Page 13

2 D&D Challenges in the DOE Complex

The Department of Energy (DOE) constructed over 20,000 facilities to support nuclear weapons production and other activities, and approximately 5,000 of these facilities were identified as surplus in 1996 (DOE, 1997a). DOE's strategy for managing its surplus facilities is to turn them over to its Office of Environmental Management (EM) to become part of EM's overall site cleanup program (see Figure 2.1). EM will begin accepting additional facilities in 2002 and expects eventually to receive most of the remaining facilities. Many of these facilities are contaminated with radioactive materials and hazardous materials, such as mercury, asbestos, and lead. These facilities require continued monitoring and maintenance, because deterioration could eventually make them unsafe for workers to enter or increase the risk of releasing contaminants to the environment.

EM has a two-part strategy for dealing with the surplus facilities that it has accepted: deactivation to stabilize each facility and reduce its maintenance costs, and decommissioning when technically and financially appropriate. Facilities that will eventually require deactivation and decommissioning (D&D) include the following:

-

production reactors,

-

research reactors,

-

chemical processing buildings,

-

uranium, plutonium, and tritium production facilities, and

-

gaseous diffusion plants.

DOE defines deactivation as “a set of integrated and systematic actions [that] render a facility safe and stable until it can be decommissioned” (DOE, 1999c, p. 1). It is a process whereby nuclear materials and chemicals, equipment, and operating systems are placed in a low-risk, low-cost, and mostly passive condition. Included in a facility

Page 14

~ enlarge ~

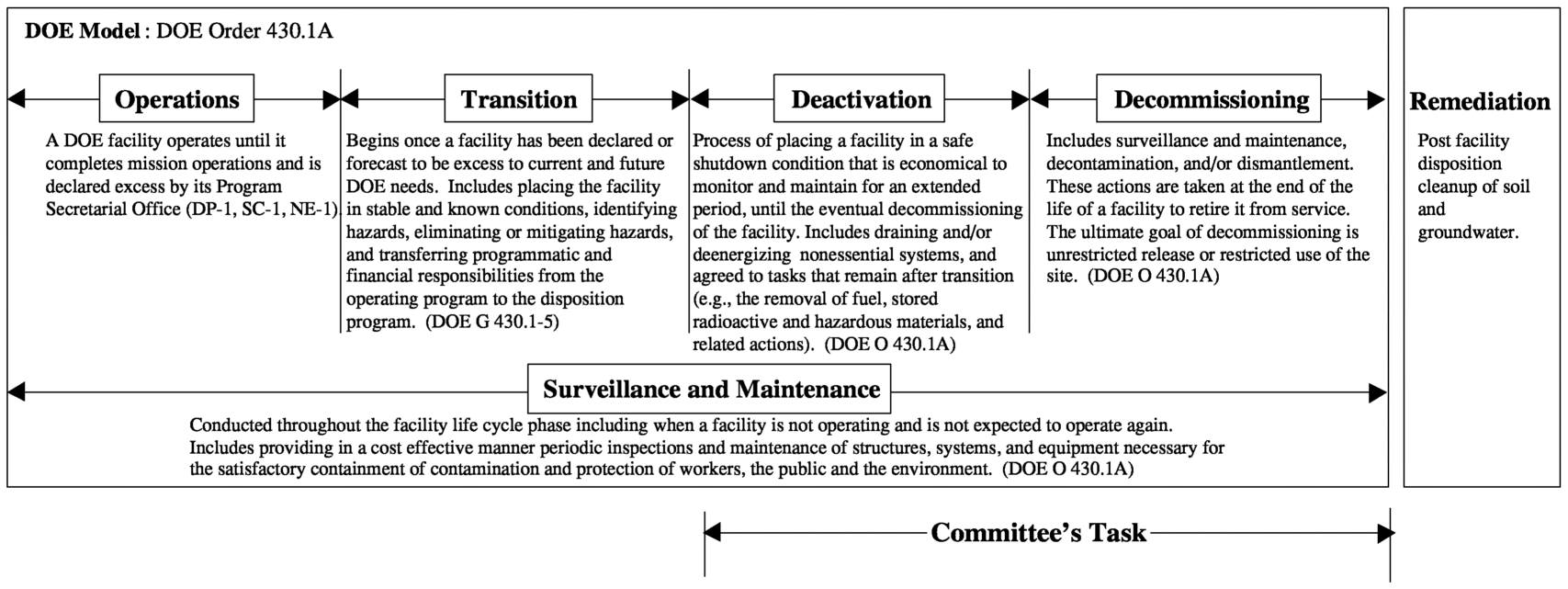

FIGURE 2.1 Transition and disposition phases of a DOE facility's life cycle.

Source: DOE.

deactivation, for example, could be the selective shut down of ventilation, electrical, and security systems; removing items from glove boxes and laboratory hoods; and flushing out chemical processing equipment and associated process piping and instrumentation. To ensure safety, surveillance and maintenance of deactivated facilities must continue. However, the cost of these continued activities is expected to be reduced after the deactivation process (Boyd, 2000).

Decommissioning, according to DOE, takes place after deactivation and includes surveillance and maintenance, decontamination, and/or dismantlement (see Figure 2.1). The intended result of decommissioning (referred to as the “end state”) is typically decided individually for each facility. In some cases the facility is completely removed and the area is returned to a greenfield with unrestricted future use. In other cases the facility may be reused, and in others sufficient contamination remains to warrant long-term surveillance and institutional control. Post-D&D activities, which are part of DOE's overall site-cleanup program, may include remediating soil or groundwater contamination or long-term surveillance.

D&D work must be done in compliance with all applicable regulations, including those of DOE, the Nuclear Regulatory Commission (USNRC), the Environmental Protection Agency (EPA), and state agencies. In most cases where only DOE has legal authority over its facilities, its regulations are consistent with standards set by USNRC and EPA. DOE is committed to adhering to the ALARA (as low as reasonably achievable) principle for radiation exposure to workers while at the same time minimizing the cost of a D&D project. Deciding the end state of a facility also requires balance between cost and future risks. While these issues are outside the task of this committee, the committee believes that scientific research can provide new ways to reduce radiation exposure and other health risks while reducing cost, and its research recommendations ( Chapter 4) are made with these benefits in mind. Better

Page 15

scientific knowledge as input to risk analysis and public decision making will improve all of DOE's site-cleanup activities.

In keeping with the charge to the committee, this chapter first describes many of the DOE facilities that will eventually undergo D&D, with emphasis on those that could be problematic (e.g., expensive or pose potential risk to workers, the public, or the environment) to D&D with currently available (baseline) technologies. 1 This chapter next describes the phases of a D&D project, with emphasis on steps where the committee believes that new technologies could be most useful and where research may provide the greatest benefit. Finally the chapter discusses the objectives (“end states”) for facility decommissioning and where research is needed to help support the selection of end states.

