PANEL MEMBERS

Marvin F.DeVries, University of Wisconsin-Madison, Chair

Richard A.Curless, Cincinnati Machine, a UNOVA Company, Vice Chair

Hadi A.Akeel, FANUC Robotics NA, Inc.

Christopher P.Ausschnitt, IBM Microelectronics Division

Mary A.Austin, Pratt and Whitney

Jerry Banks, Brooks Automation, AutoSimulations Division

Thomas Charlton, Brown & Sharpe Mfg. Co.

James E.Costa, Remedy Corporation

Jose B.Cruz, Jr., Ohio State University

Richard E.DeVor, University of Illinois at Urbana-Champaign

Richard J.Furness, Ford Motor Company

David E.Hardt, Massachusetts Institute of Technology

Michael E.Kahn, KLA-Tencor Instruments (retired)

Wolfgang H.Sachse, Cornell University

Donald L.Sage, Lucent Technologies (retired)

Masayoshi Tomizuka, University of California at Berkeley

Submitted for the panel by its Chair, Marvin F.DeVries, and its Vice Chair, Richard A.Curless, this assessment of the fiscal year 2001 activities of the Manufacturing Engineering Laboratory is based on site visits by individual panel members, a formal meeting of the panel on March 20–21, 2001, in Gaithersburg, Md., and the documents provided by the laboratory.1

LABORATORY-LEVEL REVIEW

Technical Merit

According to laboratory documentation, the mission of the Manufacturing Engineering Laboratory (MEL) is to satisfy the measurements and standards needs of the U.S. discrete-parts manufacturers in mechanical and dimensional metrology and in advanced manufacturing technology by conducting research and development, providing services, and participating in standards activities.

The panel believes the programs established by the MEL support both the laboratory and NIST missions. The divisional mission statements are clearly linked to the MEL mission, and these connections help ensure that the longer-term research projects performed in the divisions directly contribute to the MEL responsibility for developing and maintaining physical and informational measurements and standards for new and emerging technologies.

Overall, the laboratory is undergoing a period of transition. Flat budgets and a declining number of staff have put significant pressure on laboratory management, forcing it to closely examine the current portfolio of projects in order to eliminate redundancy and identify and exploit opportunities for synergy. A few years ago, the laboratory implemented an annual planning process that prioritizes potential and current work in order to help its management select new program areas or reorganize existing ones. The panel supports this approach and is pleased to observe progress being made in several areas, including the consolidation of programs, the solicitation of technical staff input in program planning and selection processes, and the definition of criteria for project selection. These ongoing efforts to keep the laboratory’s project portfolio focused and up to date are essential to maximize impact and utilize resources efficiently. The panel cautions that the programs created should not just be umbrella structures encompassing loosely or ill-related topics, but rather a coherent collection of activities focused on achieving complementary goals. The laboratory has made a good start, and now the goal should be for management and staff to embrace a systematic approach to setting priorities, gathering information from customers, and defining the potential impact for all MEL programs.

Last year, the panel suggested that the laboratory perform prospective studies of project and program impact, and there is evidence that this approach is being adopted with success by the MEL. Incorporating the results of these studies into the program planning process is helping the laboratory select new research areas that not only support the measurement and standards needs of industry but also maximize the value of the government investment. The panel notes that prospective studies of impact do not always need to be formal and highly detailed; the key step is gathering facts to demonstrate how results from the proposed NIST activities can be realistically expected to provide significant benefits to industry. Intuition can be a useful guide to pointing staff toward areas worth considering and suggesting possible ways in which MEL work might have an impact, but before new programs are selected and begun, the panel recommends that the status of the industries targeted by the proposed efforts should be investigated and information demonstrating how the planned NIST outputs will make a difference should be documented.

Another suggestion from last year’s report was that the MEL develop quantitative data on the balance of short-term and long-term programs currently under way in the laboratory. The goal would be to understand how much MEL effort is directed at developing and implementing measurements and standards with immediate utility for industry and how much time and resources are devoted to fundamental research on advanced manufacturing technologies. The laboratory has made some progress on determining the relative emphasis on these two types of activities, but the panel feels that more remains to be done in this area. At the moment, the relationship between the investigations of advanced manufacturing technologies and the measurements and standards work is better defined in some of the

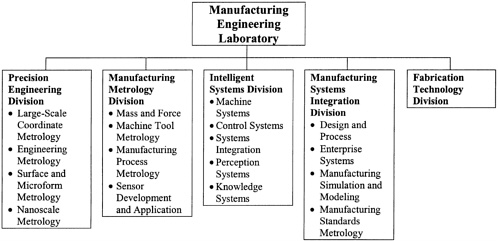

FIGURE 3.1 Organizational structure of the Manufacturing Engineering Laboratory. Listed under each division are the division’s groups.

divisions than in others. It is important to understand not only the balance between the activities but also how the goals of the longer- and shorter-term programs are connected. The laboratory needs to define its overall priorities in order to systematically build a coherent program portfolio, and clarifying how the general research projects feed into and align with the laboratory’s core measurements and standards mission will help MEL sharpen its focus and determine which and how many long-range projects are needed to lay the groundwork for future measurements and standards.

The Manufacturing Engineering Laboratory is organized into five divisions (see Figure 3.1), and the panel comments on the activities in the four research divisions in separate sections later in this chapter. The fifth division, Fabrication Technology, contains the shops that provide technical services (such as machining, glassblowing, and metal and optical fabrication) for experimental work throughout NIST. As discussed in last year’s assessment, support for this division is in transition away from partial funding from NIST overhead toward totally reimbursable funding tied to specific activities or services. This year, the division is under new leadership and is in the process of implementing a new three-phase strategic plan. Progress has been observed, and the panel encourages the division to continue to focus on strategic issues during this challenging transition.

The divisional organization of the laboratory is supplemented by a programmatic structure. The laboratory’s activities have been organized into 18 programs, many of which include projects from more than one division. The panel believes that the MEL has successfully balanced divisional and programmatic organizations and that this mix is appropriate for carrying out the MEL mission. The programmatic component of this approach also helps facilitate cross-divisional collaborations, but the key factor in the effectiveness of intra- and interlaboratory interactions is the existence of an informal but active network linking technical staff throughout the MEL and NIST. It is clear to the panel that these relationships are based on mutual respect between staff members and that the strength of this network enhances the quality of the research performed.

The technical merit of programs and projects under way in the MEL varies considerably, although a clear majority were, in the panel’s opinion, very good. In general, the best projects seemed to be those with a sharp focus and a clear understanding of which customers will be served by the project results. The breadth of the laboratory’s mission and the importance to industry of work in measurements and standards mean that there are a staggering number of issues and potential projects that MEL could productively tackle. However, as in most research laboratories around the world, the resources available are limited, so the laboratory is making an effort to more clearly identify industry issues related to its mission. The panel believes this approach will help strengthen all of the programs by providing clearer direction for the work.

A key benefit of the laboratory’s program planning process is that it takes a formal approach to prioritizing activities, which allows MEL to recognize when it is necessary to eliminate certain projects in order to gain sufficient resources for others judged to be of more importance. These decisions must take into account not only the technical quality of the programs being eliminated but also the needs of industry and the question of redundancy both within and outside NIST.

