3

The Modified Baseline Process

INTRODUCTION

The modified baseline process derived from the experiences at JACADS and considered in this report has been tailored to meet the requirements for disposal of the mustard agent munitions stockpile of projectiles and mortar shells at PCD. A parallel objective in the design and operation of this process is ensuring safety and minimizing health risks to workers, the surrounding populace, and the environment. Secondary objectives are minimizing the risks of prolonging the schedule and not exceeding the budgets for disposal processing of the PCD stockpile.

In both the baseline incineration system and the modified baseline process, energetics are removed in explosive containment rooms (ECRs) as part of the agent destruction operation in the munitions demilitarization building (MDB). A work-in-progress (WIP) buffer inventory is provided between the energetics removal step and the rest of the operation. The same type of energetics removal equipment is used in both the baseline system and the modified baseline process.

The modified baseline process concept differs from the baseline incineration system in two essential features (U.S. Army, 2000c):

-

In the modified baseline process, draining agent from a munition is replaced by freezing it inside the munition to minimize the foaming and frothing that occurred during accessing mustard agent at JACADS.

-

All agent is thermally oxidized in the MPF and its afterburner and the LIC has been eliminated. This step is justified by the results of the 1999 trial burn tests at JACADS, which demonstrated that 99.9999 percent of the agent was destroyed in the MPF and afterburner, as discussed in Chapter 2.

Major features of the baseline system and the modified baseline process are shown in Table 3–1.

DESCRIPTION OF THE MODIFIED BASELINE PROCESS

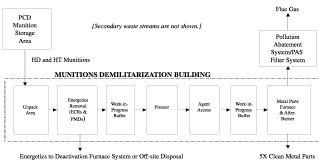

A preliminary flow diagram for the modified baseline process is shown in Figure 3–1.

Transport of Munitions

The plan for a modified baseline process for PCD envisions transporting munitions to and from the storage igloos in modified ammunition vans (MAVs), provided the risks are acceptable compared with those from using on-site containers (ONCs) at baseline system sites such as Tooele. No incidents occurred during the transport of munitions by MAVs from the Johnston Island storage area to JACADS during the disposal campaigns conducted there. A 1991 study by Mitre concluded that the risk associated with the use of MAVs was substantially the same as the risk with bulky, tightly sealed ONCs (Mitre, 1991). As this report was being prepared, Science Applications International Corporation (SAIC) was conducting a new risk analysis for PMCD (noted in Chapter 4). The use of MAVs may have other advantages: helping PUCDF meet the disposal schedule and being less expensive than ONCs to procure and operate.

Removal of Energetics

An existing munitions maintenance building at PCD, which has been used for years to process munitions manually, could be used for the removal of propellants from the 28,375 stockpiled 105-mm munitions that are complete rounds stored in field cartridge cases with propellant (see Appendix A). This process is known as reconfiguration. All of the remaining energetics in the munitions in the Pueblo stockpile would be removed by automated projectile/mortar disassembly (PMD) machines in ECRs, as they are in baseline system facilities. In the proposed modified baseline process for Pueblo, there are three ECRs in the MDB instead

TABLE 3–1 Comparision of Major Features of the baseline Incineration System and the Modified Basline Process

|

Process Step |

Baseline Incineration System |

Modified Baseline Process |

|

Munitions demilitarization building (MDB) |

The baseline munitions demilitarization building is a large two-story building containing three or more furnaces, equipment for energetics removal, agent draining and munitions-handling facilities, and a control room, corridors, and utilities. |

This MDB is a smaller, one-story building containing equipment for energetics removal and munitions freezing and handling and a metal parts furnace (MPF) (and a deactivation furnace system, if energetics cannot be shipped off site). |

|

Transportation and unpacking of munitions |

Munitions are moved from igloos to the MDB in on-site containers (ONCs), which are received at a separate container handling building (CHB) and lifted to the second floor unpack area, where the munitions are unpacked and put on input conveyers to the MDB. |

Munitions are moved from igloos in modified ammunition vans to the MDB ground floor loading dock instead of a CHB. Munitions are unpacked there and put on conveyers. |

|

Removal of energetics (fuzes, bursters, propellant charges) |

There are two explosion containment rooms (ECRs) within the MDB where energetics are removed by projectile/mortar disassembly (PMD) machines, one in each ECR. After removal, the energetics drop through feed chutes to the deactivation furnace system (DFS). |

The MDB contains three ECRs, each with a PMD machine. These ECRs have lower blast level specifications than baseline system ECRs. Removed energetics are tested for agent contamination. Those passing the 3X test are stored for off-site shipment or for use as feedstock to a separate DFS, if that is required. Contaminated energetics will be disposed of separately. |

|

Agent access and draining |

Three multipurpose demilitarization machines remove the burster well, drain the agent, and then reinsert the burster well. The agent then flows into agent holding tanks. |

Agent is not drained. Instead, it is first frozen. Then, a new machine either drills, cuts, or punches the munitions to access the agent. |

|

Destruction of agent |

The liquid agent is burned in a liquid incinerator (LIC). |

Frozen agent-containing munitions are loaded on trays and processed through the MPF, where the agent is burned. There is no LIC. |

|

Destruction of energetics |

Energetics are burned in the DFS. |

Energetics are shipped off site, if allowed. Otherwise they are burned in a DFS. |

|

Decontamination of metal parts |

Drained munitions, which may contain a heel of agent, are processed in a three-zone MPF and afterburner. Because liquid agent has been drained, less agent is fed to the MPF than in the modified baseline process. |

Undrained munitions are processed in a four-zone MPF with an afterburner. Four zones provide the extra heating to burn the larger amounts of agent. |

|

Treatment of furnace off-gases to convert sulfur and chlorine acid gases to salts and temper the off-gases |

Exhaust gases pass through a pollution abatement system (PAS) that has a quench tower, a scrubber, a demister, a high-efficiency particulate air (HEPA) filter and carbon filters, and an induced draft blower. Each furnace has a PAS. |