Overview of DOE Facilities

Nuclear weapons production in the United States was a complex series of integrated activities executed at multiple sites across the country. These activities can be grouped into eight major processes:

-

mining, milling, and refining of uranium;

-

isotope separation of uranium, lithium, boron and heavy water;

-

fuel and target fabrication for production reactors;

-

reactor operations to irradiate fuel and targets to produce nuclear materials;

-

chemical separations of plutonium, uranium, and tritium from irradiated fuel and target elements;

-

component fabrication of both nuclear and nonnuclear components;

-

weapon operations, including assembly, maintenance, modification, and dismantlement of nuclear weapons; and

-

research, development, and testing. 2

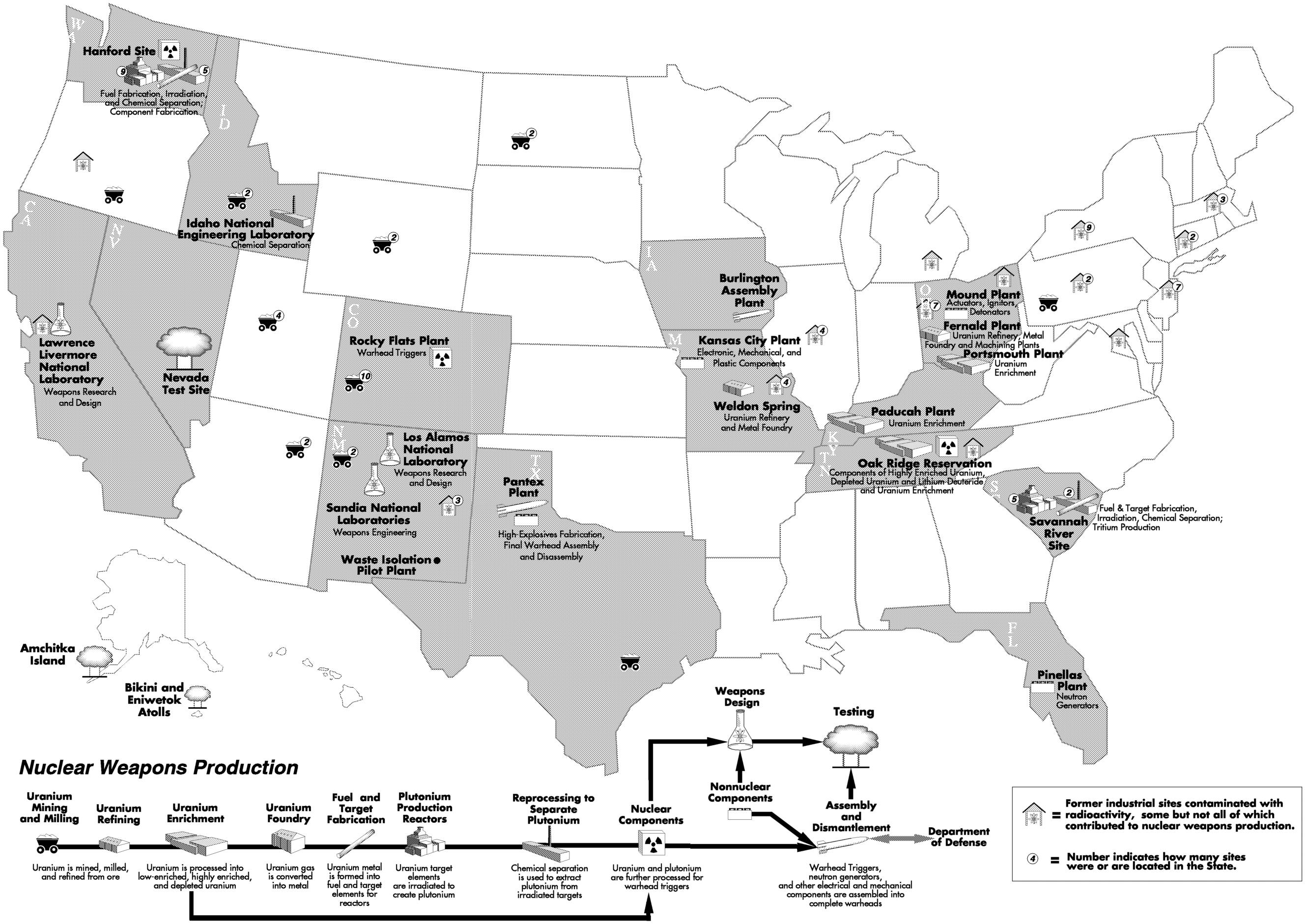

Figure 2.2 illustrates these processes and locates the major sites where they were used (DOE, 1997a, p.15), and Table 2.1 lists the processes and facilities in greater detail.

1Within EM, baseline technologies are currently available and sufficiently established for a contractor to use as the basis for estimating cost and duration of a D&D task.

2Nuclear weapons research, development, and testing take place concurrently with the other seven processes. Research and development are mostly complete before component fabrication begins, but testing may continue until a weapons system is retired from the stockpile.

Page 16

~ enlarge ~

FIGURE 2.2 The United States nuclear weapons complex included facilities that were constructed throughout the country. This figure indicates the location of some of the major facilities and depicts the key production steps.

Source: DOE, 1996.

Page 18

|

Step |

Process Major |

Sites |

|

1 |

Uranium mining, milling, and refining |

Mining and Milling: Uranium Mill Tailing Remedial Action Project mining and milling sites; other commercial-owned domestic mines; other commercial-and government-owned mills;foreign suppliers. Ore sampling: Fernald and Middlesex Refining: Fernald and Weldon Spring (natural, depleted, and enriched uranium reactor fuel and targets); Oak Ridge Y-12 (weapon parts and highly enriched reactor fuel); Oak Ridge K-25, Paducah, and Portsmouth gaseous diffusion plants (production of UF6 feed). |

|

2 |

Isotope separation |

Uranium: Oak Ridge K-25; Paducah; and Portsmouth gaseous diffusion plants. Lithium: Oak Ridge Y-12 COLEX and ELEX Plants. Heavy water: Savannah River Site Heavy Water Plant; Dana Heavy Water Plant. |

|

3 |

Fuel and target fabrication |

HEU: Savannah River Site 300 M Area. Other uranium: Fernald; Ashtabula; Hanford 300 Area; and Savannah River Site 300 M Area. Enriched lithium: Oak Ridge Y-12 and Savannah River Site M Area. |

|

4 |

Production reactor operations |

Hanford: B, D, F, H, DR, C, KW, KE, and N reactors, Savannah River Site: R, P, K, L, and C reactors. |

