LANDFILL PROBLEMS IN SAN FRANCISCO BAY

Frank C.Boerger

Harding-Lawson Associates

Navigation is an important beneficial use of the waters of the San Francisco Bay system; however, to continue using the marine facilities that have been developed over the years, dredging of artificial channels is required throughout the system. Appropriate methods of disposing of dredged material have been considered over a long period. This paper will consider the problems involved with land disposal of dredged materials.

BACKGROUND

New federal and state laws and agency regulations have had a significant impact on traditional approaches to dredged material disposal. For example, in the early 1970s the number of authorized open-water disposal sites in the bay area was reduced from 13 to 3: one near Carquinez Strait, one in San Pablo Bay, and one near Alcatraz in the central bay. These sites were established based on the principle that dredged materials would always be moved downstream toward the Golden Gate. In addition, a series of parameters based on the Jensen criteria were established as tests of the pollution of the sediments, with minimum standards set for each of the disposal areas. This approach dictated that the majority of the sediments scheduled for disposal in the bay be transported to the Alcatraz site.

In 1978 the San Francisco District of the Corps of Engineers published under Public Notice 78–1 the procedure for establishing a temporary site for aquatic disposal of dredged materials over the objections of several state and federal agencies. Its provisions had been applied previously to two small dredging projects with careful monitoring before, during, and after dredging activities, all of which showed no long-term significant environmental degradation. However, the procedures and testing required were so extensive they discouraged others from attempting this type of activity.

In 1983 the Corps’ San Francisco district was alerted that the Alcatraz site was filled and was causing a hazard to navigation. Mounding in the disposal site had not been expected to occur based on early tests using the San Francisco Bay delta model in Sausalito. The

size of the mound was reduced by dredging, and new interim controls were imposed on the site. The Corps is presently completing a longer term plan for dealing with disposal at Alcatraz. At the same time, it is evaluating ocean disposal sites outside the Golden Gate as possible alternatives to disposal in the bay. In fact the site was closed during July 1986 to allow the monitoring of a single disposal operation.

The above is presented as background to a discussion of land disposal as an alternative method of dealing with the 8+ million yd3 of dredged material disposed each year in the San Francisco Bay area. It is obvious that the pressures to relieve the use of disposal sites in the bay increased the need for consideration of land disposal sites.

REUSE VERSUS DISPOSAL

From an engineering viewpoint, dredged materials represent a valuable asset, particularly granular materials dredged in some sectors of the estuary, which constitute a valuable construction material. In some early projects these materials were deposited in a land disposal site, then hauled away for sale when dried. In this way the materials were removed from the estuarine system and therefore did not cause additional problems in downstream areas or with water quality. It is also noteworthy that at some locations in the estuary the sand is mined by extraction companies for use as a construction material and a component of aggregates.

Some of the lower reaches of the estuary contain fine-grained silts and clays, materials that can be reused. Reuse practices include deposition in relatively shallow layers with constant working of the disposal site during the drying period; this increases the rate of evaporation and brings the wetter material to the surface so that the entire mass can be dried.

REGULATORY LIMITATIONS TO LAND DISPOSAL

Several important developments at the state and federal level have made the development of land disposal areas more difficult. In 1965 the California State Legislature approved the McAteer/Petris Act, establishing the San Francisco Bay Conservation and Development Commission (BCDC). One of the major tasks assigned to this commission was a study of the filling of the bay and its effect on the estuary. The result was the establishment of a permanent BCDC that regulates the filling of any lands subject to tidal action and at elevations below +5 ft NGVD (National Geodetic Vertical Datum). Since the use of such lands solely for disposal of dredged materials was considered to be an inappropriate use of those lands, the availability of land disposal sites around the periphery of the bay became severely limited.

Passage of the federal Water Pollution Control Act and Amendments of 1972 (later renamed the Clean Water Act), establishing the basis for the Section 404 regulations of the Environmental Protection Agency, provided another obstacle to the establishment of land disposal areas. Based on interpretations of that law and the 1899 Navigation Act, the Corps of Engineers was assigned responsibility for controlling filling of lands behind dikes if they were either below the elevation of mean high water or subject to jurisdiction under the guidelines established under Section 404. Thus many of the lands around the periphery of the bay were found to be unsuitable for uses that were not considered to be “water dependent.” The Environmental Protection Agency and the U.S. Fish and Wildlife Service do not define disposal of dredged materials as a water-dependent use of such wetlands.

Applications of the National Environmental Policy Act of 1969 have been interpreted to require mitigation for any project that eliminated wetlands from the bay area. The extent of mitigation required has been variously based on different interpretations of the requirements ranging from acre-by-acre replacement of lost wetlands (as interpreted by the state of California and its Department of Fish and Game) to a more extensive replacement in accordance with the habitat evaluation procedure utilized by the U.S. Fish and Wildlife Service. The predominant approach of the required mitigation efforts has been to return the mitigation lands to tidal action by removing portions of the dikes that separate them from the estuary. Obviously, such mitigation practices remove from consideration potential future sites for dredged material disposal.

Another significant limit to the possible use of lands peripheral to the bay is the Endangered Species Act. Two of the endangered wildlife species that have impacted many projects in the bay area are the salt marsh harvest mouse and the clapper rail, both inhabitants of the inner tidal zone where salt water nourishes pickleweed (Salicornia). Two subspecies of the harvest mouse are present, one in the south bay and one in the north bay. To promote the survival of these endangered species, programs to expand available habitat are planned and are being developed through the mitigation measures required by the Section 7 consultation [in the permitting] process.

It is apparent that the various regulatory approaches to disposal of dredged material lack a consistent direction. On the one hand, disposal in the waters of the estuary has been regulated on an increasing basis despite (1) the findings of the Dredge Material Research Project at the Waterways Experiment Station of the Corps of Engineers, and (2) a dredged material disposal study by the San Francisco District applied specifically to the waters of the estuary. Many of the environmental agencies have continually opposed aquatic disposal of dredged materials. At the same time many of the same agencies have adopted regulations that severely restrict the areas that might be available for land disposal. Since much of the periphery of the bay is surrounded by hills, and since the low-lying lands adjacent to the bay have been judged in most cases to be subject to Corps of Engineers and BCDC jurisdiction, these lands are unavailable because

they are considered to be wetlands or historical baylands. Therefore, the practical possibilities for land disposal are also severely limited. Further, the trends in the 1980s to expand the definition of wetlands to include seasonal wetlands has led to the inclusion of numerous upland disposal sites that could have been considered in the past.

OPPORTUNITIES CREATED BY REGULATION

Despite the constraints discussed above, some recent projects have in fact become viable within the regulatory constraints. A project to dredge a channel to a ferry terminal in Marin County provided for spoils disposal on a portion of marshland that had been diked off. Following the channel dredging, the dikes were opened in certain areas of the marshland to allow tidal waters to enter these areas (where elevations had been increased sufficiently to support appropriate marsh plants). The dredged material disposal site was turned over to wildlife agency management after the project was completed.

In conjunction with the channel deepening project to the Port of Stockton, land disposal has been used in several ways. Some land disposal sites contained areas that were built up for development as recreation areas in the delta. In other cases, open-water disposal was used in the repair of delta island dikes which were broken during the flooding season. Open-water disposal was also used to raise normally inundated areas to an elevation that created habitat for shorebirds and other wildlife. Also as part of this project, an area that had previously been used for dredged material disposal (and from which the material had been dried and hauled away) is being reused for this purpose; again, the material will be removed for other uses. In another application of this land disposal procedure, materials are being disposed at a duck club property on a low-lying island to provide an incremental increase in the elevation of the island so that, when flooded, it will provide adequate water depth for vegetation to attract ducks. In another portion of the duck club property, material is being deposited in the vicinity of the dikes for later use in maintaining the dikes as they are eroded by wave action and eventually consolidate and sink into the bay mud.

Many of these practices were adopted with minimum acceptance by many of the commenting agencies. Close observation of the results of these practices may reveal that they could be used more extensively with less concern for values lost and more appreciation of values gained.

LONG-TERM SOLUTIONS

The developments outlined above present the basis for extrapolating two long-term solutions for dredged material disposal. First, there is

a continuing need for aquatic disposal sites; those already established, and new sites in the bay estuary and in the nearshore areas of the ocean. Second, specific land disposal sites that are available to all could be established, based on a revised interpretation of water-dependent uses to include those wetland sites that are reusable for dredged material disposal. The definition of “water dependent” should be expanded to include the disposal of dredged material from channels that support commercial navigation, fishing, and recreational boating.