The MPF PAS is similar to, but larger than, the PAS for the baseline MPF in order to handle the higher salt loading produced from burning a larger amount of agent. If there is a DFS, it will have its own PAS. |

|

Processing of brine |

A brine reduction area (BRA) containing evaporators and drum dryers was included in the original baseline designs. At TOCDF, brine is being shipped off site, and the BRA is not used. It has been eliminated from newer baseline facilities. |

It is assumed that the brine can be shipped off site. No BRA is included. |

|

Monitoring of agent |

ACAMS and DAAMS |

The same systems are used, but fewer are required, because there are fewer furnaces and PAS systems. |

|

Secondary Waste Treatment |

||

|

Treatment of dunnage (paper and wood waste products) |

A dunnage incinerator was included in the baseline designs but has not been used. At JACADS, dunnage was burned in the MPF. |

If dunnage is proven to be uncontaminated, it will be shipped off site. Otherwise it will be burned in the MPF. |

|

Treatment of spent filter carbon |

If uncontaminated, spent carbon is shipped off site. Otherwise, it is incinerated on site in the MPF or a micronizer and burner. |

Same. |

|

Treatment of spent decontamination solution |

Spent decontamination solution (SDS) is injected into the LIC afterburner and burned. |

SDS is injected into the MPF afterburner. |

FIGURE 3–1 Pueblo modified baseline process.

of the two in baseline system facilities. A single PMD machine in each ECR can provide the necessary throughput, thus eliminating the need for a large WIP inventory of munitions waiting for processing (Tomanek, 2000a, 2000b).

The ECRs in the modified baseline process for Pueblo will probably have lower construction costs than the corresponding ECRs in baseline system facilities at other sites because the ECRs at Pueblo can be designed to withstand a lower explosive load from the relatively small mustard-filled munitions and will therefore require less concrete and reinforcement. ECRs at JACADS were designed to withstand simultaneous detonation of two 8-inch projectiles containing a total of 14 lb of explosives. The largest munition in the stockpile at Pueblo is a 155-mm round with 0.41 lb of explosives. Current plans are to process three rounds simultaneously on a PMD, a total design load of 1.23 lb of explosives in an ECR.

ECRs, with only one PMD machine each, have the added advantage that if an ECR becomes contaminated, the other two PMD machines in their separate ECRs can continue operations. Thus, the impact on facility throughput from a contaminated ECR is lower than if there were several PMD machines in fewer ECRs.

A preliminary estimate is that 1,000 munitions from the PCD stockpile will leak agent during transport to the ECRs. Leakers would be repacked in sealed overpack containers, safely stored, and later destroyed (Battelle, 1999).

Energetics Disposal

There are two options for disposing of energetics. PMCD prefers the simpler option of sending them to existing off-site treatment, storage, and disposal facilities (TSDFs) that routinely dispose of similar energetics. Before energetics removed from chemical munitions can be shipped off site, however, efficient analytical procedures must be applied to ensure that the energetics meet the required 3X decontamination level.1 A contract with a TSDF to take the energetics, as well as permission to ship them there, would also be required. PMCD conducted a survey of TSDFs and found several willing to accept energetic materials designated 3X. Whether off-site transport of uncontaminated energetics will be permitted has not been determined, but a study of transportation risks is under way (Venkatadri, 2000).

If off-site transport of energetics is not permitted, the second option is on-site disposal. If this is done in the modified baseline process, they would be incinerated in a DFS with a dedicated PAS, similar to the one in the baseline system.

Obtaining approvals for off-site transport might cause delays. If the destruction of energetics must be completed by the CWC deadline, PMCD should set a date by which construction of the DFS must be started if no off-site permit has been received or if the receiving facility does not have a valid permit. A permit for DFS construction should be relatively easy to obtain because of its successful use at both JACADS and TOCDF. However, enough time must be allowed in the schedule for permit application and approval. In view of the opposition to incineration by some Pueblo stakeholders, the prompt receipt of a DFS permit cannot be assumed.

Finding 3–1. The Army has not determined when a commitment to an on-site deactivation furnace system as part of a modified baseline process at Pueblo must be made if a permit for the off-site transport of energetics has not been received.

Recommendation 3–1. The Army should develop a process and schedule to determine when a decision must be made between the off-site transport of energetics or their on-site disposal in a deactivation furnace system. To avoid schedule delays, the decision mechanism must account for uncertainties in the permitting process.

Decontamination of Energetics

Although not many cases are expected, any energetic materials contaminated with agent must be decontaminated or destroyed. One alternative is to dissolve the entire munition in an acid bath (Battelle, 1999). Another is to destroy the energetics in the Army’s explosive destruction system (EDS),2 a portable self-contained chamber in which two to six bursters can be handled at one time (Thompson, 2000a; U.S. Army, 2001a).

Freezing of Projectiles That Contain Agent

In the modified baseline process for Pueblo, following removal of bursters and fuzes, munitions will be frozen prior to accessing the agent to minimize foaming or frothing. Six freeze rooms of a standard industrial design will operate at −20°F to −10°F. Munitions will have a residence time of 11 to 15 hours, based on a heat-transfer model for freezing developed by SAIC (Coughlin, 2000). After removal from the freeze room, munitions will remain frozen below 55°F, the freezing point of mustard, for 3 hours. The freezing operation is an important design consideration for the modified baseline process because it will minimize the maintenance problems from frothing that sometimes occur when mustard munitions are processed at normal temperatures through MDMs.

