PANEL MEMBERS

Ralph K.Cavin III, Semiconductor Research Corporation, Chair

Lori S.Nye, Consultant, Mountain View, California, Vice Chair

Thomas E.Anderson, Airtron, Division of Litton Systems, Inc.

Constance J.Chang-Hasnain, University of California at Berkeley

Jack H.Corley, Advanced Technology Institute

Jerome J.Cuomo, North Carolina State University

Russell D.Dupuis, University of Texas at Austin

Thomas J.Gramila, Ohio State University

Donald B.Keck, Corning, Inc.

David C.Larbalestier, University of Wisconsin-Madison

Tingye Li, AT&T Research (retired)

Tso-Ping Ma, Yale University

Solomon Max, LTX Corporation

Robert C.McDonald, Intel Corporation (retired)

Bruce Melson, GE Aircraft Engines

Terry P.Orlando, Massachusetts Institute of Technology

Ghery S.Pettit, Intel Corporation

Robert Rottmayer, Seagate Research

Douglas K.Rytting, Agilent Technologies, Inc.

Dennis E.Speliotis, ADE Technologies, Inc.

Peter W.Staecker, Consultant, Lexington, Massachusetts

Dale J.Van Harlingen, University of Illinois at Urbana-Champaign

John A.Wehrmeyer, Quality Consultants of New York

H.Lee Willis, ABB Power T&D Company

Donald L.Wollesen, Advanced Micro Devices, Inc. (retired)

Submitted for the panel by its Chair, Ralph K.Cavin III, and its Vice Chair, Lori S.Nye, this assessment of the fiscal year 2001 activities of the Electronics and Electrical Engineering Laboratory is based on site visits by individual panel members, a formal meeting of the panel on February 15–16, 2001, in Gaithersburg, Maryland, and documents provided by the laboratory.1

LABORATORY-LEVEL REVIEW

Technical Merit

According to laboratory documentation, the mission of the Electronics and Electrical Engineering Laboratory is to strengthen the U.S. economy and improve the quality of life by providing measurement science and technology and by advancing standards, primarily for the electronics and electrical industries.

The EEEL mission statement is a revised version of the 2000 mission statement and is more closely aligned with the NIST mission statement. The panel endorses the emphasis on the role of EEEL in improving the quality of life for citizens and agrees with the importance given to the laboratory’s role in the creation of metrology standards. Moreover, the mission statements of the EEEL divisions conform with the new EEEL mission statement.

In the past year, EEEL focused intensely on making strategic planning a critical component of laboratory management activities. The result of this effort is a revised 5-year strategic plan for the laboratory,2 clear vision and mission statements, and a short but appropriate list of values. These basic documents together define the basic priorities of the laboratory in a manner that allows management and staff to select projects to be pursued based on objective criteria including customer need, relevance to the mission, and likelihood of success. The strategic plan enunciates four overarching goals for the laboratory: strengthen the foundation for all electrical measurements, provide the measurement capability required for a world-class electronics industry, provide the measurement capability required for a world-class electrical industry, and provide technical support for law enforcement. Each of these goals is supported by several objectives, with performance metrics, and the plan and its goals relate well to the missions of the laboratory’s individual divisions and offices.

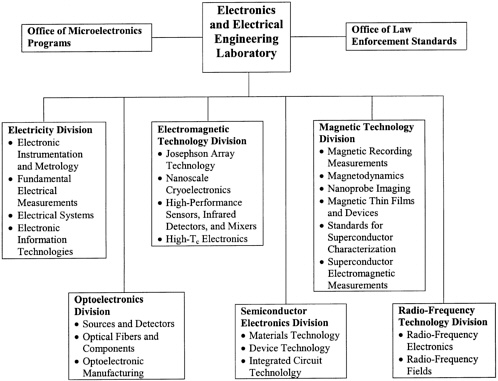

The Electronics and Electrical Engineering Laboratory is organized into six divisions and two offices: Electricity Division, Semiconductor Electronics Division, Radio-Frequency Technology Division, Electromagnetic Technology Division, Optoelectronics Division, Magnetic Technology Division, Office of Microelectronics Programs, and Office of Law Enforcement Standards (OLES) (see Figure 2.1). Each division and the Office of Law Enforcement Standards are reviewed in individual sections later in this chapter. This year, the Office of Microelectronics Programs is reviewed in a separate chapter of this report, as part of a special assessment of microelectronics activities throughout the NIST Measurement and Standards Laboratories.

The Magnetic Technology Division is a new unit this year; it contains magnetic and superconducting materials programs split off from the Electromagnetic Technology Division. The panel supports the decision to reorganize the laboratory in this manner and notes that the transition seems to have gone smoothly, and that staff morale has been significantly improved. A minor concern is the potential confusion that the names of these two divisions might produce in people outside NIST; the names are very similar, and the Electromagnetic Technology Division title does not clearly reflect the current activities in that division.

During the assessment, the panel reviewed a wide range of technical programs in all of the divisions. There were many examples of excellence, due mainly to the efforts of the high-quality staff who are the

FIGURE 2.1 Organizational structure of the Electronics and Electrical Engineering Laboratory. Listed under each division are the division’s groups.

primary resource of EEEL. Some achievements of the laboratory are described below, and more details on the technical accomplishments can be found in the divisional reports contained later in this chapter.

In the Electricity Division, exceptional progress has been made on the electronic kilogram project, which aims to use a watt balance apparatus to define an alternative to the artifactual kilogram standard; high-impact and ingenious work is occurring on characterizing flat panel displays; resistance calibration capabilities were expanded up to the 100 TΩ level; and cutting-edge investigations into the role of single-electron tunneling technologies in metrology continue. In the Semiconductor Electronics Division, staff are designing test structures based on microelectromechanical systems (MEMS) technology to measure stress and strain of thin films on integrated circuit (IC) structures, developing scanning capacitance microscopy measurement techniques and related software for two-dimensional dopant profiling, developing test systems for characterization of silicon carbide devices, and producing oxide reliability standards that have been adopted by U.S. industry as well as foreign standards organizations and companies. In the Radio-Frequency Technology Division, proactive efforts on standards for fixed broadband wireless systems will help accelerate deployment of this new technology, and new and

general methods of characterizing nonlinear devices and components for digital wireless communications are being developed and transferred to industrial laboratories.

In the Electromagnetic Technology Division, a new capacitance standard is based on using a single electron pump device to count electrons delivered to a capacitive structure; the use of bolometer arrays to detect concealed weapons is being investigated; and the work on the single photon turnstile has potential implication for the fields of quantum computing and communications. In the Optoelectronics Division, metrology is being developed in the ultraviolet (UV) regime in anticipation of the evolution to 157-nm lithography by the semiconductor industry; study of InGaAs quantum dots is focused on preparing for future standards development for such nanostructures; and work on a time-domain electrooptic sampling technique for calibrating oscilloscopes is laying the groundwork for increasing measurement bandwidth beyond 40 GHz, perhaps up as far as 110 GHz. In the Magnetic Technology Division, staff are using the new microfabrication capabilities in Boulder to construct a “magnetometer-on-a-chip” for measuring many fundamental magnetic parameters on a nanometer scale; magnetodynamics work is leading to a deeper understanding of high-speed switching phenomena, which in turn has inspired an innovative new project on spintronics; and NIST provided unique facilities and expertise for testing of superconductors to be used in high-energy physics experiments and in the program to develop high-temperature superconductors for electric power technology. In the Office of Law Enforcement Standards, NIST staff supervise a wide array of high-quality, customer-driven programs in weapons and protective systems, detection and enforcement technologies, chemical systems and materials, forensic services, and public safety communication standards.