There is an increasing need for appreciation by all agencies that the solutions to these problems must have a sound economic as well as environmental basis. Continued utilization of deep-water channels for commercial navigation and of port and terminal facilities is essential to the bay area and the nation. Also of great importance is the need to expand and maintain facilities to support the increasing recreational use of the bay. Revised policies to facilitate the disposal of dredged materials should therefore be encouraged.

PROBLEMS ASSOCIATED WITH UPLAND DISPOSAL OF DREDGED MATERIAL FROM TAMPA BAY

William K.Fehring

Greiner Engineering, Inc.

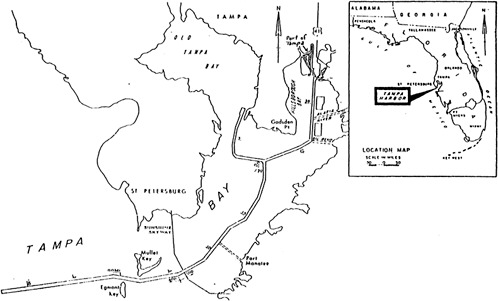

Tampa Bay is a subtropical estuary located centrally on the west coast of the Florida peninsula. The bay has an area of approximately 350 mi2 and an average natural depth of about 10 ft. The Port of Tampa is located at the head of the estuary, some 35 mi from the open waters of the Gulf of Mexico (Figure 1). Project depths for the port are −43 ft in the main channel and −34 ft in the branch channels. The port is primarily a bulk cargo complex with phosphate-related bulk cargos comprising the major portion of both imports and exports.

The subtropical waters of the bay and adjacent gulf were historically nutrient-poor, and therefore clear. Bay bottoms are primarily sand and were historically covered with seagrasses to a depth’ of about two fathoms. Offshore bottoms are generally sand, except for scattered rock outcroppings which support a limited coral and sponge community.

Dredged material from Tampa Bay is primarily sand. Sand from construction dredging is often mixed with limestone and clays. Sand from maintenance dredging often contains varying amounts of silt (54 percent), but due to the relatively low overall industrialization of the watershed and low upland sediment loading to the estuary, this material generally meets the Environmental Protection Agency (EPA) criteria for open-water disposal.

Due to the historical clarity of its waters and its tourist-dominated economy, Florida has adopted some of the most stringent water quality protection measures in the nation. The state environmental protection program is so oriented toward water quality concerns that fish and wildlife values were not even formally considered until 1985. This bias has resulted in several policies applicable to this discussion:

-

An effective ban on the use of hopper dredges, except for the cleanest sands, since overflow of the hoppers is generally not permitted.

-

A severe bias against any form of open-water disposal of material into state waters, even for badly needed beach renourishment projects.

-

A general policy that confined upland disposal is always preferable to other methods of disposal, even to the extent that maintenance dredging with complete containment within an upland site, is generally exempted from the need for a state permit.

These state policies have restricted the disposal options available to sponsors of both federal and local dredging projects to an extent significantly greater than might be experienced under application of the EPA Section 404 b(1) guidelines. One notable recent exception has been the deepening of the Tampa Harbor main channels. Because this project was authorized prior to the adoption of many current regulations, all of the 72 million yd3 of material from this project were disposed of in state and federal waters. A large percentage of this material was used to build two large diked islands for future maintenance disposal or was placed in ocean dump sites in the Gulf of Mexico. Only a moderate portion of the material, all clean sand, was simply “disposed of” in state waters along the channel.

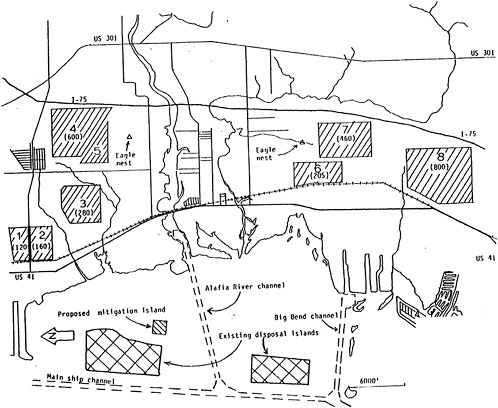

The large diked islands, which are indicated in Figure 2, were designed to hold all maintenance dredging material from the upper portions of the main channels for 35 to 50 years. They were constructed in anticipation of evolving state regulations restricting open-water disposal of maintenance materials. These islands have a present capacity of about 13 million yd3 and involved the filling of approximately 1,250 acres of bay bottom in the most landward portion of the estuary. Their size, along with subsequent shoreline erosion problems, have created significant resistance to additional disposal islands or lateral expansion of the existing islands.

When the harbor deepening project was nearing completion, a lawsuit was filed by a neighboring coastal county to block further use of the existing ocean dump site in the Gulf of Mexico. This suit was successful in forcing designation of a new temporary disposal area more than 18 mi offshore, which is designated only for disposal of construction material from now completed portions of the main channel. This action has legally and economically restricted ocean dumping as an alternative for other port development and maintenance projects unless a permanent disposal site is designated within a reasonable distance from the coast.

As a result, project planning since the mid 1970s has been based almost exclusively on confined upland disposal for both construction and maintenance material—with the result that no significant new projects have been initiated. The reasons for this stalemate can perhaps be best illustrated using an actual proposed project as an example, the proposed deepening and federal maintenance of the Alafia River and Big Bend branch channels.

The Alafia/Big Bend channel project was the subject of a Corps of Engineers feasibility study authorized in 1979 and completed in 1984. Under the proposed project the two channels, 3.6 and 2.2 mi long respectively, would be widened from 200 ft to 300 ft and deepened from −32 ft to −43 ft. The project would involve excavation of some 9.5 million yd3 of sand and clay and some 1.5 million yd3 of limestone, the latter entirely from the Alafia River channel.

Excavated rock would be utilized to construct shoreline revetments on the existing diked disposal islands. For the sand and clay material from each channel, both upland and ocean disposal were considered. The locations of the eight upland disposal sites considered are shown in Figure 2.

The Corps’ feasibility report states that for each channel both ocean and upland disposal plans were “economically feasible.” However, the report goes on to state that with the use of upland disposal “the total project first costs are significantly less than for offshore disposal.” On this basis offshore disposal alternatives were not considered during detailed studies.

The comparative costs on which this decision was based are presented in Table 1. It is clear that the difference between the upland and ocean disposal costs was not “substantial” (3 percent), and that the Corps’ decision was based at least in part on uncertainty associated with the designation of a usable ocean dump site. Whether the actual costs of implementing the upland disposal plans would have been substantially higher than estimated, therefore reversing the relationship of the two alternatives, will be addressed below.

TABLE 1 Construction Costs for Upland and Ocean Disposal Alternatives for a −43 ft. Project Depth as Projected in the Corps’ Feasibility Report (in thousands)

|

Cost Items |

Big Bend Channel |

Alafia River Channel |

|||

|

Upland |

Ocean |

Upland |

Ocean |

||

|

Mobilization/demobilization |

1,600 |

1,500 |

1,600 |

1,600 |

|

|

Excavation: |

Sand |

10,540 |

20,020 |

14,580 |

14,580 |

|

|

Rock |

--- |

--- |

10,310 |

10,310 |

|

Land costs |

860 |

--- |

1,000 |

--- |

|

|

Clearing and grubbing |

100 |

--- |

110 |

--- |

|

|

Diking |

2,030 |

--- |

1,680 |

--- |

|

|

Weirs |

170 |

--- |

170 |

--- |

|

|

Mitigation |

--- |

--- |

1,460 |

1,460 |

|

|

Slope protection |

--- |

--- |

3,900 |

2,280 |

|

|

Environmental monitoring |

110 |

100 |

120 |

120 |

|

|

Total |

$15,410 |

$21,620 |

$34,930 |

$30,350 |

|

|

Total for upland disposal plans: |

$50,340 |

|

|||

|

Total for ocean disposal plans: |

$51,970 |

||||

I would now like, to address the engineering, environmental, and social factors that were addressed by the Corps in assessing various potential upland sites. The distribution of tentative sites shown in Figure 2 illustrates the impact of these factors on the planning process. Engineering factors included overall pumping distances, crossings of major north-south corridors, and minimum areas needed to provide containment with limited dike heights and high groundwater levels. Environmental factors included avoidance of wetlands, potential groundwater contamination, and potential impacts on endangered species. Social factors included impacts on archaeological resources and on prime and unique farmlands.

