2

Environmental Control

Commercial jet aircraft are designed to carry passengers safely and comfortably from one point to another. The external environments of the aircraft include taxiing, takeoff, cruise, and descent; outside temperature from below −55°C (−65°F) to over 50°C (122°F); ambient pressure from about 10.1 kPa (1.5 psi) to 101 kPa (15 psi); and water content from virtually dry to greater than saturation. For aircraft to transport people in those extremes of external environment, they are equipped with environmental control systems (ECSs) that provide a suitable indoor environment.

A number of aircraft systems are involved in meeting the environmental needs, including the propulsion system (engines), which is a source of pressurized air; the pneumatic system, which processes and distributes the pressurized air; and the ECS, which conditions the pressurized air and supplies it to the cabin. For the purposes of this report, each component or subsystem that is integral in providing the necessary environmental conditions in the aircraft cabin is considered to be part of the ECS, even if it is technically part of another aircraft system.

This chapter first describes the important functions of the ECS, including background information on principles of ventilation, temperature control, and humidity control. It then describes the equipment and subsystems that make up the ECS; the descriptions of aircraft systems in this chapter apply principally to large aircraft (more than 100 passengers) and might not be applicable to all aircraft. Finally, standards that are potentially related to aircraft cabin environments and aircraft ECSs are examined.

ENVIRONMENTAL CONDITIONS

During flight, the aircraft cabin is a ventilated, enclosed environment whose occupants are totally dependent on the air provided by the ECS. The ECS is designed to provide a healthy and comfortable environment for the aircraft occupants from the time crew members and passengers first board for a flight until all passengers and crew members deplane after a flight. The ECS must pressurize the aircraft cabin and maintain its temperature within tolerable limits. Most other functions are subordinate to those requirements at cruise altitudes.

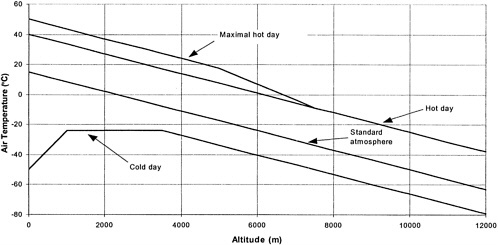

The aircraft ECS is different from ECSs used in most other applications, such as buildings and surface vehicles, in that it must be able to operate in extremes of temperature, ambient air quality, and air pressure. The primary role of an aircraft ECS is to protect the occupants of the aircraft from those extreme conditions. Commercial aircraft operate over a broad range of temperatures from −55°C to 50°C (−65°F to 122°F) at ground level and as low as −80°C (−112°F) at an altitude of 12,000 m (39,400 ft). As shown in Figure 2–1, at a typical cruise altitude of 11,000 m (36,000 ft), the air temperature is usually about −55°C (−65°F) but can range from about −70°C to −30°C (−92°F to −20°F) (ASHRAE 1999a).

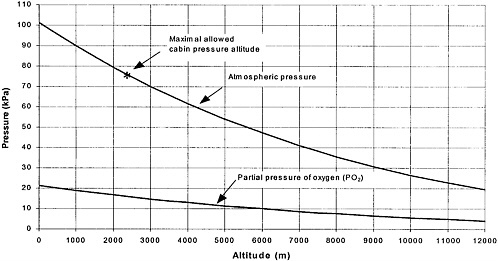

More critically, at a typical cruise altitude of 11,000 m (36,000 ft), the atmospheric pressure is only about one-fifth that at sea level (Figure 2–2). Although the relative concentration of oxygen at that altitude is nearly the same as at sea level, the partial pressure of the oxygen (PO2) is only about 4.7 kPa(0.69 psi) compared with 21 kPa (3.1 psi) at sea level and is far below what is necessary to sustain human life. Furthermore, the ambient air quality on the ground and at low altitudes can range from pristine to extremely polluted in urban environments. The ECS meets those needs through integrated subsystems that pressurize the cabin when in flight, control thermal conditions in the cabin, and ventilate the cabin with outside air to prevent a buildup of contaminants that might cause discomfort or present a health hazard.

Pressure

In flight, the ECS maintains the cabin pressure and therefore the oxygen partial pressure at acceptable levels by compressing the low-pressure outside air and supplying it to the cabin. The air pressure in aircraft cabins is com-

monly expressed as a “pressure altitude” equivalent. Cabin pressure altitude is the distance above sea level at which the atmosphere exerts the same pressure as the actual pressure in the aircraft cabin. The relationship between atmospheric pressure and pressure altitude is based on the corresponding curve in Figure 2–2. The minimal cabin pressure is set by Federal Aviation Regulation (FAR) 25, which requires the pressurization system to “provide a cabin pressure altitude of not more than 8000 ft [2,440 m]” under normal operating conditions. This limit of 2,440 m (8,000 ft) corresponds to a cabin pressure of 75 kPa (10.9 psi) as shown in Figure 2–2. Thus, the cabin pressure can range from a maximum of 101 kPa (14.7 psi) on the ground at sea level to a minimum of 75 kPa (10.9 psi) in flight regardless of the altitude at which the aircraft flies.

The primary purpose of the pressurization is to maintain the PO2 at acceptable levels. Figure 2–2 shows that PO2 values at sea level and at a pressure altitude of 2,440 m (8,000 ft) are 21 kPa (3.1 psi) and 16 kPa (2.3 psi), respectively. Thus, the minimal PO2 allowed in the aircraft cabin at the maximal allowed cabin pressure altitude of 2,440 m (8,000 ft) is 74% of the sea level value (Federal Aviation Regulations (FAR) Section 25.841).

In addition to generating enough pressure to maintain the necessary PO2 in the cabin, the ECS must prevent rapid changes in cabin pressure. Rapid changes in pressure can cause changes in the volume occupied by gases in the body cavities and result in discomfort. Controlling the rate of change in pressure is particularly important during ascent and descent. During normal operation, the rate of change in cabin pressure altitude is limited to not more than 5 m/s (about 1,000 ft/min), sea-level equivalent, during climb and 2.3 m/s (450 ft/min) during descent (ASHRAE 1999a).

The aircraft skin and pressure bulkhead at the rear of the cabin form a pressure hull that allows the aircraft to withstand the pressurization necessary during flight. In flight, pressurized air from the engine compressors is supplied continuously to the cabin, and the cabin pressure is controlled by outflow valves; the valves are automatically controlled to maintain cabin pressure but can be manually overridden by controls in the cockpit.

For structural reasons, the difference between internal and external pressures is not allowed to exceed about 55–62 kPa (8–9 psi), depending on the aircraft. On some aircraft, the cabin pressure altitude is controlled to the lowest possible value (highest cabin pressure) and would not reach 2,440 m (8,000 ft) until the aircraft reaches its maximum operational altitude (e.g., 14,300 m [47,000 ft]). On other aircraft, the cabin pressure altitude is con-

trolled to the highest allowed value (lowest pressure) to minimize structural loads from pressurization. Because of the interrelationships between flight altitude, cabin pressure, and structural load on the aircraft, any change in pressure altitude requirements will affect the altitudes at which many aircraft can operate.

Contamination

Contaminants generated in the aircraft cabin air are eliminated by ventilating the cabin with outside air. The compressed outside air that is used for pressurization in the cabin is the same air that is used for ventilation. Pressurization and ventilation, however, serve very different purposes. For ventilation, outside air is used to dilute contaminants in the air and flush them out of the cabin. As described below, the rate of flow of outside air has a substantial and direct impact on the concentration of contaminants in the cabin air. The flow rate has a negligible effect on the PO2, in that only a tiny portion of the oxygen in this air is consumed by the aircraft occupants. A typical sedentary adult consumes oxygen at about 0.44 g/min (0.001 lb/min) (Nishi 1981). With the FAR 25 minimal design outside-air flow rate of 0.25 kg/min (0.55 lb/min) per cabin occupant, oxygen is brought into the cabin at 0.058 kg/min (0.127 lb/min) per person. Oxygen consumption by the occupants reduces the PO2 levels by about 0.8% in this case, compared with a PO2 reduction of up to 25% due to the reduced cabin pressure, as explained earlier. Thus, adequate oxygen concentrations in the cabin are maintained, even at ventilation rates far below those specified in FAR 25, as long as the cabin is adequately pressurized.

Contaminants can originate in the cabin itself or in sources outside the cabin. Furthermore, the concentrations of contaminants in the cabin are subject to change as a result of fluctuations in the source emission and ventilation rates. Some contaminants degrade or react with other chemicals in the cabin. The following sections discuss the generation, distribution, and elimination of contaminants in cabin air.

Contaminants Originating in the Cabin

The basic steady-state ventilation equation for a particular contaminant “i” may be expressed as follows (derived from ASHRAE 1997a):

Dc,i=Do,i+Si/Vo,

(2–1)

where

Dc is contaminant density in cabin air, kg/m3 (lb/ft3),

Do is density of contaminant in outside air used for ventilation, kg/m3 (lb/ft3),

S is strength of contaminant source, kg/s (lb/s), and

Vo is ventilation rate of outside air, m3/s (ft3/s).