|

5 |

Chemical separations |

Weapons plutonium: Hanford 200 East and West areas (PUREX, REDOX, T and B plants, 231-Z Plant); Savannah River Site (F Canyon complex). Uranium recycling: Hanford (PUREX, UO3 Plant, REDOX, U Plant); Savannah River Site (H Canyon complex); Idaho National Environmental Engineering Laboratory (Idaho Chemical Processing Plant). Tritium: Savannah River Site (Tritium Facility 230H series). |

|

6 |

Weapons component fabrication |

Plutonium: Rocky Flats; Hanford 234-5 Plutonium Finishing Plant; Los Alamos (TA-21 and TA-55). Highly enriched and depleted uranium: Oak Ridge Y-12; Rocky Flats. Tritium (including recovery and recycling): Mound; Savannah River Site (Tritium Facility). Lithium-6 deuteride (including recovery and recycling): Oak Ridge Y-12. Plutonium recycling: Rocky Flats; Los Alamos (TA-55); Hanford Plutonium Finishing Plant. |

|

7 |

Weapons operations |

Other non-nuclear: Pantex; Oak Ridge Y-12; Mound; Kansas City;Pinellas. Assembly and dismantlement: Sandia; Pantex; Burlington. Modifications and maintenance: Pantex; Burlington; Sandia; Clarksville; Medina modification centers. |

|

8 |

Research, development, and testing |

National laboratories: Los Alamos; Lawrence Livermore; Sandia (New Mexico and California), Test sites: Nevada Test Site; Bikini and Eniwetok Atolls; Christmas and Johnston Islands; Amchitaka Island; Tonopah Test Range; Salton Sea Test Base. |

Source: DOE, 1996, 1997a.

In addition to these historical operations, currently operating (the Defense Waste Processing Facility at the Savannah River Site) and future facilities (e.g., at the Hanford Site and the Idaho National Engineering and Environmental Laboratory) to treat highly radioactive wastes that resulted from DOE's production activities must eventually undergo D&D. Together these facilities represent the spectrum of challenges that EM faces in its D&D task.

Page 19

Uranium Mining, Milling, and Refining

Mining and milling involve extracting uranium ore from the earth and chemically processing it to prepare uranium concentrate (U3O8), sometimes called uranium octaoxide or yellowcake. Uranium concentrates were chemically converted to purified forms suitable as feed materials for the next step in the process. Examples of these feed materials are uranium hexafluoride (UF6) for enrichment at gaseous diffusion plants and uranium tetrafluoride (UF4) or uranium metal for fuel and target fabrication. Refining, as discussed in this report, also involves the recycling of various production scraps, production residues, and uranium recovered from fuel reprocessing.

Wartime uranium refining was performed by various contractors in several eastern states. After the war, the Atomic Energy Commission (the predecessor of the DOE) built uranium refineries in Fernald, Ohio, and Weldon Spring, Missouri.

Isotope Separation (Enrichment)

Enrichment is the process of separating naturally occurring isotopes of the same element in order to concentrate the isotope of interest. The three elements that have been isotopically enriched in large quantities for use in the nuclear weapons complex are uranium, lithium, and hydrogen.

Uranium Enrichment

The first U.S. uranium enrichment facilities were located in Oak Ridge, Tennessee. Additional enrichment plants were later built in Piketon, Ohio, and Paducah, Kentucky. Uranium enrichment began with natural uranium and resulted in enriched uranium and depleted uranium. Highly enriched uranium (HEU) contains 20 weight percent or more of uranium-235; it was fashioned into weapons components and also used as reactor fuel. Low enriched uranium (LEU), which contains less than 20 weight percent of uranium-235, and natural uranium were used as reactor fuel for plutonium production. Depleted uranium was used in weapon components and as targets for the plutonium-239 production. All the uranium enriched during the Manhattan Project was HEU for weapons components. However, as early as 1950, LEU was used for reactor fuel.

Uranium enrichment has resulted in large amounts of depleted uranium in storage, large surplus facilities, uranium-contaminated scrap metal (from facility dismantlement), and waste contaminated with poly-

Page 20

chlorinated biphenyls (from electrical equipment used in the enrichment facilities). Uranium, technetium-99, and organic solvent contamination of soils and groundwater have occurred at a number of DOE sites as a result of uranium enrichment.

Lithium Enrichment

Lithium enriched in the lighter lithium-6 isotope was placed in production reactors to produce tritium and was also chemically compounded with deuterium to be used as a component in nuclear weapons. Lithium was enriched at the Y-12 Plant in Oak Ridge, Tennessee, using the column exchange (COLEX) and electric exchange (ELEX) processes. Both lithium enrichment processes used large amounts of mercury, and as a result, mercury is a major feature of the contaminated facilities at Y-12.

Heavy Water Production

Heavy water is used as a source of deuterium for weapons and as a moderator and coolant for nuclear reactors. Natural water contains small amounts of deuterium (0.01 5 percent), which was concentrated by a combination of hydrogen sulfide-water chemical exchange, water distillation, and electrolytic processes. Heavy water plants were located in Newport, Indiana, and at the Savannah River Site in South Carolina. Routine industrial practices were used to decommission and dismantle these plants, and no long-term environmental challenges are foreseen.

Fuel and Target Fabrication

Fuel and target fabrication consists of the foundry and machine shop operations required to convert uranium feed material, principally metal, into fuel and target elements used in nuclear materials production reactors. Some later production reactors used separate fuel and target elements, while early production reactors used the same elements for both fuel and targets. Uranium ingots were extruded, rolled, drawn, swaged, straightened, and outgassed to produce rods and plates. The rods were machined, ground, cleaned, coated, clad, and assembled into finished fuel.

Reactor fuel and target fabrication was initially carried out by private contractors and at the Hanford, Washington, and the Savannah River, South Carolina, production reactor sites. Within a decade, government-owned plants in Fernald, Ohio, and Weldon Spring, Missouri, took over part of this mission, supplying the fuel manufacturing plants at Hanford and the Savannah River Site.

Page 21

Chemical conversion of uranium feed to metal and processing of uranium scrap and residue resulted in facilities contaminated with uranium, acids, and solvents. Uranium metallurgy and machining also resulted in facilities becoming contaminated with uranium.