The need to employ booster pumps to transport hydraulically dredged material rapidly escalates the cost of dredging. This is particularly true for heavier material such as the limestone fragments that would be excavated from the Alafia River. Therefore, sites more than 2 or 3 mi inland would probably not be economically viable for this project. As an illustration, Disposal Area 4 is 2.5 mi inland but would require several booster pumps to transport material through the 6 mi of pipe it would take to reach it.

Crossing major transportation corridors could involve significant disruption of traffic operations or the need to construct significant temporary structures to route piping over or under rights-of-way. In the case of the Alafia/Big Bend project, crossing the U.S. 41 corridor was unavoidable, but crossing the Interstate 75 corridor involved potential costs that needed to be avoided. Therefore, because of pumping distance, corridor crossings, and groundwater considerations, the I-75 corridor was considered a reasonable eastern boundary to the study area.

Central Florida lies over a limestone karst formation and is susceptible to sinkhole development. Therefore, dikes must have broad foundations, which limit their height. In the case of this project, dike heights of some 30 ft were proposed, in keeping with required safety considerations. In order to contain the 9.5 million yd3 of sand and clay projected to be produced by construction along with future maintenance volumes, a total of 670 acres of disposal area are required, 250 acres for the Alafia River channel and 420 acres for the Big Bend channel. Use of multiple smaller sites significantly increases diking costs and decreases the efficiency of land use. Therefore two sites of at least the above areas were required.

Due to past coastal development practices, all of the existing undeveloped shoreside lands in the vicinity of these channels are either the port lands that they serve or areas entirely or partly consisting of wetlands. Therefore, no potential disposal areas exist west of the U.S. 41 corridor. As a result, all of the proposed disposal site alternatives were found east of this corridor, where wetlands are generally isolated, intermittent, or stressed.

Almost all drinking water in Florida comes from goundwater, and protection of this resource is a high priority. Due to rapidly increasing withdrawal rates resulting from the urbanization of the area, along with lack of proper controls, many areas immediately

adjacent to the coast have suffered saltwater intrusion, which has rendered aquifers unusable. This is the case in the vicinity of the Alafia/Big Bend channels, but it is a situation that is limited to an area within 1 or 2 mi of the coast. Due to the potential for salt water (salinity 20o/oo) or released contaminants leaching down from disposal areas or return-water streams into usable aquifers, disposal areas must be located within 2 or 3 mi of the shoreline. In the case of this project the I-75 corridor once again made a convenient eastern boundary for potential sites.

Avoiding impacts on endangered species must, of course, be incorporated into project planning. In the case of this study two potentially active bald eagle nests were located within the general study area. Their locations are indicated in Figure 2. The proposed sizes of potential disposal areas 5 and 7 had to be reduced to provide the buffers between the sites and the nests required by the U.S. Fish and Wildlife Service. This reduced the potential size of Area 5 to the point where it could not be considered further.

The area southeast of Tampa has historically been a very active agricultural area, with tomatoes being the primary vegetable crop. The sandy soils in this area often qualify as unique, but not prime, farmlands. While the loss of some unique farmlands would result from the use of several of the potential disposal sites, the projected conversion of these areas to other uses due to the general urbanization of the area made this a limited factor in this analysis.

Archaeological sites have been found scattered throughout the Tampa Bay area. Such sites have been found and are suspected within the general area of the Alafia River and other coastal stream. The use of any site within the study area would require a preliminary archaeological survey. Thus, this consideration had little impact in the choice of sites.

The overall impact of these factors was to limit potential upland disposal sites to a relatively narrow corridor along the western side of the new I-75 roadway. The recommended plan contained in the feasibility report includes the use of a 250 acre disposal site within Area 4 and a 420 acre disposal site within Area 8.

The Tampa Port Authority has asked that the feasibility report be held in abeyance pending further study, in part because the port authority believes that the recommended disposal plan is not feasible. The reasons behind this position involve two related planning considerations that have not been adequately considered in this and other federal studies for dredging projects: land-use conflicts and realistic land acquisition costs in urban coastal areas.

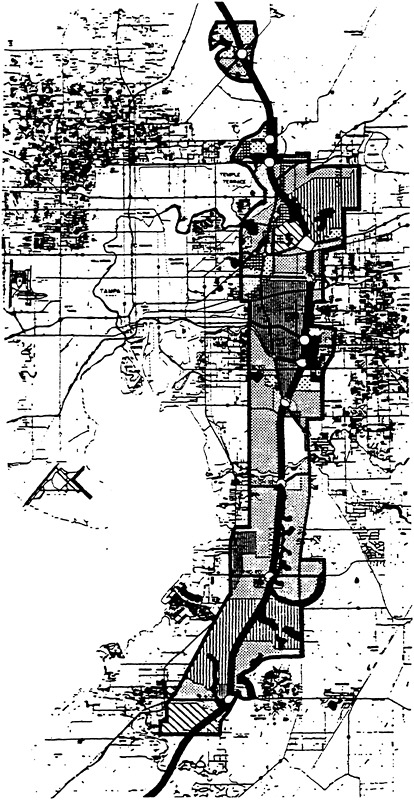

Figure 3 depicts the existing land use designations in a corridor of land adjacent to the I-75 alignment. As indicated, all of the lands where potential disposal areas were located in the Alafia/Big Bend study are presently planned for medium-density residential, educational, community commercial, and light industrial/corporate park uses. However, because of the proximity of these areas to the newly-opened interstate highway, local landowners have applied strong political pressure to allow even more intense land uses, particularly more

research/corporate parks. These proposed changes in the existing land use plan are under study and will probably be adopted.

Since the land use maps generally reflect the most conservative development expectations of area landowners and county officials it is not surprising that when the Corps and the Tampa Port Authority held a public hearing on the Alafia/Big Bend feasibility study, they received intense opposition to the proposed plan. Even now that the initial reaction has passed, county officials continue to tell the authority that it is very doubtful that these areas could be rezoned for use as disposal areas, reflecting continuing and growing political opposition to the plan.

Objections to the siting of disposal areas at these locations are based on very real social problems. Due to the subtropical climate such areas create localized problems with odors and wider problems with mosquitoes throughout the year. In addition, with the very flat local terrain, 30 ft dikes are visible for some distance, creating what many consider to be an objectionable visual impact. This is probably because dredged material “dump sites” are equated to sanitary landfills in the minds of many people. In any case, they are facilities that citizens and planning officials do not want to see located adjacent to residential areas, schools, and other sensitive human-use facilities.

The only way in which disposal sites could be located in these areas would be to purchase sufficient land to provide buffer zones around the actual diked disposal sites, thus requiring acquisition of considerably more than the 670 acres cited in the feasibility report. This further exacerbates the second consideration cited above, rapidly escalating land costs. The same development expectations that have caused land use designations to be changed have caused land prices to skyrocket.

Table 1 indicates that the Corps of Engineers estimated a cost of $1 million to acquire 250 acres for the Alafia River channel project and $860,000 to acquire 420 acres for the Big Bend channel work. This calculates to land costs of $4,000 and $2,048 per acre, respectively. In fact, land values in these areas are now running between $20,000 and $25,000 per acre for large tracts. As an example, a 400 acre tract entirely within the Corps’ proposed Disposal Area 8 recently sold for $8.5 million. Obviously, the projected costs for the upland disposal plans presented in Table 1 are considerably less than those that can realistically be expected.

Let us assume that the local sponsor would have to acquire all of Disposal Areas 4 and 8, as depicted in Figure 2, in order to provide buffer zones and not leave existing landowners with unusable parcels. Let us also assume a more realistic average land cost of $22,500 per acre. Under these conditions, with other costs left unchanged, a more realistic projection of project costs might be those presented in Table 2.