To be accurate, both Vo and Do,i should be evaluated at cabin temperature and pressure (see Box 2–1). For gaseous contaminants, it is easier to work in terms of concentrations rather than densities, and the above equation can be expressed as follows:

Cc,i=Co,i+(Si MWa)/(mo MWi),

(2–2)

where

Cc is volume fraction of contaminant in cabin air,

Co is volume fraction of contaminant in outside air used for ventilation,

S is strength of contaminant source, kg/s (lb/s),

mo is ventilation rate of outside air, kg/s (lb/s),

MWa is molecular weight of air (28.96), and

MW is molecular weight of contaminant.

An example of the application of Equation 2–2 for carbon dioxide (CO2) is as follows. The CO2 concentration in the cabin air may be related to the rate at which outside air is supplied to the cabin by the ventilation system. A typical sedentary person will generate CO2 at about 7.7×10−6 kg/s (ASHRAE 1999b). The concentration of CO2 in clean outdoor air is about 0.037%. The molecular weight of CO2 is 44.01 g/mol. If the occupants are the only source of CO2 in the cabin, Equation 2–2 becomes

Cc,CO2=0.00037+N(7.7×10−6)(0.658/mo),

(2–3)

where N is the number of occupants and 0.658 is the ratio of the molecular weights of air and CO2. Equation 2–3 can be used to relate ventilation rates to measured values of CO2 concentrations as long as respiration is the dominant source of CO2 in the cabin and the outside CO2 concentration is not above typical values. The CO2 concentration with the FAR 25 minimal design ventilation rate for aircraft of 0.0042 kg/s per person (0.25 kg/min) can be estimated as

Cc,CO2=0.00037+(7.7×10−6)(0.658/0.0042)=0.00158=1,580 ppm.

Other ventilation rates will result in higher or lower CO2 concentrations according to Equation 2–3. It should be pointed out that CO2, at the concentrations present in this example is not noticeable by the occupants, nor is it considered hazardous. However, occupant-generated CO2 is produced roughly in proportion to other occupant-generated bioeffluents that can affect perceived air quality. The concentration of CO2 is sometimes used as an indicator of the concentration of other contaminants (ASHRAE 1999b).

The ventilation requirements in the FAR are given in terms of mass flow. However, it is common to state ventilation flows in volumetric terms such as liters per second or cubic feet per minute; this practice can lead to confusion in that the relationship between mass flows and volumetric flows depends on the ambient pressure and temperature (see Box 2–1).

Contaminants Originating Outside the Cabin

The preceding discussion dealt with contaminants that are generated in the cabin and that can be effectively controlled by ventilation. However, other contaminants can be in the outside air, such as ozone (O3) or can be picked up in the air supply system, such as leaking oil. Obviously, it is not possible to control or eliminate those contaminants through an increased ventilation flow rate. If the source of the contaminant exists for only a short time (e.g., during deicing), effective control can be achieved by turning off the flow of outside air while the source is present. That control measure is not an option in flight, because of the requirements for pressurization; nor is it an option when the source is present for more than a short time (e.g., 15 min). Some reduction in concentrations of such cabin air contaminants can be achieved by using the minimal practical flow of outside air and increasing the flow of recirculated air if the recirculation filters are effective at removing the contaminants in question (see recirculation section later in this chapter).

At high altitudes, especially at high latitudes, O3 concentrations in the outside air can be high enough for their introduction into the cabin to result in O3 concentrations that exceed the FAR 25 limit of 0.25 ppm by volume at any time above 32,000 ft (9,800 m) or above a time-weighted average of 0.1 ppm during any 3-h flight above 27,000 ft (8,200 m). Therefore, catalytic destruction of the O3 in the incoming air is used on some aircraft ECS to meet the FAR requirement.

|

BOX 2–1 Units for Expressing Ventilation It is common to express ventilation flow rates in volumetric terms—liters per second (L/s) or cubic feet per minute (cfm). However, this practice leads to ambiguity unless the pressure and temperature are also stated. Air density is proportional to atmospheric pressure and inversely proportional to absolute temperature. Thus, air that will occupy 1 m3 (35 ft3) at sea level will expand to over 3 m3 (106 ft3) at pressures and temperatures typical of outside air at cruise altitudes. The importance of this effect can be demonstrated by examining the ventilation requirement of 0.25 kg/min (0.55 lb/min) in FAR 25. At sea level and the standard atmospheric temperature of 15°C (59°F), the corresponding volumetric flow rate is 3.4 L/s (7.2 cfm); at the maximal allowed cabin pressure altitude of 2,440 m (8,000 ft) and a typical cabin temperature of 22°C (72°F), it is 4.7 L/s (9.9 cfm). At ambient atmospheric pressure at an altitude of 12,000 m (39,300 ft) and standard atmospheric temperature of −63°C (−81°F), the flow rate is 13.0 L/s (27.6 cfm). For ventilation purposes, the mass flow rate, not the volume flow rate, is most important. Thus, FAR 25 is correctly stated in this regard. Unfortunately, the data on most ventilation systems, including aircraft ventilation systems, are expressed in terms of volumetric flow. Temperature and pressure information generally is not included with those data, so there can be uncertainty as to the amount of air flowing. For aircraft, it can be assumed that the flow data do not correspond to outside ambient conditions at cruise altitudes. However, it is not always clear whether they correspond to cabin conditions, standard conditions, or some other conditions. |

With the exception of O3, the outside air at cruise altitudes is generally quite pure and requires no additional cleaning. The outside air at or near ground level, however, can contain a wide variety of contaminants from industrial and urban sources. In addition to outside air contaminants, leaking hydraulic fluid, spilled fuel, or deicing fluid can be entrained in the air supply systems; few, if any, aircraft have cleaning systems to remove any of these contaminants.

Transient Response of Cabin Environmental Conditions

Equations 2–1 through 2–3 describe contaminant concentrations under steady-state conditions. Contaminant concentrations in the cabin do not

change immediately when the controlling characteristics of ventilation flow rate and contaminant source strength are changed. It takes time for contaminant concentrations to build up to steady-state conditions after introduction of a source and to decline after the source is removed or ventilation begins. The time it takes for contaminant concentrations to approach steady-state conditions in aircraft is short, typically around 5–15 min, and is proportional to the quantity derived by dividing the volume of the space being ventilated by the ventilation rate. Such a rapid response means that there is only a short lag in the buildup of contaminants once they are introduced. It also means that the contaminants are flushed from the cabin quickly once the source is eliminated. In that respect, aircraft differ from buildings, in which it can take several hours to reach a steady state when ventilation rates are those recommended in American Society of Heating, Refrigeration, and Air-conditioning Engineers (ASHRAE) Standard 62 (1999b).

Because contaminants can concentrate so quickly in an aircraft cabin, it is important that the ECS not be shut down for an extended period when the aircraft is occupied (except in an emergency). When the ECS is not operating, contaminant concentrations can become excessive and temperature uncomfortably high rapidly—in less than 15 min for a fully loaded aircraft in a hot environment.

Reactive Contaminants

Some contaminants react with other substances or decompose after they enter the cabin environment. Whether the contaminants decompose or combine with other chemicals once they are in the cabin can have an important effect on the contaminant concentrations in the cabin (Weschler and Shields 2000). The residence time of a contaminant in the cabin (the average length of time from introduction of the contaminant until it is flushed from the cabin by ventilation) has an important influence on the concentration of reactive contaminants in that it determines how long a contaminant has to decompose or react. As with transient responses discussed previously, residence time is proportional to the quantity derived by dividing the volume of the space by the ventilation flow rate, so residence time in aircraft is typically much shorter than in buildings. Residence time is particularly important for O3 and its byproducts (see Chapter 3 for additional discussion).

Temperature Control

Temperature control in the aircraft cabin is critical for safety at high altitudes and is important for occupant comfort at all altitudes. Comfortable conditions are maintained in the cabin by supplying cool or warm air to the cabin as needed. Because of the high occupant density, cooling of the cabin is required in most circumstances, particularly on the ground and at low altitudes in warm climates. Supplying air to the cabin at an appropriate temperature is a key function of the ECS.

The temperature of the air that must be provided to the cabin can be determined from the steady-state heat balance for an aircraft cabin, which in equation form is analogous to Equation 2–2:

Tc=Ts+(Q/ms)(1/cp),

(2–4)

where

Tc is the temperature of the air in the cabin, °C (°F),

Ts is the temperature of the air supplied to the cabin, °C (°F),

Q is the amount of heat that must be removed from the cabin, W (Btu/s),

ms is the flow rate of conditioned air supplied to the cabin, kg/s (lb/s), and

cp is the specific heat of the air, 1000 J/kg·°C, (0.25 Btu/lb·°F).

The ECS designer must determine the combination of ms and Ts that will result in the desired Tc for a given Q.