An example of an area in which the question of redundancy is particularly significant is the laboratory’s many projects in dimensional and mechanical metrology. The Manufacturing Engineering Laboratory has stated that one of its ongoing goals is to be the best in the world in all of the subareas of dimensional and mechanical metrology. The panel acknowledges that the laboratory’s projects in this area are technically superior and that MEL’s position at the cutting edge of measurement and standards capabilities is repeatedly confirmed in international benchmarking exercises. The products and services supported by MEL projects in these areas meet key needs of industry and contribute to maintaining the competitive position of U.S. companies, so their appropriateness and quality are not in doubt. However, a serious commitment of resources is necessary to maintain this level of work in all of the subareas of dimensional and mechanical metrology, and the panel questions if the laboratory can realistically expect to continue this commitment in light of the many potential new projects and the limited resources available. Planning might be initiated with the national measurement institutes (NMIs) of other countries to discuss how measurements and standards programs and capabilities can be made accessible to companies throughout the world, thus satisfying current industrial needs without unnecessary duplication of effort by the NMIs.

That it might be possible to share responsibility for providing standards and measurement products and services with other NMIs is in part due to the MEL’s effective use of information technology to interact with other laboratories. SIMnet, MEASUREnet, and WORLDnet enhance national and international collaborations on mass and length standards among different laboratories, and the panel commends the MEL’s accomplishments in this area. These innovative Internet applications could well serve as cost-effective models for communication within any sort of multinational network.

Program Relevance and Effectiveness

NIST is celebrating the centennial of its founding this year. A number of activities occurred to highlight the value of NIST’s contributions over the years. At the MEL, the celebration of the history of the Automated Manufacturing Research Facility is an appropriate salute to a unique program that had a significant impact on both NIST and industry.2 Today, the MEL continues to produce important results

and provide key services for U.S. industry. Specific examples are provided in the divisional assessments that follow, but overall, the productivity improvements achieved through the deployment of new or improved standards based on MEL work clearly demonstrate the impact of the laboratory’s activities on industry.

Further evidence for the key role MEL plays in the technological advancement of manufacturing can be seen in the quantity and quality of the awards and recognitions received by the staff. The focus of the laboratory is, appropriately, on ensuring that NIST results can be adopted by industry, and the awards, several for technology transfer, reflect this emphasis. An important element in the MEL’s overall success in communicating its results to relevant communities is industry’s respect for the laboratory’s technical staff. The excellence of MEL personnel is confirmed by the many recognitions accorded to the staff by professional organizations such as the American Society of Mechanical Engineers (ASME), IEEE, and ASTM. All of the awards received by individual staff members or by specific laboratory products not only confirm the value of past NIST work, but also increase MEL’s visibility and reputation within the communities most likely to benefit from its activities. The laboratory’s visibility is also being increased by the ongoing Charters of Freedom project, in which MEL staff are contributing to NIST’s design and construction of new display and preservation cases for the Declaration of Independence, the Bill of Rights, and the Constitution. The success of past projects, the awards to MEL staff, and the participation in high-profile activities all lay the groundwork for future technology transfer and new and stronger relationships with NIST customers.

As noted in the previous section, the laboratory is increasing its efforts to prioritize its programs based on factors like potential impact on industry. The panel observes that a critical step in putting together an effective portfolio of projects should be seeking out MEL’s customers and having them identify important current and future issues in measurements and standards. This information will help the laboratory determine priorities and organize programs to ensure that results are delivered in time to meet companies’ needs and to be smoothly adopted into industrial systems. Interactions with customers before individual projects begin is also a good way to ensure that the projects are appropriately directed and that industry is interested in and ready to use the planned NIST results.

As part of the continuing effort to focus its programs, the laboratory adopted statements defining its core purpose, core values, aspirations, and customer focus during the most recent annual strategic planning cycle. The panel commends the laboratory for this effort to sharpen MEL’s focus but does have one concern. The customer focus statement declares that the laboratory takes “responsibility for understanding the manufacturing needs of the U.S. automotive and aerospace industries and for seeing that their measurement and standards needs are addressed.” The emphasis on measurement and standards is clearly appropriate and consistent with NIST’s core mission. However, by explicitly mentioning the automotive and aerospace industries, the statement becomes open to misinterpretation by NIST staff and by potential external customers. The MEL programs serve a wide array of other industries and communities, including semiconductor companies and nanotechnology research and development organizations. As it is now worded, the statement could cause MEL staff working in these other areas to infer that their work was less valuable than work on the automotive and aerospace projects. Also, based on this statement, companies and organizations outside NIST might not realize the full breadth of the MEL programs.

An essential component of the laboratory’s work is standards-related activities, from the development of measurement techniques used to define standards and the production of physical standard artifacts, to the involvement in international intercomparisons and the participation on standards committees. This year, the panel specifically requested that the laboratory provide more information about its involvement in international standards activities, and MEL supplied good documentation describing

these staff activities and the impact they are having on customers. Based in part on the work done in preparation for the panel meeting, the laboratory has now developed a formal guidebook to support its decisions on which standards to become involved with. The panel commends this effort; the guidebook might serve as a model for similar documents in other NIST laboratories or NIST-wide. In addition, the information gathered in the course of assessing MEL’s portfolio of standards activities could serve as a base for beginning discussions with other NMIs about how to avoid unnecessary duplication of standards activities, as suggested earlier in this chapter.

Laboratory Resources

Funding sources for the Manufacturing Engineering Laboratory are shown in Table 3.1. As of January 2001, staffing for the Manufacturing Engineering Laboratory included 211 full-time permanent positions, of which 142 were for technical professionals. There were also 30 nonpermanent or supplemental personnel, such as postdoctoral research associates and temporary or part-time workers.

MEL’s funding is flat, and the number of personnel has been steadily dropping. As discussed earlier in the report, the laboratory has begun to consolidate and refocus its programs in response to these

TABLE 3.1 Sources of Funding for the Manufacturing Engineering Laboratory (in millions of dollars), FY 1998 to FY 2001

|

Source of Funding |

Fiscal Year 1998 (actual) |

Fiscal Year 1999 (actual) |

Fiscal Year 2000 (actual) |

Fiscal Year 2001 (estimated) |

|

NIST-STRS, excluding Competence |

26.4 |

27.9 |

27.3 |

28.1 |

|

Competence |

1.8 |

1.4 |

1.1 |

1.0 |

|

ATP |

2.4 |

2.0 |

1.8 |

0.3 |

|

Measurement Services (SRM production) |

0.0 |

0.1 |

0.1 |

0.1 |

|

OA/NFG/CRADA |

7.1 |

4.6 |

6.1 |

6.6 |

|

Other Reimbursable |

4.5 |

4.8 |

5.1 |

4.8 |

|

Total |

42.2 |

40.8 |

41.5 |

40.9 |

|

Full-time permanent staff (total)a |

254 |

239 |

232 |

211 |

|

NOTE: Funding for the NIST Measurement and Standards Laboratories comes from a variety of sources. The laboratories receive appropriations from Congress, known as Scientific and Technical Research and Services (STRS) funding. Competence funding also comes from NIST’s congressional appropriations but is allocated by the NIST director’s office in multiyear grants for projects that advance NIST’s capabilities in new and emerging areas of measurement science. Advanced Technology Program (ATP) funding reflects support from NIST’s ATP for work done at the NIST laboratories in collaboration with or in support of ATP projects. Funding to support production of Standard Reference Materials (SRMs) is tied to the use of such products and is classified as Measurement Services. NIST laboratories also receive funding through grants or contracts from other government agencies (OA), from nonfederal government (NFG) agencies, and from industry in the form of Cooperative Research and Development Agreements (CRADAs). All other laboratory funding, including that for Calibration Services, is grouped under “Other Reimbursable.” aThe number of full-time permanent staff is as of January of that fiscal year. |