Program Relevance and Effectiveness

EEEL strives to ensure that the projects undertaken are responsive to the metrology needs of the laboratory’s customers, which include industry, scientific research communities, and other government agencies. Divisional staff interact with these customers in a variety of ways to get input on industrial needs and the current state of the art and to disseminate information about EEEL programs, services, and results. Recently, the acting director of NIST began emphasizing the importance of also “closing the loop” with customers by seeking their direct evaluation of the quality and relevance of NIST work upon completion of a task. The panel commends this initiative as it will provide yet more input to help maintain the relevance of EEEL programs.

Each division of EEEL serves industry differently, so the range of mechanisms for customer interactions is quite broad. Some examples are listed below to illustrate the variety and effectiveness of these methods for determining customer need and disseminating NIST results.

EEEL staff are very active in standards organizations and participate in a large number of standards committees (for example, one serves as chair of the Institute of Electrical and Electronics Engineers [IEEE] Committee on Broadband Wireless Access and another as task force leader for the International Electrotechnical Commission [IEC] Committee on Power Quality Measurements). The divisions work with a number of government agencies and interact closely with the research communities of those agencies (examples are the measurement of superconductors used in high-energy physics experiments for the Department of Energy [DOE] and the investigation of bolometer arrays for high-frequency radio astronomy for the National Aeronautics and Space Administration [NASA]). In a similar vein, OLES staff are continually reaching out to the law enforcement community with technical advice and relevant standards. NIST also takes the lead in organizing key workshops and conferences (for example, the biennial Symposium on Optical Fiber Measurements and the biennial International Conference on Characterization and Metrology for ULSI Technology). Divisional calibration services staff have direct

interactions with their customers, which can result in technical improvements with an immediate impact (for example, the development of a new coaxial radiometer for noise-temperature measurements that expanded the range of services provided and reduced the time per calibration). Staff also are involved with industry-sector roadmapping activities like those put together by the Semiconductor Industry Association, the Optoelectronics Industry Development Association (OIDA), and the National Electronics Manufacturing Initiative; they partner directly with industry consortia such as International SEMATECH and the National Storage Industry Consortium (NSIC) and participate in professional organizations like the IEEE.

This range of interactions produces an array of programs that are responsive to customer needs. The panel commends EEEL on its efforts to ensure the relevance of its programs but notes that although the basic exploratory research ongoing in the laboratory today accounts for only a small percentage of the laboratory’s work, it is a necessary element of the NIST portfolio. Such basic research is intended to both enhance the professional competence of the staff and to anticipate the needs of industry. EEEL management should continue to support exploratory programs, even in the face of significant budget pressures, because they contribute to the intellectually vigorous environment, which enhances employee morale and retention and provides the knowledge and experience necessary for NIST to maintain its position as a international technical leader in measurement and standards technologies.

Laboratory Resources

Funding sources for the Electronics and Electrical Engineering Laboratory are shown in Table 2.1. As of January 2001, staffing for the EEEL included 244 full-time permanent positions, of which 206 were for technical professionals. There were also 27 nonpermanent and supplemental personnel, such as postdoctoral research associates and temporary or part-time workers.

It appears that in fiscal year 2001, EEEL will see an increase of approximately 5 percent in total funding. However, governmentally mandated cost-of-living adjustments to salaries consume a significant portion of any additional funds, making it difficult for the divisions to recruit new staff. Indeed, the number of full-time permanent staff in EEEL has dropped by 10 percent in the past 2 years, mainly because departing personnel have not been replaced. In some divisions, these departures are due to retirements, but in other areas, NIST employees have left for more lucrative opportunities in the private sector. In these cases, finding replacements is not just a matter of funding to support the new hires but also a question of how to recruit high-quality technical staff in a very tight labor market. In any case, the overall decrease in laboratory staff has resulted in a growing number of areas in which there is single-point coverage; this situation is risky, as entire programs can be delayed or ended if one particular employee is lost. Spreading personnel so thin may also affect morale, as staff can feel isolated without contact with other experts in their field. This point is a particular issue for younger staff members, who need technical and professional mentoring from more senior personnel and who are more likely to be concerned that flat budgets portend serious problems for the long-term viability of the laboratory. The morale throughout the laboratory is also affected by the number of key management positions filled by acting personnel. Having permanent staff in these positions would provide a sense of stability.

Another way in which the laboratory’s shortage of funds impacts technical performance is problems with equipment. The industries supported by EEEL continually require more accurate measurements and more precise techniques, and the cost of the instruments necessary to support the development of advanced metrology is increasing substantially. The current annual capital equipment budget for EEEL is approximately $3.8 million, which is not adequate for the instrumentation purchases and upgrades needed to maintain core technologies, let alone for the purchase of equipment needed for EEEL projects in new areas.

TABLE 2.1 Sources of Funding for the Electronics and Electrical Engineering Laboratory (in millions of dollars), FY 1998 to FY 2001

|

Source of Funding |

Fiscal Year 1998 (actual) |

Fiscal Year 1999 (actual) |

Fiscal Year 2000 (actual) |

Fiscal Year 2001 (estimated) |

|

NIST-STRS, excluding Competence |

31.5 |

33.2 |

32.5 |

33.8 |

|

Competence |

2.2 |

1.9 |

2.1 |

1.8 |

|

ATP |

2.1 |

1.9 |

1.4 |

1.7 |

|

Measurement Services (SRM production) |

0.1 |

0.1 |

0.2 |

0.2 |

|

OA/NFG/CRADA |

10.2 |

10.9 |

13.8 |

15.3 |

|

Other Reimbursable |

2.9 |

2.7 |

2.8 |

2.6 |

|

Total |

49.0 |

50.7 |

52.7 |

55.4 |

|

Full-time permanent staff (total)a |

270 |

270 |

259 |

244 |

|

NOTE: Funding for the NIST Measurement and Standards Laboratories comes from a variety of sources. The laboratories receive appropriations from Congress, known as Scientific and Technical Research and Services (STRS) funding. Competence funding also comes from NIST’s congressional appropriations but is allocated by the NIST director’s office in multiyear grants for projects that advance NIST’s capabilities in new and emerging areas of measurement science. Advanced Technology Program (ATP) funding reflects support from NIST' s ATP for work done at the NIST laboratories in collaboration with or in support of ATP projects. Funding to support production of Standard Reference Materials (SRMs) is tied to the use of such products and is classified as Measurement Services. NIST laboratories also receive funding through grants or contracts from other government agencies (OA), from nonfederal government (NFG) agencies, and from industry in the form of Cooperative Research and Development Agreements (CRADAs). All other laboratory funding, including that for Calibration Services, is grouped under “Other Reimbursable.” aThe number of full-time permanent staff is as of January of that fiscal year. |

||||

In an effort to work around this problem, laboratory staff often construct their own equipment, even when it is commercially available. While this approach saves capital equipment funds, it interferes with the effective deployment of staff time and efforts and reduces productivity. The lack of equipment comparable to that possessed by industry or by other national measurement institutes also impacts staff morale. EEEL is encouraged by the panel to devise creative ways to work with industry and other government agencies to obtain some of the needed instrumentation or access to that instrumentation.