This feature of the modified baseline process is based on the experience at J AC ADS, where 201 rounds were frozen before the agent was accessed. The frozen rounds did not exhibit foaming or frothing during the agent accessing operation (U.S. Army, 2001a). However, information provided to the committee indicates that the frozen rounds had thawed (i.e., were not in a frozen state) by the time they entered the MPF (U.S. Army, 2001a). Although the modified baseline process design calls for putting frozen rounds into the MPF, there is no prior experience with the thermal oxidation of mustard entering in the frozen state. Heating frozen projectiles in the MPF could potentially result in the erratic ejection of agent, causing spikes in pressure and temperature; solid agent might even be propelled against internal surfaces of the MPF. Apparently, there are no data bearing on this issue from JACADS or elsewhere (U.S. Army, 2001a).

Finding 3–2. If the Army intends to use the freezing process at Pueblo, data on the behavior of frozen rounds will be essential to confirm the feasibility of a modified baseline process that integrates freezing of the munitions for agent accessing prior to their treatment in the metal parts furnace.

Recommendation 3–2. The Army should obtain experimental data on the behavior of frozen mustard rounds fed into the metal parts furnace (MPF). At a minimum, these data should demonstrate that:

-

Frozen rounds (HD and HT) can be processed in the MPF without adverse consequences from the simultaneous presence of agent in solid, liquid, and gas phases, which might lead to spiking of furnace temperatures and pressures from agent confinement and rapid subsequent release in the gaseous phase.

-

Complete volatilization and destruction of the frozen agent in the MPF can be achieved.

-

Solid agent will not be ejected and propelled against internal surfaces of the MPF.

-

Temperatures and residence times necessary to achieve destruction have been determined.

Finding 3–3. The committee could not determine whether an experimental program to verify the feasibility of processing frozen mustard rounds in the metal parts furnace would delay the disposal schedule for the Pueblo Chemical Agent Disposal Facility. However, the need for experimental verification is not only a technical consideration, but also a regulatory issue. Although the committee did not evaluate the regulatory climate at Pueblo concerning this issue, obtaining a permit for a one-of-a-kind modified baseline process may be more difficult and more time consuming than obtaining a permit for the baseline system, which has been successfully demonstrated at two facilities and supported with extensive trial burn data.

Recommendation 3–3a. The Army should evaluate the risk of delay in obtaining a permit for the proposed modified baseline process at Pueblo that includes the treatment of frozen mustard rounds in the metal parts furnace (MPF). The evaluation should take into account the permitting experience for the process used at J AC ADS to freeze 201 mustard rounds and feed partially thawed, 100-percent-filled mustard agent rounds into the MPF.

Recommendation 3–3b. The Army should evaluate the efficacy of allowing frozen munitions to thaw before feeding them into the metal parts furnace of a modified baseline process in a manner similar to the procedure used at JACADS. If the Army intends to include this process step, associated safety, design, maintenance, and regulatory approval issues should be assessed.

Opening of Munitions to Access Agent

In the modified baseline process for Pueblo, frozen munitions will be conveyed to six agent accessing machines operating in parallel and sized to handle 27 munitions per hour each (Tomanek, 2000a, 2000b). These will not be baseline system MDMs but new machines that would have to be developed and tested. Prototype testing would take place at the Chemical Demilitarization Training Facility in Aberdeen, Maryland.

The new machines will not pull the burster well; they will instead open the agent cavity and verify that it is open (see Appendix A for cross-sectional views of projectiles). Four options were originally considered (Thompson, 2000b):

-

drilling or milling the top of the munitions off center

-

cutting through the burster well

-

punching the munition from the side to penetrate the shell

-

pressing the adapter base (the fitting at the top of the shell casing into which the fuze housing is inserted) down into the munition so the top of the shell is opened

The Army has eliminated the first two options, and it is expected to recommend either the third or fourth option by mid-August 2001 (Thomas, 2001).

Baseline system facilities at Tooele, Utah; Anniston, Alabama; Umatilla, Oregon; and Pine Bluff, Arkansas, are or will become operational prior to the PUCDF. Disposal campaigns at all these facilities but Pine Bluff are scheduled to process mustard agent munitions and therefore will have to deal with the foaming and frothing problem identified at JACADS, if it arises. Currently, freezing is not planned at any of these facilities. An alternative method (a froth collection system on the MDM) has been designed for capturing agent at all sites processing projectiles if foaming or frothing occurs during agent accessing operations (personal communication from Conrad Whyne, Project Manager for Chemical Disposal Operations Team, March 28, 2001).

Finding 3–4. The machines proposed for accessing agent in the modified baseline process differ from the multipurpose demilitarization machines used for this purpose at JACADS. The method proposed for accessing mustard agent should open the munition cavity sufficiently to enable complete destruction of the agent in the metal parts furnace.

Recommendation 3–4a. The Army should demonstrate that the method selected for accessing mustard agent opens the munition agent cavity sufficiently to enable complete destruction of the agent in the metal parts furnace.

Recommendation 3–4b. If the development and testing of the machines for accessing agent in the modified baseline process would delay disposal operations past the Chemical Weapons Convention deadline, the Army should consider installing another technology at Pueblo.

Finding 3–5. Freezing mustard munitions to avoid problems with foaming/frothing of agent is not currently planned for any of the baseline facilities in the continental United States.

Recommendation 3–5. The Army should determine whether the method proposed for capturing mustard agent during agent accessing at baseline system facilities could be adapted for use at Pueblo with a potential savings over the cost of developing and testing freezing methods.