The air conditioning systems can provide air at a wide range of temperatures. However, there is a lower limit at which air can be supplied to the cabin without creating uncomfortable cold drafts near the inlets, typically about 10°C (50°F), and even at that temperature only with good air circulation in the cabin and good diffuser design (ASHRAE 1997a). Consequently, the system must be designed with an air flow rate that is adequate to meet the largest heat load with this temperature of supply air. An example will demonstrate this principle.

The average heat generation by a comfortable, sedentary person, excluding heat loss due to evaporation of moisture, is about 70 W (ASHRAE 1997b). The total heat load in an aircraft cabin will include heat loads from electronics and heat gain through the aircraft skin. For the purpose of this example, the total heat load will be taken as twice the occupant-generated amount, or

140 W/person. If the cabin temperature is kept in the middle of the ASHRAE “comfort envelope” (ASHRAE 1992) at 23°C and the air is supplied to the cabin at 10°C, Equation 2–4 can be used to determine the required rate of flow of conditioned air to the cabin:

23°C=10°C+(140/ms)(1/1,000)=>ms=0.0108 kg/s·person= 0.646 kg/min·person.

That is, adequate temperature control in the cabin requires that conditioned air be supplied to the cabin at about 0.65 kg/min (1.4 lb/min) per person to maintain a comfortable temperature. This requirement is more than twice the FAR 25 requirement of 0.25 kg/min per person for outside air and provides one rationale for recirculating cabin air (see section on recirculation).

Air Distribution and Circulation

The ventilation system does more than supply outside air to the cabin. It also distributes and circulates air in the cabin. Moving outside air into the cabin at one or a few locations will not provide adequate contaminant removal and acceptable thermal conditions throughout the cabin. On the contrary, parts of the cabin would get very cold and other parts hot; similarly, parts of the cabin would have clean, fresh air and other parts stagnant, stale, and unpleasant air. An important function of the ECS is to distribute fresh air throughout the cabin by providing good air circulation for uniform temperature conditions; another is to flush out contaminated air.

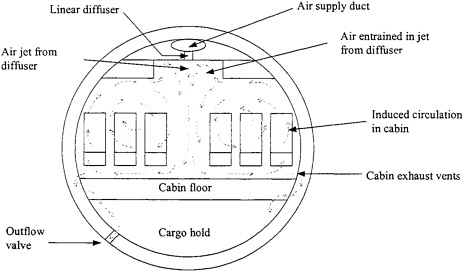

Figure 2–3 shows an example of air circulation in an aircraft cabin. Typically, air is supplied and exhausted along the whole length of the cabin. Although the air mixes locally in the cabin, the air supply and air exhaust flow rates are matched along the length of the cabin as much as possible to minimize net flows along the length of the aircraft. Distribution of the air to the cabin occurs through diffusers located in the center of the ceiling of the aisles, above the windows, or along the overhead baggage compartments. Generally, it is supplied to the cabin from one or more linear diffusers that run the length of the cabin. Wide-body aircraft, in particular, use multiple diffusers.

The velocities and circulation patterns in the cabin are determined by the location, configuration, and flow rates of the inlet diffusers. The incoming air must be balanced with exhaust of an equal amount of air from the cabin.

FIGURE 2–3 Cross-section of aircraft with air circulation paths.

Exhausted air generally is removed from the cabin at floor level and at the side walls and sometimes through the ceiling. Some of the exhausted air is recirculated to the cabin after passing through a filter, the balance of the exhausted air may pass around or through the cargo hold before being dumped overboard through an outflow valve. Exhaust fans extract air from the lavatories and galley areas, and it is ducted directly to the outflow valves to avoid contaminating air in other parts of the cabin with odors or other contaminants from these areas.

Ideally, the spread of contaminants along the length of the cabin is avoided by balancing inflow and outflow at all locations. That is not 100% effective even if the inlet and exhaust flows are perfectly matched at all locations, inasmuch as the circulation generated by the ECS transports contaminants from one part of the cabin to other parts and a substantial random component of the air motion transports airborne contaminants in all directions. Random velocity components of about 0.1–0.2 m/s (20–40 fpm) may exist throughout much of the occupied zone of a typical aircraft cabin (Jones et al. 2001).

The need for circulation to provide thermal uniformity generally sets the requirement for the total flow rate of air that must be supplied to the cabin. The circulation is induced by the air flowing out of the diffusers into the cabin;

with good diffuser design, the circulation will be greater than the incoming flow by a factor of 5 or more (ASHRAE 1997a). If ∆Tal is the maximal acceptable temperature variation from one spot to another in the cabin, the minimal acceptable temperature of the inlet air is given, to a first approximation, by

Ti=Tc−K∆Tal,

(2–5)

where

Ti is the temperature of the air supplied to the cabin, °C (°F),

Tc is the temperature of the cabin air, °C (°F), and

K is the ratio of the circulation to the inlet air flow, dimensionless.

If conditioned air is supplied directly to the cabin, Ti is the same as Ts in Equation 2–4, and the flow rate of air, ms, must be set accordingly. If the conditioned air is first mixed with recirculated air, Ti will be greater than Ts, and the total flow rate of air will be greater than the flow rate of conditioned air required according to Equation 2–4.

Recirculation

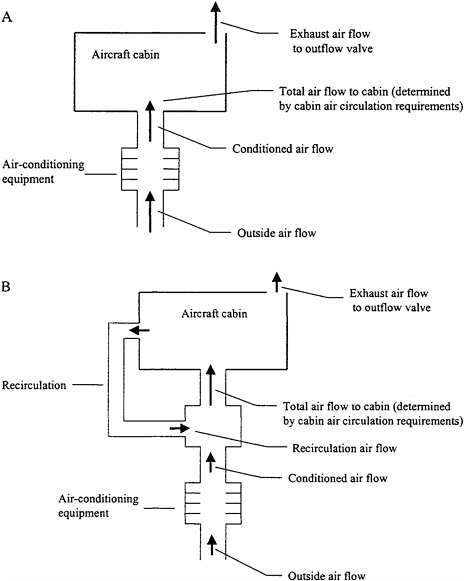

Aircraft designers have four important factors that must be considered when determining flow rate requirements for the ECS: the flow rate of outside air required to remove contaminants from the cabin, the flow rate of conditioned air required to remove heat from the cabin, the total flow rate of air required to provide adequate circulation in the cabin, and the flow rate of outside air required to pressurize the aircraft. In older aircraft (see Table 2–1), all the air supplied to the cabin comes from outside air, as shown in Figure 2–4. The flow rate of outside air must be large enough to meet the maximums of all four requirements even though it results in outside air flow rates larger than specified in FAR 25. This practice is inefficient in that supplying compressed air to the cabin in flight has a substantial energy cost.

The FAR 25 requirement for outside air for ventilation purposes is generally more than adequate for pressurization purposes as well; in the context of this discussion, pressurization is not a controlling factor for determining flow rates. The flow requirements needed to address the three remaining factors do not necessarily coincide. It was seen in a previous example that the required flow of conditioned air required for temperature control could be more

FIGURE 2–4 Cabin air supply without recirculation and with recirculation: (A) without recirculation—all flow of air to cabin comes from outside air, and flow rate of outside air must be large enough to meet greatest needs for cabin air circulation, temperature control, and contaminant control; (B) with recirculation—total flow of air to cabin is outside air flow and recirculation air flow combined. Flow rate of outside air is matched to needs for contaminant and temperature control and extra flow needed for cabin circulation is met with recirculation air.