Overall, EEEL’s facilities in both Gaithersburg and Boulder continue to be marginal at best. There were some areas of improvement in 2000. In Boulder, clean rooms with microfabrication capabilities are now fully operational, and remodeling of several of the large laboratories for the Radio-Frequency Technology Division is nearly complete. In Gaithersburg, EEEL management has been supportive of OLES efforts to arrange for a ballistics facility, and the Semiconductor Electronics Division has finished restoring its clean room. However, serious problems still exist on both campuses. In Boulder, temperatures in the laboratories can vary widely in the course of just one day. The open air test site is becoming increasingly affected by electromagnetic contamination from the growing pervasiveness of new technologies like wireless communications and high-definition television. In Gaithersburg, the laboratory buildings are in reasonable shape, considering their age. However, these facilities were certainly not designed to have the temperature, air quality, or vibration control or power stability needed to support

the metrology needs of modern electronic systems. While the panel is certainly pleased that work has begun on the Advanced Measurement Laboratory at Gaithersburg, this facility is not scheduled to be completed until 2004. In the meantime, innovative solutions are needed to meet the varied clean room requirements that are mandatory to sustain metrology development in the divisions at Gaithersburg.

The bottom-line consequence of the difficult budget situation in EEEL is that the divisions are finding it more and more difficult to effectively serve the needs of the electronics and electrical industries, one of the highest value-added sectors in the U.S. economy. In each division, there are examples of projects that would fulfill key measurement and standards needs of industry if EEEL had the resources to pursue them. In some cases, these are areas in which NIST has had to scale back existing programs. In the Electricity Division, NIST is now planning to rely on the Canadian National Research Council to supply some 60-Hz voltage metrology services. In the Semiconductor Electronics Division, NIST was a leader in providing test structures for evaluating the reliability of aluminum interconnect systems, but as the semiconductor industry has moved to copper interconnect systems, EEEL has been unable to find the funding or the personnel to develop similar test structures for copper. In other cases, NIST simply cannot fund programs in new areas that will be critical to meeting industrial measurements and standards needs. In the Optoelectronics Division, the current program portfolio would be enhanced by work on planar optics, optical MEMS metrology, optical data storage, the semiconductor lighting initiative, and bio-optics. Indeed, in this area, the panel continues to stridently call for funding for the proposed Office of Optoelectronics Programs, which would help EEEL support a growing industry and coordinate work in this area through the NIST Measurements and Standards Laboratories. In the Magnetic Technology Division, flux standards for magnetic recording media are needed, as are standards for high-temperature superconductors at power frequencies, and the work on spintronics and perpendicular recording technologies could be expanded. In the Electromagnetic Technology Division, preliminary research on several promising new ideas for quantum-based standards is now reaching fruition, and the next step, practical implementation of the standards, will require additional resources. In the Radio-Frequency Technology Division, the primary issue is access to the equipment and facilities needed to perform high-accuracy measurements.

The panel is not suggesting that the above work is more important than the laboratory’s current activities. Rather, it is calling attention to the cost to the U.S. economy that is being incurred because NIST is severely limited in the projects that it can take on. The work done in EEEL is unique for a variety of reasons, either because of the technical expertise available in the divisions, the focus on measurement technologies, or NIST’s reputation as an objective, technically informed, neutral party. Some of the laboratory’s services could not be provided elsewhere; for example certain international standards require traceability to a national measurement institute. The panel believes that while NIST is effectively managing its limited resources, flat budgets and exploding industry needs are simply overwhelming its capacity to meet all of the high-priority needs of its customers.

DIVISIONAL REVIEWS

Electricity Division

Technical Merit

According to division documentation, the mission of the Electricity Division is to provide the world’s most technically advanced and fundamentally sound basis for all electrical measurements in the United States. To accomplish this mission, the Electricity Division’s programs involve three principal

elements: realizing the International System (SI) of electrical units, developing improved measurement methods and calibration services, and supporting the measurements and standard infrastructure needed by U.S. industry to develop new products, ensure quality, and compete economically in the world’s markets.3

The Electricity Division’s mission seems particularly appropriate given the major role that electrical and electronics equipment and systems play in international commerce and the leadership role that American companies have developed and wish to maintain in this field. Recognizing the growing importance of supporting U.S. industry in the international marketplace, the division has increased its participation in international documentary and physical standards activities. In general, the division conducts its business in a manner that supports its stated mission, which is well aligned with the EEEL and NIST missions.

The technical quality of the projects reviewed was of uniformly high caliber throughout the division, from the more established calibration efforts to the new initiatives on technology development. Recognition of current and anticipated needs of U.S. industry and commerce appears to be the driving force for decision-making. The technical efforts involved in maintaining state-of-the-art capabilities are an essential strength of this division. A superb degree of technical skill, innovative approaches, and good judgment are evident throughout the programs. One example of the excellent work under way in this division is the Electronic Kilogram project, which addresses an important and elementary need of the laboratory: the development of an alternative means to monitor mass standards. This long-term effort is well justified by the observable differences between the artifactual kilograms maintained throughout the world. The project leverages a number of established world-class capabilities within the division to facilitate the development of a new measurement method that has the potential to significantly advance the state of the art. The technical requirements of this effort are exacting and span a wide range of technologies; along the way, the staff have developed some important new approaches and demonstrated an impressive capability for creative problem solving. With this project and the Metrology Triangle initiative, which aims to link the volt, ohm, and ampere standards, the Electricity Division is positioned as an international leader in fundamental metrology of SI units. The panel believes that such leadership produces both prestige for NIST and a technical advantage that is a key element in NIST’s support of U.S. industrial competitiveness in the global electronics and electrical markets.

A similar degree of technical excellence is evident in many other programs. The Voltage Metrology program, for example, continues to lead the world in sustaining current methods and developing new technologies for the maintenance of the legal volt. At present, efforts are focused on development of a portable Josephson junction array that will facilitate comparisons of the NIST volt to standards maintained by other organizations. This new approach is sorely needed as the Zener references now used as standard transfer devices only allow intercomparisons with uncertainties of about 3 parts in 108, while the portable Josephson junction arrays are expected to enable comparisons with uncertainties in the range of 1 part in 109 to 1010, a significant improvement. In addition to working on this new technology, the staff in the voltage metrology area also provide important calibration services for the Zener references and saturated cells commonly used by companies today. The historical data on the reference and working standards maintained at NIST and the high level of staff expertise in this area allow NIST to provide these services to U.S. industry at a world-class level.

Another area in which the Electricity Division is balancing the development of new technologies and the provision of traditional calibration services is resistance standards and metrology. Within the current program, the service provided to NIST calibration customers continues to be of high quality, and the division has recently expanded its range of capabilities to the 100 TW level. In the work on new methods, NIST has the only alternating currents (AC) quantum Hall resistance facility that is currently operational in the United States. Staff continue to improve the equipment in this facility; most recently, a new cryogenic probe was built based on a new design that is expected to reduce noise in the measurements and correspondingly reduce uncertainties. In addition, staff are working on building a cryogenic current comparator, a piece of equipment that is not available commercially. This equipment is needed to realize the benefits of the quantum Hall resistance approach over a useful range. On another front, staff are investigating how current resistance metrology techniques can be extended beyond direct current (DC) measurements to AC. The division staff have developed impressive expertise during the work on DC measurements. These skills allowed the careful and exacting analysis of NIST’s measurement scheme, which in turn permitted the discovery of errors and faults in approaches being adopted in standards laboratories in other countries. This work laid the foundation for the current effort to extend the measurement approach to AC.