Processing of Agent-Containing Munitions in the Metal Parts Furnace

Unlike the baseline system, which uses a LIC to destroy most of the agent, in the modified baseline process, all agent is destroyed in the MPF and its afterburner. Consequently, the MPF is the critical element in the modified baseline process. Sufficient machinery for accessing agent and sufficient WIP buffer inventory will be necessary to ensure that facility throughput is determined by the capacity of the MPF and that the MPF is not starved for input feed materials. Several MPF design alternatives were considered:

-

a furnace with three zones, much like the one at JACADS

-

a furnace with four zones

-

parallel three- or four-zone furnaces

PMCD evaluated the trade-offs among these alternatives and reports that the single four-zone furnace appears to be the best and most operable option (Thompson, 2000c). The nominal design temperature setting for the first zone is 1,450°F and for zones 2, 3, and 4 is 1,600°F. HD vaporization rate modeling by Continental Research and Engineering (CR&E) for fully loaded munitions in a four-zone MPF that includes top and bottom water sprays in zones 1, 2, and 3 to control the temperature and therefore the rate of HD vaporization indicates that the peak HD vaporization rates, which occur in zones 1 and 2, do not significantly overlap or exceed the maximum capacity of the MPF afterburner, the PAS, the PFS, or the induced draft fans (CR&E, 2000). For 5X decontamination, zones 3 and 4 provide a 1,600°F furnace environment for thermal desorption of any residual mustard or breakdown products and for heating to and holding the mu-

nitions at >1,000°F for at least 15 minutes. At the recommendation of a PMCD consultant, a four-zone MPF versus a three-zone MPF was used to increase throughput by 33 percent, which would allow the 780,078 munitions in the Pueblo stockpile to be processed in approximately 25 months (U.S. Army, 2000a). The design throughput basis for the four-zone MPF is provided in Table 3–2.

A number of improvements are being incorporated into the design (Webster, 2000). The conveyers will have a higher load capacity than those in the normal baseline system design and will have individual motor-driven rollers. Water-spray flow valves will be upgraded. The inlet gasket channel will be redesigned to prevent dislodging of the gasket. A third standby automatic continuous air monitoring system (ACAMS) monitor will be installed in the emissions monitoring system. The MPF will be the only source of stack emissions unless a DFS is also installed. The furnace(s) and the downstream PAS will be sized to accommodate the lower barometric pressure at Pueblo (elevation 4,600 feet).

Off-gas emissions from the modified baseline process MPF will pass through a separately fired afterburner maintained at a temperature of 2,000°F. The committee was told that the afterburner design is patterned after the successful afterburner operations at JACADS and TOCDF (Webster, 2000). The key design parameter for the afterburner is to have a one-second residence time at 2,000°F (CR&E, 2000). Off-gas emissions then pass through the PAS, which includes high-efficiency particulate air (HEPA) and carbon filtration. Metal parts emerging from the MPF will be disposed of as scrap metal.

An extremely important operating requirement for the MPF is the safe shutdown and restarting of the unit if there is a loss of the air supply for combustion, loss of exhaust fan capacity, or both. A loss of electrical power is the usual cause of such an occurrence. If this happens, there is a significant probability that the munitions in the MPF will still be vaporizing uncombusted agent when the furnace temperature drops below 1,200°F. At JACADS, the solution was to cool the furnace to 400°F with water sprays, then to back the trays into a buffer storage zone upstream of the MPF (MR&E, 1996). Once the furnace was restarted, the trays were processed normally.

At Anniston and Umatilla, diesel-powered emergency electrical power systems sized to handle the power requirements of the facilities will start up if normal electrical power fails. These standby systems are tested regularly. Pueblo will also have a standby system.

Finding 3–6. Continuous throughput and safe operation of the metal parts furnace are the most critical aspects of the proposed modified baseline process for Pueblo. The furnace can be sized to operate safely and reliably with substantial loading.

Recommendation 3–6. A modified baseline process at Pueblo should include a four-zone (rather than three-zone) metal parts furnace with design provisions to ensure safe shutdown and restarting in the event of operational upsets, such as a loss of electrical power, combustion air supply, or exhaust gas capability.

Treatment of the Off-Gas from the Metal Parts Furnace

As in the baseline system, the gases from the MPF afterburner of the modified baseline process are passed through the quench tower and scrubber of the PAS to cool and neutralize acidic gases (mostly HC1) formed from the combustion of agent. Roughly 1.6 lb of salts are formed for every pound of HD agent oxidized. Because more agent will be oxidized per hour in the MPF of the modified baseline process than in the baseline system, the size of the quench tower will be increased to accommodate the larger volume of acid gases. Larger and better strainers will be added to the spray nozzles, and improved instrumentation will be installed. From the quench tower, the gases pass through a venturi scrubber, a scrubber, and a mist eliminator. The gases are then reheated and drawn by two induced-draft fans in series through the PAS filter system (PFS), which has activated carbon filters with HEPA filters upstream and downstream of the carbon filters. The PFS is a new component for baseline system facilities and will first be used at Anniston, Umatilla, and Pine Bluff. The PFS filters will be tested during systemization at Anniston (personal communication from Conrad Whyne, Deputy Project Manager for Chemical Stockpile Disposal, March 28, 2001).

Models were used to obtain vapor rate profiles in the MPF and they show a more uniform profile for the four-zone MPF than the three-zone MPF used for the fully loaded HD muni-

TABLE 3–2 Summary of Materials to Be Processed in a Four-zone MPF at Pueblo

|

Munition Type |

Munitions per Tray |

Agent (lb/tray) |

Metal (lb/tray) |

Cycle Time (min/tray) |

Peak Rate (munitions/hr) |

Peak Agent (lb/hr) |

Metal (lb/hr) |

|

105-mm projectile |

96 |

288 |

6,166 |

36 |

160 |

480 |

10,277 |

|

155-mm projectile |

48 |

562 |

7,414 |

37 |

77.8 |

911 |

12,023 |

|

4.2-inch mortar |

96 |

576 |

4,352 |

44.5 |

129.4 |

777 |

5,867 |

|

Source: Adapted from CR&E, 2000. |

|||||||

tion trial burn at JACADS. This provides some assurance that the formation of products of incomplete combustion (PICs) should be no worse than those experienced during the 1999 trial burn at JACADS (U.S. Army, 1999b).

Particulate emissions from the MPF that pass through the PFS are expected to be captured by the HEP A filters. If any dioxins, furans, or other PICs are emitted, they are expected to be adsorbed on the carbon filters.

