3

Technologies in Exploration, Mining, and Processing

INTRODUCTION

The life cycle of mining begins with exploration, continues through production, and ends with closure and postmining land use. New technologies can benefit the mining industry and consumers in all stages of this life cycle. This report does not include downstream processing, such as smelting of mineral concentrates or refining of metals. The discussion is limited to the technologies that affect steps leading to the sale of the first commercial product after extraction.

The three major components of mining (exploration, mining, and processing) overlap somewhat. After a mineral deposit has been identified through exploration, the industry must make a considerable investment in mine development before production begins. Further exploration near the deposit and further development drilling within the deposit are done while the mining is ongoing. Comminution (i.e., the breaking of rock to facilitate the separation of ore minerals from waste) combines blasting (a unit process of mining) with crushing and grinding (processing steps). In-situ mining, which is treated under a separate heading in this chapter, is a special case that combines aspects of mining and processing but does not require the excavation, comminution, and waste disposal steps. The major components can also be combined innovatively, such as when in-situ leaching of copper is undertaken after conventional mining has rubblized ore in underground block-caving operations.

EXPLORATION

Modern mineral exploration has been driven largely by technology. Many mineral discoveries since the 1950s can be attributed to geophysical and geochemical technologies developed by both industry and government. Even though industrial investment in in-house exploration research and development in the United States decreased during the 1990s, new technologies, such as tomographic imaging (developed by the medical community) and GPS (developed by the defense community), were newly applied to mineral exploration. Research in basic geological sciences, geophysical and geochemical methods, and drilling technologies could improve the effectiveness and productivity of mineral exploration. These fields sometimes overlap, and developments in one area are likely to cross-fertilize research and development in other areas.

Geological Methods

Underlying physical and chemical processes of formation are common to many metallic and nonmetallic ore deposits. A good deal of data is lacking about the processes of ore formation, ranging from how metals are released from source rocks through transport to deposition and post-deposition alteration. Modeling of these processes has been limited by significant gaps in thermodynamic and kinetic data on ore and gangue (waste) minerals, wall-rock minerals, and alteration products. With the exception of proprietary data held by companies, detailed geologic maps and geochronological and petrogenetic data for interpreting geologic structures in and around mining districts and in frontier areas that might have significant mineral deposits are not available. These data are critical to an understanding of the geological history of ore formation. A geologic database would be beneficial not only to the mining industry but also to land-use planners and environmental scientists. In many instances, particularly in arid environments where rocks are exposed, detailed geologic and alteration mapping has been the key factor in the discovery of major copper and gold deposits.

Most metallic ore deposits are formed through the interaction of an aqueous fluid and host rocks. At some point along the fluid flow pathway through the Earth’s crust, the fluids encounter changes in physical or chemical conditions that cause the dissolved metals to precipitate. In research on ore deposits, the focus has traditionally been on the location of metal depositions, that is, the ore deposit itself. However,

the fluids responsible for the deposit must continue through the crust or into another medium, such as seawater, to maintain a high fluid flux. After formation of a metallic ore deposit, oxidation by meteoric water commonly remobilizes and disperses metals and associated elements, thereby creating geochemical and mineralogical haloes that are used in exploration. In addition, the process of mining commonly exposes ore to more rapid oxidation by meteoric water, which naturally affects the environment. Therefore, understanding the movement of fluids through the Earth, for example, through enhanced hydrologic models, will be critical for future mineral exploration, as well as for effectively closing mines that have completed their life cycle (NRC, 1996b).

The focus of research on geological ore deposits has changed with new mineral discoveries and with swings in commodity prices. Geoscientists have developed numerous models of ore deposits (Cox and Singer, 1992). Models for ore deposits that, when mined, have minimal impacts on the environment (such as deposits with no acid-generating capacity) and for deposits that may be amenable to innovative in-situ extraction will be important for the future. Because the costs of reclamation, closure, postmining land use, and long-term environmental monitoring must be integrated into mine feasibility studies, the health and environmental aspects of an orebody must be well understood during the exploration stage (see Sidebars 3-1 and 3-2). The need for characterizations of potential waste rock and surrounding wall rocks, which may either serve as chemical buffers or provide fluid pathways for escape to the broader environment. Baseline studies to determine hydrologic conditions and natural occurrences of potentially toxic elements in rocks, soils, and waters are also becoming critical. The baseline data will be vital to determining how mining may change hydrologic and geochemical conditions. Baseline climatological, hydrological, and mineralogical data are vital; for example, acid-rock drainage will be greatly minimized in arid climates where natural oxidation has already destroyed acid-generating sulfide minerals or where water flows are negligible.

A wealth of geologic data has been collected for some mining districts, but the data are not currently being used because much of the data is on paper and would be costly to convert to digital format. Individual companies have large databases, but these are not available to the research community or industrial competitors. Ideally, geological research on ore deposits should be carried out by teams of geoscientists from industry, government, and academia. Industry geoscientists have access to confidential company databases and a focus on solving industrial problems; government and academic geoscientists have access to state-of-the-art analytical tools and a focus on tackling research issues. Currently, geological research activities in the United States are not well coordinated and are limited primarily to studies of individual deposits by university groups and, to a much lesser extent, by the USGS. More effective research is being carried out in Australia and Canada by industry consortia working with government and academia to identify research problems, develop teams with the skills appropriate to addressing those problems, and pool available funding. Both Canada and Australia have resolved issues of intellectual property rights in the industry-university programs, but these issues have yet to be resolved in the United States.