In addition to the work on the volt and the ohm described above, the Electricity Division is also responsible for realizing the SI unit for capacitance, the farad. The central facility for this work is the NIST calculable capacitor, which has existed for over 30 years. Division staff continue to improve this facility; currently uncertainties are down to roughly 2 parts in 108. The latest effort focuses on developing the technologies needed to provide calibration measurements at 1000 Hz (as well as at the present standard, 1592 Hz). This additional capability will reduce the uncertainties currently experienced when NIST customers are measuring the 10-pF fused silica capacitors, which are monitored at that frequency. Although there is little room for future improvement in the calculable capacitor, it is essential to maintain this program in support of one of the key SI units,

The Single-Electron Tunneling (SET) project is another activity in which NIST staff are pushing the boundaries of current technologies in order to achieve fundamental advances in electrical metrology. One element of this effort is the investigation of whether SET technologies can be used to provide a fundamental representation of capacitance. A major technical challenge is how to scale the SET devices to provide the currents required for work with resistors. Tackling the complex materials issues associated with this challenge will likely involve considerable collaboration with groups outside NIST. In the past year, the staff have clearly identified the relevant technical issues and laid the groundwork for the needed external collaborations. One reason this project is so appropriate for NIST is the significant benefit that will accrue from the ability of staff to compare results from this activity with those from the calculable capacitor that the Electricity Division uses to maintain the farad.

In the Measurement for Complex Electronic Systems project, staff are using sophisticated mathematical techniques to extend efforts into the thorny area of IDDQ testing, in which the power supply current of a semiconductor device is measured as a function of the digital state of the device. This technique may prove to be a very effective tool for determining optimum testing strategies. The Infrastructure for Integrated Electronic Design and Manufacturing projects are very appropriate NIST activities because they aim to generate standards that will be accepted by industry. The work is based on the sophisticated use of the Internet. Perhaps future additions to the intrastructure might include an efficient method for continually improving the infrastructure. Ideally, such an enhancement would include a system for conveniently reporting problems and shortcomings and for tracking resolution of the reported issues. The AC-DC Difference Standards and Measurement Techniques program includes several projects that are contributing pioneering work in this field. The panel was impressed by the high

quality of four specific research projects: the development of a cryogenic-based thermal transfer standard, the use of thin-film multijunction thermal converters as new high-performance reference and working standards, the expansion of the range of currents (up to 100 A and down to 10 mA) at which broadband calibrations of shunts can be performed, and the investigation of how binary inductive voltage dividers can be used to independently verify converters up to 1 kV.

Program Relevance and Effectiveness

The Electricity Division appears to understand and even anticipate the needs of its customers well, and both individual investigators and management interact with appropriate elements of the relevant industries. The panel continues to be impressed with the willingness of the division’s professional staff to be available for face-to-face or telephone conversations with their customers and notes that this tradition of openness creates an atmosphere of accessibility that many EEEL customers view as one of the laboratory’s most valuable characteristics. NIST personnel, in turn, use the information gathered in these interactions to help determine the direction of division programs, especially when it comes to starting new efforts directed at meeting industrial needs.

Once projects were under way, however, the panel observed that less external input was sought and utilized. Customer relations might be strengthened by having more clearly defined checkpoints at which customers could be called on to validate the appropriateness of divisional programs or to help make mid-course corrections. Checkpoints clearly do exist within the more formal collaborative arrangements (such as Cooperative Research and Development Agreements [CRADAs]), and productive interactions with customers do occur informally in some other activities, but in some cases, intraprogram decision points pass without staff seizing the opportunity to seek customer input or potential redirection. While the timing or even the existence of such turning points is usually difficult to predict for an individual project, educating program managers about the usefulness of reaching out to their customers when such a point arises might help build a culture in which such interactions are a natural part of a project. One ongoing project in which open communications with an external organization have contributed positively to the effort is the work on construction of thin-film devices for the AC-DC Difference program. The division has worked cooperatively with the DOE in this area, and the frequent discussions that took place when problems arose and decisions needed to be made have benefited the project and enabled the two government agencies to use the money of U.S. taxpayers as efficiently as possible.

The Electricity Division is very active in disseminating information about NIST results, activities, and services and maintaining the international visibility of NIST’s high-quality programs and technical capabilities. The number of publications remains large (72 in 2000) despite the fact that several professional staff retired last year, leaving just 51 technical professionals. Division personnel give numerous presentations, seminars, and symposia and represent NIST in a number of professional and technical organizations. One example is the National Conference of Standards Laboratories International (NCSLI). NCSLI’s Committee for National Measurement Requirements receives input on present and future metrology needs from over 1400 organizations, and interaction with this committee provides the Electricity Division with information on the status of international measurement and standards activities. Staff also gather important data on customer needs at events such as the annual Measurement Science Conference and the biennial international Conference on Precision Electromagnetic Measurements. The requirements and priorities of individual companies are gathered through CRADAs.

The Electricity Division is using all of these inputs appropriately to direct its limited resources to programs with significant impact. One illustration of the division’s responsiveness is the recent increase

in funding for projects that support the electrical power industry. This shift was a reaction to the increasing deregulation of the power industry and the power supply crises in California and is backed by a recent prospective study of the potential economic impact of NIST’s work.4 Another example is the project on Display Measurement Assessment Transfer Standard (DMATS), which focuses on characterizing flat panel displays. This work grew out of divisional staffs awareness of customer needs in this area, bolstered by a close relationship with the Council for Optical Radiation Measurements. Twenty customers have already asked to be included in a program to test the implementation of DMATS.

On the whole, the division’s ongoing efforts to disseminate information to its client industries about NIST results, products, services, and expertise are effective. However, the panel is concerned that the overall dissemination effort is much too small. Perhaps more aggressive marketing of the NIST products and results and better education of the public about how NIST contributes to industrial competitiveness would increase appreciation of NIST’s value. A higher profile might lead to increased funding from industry sources or from Congress.

Electricity Division management has clearly taken great care to consider the relevance of all its current activities, particularly in light of the budgetary restrictions of recent years. Examples of the types of ongoing projects that are appropriate and justifiable for the division include work that directly meets current industry needs as well as research and development necessary to maintain and extend technologies to meet future industry needs. To illustrate the relationship of the Electricity Division with its customers, the panel describes below the impact of several division projects. Some have more general effects, while others are targeted toward specific industries.

A good example of how NIST activities serve to maintain and protect the competitiveness of U.S. industry is the international role played by NIST personnel. Electricity Division staff participate in many international standards activities and engage in cooperative programs with other national measurement institutes. This work helps to ensure that the technical methods developed at NIST are disseminated and accepted globally and that the United States has a voice in the application of standards for the international marketplace. However, while NIST encourages its staff to engage in such activities, there does not appear to be a strategic plan at the institutional level to guide participation in these international standards groups. Technical standards can be and occasionally are used as barriers to trade, and lack of a coherently planned and managed program for participation in international standards activities may be hurting U.S. competitiveness in the electrical and electronics industries. Perhaps NIST should consider identifying and targeting specific areas of international standards for participation. The goal would be to determine and prioritize the areas in which experienced NIST staff could provide objective expert technical advice and promote neutral, open standards.