Reactor Operations

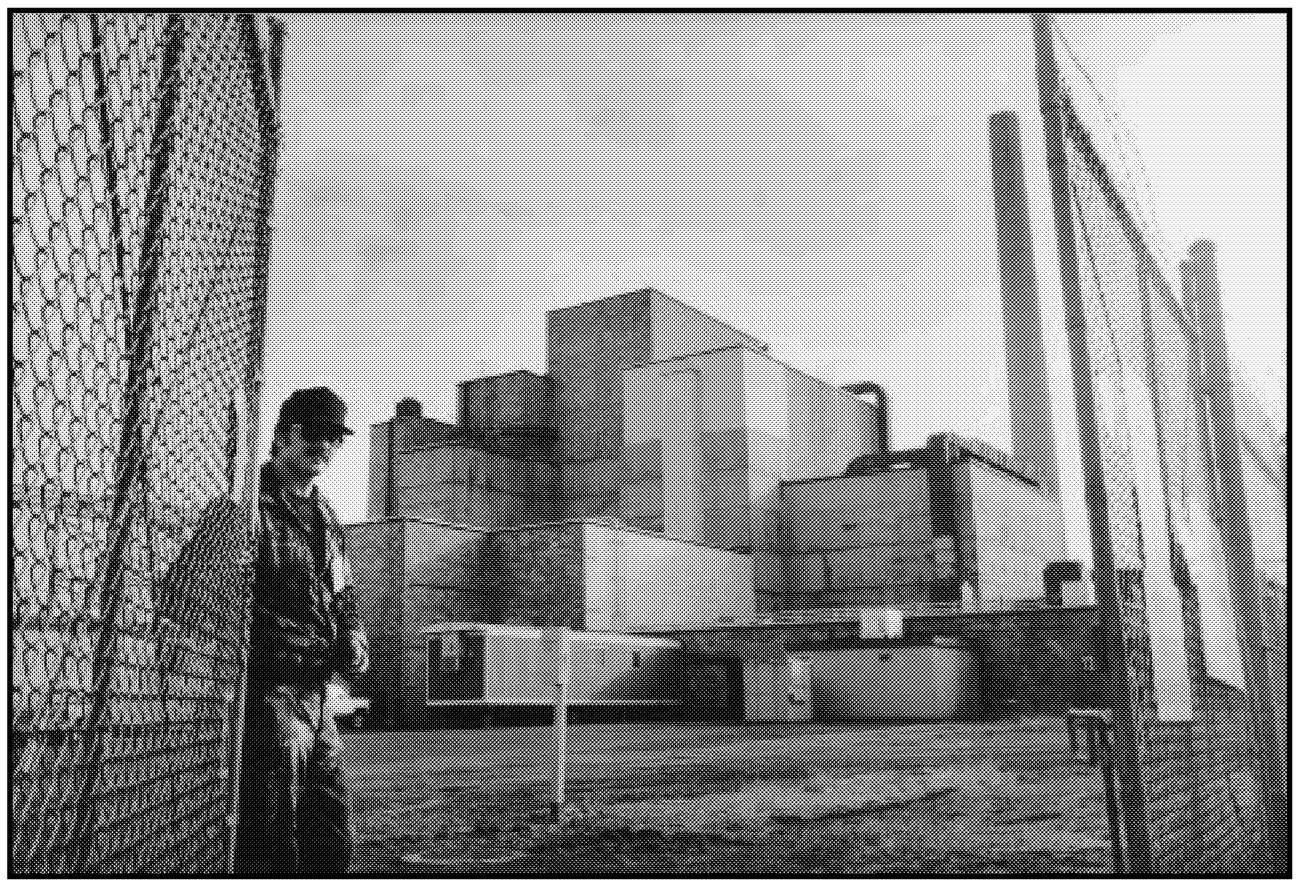

Reactor operations include loading and removal of fuel and target elements, reactor maintenance, and the operation of the reactor itself. Early experimental reactors were built in the Chicago area, at Oak Ridge, and at Hanford. Nine full-scale production reactors were located at Hanford, Washington, and five others were built at the Savannah River Site in South Carolina. Figure 2.3 shows the Hanford B reactor, which is currently undergoing D&D for future use as a museum.

Reactor operations created essentially all the radioactive materials used in the DOE complex. Irradiated fuel and targets were highly radioactive. The components of the reactor cores also became highly radioactive over time. The highly radioactive spent fuel and target materials typically went on to chemical separations, although an inventory of unprocessed spent fuel and targets remains in storage. The reactors also required a large number of support facilities that are now contaminated surplus.

~ enlarge ~

FIGURE 2.3 Built in less than one year, Hanford's B reactor was the world's first plutonium production reactor. After decommissioning it will be preserved as a National Historic Landmark.

Source: DOE, 1996.

Page 22

Chemical Separations

Chemical separation is the process of dissolving spent nuclear fuel and targets and isolating and concentrating the plutonium, uranium, and other nuclear materials they contain. This category also includes the reprocessing of spent nuclear fuel to recover, purify, and recycle uranium for reuse in the nuclear weapons programs and the recovery of uranium from high-level waste at Hanford. Three basic chemical separation processes were used on a production scale in the United States: bismuth phosphate, reduction oxidation (REDOX), and plutonium uranium extraction (PUREX). Chemical separation plants were located at Hanford, Washington; the Savannah River Site, South Carolina; and the Idaho National Engineering and Environmental Laboratory.

Chemical separation of spent fuel and target elements produced large volumes of highly radioactive waste (high-level waste) and large quantities of low-level radioactive wastewater, solid low-level waste, and mixed low-level waste. Also included in this category is chemical processing to recover, purify, and recycle plutonium, uranium, tritium, and lithium from retired warheads, from component production scrap and residues, and from the maintenance, recharging, dismantling, and materials recovery conducted separately on individual components.

Component Fabrication

Weapons component fabrication includes the manufacture, assembly, inspection, bench testing, and verification of specialized nuclear and non-nuclear parts and major subassemblies. The major nuclear component fabrication sites were Los Alamos National Laboratory in New Mexico; the Rocky Flats Plant near Boulder, Colorado; the Y-12 Plant in Oak Ridge, Tennessee; and the Plutonium Finishing Plant in Hanford, Washington. Non-nuclear components were manufactured chiefly at the Mound Plant in Miamisburg, Ohio, the Kansas City Plant in Missouri, the Pinellas Plant in Largo, Florida, and the Pantex Plant near Amarillo, Texas.

Like many conventional manufacturing processes, non-nuclear component fabrication activities have resulted in hazardous waste and contamination of facilities by solvents and heavy metals. The manufacture of high explosives for warheads has resulted in facilities and environmental media that are contaminated with explosive materials.

Weapon Operations

Weapons operations include the assembly, maintenance, and dismantlement of nuclear weapons. Assembly is the final process of join

Page 23

ing together separately manufactured components and major parts into complete, functional, and certified nuclear warheads for delivery to the Department of Defense. Maintenance includes the modification and upkeep of a nuclear weapon during its life cycle. Dismantlement involves the reduction of retired warheads to a nonfunctional state and the disposition of their component parts. The dismantlement process yields parts containing special nuclear materials, high explosives, hazardous materials, and other components with hazardous and non-hazardous properties. Some parts are returned to the facility where they were originally produced. Other parts are maintained in storage (e.g., plutonium pits) or are dispositioned onsite. Disposition processes include crushing, shredding, burning of main high-explosive charges, and firing of small energetic components. DOE is the steward of the weapon until all components have been stabilized, stored, and disposed.