Geochemical and Geophysical Methods

Surface geochemical prospecting involves analyzing soil, rock, water, vegetation, and vapor (e.g., mercury and hydrocarbons in soil gas) for trace amounts of metals or other elements that may indicate the presence of a buried ore deposit. Geochemical techniques have played a key role in the discovery of numerous mineral deposits, and they continue to be a standard method of exploration. With

|

SIDEBAR 3-1 Examples of Environmental and Health Concerns That Should Be Identified During Exploration

|

|

SIDEBAR 3-2 Models for Ore Deposits with Little Environmental Impact Ore has traditionally been defined as natural material that contains a mineral substance of interest and that can be mined at a profit. The costs of mine closure and reclamation of the site now constitute a significant portion of mining cost. Hence, ore bodies that can be mined in a way that produces virtually no waste and that leaves a small surface “footprint” may have distinct economic and environmental advantages over ore bodies that produce large amounts of waste and create large land disturbances. Until recently, these criteria have generally not figured significantly in decisions about mineral exploration. Exploration geologists are now developing new ore-deposit models to improve the chances of finding such “environmentally friendly” ore bodies. The copper ore bodies mined from 1911 to 1938 at Kennecott, Alaska (now within the Wrangell–St. Elias National Park and Preserve), are examples of potentially environmentally “friendly” ore deposits. The ore bodies consisted of veins of massive chalcocite (a mineral consisting of copper and sulfur). The deposits contained nearly 4.5 million tons of 13 percent copper and 65 grams of silver per ton, some of the highest grade deposits ever mined (Bateman, 1942). The ore at Kennecott contained an amount of copper equivalent to a 100-million-ton typical porphyry copper deposit, which is currently one of the primary types of copper deposits being mined worldwide. The Kennecott deposits were an economically attractive target for exploration. They were also environmentally attractive because they had a large amount of copper in a small volume of rock, so extraction would cause minimal disturbance, and they consisted primarily of chalcocite with little or no iron sulfide that would produce acid-rock drainage. In addition, their location within massive carbonate rock ensured that any acid generated by the oxidation of sulfides would be quickly neutralized (Eppinger et al., 2000). Deposits similar to those at Kennecott have not been a target for exploration by many companies primarily because exploration geologists have not developed a robust exploration model for this type of deposit and because their small size makes them difficult to locate. Nevertheless, the development of new, robust models for locating deposits of this and other types of ore bodies that can be mined with little adverse environmental impact could have important economic benefits. |

increasingly sophisticated analytical techniques and equipment developed in the past 50 years, exploration geologists have been able to detect smaller and smaller concentrations of the elements of interest. Available analytical tools are sufficient for most types of analyses required by the industry. However, new technologies, such as laser fluorescence scanning and portable X-ray fluorescence, which can directly determine concentrations of elements in rocks, and differential leaching techniques are also being developed and used for exploration. As analytical equipment is miniaturized, inexpensive hand-held devices that could be used in the field or in mines to provide real-time analytical results would significantly benefit both mineral exploration and mining, as well as environmental regulators.

Other research that could benefit the minerals industry includes the development of a more thorough understanding of the media being sampled, such as soils. The complex processes that result in soil formation and the behavior of various elements in different soil types are still poorly understood. A recent NRC report on Basic Research Opportunities in Earth Sciences calls for multidisciplinary integrative studies of soils (NRC, 2001). Fundamental research in soil science could produce significant spin-offs that would affect geochemical exploration and would contribute to a more thorough understanding of soil ecology for agriculture. Geoscientists are just beginning to understand how organisms concentrate metals. Even though geobotanical exploration was used by a number of companies in the 1970s and 1980s, research in this field, together with investigations of metal concentrations by other organisms, such as bacteria and fungi, has not been focused on mineral exploration. Other relevant areas of research include soil-gas geochemistry and water geochemistry. The NRC report on Basic Research Opportunities in Earth Sciences also highlighted the need for geobiological research (NRC, 2001).

Industrial research and development in geophysical methods of mineral exploration have been ongoing since World War II. Canada has led the world in geophysical innovations, primarily through industry support for academic programs and through in-house corporate development of new techniques. An example of the latter is the recent development by the mining industry of a prototype airborne gravity system. Gravity measurements are a typical means of locating dense metallic mineral deposits and of mapping different rock types in the Earth’s crust. However, traditional ground-based surveys are time consuming and therefore expensive. As an NRC report in 1997 pointed out, the ability to gather gravity data from an aircraft would significantly increase productivity and reduce the invasiveness of mineral exploration (NRC, 1997b).