One project whose impact is very broad is the Information System to Support Calibrations. This system has been installed throughout the NIST laboratories to support various calibration services and has effectively systematized the interface between NIST and its customers from a wide range of industries. Another project—the Measurements for Complex Electronic Systems Project—is closely tied to the needs of a specific industry. This project, which involves analyzing complex electronic systems using only a limited number of key measurements, is relevant to the instrumentation needs of the automatic test equipment industry and is a particularly useful extension of existing metrology technology.

The Infrastructure for Integrated Electronic Design and Manufacturing programs include projects to develop open standards and to provide environments for electrical component testing and evaluating technologies and tools. Its purpose is to provide support for infrastructures for integrated electronic design and electronic manufacturing and for Internet commerce among trading partners involved in the electronics industry. The design project addresses an infrastructure-created problem related to component and printed circuit board specifications. The project goal is to develop a system that will allow manufacturers of board subassemblies to incorporate all the relevant specifications and to receive and generate quotes based on a common, industry-accepted standard, via the Internet or corporate intranets. Similarly, the manufacturing project aims to create a standard way of describing the specifications that must be met by the subassembly. Both the design and manufacturing programs could have a very great impact on U.S. competitiveness in the electronics field, where the standards and environments developed at NIST could help reduce cost, eliminate inefficiencies and quality problems, and shorten product cycle times significantly. NIST may wish to consider to what extent the concepts being developed could be extended beyond the electronic components industry, as many of the issues and functions being dealt with are relevant to other types of manufacturing and commerce.

In the Flat Panel Display Metrology program, the primary impact will be advancement of the quality of computer interfaces through the development of metrology to characterize electronic displays. The work under this program is of high quality, unique, and sorely needed by industry. The latest project in this area is the work on the Display Measurement Assessment Transfer Standards prototype. This device will allow for the evaluation of colorimeters over many different parameters, such as the entire color space, luminance, polarity checks, and contrast ratio.

The AC-DC Difference Standards and Measurement Techniques program interacts with a variety of external organizations, including manufacturers of electronic instrumentation and test equipment, the U.S. Department of Defense, and commercial testing laboratories. Each year, the division’s calibration service in this area provides its customers with about 10 reports containing about 400 test points. Results from this program have been used for laboratory accreditation, product development, and expansion of calibration capabilities.

In the Waveform Synthesis and Impedance Metrology project, the standards community is benefiting from new applications of inductance and capacitance measurement technologies, which allow impedance measurements to be performed at arbitrary frequencies. In the Waveform Acquisition Devices and Standards project, one goal is to bridge the gap in existing instrumentation technology; currently AC waveforms in the 1-kHz to 1-MHz ranges cannot be measured accurately and rapidly. The increased measurement capabilities and the high-speed comparator algorithm used in this work may have widespread and significant application in the instrumentation industry. The development of such a comparator will allow rapid, accurate measurements of signals used by digital subscriber line modems and waveform synthesizers.

A final example of a key customer well served by the Electricity Division is the electric power industry, which provides critical infrastructure for the U.S. economy. Division projects relevant to this industry include Metrology for Electric Power Systems and Advanced Power System Measurements. The former project provides essential voltage and current calibration services to industry in support of applications such as the transmission and distribution of electric power and high-current welding. The latter project is focused on the future measurement needs of the U.S. electric power industry. A noteworthy element of this work is the ongoing development of testing procedures that will allow NIST to provide calibration services for optical current transducers. Both projects are of uniformly high quality and seem to be well synchronized with the evolving needs of both the electric utility industry and the industrial and commercial users of electric power. The division has been commendably proactive in

seeking input on the needs of its customers; for example, in December of 1999, NIST sponsored a workshop on the metrology requirements of the deregulated power industry.

In addition to the above projects in support of the electric power industry, the Electricity Division recently received $300,000 for a new initiative focused on the development of security, communication, and measurement protocols for maintaining the integrity of the data communications and computing/ control systems required for reliable operation of power grids. This initiative represents a very sound combination of technology and relevance, and the activity will benefit from the Electricity Division’s familiarity with power industry needs and NIST’s leadership in encryption and computer/data communication security technology. The initiative appears to be particularly timely in light of the power outages that occurred as a result of system equipment failures in the summer of 1999, the recent problems in power supply operation in California, and the critical role that dependable and plentiful supplies of reliable power play in the national economy. The panel’s only question is, Given the complexity of the issues under investigation, the size of the industry and the infrastructure that will be affected, and their importance to the U.S. economy and its global competitiveness, will a larger and longer-term commitment be needed to establish standards for power system communications and control security and to develop appropriate measurement technologies and standards for their implementation in a timely and efficient fashion?

The Electricity Division’s current efforts in support of the electric power industry are important and effective. However, given recent developments in the industry, an increased commitment and an expansion of effort may be needed. A combination of deregulation and the growing need for very good power quality to support the digital economy have created a rapidly changing venue for commerce directly associated with electric power. In this new environment, there is a great need for leadership, standards, and traceable calibrations to measure power quality, characterize power system capabilities, and enable power trading. A specific example of an area in which the division might consider a new project is the measurement of and testing for harmonics and for voltage surges and sags. This effort would support the power quality measurements and standards upon which premium power contracts and electric utility performance-based regulation can be based and by means of which disputes over power quality and reliability can be resolved.

Division Resources

Funding sources for the Electricity Division are shown in Table 2.2. As of January 2001, staffing for the Electricity Division included 57 full-time permanent positions, of which 51 were for technical professionals. There were also 7 nonpermanent and supplemental personnel, such as postdoctoral research associates and temporary or part-time workers.

Electricity Division funding has remained essentially flat over the past 5 years, but the number of personnel has dropped by 20 percent. While the Electricity Division appears to still have sufficient technical ability to meet the needs currently identified, the panel is concerned that programmatic deficiencies may arise if the staff reduction trend continues. Much of the decrease in head count has been due to retirement of technical staff members with considerable experience and long-standing ties to relevant areas of U.S. industry. Their retirement has eroded the division’s expertise and industrial contacts. At present, there are some areas in which critical divisional functions are served by a single person, with no redundancy to provide for naturally occurring changes in staff. In these areas, staffing has been stretched so thin that further loss or changes would require the postponement, if not the cancellation, of planned activities, and capabilities and function would probably suffer an irreversible loss. Also, the personnel and budgetary limitations mean that in some programs, work is limited to

TABLE 2.2 Sources of Funding for the Electricity Division (in millions of dollars), FY 1998 to FY 2001

|

Source of Funding |

Fiscal Year 1998 (actual) |

Fiscal Year 1999 (actual) |

Fiscal Year 2000 (actual) |

Fiscal Year 2001 (estimated) |

|

NIST-STRS, excluding Competence |

7.8 |

7.8 |

7.6 |

7.6 |

|

Competence |

1.1 |

0.9 |

0.5 |

0.4 |

|

ATP |

0.3 |

0.3 |

0.2 |

0.2 |

|

OA/NFG/CRADA |

1.5 |

1.3 |

1.7 |

2.1 |

|

Other Reimbursable |

1.1 |

1.2 |

1.1 |

1.2 |

|

Total |

11.8 |

11.5 |

11.1 |

11.5 |

|

Full-time permanent staff (total)a |

70 |

65 |

63 |

57 |

|

NOTE: Sources of funding are as described in the note accompanying Table 2.1. aThe number of full-time permanent staff is as of January of that fiscal year. |

||||

maintaining equipment and meeting current needs and there is no time or money to develop the technologies that will be necessary to provide the metrology required by industry in the future. The panel is therefore concerned that the current limitations on resources may interfere with the Electricity Division’s ability to sustain its leadership in electrical metrology to the extent necessary to support U.S. industry.