||||

resource constraints. The skill set of the current collection of personnel is appropriate to support the division, laboratory, and NIST missions, but staff are currently stretched quite thin in many areas. The panel’s most serious concern is about future staffing for the MEL. Analyses presented by the laboratory indicate that senior individuals are retiring or departing and that the MEL is having difficulty bringing in permanent entry-level research personnel (see Figure 1.1). People with considerable measurement expertise are being lost before they can train their replacements, and the situation is seriously compromising the institutional memory. The inability to hire a sufficient number of new junior staff interferes with the laboratory’s ability to sustain current core competencies or develop any new ones. Currently the laboratory is using guest workers to infuse new technical expertise and insight into the divisions; while effective in the short term, this approach is only a temporary fix. The panel commends the MEL for performing an in-depth analysis of the human resource issues, including factors affecting retention, recruitment, and morale, and notes that the laboratory clearly recognizes the importance of finding creative solutions to this issue.

Despite the resource limitations, the panel observed that overall morale is very good among the laboratory personnel. MEL managers are introducing new channels of communication within the laboratory, and the panel encourages them to test these mechanisms in ways that the very busy staff do not perceive as burdensome. The panel believes that the key communications issue is how to effectively provide staff with information about management decisions and the reasoning behind them. Whether management goals at both the NIST and MEL levels are being clearly communicated to all laboratory staff is another question that would benefit from management attention. If a lack of awareness and understanding of management actions and plans is allowed to develop, morale may be negatively affected.

Over the years, the MEL has demonstrated an appropriate willingness to make significant investments in expensive equipment. However, as the cost of equipment grows, it will be increasingly difficult for the laboratory to equip its core activities. The panel recognizes that while funding for equipment purchases comes from the NIST Working Capital Fund, the need to pay back that fund via depreciation expenses forces the laboratory to make difficult trade-offs between new equipment and labor. Creative solutions to this problem should be explored, particularly in light of the new instruments that will probably be needed for the Advanced Measurement Laboratory (AML), scheduled for completion in 2004. The laboratory has already begun preliminary planning on how to allocate space for the MEL activities that will be housed in the AML, and the panel suggests that a time line for the procurement of the capital equipment needed for that facility be developed soon. Long-range planning is necessary as the laboratory has to consider if and how to retire equipment of lesser importance to the laboratory mission. Also, the trade-offs between constructing the laboratory’s own instruments and purchasing or borrowing commercial products need to be weighed.

DIVISIONAL REVIEWS

Precision Engineering Division

Technical Merit

According to division documentation, the mission of the Precision Engineering Division is to provide the foundation of dimensional measurement that meets the needs of the U.S. industrial and scientific communities by conducting research in dimensional measurements; developing measurement methods; providing measurement services; and disseminating the resulting technology and length-based

standards. The division is organized into four groups: Large-Scale Coordinate Metrology, Engineering Metrology, Surface and Microform Metrology, and Nanoscale Metrology.

The panel is very impressed with the quality of the work and the array of capabilities represented within the division. The division performs length measurements over 12 orders of magnitude, all at state-of-the-art precision for NMIs. This range is divided into four overlapping segments, with a specific group responsible for addressing each segment. Each of the groups has successfully achieved many well-defined goals since the last review in 2000 and is making a significant contribution to the overall success of the division. The division’s staff continues to perform outstanding work that is recorded in archival publications. The technical quality of the measurement work is also increasingly being quantitatively benchmarked by round-robin measurement activities with other NMIs around the world, with results that reflect well on NIST. The division has primary responsibility for the nanometer-scale metrology program, the surface metrology program, the engineering metrology program, and the large-scale metrology program, and contributes to the Shop Floor As NMI program. The division also has begun exploring ways to satisfy broad future needs of industry for task-specific calibrations.

The program on nanoscale metrology extends dimensional metrology to the submicron scale, providing standards, measurement capability, and measurement uncertainty guidelines for the semiconductor and nanotechnology industries. The program goal is to enable the microelectronics industry to sustain and improve production by adopting NIST-traceable length standards and infrastructural metrology methodologies for nanometer- to meter-scale lengths. The program has been strongly guided by the International Technology Roadmap for Semiconductors;3 it has worked in close collaboration with the industry consortium, International SEMATECH, and seeks to enable the industry’s production goal of 100-nm devices by 2005. In the past fiscal year the division made progress on a two-dimensional grid artifact Standard Reference Material (SRM) that should ultimately enable the most accurate, traceable feature placement standard for photomask lithography. Various projects are under way to improve the optimization and control of commercial scanning electron microscopy (SEM) metrology tools. For example, a collaboration with International SEMATECH seeks to enhance the performance of critical-dimension scanning electron microscopes (SEMs) by using nano-sharp tips to improve image resolution and brightness. Initial results are very positive, and evaluation will continue with tips fabricated by a number of sources. NIST work in support of wafer metrology is more developmental in nature and includes work on a possible future overlay metrology SRM.

Following last year’s decision to reduce the scope of the Molecular Measuring Machine (M3) project, the division took advantage of the opportunity to reduce staff on this project (via one retirement and the departure of a guest worker). Efforts to enhance M3’s capabilities have been redirected to applying its current capabilities and making the instrument a functioning metrology platform. To this end, the division demonstrated its first lattice-resolution measurements and images of an organic electrically conductive crystal, (TEET)[Ni(dmit)2]2.

While its current technical capability is high and its researchers are well-recognized by their peers, the nanometer-scale metrology program faces serious challenges in maintaining this technical level in support of the capital-intensive semiconductor industry. As device dimensions shrink, there is an increasing need for state-of-the-art metrology equipment. In particular, the transition of commercial photomask metrology from optical to SEM tools will render much of the current NIST calibration capability obsolete. The division’s lack of advanced metrology equipment comparable to what is used

|

3 |

See <http://www.semichips.org>. |

in semiconductor manufacturing facilities will handicap its efforts to support the semiconductor industry in the near future.