TABLE 2–1 Basic Characteristics of Aircraft Ventilation Systems

|

Aircraft |

Air Source |

Air Recirculation, %a |

|||||

|

Manufacturer |

Model No. |

Ram Air |

Bleed Air |

Cabin |

Cockpitc |

Cabin |

Cockpitc |

|

Boeing |

707, 720 |

|

|||||

|

Turbojet |

|

|

0 |

0 |

NA |

NA |

|

|

Turbo fan |

|

|

0 |

0 |

NA |

NA |

|

|

727–100 |

Backup |

|

0 |

0 |

21.6–24.8 |

31.7–36.2 |

|

|

727–200 |

Backup |

|

0 |

0 |

23.6–29.2 |

42.2–56.8 |

|

|

737–100 |

|

|

0 |

0 |

12.0–26.1 |

17.5–43.5 |

|

|

737–200 |

|

|

0 |

0 |

11.0–23.9 |

17.5–43.5 |

|

|

737–300 |

|

|

37–47 |

0 |

21.8–24.8 |

35.0–40.5 |

|

|

747–100 |

|

|

23–27 |

0 |

19.2–22.6 |

29.9–37.1 |

|

|

747–200 |

|

|

23–27 |

0 |

19.2–22.6 |

29.9–37.1 |

|

|

747–300 |

|

|

23–27 |

0 |

18.0–21.3 |

29.9–37.1 |

|

|

757 |

|

|

48–55 |

0 |

29.7–34.3 |

57.6–61.9 |

|

|

767–200 |

|

|

45–53 |

49–55 |

20.1–24.6 |

61.3–68.4 |

|

|

Douglas |

DC-8–10 |

|

Backup |

0 |

0 |

20.3 |

22.8 |

|

DC-8–50 |

|

Backup |

0 |

0 |

20.3 |

22.8 |

|

|

DC-8–62 |

|

Backup |

0 |

0 |

19.2 |

22.8 |

|

|

DC-8–71 |

|

Backup |

34–49 |

0 |

26.6–31.5 |

25.0–35.7 |

|

|

DC-8–72 |

|

Backup |

34–49 |

0 |

20.9–24.7 |

25.0–35.7 |

|

|

DC-8–73 |

|

Backup |

34–49 |

0 |

26.6–31.5 |

25.0–35.7 |

|

than twice the FAR-specified value for outside air for contaminant control. The practice of recirculation was introduced to address this issue. As shown in Figure 2–4B, recirculation is accomplished by extracting air from the cabin and mixing it with conditioned outside air. Recirculation provides two benefits: it allows the total air flow rate to be higher than the flow rate of outside air, so good circulation in the cabin can be maintained independently of the flow of outside air; and the conditioned air is mixed with the comparatively warm recirculated air before being introduced into the cabin. Consequently, the conditioned air can be supplied at a much lower temperature (Ts in Equation 2–4) without causing discomfort from cold drafts, and the maximal flow rates of conditioned air required for temperature control can be reduced to match those required for contaminant control more closely.

Because recirculation removes air from the cabin and returns it to the cabin, it has no effect on average contaminant concentrations throughout the cabin, if it is unfiltered. Equation 2–2 still applies, and the average concentration of contaminants in the cabin air is determined by the flow rate of outside air, independently of the amount of recirculation. If the recirculation air is cleaned of contaminants, it has the same effect on contaminant concentrations in the cabin air as does clean outside air.

Current practice is to use only particle filters on recirculation air. Filter efficiencies are at least 40% (Mil Std 282) on the MD-80 series, but exceeds 93% on all other aircraft1 (Mil Std 282) (Boeing responses to NAS, April 10, 2001). Most aircraft manufactured more recently use HEPA filters. HEPA filters are highly effective (99.97% efficiency, Mil Std 282). Air filters are generally changed at the aircraft scheduled “c”-check, generally between 4,000 and 12,000 flight-hours (J.Lundquist, Pall Aerospace, personal communication, July 5, 2001). HEPA filters remove essentially all airborne pathogens and other particulate matter from an airstream that passes through them with a minimal efficiency of 99.97% for 0.3-μm particles. Although they are effective in removing particles, including bacteria and viruses, from the recirculated air and preventing their spread through the cabin by this route, they do not remove gaseous contaminants. Chemical adsorption of gaseous contaminants with activated charcoal or other types of filters may be used to clean the

recirculation air. These filters are available as an option on some aircraft to adsorb organic gases that are not trapped by the HEPA filters, but they are not widely used.

It should be emphasized that recirculation air is not a substitute for outside air and that the flow rate of outside air required to maintain acceptable concentrations of gaseous contaminants is not reduced by using recirculation. Furthermore, the use of recirculation has no detrimental effect on cabin air quality for a given rate of flow of outside air and, when combined with effective HEPA filtration, does not contribute to the spread of infectious agents in the cabin.

Recirculation air is obtained from the area above the cabin, under the floor, or both. Only air from the passenger cabin is recirculated. Air from the cargo bay, lavatories, and galleys is not recirculated (Boeing Co. 1988) but is separately vented overboard so that odors and cargo-bay fire-fighting chemicals that could be used in the event of a fire are not introduced into the cabin (Boeing Co. 1995).

The flow rate of outside air per seat ranges from 5.9 to 9.6 L/s (12.4 to 20.4 cfm) on older aircraft without recirculation and from 3.6 to 7.4 L/s (7.6 to 15.6 cfm) on aircraft with recirculation (M.Dechow, Airbus, personal communication, Feb. 16 and March 8, 2001; Boeing responses to NAS, April 10, 2001). The percentage of recirculated air distributed to the passenger cabin typically is 30–55% of the total air supply. Some models of aircraft can use different amounts of recirculation or turn recirculation off. Other models are programmed to use different amounts of recirculated air during climb or descent compared with cruise.

Table 2–1 summarizes the characteristics of the ventilation systems of various aircraft models (adapted from Lorengo and Porter 1986). It shows that most aircraft use bleed air rather than ram air as the source of cabin air, and it demonstrates that as aircraft have moved from 100% bleed air to recirculated air, the amount of outdoor air has decreased.

The use of recirculation has been common in the design of building environmental control systems for many years. In contrast with aircraft, in which the total air flow to the cabin varies from 0% to 55% of recirculated air, building environmental control systems are commonly designed and operated with up to 90% recirculated air. However, the buildings still must maintain flow rates of outside air of about 0.5 kg/min (1.1 lb/min) per person or more to meet ventilation requirements regardless of the amount of recirculation (ASHRAE 1999b).

Relative Humidity

Humidity in the aircraft is controlled both for human comfort and for aircraft safety. The two needs are sometimes compatible, sometimes in conflict. High humidity in the cabin air (e.g., greater than 70% relative humidity), especially when accompanied by high temperature leads to passenger discomfort. High humidity can also lead to condensation, dripping, and freezing of moisture on the inside of the aircraft shell, which can lead to a variety of safety problems, including corrosion on the shell. Condensation can lead to biological growth and potential adverse effects on cabin air quality. The ECS must be able to prevent excessive humidity in the cabin air by removing moisture from the outside air before it is supplied to the cabin.

At cruise altitudes, the outside air contains very little moisture, and the main sources of humidity in the cabin air are respiration and evaporation from the skin of occupants. The steady supply of dry outside air is more than sufficient to flush the human-generated moisture from the cabin and maintain a low moisture content in the air, typically 10–20% relative humidity at cruise altitudes. Such values of relative humidity are below comfort guidelines (ASHRAE 1992).

Theoretically, at least, cabin air could be humidified to comfortable values. But a number of problems are associated with such humidification, including the weight penalty associated with the water that would need to be carried, the biological growth that is often associated with humidifiers, and the maintenance requirements of humidification systems. In addition, the humidity required for passenger comfort might exceed that which generates some of the safety concerns for the aircraft operations described previously. Whole-cabin humidification systems are therefore not normally included on aircraft. Air supplied to the cockpit is humidified on a small fraction of the current aircraft fleet, but on most aircraft the cockpit is normally drier than the passenger cabin air because of the higher ventilation rates in the cockpit.

Humidity that is too low can be avoided to some extent by using the lowest feasible flow rate of outside air at cruise altitudes. There is an inherent conflict between humidity control and contaminant control: increasing the flow of outside air to reduce contaminant concentrations in the cabin reduces the humidity level, and decreasing the flow of outside air to raise the humidity increases contaminant concentrations.

Although water vapor is not considered a contaminant in this context, Equation 2–2 can be used to evaluate its concentration in cabin air. Relationships developed by Fanger (1982) can be used to estimate the typical moisture

generation by sedentary people in comfort (not sweating) in a low-humidity environment as 0.013 g/s per person. With that amount of moisture generation and the FAA minimal design flow rate of outside air of 0.042 kg/s, the water vapor concentration in the cabin air will be 0.0050, or 0.5%; this corresponds to a relative humidity of about 18% at typical cabin air temperatures.

That value might be a slight underestimate of the humidity because some occupants, particularly the cabin crew, will be more active than others. In addition, because of individual variations, some of the occupants might be sweating, even though the temperature is comfortable for the average person. Nevertheless, the value is a good indication of the humidity that can be expected with the FAA minimal design flow rate of outside air and is consistent with the humidity measured in aircraft (see Table 1–2).

Whether the FAA minimal design flow rate of outside air is appropriate for ventilation might be controversial. However, any attempt to increase cabin humidity by decreasing the ventilation flow rate will increase contaminant concentrations in the cabin air, and any attempt to reduce contaminant concentrations in the cabin by increasing the ventilation flow rate above the FAA minimum reduces humidity in the cabin further. The dilemma could be resolved, in theory, by using humidifiers; but they have their own problems, as discussed above. As a result, low humidity in aircraft cabins is not readily corrected.