PIC data were well documented in the committee’s 1999 report Carbon Filtration for Reducing Emissions from Chemical Agent Incineration, which provided the results of an in-depth statistical review of trial burn data from JACADS and TOCDF (NRC, 1999a). In addition to particulates and hydrogen chloride, the emissions data encompassed measurements for 22 elements, halogen-containing species, 204 trace organics, light hydrocarbons with boiling points lower than 100°C (212°F), and nonvolatile hydrocarbons with boiling points higher than 300°C (572°F). The report noted, “For JACADS and the TOCDF, the vast majority of emittants that were analyzed are below the analytical detection limit.” For the data analyzed, the report also noted that “the reported emission concentrations are among the lowest for all hazardous waste incinerators in the EPA’s Hazardous Waste Combustor Emissions Database.” More recent data evaluated by the committee on formation of PICS can be found in the JACADS 1999 trial burn report (U.S. Army, 1999b). The total toxicity equivalent from dioxins and furans reported was less than 1.86 E-11 g/sec, which is the detection limit. For 16 PCBs, the total toxicity equivalent was also below the detection limit of 3.02 E-10 g/sec. None of the 138 semivolatile organic compounds that were sampled was detected. The committee believes that this is sufficient evidence to indicate that PIC formation is not a concern.

Formation of PICs in the downstream off-gas treatment units (PAS and PFS) is not expected, as the temperatures of these units are well below PIC formation temperatures. The off-gas is quenched rapidly after the high-temperature afterburner, minimizing the time at temperature where PICs may form. The committee believes that PICS are no more of a concern in the modified process than in the current operating units of the baseline system.

Finding 3–7. The control of emissions of cadmium and mercury by the PFS HEPA and carbon filters has yet to be demonstrated. The PFS filters will be tested during systemization at Anniston Chemical Agent Disposal Facility.

Recommendation 3–7. Tests and analyses for the control of metal emissions, especially cadmium and mercury (elemental and total) and organics (products of incomplete combustion), should be conducted for the metal parts furnace and afterburner and PAS/PFS prior to completion of the design for the modified baseline process to ensure that emissions are within required limits. Necessary control technologies should be incorporated into the plant design.

Handling of Brine Generated in the Quench Tower

A brine reduction area, in which brine is evaporated and dried to salt, is a feature of the JACADS and TOCDF baseline system designs. The brine qualifies as a RCRA hazardous waste and can be shipped off site (after appropriate testing) and disposed of in a permitted TSDF. This is now being done at TOCDF, is planned at the other baseline system sites, and is the preferred alternative for the modified baseline process at Pueblo. The amount of brine expected over the life of Pueblo stockpile disposal operations is 14.5 million gallons (WIPT, 2000a, 2000b, 2000c).

Handling of Secondary Wastes

Secondary wastes include SDS, DPE suits, spent carbon, dunnage, slag, and ash. In the modified baseline process, the plan is to process agent-contaminated dunnage and DPE suits through the MPF. These materials were reported to be successfully processed in the MPF at JACADS and, therefore, should be processed similarly at Pueblo. The throughput rates remain to be demonstrated. SDS was processed in the LIC afterburner at JACADS, which supports the likelihood that SDS can be treated in the MPF afterburner in the modified baseline process, but this remains to be proven (Thompson, 2000d).

The disposal procedures for spent carbon have not been determined. Carbon may be processed through the MPF, or through the DFS if one is included. Another alternative may be to use a micronizer to grind the carbon to a fine powder, which could then be burned in a combustion chamber coupled with the micronizer (personal communication from Gary W.McCloskey, PMCD JACADS Site Project Manager, June 22, 2000). Uncontaminated carbon, dunnage, and slag (from the MPF afterburner burning SDS and ash from the MPF) will be shipped to permitted hazardous waste disposal facilities after they can be shown to be substantially free of agent. Analytical techniques to measure agent in spent carbon and liquid media are being evaluated. These issues are discussed at length in an NRC report on monitoring at chemical stockpile disposal facilities (NRC, 2001).

Finding 3–8. Secondary wastes, which include contaminated dunnage, DPE suits, spent decontamination solution, and contaminated spent carbon, were treated at JACADS using a combination of furnaces and afterburners, or a micronizer and a burner system for spent carbon. Uncontaminated dunnage and spent carbon, slag, and ash were shipped off site to permitted waste disposal facilities after being tested to ensure they were suitable for shipment.

Recommendation 3–8. Lessons learned at JACADS from the disposal or decontamination of demilitarization protective ensemble suits and dunnage in the metal parts furnace should be incorporated into the design and operation of the

comparable furnace (MPF) of the modified baseline process. Spent decontamination fluid should be injected into the MPF afterburner (or deactivation furnace system [DFS] afterburner) if it cannot be shipped off site. Similarly, contaminated spent carbon can be processed through either the MPF or the DFS if there is one. Uncontaminated dunnage and spent carbon, slag, and ash can be shipped off site to permitted waste disposal facilities after being tested to ensure they meet all requirements for off-site disposal.

Monitoring of Agent and Other Pollutants

The agent monitoring system for a modified baseline process at Pueblo would be patterned after the one at J AC ADS and the other baseline incineration system facilities. Automatic continuous air monitoring system (ACAMS) and depot area air monitoring system (DAAMS) units will be installed at various locations inside PUCDF and at other spots around the perimeter of the PCD. ACAMS monitors provide for rapid detection of the presence of agent in air; DAAMS monitors provide accurate measurements of actual agent concentrations averaged over a period of time. A third, standby ACAMS monitor will be added to the MPF to ensure that monitoring is not interrupted. Because there is no LIC, and possibly no DFS, both of which require ACAMS monitors, fewer ACAMS will be needed in the modified baseline process than in a baseline system.

In 1995, the amendments to the Clean Air Act included requirements for maximum achievable control technology (MACT) for pollutants, including dioxins and metals. The EPA has since promulgated regulations that will have to be met by a modified baseline process for the Pueblo site (EPA, 1999). In addition, EPA is reviewing the effects of dioxins on human health because some evidence indicates dioxins may be more harmful in the food chain than previously thought (Kaiser, 2000). If dioxin emission standards are modified, analytical procedures will need to be reviewed.