The surface metrology program has as its goal to deliver to U.S. industry measurement services in surface and microform metrology of unimpeachable quality and of the variety that industry requires. Program staff are engaged in calibrated step-height and surface roughness measurement that has wide industrial applicability. The program also has a subcontract with government law-enforcement agencies to provide SRM bullets. Ongoing research in this program is generally of high quality and, judging by the number of invited publications and awards, has earned the participants widespread recognition as experts in their fields. The surface metrology program employs a variety of microscopy techniques, including SEM, atomic force microscopy (AFM), optical interference, and others. Several projects require particular comment. An industrial measurement comparison of single-atom silicon step artifacts was completed, yielding a best uncertainty of 5 pm. The calibrated AFM project has resulted in publication of a paper describing use of AFM techniques to measure pitch, step height, and line widths on the scale of tens of nanometers. This important work has unfortunately been delayed due to the departure of a key guest researcher. Similarly, aging SEM equipment is delaying recertification of the SEM magnification SRM. While many projects in the surface metrology program are producing significant results, project objectives do not appear to be directed toward the stated overall program objective of saving industry $80 million over the next 5 years.

The engineering metrology program focuses on submillimeter to meter-plus dimensions and provides the bulk of the everyday calibrations of mechanical artifacts used by discrete parts manufacturers. This group’s core competency is its ability to deliver state-of-the-art measurement results on the international standard of length. The primary benchmark of such ability is round-robin measurement intercomparisons with other leading NMIs. As part of an international effort to improve mutual recognition of calibrations among the world’s trading partners, an extensive series of key comparisons is now under way under the auspices of the Consultative Committee on Length (CCL). The results of the first key comparison, CCL-K1, the interferometric measurement of gage blocks, places NIST results near the world mean, well within their expanded uncertainty, for both steel and tungsten carbide blocks. While the results of CCL-K2, measurement of long end standards, are not yet final, internal reproducibility studies using three different measurement methods again produced results within their uncertainties. Measurement of gage blocks from 175 mm to 900 mm yielded an excellent uncertainty of less than 135 nm. This program continues to pursue the use of new technical approaches to standard measurements to expand its measurement capabilities.

The large-scale metrology program focuses on measuring dimensions greater than a meter to very low tolerances, including measurements for large objects such as airplanes and ships. Primary technical activities center on evaluating, characterizing, and improving the accuracy of performing such measurements. As an example of this, excellent earlier work on characterizing the measurement errors of large coordinate measuring machines (CMMs) is now being applied to laser tracker systems, with the goal of improving the accuracy of measurements with these commonly used systems. This program also makes significant contributions to large-scale industrial measurements by assisting in the development of voluntary industrial consensus standards for new measurement technology. Program researchers continue to be respected key participants in many such standards activities, both at the national level (ASME) and the international level (ISO).

The Shop Floor As NMI program is aimed at the development of validated non-task-specific methods by which industry may perform their own NMI-quality traceable task-specific measurements of parts on the shop floor. This program is motivated by both the increasing need for the most precise metrology attainable and the MEL’s decreasing ability to meet industry demand for calibrations and

other traceability measurements. Specific technical projects within this program are making good progress and have attracted some favorable industrial interest. But the panel remains concerned that the program is inadequately scoped and funded to meet its ambitious goals. In response to concerns voiced by the panel in its previous report, the division has taken some positive steps to improve the chances of program success. A new, well-qualified technical program manager has been appointed to the program. A preliminary effort to benchmark the MEL approach to this problem with the approaches of other similar NMIs has been undertaken. However, there is little evidence that MEL management has substantially rethought the full range of issues that must be addressed for successful implementation of this program. A full systems analysis, including provision for the integration of all critical technologies, must be developed to make this revolutionary approach realistic and successful.

Program Relevance and Effectiveness

The Precision Engineering Division’s activities have great relevance to a wide range of customers, including industrial, academic, and governmental organizations. Results of the division’s work are effectively disseminated and are contributing to U.S. industry’s technical capabilities and competitiveness, reaching customers in both the traditional discrete parts industry and in semiconductor manufacturing.

In fiscal year 2000, the division provided $827,000 in measurement and calibration services in a variety of areas. These included the performance verification of laser trackers utilized in aircraft manufacturing; calibration of over 5000 gage blocks, ring gages, and other artifacts used in numerous discrete part manufacturing industries; silicon single atom step height artifacts for the semiconductor industry; standard bullets and casings for law enforcement; and numerous interferometric length calibrations of customer materials.

In fiscal year 2000, the division expended $124,500 in producing SRMs for U.S. industry. It introduced new SRMs for SEM pitch measurement and optical overlay targets for standards work in semiconductor manufacturing. It also made available a sinusoidal reference profile SRM, which will be important in manufacturing process control of surface roughness. Using a UV scanning microscope, substantial progress was made toward the issuance of a micrometer-scale SRM.

Precision measurement collaborations and round-robin measurement comparisons were completed with other laboratories and industrial organizations. For example, comparisons with industry of the height of silicon single-atom steps, which showed a standard deviation of approximately 5 pm, may lead to a new step height standard for calibrating atomic force microscopes. Current wafer line width and overlay metrology programs are focused on problems that are important to the semiconductor industry.

The division staff produced 49 technical papers during fiscal year 2000. Division staff continued their participation in international and national standards committees, including ISO technical committees on dimensional and geometrical product specifications, optics and optical instruments, and industrial automation systems, and the Joint Committee on Guides to Metrology. In addition, staff members participate in a number of international governmental and industrial working committees and consultative committees on a wide range of measurement standards and metrology methodologies. The panel believes the division’s work on standards committees to be particularly important and strongly urges that this work continue.

The division staff has been recognized with numerous honors and professional appointments in the past year. Several members of the staff were awarded a year 2000 Federal Laboratory Consortium Award for Excellence in Technology Transfer for the development of the SEM Monitor with Hewlett-Packard and SPECTEL Co. This technology has been adopted in a number of semiconductor fabrication facilities and resulted in significant improvements in SEM performance. A staff member was

awarded a research fellowship by Japan’s Science and Technology Agency. Staff members were elected to several prestigious positions including member of the Board on Standardization of the ASME, secretary of the CIRP Committee on Precision Engineering and Metrology, and member of the International Joint Committee on Guides to Metrology. One staff member was appointed as advisory professor, Harbin Institute of Technology in the People’s Republic of China and as editor of the NIST Journal of Research. A staff member was commended by the Physical Review for incisive reviews and contributions to maintaining the journal’s standards.

The division’s programs strike an appropriate balance between the development of metrology systems for measuring and production machines and measurement services for length-related standards. However, the division decisions continue to be driven by the program selection process of the MEL and a long-term reduction in budget available to carry out the mission. The panel believes that realizing the main elements laid out in the Precision Engineering Division’s strategic plan is critical to fulfilling the NIST mission and that the division’s strategic plan should therefore be given a higher priority. The panel commends the division for its continuing productiveness and impact in a time of constrained funding and resources.

Division Resources

Funding sources for the Precision Engineering Division are shown in Table 3.2. As of January 2001, staffing for the Precision Engineering Division included 36 full-time permanent positions, of which 32 were for technical professionals. There were also 6 nonpermanent or supplemental personnel, such as postdoctoral research associates and temporary or part-time workers.