Magnetic surveys are commonly conducted by aircraft that must fly at a fixed distance above the ground surface for optimal data acquisition (Figures 3-1 and 3-2). These surveys are difficult to conduct and risky in rugged terrain. The

FIGURE 3-1 Helicopter-borne, aeromagnetic survey system.

SOURCE: Newmont Mining Corporation.

FIGURE 3-2 Helicopter-borne, aeromagnetic survey system.

SOURCE: Newmont Mining Corporation.

recent development of drones, primarily by the U.S. military, has made more effective geophysical surveys possible. This technology is currently being explored by industry-government consortia in Australia.

Seismic exploration, although already an integral part of petroleum exploration, is rarely used in mineral exploration. The primary reasons are technological and economic. Current seismic technology is used to gather data at relatively great depths (thousands of meters below those typical of mineral deposits). Near-surface seismic imaging is possible but will require the development of new strategies for collecting and processing the data (NRC, 2000). Typical seismic surveys are expensive in terms of data collection and data processing. New computing capabilities have led to cost reductions although the costs are still beyond most budgets for mineral exploration. Thus, seismic companies have had little financial incentive to engage in this type of research and development, and virtually no governmental support has been available.

Geophysical techniques that can deduce geological structures and changes in physical properties between bore holes, such as cross-bore-hole seismic tomography, are promising technologies (NRC, 1996b).

Remote sensing is the recording of spectral data (visible to infrared and ultraviolet wavelengths) from the Earth’s surface via an airborne platform, generally a high-flying aircraft, or from near-Earth orbit (NRC, 2000). Government support was critical in initiating this technology. Current technologies include the Landsat thematic mapper and the enhanced thematic mapper multispectral imager by the United States and high-resolution panchromatic imaging technology (SPOT) developed by the French Space Agency, as well as radar imaging (RadarSat) of topography for cloud-covered or heavily vegetated areas. The U.S. government transferred some existing systems to the commercial sector, and several privately owned satellites are currently in operation and providing detailed (4-meter resolution) multispectral imagery. These data are used by the mineral exploration sector, as well as many other industrial, academic, and government groups. Promising new multispectral technologies are being developed by both government and industry groups. The shuttle radar topographic mapping (SRTM) system will provide high-quality, detailed digital topographic and image data. The advanced spaceborne and thermal emission and reflection (ASTER) mission will provide multiband thermal data.

Hyperspectral technologies are being developed to gather additional data that can be used to map the mineralogy of the ground surface. A high-altitude aircraft system, airborne visible/infrared imaging spectrometer (AVIRIS), has been developed by the National Aeronautics and Space Administration (NASA). Data from this sensor have been successfully used for both mineral exploration and mine closures at several sites in the United States. Spaceborne hyperspectral systems are also being developed. The Hyperion is being

readied for deployment on the Earth Observing-1 (EO-1) satellite. Foreign systems include the Orbview-4 (Warfighter) and the airborne infrared echelle spectrometer (AIRES) instrument being developed by Australia.

Currently, a number of research challenges are being addressed for hyperspectral technology, especially for spaceborne systems. These include the development of focal planes with adequate signal-to-noise spectral resolution to resolve mineral species of importance and the capability of acquiring data at a 10-meter spatial resolution while maintaining a minimum swath width of 10 kilometers. The focal planes must also be compact, lightweight, have accurate pointing capabilities, and be robust enough to maintain calibration for long-duration spaceflights.

Routine use of existing hyperspectral systems by the minerals industry has been hampered by the unavailability of systems for industrial use, the high cost of hyperspectral data (when available) compared to typical multispectral data, and the need for additional research into the processing of hyperspectral data. Government support for system development and deployment, as well as for basic research on the analysis of hyperspectral data, would ensure that these new technologies would be useful for the mineral exploration industry, as well as for a wide range of other users, including land-use planners and environmental scientists.

Drilling Technologies

Almost all mineral exploration involves drilling to discover what is below the surface. No significant changes in mineral drilling technology or techniques have been made for more than three decades (NRC, 1994b). This contrasts sharply with spectacular advances in drilling technologies, including highly directional drilling, horizontal drilling, and a wide range of drilling tools for the in-situ measurement of rock properties, for the petroleum and geothermal sectors. Mineral exploration involves both percussion and rotary drilling that produce rock chips and intact samples of core. The diameter of mineral exploration drill holes (called slimholes) is generally much smaller than the diameter of either petroleum or geothermal wells. Therefore, many of the down-hole tools used for drilling in the petroleum and geothermal fields are too large to be used in the mineral exploration slimholes. The need for miniaturization of existing drilling equipment is growing not only in the mineral industry but also for NASA to investigate drilling on Mars. The development of guided microdrill systems for the shallow depths of many mineral exploration projects will be challenging.

Drilling generally represents the largest single cost associated with mineral exploration and the delineation of an ore deposit once it has been discovered. Hundreds of drill holes may be required to define the boundaries and evaluate the quality of an orebody. Decreasing the number of drill holes, increasing the drilling rate, or reducing the energy requirements for drilling would have a substantial impact on mineral exploration and development costs. In many situations directional drilling could significantly reduce the number of drill holes required to discover a resource in the ground. Novel drilling technologies, such as down-hole hammers, turbodrills, in-hole drilling motors, and jet drilling systems, have the potential to increase the drilling rate. Novel technologies, together with more efficient rock bits, could also reduce energy requirements for drilling.