ENVIRONMENTAL CONTROL SYSTEMS

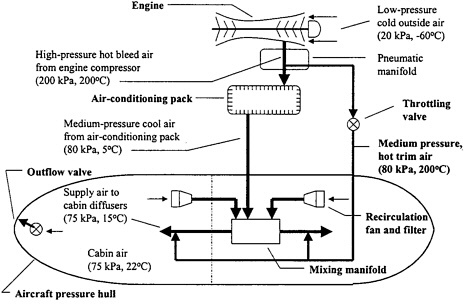

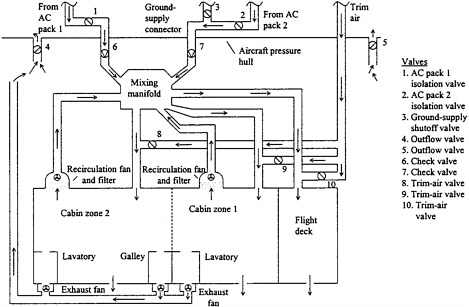

All large commercial passenger aircraft manufactured today and nearly all such aircraft in service use ECSs based on engine bleed air. Figure 2–5 presents an overview of bleed-air-based aircraft ECSs and equipment. Compressed air called bleed air is extracted from propulsion engine compressors and supplied to one or more air-conditioning “packs,” where it is further compressed, cooled, and then expanded in a rotating air-cycle machine to produce low-temperature air that is supplied to the aircraft cabin. The conditioned air from the packs is supplied to a mixing manifold that distributes it to zones in the cabin. Recirculation fans extract air from the cabin, pass it through filters, and supply it to the mixing manifold, where it mixes with the conditioned air from the packs. Trim air is hot bleed air that bypasses the air-conditioning packs. Small amounts of trim air are mixed with the air supplied to the cabin from the mixing manifold to provide independent fine temperature control in each zone. The bleed air from the engines is at a pressure sufficient to operate the air-

FIGURE 2–5 Simplified depiction of aircraft environmental control systems. (Temperatures and pressures listed are examples only and are typical of some aircraft in cruise conditions.)

conditioning packs and pressurize the cabin. Accurate cabin pressure is maintained by one or more outflow valves that automatically regulate the flow of air out of the aircraft pressure hull to the ambient environment to maintain the desired cabin pressure.

Each of the ECS component systems is discussed in more detail below. It should be understood that aircraft models vary in their systems and that, although the descriptions presented here are for typical aircraft, some of the details might not apply to a specific aircraft model.

Bleed-Air Supply

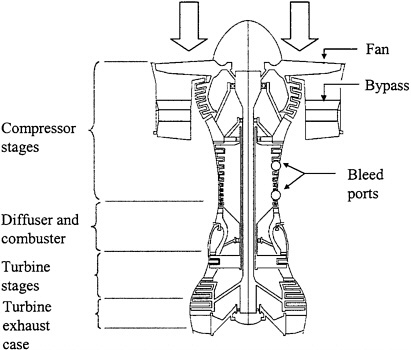

Figure 2–6 shows the key features of a modern fan-jet engine as is used on most commercial passenger aircraft. All the air entering the engine passes through the fan at the front and divides into two flow paths. The outer flow, which receives no compression other than that provided by the fan, is used directly for propulsion. The inner flow is used by the gas turbine that powers

FIGURE 2–6 Basic components of a fan-jet engine.

the engine. A multiple-stage compressor compresses the inner air flow to high pressure. From the compressor, it flows into the combustion chamber, where fuel is burned. The combustion chamber does not increase the pressure, but it heats the air to a high temperature, which causes it to expand. The high-pressure, high-temperature air then passes through the turbine, which expands the air and extracts energy from it to drive the compressor. The air leaves the turbine at high velocity and provides additional thrust for propulsion.

The compressor consists of many sets of rotating blades; each set is referred to as a stage. The pressure of the air is increased as it passes through each stage. The pressure ratio relevant to ambient pressure at any stage of the compressor depends on the speed at which the compressor is rotating. At a given stage, the pressure increases as the speed increases.

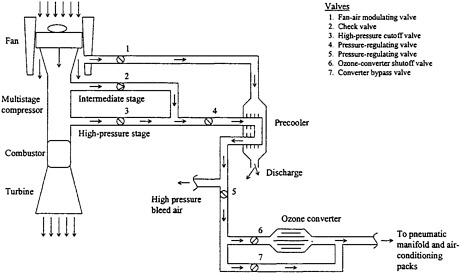

Bleed air is compressed air that is extracted from the engine compressor. Figure 2–7 shows a typical bleed-air system. Most bleed-air systems have at least two extraction ports, one near the end of the compressor to get the highest possible pressure when the engine is operating at low speed and an inter-

FIGURE 2–7 Common bleed air supply from engine.

mediate stage where the pressure is adequate during normal cruise and at high-power conditions. The bleed-air extraction from the high-pressure stage is automatically turned off when the pressure at the intermediate stage is adequate and is automatically turned on when the pressure from the intermediate stage is not adequate. The high-pressure port is used only during taxi and descent.

The bleed air coming off the engine is at high temperature and pressure; the exact conditions depend on the mode of operation of the engine. Table 2–2 shows typical temperatures and pressures of bleed air from the engine.

The high temperature of the bleed air is a result of compression. There is no combustion of fuel in the compressor. Under most conditions, the bleed air extracted from the engine is hotter than necessary and can be too hot to pipe safely to other parts of the aircraft; therefore, it passes through a precooler immediately after it is extracted from the engine. The precooler is a heat exchanger that uses comparatively cool air from the fan stage of the engine (fan air) to cool the bleed air. The temperature of the bleed air supplied to the aircraft is regulated by controlling the flow of fan air through the heat exchanger. The temperature is typically controlled to about 175°C (350°F). If there is a malfunction of the precooler and the temperature exceeds about 240°C (470°F), a fault will be indicated.

Not all the bleed air is used by the ECS. Some is used to heat leading-

TABLE 2–2 Typical Conditions of Bleed Air from Engine

|

Mode of Operation |

Temperature, °C (°F) |

Absolute Pressure, kPa (psi) |

Extraction Stage |

|

Takeoff—maximal powera |

350 (660) |

1170 (170) |

Low pressure |

|

Top of climb |

310 (590) |

690 (100) |

Low pressure |

|

Cruise |

250 (480) |

340 (50) |

Low pressure |

|

Initial descent |

185 (365) |

200 (29) |

High pressure |

|

End of descent (ground level) |

230 (445) |

460 (67) |

High pressure |

|

Switchover from high to low pressureb |

280 (535) |

480 (70) |

High pressure |

|

Ground operations |

170 (340) |

— |

Auxiliary power unit |

|

aSome engines (e.g., Avro/4GRJ) have only one bleed port; during takeoff, temperatures might exceed values given. bMaximal temperature and pressure for high-pressure stage occur just before bleed air system automatically switches from high-pressure port to low-pressure port. Source: Responses from Boeing to committee questions, July 13, 2001 . |

|||

edge surfaces to prevent ice accumulation and for engine-starting. High-pressure bleed air is tapped off for those purposes before it is supplied to the ECS. The pressure of the bleed air can be as high as 1,170 kPa (170 psi) when it is extracted from the engine. Pressure regulators reduce the pressure to 410–480 kPa (60–70 psi) gauge pressure for the high-pressure bleed air and reduce it further to 310 kPa (45 psi) gauge pressure in the pneumatic distribution manifold, which supplies the air-conditioning packs.

At cruise altitudes, the air can contain excessive O3. The bleed-air systems of some aircraft are equipped with O3 converters to reduce the O3 in the bleed air to acceptable concentrations before it is supplied to the ECS. The O3 converter consists of a honeycomb lattice, which provides for a large surface area on which O3 decomposition reactions can occur. The lattice is made of a chemically inert substrate coated with a proprietary catalyst, which speeds the kinetics of the decomposition reaction.

With the exception of the O3 converter, all the components of the bleed-air system shown in Figure 2–7 are as close as practical to the engine to avoid ducting very hot air around the aircraft. The location of the O3 converter depends on the aircraft; it can be in the wing or with the air-conditioning packs. It should be noted that some aircraft models have an O3 converter bypass feature that permits bleed air to enter the cabin without passing through the converter, but most do not. This bypass feature can be used to prevent poison

ing of the converter catalyst at low altitudes when the outside air might be contaminated, such as when the aircraft is sitting in a takeoff queue. Other aircraft models use in-line O3 converters, which cannot be bypassed.

Auxiliary Power Unit

In addition to the engines for propulsion, most aircraft have an auxiliary power unit (APU). The APU is a small gas turbine mounted in the tail cone of the aircraft with an electric generator to supply electric power to the aircraft. Compressed, unfiltered air from the APU is used to supply the pneumatic system of the aircraft, which supplies air to the ECS packs. The APU is normally operated to supply air when the aircraft’s main engines are not running (e.g., when the aircraft is sitting at the gate) or are not running at power adequate to generate the necessary bleed air or electric power. The location of the air inlet relative to the APU varies with the model of aircraft; it is generally near the APU.

There are several suppliers of APUs, but there are two basic designs. In one, compressed air is extracted from the APU turbine engine compressor before it reaches the combustion chamber in much the same way that bleed air is derived from the propulsion engines. In the second, the APU drives a second compressor that has no function other than to supply compressed air to the pneumatic system and can be optimized for that purpose.