At the present time, continuous monitoring of mercury, dioxins, and PIC emissions from incinerators is not required, and the Army has no plans for continuous monitoring at PUCDF or any other chemical agent disposal facility, except during trial burns. Analytical equipment for truly continuous monitoring has not yet been proven in commercial operations but is under development. Although the PFS HEPA filters are expected to capture particulates and the activated carbon filters are expected to adsorb and hold emissions of mercury, dioxins, and PICs, these emissions are of great concern to the stakeholders living around stockpile disposal facilities, who may not be satisfied with these measures. Developing monitors for metals and organics and conducting stack tests could go a long way toward demonstrating the Army’s sensitivity to the concerns of the surrounding communities.

Finding 3–9. Monitoring systems currently used at existing baseline system facilities appear to be adequate for use in a modified baseline process at Pueblo. The addition of a third, standby automatic continuous air monitoring system unit in the area of the metal parts furnace (MPF) is a reasonable modification in light of the increase in agent throughput over the throughput for the MPF of the baseline system. Notwithstanding the current lack of regulatory requirements for continuous monitoring, further development of monitors for metals and organics is likely to be beneficial for confirming clean emissions. This would also support the Army’s interaction with local citizens by making definitive emissions data more available to the public.

Recommendation 3–9. The Army should evaluate state-of-the-art analytical tools for continuous monitoring of emissions of metals, dioxins, and products of incomplete combustion. If they are effective, the Army could install them at chemical agent disposal facilities where applicable. If continuous monitors are not effective, the Army could conduct stack tests for dioxins/furans, mercury, and organics at suitable intervals to provide some additional assurance to the surrounding communities that the modified baseline process is working properly.

Infrastructure

Regardless of which technology is chosen for destruction of the chemical munitions stockpile at Pueblo, infrastructure to provide electrical power (including standby generating facilities), water, sewage disposal, natural gas, and road access will be necessary. Recognizing this, PMCD has obtained approval from government and regulatory authorities to allow construction to begin on some infrastructure facilities that will be required regardless of the technology selected.

Overall Throughput

The committee was provided an overview of throughput specifications for a modified baseline process design for Pueblo (Tomanek, 2000a, 2000b). The rate at which the MPF can process munitions or waste is the rate-limiting step in the design. All other equipment and feed conveyors in the MDB, including those in the unpack area, the munitions freeze area, the agent accessing area, and the munitions staging area, will be sized to meet the maximum MPF throughput rates. The rates per day are 3,105 4.2-inch mortar shells, 3,840 105-mm projectiles, or 1,867 155-mm projectiles. At JACADS, overall availability3 was limited by the brine-

TABLE 3–3 MPF Design Throughput Rates for Processing Munitions

|

Munition Type |

Peak Rate (no./hr) |

Furnace Availability (%) |

Regulatory Rate Restrictiona (%) |

Average Throughput (no./hr) |

|

105-mm projectile |

160.0 |

60 |

75 |

72.0 |

|

|

|

100 |

75 |

120.0 |

|

155-mm projectile |

77.8 |

60 |

75 |

35.0 |

|

|

|

100 |

None |

77.8 |

|

4.2-in. mortar |

129.4 |

60 |

50 |

38.8 |

|

|

|

100 |

50 |

64.7 |

|

aThe restrictions provide a period of conservative, reduced-rate operation between the time a trial burn has been completed and the data from the trial burn have been analyzed and finally approved. Generally, fewer munitions are placed in a tray when the unit is operating under the restriction. The restriction applies to baseline operations. Source: Jacobs Engineering, 2000. |

||||

processing capacity, but in the modified baseline process, brine will be shipped off site.

The design basis for MPF availability for processing munitions in the modified baseline process is 60 percent. Another 10 percent availability is required to handle secondary wastes, so the total required MPF availability is 70 percent. The MPF availability at JACADS in operations on 4.2-inch HD mortar projectiles was 53 percent, but anticipated improvements in conveyers, water spray valves, gate gaskets, the continuous emissions monitoring system, and expansion of the PAS in the modified baseline process are predicted to raise overall MPF availability to 70 percent or higher (Tomanek, 2000a, 2000b). Table 3–3 provides MPF availability rates for processing munitions (but not secondary wastes).

The single MPF is coupled to upstream activities in the MDB. As one example of a problem that might arise in this tightly coupled system, the ability of the PMD lines to supply the right quantities of energetic-free munitions to the freezers and agent access machines to keep the MPF full may be critically dependent on a correct assumption about the number of entries into the ECRs for maintenance and repair. Possible methods of mitigating this problem may include providing more agent-accessing machines for redundancy or providing for larger WIP buffers just before the MPF. The committee could not quantitatively assess the potential effects of these methods for ensuring optimum use of the MPF.

Closure of the Facility

One of the lessons learned from the JACADS experience is that planning and designing for the closure of a facility at the time of initial design are extremely important and can greatly reduce the time and costs of closure. Rapid closure will be particularly important for PUCDF, because the Pueblo community wants to redevelop a large portion of PCD property for commercial purposes as soon as possible after the stockpiled munitions have been destroyed. In fact, some redevelopment has already begun (see Chapter 4) in areas of PCD known to be free of agent and environmental contamination. In any case, a safe, efficient, rapid closure of PUCDF would be beneficial and cost effective.

According to current plans, the portion of PCD not being considered for commercial development will be converted into a wildlife refuge. The exact end-use requirements of the site have not been determined; some areas are classified for residential use, others for industrial use, and still others for a wildlife refuge.