Flat or nearly flat budgets, combined with increasing labor costs, are eroding the capabilities of the division. Table 3.2 shows the decline in full-time permanent staffing. Budgets are also impacting the division’s capacity to obtain and maintain state-of-the-art equipment for its research.

TABLE 3.2 Sources of Funding for the Precision Engineering Division (in millions of dollars), FY 1998 to FY 2001

|

Source of Funding |

Fiscal Year 1998 (actual) |

Fiscal Year 1999 (actual) |

Fiscal Year 2000 (actual) |

Fiscal Year 2001 (estimated) |

|

NIST-STRS, excluding Competence |

5.4 |

5.8 |

6.1 |

6.3 |

|

Competence |

1.0 |

0.6 |

0.4 |

0.4 |

|

ATP |

0.3 |

0.4 |

0.2 |

0.2 |

|

Measurement Services (SRM production) |

0.0 |

0.1 |

0.1 |

0.1 |

|

OA/NFG/CRADA |

0.8 |

0.7 |

0.8 |

0.9 |

|

Other Reimbursable |

0.8 |

0.8 |

0.8 |

0.7 |

|

Total |

8.3 |

8.4 |

8.4 |

8.6 |

|

Full-time permanent staff (total)a |

50 |

42 |

41 |

36 |

|

NOTE: Sources of funding are as described in the note accompanying Table 3.1. aThe number of full-time permanent staff is as of January of that fiscal year. |

||||

Resource issues are impacting the morale of the division staff. In meetings with panel members, staff opined that further reductions in resources would make continued work on current programs impossible. They felt that division management needed to take more active steps to secure outside agency and industry funding and to address staff retention.

Much excellent technical work has been performed by division staff with relatively little capital expenditure, using outdated, home-built equipment. This is both commendable and disturbing. It demonstrates the resourcefulness and capabilities of the NIST staff, and their intimate knowledge of their home-built equipment provides them with the understanding of error sources that advances in measurement accuracy require. However, this approach does not utilize staff time efficiently or leverage the collective learning of industry in developing advanced metrology equipment, particularly when the customers are capital-intensive industries like semiconductors or aerospace. If uncorrected, the capital equipment deficiency will lead inevitably to a decline in the NIST metrology capability.

The lack of long-term capital equipment planning for the AML is another area of concern. The new facility will help the division to meet the current and future measurement needs of the United States. However, the division is not prepared to fulfill its long-term capital equipment needs, especially given the new hardware that will be required in the AML and the fact that equipment used in the current facilities may be too dirty to move to the new clean room facilities. The panel believes that the division, in concert with MEL management, needs to develop a strategy for long-term capital planning to assure that this and other divisions will have the equipment necessary to remain globally competitive.

The panel notes for a second time the lack of an objective process to determine whether a program will continue or terminate. In times of tight funding, prioritization is key, and the lack of such a process is impacting staff morale. In the absence of directly appropriated funding increases, the division also requires a plan to obtain funding from other agencies and industry that will allow it to accomplish its mission. The panel has seen no progress on this issue since the last review.

Manufacturing Metrology Division

Technical Merit

According to division documentation, the mission of the Manufacturing Metrology Division is to fulfill the measurements and standards needs of the United States in mechanical metrology and advanced manufacturing technology by conducting research and development in realizing, maintaining, and disseminating SI mechanical units; developing methods, models, sensors, and data to improve machines, processes, and metrology; providing services in mechanical, machine, and process metrology and sensor integration; and leading the development of national and international standards. The division is organized into four groups: Mass and Force, Machine Tool Metrology, Manufacturing Process Metrology, and Sensor Development and Application.

The Manufacturing Metrology Division was formed in the past year when the Automated Production Technology division was reorganized and renamed. The name of the division implies a broad scope of activities (manufacturing), and the mission can also be interpreted as all-inclusive. However, division management has made a strategic decision to limit the scope of its programs. Current programs being carried out by the division are advanced optics metrology, mechanical metrology, metrology and smart sensor systems for manufacturing equipment, nanomanufacturing, and predictive process engineering. The division also participates in the Shop Floor As NMI program. The panel commends the division for limiting its scope to improve the potential impact of each program. These programs, and the projects within them, are closely tied to the core competencies of the division. In fact, many appear to

be new packaging for previously existing projects. The panel recommends that the division carefully review the programs and their projects and determine a more cohesive development strategy for the new organization.

Overall, the programs on advanced optics metrology, mechanical metrology, and metrology and smart sensor systems for manufacturing equipment are focused and of high technical quality. In the predictive process engineering program, the panel was impressed with projects on process metrology and materials data for machining simulation, assessment of machining models, and grinding and polishing technologies. The panel wishes to give special recognition to the interdisciplinary project on microforce measurements. Such interlaboratory collaborations should be encouraged, and cross-laboratory work should become a normal part of MEL culture.

Based on feedback from the previous panel review, the division continues to concentrate on improving metrology for machines and processes. The predictive process engineering program revisited its objectives to ensure their alignment with the overall program goal. However, the panel had difficulty understanding how the various projects within the program were integrated or how they related to the goal. The division should thoroughly reevaluate the overall plan of the predictive process engineering program to ensure that it conforms with the division’s mission and customer needs. The scope of all future projects directed toward this program goal must be critically evaluated and managed to maximize benefits. Without such oversight, efforts in this area could become too diluted. While some individual projects are excellent, the overall program does not provide an adequate framework to link these distinct contributions. It is not clear whether the current elements of the program are sufficient to achieve the expected outcomes. In addition, some elements of this program may not be achievable within the current core competencies of the division. A rational reappraisal of this program, including development of roadmaps and realistic timelines, is needed.

The program in metrology and smart sensor systems for manufacturing equipment is specifically aimed at providing services in mechanical, machine, and process metrology and in sensor integration, to support industry needs for evaluation of the latest manufacturing equipment and processes. Many projects in this program are outstanding, such as the smart sensor interface and machine tool metrology projects. However, the assessment panel again had difficulty understanding how the program’s various projects were integrated or how they related to the overall goal. At this point, the programs seem to serve as new packaging for legacy projects. The panel recommends that in the coming year the division develop roadmaps and realistic time lines for this and other programs.

The role of the division as a leader in the development of national and international standards ensures that the interests of the United States are protected. For this reason, the division must continue to provide adequate resources in this area. The division devotes significant resources to the key comparisons and other requirements called for in the Mutual Recognition Agreement signed in 1999 by the NMIs of the 38 member states of the Metre Convention, and it must continue to play an active role in this area.

Program Relevance and Effectiveness

Based on its mission statement, the Manufacturing Metrology Division can be said to serve two primary roles. First, it is the nation’s reference laboratory for the units of mass, force, acceleration, sound pressure, and ultrasonic power. In this role, the division serves the nation by providing calibration services, developing advanced methods for mechanical metrology, developing national and international standards, and leading efforts with international standards organizations. While not highly visible, this first role is critical for the nation’s manufacturing industry. The division retains world-class

capabilities and has state-of-the-art facilities for metrology services. However, the panel is concerned that this leadership in current measurements may quickly erode as limited resources are being dedicated to new standards and services development. In particular, ultrasonics capabilities have diminished to the point that there is no chance the division can impact active and passive ultrasonic measurement systems for materials testing and evaluation and for biomedical applications. The second major role of the division is to develop manufacturing and mechanical metrology. The customers of this effort include both the industrial and governmental communities. The division fulfills this role through its own internal projects and by acting as a catalyst or facilitator for collaborative efforts among government, industry, and academia.

