confinement of both failures and changes,

Page 35

forming the basis for the need for expensive, time-consuming regression testing after modifications or upgrades. The impact on TOC could be significant.

With advances in modern design tools, however, an affordable solution may be in sight. These tools provide high-fidelity emulation of detailed circuit operation, and, with some additional effort, could be formulated as stand-alone digital models of the product. Combined with the disciplined interface definitions inherent in MOSA, these models have the potential to streamline the verification and validation process. The committee suggests that avionics suppliers be encouraged to construct high-fidelity surrogates for expensive hardware to facilitate system-level testing by including this as a source-selection criterion.

An analogous recertification problem is currently being addressed jointly by the FAA and suppliers of commercial avionics systems, with the emphasis on the reuse and multiple application of software modules. A procedure is being established to give “credit” for full or partial compliance with certification requirements for software components that were originally certified for one application and are targeted for use in a new application. Under the rating/credit arrangement, total-system testing can take “credit” for tests on the reused module, which can concentrate on end-to-end performance requirements and operational safety assessments (FAA, 2000).

The commercial sector has also developed modeling, simulation, and diagnostic tools to ensure the integrity of certification processes and significantly improve the efficiency and shorten the cycle time of avionics testing. The processes established by the FAA and the commercial avionics industry could be used, at least in part, as a model for the Air Force's strategy for requalification testing.

BUSINESS ISSUES

The problem of DMS/OP for avionics maintenance is partly the result of the rapid development of commercial markets for suppliers as new commercial technologies emerged; at the same time, the small defense market dwindled. Inventories of defense-unique parts were naturally depleted, and small orders became unduly expensive as production lines were configured for new markets. Low-volume redesigns of the parts presented huge economic penalties. Thus, both DoD and suppliers were in a losing situation. To cope with this situation today, the Air Force and industry have adopted brute force methods, such as parts substitutions, platform cannibalization, and technology upgrades, as demand requires. Almost everything is done in an unplanned, uncoordinated, reactive way in a budget-constrained environment.

Faced with a somewhat similar situation, the commercial airline industry has resolved the problem through a straightforward analysis of return on investment. When the unreliability of an aircraft or the cost of spares and repairs become unacceptable, and if an alternate solution can be found, the airlines upgrade their avionics components and systems. The future savings are used to justify the cost. In the commercial environment, the supplier is responsible for a significant share of avionics support by providing spare parts throughout most of the service life of the aircraft. In most instances, the avionics supplier has configuration management control, allowing more flexibility in dealing with parts substitution.

The Air Force does not have a comparable business model and the data necessary to make a return-on-investment analysis are dispersed and fragmented. In addition, industry has no incentive to propose alternative solutions to the Air Force's problems. In fact, niche businesses are thriving on the Air Force's dilemma and are content to continue operating with the status quo.

Concerns of Avionics Suppliers

The problems in the business environment related to avionics upgrades are, for the most part, of the traditional, competitive variety. The problems of instabilities, delays, and budgetary constraints are all too familiar in the government/industry business environment. The problem is more complex, however. Avionics suppliers consider upgrades as opportunities to apply their most current technologies and improve their competitive position. Aircraft platform suppliers (“primes”) consider upgrades a vehicle for filling in business voids caused by the decrease in new platform opportunities. The tug of war between avionics suppliers and primes intensifies as the supplier wants to maintain its avionics product/system base while the prime attempts to become more vertically integrated to supplement its platform base. DoD/Air Force acquisition practices can affect the “balance” because the buyer determines whether the prime or subsystem supplier is responsible for various upgrade programs. As a rule, normal market forces will resolve these issues, but DoD should consider industrial base issues as part of its acquisition process.

Page 36

DoD considers upgrades a logical approach to adding functionality and increasing the effectiveness and reliability of avionics systems. The upgrade process is considered an opportunity for introducing new commercial technologies in the form of COTS products and components. Procurements involving pure COTS technology and processes are straightforward. Problems arise when DoD requires changes/modifications/additions to COTS equipment (“COTS plus”) to meet unique requirements. The costs (in dollars and human resources) for redesign can be significant; in addition, changes to COTs equipment then raise questions about who owns the new intellectual property.