Down-hole logging is a standard technique in petroleum exploration. However, it is rarely used in mineral exploration. Standard petroleum well-logging techniques include gamma-ray surveys (to distinguish different rock types based on natural radioactivity), spontaneous potential (to determine the location of shales and zones with saline groundwater), mechanical caliper and dipmeter test (to determine dip and structure of the rock mass penetrated), and a variety of other geophysical tests (resistivity, induction, density, and neutron activation). These tests determine the physical properties of the drilled rock mass and differentiate rock types. Typically, the minerals industry has obtained some of this information by taking samples of rock (either drill chips or drill cores) for analysis. The development of down-hole analytical devices, such as spectrometers, would make it possible to conduct in-situ, real-time analyses of trace elements in the rock mass that could dramatically shorten the time required to determine if a drill hole had “hit” or not. Miniaturization will be necessary for existing down-hole technologies to be used in slimholes.

Drilling and access for drilling generally represent the most invasive aspect of mineral exploration. The environmental impacts of exploration activities could be significantly reduced by the development of drilling technologies that would minimize the footprint of these activities on the ground, such as the miniturization of drilling rigs, the ability to test larger areas from each drill site, and better initial targeting to minimize the number of holes.

Recommendations for Research on Exploration Technologies

Numerous opportunities exist for research and development that would significantly benefit exploration (Table 3-1), many of which involve the application of existing technologies from other fields. Support for technological development, primarily the miniaturization of drilling technologies and analytical tools, could dramatically improve the efficiency of exploration and improve the mining process. Although industry currently supports the development of most new geochemical and geophysical technologies, basic research on the chemistry, biology, and spectral characterization of soils could significantly benefit the mineral industry. Continued government support for spaceborne remote sensing, particularly hyperspectral systems, will be necessary to ensure that this technology reaches a stage at which it could

TABLE 3-1 Opportunities for Research and Technology Development in Exploration

|

Geological Methods • more robust thermodynamic and kinetic geochemical dataa,b • new ore-deposit models, particularly for deposits with less environmental impact when mined • better geohydrological models • geological maps of more mineralized areas • databases for mineralized areas |

|

Geochemical/Geophysical Methods • hand-held and down-hole analytical instrumentsb • cross-bore-hole characterization • better understanding of element mobility in soils • drones for airborne geophysics • low-cost, shallow seismic methods • better intrepretation of hyperspectral data |

|

Drilling Technology • application of existing petroleum and geothermal drilling technologies to minerals sector (directional drilling, better bits, down-hole logging)b • novel drilling techniques (e.g., improvements in slimhole drilling and in-situ measurements) |

|

a Highest priority for this category. b Has applications for other aspects of the mining industries. |

be commercialized. In the field of geological sciences more support for basic science, including geological mapping and geochemical research, would provide significant though gradual improvements in mineral exploration. Filling gaps in fundamental knowledge, including thermodynamic-kinetic data and detailed four-dimensional geological frameworks of ore systems, would provide benefits not only for mineral exploration and development but also for mining and mineral processing. The thermodynamic-kinetic data would lead to a better understanding of how the ore systems evolved through time, how the minerals in the ores and waste rocks will react after exposure to postmining changes in hydrology, and how new processing technologies should be developed. The geological framework of an ore system includes the three-dimensional distribution of rock types and structure, such as faults and fractures, as well as the fourth dimension of time—how the rocks and structures formed. This framework is important to successful exploration, efficient mining, and later reclamation. Focused research on the development of exploration models for “environmentally friendly” ore deposits might yield important results in the short term. A mechanism for focusing research on the most important issues, as identified by industry, would help focus industrial, governmental, and academic resources on these problems.

MINING

Mining can be broadly divided into two categories: surface mining and underground mining. Nonentry mining is associated with in-situ mining and augering. Each type of mining has numerous variations, depending on the combination of deposit type, rock strength, depth, thickness, inclination, roof, and floor strata. The extraction of narrow veins, steeply inclined deposits, and deposits at great depth present significant challenges.

Surface mining, wherever applicable, is more advantageous than underground mining in terms of ore recovery, operational flexibility, productivity, safety, and cost. Currently, almost all nonmetallic minerals (more than 95 percent), most metallic ores (more than 90 percent), and a large fraction of coal (more than 60 percent) are mined by surface methods (Hartman, 1987). However, as surface mineral deposits are exhausted, underground mining will inevitably become more prevalent. In addition, as more easily minable deposits are depleted, mining technology and equipment and mining systems for extracting problematic deposits will have to be developed.