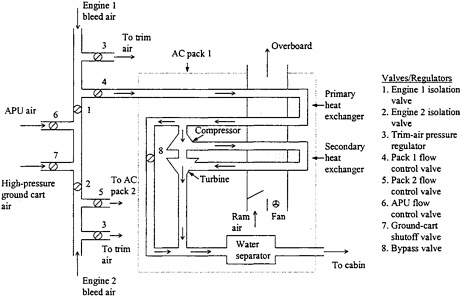

Air-Conditioning Packs

Bleed air from the engines or the APU is used to pressurize, heat, cool, and ventilate the aircraft cabin. Air-conditioning packs are used to cool and, if necessary, dehumidify the bleed air from the engines or APU before it is supplied to the aircraft cabin. Commercial passenger aircraft typically have two to four air-conditioning packs. Figure 2–8 shows a typical air-conditioning system; this figure is for an aircraft with two engines and two air-conditioning packs, but the basic principles of operation are the same with more engines or packs.

The air-conditioning pack includes two heat exchangers cooled by ram (outside) air, a compressor, and a turbine. The inlet for the ram-air duct faces the airflow over the aircraft, thereby pressurizing the ram air to flow through the heat exchanger when the aircraft is in flight. When the aircraft is on the

FIGURE 2–8 Common configuration of air-conditioning packs.

ground, however, a fan is required to drive the cooling air through the heat exchanger. The functions of the compressor and turbine in the pack are different from those in the engine. The air-conditioning pack has no fuel or combustion and the power to operate the pack is derived from the pressure of the conditioned air stream. Also, the pack compressor and turbine use air bearings to eliminate the need for lubricants.

Bleed air from the aircraft engines or APU enters a pneumatic manifold and is supplied to the air-conditioning packs. It passes through the primary heat exchanger where it is cooled, and then is compressed to a higher pressure in the compressor, increasing its temperature. That hot, high-pressure air is cooled again in the secondary heat exchanger. The air is then expanded, and its pressure is reduced in the turbine. Sufficient energy to operate the compressor is extracted from the pressurized air by the turbine. As a result, the temperature of the air drops markedly and is cold enough to provide cooling for the cabin even in hot environments.

Under typical cruise conditions, the ram air is cold enough to cool the bleed air, and the bleed air is sufficiently dry so that no moisture has to be removed. Under these conditions, a bypass valve is opened, and without further condi-

tioning, the bleed air goes directly from the primary heat exchanger in the air-conditioning pack to the cabin.

When the aircraft is on or near the ground in a humid environment, moisture will condense from the air when it expands in the turbine. That moisture is removed from the air stream by a water separator downstream of the turbine. The water separator cannot be allowed to freeze, and this requirement often establishes the lower temperature limit for the air from the air-conditioning pack. The need to prevent freezing in the water separator is an important limitation on the system described in Figure 2–8. Many aircraft are now being equipped with newer, more sophisticated packs that include additional heat exchangers that allow air to be supplied at a lower temperature and that eliminate the problem of freezing in the water separator.

Air Distribution System

Figure 2–9 shows a typical air distribution system for an aircraft passenger cabin. Of all the systems described in this chapter, the cabin air distribution system probably varies most from aircraft to aircraft, so the specific details of the system described here do not necessarily apply to every aircraft.

Conditioned air from one or more air-conditioning packs is supplied to a central mixing manifold (there is more than one manifold on some aircraft), where it is mixed with recirculation air. The aircraft cabin can have up to seven separate ventilation zones, and the resulting mixture of conditioned and recirculation air is supplied to each zone of the cabin as needed. The amount of air distributed in the cabin varies for each zone and is controlled by orifices (vents) in the supply ducts. Air supplied to any zone depends on the number of seats and on other heat sources, such as the lighting and entertainment systems. The metabolic heat loads from passengers and cabin crew may at times account for only about half the heat load in the cabin, and the remainder is generated by solar radiation, lighting, entertainment systems, and heat exchange with the outside environment.

The temperature of the air distributed to the cabin and cockpit is controlled by mixing hot trim air with the conditioned air from the mixing manifold before it enters the cabin. There is a separate trim-air valve for each zone. The trim-air valves regulate the flow of trim air to control the temperature of the zones. Although the cockpit crew sets the cabin temperature, the temperature in each

FIGURE 2–9 Common cabin air distribution system.

zone can be separately controlled by means of a thermostat that governs the amount of hot trim air mixed with the bleed air.

Additional thermal control is available to each passenger on some aircraft through gaspers. Gaspers are small outlets above the passenger seats that supply high-velocity air directly to individual passengers, who can control the quantity and direction of the air flow. The air supply for gaspers can be outside air from the air-conditioning system, recirculated air, or air from the mixing plenum, depending on the make and model of the aircraft. A separate gasper fan is used on some aircraft to circulate air through the gasper system. In some aircraft, air for the gaspers is extracted from the cabin and is independent of the recirculated air supplied to the mixing plenum. A separate gasper-air filter, similar to the filter for recirculated air, is used in these applications. The flow of air to the gasper system is controlled by the flight crew in some aircraft, and its operation is indicated by a light on the cabin-temperature control panel. Although the gaspers can influence individual thermal comfort, they play a relatively minor role in overall cabin ventilation.

Ground-Based Systems

It is sometimes desirable to provide pneumatic or conditioned air to the aircraft from ground-based sources rather than use the aircraft engines or APU. Ground-based equipment can be less expensive to operate, can prevent overheating of aircraft due to prolonged operation of packs on the ground, and can substitute for inoperable ECSs. Depending on the airport, one or more ground-based systems may be available. Ground-based systems include the high-pressure ground cart, the low-pressure ground cart, and the low-pressure fixed source.

The high-pressure ground cart is essentially an APU on wheels with a filter on the inlet to protect the cart from debris that might be entrained in the airflow. A pneumatic air line from the ground cart is attached to a fitting on the belly of the aircraft that connects to the aircraft pneumatic manifold (see Figure 2–8). This air is conditioned by the aircraft air-conditioning packs before being supplied to the cabin.

Airlines also have the option of supplying air to the aircraft downstream of the packs by using a low-pressure ground cart, which is essentially a conventional air conditioner on a mobile cart. With this method, air is supplied only to the cabin air supply system, not to the pneumatic system, and no filter is used (see Figure 2–9). The temperature of the air is adjustable and controlled by the cart. The flow rate is fixed but generally is nearly equal to the normal total output of the packs. A variation of the low-pressure ground cart operates by replacing the air conditioner with a heater. This approach is more economical and is typically used when only warm air is needed. Again, the air is normally not filtered.

Airlines have also begun to install fixed, low-pressure systems at each gate to replace the low-pressure ground carts. Rather than use an air conditioner mounted on a cart, the fixed system uses an air conditioner that is permanently mounted on the ground or in the terminal building and is connected to the aircraft by a flexible duct. The fixed system connects to the aircraft in the same manner as the low-pressure ground cart.

ALTERNATIVE ENVIRONMENTAL CONTROL SYSTEMS

Aircraft manufacturers and aircraft systems manufacturers might be investigating the use of alternatives to bleed-air-based ECSs, but any such work is highly confidential because of the competitive nature of this industry,

and no information about alternative systems was provided to the committee. Nor did the committee encounter any information about new alternative systems in its literature review. Consequently, the committee had little information to review in preparing this report. However, a brief examination of the potential for alternative systems is given below.

As explained earlier in this chapter, the ECS functions to pressurize the cabin, provide an adequate supply of clean air throughout the cabin, control the air temperature in the cabin, and to some degree regulate the humidity in the cabin. Any alternative to a bleed-air-based ECS must meet the same requirements.

The key features that distinguish the bleed-air-based ECS from other possible systems are the use of engine bleed air as the source of outside air and the use of rotating air-cycle equipment to cool this air. Those two features are fully integrated; not only does the high-pressure bleed air provide enough pressure to pressurize the cabin, but the pressure is high enough to operate the rotating air-cycle cooling equipment without external power sources.

An ECS that uses an alternative source of outside air (e.g., ram air) must, at a minimum, include compression equipment that can compress the outside air enough to meet the pressurization needs of the cabin. The compression equipment must be lubricated, and it must have power sources to drive it, such as electric motors, gas-turbine engines, or compressed-air turbines that use bleed air as the power source. Just as the engine compressors have the potential for contaminating the supply air, any alternative means of compressing the air also has the potential for contamination, although the nature of the potential contamination can be different. Thus, using an alternative to the bleed air as a source of outside air does not automatically ensure uncontaminated air. Because of the need for a separate compressor and compressor drive mechanism, they can impose a substantial weight penalty as well.

If the air is compressed just enough to pressurize the cabin rather than being compressed to a point where it can operate rotating air-cycle equipment, the temperatures attained in the compression could possibly be limited enough to avoid pyrolysis of contaminants, such as hydraulic fluid or lubricating oils. However, an alternative means of cooling the air would be required. The most obvious method is vapor-compression air-conditioning equipment similar to that used in most buildings and in many land vehicles. That equipment works well in ground-based applications, but its size and weight might be unacceptable for aircraft.