The panel would like to cite three examples from the past year of actual or potential consequences of the budgetary constraints. A particularly egregious case was the delay in the Electronic Kilogram project. Because there was no money available to purchase liquid helium for cooling the system, staff were unable to take measurements for several months. Another potential problem could be in the Voltage Metrology program. There are tentative plans to suspend some 60-hertz voltage metrology services. This decision appears to have been entirely motivated by budget limitations. While the plan currently calls for U.S. needs in this area to be fulfilled by testing facilities at the Canadian National Research Council’s Institute for National Measurement Standards, an alternative approach might be to partner with an American commercial laboratory, which could offer voltage metrology as a profit-making or cost-recovery-priced service. Such a laboratory would allow the United States to retain a basic metrology service for voltage measurement capability within its borders. Another programmatic cutback attributable to resource constraints was the scaling back of work on partial discharge detection methods. Partial discharge diagnostic approaches are particularly appropriate for condition assessment (determination of wear) of major electric power equipment and for detection of incipient failures in power grids. Given the aging infrastructure of the U.S. power grid, such testing methods could be of immense value.

The panel is deeply concerned about the long-term consequences of the limitations on human and fiscal resources in the Electricity Division. This group has a vital role to play in supporting the ability of U.S. companies to participate in global markets. Standards are occasionally used as trade barriers, and extensive financial backing is given to standards organizations in Europe and Asia. The panel is concerned that U.S. electronics and electrical industries may suffer a competitive disadvantage if NIST, the American standards laboratory, cannot maintain its traditionally high quality of technical work. If

the trend of flat or shrinking budgets continues, the panel expects that EEEL will find it increasingly difficult to play its critical role as a leader in metrology research and services for the relevant American industries. A survey of the measurement capabilities of other laboratories might help NIST with difficult decisions about dropping or curtailing some of its vast range of services. The panel cautions that this is not a desirable step, nor one to be taken lightly. It recommends that if services need to be discontinued, ways should be found to keep the needed capabilities within the United States so as not to depend on laboratories or resources in other countries.

This year, the panel noticed several factors that were having a discernible impact on morale. The most significant factor is the protracted budgetary restrictions. Employees have realistic concerns about their long-term ability to access the resources they need to contribute effectively to the laboratory mission. The refocusing and redirections of the past year have improved the Electricity Division’s efficiency, but a clear danger exists that morale can be undermined further by continued tightening. Another factor affecting morale is the changes and uncertainty in management personnel. In the last year, there have been two new division chiefs and one new deputy chief. Also, three levels of management (the Electricity Division Chief, the EEEL Director, and the NIST Director) are all serving in an acting capacity. Regardless of the quality and personal commitment of these managers and the reasons for these changes, the potentially temporary nature of these assignments make long-term planning and commitment to programs difficult, and the implicit lack of permanence in direction and leadership hurts morale. EEEL should provide more stability for the Electricity Division in the next year and reassure employees about the long-term stability of the division.

Another area in which clearer management goals might be helpful is the new listing of laboratory values. These were presented to the panel as (1) integrity, (2) impact, and (3) excellence. The panel agrees that these are appropriate values and recognizes that the laboratory places a great deal of emphasis on assuring that its activities are relevant to the needs of its customers and have positive impact on the U.S. economy. However, the panel is somewhat concerned that listing “excellence” below “impact” might be interpreted as meaning that quality is secondary to commercial value in EEEL’s priorities. Since a great deal of EEEL’s reputation and value is based on its image as a provider of measurements and standards of undisputedly high technical quality, the laboratory must be careful to maintain its position of leadership. The staff’s pride in their work and in being a part of the NIST environment is also based on a tradition of technical excellence, and management must be sensitive to any misinterpretation of the new list of values. Possible alternative approaches to communicating the values include listing them without enumeration or representing them graphically as the three sides of triangle in which all contribute equally to EEEL activities.

In the area of equipment and instrumentation, resources appear to be adequate to meet present needs, although the ability to prepare for and meet the future metrological requirements of industry will be impeded without serious capital investment. The panel is pleased that a new laboratory building is under construction, but planning must begin now on how NIST will fund the purchase of new equipment for these state-of-the-art laboratories. One area in which the panel sees a growing need for new instrumentation is thin-film and lithographic tools. In many cases, these tools can replace to good advantage older tools, some of which can no longer be maintained or replicated. However, acquiring the instrumentation would be a capital-intensive effort. While the need is being met effectively in the short term through the use of alternative approaches and external collaborations, in the long term this need will ultimately require additional funding. The panel is concerned that there does not appear to be a long-term plan for meeting the emerging needs in this area. The panel emphasizes that funding for thin-film tools should not come from further potentially devastating reductions in staff.

Semiconductor Electronics Division

Technical Merit

According to division documentation, the mission of the Semiconductor Electronics Division is to provide leadership in developing the semiconductor measurement infrastructure essential to improving U.S. economic competitiveness by providing necessary measurement, physical standards, and supporting data and technology, associated generic technology, and fundamental research results to industry, government, and academia.5

This mission statement is appropriate and describes accurately the programs currently under way in the division in support of the NIST and laboratory missions. Division staff are well aware of the importance of seeking out the issues facing the semiconductor industry in which the unique capabilities of NIST can be applied effectively to produce solutions in a timely manner. As a result, the industry views the Semiconductor Electronics Division’s contributions as essential. The panel applauds the division’s ability to provide, without bias, the measurement techniques and standards required by industry in a way that allows NIST work to benefit multiple companies. NIST staff are clearly aware of the future needs and opportunities of the semiconductor industry, and the division’s careful prioritization and well-thought-out planning processes reflect this knowledge. The division personnel have demonstrated high levels of management skills and technical expertise and competencies in carrying out the division mission, in selecting relevant projects and reasonable milestones, and in producing important deliverables.

The panel is pleased to see that the many industrially driven programs in the division are complemented by the basic scientific research necessary to build competencies and fundamental understanding of relevant systems. These efforts are how the Semiconductor Electronics Division is preparing to meet future measurement methods and standards needs of the silicon and compound semiconductor industries and are necessary to keep the division programs at the cutting edge of metrological technologies. Excellent examples of the sort of basic research that the panel encourages are the spectroscopic ellipsometric studies of high-k dielectrics and the determination of parameters critical to gallium arsenide (GaAs) processing. The panel stresses that these sorts of investigations of fundamental questions are an indispensable element of a balanced portfolio of programs.

The panel continues to be impressed with the technical quality of the programs under way in the Semiconductor Electronics Division. An important factor in the merit of the work is the quality of the staff, and the panel notes that the accomplishments of division personnel have been recognized by governmental and external organizations. In 2000, a three-man team received a Department of Commerce Bronze Medal for “greatly accelerating the development of scanning capacitance microscopy as a practical measurement tool,” and two individuals received, respectively, the IEEE Third Millennium Medal for outstanding achievements and expertise in the areas of wire bonding and the packaging of semiconductor chips and a Distinguished Alumnus Award from Purdue University for international leadership in the field of narrow-gap semiconductors. In 1999, another staff member received a Depart-

ment of Commerce Bronze Medal for developing standards and methods for resistivity measurements that have been widely deployed in industry.