Surface Mining

Surface mining is a generic term describing several methods of mining mineral deposits from the surface, which entails removing the vegetation, top soil, and rock (called overburden materials) above the mineral deposit, removing the deposit, and reclaiming the affected land for postmining land use. The most important factors determining whether surface mining can be done today are economic and technical— the price for the product, the cost of production, the quality and quantity of the deposit, the volume of overburden to be removed per ton of the deposit, and the feasibility of reclamation. The practice of surface mining is quite complex and can involve all or several of the following steps: site preparation, overburden drilling and blasting, loading and hauling overburden (waste), drilling and blasting the deposit, loading and hauling the ore, and reclaiming the site.

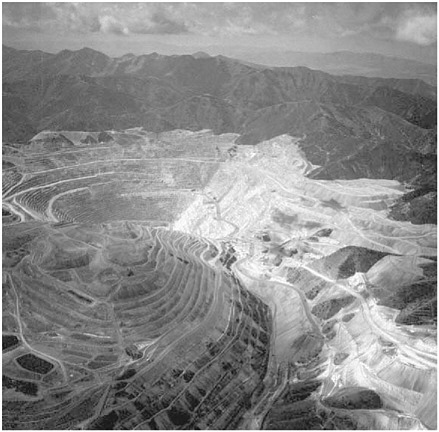

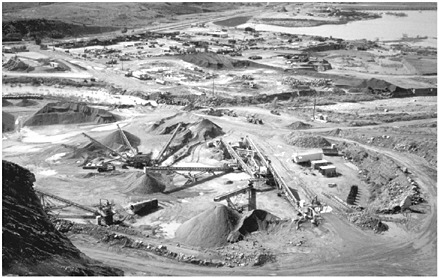

Surface mining methods can be broadly classified as open-pit mining, which includes quarrying, strip mining, contour mining, dredging, and hydraulic mining. Topography and the physical characteristics of the deposit strongly influence the choice of method. In open-pit mining waste is transported to a disposal site, and the ore is transported to a downstream processing site. This method commonly involves a sequence of benches from the surface to the deposit. As the open pit goes deeper into the ground, all of the benches above are extended outward. In appearance, an open-pit excavation resembles an inverted pyramid with its tip in the Earth (Figure 3-3). Large open-pit copper mines can produce up to a million tons of waste and ore per day and can be mined at that rate for decades. Quarrying is similar to open-pit mining except the term is commonly applied to the extraction of dimension stone and aggregates. Fewer benches are required in quarrying than in open-pit metal mining (Figure 3-4); in quarrying, most of the material extracted is marketable. In area-strip mining a trench is dug

through the overburden to expose the deposit, which is then mined. The trench is then widened by removing the overburden from a parallel adjoining cut and placing it in the previous opening where the deposit has been removed. This method is commonly used in places where the topography and the deposit are generally flat. Reclamation is generally concurrent with mining.

Strip mining is commonly used for mining coal seams and phosphate beds. In hilly terrain the mining of the overburden and the deposit (usually a coal seam) follows the contour around the hill and into the hillside up to the economic limits; hence it is called contour mining. In dredging, a suction device (an agitator and a slurry pump) or other mechanical devices are mounted on a floating barge to dig sand, gravel, or other unconsolidated materials under the water and transport them to land. As the material in a location is exhausted, the dredge moves forward, often constructing and carrying its own lake with it to new ground. Hydraulic mining uses water power to fracture and transport a bench of Earth or gravel for further processing. Hydraulic mining is used for placer deposits of gold, tin, and other metals.

Surface mining equipment is similar to construction equipment (e.g., scrapers, bulldozers, drills, shovels, front-end loaders, trucks, cranes, draglines). Surface mining today is characterized by very large equipment (e.g., trucks that can haul more than 300 tons of rock, loading shovels with buckets greater than 36 cubic meters, draglines with buckets greater than 120 cubic meters), and modern technology for planning, designing, monitoring, and controlling operations.