The first passenger jet aircraft, introduced in the early 1960s, did not use bleed air as the source of outside air. Ram air was compressed and used to

pressurize and ventilate the cabin. Bleed air was used to power a turbocompressor, which compressed the ram air to the proper pressure. That air was cooled by a Freon vapor compression-cycle air conditioner for temperature control before being distributed to the cabin. The arrangement was heavy, expensive, and inefficient because of the inefficiencies of the turbocompressor (E.Marzolf, retired, Douglas Aircraft Co., personal communication, April 29, 2001). Even more important was the high amount of maintenance that the systems required (R.Kinsel, retired, AlliedSignal, personal communication, May 7, 2001). For those reasons and because increasing the altitude of flights would have required an even larger turbocompressor and there was no discernable difference in quality between ram air and bleed air, it was decided in the late 1960s to use bleed air directly (E.Marzolf, op. cit.). New large passenger aircraft have since used bleed-air-based ECSs.

Essentially every large commercial passenger aircraft in use today is equipped with an alternative system, the APU. The APU provides a source of air that is independent of the propulsion engines. Although some APUs provide compressed air in much the same manner that the main propulsion engines provide bleed air, by extracting compressed air from the turbine-engine compressor, some APUs use a compressor, that is independent of the engine compressor, as described previously. Definitive data are not available, but the committee saw no evidence that contamination from the APU or brought into the APU is any less likely to affect cabin air adversely than is bleed air.

The committee did not investigate alternative ECSs in depth. To do so would take person-years of effort because reliable information is not readily available in the public domain, if at all. Although it is possible that alternative systems are being developed or could be developed, the committee saw no evidence that bleed-air-based systems cannot be designed, maintained, and operated to provide adequate clean air to the aircraft cabin. That statement does not imply that they always provide uncontaminated air to the cabin. As described in Chapter 3, there is evidence that air is sometimes contaminated; but the measurements that have been taken during routine operation show no contamination of concern arising from bleed-air systems (Nagda et. al. 2001). Data are available on only a few aircraft and conditions, but they are adequate to make the point that bleed air can be clean.

The committee does not want to discourage the pursuit of alternative systems, but it finds that the best method to ensure good cabin air is to have the Federal Aviation Administration (FAA) focus on ensuring that bleed-air-based systems are designed, maintained, and operated properly and that prob-

lems with them are identified and resolved. The reasons for the committee’s conclusion as follows:

-

Many uncertainties and potential disadvantages are associated with alternative ECSs, the alternative systems might have problems as yet unknown.

-

Alternative systems have been used and abandoned.

-

There is a slow turnover of the aircraft fleet, and aircraft with existing systems almost certainly will be in service for a long time.

-

There is good reason to believe that bleed-air systems can be designed and operated as to provide uncontaminated air to the cabin.

ENVIRONMENTAL CONTROL SYSTEM DESIGN AND OPERATIONAL STANDARDS

In this section of the report, the committee reviews guidelines, standards, and specifications that can have a bearing on aircraft ECS design and operation. Some of the guidelines and standards were developed primarily for building environments but might have relevance to aircraft as well. The FARs that are applicable to aircraft ECSs are discussed in Chapter 1. The FARs determine the design and operation requirements for aircraft; none of the guidelines and standards described below are legally enforceable for commercial aircraft.

For buildings, the primary indoor air-quality guideline in the United States is ASHRAE Standard 62–1999 (ASHRAE 1999b). As with all ASHRAE standards, it is a voluntary consensus guideline and is not legally binding unless adopted by the applicable regulatory body for a particular application. FAA has not adopted it for aircraft.

Standard 62–1999 was developed for and applies primarily to buildings. However, its scope claims applicability to all occupied indoor or enclosed spaces. There is no specific mention of aircraft or aircraft systems anywhere in the standard. Table 2 of the standard, which sets outdoor air requirements for various applications, has a single entry for vehicles but with no explanation as to type of vehicles (automobile, trains, buses, aircraft, and so on). In a requested interpretation, ASHRAE confirmed that aircraft are not specifically excluded from the scope of the standard but also stated: “Whether the requirements of Standard 62 should be applied to specific vehicles would be a decision for the authority having enforcement jurisdiction” (ASHRAE 2000a). In the case of aircraft, FAA is that authority.

If ASHRAE Standard 62–1999 were applied to aircraft, it would require outside air at 7 L/s (15 cfm) for each occupant. The standard does not specify the temperature and pressure that apply for this requirement. For most buildings, that omission is not critical, inasmuch as the overwhelming majority of buildings are at altitudes between sea level and 1,000 m (3,300 ft) and the density of outside air does not vary greatly over this range. However, the standard does not have any special requirement for buildings at high altitudes where the density of the air can be substantially less than that at sea level. For aircraft, that omission is more serious because they routinely operate at very high altitudes.

Using standard thermodynamic conditions of 101 kPa and a temperature of 25°C (14.7 psi and 77°F) (Howell and Buckius 1992), the Standard 62–1999 requirement translates to outside air at 0.50 kg/min (1.1 lb/min) per occupant. At the minimal allowed cabin pressure of 75 kPa (10.9 psi) and a temperature of 25°C (77°F), that would be 0.37 kg/min (0.82 lb/min). For outside conditions at a cruise altitude of 12,000 m (39,000 ft) and the standard atmospheric temperature of −63°C (−81 °F) for that altitude, it would mean only 0.067 kg/min (0.15 lb/min). Basing the requirement on outside conditions at that altitude is unrealistic, but Standard 62–1999 does not specifically prohibit it. The numbers highlight the potential folly of applying to aircraft a standard developed for terrestrial applications.

Assuming that the cabin temperature and pressure apply, and not the outside conditions, it is seen that ASHRAE Standard 62–1999 would require 50–100% more outside air than the current requirement in FAR 25. However, a provision in Section 6.1.3.4 of Standard 62–1999 might allow the outdoor air flow rate to be as little as half that listed above for some flights less than 3 h long. The provision is meant to reflect the fact that human-generated contaminants in the indoor air take some time to rise in response to occupancy. That phenomenon probably is not effective in aircraft, because of their high ventilation rates, but there is nothing in current interpretations of the provision that would prevent it from being applied to aircraft (see, for example, ASHRAE 2000b or ASHRAE 2000c)

ASHRAE Standard 62–1999 is continuously maintained. A revision being considered would divide the ventilation requirements into occupant-generated and building-generated requirements. If the revision is adopted and if aircraft are treated similarly to how buildings are treated, the ventilation requirements for aircraft might drop considerably, with the minimal outside-air requirement for a fully loaded aircraft possibly falling to 2.4–3.3 L/s (5–7 cfm) per person.

Standard 62–1999 sets maximal concentrations of contaminants in the outside air used for ventilation. If the concentrations are exceeded, the outside air must be cleaned before it is used for ventilation. Most of the requirements are based on averages over periods of 24 h to 1 yr and so have little meaning for an aircraft that spends much of its time cruising in pristine air or on the ground not operating. However, ASHRAE’s limits on carbon monoxide (CO) and O3 could apply. The limits for CO are averages of 35 ppm for 1 h and 9 ppm for 8 h. The O3 limit is an average of 0.12 ppm for 1 h.

It is not possible to compare the above requirements from ASHRAE Standard 62–1999 with those in FAR 25 directly; because the FAR 25 requirements are for cabin air and the ASHRAE requirements are for inlet air. O3, in particular, will continue to react after the air is in the cabin. An optional provision of Standard 62–1999 does have a guideline for the maximal allowed concentration of O3 in the indoor air: 0.05 ppm on a continuous basis. CO, in contrast, is mostly inert in the cabin; it is present continuously in the inlet air, the cabin concentration ultimately will match that of the inlet air. Thus, ASHRAE Standard 62–1999 is generally more restrictive than FAR 25 with respect to both O3 and CO.

The optional provisions in Standard 62–1999 also include a guideline for the maximal concentration of CO2: 700 ppm above the outside air concentration, or about 1,000–1,100 ppm in most situations. That limit is strictly for the purpose of limiting discomfort related to odors from human bioeffluents and is not meant to be a limit on exposure to CO2 (ASHRAE 2000d). It uses respiration-generated CO2 as a proxy for the human-generated odors and is approximately comparable with the 7 L/s (15 cfm) per person requirement at sea level. Obviously, it is not applicable if other sources of CO2, such as dry ice, are present. The guideline of 1,000–1,200 ppm that comes from Standard 62–1999 should not be compared with the 5,000-ppm limit in FAR 25; the latter is a limit on exposure to CO2 itself and is not intended to be a measure of ventilation.