No closure plan has been developed, but one will be prepared for the RCRA permit application (U.S. Army, 2000c). Assuming proper attention is given to closure issues during facility design and operation, the closure of a modified baseline process facility should be easier than closure of a baseline system facility for several reasons. First, because there is no burster well removal step and no draining of agent from the projectiles, there should be less agent contamination in the MDB. Second, there are no agent pipes, pumps, or storage tanks. Third, freezing would reduce both the ambient vapor pressure of the agent (so agent spread would be limited) and the chance of liquid spills in the agent accessing area. Fourth, if the floor of the freezing and agent accessing area is a welded, seamless sheet of stainless steel, this sheet could be removed at closure, cut up, and processed through the MPF.

The Stockpile Committee is preparing a report for release in 2001 on the ongoing closure activities for JACADS. This report could provide useful guidance to the Army for making timely closure decisions regardless of the technology selected for implementation at Pueblo.

Finding 3–10. Although the modified baseline concept is derived from the lessons learned at JACADS, no closure plan has been developed. The committee found no evidence of explicit considerations of closure in the design or design criteria of the modified baseline process for the PUCDF.

Recommendation 3–10. Engineering, design, and construction plans for the Pueblo Chemical Agent Disposal Facility should incorporate all of the requirements for closure identified at JACADS and other baseline system facilities. Value-engineering studies should be initiated to review all existing designs for conformance to closure principles identified in the forthcoming NRC report on the closure of JACADS. The Army should also initiate closure planning as soon as possible.

CRITICAL DECISIONS FOR PMCD AND PUEBLO

In a broad-band contractor briefing to the committee on July 28, 2000, the following 10 decision areas were identified for the modified baseline process (U.S. Army, 2000d):

-

manual/semimanual versus machine-based operations to remove energetics

-

removal of energetics in a separate facility versus in a facility integrated into the MDB

-

off-site versus on-site treatment of energetics

-

use of ONCs/container handling building versus use of MAVs

-

agent access/freeze operation versus no-freeze access

-

secondary waste treatment options

-

configuration of the MPF

-

improvements in the PAS

-

PFS versus no PFS

-

on-site versus off-site brine treatment

The following evaluation criteria were recommended for deciding on the efficacy of modifications (U.S. Army, 2000d):

-

safety

-

environmental issues, including permitting

-

schedule risk, including the feasibility of meeting the CWC deadline

-

cost risk

The “goal was to select the configuration that was judged to have the greatest probability of meeting the CWC deadline while maintaining programmatic safety and environmental performance goals” (U.S. Army, 2000d). Some trade-offs could be necessary because the “benefits from changes could be outweighed by [the] length of [the] implementation/approval process. Mature, demonstrated technologies will likely be approved more quickly” (U.S. Army, 2000d). In short, the final process configuration would only be apparent after each component of the modified baseline process had been evaluated separately. Delays in obtaining permits and approvals of the modifications could make a modification impractical compared with the baseline system because the treaty deadline might not be met.

The following modifications were “recommended” at the time of the briefing (U.S. Army, 2000d):

-

Pursue explosive separation as a remote manual operation in an ECR.

-

Perform explosive separation in a separate facility with PMDs/ECRs, assuming state regulatory authorities will agree to an accelerated permit schedule.

-

Pursue a modified DFS and off-site treatment on parallel paths until state regulatory authorities indicate whether off-site shipment is viable.

-

Eliminate the container handling building from the modified baseline process design, and design a buffer area to support transport of the munitions by MAVs.

-

Continue to investigate alternative agent-accessing equipment (alternatives to MDMs will be essential in order to meet overall throughput rates).

-

Process DPE suits in the MPF, SDS in the MPF afterburner, and carbon in the DFS (if available); pursue off-site disposal of SDS on a parallel path.

-

Use a single, four-zone MPF.

-

Use a PAS with increased capacity.

-

Incorporate the PFS in the modified baseline process for Pueblo because it has the best chance of being accepted by the public and regulators.

-

Ship brine off site for processing.

During the preparation of this report, only five decisions appeared to be firm: (1) not proceeding with manual/ semimanual removal of energetics; (2) integrating the energetics removal step into the MDB rather than in a separate facility; (3) using a single, four-zone MPF; (4) using a PAS with increased capacity; and (5) incorporating a PFS. The other decisions were under investigation, awaiting more technical information (e.g., agent-accessing approaches), or contingent on external regulatory approvals.

Although it may take some time to obtain additional technical information, prepare cost estimates, and prepare material for regulatory approval, at the time this report was prepared, no decision tree or network had been developed identifying milestone dates by which decisions had to be made to meet the CWC treaty deadline (April 29, 2007). For each decision, a milestone date must be established, at which point the modification must either be approved or abandoned. For example, approval for a decision to use MAVs must be obtained or orders for the procurement of ONCs and the design of the associated container handling building must go forward to avoid delaying the disposal schedule.

PREPROJECT PLANNING FOR A MODIFIED BASELINE PROCESS

PMCD and its contractors are experienced and knowledgeable organizations that have been involved in the design and construction of five baseline incineration system facilities. It is apparent that some of the critical decision points for Pueblo are engineering design decisions that must be made by project personnel based on technical issues, cost effectiveness, and their impact on the duration of construction and operations. An example involves determining the most cost-effective way of keeping emissions of heavy metals below prescribed regulatory standards. Another is whether fully frozen munitions can be introduced safely into the MPF, or if another approach would be equally safe and more cost effective—perhaps one that does not require freezing. A third example is whether the new machinery to cut open or drill

frozen munitions can be developed, tested, and acquired in time to meet the destruction schedule of the Pueblo stockpile by the CWC treaty deadline date.

Other decisions will be made by regulators or other agencies that are not under the control of managers for the project. An example is whether MAVs or ONCs will be permitted for transporting munitions from the PCD storage area to PUCDF. Another example is whether energetics will be permitted to be shipped off site for destruction or whether a DFS must be installed as part of the PUCDF.