Underground Mining

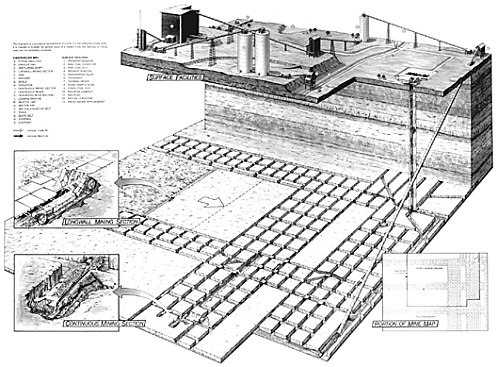

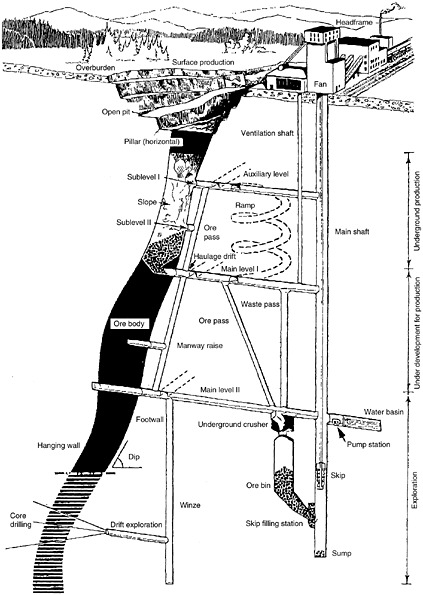

Underground mining is used when the deposit is too deep for surface mining or there is a restriction on the use of the surface land. The deposit is accessed from the surface by vertical shafts, horizontal adits, or inclines (Figure 3-5). The deposit itself is developed by criss-crossing openings (called levels, cross-cuts, raises, etc.) in the orebody, not only to create blocks of ore to be extracted according to a scheme but also to provide for human access, the transport of ore and waste, and adequate ventilation. The drilling, blasting, loading, and transporting of ore from active working areas (faces) are carried out according to a mining plan. If the deposit is soft, such as coal, potash, or salt, mechanical means can be used to cut and load the deposit, thereby eliminating the need

FIGURE 3-5 A conceptual representation of the general layout of a modern mine, the methods of mining, and the technology used. SOURCE: CONSOL, Inc. (now CONSOL Energy, Inc.)

for drilling and blasting. In hard-rock mines carefully planned drilling into the ore and blasting with dynamite or ammonium-nitrate explosives are common. Underground metal-mining methods may be unsupported, supported, and caving methods, and there are numerous variations of each. Open stopes, room-and-pillar, and sublevel stoping methods are the most common unsupported methods; cut-and-fill stoping when the fill is often waste from the mine and mill tailings is the most common method of supported underground mining (Figure 3-6). Because of the high costs associated with supported and unsupported mining methods, open stoping with caving methods is used whenever feasible.

Underground coal mining today is basically done by two methods: room-and-pillar mining with continuous miners, and longwall mining with shearers. The former is essential for developing large blocks of coal for longwall extraction.

FIGURE 3-6 Sample layout of an underground mine, identifying various mining operations and terms. SOURCE: Hustrulid, 1982.

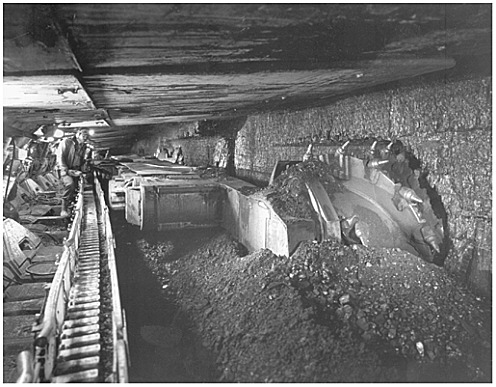

FIGURE 3-7 Photograph of longwall coal mining. SOURCE: CONSOL, Inc. (now CONSOL Energy, Inc.)

The production and productivity of individual, continuous, and longwall production units have increased consistently over the years. In the last two decades longwall mining in the U.S. coal industry has increased from less than 10 percent to nearly 50 percent of the underground tonnage (Fiscor, 1999; NMA, 1999). Currently, about 60 longwall faces produce about 180 million tons of coal per year. However, the production rate depends on the width of the face, the thickness of the seam, and the system for removing the coal from the face.

In longwall mining, operations are concentrated along face from 250 meters to 350 meters wide. The height of extraction is usually the thickness of the coal seam. The length of the longwall block is about 3,000 meters to 5,000 meters. In a 3 meter thick coal seam the amount of coal in place in a block is six to seven million tons. The basic equipment is a shearer (a cutting machine) mounted on a steel conveyor that moves it along the face (Figure 3-7). The conveyor discharges the coal onto a conveyor belt for transport out of the mine. The longwall face crew, the shearer, and the face conveyor are under a continuous canopy of steel created by supports called shields. The shields, face conveyor, and shearer are connected to each other and move in a programmed sequence so that the longwall face is always supported as the shearer continuously cuts the coal in slices about 1 meter thick. The shearer is much like a cheese slicer running back and forth across a block of cheese. Modern longwalls are very capital intensive (the equipment alone costs more than $25 million), highly instrumented and automated, employ fewer than six workers at the face, and produce more than 10,000 tons per shift (more than 5 million tons per year).

Technology Needs

In simple terms mining involves breaking in-situ materials and hauling the broken materials out of the mine, while ensuring the health and safety of miners and the economic viability of the operation. Since the early 1900s, a relentless search has been under way for new and innovative mining technologies that can improve health, safety, and productivity. In recent decades another driver has been a growing awareness of the adverse environmental and ecological impacts of mining. Markers along the trail of mining extraction technology include the invention of the safety lamp, and safe use of dynamite for fragmentation, the safe use of electricity, the development of continuous miners for cutting coal, the invention of rock bolts for ground support, open-pit mining

technology for mining massive low-grade deposits, the introduction of longwall coal mining, and recently in-situ mining and automated mining.