Weapons operations were chiefly done at the Pantex Plant near Amarillo, Texas; the Iowa Army Ordnance Plant in Burlington, Iowa; Technical Area 2 of Sandia National Laboratory; and the Clarksville, Tennessee, and Medina, Texas, modification centers.

The legacy of contaminated facilities resulting from assembly and maintenance is relatively small compared to the legacy resulting from the other weapons production steps, because all the radioactive materials handled in this process are generally in the form of sealed weapons components.

Research, Development, and Testing (RD&T)

The main U.S. nuclear weapons research and development facilities are the Los Alamos, Lawrence Livermore, and Sandia national laboratories. Nuclear weapons RD&T include the design, development, and testing of nuclear weapons and their effects. Localized RD&T to support specific site missions (such as fuel fabrication) is generally considered in this report to be part of each site's mission. The committee did not address D&D issues at the weapons test sites that are listed in Table 2.1.

Waste Processing

As a part of site cleanup, wastes that were produced by the historical operations described in the preceding sections and that are currently stored at the DOE sites must be treated and conditioned for disposal. Highly radioactive wastes will be treated in facilities that have similar layout and shielding walls as the formerly used chemical separations plants. One such facility that is now in operation is the Defense Waste Processing Facility (DWPF) at the Savannah River Site in South Carolina.

Page 24

The facility's mission is to vitrify (convert to a glass-like material) about 36 million gallons of high-level liquid wastes. This mission will be completed by 2026. Similar facilities are planned for the Hanford Site and Idaho National Engineering and Environmental Laboratory (INEEL).

Other waste treatment facilities, such as the Advanced Mixed Waste Treatment Project at INEEL, will treat DOE wastes that contain lower levels of radioactivity. Because these modern waste treatment facilities are being designed—and will be operated and shut down—in view of eventual decommissioning, they are not likely to present as great a D&D challenge as the historical facilities.

Greatest Future Challenges for D&D

DOE recognizes that its site closure program postpones the most difficult D&D tasks until well after 2006 and that this schedule allows time for the development of new technologies to perform at least some of these tasks (Hart, 2000). The committee's statement of task asked the committee to identify significant problems that cannot be addressed effectively with current technologies. As it received presentations from DOE and DOE contractors and toured facilities at Hanford, Oak Ridge, and Rocky Flats, the committee first developed a list of underlying reasons why many of the surplus DOE facilities, especially the larger facilities, will present future D&D challenges. The underlying reasons include the following:

-

personnel hazards—penetrating radiation, airborne contamination, chemical hazards, and industrial hazards;

-

number and size of the facilities and bulk of concrete shielding walls;

-

complex, crowded, often retrofitted equipment arrangements;

-

lack of knowledge concerning the history of operations and contamination in old facilities;

-

difficulty in identifying and quantifying many of the radioactive and chemical contaminants; and

-

lack of consistent, complex-wide objectives (end states) for D&D.

In the committee's view, the DOE facilities that manifest these underlying reasons will present the greatest future challenges for D&D operations. These facilities are described in this section. Overall the committee found that

Page 25

These facilities pose strong safety and economic incentives for developing and using innovative D&D technologies that may be achieved though scientific research. The long time frame for completing D&D (50 years or more) allows for substantive research to be completed and applied.