ASHRAE Standard 62–1999 does not mandate temperature or humidity requirements. Such requirements are, however, covered in ASHRAE Standard 55–1992, Thermal Environmental Conditions for Human Occupancy (ASHRAE 1992), which sets ranges of temperature and humidity that are generally found comfortable as a function of activity level and clothing. The standard’s scope claims applicability to environments “at atmospheric pressure equivalent to altitudes up to 3,000 m (10,000 ft) in indoor spaces designed for human occupancy for periods not less than 15 minutes” and thus appears to apply to aircraft. The lower relative-humidity limits range from about 20% to

30%, depending on the temperature, and might be difficult to attain in most aircraft on all but the shortest flights. A public review draft of a proposed revision of the standard removes the lower humidity limits (ASHRAE 2001).

ASHRAE is developing a standard specifically for aircraft cabin air quality and has established the special-project committee on Air Quality within Commercial Aircraft, SPC 161P, to complete the task. The scope under which the committee is working states that it “applies to commercial passenger air-carrier aircraft carrying 20 or more passengers and certified under Title 14 CFR Part 25.” Although the committee has been working on the standard for several years, the first public review draft is not expected before to 2002.

The Society of Automotive Engineers (SAE) recommended practice Procedure for Sampling and Measurement of Engine Generated Contaminants in Bleed Air Supplies from Aircraft Engines Under Normal Operating Conditions, ARP4418 (SAE 1995), includes a table from AIR4766, Air Quality for Aircraft Cabins that specifies the maximal concentrations of contaminants in engine bleed air. Those limits are presented in Table 2–3. AIR4766 is under development by SAE and has not been released to the public (SAE, personal communication, May 7, 2001).

Military Specification MIL-E-5007D, General Specifications for Aircraft Turbojet and Turbofan Engines (1973), also includes limits on contaminants in bleed air, which are presented in Table 2–4. Neither the limits in ARP4418

TABLE 2–3 Limits on Engine-Generated, Bleed-Air Contaminants Under Normal Operating Conditions

|

Contaminant |

Maximal Allowable Concentration Above Ambient |

|

CO2 |

400 ppm |

|

CO |

5 ppm |

|

Hydrogen fluoride |

1 ppm |

|

Oxides of nitrogen (nitrogen dioxide equivalent) |

1 ppm |

|

Formaldehyde |

0.3 ppm |

|

Acrolein |

0.05 ppm |

|

Organic material (synthetic oil equivalent, MW 600) |

0.4 ppm |

|

Respirable particles |

0.5 mg/m3 |

|

Source: Adapted from SAE (1995). |

|

TABLE 2–4 Limits on Engine-Generated, Bleed-Air Contaminants Under Normal Operating Conditions

|

Substance |

Maximal Allowable Concentration Above Ambient, ppm |

|

CO2 |

5,000 |

|

CO |

50 |

|

Ethanol |

1,000 |

|

Fluorine (as hydrogen fluoride) |

0.1 |

|

Hydrogen peroxide |

1.0 |

|

Aviation fuels |

250 |

|

Methyl alcohol |

200 |

|

Methyl bromide |

20 |

|

Nitrogen oxides |

5 |

|

Acrolein |

0.1 |

|

Oil breakdown products (e.g., aldehydes) |

1.0 |

|

O3 |

0.1 |

|

Source: Military Specification (MIL-E-5007D) (1973). |

|

nor the limits in MIL-E-5007D appear to be a factor in the commercial aircraft industry, because modern engines are associated with much lower contaminant concentrations under normal operating conditions when there are no equipment failures or malfunctions. Note that both specifications are for engine-generated contaminants; any contaminants in the engine inlet air would not be covered.

CONCLUSIONS

-

The adequacy of oxygen in the cabin is determined by the PO2. The cabin air pressure is the dominant factor in determining the PO2 in the cabin. The ventilation rate has little effect on PO2, and ventilation rates well below those normally present in aircraft would not seriously affect PO2.

-

The flow of outside air must be adequate for contaminant control in the cabin, whether or not recirculation is used. As long as the outside-air flow rate is appropriate for contaminant control in the cabin and the recirculation system is properly designed, operated, and maintained, recirculation does not normally affect cabin air quality adversely.

-

As aircraft have moved from using 100% bleed air for cabin ventilation to incorporating recirculated air into ECS design, the amount of outside air supplied to the cabin has decreased.

-

The mixing of the air that occurs in the cabin, with or without recirculation, and the proximity of cabin occupants makes it impossible to eliminate exposure to infectious agents and other contaminants in the cabin air.

-

The low humidity in aircraft cabins cannot be increased through ventilation controls without raising questions about the effect on air quality. A number of problems are associated with humidification of cabin air. Consequently, the low humidity common in aircraft cabins is not readily corrected.

-

The environmental conditions in an aircraft cabin respond quickly to changes in ECS operation. Consequently, it is important that the ECS not be shut down for a long period when the aircraft is occupied except in the case of an emergency, because excessive contaminant concentrations and uncomfortably high temperatures can occur quickly.

RECOMMENDATIONS

-

FAA should rigorously demonstrate in public reports the adequacy of current and proposed FARs related to cabin air quality and should provide quantitative evidence and rationales to support sections of the FARs that establish air-quality-related design and operational standards for aircraft (standards for CO, CO2, O3, ventilation, and cabin pressure). If a specific standard is found to be inadequate to protect the health and ensure the comfort of passengers and crew, FAA should revise it. For ventilation, the committee recommends that an operational standard consistent with the design standard be established.

-

The committee reiterates the recommendation of the 1986 NRC report that a regulation be established that requires removal of passengers from an aircraft within 30 min after a ventilation failure or shutdown on the ground and that full ventilation be maintained whenever on-board or ground-based air-conditioning is available.

REFERENCES

ASHRAE (American Society of Heating, Refrigerating and Air-Conditioning Engineers). 1992. Thermal Environmental Conditions for Human Occupancy. ANSI/

ASHRAE 55–1992. American Society of Heating, Refrigerating and Air-Conditioning Engineers, Atlanta, GA.

ASHRAE (American Society of Heating, Refrigerating and Air-Conditioning Engineers). 1997a. Ventilation and Infiltration. Chapter 25 in 1997 ASHRAE Handbook: Fundamentals. American Society of Heating, Refrigerating and Air-Conditioning Engineers, Atlanta, GA.

ASHRAE (American Society of Heating, Refrigerating and Air-Conditioning Engineers). 1997b. Non-Residential Heating and Cooling Load Calculations. Chapter 28 in 1997 ASHRAE Handbook: Fundamentals. American Society of Heating, Refrigerating and Air-Conditioning Engineers, Atlanta, GA.

ASHRAE (American Society of Heating Refrigerating and Air-Conditioning Engineers). 1999a. Aircraft. Chapter 9 in 1999 ASHRAE Handbook: Heating, Ventilating, and Air-Conditioning Applications. American Society of Heating, Refrigerating, and Air-Conditioning Engineers, Atlanta, GA.

ASHRAE (American Society of Heating Refrigerating and Air-Conditioning Engineers). 1999b. ASHRAE Standard—Ventilation for Acceptable Indoor Air Quality. ANSI/ASHRAE 62–1999. American Society of Heating Refrigerating and Air-Conditioning Engineers, Atlanta, GA.

ASHRAE (American Society of Heating Refrigerating and Air-Conditioning Engineers). 2000a. Ventilation for Acceptable Indoor Air Quality. Interpretation IC 62– 1999–37 of ANSI/ASHRAE 62–1999 . American Society of Heating, Refrigerating, and Air-Conditioning Engineers, Atlanta, GA.

ASHRAE (American Society of Heating Refrigerating and Air-Conditioning Engineers). 2000b. Ventilation for Acceptable Indoor Air Quality. Interpretation IC 62–1999–18 of ANSI/ASHRAE62–1999. American Society of Heating, Refrigerating, and Air-Conditioning Engineers, Atlanta, GA.

ASHRAE (American Society of Heating Refrigerating and Air-Conditioning Engineers). 2000c. Ventilation for Acceptable Indoor Air Quality. Interpretation IC 62–1999–20 of ANSI/ASHRAE 62–1999. American Society of Heating, Refrigerating, and Air-Conditioning Engineers, Atlanta, GA.

ASHRAE (American Society of Heating Refrigerating and Air-Conditioning Engineers). 2000d. Ventilation for Acceptable Indoor Air Quality. Interpretation IC 62–1999–05 of ANSI/ASHRAE 62–1999. American Society of Heating, Refrigerating, and Air-Conditioning Engineers, Atlanta, GA.

ASHRAE (American Society of Heating Refrigerating and Air-Conditioning Engineers). 2001. Thermal Environmental Conditions for Human Occupancy. BSR/ ASHRAE 55–1992R. ASHRAE Standard, Proposed Revision to American National Standard. First Public Review Draft. American Society of Heating, Refrigerating, and Air-Conditioning Engineers, Atlanta, GA. February.

Boeing Company. 1988. Air Conditioning—Description and operation. P. 1 in Boeing 747–400 Maintenance Manual. 21–00–00. Boeing Company. October 10, 1988.