At the turn of the twenty-first century, even as the U.S. mining industry is setting impressive records in underground and surface mine production, productivity, and health and safety in all sectors of the industry (metal, industrial minerals, and coal), the industry still needs more effective and efficient mining technologies. For example, the inability to ascertain the conditions ahead in the mining face impedes rapid advance and creates health and safety hazards. As mining progresses to greater depths the increase in rock stress requires innovative designs for ensuring the short-term and long-term stability of the mine structure. Truly continuous mining will require innovative fragmentation and material-handling systems. In addition, sensing, analyzing, and communicating data and information will become increasingly important. Mining environments also present unique challenges to the design and operation of equipment. Composed of a large number of complex components, mining systems must be extremely reliable. Therefore, innovative maintenance strategies, supported by modern monitoring technologies, will be necessary for increasing the productive operational time of equipment and the mining system as a whole.

Look-Ahead Technologies

Unexpected geological conditions during the mining process can threaten worker safety and may decrease productivity. Geological problems encountered in mining can include local thinning or thickening of the deposit, the loss of the deposit itself, unexpected dikes and faults, and intersections of gas and water reservoirs. Even with detailed advanced exploration at closely spaced intervals, mining operations have been affected by many problems, such as gas outbursts, water inundations, dangerous strata conditions, and severe operational problems, that can result in injuries to personnel, as well as major losses of equipment and decreases in production. Advances in in-ground geophysics could lead to the development of new technologies for predicting geological conditions in advance of the mining face (defined here as look-ahead technology). Three major technology areas are involved in systems that can interrogate the rock mass ahead of a working face: sensor systems, data processing, and visualization. All three areas should be pursued in parallel to effect progress in the development of a usable system.

Research on the development of specific sensors and sensor systems has focused on seismic methods. In underground mining the mining machine (if mining is continuous) can be used as a sound source, and receivers can be placed in arrays just behind the working face. For drilling and blasting operations, either on the surface or underground, blast pulses can be used to interrogate rock adjacent to the rock being moved. However, numerous difficulties have been encountered, even with this relatively straightforward approach. Current seismic systems are not designed to receive and process multiple signals or continuous-wave sources, such as those from the mining machine.

Some projects sponsored by DOE’s Office of Non-Proliferation and National Security have focused on the nature of seismic signals from mining operations to determine whether these signals would interfere with the monitoring of and compliance with the Comprehensive Test Ban Treaty. In another study an NRC panel concluded that controlled blasting methods could generate strong enough signals for analysis and suitable for geotechnical investigations (NRC, 1998b). Other sensing methods that could be explored include electromagnetics and ground-penetrating radar. Combinations of sensing methods should also be explored to maximize the overlaying of multiple data sets.

The second major area that requires additional research is data processing methods for interpreting sensor data. The mining industry has a critical need for processing algorithms that can take advantage of current parallel-processing technologies. Currently, the processing of seismic data can take many hours or days. Real-time turnaround (in minutes) in processing will be necessary for the data to be useful for continuous mining.

The third area of need is data display and visualization, which are closely related to the processing and interpretation of data. The data cannot be quickly assessed unless they are in a form that can be readily reviewed. The need for visualizing data, especially in three dimensions, is not unique to the mining industry. In fact, it is being addressed by many technical communities, especially in numerical analysis and simulation. Ongoing work could be leveraged and extended to meet the needs of the mining industry.

With look-ahead technology unexpected features and events could be detected and avoided or additional engineering measures put in place to prevent injuries and damage to equipment. The economic benefits of anticipating the narrowing or widening of the mined strata or other changes in the geologic nature of the orebody would also be substantial.

Cutting and Fragmentation

Mechanized cutting of rock for underground construction and mining has long been a focus area of technology development (NRC, 1995a). For coal and soft rock, high-production cutting tools and machines have been available for some time and continue to be improved, especially in cutter designs that minimize dust and optimize fragment size for downstream moving and processing. Hardrock presents much more difficult problems. Tunnel-boring machines can cut hardrock at reasonable rates, but the cutters are expensive and wear out rapidly, and the machines require very high thust and specific energy (the quantity of energy required to excavate a unit of volume). In addition, tunnel-boring machines are not mobile enough to follow sharply changing or dipping ore bodies.

Drilling and blasting methods are commonly used to excavate hardrock in both surface and underground mining. Blasting is also used to move large amounts of overburden (blast casting) in some surface mining operations. Improved blasting methods for more precise rock movement and better control of the fragment sizes would reduce the cost of overbreak removal, as well as the cost of downstream processing.

Recommended areas for research and development in cutting and fragmentation are the development of hardrock cutting methods and tools and improved blast designs. Research on the design of more mobile, rapid, and reliable hardrock excavation would benefit both the mining and underground construction industries. Early focus of this research should be on a better understanding of fracture mechanisms in rock so that better cutters can be designed (NRC, 1996b). In addition, preconditioning the rock with water jets, thermal impulses, explosive impulses, or other techniques are promising technologies for weakening rock, which would make subsequent mechanical cutting easier. Novel combinations of preconditioning and cutting should also be investigated. Numerous ideas for the rapid excavation of hard rock were explored in the early 1970s, motivated by the defense community. These concepts should be re-examined in light of technological improvements in the last 20 years that could make some of the concepts more feasible (Conroy et al., 2000).