Radiochemical Separation Facilities

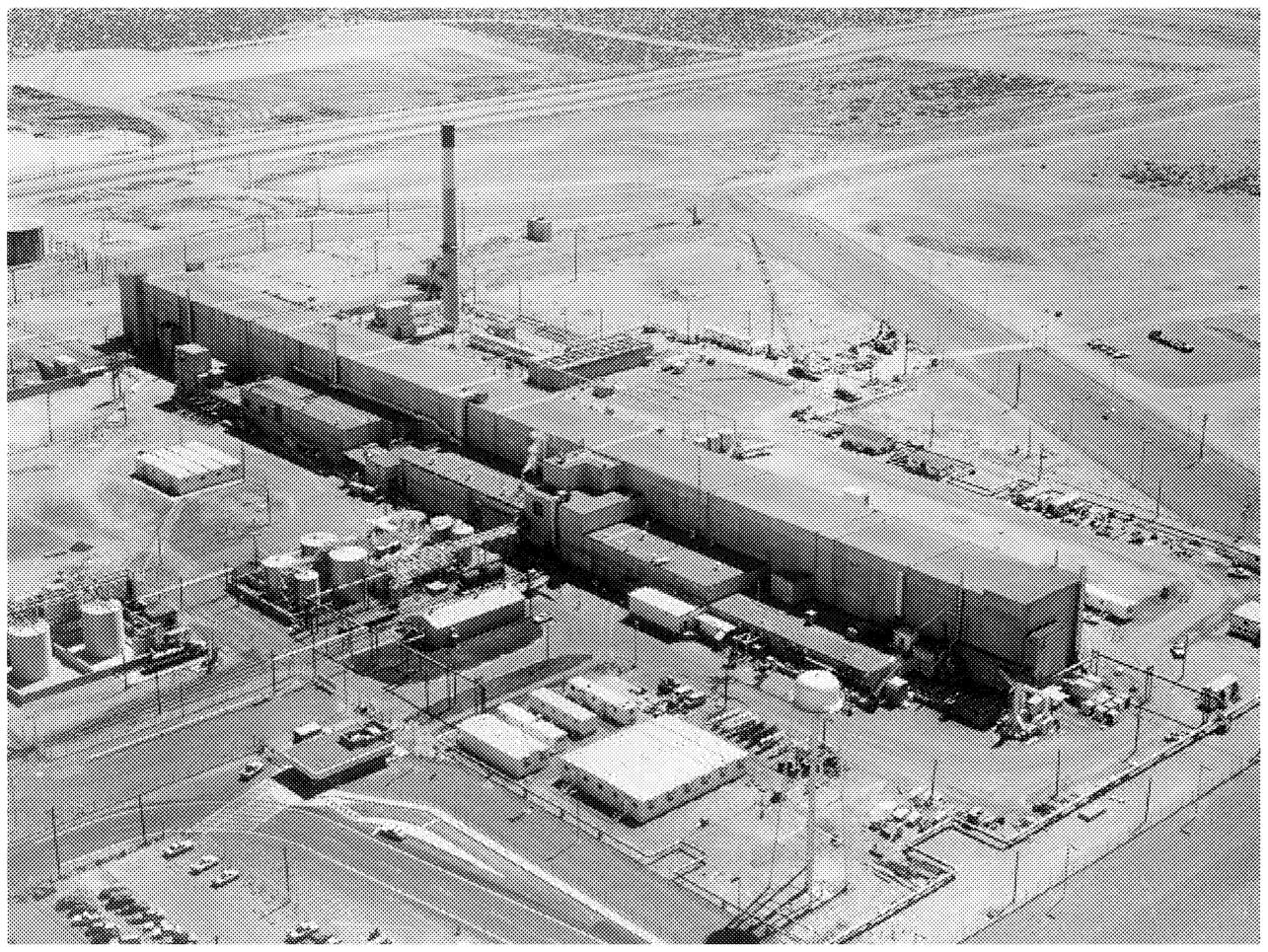

These irradiated fuel and target reprocessing facilities include Savannah River Site's F and H canyons; Hanford's PU REX, T-Plant, B-Plant, U-Plant, and REDOX; and Idaho National Engineering and Environmental Laboratory's Chemical Processing Plant. These are massive concrete structures—Hanford's PUREX plant is approximately 1000 feet long with walls up to four feet thick (see Figure 2.4). The plant interiors are heavily contaminated and have penetrating radiation levels that preclude personnel entry (DOE, 1997a). Processes have used acids, organic solvents, and hazardous chemicals like mercury and chromium compounds. Leaks and spills through years of operation have caused seepage into concrete and expansion joints, and deposits of material in obscure locations are highly probable.

~ enlarge ~

FIGURE 2.4 Chemical separation of plutonium from other radioactive materials was carried out in Hanford's PUREX plant and similar facilities. They were referred to as canyons because thick walls to protect workers from radiation surrounded the long, remotely operated processing corridor.

Source: http://www.fas.org/irp/imint/doe.htm

Page 26

Gaseous Diffusion Plants

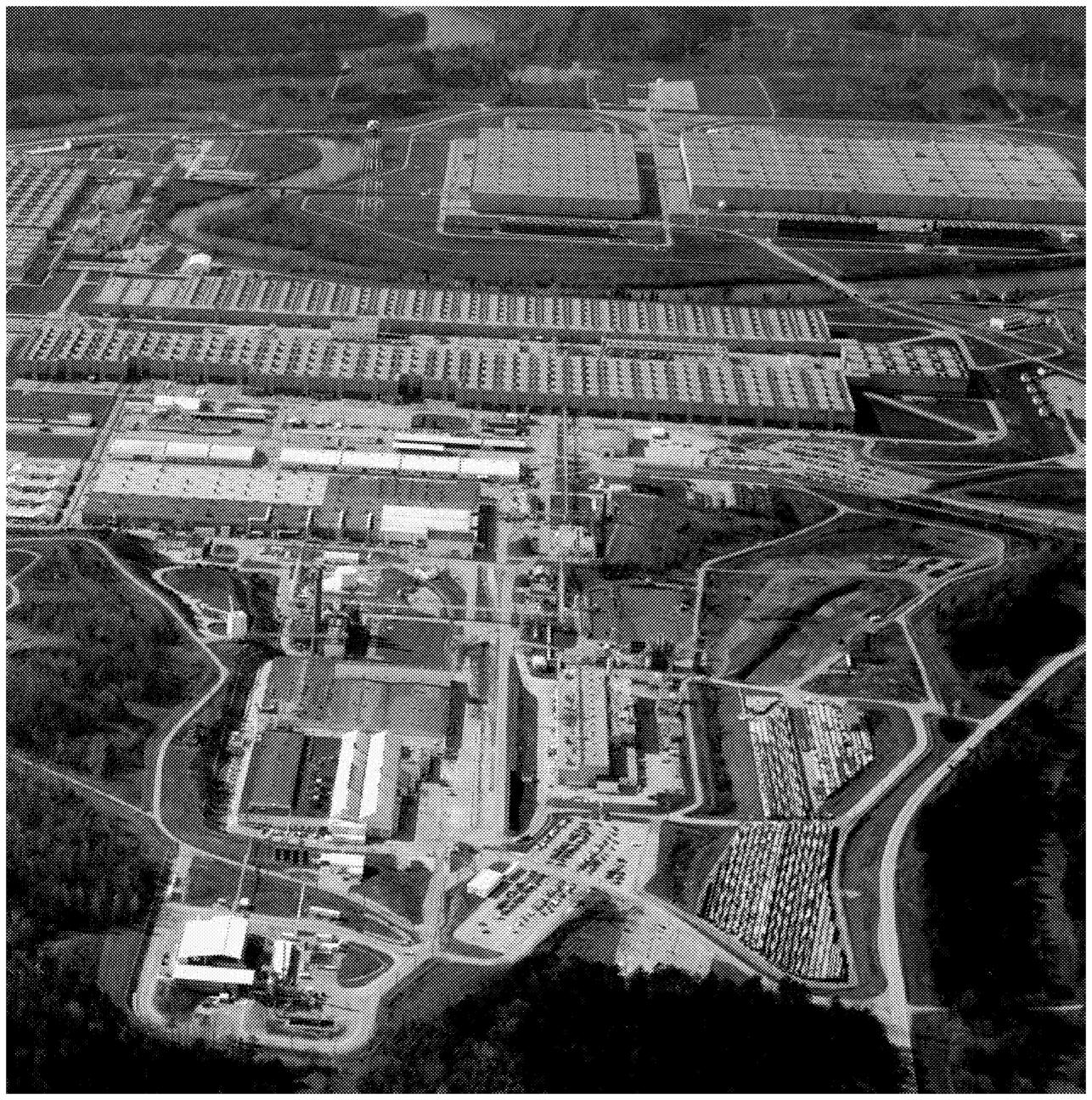

Uranium enrichment plants in Oak Ridge, Tennessee, Portsmouth, Ohio, and Paducah, Kentucky, are the largest of DOE's surplus facilities. When first built, the Oak Ridge K-25 Gaseous Diffusion Plant was one of the largest roofed structures in the world, covering nearly 43 acres. The K-25 process building is one-half-mile long and 1000 feet wide (see Figure 2.5). Operation of the enrichment plants has involved uranium, asbestos, solvents, polychlorinated biphenyls (PCBs), heavy metals, and other toxic substances (DOE, 1996, 1997a). In addition, recycled uranium has introduced fission products like technetium-99 and alphaemitting isotopes into these buildings. Opportunities for cost reduction in the D&D of gaseous diffusion plants were examined by a previous NRC committee (NRC, 1996). However, that committee's findings may be superseded by new DOE directives on release criteria for radio-actively contaminated metals from these plants (Nuclear Waste News, 2000).

~ enlarge ~

FIGURE 2.5 The K-25 site was one of several that provided enriched uranium. This site includes almost 400 buildings that have a total of about 14.4 million square feet of floor space.