MOSA will create both opportunities and concerns for avionics suppliers and for DoD. In DoD Directive 5000.2-R, MOSA is defined as follows (DoD, 2001):

...a business and engineering strategy to choose specifications and standards adopted by industry standards bodies or de facto standards (set by the market place) for selected systems interfaces (functional and physical), products, practices, and tools.

The committee endorses a strategy that is both engineering based and business based. Various models for avionics procurement are possible with the hierarchical, modular structure of MOSA-based avionics systems. Because of the modular structure, related interfaces will occur at various system levels (e.g., major system, subsystem, functional, line replaceable components of hardware and software). DoD could procure products at any of these levels as avionics systems are upgraded—or even for new systems if architectures are sufficiently predefined (e.g., for the joint tactical radio system). The issue involves choosing the hierarchy level that will support/motivate competition as contrasted with level at which the DoD/service (or prime contractor) might desire to solicit competition. If avionics procurements are mostly at low system-hierarchy levels (e.g., modules) to support incremental upgrades and modernization, the motivation for suppliers of avionics systems and/or avionics “functions” (e.g., flight control, radar, weapons management, etc.) to compete will be relatively low. The high value and competitively leveraging intellectual property (domain knowledge) of these companies is at the system/function level and subsystem level, and they support their R&D investments at these levels. At these higher levels they can also participate in the marketplace with a reasonable return on their investment. New and innovative solutions to avionics needs or requirements are conceived at the system or subsystem level. In the long run, the “system” drives the implementing technologies more than the technologies drive the system. Therefore, the benefit to DoD of competition at the modular level is highly questionable, except perhaps in a few special cases.

The existence of DoD supplier tiers exacerbates the problem. Because fewer military aircraft programs (or major programs in general) are expected in the foreseeable future, airframe suppliers will be motivated to increase their aircraft-maintenance and upgrade business. The tendency of prime contractors to retain more avionics development/manufacturing in house—and the degree of openness of the avionics architecture they propose—will have a major effect on the market (and level of function) available to traditional avionics suppliers and their subtier suppliers. Although government intervention should generally be avoided, these special circumstances dictate that DoD should monitor the developments in the industrial base to maintain at least an awareness of serious potential dislocations.

Intellectual Property

A major business concern that surfaced during this study was the ownership of intellectual property rights in a MOSA environment. The questions of who “owns” the interface standards, who owns the operational or logical information describing and characterizing a replaceable module/object, and who owns the functional avionics architecture embedded in a total system architecture will naturally arise. In most procurements, the real value of the intellectual property rights will usually exceed the “manufacturing cost” associated with a unit. Value-based competition vs. cost-based competition is certainly a related subject, and value-based metrics will be required to support sound business decisions.

Another industry concern is the role of subtier suppliers in a MOSA procurement environment, especially how these suppliers can recover their investments and operate profitably as black-box hardware is replaced by software modules. Business models of these subtier suppliers are normally based on the value of intellectual property and some form of initial payment (the license), coupled with a recurring royalty payment based on use of the property. These models are most pertinent to the intellectual property incorporated in higher volume applications where the costs to develop

Page 37

the intellectual property are high and availability/ scarcity and capability normally determine value (Warshofsky, 1994).

As avionics functionality moves away from the traditional black box, subtier suppliers will be faced with redefining their value stream and splitting their traditional hardware into application-specific hardware and applications software, which could be hosted in their own or another supplier's processing cabinet. If the number of sites or platforms is low, subtier suppliers will have to adjust their models to continue to earn a profit. This will require changing the traditional procurement model to include a fair assessment of the subtier supplier's intellectual property rights and a reasonable revenue stream.

The problem is particularly difficult for pricing software modules or “objects.” Because much of a supplier's proprietary intellectual property is embedded in software, value-based pricing, rather than cost-based pricing, of software will be necessary to support a sound business model. As indicated above, this will require a change in acquisition practices (and the buying “culture”), particularly in a MOSA environment.

Responsibility for Sustainment

The responsibility for sustaining the combat readiness of military aircraft is currently divided between government and contractor facilities. The details of how this responsibility is divided are important to both parties. The government wishes to maintain in-house expertise in certain core technologies considered critical to the national defense and to sustain minimum workload levels at its facilities. However, because contractors rely on the revenue streams from their maintenance activities to support their business model, the division of maintenance responsibility is an important business issue for them.