The division’s work is disseminated in many ways. Workshops, consortia, and standards committees disseminate many research results. Workshops also identify customer needs. Division staff are also frequently invited speakers at conferences and seminars. These presentations, the issuance of standards, and the division’s technical publications all provide evidence that the division is serving its customers, but they cannot be used to quantify the impact of the research. A clearer indication of impact is possible for the Mass and Force group, which serves individual paying customers directly via calibration services. The impact of these services is readily determined by considering the number of paying customers using them, and a recent survey of customers by the division indicates good customer satisfaction. The continuing call for the division to be involved in standards activities (e.g., IEEE 1451, ANSI/ASME standards, international standards) also demonstrates the relevance of the division’s work.

The division recently consolidated its portfolio of projects into four programs. This marks the third consecutive year of program realignment. The division now has fewer programs to manage, although the number and scope of projects remains about the same. In the opinion of the review panel, the relevance and effectiveness of the programs vary significantly. Some programs are struggling to identify their customers, the customers’ real wants and needs, and the role of the division in the technology area. For example, the predictive process engineering program needs more focus on defining and identifying customers and assuring its relevance to the division’s mission.

This year the division introduced a matrix management structure composed of group leaders, program managers, and project leaders. Although matrix management has been very successful in large organizations with several distinct cross-functional responsibilities, the panel wonders whether the same benefits can be realized when the approach is applied in a smaller organization with rather homogeneous responsibilities. A change in management style often stimulates unanticipated positive results, and for that reason the panel supports the change. However, the approach must be critically evaluated within 1 or 2 years to ascertain if the change has delivered the expected results.

The panel heard little discussion of the criteria for selecting projects. This should be an area of continual attention to assure relevance in project selection. The panel recommends that each project should be clearly connected to both MEL’s strategic plan and its mission statement.

Division Resources

Funding sources for the Manufacturing Metrology Division are shown in Table 3.3. As of January 2001, staffing for the Manufacturing Metrology Division included 42 full-time permanent positions, of which 38 were for technical professionals. There were also 4 nonpermanent or supplemental personnel, such as postdoctoral research associates and temporary or part-time workers.

Last year the panel was concerned that funding was insufficient to cover participation in the international standards activities related to the Mutual Recognition Agreement (MRA). MEL partially addressed this need by providing an additional $250,000 for this activity for fiscal year 2001, but the

TABLE 3.3 Sources of Funding for the Manufacturing Metrology Division (in millions of dollars), FY 1998 to FY 2001

|

Source of Funding |

Fiscal Year 1998 (actual) |

Fiscal Year 1999 (actual) |

Fiscal Year 2000 (actual) |

Fiscal Year 2001 (estimated) |

|

NIST-STRS, excluding Competence |

5.0 |

5.4 |

5.6 |

5.0 |

|

Competence |

0.4 |

0.4 |

0.3 |

0.3 |

|

ATP |

0.6 |

0.3 |

0.3 |

0.1 |

|

OA/NFG/CRADA |

0.7 |

1.2 |

2.0 |

1.7 |

|

Other Reimbursable |

1.2 |

1.3 |

1.2 |

0.9 |

|

Total |

7.8a |

8.6 |

9.4 |

8.0 |

|

Full-time permanent staff (total)b |

44 |

44 |

46 |

42 |

|

NOTE: Sources of funding are as described in the note accompanying Table 3.1. aFY 1998 data do not add owing to rounding. bThe number of full-time permanent staff is as of January of that fiscal year. |

||||

funding is insufficient. Because participation is critical to U.S. interests, this activity must not languish. It is recognized that standards and calibration activities often leave little time and too few resources for the fundamental research that is needed to advance current and future capability to meet the needs of U.S. commerce, and the panel is concerned that such research will be neglected in the short term until the international MRA activity subsides.

The panel commends the division for augmenting the permanent staff with postdoctoral fellows. Given the division’s inability to fund permanent staff, the panel urges the division to formulate an aggressive formal plan to hire additional postdoctoral researchers in order to enhance its capabilities. During a meeting with division staff, concerns about budget, time allocation, the matrix management system, scarce resources, and the political environment at NIST were discussed. It is clear that all these issues are of concern and affect staff morale.

Intelligent Systems Division

Technical Merit

According to division documentation, the mission of the Intelligent Systems Division is to develop the measurements and standards infrastructure needed for the application of intelligent systems by manufacturing industries and government agencies. The division is organized into five groups: Perception Systems, Knowledge Systems, Control Systems, Machine Systems, and Systems Integration. These five groups work in three program areas: research and engineering of intelligent systems, intelligent open architecture control of manufacturing systems, and intelligent control of mobility systems.

The program on research and engineering of intelligent systems aims at providing a framework within which intelligent systems can be evaluated, specified, and integrated. The technical approach being taken involves four components: developing metrics for the performance of intelligent systems;

providing knowledge engineering tools suitable for real-time perception and control; determining common architecture for intelligent systems; and integrating learning, self-optimization, self-diagnosis, and adaptive control into intelligent system controllers. The program develops principles, metrics, and standards in each of these four areas. Research results have been translated to several testbed examples (e.g., an integrated inspection testbed), and some results have been applied to programs inside and outside the laboratory.

There is no question about the importance of intelligent control in modern manufacturing systems. The program is addressing critical and needed objectives in light of the emerging technologies for integrated manufacturing, autonomous vehicles, and many others dependent on computer control and sensors. The research is timely and cutting edge. While the quality of the ongoing work is strong, the panel believes a more focused program would yield even better results. Undertaking too many projects will only dilute efforts, and results may not be of sufficient impact. The panel suggests focusing on short- to medium-range emerging technologies (5 to 10 years ahead) and addressing intelligent systems labeled as such without worrying about the abstract definition of intelligence. The program may want to define “intelligence” as it is used in current and evolving intelligent systems; doing so would allow it to focus on the practical rather than the philosophical. This program can stay on an effective course by diligently applying itself to machine intelligence without pondering the issue of human intelligence.

The goal of the program for intelligent open architecture control of manufacturing systems is to enable the “12-month car” concept (12 months from engineering to manufacture of a new vehicle) for both the automotive and aerospace industries. The program aims to create standards for open systems that are more easily integrated into factory systems with easy and simple interchangeability and interoperability. The division’s technical approach includes (1) working to get vendor agreement on a common architecture, development, and implementation of valid interface specifications and (2) establishing conformance tests for plug-and-play components.

The importance of this field goes without question, and the program’s impact on industry is considerable. As individual pieces of automated equipment proliferate from many diverse equipment vendors, the need for universal interoperability grows daily. This is perhaps the division’s most vital program relative to the near-term needs of industry and one that can pay dividends most rapidly.