It is clear that under these conditions the upland disposal alternatives would be over 50 percent more expensive than the ocean-dumping alternative. Given that all of the additional costs would be the responsibility of the local sponsor, the recommendation of the Corps

TABLE 2 Projected Construction Costs for Upland and Ocean Disposal Alternatives Using Present Land Values and Including Buffer Zones (in thousands)

|

Cost Items |

Big Bend Channel |

Alafia River Channel |

|||

|

Upland |

Ocean |

Upland |

Ocean |

||

|

Mobilization/demobilization |

1,600 |

1,500 |

1,600 |

1,600 |

|

|

Excavation: |

Sand |

10,540 |

20,020 |

14,580 |

14,580 |

|

|

Rock |

--- |

--- |

10,310 |

10,310 |

|

Land costs |

18,000 |

--- |

13,500 |

--- |

|

|

Clearing and grubbing |

100 |

--- |

110 |

--- |

|

|

Diking |

2,030 |

--- |

1,680 |

--- |

|

|

Weirs |

170 |

--- |

170 |

--- |

|

|

Mitigation |

--- |

--- |

1,460 |

1,460 |

|

|

Slope protection |

--- |

--- |

3,900 |

2,280 |

|

|

Environmental monitoring |

110 |

110 |

120 |

120 |

|

|

Total |

$32,550 |

$21,620 |

$47,430 |

$30,350 |

|

|

Total for upland disposal plans: |

$79,980 |

|

|||

|

Total for ocean disposal plans: |

$51,970 |

||||

might not differ. However, if one includes the 25 percent of traditional federal costs now being required by the Corps the total local costs for this project as recommended would be almost $47 million. This can be compared to a total local cost of $13 million for the ocean-dumping alternative. It is, therefore, not surprising that the Port Authority has asked that action on the feasibility report be deferred.

In summary, it appears that the Corps’ feasibility study of the proposed Alafia/Big Bend project dealt adequately with the environmental and engineering considerations involved. However, the Corps’ study process proved to be inadequate in assessing the social and political problems associated with the upland disposal alternative, along with the realities of land acquisition costs. It is clear that,

within the restrictions created by environmental and engineering constraints, social, political, and economic problems make upland disposal virtually impossible in a rapidly urbanizing area such as Tampa Bay.

It is equally clear that any long-term, dredged material disposal plan for the Port of Tampa must be based on alternatives to upland disposal, except for small volumes under special circumstances. Finer material, and that which is potentially contaminated, will have to be placed in the existing diked islands, the capacities of which must be increased by enhanced consolidation, raising dikes, or lateral enlargement. Clean maintenance material and construction material will have to be placed in open water at ocean dump sites or along eroding beaches, or used to create additional disposal islands.

SELECTION OF SITES FOR OPEN-WATER DISPOSAL

Willis E.Pequegnat

Consultant

Although I will evaluate the need for and the risks associated with the disposal of dredged material in the estuarine environment, when and if that option appears to be the best alternative, I will also describe a siting technique for dredged material that can be applied to any part of the marine environment. When an otherwise appropriate disposal site is properly located, much will have been done to reduce impacts as well as the frequency of channel dredging.

VOLUME AND DESTINATION OF DREDGED MATERIAL

On the order of 330 million yd3 of sediments are dredged by the Corps of Engineers each year from U.S. harbors, ports, and navigation channels. The problem of disposing of huge volumes of sediment occurs yearly. Difficulties increase when the material is found to be contaminated or when aroused groups of the public, who often consider all dredged material to be bad, demand that elaborate disposal procedures be employed at considerable cost. Interestingly, over the past few years only some 20 to 30 percent of all dredged material has been disposed of in the ocean, while about 27 percent is released into open waters of estuaries and 35 percent or more is placed into diked containment areas above the water table near the dredging sites. The record shows that over the last decade the amount of ocean-disposed dredged material from sources outside the Mississippi River has steadily decreased to a low of about 20 million yd3.

DEVELOPMENT OF THE MULTI-MEDIA APPROACH TO DISPOSAL REGULATION

Although in the United States and elsewhere in the 1970s there were serious movements by both private groups and government agencies to ban the disposal of all wastes into the ocean, there has emerged recently a shift of opinion to the belief that ocean disposal of dredged material might create fewer unacceptable adverse impacts than disposal into estuaries. At some point interested members of the general public began to comprehend that the sparkling waters of Puget Sound were not

pristine and that the azure waters of Chesapeake Bay were hiding the onset of an environmental disaster. Grasping for evident causes of these declines and hoping for a quick cure, the dredging/disposal process, which is wide open for all to see, has been cited by the public as one of the most likely culprits. Unfortunately, the impetus for this accusatory stance by the public and some officials in various environmental departments of coastal states has frequently come from superficial issues instead of being based on scientific and technical data. I believe, however, that the latter will eventually prevail.

Today some of us continue to urge acceptance of the tenet that there is no one best place or best way to dispose of dredged material. Whether it should be disposed of in the ocean, the open waters of estuaries, or upland reaches; whether it should be unconfined or contained; whether it should be removed by hydraulic or mechanical means; and whether it should be handled with special care are judgmental decisions that comprise an important facet of waste management procedures. Moreover, these decisions must be based upon sound scientific and technical findings such as those that evolved from the Corps’ Dredged Material Research Program, or from the research efforts of many Corps districts, the National Oceanic and Atmospheric Administration, and the Environmental Protection Agency.

I have little patience with those who choose to ignore these findings for their own obscure reasons. At the very least, we now have data that tell us how dredged materials differ, how their constituents act in different environments, how mitigative features act to reduce bioavailability of contaminants, and how such features can be enhanced (Engler, 1980). Also, we now understand the physico-chemical phenomena that increase the risks associated with upland disposal, and we can estimate with considerable confidence whether important species will bioaccumulate worrisome toxicants or play a role in biomagnification (Gambrell et al., 1978; Kay, 1984; Peddicord, 1984). There is no longer justification for federal and state environmental regulators to adhere to policies that create bias against any disposal medium. The prejudice against ocean disposal so common among some federal agencies was also extant among various environmental and regulatory departments in coastal states. But this may be changing. In the past few months I have visited several state environmental agencies and have found that ocean disposal of dredged material is considered an acceptable or even preferred disposal alternative. Moreover, the same shift of opinion has become evident in international forums, such as the Convention on the Prevention of Marine Pollution by Dumping of Wastes and Other Matter (The London Dumping Convention, or LDC). Even more heartening is the fact that more and more groups, including the LDC, subscribe to the multi-media approach to waste management, in which there are expressions of awareness that dredged material is of itself not the source of contaminants and that when the point sources of toxicants are choked off a major part of the disposal problem will have been solved.

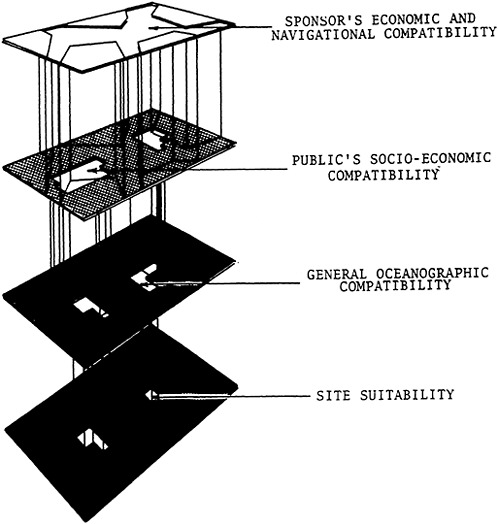

THE SIEVE TECHNIQUE FOR LOCATING DISPOSAL SITES

The sieve technique for objectively selecting the location of a dredged material dump site requires a step-by-step elimination of inappropriate or unsuitable areas of the seafloor, based on economic, recreational, aesthetic, and environmental criteria, until only acceptable areas remain (Pequegnat, 1982; Mathis and Payne, 1984). The unacceptable areas, for whatever reason, will be sieved out (screened) as they are darkened on a navigation chart. When all such areas have been screened out, the potential site areas will stand out in bold relief.