The Air Force is required to sustain an inventory of approximately 6,000 aircraft to support 195 active air wings. Maintenance is conducted at three levels: (1) the flight line; (2) intermediate maintenance levels (conducted at the air-wing level); and (3) more extended repairs and upgrades (conducted by contractors or at one of three air logistics centers or depots: Ogden, Warner Robins, or Oklahoma City). Each depot has a large number of hardware and software engineers who design and maintain legacy systems.

As the Air Force relies more heavily on COTS hardware and software and less on Military Specification components in avionics systems, the trend is toward greater reliance on commercial contractors to support these products. To protect the jobs of depot employees, Congress passed USC 2466, Title 10 (the so-called “50/50 rule”), which requires that 50 percent of the depot maintenance workload in certain core technology areas be performed by government employees. This law has had the desired effect of bringing maintenance work that had been contracted out back to the depots but has also raised serious industry concerns.2

The depots have the expertise and institutional memory to maintain legacy avionics systems most efficiently, and the committee believes they should continue to do so. However, with increased reliance on COTS and MOSA for major upgrades and new systems, the expertise and intellectual property necessary to maintain these systems will reside more and more in the private sector. Thus, government's role in maintaining these new systems will naturally evolve into overseeing the activities of contractors. Government and industry will have to work together to develop creative solutions to complying with the 50/50 rule in light of changing technological realities. The following solutions could be considered:

-

Increase the scope of Air Force logistic centers to include maintenance and modifications of aircraft structures. As the expected lifetime of the aircraft increases, the contractor's experienced workforce in that structure will diminish. For example, if the air logistics centers assume responsibility for performing service life extension programs, they would retain specific aircraft skills and free the contractor to address more of the commercial-based maintenance activities.

-

One purpose of the 50/50 rule is to retain jobs at the air logistics centers, thus minimizing negative economic impact to the surrounding community. By giving contractors “credit” for hiring and retaining former depot personnel or hiring subcontractors who retain those skills at on-site or nearby

2 On August 17, 2000, the Industry Logistics Coalition—a broad-based organization of industry suppliers—wrote to the Secretary of Defense detailing their concerns. The coalition asked Secretary Cohen to hold off on making decisions about bringing Air Force work currently performed in the private sector “in-house” to comply with the “50-50” depot maintenance requirements until a more viable, long-term alternative is developed (letter to Secretary of Defense William Cohen, August 17, 2000).

Page 38

facilities, the intent of the 50/50 role would be met. In addition, the economy in local communities would be stimulated.

LOOKING AHEAD

Neither modular nor “open” systems directly address the total DMS problem. However, a MOSA strategy would increase the probability that system components would be available from multiple sources in the future. With proper architecture, planning, and documentation, MOSA could provide an effective strategy for mitigating the problem of obsolescence by ensuring that hardware and software components could be upgraded or replaced over the lifetime of the system. However, the commercial marketplace would determine the need for, and the nature of, publicly open standards beyond those dictated by system-of-system interoperability requirements.

The good news is that the airframe and avionics systems suppliers are already developing and implementing many MOSA-based technical solutions and are working in a loosely coordinated way with DoD to identify and resolve related business issues (see Chapter 3 ). Avionics systems suppliers are rapidly developing their own modular architectures and modular interfaces. The need for system flexibility and extensibility, coupled with the tremendous competitive leverage of reusing hardware, software, and/or intellectual property, and the need to make more effective use of a limited supply of capable personnel, have forced industry in that direction.

Joint industry/government development of the architecture for the joint tactical radio system, industry interaction with the Open System Joint Task Force, and support from the National Center for Advanced Technologies to the Office for Aging Avionics, Aeronautical Systems Center, and the Open System Joint Task Force for MOSA, are examples of effective industry/ government relationships. More coordinated, enterprise-level interactions with industry would be beneficial. By working jointly with industry to resolve business issues, as well as by addressing internal management, budgetary, and technical issues, the Air Force can continue to make progress in mitigating the aging avionics problem.