Source: http://www.fas.org/irp/imint/doe.htm

Page 27

Plutonium Processing Facilities

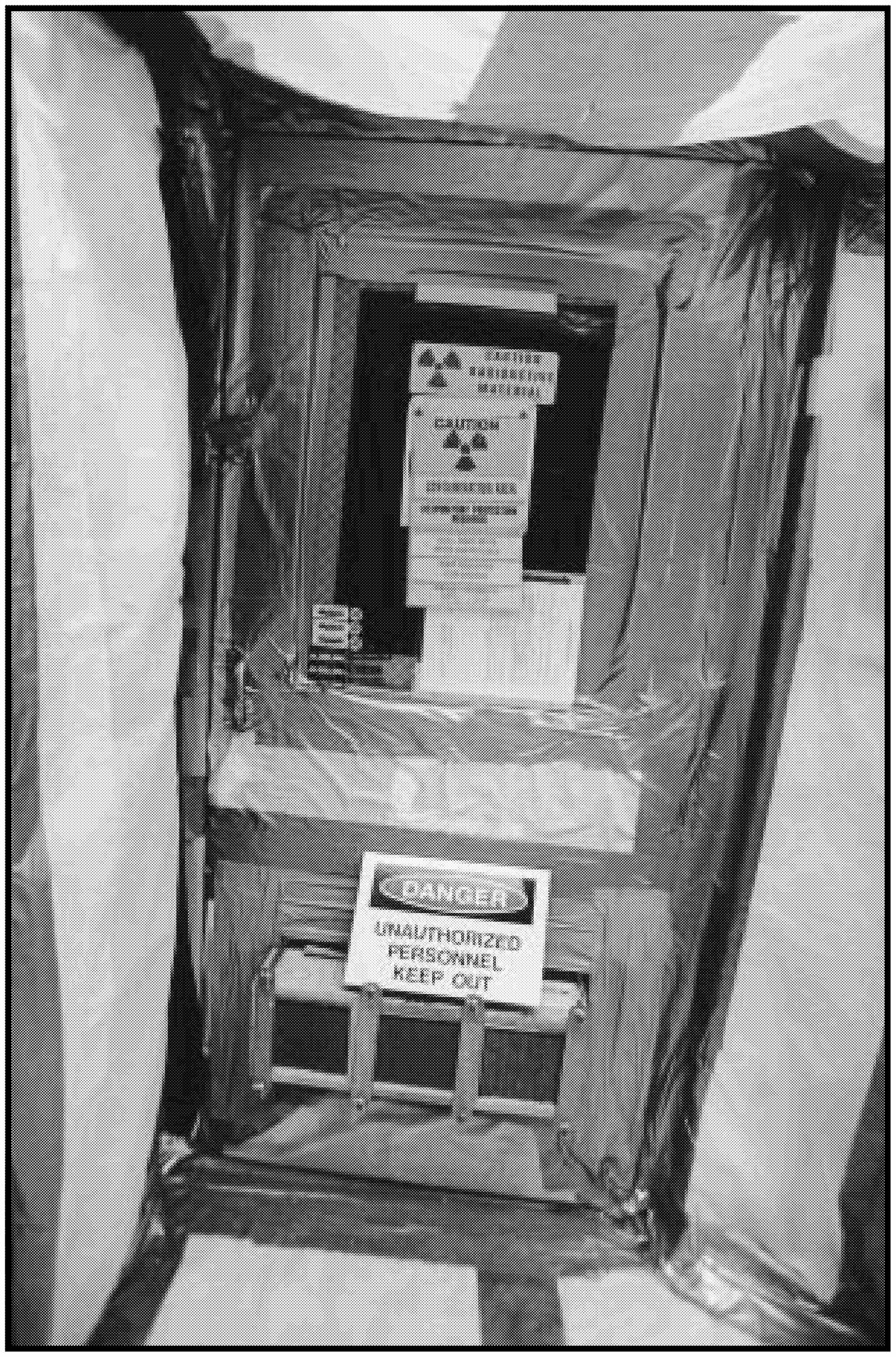

Plutonium processing facilities include a variety of chemical processing and weapons component fabrication facilities like Hanford's 231-Z Plant and Plutonium Finishing Plant (234-S); Savannah River Site's FB-Line and HB-Line; Los Alamos TA-55; and Rocky Flats Buildings 707, 771, 776, and 777 (see Figure 2.6). Most of these facili

~ enlarge ~

FIGURE 2.6 Door leading into a plutonium processing room at the Rocky Flats Site is sealed due to very high levels of alpha radiation within the room. There are more than 20 such rooms at the site.

Source: DOE, 1996.

Page 28

ties used glove boxes or gloved cabinets at negative pressure to safely handle the plutonium.

The dominant D&D hazard arises from small, airborne particles of plutonium that can be inhaled or ingested or assimilated through puncture wounds or other industrial injuries. In addition, neutron exposure is significant due to alpha/neutron reactions from plutonium alpha particles interacting with low-atomic-weight elements like oxygen and fluorine. Furthermore, the penetrating radiation dose in plutonium facilities increases over time due to the ingrowth of americium-241 (from beta decay of plutonium-241). Potential accumulation of plutonium in piping, vessels, and ventilation ducts could be encountered during D&D. In some cases accumulation may be sufficient to raise nuclear criticality issues. 3 A variety of acids, solvents, and other chemicals were used in the facilities.

Glove boxes are often crowded with equipment, and modifications have created areas where there is little room for workers to perform D&D tasks. These areas are also highly contaminated, which leads to slow D&D work, with workers encumbered by protective clothing, including respirators or plastic suits to provide clean air for breathing.

Tritium Processing Facilities

Tritium facilities, although fewer than DOE plutonium and uranium facilities, are D&D challenges. The Savannah River Site has been the United States' primary tritium production facility since the mid-1950s. The Savannah River Site also purifies and loads tritium into weapons components.

Tritium represents a unique radiological hazard because of its volatile forms and ability to undergo isotopic exchange with any hydrogen-containing material (e.g., water, grease) that it contacts. Because it is a very-low-energy beta emitter, it is difficult to detect inside equipment and waste packages. Further, it diffuses into metals and concrete. Hazardous metals like mercury are also present in tritium facilities; for example, mercury diffusion pumps are commonly used. The mercury becomes contaminated with tritium and can be spilled inside the process lines during maintenance work. D&D waste will likely present challenging characterization problems to distinguish between low-level radioactive versus low-level mixed waste.

3According to DOE, the sudden shutdown of plants that handled plutonium residues and scraps stranded 26 tons of plutonium in intermediate processing steps (DOE, 1996).