Semiconductor Electronics Division staff are organized into three groups: Materials Technology, Device Technology, and Integrated Circuit (IC) Technology. Within these groups, there are eight programs, highlights and issues from each of which are discussed below.

The newest activity in the division is the high-visibility Competence project on molecular electronics (sometimes called “moletronics”). This state-of-the-art effort explores the viability of molecular microelectronic devices and aims to develop the metrology needed to support the construction and use of such devices. This is an interdisciplinary project, and the issues will be tackled by a large-scale collaboration among the Semiconductor Electronics Division, the NIST Chemical Science and Technology Laboratory, and Yale, Rice, and Pennsylvania State Universities. The panel found this team to be a balanced collection of personnel committed to a series of tasks with well-defined and realistic overall goals. Current plans call for specific molecules to be examined as potential circuit elements, such as wires, diodes, amplifiers, and switches. The division staff will provide expertise in MEMS, which will be used to fabricate novel molecular test structures through molecular self-assembly.

This is a high-risk project, and the panel cautions that the division and NIST must be tolerant of setbacks, which are likely to occur in basic research activities such as this one. A long-term commitment is needed if this work is to be successful and the NIST effort is to keep pace with the programs already under way at the collaborating universities. This project, with its focus on technologies so far in advance of what is currently being used or planned for in industry, is not like the normal activities in the Semiconductor Electronics Division. However, the panel finds that it is indeed consistent with the overall objectives of the division and of NIST because it will build expertise in an area from which many people expect the next generation of higher density, faster microelectronic devices to arise. While there are many active programs in this area at universities and other government agencies, NIST’s unique capabilities will allow it to make significant contributions in characterization and standard test structure development.

The Metrology for Compound Semiconductor Manufacturing program investigates process characterization tools and methods for optimal growth of epitaxial GaAs device structures. A major accomplishment of this effort is the development of a state-of-the-art molecular beam epitaxy (MBE) facility, which is equipped with an extensive set of in situ characterization tools for monitoring and control of GaAs process parameters. Using this facility, NIST staff have been able to develop characterization and control techniques necessary to optimize GaAs processing. Techniques identified and optimized by the staff include the process of delta doping for pseudomorphic high-electron-mobility transistors (pHEMT) and the use of diffuse reflectance spectrometry (DRS) for temperature measurement and control. The Semiconductor Electronics Division’s findings have been successfully transferred to industry, resulting in improved device properties and yields. The next challenge in this program will be how to broaden the scope of the effort to include emerging compound semiconductor materials such as group III nitrides, indium phosphide (InP), and silicon carbide (SiC). Unfortunately, the existing MBE system is not equipped to work with these novel materials, and significant capital investment is likely to be required to allow the division to make the necessary modifications.

In the Scanning Probe Microscope Metrology program, the division has led the community in the development of SCM as a tool for the two- and three-dimensional dopant profiling required for transistor analysis and computer-aided design characterization. The International Technology Roadmap for Semiconductors (ITRS) says that industry will need 3-nm spatial resolution in the profiling by 2001, and although NIST is somewhat short of this goal, the technique developed here is still far ahead of any viable alternative method. The panel commends the division’s work in this area and notes that further

demanding tasks lie ahead, including the design of new probes to continue increasing the spatial resolution, the addition of new capabilities for accurate gate/junction edge location measurement, and the development of software to support all of the new techniques.

In the work on Thin-Film Process Metrology, optical data, optical models, and measurement capabilities are being developed to support key ITRS needs for the characterization of candidate advanced gate dielectric materials. The panel finds this work to be timely and the measurement methodologies being developed for spectroscopic ellipsometry and for comparison of current-voltage (C-V) characterization models to be highly relevant to industrial needs. Recent accomplishments include the development of a software package for extracting the thickness distributions and dielectric constants of multilayer dielectric stacks and successful use of this software to model a number of high-k dielectrics of current interest, including tantalum oxide (Ta2O5), zirconium oxide (ZrO2), and hafnium oxide (HfO2). The software appears to be a very valuable tool and is currently being disseminated to potential users in industry, although the panel feels that a mechanism for how commercial vendors will incorporate the software package into their instruments has not yet been clearly defined. The experimental measurements are done on a custom-built ellipsometer, the most accurate in the world for precision characterization, and while the panel is impressed by this instrument, it notes that issues related to its long-term stability still need to be resolved. Another challenge is producing systematic methods for selecting high-k dielectrics for in-depth study in the absence of a good understanding of relevant materials properties.

The Metrology for Simulation and Computer-Aided Design (CAD) program aims to facilitate the efficient and reliable application of semiconductor CAD to the development of a whole range of modeling methodologies and validating and benchmarking procedures. The staff on this project have demonstrated superb technical competence in recent years, especially in their work on insulated gate bipolar transistor (IGBT) modeling, which has had a significant impact on industry. The IGBT project has successfully concluded, and resources have been shifted to several new projects. Two impressive examples of the emerging, industry-relevant efforts in this program are the project on metrology for SiC diode characterization and the work on a high-speed thermal imaging system. In the first area, staff have developed a highly capable test system for measuring transient responses of high-voltage, high-current switching events. An impressive collection of data on state-of-the-art SiC diodes has been obtained under a full range of application conditions. To date, samples for these tests have been supplied by a single company, and the panel strongly encourages staff to reach out to other companies and expand this industrial collaboration as soon as possible. The other impressive new thrust within the Metrology for Simulation and CAD program is the development of a high-speed thermal imaging system. This system enables scientists to view instantaneous temperature distributions of small heat sources, and the capabilities have been demonstrated in a movie showing the time evolution of heat distribution on a functioning transistor. Imaging capabilities like this have significant potential to increase the understanding of a variety of systems and to support new process monitoring approaches; the panel feels this technology is likely to be developed into a commercial instrument.

The team working on MEMS has designed unique static and dynamic test structures that utilize MEMS technology to measure the stress and strain of thin films on IC structures. To confirm industrial applicability, staff have demonstrated that the test structures and fabrication methods are compatible with standard IC process techniques and can be imbedded in certain industrial IC processes for measurement purposes. This work is still in the early stages, and staff are fully aware of the many fundamental issues that remain to be addressed. Other efforts in this area include work on technologies to measure bond pad temperatures during ultrasonic wire bonding. The structures developed at NIST are providing the first accurate in situ measurements of these temperatures and are expected to allow better character-

ization and optimization of the bonding processes. The panel observed that a number of groups in the NIST Measurements and Standards Laboratories are working in the area of MEMS technologies; better coordination and a more coherent approach to MEMS-related activities is needed and would strengthen the overall NIST effort in this area.