The program on intelligent control of mobility systems addresses the needs of industry and government agencies for standards and measurements associated with intelligent mobile systems. It concerns issues of interoperability, real time sensing, and performance for components and systems. The division is conducting pioneering work in this area. The program continues to provide an excellent testbed for the 4D real-time control system (4D-RCS) for intelligent vehicle architecture. There is no doubt that this is a timely program that could have a critical impact on the future of intelligent mobile vehicles for industry and military applications.

The division has an excellent track record of delivering intelligent control systems in mobile vehicles for military applications. It continues its support of the Army Research Laboratory’s Demo III Unmanned Ground Vehicle program, which attests to the Army’s confidence in the division’s capabilities. The division was also awarded a new project, on performance evaluation of road and land departure warning systems, which is supported by the Department of Transportation’s (DOT’s) Intelligent Vehicle Initiative (IVI) program. This is additional evidence of the leadership status of the division in this area.

The division mission is to develop the measurement and standards infrastructure that will allow manufacturing industries and government agencies to apply intelligent systems. The panel is convinced that the measurements, standards, and technologies under development in this program can be trans-

ferred to the civilian manufacturing industries: Just how remains to be seen. In this regard, the division’s project on road and land departure warning systems and its Industrial Autonomous Vehicles (IAV) project are both very important, and the panel is looking forward to progress on these projects.

Program Relevance and Effectiveness

The program on the research and engineering of intelligent systems has had significant influence on industry standards activities. The fundamental work in this program has served as the basis for all of the current metrology standards work for intelligent systems (common CMM interface, dimensional measuring interface standard [DMIS] review, DMIS/AP219 harmonization, AP219 DTDs, and the proposed national metrology testbed). The technical expertise to support STEP/NC (ISO 10649) also comes from the program’s feature-based inspection and control project. The panel understands that a future program direction is the extension of the real-time control system (RCS) architecture to include learning, self-optimization, self-diagnostics, and adaptive control. Such an integration effort is likely to lead to the standards and roadmaps of practical impact industry is waiting for.

The program on intelligent open-architecture control of manufacturing systems has focused on several key industrial objectives, including the 12-month car concept and more specific applications, such as integrated welding automation systems and integrated measurement systems. The program is working closely with assemblers and suppliers in the automotive sector as well as with industry organizations related to automation equipment, such as the Robotics Industries Associations, the Metrology Automation Association, and the Open Modular Architecture Controller consortium. The problem of poor interoperability starts with the large number of small- and medium-size enterprises that constitute the equipment industry, and working with these enterprises to achieve harmonious standards is essential.

The relevance of the program on intelligent control of mobility systems is evident from the continued support it enjoys from several customers. Those customers have provided funding for new projects such as the Army Research Labs Demo III unmanned ground vehicles, the Autonav research project for the German and U.S. defense departments, and the DARPA Tactical Mobile Robot and Mobile Autonomous Robot software programs. Many other programs are impacted by the application of RCS architecture and real-time sensing/measurements. The dramatic potential saving of both costs and human lives justifies research on autonomous mobile systems for military applications. Results from this program are regularly provided to its principal sponsors, the Army and DOT. The panel is pleased to see the division capitalizing on the recognition it has earned for its work on military vehicles. Now it has two new projects, the DOT IVI metrics development project and the IAV project. Each project has unique features and is looking into problems other than military problems. It is appropriate that automated guided vehicle industry discussions and site visits are in progress in the IAV project. The panel notes that an intelligent transportation system is receiving worldwide attention and vigorous research programs are in progress in Europe, Asia, and the United States. As it identifies needs for standards for automotive safety, the division should consider the needs in the global marketplace as well as in the United States.

The three programs in the division taken together seem to have an excellent balance of industrial impact, development of standards, and new technology development. Three workshops (First Part Correct, Open Architecture for Metrology, and Automation and Performance Metrics for Intelligent Systems) were organized by the division last year. The workshops were well attended and the proceedings have been published. The division is developing Web-based dissemination of such results.

Since new standards in intelligent systems involve the development of open-architecture concepts, the division has a clear role to play in this area and seems to be doing it well. However, it may be following a somewhat fragmented path by working with separate industry associations on very similar

but distinct standards. The panel is concerned that separate efforts for each industry segment—e.g., welding, measurement systems, and robot systems—may lead to fragmented standards and delay the implementation of an open architecture. The panel encourages the division to continue to work with the users (in this case the automotive and aerospace industries primarily) to create the architecture they need. The focus should be on supporting systems that are generally process-independent—the 12-month car is a powerful example of this. NIST can play roles as critical catalyst and honest broker between the user and the supplier associations.

The division has been very effective in promulgating standards, having played a leading role in STEP/NC for machine tools, and in developing new standards and systems that integrate digital part descriptions with CMM data acquisition. It has teamed well with the industry to develop a new American Welding Society standard for interfacing welding equipment.

The importance of intelligent control is well recognized by both the academic community and the manufacturing industry. There have been vigorous research and development efforts on intelligent control in academia, but these efforts tend to be abstract. The division can bridge the academic community and the manufacturing industry. The Workshop on Performance Metrics for Intelligent Systems did this effectively, and more than 60 papers were presented. The division must now compile the workshop results into a form useful for industry. In this regard, it should conduct a follow-up analysis and study of the workshop.

Division Resources

Funding sources for the Intelligent Systems Division are shown in Table 3.4. As of January 2001, staffing for the Intelligent Systems Division included 36 full-time permanent positions, of which 32 were for technical professionals. There were also 5 nonpermanent or supplemental personnel, such as postdoctoral research associates and temporary or part-time workers.

Division personnel are highly qualified, and they appear to be highly motivated. Staff morale appears high.

Current funding and staffing are adequate for the stated objectives and scope of the division’s programs. The laboratory is well equipped for conducting research on mobile vehicles. The leverage of

TABLE 3.4 Sources of Funding for the Intelligent Systems Division (in millions of dollars), FY 1998 to FY 2001

|

Source of Funding |

Fiscal Year 1998 (actual) |

Fiscal Year 1999 (actual) |

Fiscal Year 2000 (actual) |

Fiscal Year 2001 (estimated) |

|

NIST-STRS, excluding Competence |

6.2 |

5.9 |

5.9 |

5.4 |

|

ATP |

0.5 |

0.5 |

0.3 |

0.1 |

|

OA/NFG/CRADA |

1.4 |

1.5 |

2.0 |

2.2 |

|

Total |

8.1 |

7.9 |

8.2 |

7.7 |

|

Full-time permanent staff (total)a |

48 |

42 |

38 |

36 |

|

NOTE: Sources of funding are as described in the note accompanying Table 3.1. aThe number of full-time permanent staff is as of January of that fiscal year. |

||||

laboratory resources by collaboration with other research agencies, such as the NASA Jet Propulsion Laboratory and Carnegie Mellon University, is commendable. However, resources may not be adequate to provide results in time to have an appropriate impact. The potentially large impact of promising emerging technologies could justify increasing funding and raising personnel levels to expedite the results or expand the scope of research.