Page 29

The original Savannah River Site tritium processing facility, Building 232-F, has been decommissioned. It began extracting tritium from lithium-6 aluminum target elements irradiated in the five Savannah River Site production reactors in 1955, was replaced in 1958, and sat idle until it was decommissioned between 1994 and 1996. During D&D, surprises were encountered that prompted a search for better detection, bulk sampling, and laboratory analysis methods for characterizing contaminated concrete (Hochel, 2000).

Phases of a D&D Project

The D&D of nuclear facilities is a complex, multi-step process. The DOE model shown in Figure 2.1 describes some of the steps. As an aid to its own fact finding and discussions, the committee has chosen to describe D&D, in a simplified way, as a five-step process that begins with deactivation and ends with formal closing of the project (see Table 2.2):

-

a facility deactivation phase following the permanent shutdown of all operations;

-

an assessment and decision making phase;

-

a planning phase for the development of the D&D plan;

-

the physical decontamination and decommissioning operations phase; and

-

a closeout phase during which the end-state requirements have been verified and the facility can be released for its intended end use or long-term monitoring.

Table 2.2 illustrates these five phases and some of the key activities that occur in each phase. Table 2.2 also notes areas where the committee identified opportunities to significantly reduce cost and enhance the safety of workers, the public, and the environment. These areas are characterization, decontamination, robotics, and scientific input into determining the facility end state. In Chapter 4, the committee provides research recommendations for each of these areas.

Facility End States

For a facility undergoing D&D, the project's objective is a major determinant of the cost, schedule, and amount of work required (which affects risk to workers). This objective is often referred to as the facility

Page 30

|

Phase 1 Facility Deactivation (Surveillance and Maintenance) |

Phase 2 Assessment and Decision Making |

|

Shut down Systems |

Establish D&D Objectives: -Facility End Use & End State |

|

Regulatory Compliance |

-Regulatory Requirements -Financial Considerations |

|

Public & Community |

|

|

Communications Program |

Identify Technology and Science Needs |

|

CHARACTERIZATION |

|

|

-Contamination Control and Surveillance |

Perform Risk Assessments |

|

- Safeguards and Security |

Obtain External Science Reviews |

|

DECONTAMINATION -Personnel access |

Evaluate Alternatives |

|

-Contamination control |

Encourage Public Involvement |

|

ROBOTICS -Inspection |

Select D&D Alternative |

|

-Maintenance |

CHARACTERIZATION |

|

-Monitoring |

-Conduct Surveys -Obtain & Analyze Samples |

end state. End states for individual facilities or buildings on a site are generally part of the overall cleanup agreement for the site—the site “end state.” Even if a facility is completely removed, there are post-D&D remediation activities as shown in Figure 2.1. End states are negotiated by the DOE working with state and federal regulators and local stakeholders, and for most facilities and buildings they have not been defined. Viewed from this perspective it is not surprising or undesirable that there is no complex-wide, consistent definition of end states.

Previous NRC study committees have examined the question of end states for DOE cleanup activities. One of these reports discussed end states in terms of alternative scenarios and accordingly defined end state as the “the final product of a waste processing, remediation, or management scenario characterized well enough in terms of chemical, physical, and radioactive attributes to allow details of scenarios to be

Page 31

|

Phase 3 D&D Plan Development |

Phase 4 Decommissioning Operations |

Phase 5 Facility Closeout |

|

Select Acquisition Strategy |

Equipment & Structure Removal |

Post Decommissioning |

|

Schedule Baseline -Cost Baseline |

Monitoring of Workers |

Regulatory Reviews |

|

Initiate New Technology Development |

Area Monitoring and Interim Release of Areas |

Release Facility for Reuse, Monitoring or Long-term Stewardship |

|

Implement D&D Safety Program |

Issue Lessons Learned |

|

|

Use CHARACTERIZATION DATA to Complete D&D Plans -D&D Sequence -Permits & Licenses -Man-Rem Estimates -Waste Quantities Est. |

Continue Public Communications Program |

CHARACTERIZATION to Verify END STATE -Independent Contractor Surveys -Issue Post Decommissioning Report |

|

DECONTAMINATION of Components, Systems, and Structures |

||

|

Select CHARACTERIZATION and Monitoring Methodology |

DECONTAMINATION & CHARACTERIZATION of Materials |

|

|

Establish END STATE Requirements |

||

|

Select ROBOTIC Systems |

CHARACTERIZATION and Management of Waste |

specified” (NRC, 1999a, p. 2). Another study viewed end states as guides to site disposition decisions and found that “end states appear at present to be emerging as the de facto result of multiple interim actions” (NRC, 2000b, p. 21). Decisions could in principle be revised as new information became available or as ideas change. Focusing more narrowly on end states for facility D&D, the previous study of the D&D focus area (see Chapter 3) found that “[w]ithout defining ‘how clean is clean enough' the necessary technology, cost, and schedule for a D&D project cannot be determined” (NRC, 1998a, p. 3).

In its fact finding the committee encountered a variety of site agreements and guidelines for D&D end states. For most facilities at Rocky Flats the end state is complete removal of the building. Re-industrialization, including decontamination and reuse of many buildings, is planned for much of the Oak Ridge Site and parts of the Hanford Site.

Page 32

The Canyon Disposition Initiative at Hanford is considering an option of partly decontaminating a separations building, filling the building with low-level waste, and mounding earth over the building. In the latter two examples, the agreed upon end state will determine the degree to which the facilities must be decontaminated.

While establishing end states is clearly a matter of public negotiation and decision making, the committee believes that a better scientific underpinning for the selection of facility end states is needed. The committee believes that there are two major areas in which the scientific basis for evaluating the risk to public and worker health and safety of various end states is inadequate.

The first area is the understanding of the actual health risk of residual levels of radioactive and hazardous materials (MacLachlan, 2000). The EMSP has acknowledged that “[t]here is scientific uncertainty regarding a safe level of risk to human health and the environment for the end state of the Department's cleanup effort” (DOE, 2000g, p. 7). In cooperation with the DOE Office of Science, the EMSP recently issued a research solicitation on low-dose radiation effects, which included four specific areas aimed at developing a better understanding of risks. The Nuclear Regulatory Commission (USNRC) has recently asked for advice on the technical bases for criteria to control release of slightly contaminated solids from USNRC-licensed facilities. 4 Data on radiation exposure to D&D workers will be valuable for future epidemiological studies.

The other area in which there is inadequate scientific basis for evaluating the health risk of end states is the fate and behavior of contaminants in D&D facilities. The EMSP recognizes that “[a]ccurate risk analysis requires thorough knowledge of contaminant characteristics. . . . Research is needed to define transport dynamics of toxic chemicals and radionuclides” (DOE, 2000g, p. 7). The committee's recommendations for research in this area are given in Chapter 4.

4Board on Energy and Environmental Systems, “Alternatives for Controlling the Release of Solid Materials from Nuclear Regulatory Commission-Licensed Facilities.” In progress.