In the Linewidth and Overlay Standards for Nanometer Metrology program, the primary accomplishment is the demonstration of prototype state-of-the-art, low-cost critical dimension (CD) measurement standards. In these standard wafers, representative structures are calibrated using atomic lattice spacing measurements from transmission electron microscopy (TEM) cross-sectional imaging. Other devices on the same wafers are then calibrated against the atomically measured structures by electrical resistivity measurements. Using this technique, the numerous low-cost calibrated structures critically needed by industry can be manufactured cost-effectively with traceability to atomic level spacing. This approach has been enthusiastically received by industry, and a plan to transfer the methodology and the manufacture of these standard wafers to a commercial supplier is in place. Several factors contributed to delays in the transfer, but the work is now back on track, and the panel notes that the transfer mechanism for this division result is a good one and could serve as a model for other division results.

The Dielectric and Interconnect Reliability program aims to produce standardized test methods, physical models, tools, and diagnostic procedures as well as actual reliability data and electrical characterization results. Customers for NIST results include manufacturers, standards organizations, and instrument makers such as Hewlett-Packard, Keithley, Qualitau, and Reedholm. This wide array of groups interested in the program’s outputs is a result of the NIST reputation for leadership in this field. The quality of this program is also demonstrated by the fact that foreign standards organizations and companies have adopted the NIST standards produced in this area. One recent accomplishment of the Semiconductor Electronics Division is the development of reliability test methods for metal-oxide-semiconductor transistor devices with ultrathin silicon dioxide layers. When using these ultrathin (less than 3 nm thick) oxides, it is advantageous to fabricate alternative dielectric films; currently the most common approach is adding nitrogen to the silicon dioxide films. These new approaches require development and characterization of new reliability test methods, and NIST is successfully working in this area.

The one concern about the Dielectric and Interconnect Reliability Metrology program is in the area of interconnect reliability metrology. Historically, the division provided leadership in the development of test structures and methods for characterization of aluminum interconnect films, and NIST techniques are now commonly used throughout the semiconductor industry. However, industry is now in the middle of the transition to copper interconnects, and several companies have already started high-volume manufacturing of products based on the new copper technologies. This transition was planned, and the Semiconductor Electronics Division recognized that test structures and methods would be needed to characterize the new interconnects, but a lack of resources has prevented NIST from making any progress in this area. The panel is deeply disappointed that this important industrial need has had to go unmet.

Program Relevance and Effectiveness

The Semiconductor Electronics Division has played a key role in the phenomenal growth of the semiconductor industry and in helping U.S. companies maintain leadership in the development and manufacture of silicon and compound semiconductors. NIST continues to provide the state-of-the-art measurement capabilities and standards necessary to support industry’s ongoing efforts to push physical and chemical limits in the production of new devices and processes. The panel finds the division’s

efforts to be relevant to industry needs and an important element in sustaining the productivity of this sector of the U.S. economy.

Division staff effectively reach out to industry through participation in roadmapping activities, industrial partnerships, international conferences, standards bodies, and industry consortia. These activities provide NIST personnel with a comprehensive working knowledge of current and future critical measurement and standard needs of the semiconductor industry. As noted in past reports, the panel is supportive of staff’s key roles in working groups that set the metrology requirements in the ITRS. Semiconductor Electronics Division personnel have been active in the industrial effort to develop the first compound semiconductor roadmap. This push started at the 2000 International Conference on Compound Semiconductor Manufacturing Technology, and efforts will continue at the 2001 meeting. A NIST project leader serves on the organizing committee for these conferences. Other important international activities in which staff participate include an International Standards Forum Workshop on MEMS standardization, which focused on the accurate measurement of thin-film properties, and a Joint Electron Device Engineering Council (JEDEC) committee responsible for providing an unbiased method for determining gate oxide reliability. The division also continues to organize the well-attended series International Conferences on Characterization and Metrology for Ultralarge-Scale Integration (ULSI) Technology; the 2000 conference was a success, and planning for the 2002 meeting is already under way. Outreach by the division is not limited to face-to-face interactions with relevant communities; the staff also use the Web. For example, the Semiconductor Electronics Division has a Web site dedicated to teaching and standardizing the Hall measurement process for compound semiconductors. This reference site is a good example of effective use of the Internet to make NIST expertise widely available and is complemented by NIST’s organization of a round-robin among 11 domestic and international companies; the intercomparison is designed to assess how well these measurements are being carried out in practical situations.

An important mechanism for disseminating division results is the extensive partnerships forged with external organizations, including individual companies, industry consortia, university researchers, and other U.S. government laboratories. These collaborations and informal relationships not only provide input on how to address key industry needs before and during divisional projects, but also facilitate the rapid transfer and implementation of NIST results. For example, staff set up collaborations with companies from both the equipment and device manufacturing sectors in order to demonstrate that NIST-developed techniques for using pHEMT and DRS can enhance the tools currently used for in situ process characterization. Another area in which the Semiconductor Electronics Division’s extensive array of partners has made a significant difference is work on SCM measurements and related software for two-dimensional dopant profiling. During the development process, NIST collaborated with two DOE laboratories (Los Alamos and Sandia) and three universities, and for technology transfer, staff partnered successfully with Lucent, Texas Instruments, Motorola, and Intel. This work was a very good example of how NIST staff make a difference: they solve industry problems quickly and correctly and then share the resulting methodologies with equipment makers and the rest of the community. In this particular case, the measurement techniques are used to characterize junction profiles and the data produce higher accuracy in the models used to design IC products. The primary result is a much shorter design cycle and quicker transition to the production stage, which has significant economic benefits for all parties.

The semiconductor industry is an international collection of companies operating in a global marketplace. While the focus of the Semiconductor Electronics Division is on benefiting the U.S. economy, many of the division’s research and development projects and standards activities have international effects. At the most basic level, the interdependent nature of the complex supply and manufacturing

processes employed by a vast number of companies in different locations implies that the adoption of standards is necessary for the industry to survive. NIST develops standards and related technologies that are usually the most accurate and advanced in the world. These products are adopted first by U.S. companies (providing them with an initial advantage in the marketplace) and then spread rapidly to the rest of the world. Mechanisms for this dissemination include sales to foreign companies of equipment made by U.S. instrument manufacturers, use of NIST products by foreign standards laboratories, and adoption of NIST standards or methods by U.S. standards organizations, such as the Electronics Industries Alliance, JEDEC, or the American Society for Testing and Materials (ASTM), which serve international communities. Examples of areas in which NIST standards have been disseminated globally include the use of gate oxide standards by the Electronic Industries Association of Japan.

Division Resources

Funding sources for the Semiconductor Electronics Division are shown in Table 2.3. As of January 2001, staffing for the Semiconductor Electronics Division included 38 full-time permanent positions, of which 33 were for technical professionals. There were also 3 nonpermanent and supplemental personnel, such as postdoctoral research associates and temporary or part-time workers.

In the past year the division was not able to make progress on its goal of increasing funding from external sources, specifically other government agencies or companies. The panel cautiously encourages renewed efforts in this area. The objective should be to find funding to support projects that are in line with the division mission and will not distract staff from making progress on programs already identified as high priorities for the division. A good example of how the division can effectively leverage other agency money to support relevant work is the project on metrology for SiC diode characterization, which is funded by the Defense Advanced Research Projects Agency (DARPA). An example of the dangers of relying on noncore funding is the current concern about support for the MEMS project. This work depends in large part on money from the Advanced Technology Program

TABLE 2.3 Sources of Funding for the Semiconductor Electronics Division (in millions of dollars), FY 1998 to FY 2001

|

Source of Funding |

Fiscal Year 1998 (actual) |

Fiscal Year 1999 (actual) |