The Intelligent Systems Division is fortunate to have the only NIST fellow in the Manufacturing Engineering Laboratory. The panel would like to better understand how such a resource is being utilized by MEL.

Manufacturing Systems Integration Division

Technical Merit

According to division documentation, the mission of the Manufacturing Systems Integration Division is to promote economic growth by working with industry to develop and apply measurements and standards that advance the use of information-based manufacturing technology. The division is organized into four groups: Design and Process, Enterprise Systems, Manufacturing Simulation and Modeling, and Manufacturing Standards Metrology. The division also houses the Systems Integration for Manufacturing Applications Office.

Many of the projects reviewed were state of the art in concept and implementation. The researchers take good advantage of new software and programming technologies and contact with external organizations. They show strong leadership in a number of national and international organizations developing standards for manufacturing software. The division’s programs are extremely important for future business-to-business interactions. The division has focused on working with industry to define infrastructure standards now and, later, to promote self-integration technologies. The division management is aware the staff cannot participate in all relevant endeavors and need to select those where they can have maximum impacts. The division is doing well with this issue and looking hard at what commitments should be made, consistent with the division mission and the NIST mission. One subject under discussion is how to leverage the idea of software measurements with the concept of NIST-traceable compliance.

The panel offers specific comments on two programs: the Manufacturing Enterprise Integration program and the Manufacturing Simulation and Visualization program. Recent lack of success in securing funding for Manufacturing Enterprise Integration have left this effort close to, if not below, the critical mass needed for impact. Unless funding levels improve, the Manufacturing Enterprise Integration program may not be viable. Enterprise resource planning (ERP), product data management (PDM), and supply chain management software have not had great success in the industrial sector, so the panel questions the approach of building on these products in the Manufacturing Enterprise Integration program. However, researching why these products have failed to find acceptance could have value. In the Manufacturing Simulation and Visualization program, a better value proposition is needed, and perhaps a statement of anticipated return on investment. Integrating different simulation models and data exchange standards is a good idea, but the panel has concerns about the ability and commitment of the international community to embrace the multinational effort known as Intelligent Manufacturing Systems Modeling and Simulation Environments for Design, Planning, and Operation of Globally Distributed Enterprises.

The division is technically in a key position to support other programs within MEL and NIST. The division personnel have positions of leadership in a number of internal information technology projects.

Program Relevance and Effectiveness

The division mission is an appropriate one for a NIST organization to focus on. The division clearly recognizes both the importance of its mission and the fact that the mission is far too big for it to accomplish alone. The panel noted a shift in attitude since the previous assessment—the division declared much more forcefully that it cannot succeed by serving on just a handful of the many de facto industrial standards committees. It knows it must strive to provide leadership in manufacturing software interoperability. This shift in attitude could place the division in a better position to meet future U.S. manufacturing needs.

One important function for the division is maintaining an industry-neutral position with respect to technical capabilities. The division reaches out to all software vendors and their potential manufacturing users. This keeps the division strongly connected to both present and future needs of its manufacturing customers. In a number of cases it has responded to direct requests from individual companies as well as industrial consortia.

Ongoing programs have differing levels of success in accomplishing their stated missions. All programs should have tightly defined goals and deliverables. The mission statement may need more focus. In particular the panel questions how the division will measure its progress toward the stated goal of “promoting economic growth.” While the division has presented reports on the cost to industry of lack of software interoperability, its program outputs don’t seem to be tied directly to the results of these reports. There is no clear statement of what economic growth can be attributed to the division’s efforts.

The division staff are concerned that issues in information technology, particularly software, are not well understood by most of the organization. Some staff feel that more traditional NIST activities (i.e., weights, measures, physical artifacts) stand a better chance of garnering internal resources. The role of information technology (as opposed to computer science) for manufacturing and beyond may need discussion at a higher level within NIST.

Division Resources

Funding sources for the Manufacturing Systems Integration Division are shown in Table 3.5. As of

TABLE 3.5 Sources of Funding for the Manufacturing Systems Integration Division (in millions of dollars), FY 1998 to FY 2001

|

Source of Funding |

Fiscal Year 1998 (actual) |

Fiscal Year 1999 (actual) |

Fiscal Year 2000 (actual) |

Fiscal Year 2001 (estimated) |

|

NIST-STRS, excluding Competence |

7.5 |

7.9 |

7.5 |

8.1 |

|

Competence |

0.4 |

0.4 |

0.4 |

0.3 |

|

ATP |

1.1 |

0.9 |

1.0 |

0.0 |

|

OA/NFG/CRADA |

4.2 |

1.0 |

0.9 |

0.7 |

|

Total |

13.1 |

10.2 |

9.8 |

9.1 |

|

Full-time permanent staff (total)a |

48 |

41 |

35 |

32 |

|

NOTE: Sources of funding are as described in the note accompanying Table 3.1. aThe number of full-time permanent staff is as of January of that fiscal year. |

||||

January 2001, staffing for the Manufacturing Systems Integration Division included 32 full-time permanent positions, of which 25 were for technical professionals. There were also 13 nonpermanent or supplemental personnel, such as postdoctoral research associates and temporary or part-time workers.

The sharp decrease in permanent staff is the single biggest issue threatening the effectiveness of the division’s efforts. No permanent staff positions have been filled in the last 3 years, and there are very few applicants for postdoctoral positions. This trend, if not reversed, points to a very clear and unfavorable outlook for the division and its programs. Staffing shortfalls have so far been dealt with by using large numbers of guest workers. While this strong reliance on guests has the advantage of bringing a constant flow of new ideas and perspectives to the laboratory, it puts the organizational knowledge base at risk. Core competencies can decay, and “corporate memory” can be lost. The panel is concerned that some damage may have already been done, and future damage is certain if the trend continues.

MAJOR OBSERVATIONS

The panel presents the following major observations:

-

The technical merit of a majority of the Manufacturing Engineering Laboratory’s projects is very good. Laboratory staff are well respected in the relevant industrial communities, and MEL projects and personnel receive awards and recognitions that attest to the laboratory’s value to these communities.

-

The laboratory’s staffing situation is a serious concern of the panel. Senior individuals are retiring or departing, and the MEL is having difficulty bringing in permanent entry-level research personnel. Institutional memory is being lost, and the laboratory’s ability to sustain current core competencies or develop new ones is being impeded.

-

Progress on program planning at the laboratory level continues. Having defined criteria for project selection, the MEL now needs to take a systematic approach to determining priorities, demonstrating potential impact, and reaching out to relevant industries. The connection between project outputs and overall goals, such as promoting economic growth for industry, should be clarified. The balance between projects with short-term goals and products and projects focused on more basic research needs to be considered, and the connections between the two types of activities need to be defined. Finally, an objective process to determine program continuation or termination should be developed and implemented.

-

To continue to provide the state-of-the-art standards and measurement techniques needed by U.S. industry, MEL staff must have access to modern equipment comparable to that used by the laboratory’s industrial customers. A long-range plan for procuring the instrumentation necessary to support laboratory programs should be developed. An important element of this plan will be a time line describing how the equipment needed for the Advanced Measurement Laboratory will be obtained.