Application of the Sieve Technique

Step One

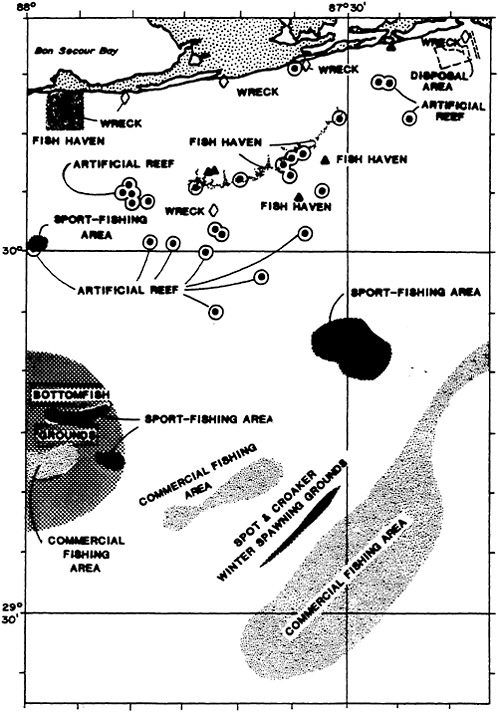

The first step in applying the technique is to establish the acceptable economic limit for transportation of the dredged material. Without exception, in the open ocean distance must extend to waters deep enough to eliminate excessive transport of the disposed material by forces intrinsic to surface waves and currents. Assuming that this distance is 12 nmi from the entrance to the estuary, an arc of this radius is scribed on the chart so that it intersects the preferred isobath (e.g., 20 or 30 m) at each end (Figure 1). The depth selected is simply a “best estimate” based on normal and storm wave characteristics (e.g., heights, periods, and direction).

Step Two

Next, it is often advisable to screen out and darken all shipping fairways, although the necessity for this will depend upon the amount of traffic and the frequency of site usage. However, it is always advisable to select an acceptable location downcurrent of the harbor entrance in order to reduce opportunities for disposed sediments to move back into the estuary. In the northern hemisphere such locations will be found to the right of the entrance when looking seaward along the channel.

Step Three

Unless it has been done at an earlier time one should conduct a thorough review of the relevant environmental and marine resource literature, enter into consultations with appropriate public officials and interested environmental and recreational groups, and consult EPA’s specific criteria (Federal Register, Vol. 42, No. 7, 1977). Armed with this knowledge, it is time to scribe on the chart, within the economic limit, the locations of such features as

-

commercial fishing and shellfishing grounds,

-

spawning grounds of important marine species (including turtles) and their food organisms,

-

recreational fishing and diving reefs,

-

migration routes of important finfish or shellfish, including passes into estuaries,

-

archaeological and other submarine historical features, and

-

beaches and other important amenities (see Figure 2).

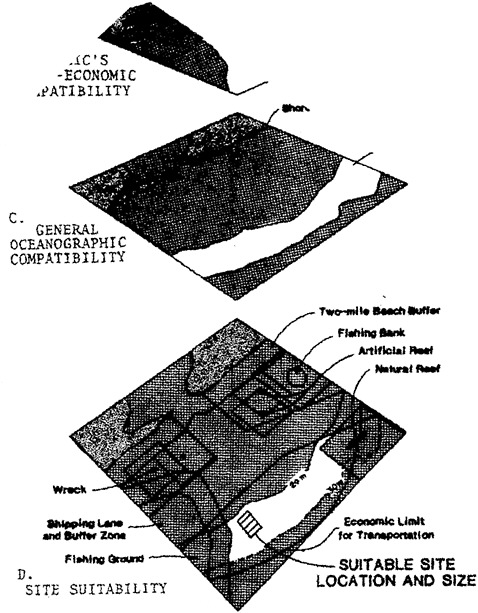

FIGURE 1 General representation of the sieve technique for siting. Unsuitable areas are eliminated step-by-step until the white areas suitable for the site stand out very clearly.

FIGURE 2 A plot of sensitive environmental areas that must be protected by buffer zones and screened out by the sieve technique, resulting in Figure 3.

Step 4

It is essential that each of the above features be surrounded by a protective space, the dimensions of which are related to the “mixing zone” of EPA’s regulations for ocean dumping. These protective spaces are called buffer zones (Figure 2).

Since it is reasonable to assume that bottom currents in the open ocean may attain speeds up to 0.5 kn (will travel 0.5 nmi in 1 h) and that much of the dredged material except the very finest grains (clays) will settle to the bottom in less than 4 h (period of initial mixing in Ocean Dumping Regulations and Criteria), it is prudent to protect any amenity or fixed living resource by establishing the adjacent edge of the proposed dump site no closer than 2 nmi to these features (the distance a 0.5 kn current would carry suspended material in 4 h). Accordingly, step 4 involves screening out these features and their buffer zones by darkening them directly on the chart or on overlays.

Final Steps

Having screened out all of the above features and their buffer zones, the remaining unshaded areas within the arc of the economic limit for hopper dredge or barge transport will stand out as those areas that can accommodate the proposed dump site (Figure 3). At this point, in addition to placing the site downstream from the estuary mouth, one should give consideration to such parameters as distance from shore, specific depth, and sediment type.

Size of Sites

The Ocean Dumping Regulations or Criteria call for limiting the size of ocean disposal sites in order to perceive and control adverse impacts and to establish effective monitoring programs. Study of the volume of dredged material that Corps of Engineers districts need to dispose annually into the ocean reveals a range of from a few thousand yd3 to about 9 million yd3 in the New York District. Previous calculations indicate that a site having an area of 3 nmi2 (10.3 million m2), which is one-third greater than the Mud Dump in the New York Bight, could handle up to 39 million yd3 in a year without abnormally high initial mounding before compaction (Pequegnat, 1982).

APPLICATION OF ESTUARIES

Essentially the same stepwise procedures can be followed in establishing a disposal site in estuarine waters, provided that in so doing one complies with the aims of the criteria promulgated in Section 403(C) of the Clean Water Act, even though the latter do not specifically apply to discharge of dredged material. As will be pointed out

FIGURE 3 Complete application of the sieve technique to the geographic area shown in Figure 2. A. Shows the screened out area beyond the haul distance arc and the shipping fairways. B. Shows areas screened out because of nature preserves and public beaches. C. shows depth compatibility. D. Shows all the screened out areas and placement of the site.

later, three considerations are important here: (1) depth of water, (2) texture of the sediments, and (3) the expected dredging process.

Environmental Risks

The environmental risks associated with estuarine disposal of dredged material are under very close scrutiny at the present time by the Corps of Engineers, EPA, and other agencies. The degree of risk obviously varies with the type of disposal site and method of release, the characteristics of the dredged sediments, and with the physiographic and oceanographic characteristics of the estuary. Several disposal site options are available, including

-

unconfined open water with or without capping,

-

subaqueous pits with or without capping,

-

uncontained intertidal,

-

contained intertidal,

-

upland containment, and

-

containment islands.

Obviously some of these alternatives are appropriate to accommodate highly contaminated dredged material whereas others are not. Also, per yard costs associated with these options range widely from a low for unconfined open-water disposal to a high for upland containment or containment islands.

Although in general, I am inclined for several important reasons to conclude that ocean disposal is preferable to open-water disposal in estuaries, there are extenuating circumstances associated with geographic location where the latter alternative may be the only feasible approach to managing large quantities of material. For instance, some channels that require dredging in Chesapeake Bay are many miles from the ocean, but to require the material to be placed in containment would be uneconomical. To this end, and to save the capacity of Hart-Miller Island for highly contaminated material, the Corps of Engineers and Maryland’s Department of Natural Resources are considering the advisability of permitting open-water disposal in trough-like depressions that range in depth from 80 to 120 ft. Depth, I think, is a most important criterion to apply in order to meet two requirements:

-

It ensures that the material stays in place. This will prevent spreading that will cover bottom areas beyond the site boundaries, preclude any possibility of interfering with navigation, and will not increase the need for additional maintenance dredging of channels.

-

It reduces the possibilities of damaging valuable living resources.

By employing the same criterion one can make a case that very little environmental harm will result from dumping dredged material in

the open waters of the deeper aspects of Puget Sound. However, it is more difficult to support such disposal practices in very shallow, muddy estuaries characteristic of the northern coast of the Gulf of Mexico. Thus, the alternative of unconfined open-water disposal is favored in Puget Sound because of the availability of deep water, the long hauling distance to the ocean, and the scarcity of good upland sites. Accordingly, the Puget Sound Dredged Disposal Analysis goal is to provide through research the basis for sound guidelines and plans for governing unconfined disposal of dredged material in Puget Sound. At the same time plans to significantly reduce the amounts of contaminants entering the sound and the bottom sediments are being developed.