A well-conceived preproject plan should be developed to anticipate and account for such exigencies. The ideal plan would be in the form of a decision network showing the various paths from alternative decisions. The paths would be measured and weighted in terms of the probabilities of completing them in a prescribed time. For every alternative outcome at each of the decision points, a path should lead to the completion of stockpile destruction by the CWC treaty date. If a path does not meet the treaty date, then either the decisions on that path must be made earlier or that path must be eliminated from consideration. For a path to be viable, the decisions on that path must be within the authority of project managers or steps must be taken as soon as possible to correct this situation.

One of the examples given above involves off-site shipment. If there is some likelihood of off-site transport being permitted, then this remains a viable option. But a date for the permitting decision should be determined, after which this option should no longer be considered viable. One of the functions of preproject planning is to identify these issues before it is too late.

The schedules shown to the committee were simply lists of things that had to be done and the time estimated to complete each of them. Alternative paths that would be generated as decisions were made were not evident, nor were any time-related probabilities assigned. The “schedules” presented to the committee are extremely vulnerable to unforeseen or external events. Moreover, the committee was not provided with total project cost estimates, even of a conceptual or preliminary nature. Without these estimates, it is extremely difficult to evaluate engineering decisions and select the most cost-effective technologies. Based on the lack of documentation, the committee concluded that an adequate preproject plan for a modified baseline process at Pueblo may not exist. If this is true, the completion of the project on schedule and within budget is unlikely.

Fortunately, industry and some government agencies have a good understanding of what constitutes best practices in project management and preproject planning for complex, time-critical projects. The standards and good practices for preproject planning have been developed by several organizations, such as the Business Roundtable, the Construction Industry Institute, and the Federal Facilities Council (BRT, 1997; CII, 1991, 1994; FFC, 1998).

Comparing the status of PUCDF planning with the characteristics of successful megaprojects identified in a 1999 NRC report (NRC, 1999b) indicates that some characteristics categorized as “essential to success” and “important to success,” such as schedules and risk analyses required by Office of Management and Budget Circulars A-94 and A-11 for projects undertaken by government agencies, are not included in PUCDF planning (OMB, 1992,1998). “Essential” conditions for success occur when:

-

schedules and cost estimates are prepared together based on the work breakdown structure and production rates, crew size, physical constraints, and other time-impacting issues

-

schedules, like cost budgets, include a contingency increment, the magnitude of which must be known to the project manager so that it can be considered continuously in making management decisions

-

• benefits of early completion of the work are high, and schedules are aggressive and planned so as to complete the project as early as possible

-

the schedule is aggressive and pursued vigorously to minimize exposure to internal and external changes

-

milestones, including owner actions, are clearly defined, listed, tracked for performance, and continuously monitored against performance

Conditions considered “important” to success occur when:

-

schedule contingencies decrease as the work progresses and fewer unknowns remain to be resolved

-

risk analysis and probability techniques are applied to task durations

-

independent reviewers evaluate the assumptions used in making the schedules and confirm the realism in the major milestones and completion date(s)

Further guidelines found in OMB Circular A-94 for ontime completion of projects are (OMB, 1992):

9. Treatment of uncertainty. Estimates of benefits and costs are typically uncertain because of imprecision in both underlying data and modeling assumptions. Because such uncertainty is basic to many analyses, its effects should be analyzed and reported. Useful information in such a report would include the key sources of uncertainty, expected value estimates of outcomes, the sensitivity of results to important sources of uncertainty, and where possible, the probability distributions of benefits, costs, and net benefits.

a. Characterizing uncertainty. Analyses should attempt to characterize the sources of uncertainty. Ideally, probability distributions of potential benefits, costs, and net benefits should be presented. It should be recognized that many phenomena that are treated as deterministic or certain are, in fact, uncertain. In analyzing uncertain data, objective

estimates of probabilities should be used whenever possible. Market data, such as private insurance payments or interest rate differentials, may be useful in identifying and estimating relevant risks. Stochastic simulation methods can be useful for analyzing such phenomena and developing insights into the relevant probability distributions. In any case, the basis for the probability distribution assumptions should be reported. Any limitations of the analysis because of uncertainty or biases surrounding data or assumptions should be discussed.

b. Expected values. The expected values of the distributions of benefits, costs, and net benefits can be obtained by weighing each outcome by its probability of occurrence and then summing across all potential outcomes. If estimated benefits, costs, and net benefits are characterized by point estimates rather than as probability distributions, the expected value (an unbiased estimate) is the appropriate estimate for use. Estimates that differ from expected values (such as worst-case estimates) may be provided in addition to expected values, but the rationale for such estimates must be clearly presented. For any such estimate, the analysis should identify the nature and magnitude of any bias. For example, studies of past activities have documented tendencies for cost growth beyond initial expectations; analyses should consider whether past experience suggests that initial estimates of benefits or costs are optimistic.

Finally, in 1998, the OMB established the requirements for capital asset planning and budgeting to implement the Government Performance and Results Act of 1993 (GPRA) in OMB Circular No. A-11 (OMB, 1998), which states under the heading of “Risk Management”:

Risk management should be central to the planning, budgeting, and acquisition process. Failure to analyze and manage the inherent risk in all capital asset acquisitions may contribute to cost overruns, schedule shortfalls, and acquisitions that fail to perform as expected. For each major capital project, a risk analysis that includes how risks will be isolated, minimized, monitored, and controlled may help prevent these problems.

The project cost, schedule and performance goals established through the planning phase of the project are the basis for approval to procure the asset and the basis for assessing risk.

Finding 3–11. Preproject planning is key to successful large endeavors. OMB Circulars A-94 and A-11 provide guidance for the planning of such projects, particularly with regard to schedules and risk analyses. A planning document of this nature was not provided to the committee.

Recommendation 3–11. PMCD should follow the requirements of OMB Circular A-94 and OMB Circular A-11 for capital projects performed by government agencies to improve the prospects for avoiding schedule overruns. Detailed preproject and project plans should be prepared and used as a basis for making important decisions.