Disposal in Shallow Bays

Meanwhile, in Texas there is an upsurge of opposition to unconfined open-water disposal in shallow bays. The claim is made that when the muddy material is dumped in water that is only about 12 ft deep, it spreads well beyond the disposal site boundaries, thereby covering valuable marine resources. There is also a distinct possibility that such practices (1) increase the amount of maintenance dredging in navigation channels, and (2) affect normal water circulation in the embayments to the detriment of the biota. The proximity of available ocean disposal sites, and in some cases upland sites, argues against open-water disposal in shallow, muddy estuaries of the northern Gulf of Mexico.

One must accept the fact that even on historical time scales estuaries must be viewed as ephemeral. Unless upstream protective measures are instituted, much of the sediment carried by their associated rivers will be deposited in the basin until shoaling depths are reached. Also, most estuaries receive sediments from the ocean that are carried into the estuary’s channels by the tide-controlled saltwater wedge as it moves inland along the bottom. Thus, we must believe that for a dredger to dump material into a shallow estuary can only hasten its demise, even if the material is dredged nearby in the same estuary. Obviously, such practices will of necessity increase the amount of maintenance dredging required to keep navigation channels open.

DISPOSAL TECHNIQUES

On the order of 3 to 5 percent of all dredged material in the United States is contaminated enough to require one or another of the special care techniques of disposal that have been designed to partition contaminants from the biota. Although there are many ways this can be achieved, the four techniques that have been tested with apparent success at the present time are

-

open-water capping on level bottoms,

-

open-water capping in subaqueous pits,

-

upland containment areas, and

-

containment islands.

Level Bottom Capping

This technique has been employed by the Corps’ New England Division in Long Island Sound as part of the DAMOS Project (DAMOS, 1984), and by the Corps’ New York District at the Mud Dump in the New York Bight (Mansky, 1984). Capping attempts to isolate contaminated dredged material from the biota by covering it with uncontaminated material (Brannon et al., 1985; Montgomery, 1985). One of the important environmental advantages of capping is that the material remains in the anaerobic state so that contaminants remain tightly bound to various constituents. Although it is best done in relatively quiescent areas, it can be successful in the open sea at depths between 80 and 100 ft. Caps require about three times the volume of the contaminated material. Although costly, this technique is generally cheaper than upland or island containment.

Subaqueous Pits

The use of natural or man-made subaqueous pits for disposal and capping of contaminated dredged material has several advantages over level bottom capping. Because the potential for erosion is reduced, as compared with the mound produced by capping on level bottoms, it can be carried out in relatively shallow water (Bokuniewicz, 1983). Submarine pit capping has the advantage of enhancing the seabed environment when partially filled with contaminated dredged material and then smoothed with a cap of clean sediments texturally comparable to surrounding areas. The Corps of Engineers Seattle district and Waterways Experiment Station have cooperated in a subaqueous pit capping project in the Duwamish waterway that has been judged to be successful (Truitt, 1986). The New York district has completed the first phase of pit capping in the Lower New York-New Jersey Harbor.

Upland Containment Sites

Although upland containment has been the alternative of choice by some regulatory agencies for holding contaminated sediments dredged from estuarine channels, appropriate areas are becoming scarce where they are needed most. Moreover, research conducted during the Dredged Material Research Program (DMRP) revealed that contaminants could escape from the site if the materials were permitted to dry out above the water table. Also, it was discovered that clay liners would develop cracks during drying and groundwater integrity was a risk. The

potential for uptake of heavy metals by plants and animals living in the containment area increases when the dredged material becomes oxygenated upon drying.

Containment Islands

Mention has already been made of such containment islands as Hart-Miller, which was finished in Chesapeake Bay in 1984. To date such sites have only been constructed in protected estuaries and nearshore areas. Some people believe that such an island could be constructed in Raritan Bay to replace the Mud Dump (Pequegnat, 1986b). The early advantage of islands over upland containment areas is that the contaminated material is maintained in a saturated and reduced chemical environment that curtails or eliminates the movement of contaminants in the dredged material. Also, such islands would not place groundwater sources at risk as some upland sites have done. Great care has to be taken in selecting the site of construction of an island to preclude chances of covering productive estuarine bottom, of impacting the biota by changing the circulation pattern, and of course of creating hazards to ship traffic.

COSTS

When one considers comparative costs of unconfined open-water disposal versus capping and upland or island containment, it is easy to see why Corps districts opt for the former method. Approximate costs, which may vary from one part of the country to another, are shown in Table 1.

Because of transport, ocean disposal costs will be somewhat higher than unconfined open water. Furthermore, the above costs do not reflect the costs of constructing island sites nor do they factor in monitoring costs, which can be appreciable over the span of years containment sites are in use. For instance, one may cite Hart-Miller Containment Island which cost $59 million to construct, with a capacity of some 53 million yd3 of material. To this cost must be added that in 1984 and 1985 the Corps dumped 7–8 million yd3 into the site at a cost ranging from $3 to $4.65/yd3 (Pequegnat, 1986b).

TABLE 1 Disposal Costs Per Cubic Yard for Clean and Contaminated Dredged Material

|

|

|

Containment |

||

|

Open Water |

Ordinary |

Upland With Treatment |

Upland Island |

|

|

Unconfined |

With Capping |

|||

|

$0.50 to $2 |

$3 to $6 |

$5 to $20 |

$30 to $60 |

$3 to $% |

With some Corps districts adhering to the desire to utilize unconfined open-water disposal at the very time when state regulators may be lining up in opposition, it seems inevitable that litigation will occur. My assessment of the situation is simply that the dredging managers will only relinquish their position if the results of competent research efforts demonstrate that their chosen disposal option will cause unacceptable adverse Impacts in the benthic environment.

REDUCING THE NEED TO DREDGE

There are several things that can be done to reduce the amount of dredging required in order to effectively maintain the nation’s navigation channels (Holliday et al., 1984). The actions cited below are not necessarily listed in any order of importance.

-

Encourage agriculture, forestry, real estate, and roadway interests to eliminate careless practices that encourage erosion with subsequent transport of large loads of sediments to the estuary.

-

Create catchment pits at the junction between river and harbor to trap sediments. Also, a pit can be dredged across but deeper than the channel inside the harbor entrance. Once collected, the sediment in the pits can be removed efficiently by using a stationary suction dredge and then pumping it via a permanent pipeline to a disposal point.

-

Reposition some ocean disposal sites on the downcurrent side of the harbor entrance to reduce inflow of sea sediments along the bottom.

-

Position open-water disposal sites far enough from shipping channels to prevent fluid mud from flowing back into adjacent channels.

-

Recent studies indicate that it is not necessary to remove the top bed-layer of navigation channels having densities of 1,200 kg/m3 or less in order for ships to navigate and maneuver effectively.

-

To reduce the frequency of dredging, overdredge important channels to a certain extent below their design depth.

-

Use open-water disposal sites as much as possible when currents are flowing out of the harbor, rather than into it.

-

Where possible, modify designs of channels and berthing areas to eliminate shoaling by taking advantage of natural flushing processes.

REFERENCES

Bokuniewicz, H.J. 1983. Submarine borrow pits as containment sites for dredged sediment. In Dredged-material Disposal in the Ocean, Wastes in the Ocean. Vol. 2, Kester, Ketcham, Ruedall, and Park, eds. New York: John Wiley & Sons.

Brannon, J.M., R.E.Hoeppel, T.C.Sturgis, I.Smith, Jr., and D.Gunnison. 1985. Effectiveness of capping in isolating contaminated dredged material from biota and the overlaying water. Tech. Rep. D-85–10, Vicksburg, Miss.: U.S. Army Engineer Waterways Experiment Station.

DAMOS. 1984. Summary of program results 1981–1984. Vol. 1. Overview of the DAMOS Program. Contr. 46, U.S. Army Corps of Engineers, New England Division.

Engler, R.M. 1980. Prediction of pollution potential through geochemical and biological procedures: Development of regulatory guidelines and criteria for the discharge of dredged and fill material. In Contaminants and Sediments. Vol. 1, R.A.Baker, ed. Ann Arbor, Michigan: Ann Arbor Sci. Publ.

Gambrell, R.P., R.A.Khalid, and W.H.Patrick, Jr. 1978. Disposal alternatives of contaminated dredged material as a management tool to minimize adverse environmental effects. Tech. Rep. DS-78–8. Vicksburg, Miss.: U.S. Army Engineer Waterways Experiment Station.

Holliday, B.W., M.J.Wutkowski, and L.Vallianos. 1984. Shoaling problems and improvements: Sunny Point, North Carolina. Conf. Procs. Dredging and Dredged Material Disposal, American Society of Civil Engineers.

Kay, S.H. 1984. Potential for biomagnification of contaminants within marine and freshwater food webs. Tech. Rep. D-84–7. Vicksburg, Miss.: U.S. Army Engineer Waterways Experiment Station.

Mansky, J.M. Capping of dredged material disposal management for New York Harbor. In Management of Bottom Sediments Containing Toxic Substances. Proc. 8th U.S./Japan Experts Meeting, T.R.Patin, ed. Tokyo, Japan.

Mathis, D.B. and B.S.Payne. 1984. Guidance for designation of ocean sites for dredged material disposal. Information Exchange Bulletin, Vol. D-84–2. Vicksburg, Miss.: U.S. Army Engineer Waterways Experiment Station.

Montgomery, R.L. 1985. Engineering aspects of capping dredged material. Procs. of the 16th Dredging Seminar. College Station, Tex.: Texas A&M University.

Peddicord, R.K. 1984. Aquatic bioassays in dredged material management. Conf. Procs. Dredging and Dredged Material Disposal. American Society of Civil Engineers. November.

Pequegnat, W.E. 1982. Specifications of a model ocean disposal site for dredged material. In Management of Bottom Sediments Containing Toxic Substances. Proc. 8th U.S./Japan Experts Meeting, T.R.Patin, ed. Tokyo, Japan.

Pequegnat, W.E. 1986a. An overview of dredged material disposal practices. Report to Office of Technology Assessment, U.S. Congress, Washington, D.C. Contract No. 533–2250.

Pequegnat, W.E. 1986b. Disposal of dredged material case studies. Report to Office of Technology Assessment, U.S. Congress, Washington, D.C. Contract No. 533–2250.

Truitt, C.L. 1986. The Duwamish Waterway capping demonstration project: Engineering analysis and results of physical monitoring. Tech. Rep. D-86–2. LEDO Program. Vicksburg, Miss.: U.S. Army Engineer Waterways Experiment Station.

EQUIPMENT EFFECTS

William R.Murden

Water Resources Support Center

U.S. Army Corps of Engineers

Presented By

Charles W.Hummer

The dredging program managed by the U.S. Army Corps of Engineers involves the maintenance and improvement of some 25,000 linear mi of commercially navigable channels, both inland and coastal, which serve over 400 ports. Annually, the Corps of Engineers excavates about 330 million yd3 at a cost of $450 million. It is a large program, which merits a reasonable research effort. In 1978, based on the provisions of Public Law 95–269, the Corps initiated a major change in the national dredging program to reduce the size of the Corps’ fleet to a minimum level required to provide an immediate response to emergency and national defense needs, both in the United States and overseas. Today, the dredging industry performs over 80 percent of the workload, which is about the percentage previously performed with Corps dredges.

There are two basic types of dredging equipment—mechanical and hydraulic. The determination of which type to use depends on the material to be dredged, the site and its accessibility, the disposal method, and the wave and weather conditions. Each type of dredge has distinct advantages and disadvantages and these features should be considered in the selection process on a site-specific project basis.

Mechanical dredges rely on the shearing action between the leading edge of the excavating component and the material to be removed. The various types of equipment in this category include dredges that utilize buckets, shovels, and scrapers, the sizes of which vary over a wide range. They include bucket, grab, dipper, backhoe, and scraper dredges. A major advantage of mechanical equipment is the high material-to-water ratio. This is a very important factor when material must be hauled over long distances or placed in diked containment areas. Mechanical dredges also have the ability to operate efficiently and safely in proximity to docks, bulkheads, piers, and other structures.

Grab or clamshell dredges are effective in the excavation of soils with a high voids ratio and can be used to dig to extensive depths. Dipper and ladder bucket dredges are efficient in removing compact material such as fine-grained sand, clay, and some forms of rock. The major disadvantage of mechanical dredges is their relatively limited production rate which results from the bucket cycle—lowering to the

bottom, rising above the water level, and then swinging to unload into hopper barges. Generally speaking, mechanical dredging is a slow process that is not suitable for the removal of large volumes unless there are compelling environmental factors.

Hydraulic dredges, which include cutterheads, dustpans, sidecasters, and hoppers, use involute centrifugal pumps to excavate material from the waterways. A vacuum, or pressure differential, is created on the intake or suction side of the pump casing by the rotational speed of the pump impeller and the hydrostatic head. The material mixes with water to form a slurry, which is then pumped through a discharge pipeline to a disposal area or, in the case of hopper and sidecaster dredges, the material is usually unloaded into open-water sites. Hydraulic dredges have a very high production rate when the materials to be excavated contain a high ratio of water. They can be utilized for the removal of soils that are fairly dense in nature, but they cannot usually compete with mechanical dredges when the materials to be removed are very dense and compacted.

The shearing action of the cutterheads makes them best suited for the removal of large volumes of consolidated material, including clay, silt, sand, gravel, and even some grades of rock. This type of hydraulic dredge can be used to move materials great distances and to reasonable elevations above the water surface by the horsepower being applied to the centrifugal pump. Placing booster pumps in the discharge pipeline can significantly extend these capabilities. For these reasons, the cutterhead dredge is the most widely used type of dredge in the world. The hull configuration of most hydrualic cutterhead dredges is of the barge type, which is not suitable for operation in waves of any magnitude. Therefore, in most cases, cutterhead dredges are used in inland waterways, estuaries, and other semiprotected areas. However, with coordinated sea state forecasting and special operational techniques, they are also used in exposed waters for the excavation and transportation of materials to nourish or restore eroded shorelines. When used in open coastal waters, a general requirement is that there be a nearby harbor of refuge to which the equipment can be transported when storm conditions are forecasted.

Dustpan dredges are a special type of hydraulic dredge invented by the U.S. Army Corps of Engineers to handle the large volume of sediments removed from the Mississippi River each year. They use high-pressure water jets to fluidize the bottom materials before the material is transported through a pipeline by centrifugal pumps.

Hoppers are also hydraulic dredges. They are distinguished by the shipboard containers (hoppers) that are used to transport the material to open-water or ocean disposal sites. They can also be used to discharge and place materials in coastal waters that are in reasonable proximity to the shoreline. Depending on the water depth where the material is discharged and the littoral processes in the region, some of the material accretes twoard the shoreline and provides a measure of beach nourishment. The Corps uses hopper dredges primarily to maintain ocean entrance and estuary channels to major ports and waterways. Many hopper dredges include the necessary equipment to pump the dredged

materials from the hoppers or bin sections of the vessels through pipelines to the strand and surf zone to nourish or restore beaches, and into diked containment areas when polluted materials are involved. As in the case of cutterhead dredges, booster pump units can be placed in the discharge pipeline to increase the pumping distances as may be required for specific projects.

A trailing arm hopper dredge is an oceangoing ship used for maintaining ocean entrance channels. It is equipped with pumps and other supportive machinery that lift bottom materials in a slurry, retain them in a hopper, transport them, and deposit them in a designated disposal area. The loading rate is a major factor in how well a vessel accomplishes this task. That rate depends, to a large extent, on the size of the dragpipe and pumps as well as the shape of the draghead (the intake of the dragpipe) and the volumetric capacity of the hoppers.

The split hull hopper dredge has become rather popular in the past ten years or so. Its big advantage is a rapid unloading rate due to the opening between the hull sections. The use of this design feature becomes questionable as the size of the hopper approaches the large class hopper dredge classification of over 6,000 yd3.

Sidecasters are another type of hydraulic dredge invented by the Corps to operate in shallow and migrating ocean inlets. They are self-propelled and similar in configuration to hopper dredges because they have a ship form of hull, which enables them to operate in unprotected coastal waters. These vessels do not include any hopper sections. The dredged material is pumped directly overboard through an elevated discharge pipeline. The direction of the discharge should conform with the direction of littoral current movement. The material is neither added nor removed from the overall bottom cross section of the waterway serving navigation. The bottom geometry is simply rearranged to form a more efficient hydraulic cross section so that navigation can be maintained without altering the hydraulics of the estuary. In general, sidecasting dredges are used on projects where the controlling water depths are too shallow for hopper dredge operations and where wave action is too severe for cutterhead dredge operations. In addition, the resultant side slopes of migrating shoals into a navigation channel are often very steep and, on some projects, sidecasting equipment is used to dredge the upper portion of the slope to create a more gentle gradient rather than using the deeper draft hopper dredges.

Pneumatic dredges are hydraulic dredges that utilize compressed air rather than centrifugal pumps to supplement the hydrostatic head that exists between the water surface and the bottom of the waterway. The compressed air and the hydrostatic head create a pressure differential between the pump chamber and the ambient water pressure. Sediments enter the chamber by the force of the hydrostatic head and are then forced out the discharge line by high pressure air. Since there is no mechanical shearing action involved in the excavating process, the system minimizes agitation and turbidity in the contiguous water column, which is important when dredging polluted material. The

percentage of solids in the slurry removed by the pneumatic dredges is significantly higher than that removed by hydraulic dredges, an important factor when material must be placed in diked containment areas with limited retention capacity. The usage of these dredges has been limited to small-scale dredging operations because the pneumatic dredge has a relatively low production rate.

Production methods for dredging silts with hopper dredges are different than those for sand. Sand is dredged through an erosion process. As the draghead follows the bottom surface, water moving at high velocities erodes sand along the edges of the draghead and into the system. In the hopper, the sand rapidly settles as the water drains out of the overflow weirs. In contrast, dredging silt is a process of pumping plastic materials. The draghead is submerged in the silt layer, and the material is brought into the dredging system in as dense a slurry as possible. Excess water retards settlement of silt in the hopper.

The California type draghead was originally designed by the Corps and is currently in use on some of the seagoing hopper dredges in the United States and overseas. The hinged portion is self-adjusting through a 30° arc. The ratio of the area of the grate opening to that of the dragpipe area is about 3:1. The U-shaped portion is designed to provide a long grate perimeter for the inflow of material under the edges of the grate, and to facilitate flow into the center section of the draghead and suction pipe. California-type dragheads were a part of the original equipment on the dredge Essayons and proved to be effective in dredging silt and sandy materials.

The IHC silt draghead was developed by IHC-Holland. The feature that makes it so unique is the cylinder at the end of the draghead assemblage. The free rotation of the cylinder or roller reduces the resistance and friction of the draghead moving over the bottom and thus requires less propulsion power. The roller is watertight and can be ballasted so that the swell compensator can be used through a wide range of vessel speeds and mixture densities. The inlet is at the forward end of the head and is adjustable to suit the thickness of the ilt layer to be removed. Because of these features, the Corps of Engineers acquired two of the IHC dragheads so that their efficiency could be tested in silts and compared with other types of heads on the Essayons. The Corps attempted to conduct comparative tests in 1984 while dredging in Pearl Harbor, Hawaii. However, such a large volume of debris was encountered that the operation was discontinued. Comparative tests are planned to be conducted during channel maintenance dredging in the Mare Island Strait navigation channel of San Francisco Bay in 1987.

The disposal of dredged material is still the most difficult problem in the national dredging program. There are three basic options of disposal for the many millions of cubic yards of material that are dredged each year. About 65 million yd3 are disposed in ocean waters, another 135 million yd3 are disposed in diked areas, and the remainder goes inland to open waters. Only about 20 to 25 percent of the material from routine maintenance is deposited in ocean

or ocean-fringing sites. Even so, dredged material, by far, comprises the largest portion of all materials dumped into the oceans of the United States.

Based on current trends, the Corps anticipates a significant increase in demand for using the ocean disposal option for dredged material disposal. Two major activities presently under consideration which may significantly increase this demand are the proposed commercial port deepenings and required coastal facility upgrades for the Navy’s homeporting concept. At present, Congress is considering various legislative packages which include the deepening of over 40 coastal projects. A large number of these proposed new work projects are located within the South Atlantic and Gulf coast regions. Construction will, of course, be contingent on arriving at suitable cost-sharing arrangements with the project sponsors.

Nationally, the six largest of these proposed commercial deepening projects would require dredging and disposal of well over a billion yd3 of new work dredged material to complete the improvements. In general, the Corps is faced with developing environmentally acceptable, fiscally responsible methods of disposing large volumes of material within the coastal zone, primarily sand, and with overriding environmental concern for physical impacts. Needless to say, this will require a great deal of work and innovation on the part of all scientists and engineers involved in these projects to ensure that the deepenings are accomplished in an environmentally responsible and cost-effective manner.

Based on extensive sediment testing and research and development programs completed to date, it is known that, on average, over 90 percent of the sediments dredged each year from federal projects are nontoxic and suitable for a wide range of beneficial use applications. Most, if not all, of the proposed new work dredged material which would be generated is uncontaminated and fully suitable for a wide range of beneficial uses. Traditionally, dredged material not disposed in open waters was used for various agricultural, commercial, or industrial applications. However, this limited approach changed in the late 1960s and early 1970s with the increased environmental awareness of the sometimes fragile nature of our coastal resources. The Corps’ research program now focuses on minimizing adverse environmental effects and seeking opportunities to balance them with uses of dredged material that are socially and environmentally beneficial.

Unfortunately, in spite of these extensive research efforts and an expenditure of about $100 million, the common perception still seems to be that anything that is dredged is “spoil.” I often hear the phrase “sewage sludge and dredged material,” which gives the impression that these materials have the same properties. If those of us in the marine-related industry use the word spoil, we cannot fault a continuation of a perception by the public that dredged material is inherently bad. Therefore let us resolve to stop using the word “spoil” when we discuss dredging operations.

Dredged material has long been recognized as a valuable material for building or restoring beaches. Coarser-grained sands increase

shore stability and reduce the erosion rate. Sands may be stockpiled or placed on “feeder beaches” strategically located to allow longshore currents to transport the material to the eroding beach. Groin fields can be filled to reduce downdrift erosion.

Dredged rock can be used to riprap the upper beach or build coastal structures to provide shore protection. Rock has also been used to create artificial fishing reefs when the material is placed on soft bottoms. Conversely, soft materials such a sands and silts increase habitat types and the biological diversity when placed in predominantly hard-bottom areas. The increases in fishing productivity can be dramatic.

Underwater berms, when placed offshore where they can cause storm waves to break earlier before hitting the shore directly, not only create improved fish habitat, but help to reduce wave energy and consequent shore erosion. Application of this concept can provide a significant reduction in the cost of deepening the channels of our major coastal ports. For example, it appears that over $30 million could be saved in the Norfolk Harbor deepening project by using this methodology. Saltwater wedges in estuaries can also be controlled by careful placement of dredged material.

Dredged material has been used to create artificial islands, many of which have been established as wildlife refuges because of the heavy use by shorebirds, especially endangered species such as the whooping crane and the brown pelican. Marshlands have been created or restored using dredged material, resulting in improved fish and wildlife habitat for many commercial and game species dependent on marshland for some phase of their life history. Shoreline erosion can also be reduced, and lands lost through subsidence or sea-level rise can be restored.

On land as well as in water, clean dredged sediments can be used to cap contaminated sediments and areas such as landfills. Vistas can be improved through careful planning and landscaping using dredged materials. Many dredged sediments contain silts with topsoil qualities that can be used to improve existing upland soils to produce crops, grow trees, and provide improved wildlife habitat. Dredged materials have been used to create land near or adjacent to the shore for recreational parks and for residential, commercial, and industrial sites. Concrete aggregates and material for sanding icy streets have been obtained from dredged material as well.

Dikes, levees, and roadways have also been built with dredged material. Dunes have been constructed of dredged material for hurricane protection on barrier islands. Diked containment areas are used for tree farming and have been investigated as aquaculture ponds. Recent advances in this science show reasonable potential for the profitable production of shellfish, such as shrimp or prawns, and finfish.

There are many other beneficial use applications that are either not yet fully tried and tested or that may now be routinely applied in some areas, but which have not yet been widely recognized and accepted. The creation of wetlands is a good example. The Chicago

based Wetlands Research, Inc., a nonprofit organization, has come up with a plan to convert a 450 acre watershed area from an essentially sterile condition into a productive environmental status. The present narrow, single channel of the Des Plaines River, which in many parts is turbid and stagnant, would be changed into a multiple-channel complex. The flow would then be directed through a wider cross section of the watershed and through a series of abandoned quarries. By using a pumping station, the water level would be raised to the upper edge of the flood plain in compartmented areas enclosed by berms. This would allow the water and the suspended sediments to remain in the compartments and create wetlands, restoring the natural conditions of the waterways that existed before the advent of urbanization.