Improvements in blast design (e.g., computer-simulation-assisted design) would improve perimeter control, casting, and control of fragment size and would result in large energy savings by decreasing the need for downstream crushing and grinding. New methods of explosive tailoring and timing would also have significant benefits. Research into novel applications of blasting technology for the preparation of in-situ rubble beds for processing would help overcome some of the major barriers to the development of large-scale, in-situ processing methods. New developments in micro-explosives that could be pumped into thin fractures and detonated should be explored for their applications to in-situ fracturing and increasing permeability for processing. These methods would also have applications for coal gasification and in-situ leaching.

The development of better and faster rock-cutting and fragmentation methods, especially for applications to hard rock and in-situ mining, would result in dramatic improvements in productivity and would have some ancillary health and environmental risks and benefits. Mechanized, continuous mining operations are recognized as inherently safer than conventional drill-and-blast mining because it requires fewer unit operations, enables faster installation of ground support, and exposes fewer personnel to hazards. Continuous mining methods for underground hard-rock mining would also raise the level of productivity considerably. The environmental risks associated with in-situ mine-bed preparation by injection of explosives or other means of creating permeability will have to be evaluated. This evaluation should include the hazardous effects of unexploded materials or poisonous by-products in the case of chemical generation of permeability. Current thinking is that these risks would not be high relative to the risks of the processing operations used in in-situ mineral extraction (e.g., retorting and leaching).

Ground Control

The planning and design of virtually all elements of a mining system—openings, roadways, pillars, supports, mining method, sequence of extraction, and equipment—are dictated by the geological and geotechnical characterization of the mine site. The objective of ground control is to use site information and the principles of rock mechanics to engineer mine structures for designed purposes. Massive failures of pillars in underground mines, severe coal and rock bursts, open-pit slope failures, and roof and side falls all represent unexpected failures of the system to meet its design standard. These failures often result in loss of lives, equipment, and in some cases large portions of the reserves. Mining-related environmental problems, such as subsidence, slope instability, and impoundment failures, also reflect the need for more attention to the long-term effects of ground control on mine closures and facility construction.

Advances in numerical modeling, seismic monitoring, acoustic tomography, and rock-mass characterization have contributed immensely to the evolution of modern, ground-control design practices. Problems in mine design and rock engineering are complicated by the difficulties of characterizing rock and rock-mass behavior, inhomogenity and anisotropy, fractures, in-situ stresses, induced stress, and groundwater. The increasing scale of mining operations and equipment, coupled with the greater depths of mining and higher extraction rates, will require improved procedures for ground-control design and monitoring and improved prediction systems for operational ground control.

Site-characterization methods for determining the distributions of intact rock properties and the collective properties of the rock mass will require further development of geostatistical methods and their incorporation into design methodologies for ground support (NRC, 1995b). So far, automated monitoring data, such as data from seismic and/or other geophysical monitoring networks, have not been successfully integrated into the design of mine structures. In addition, ground-support elements, such as rock bolts, could be installed at selected locations and instrumented to monitor stress, support loads, and conditions (to determine maintenance intervals) to validate ground-support designs. With rapid advances in mathematics and numerical modeling, research should focus on approaches, such as real-time analysis and interrogation of data with three-dimensional models. In addition, the heterogeneity of rock strata and the diverse processes acting on the mine system (e.g., geologic, hydrologic, mechanical, and engineering processes) should

be considered through stochastic and coupled-system modeling. The technology development advocated for look-ahead technologies should also be beneficial for assessing stability in the immediate vicinity of mining.

The failure of ground control has been a perpetual source of safety and environmental concern. Establishing and adopting better engineering approaches, analytical methods, and design methodologies, along with the other characterization technologies described above, would considerably reduce risks from ground-control failures and provide a safer working environment.

Materials Handling

The design and proper operation of clearance systems for transporting mined materials from the point of mining to processing locations are critical for enhancing production. In many cases the system for loading and hauling the mineral is not truly continuous. Belt and slurry transportation systems have provided continuous haulage in some mining systems. Longwall systems in underground mines, bucket-wheel excavator systems in surface mines, and mobile crushers hooked to conveyor belts in crushed-stone quarries are successful steps in the development of a continuous materials-handling system. Even in these systems haulage is regarded as one of the weakest components. In most cases, both in underground and surface mining, the loading and hauling functions are performed cyclically with loaders and haulers.

The major problem in the development of continuous haulage for underground mining is maneuvering around corners. To increase productivity a truly continuous haulage system will have to advance with the advancing cutter-loader. If the strata conditions require regular support of the roof as mining advances, the support function must also be addressed simultaneously. Therefore, research should also focus on automated roof bolting and integration with the cutting and hauling functions.

The increasing size of loaders and haulers in both surface and underground mines has increased productivity. However, larger equipment is associated with several health and safety hazards from reduced operator visibility. Research should, therefore, focus on advanced technology development for integrating location sensors, obstacle-detection sensors, travel-protection devices, communication tools, and automatic controls.

Reducing the amount of material hauled from underground mines by clearly identifying the waste and ore components at the mine face would result in both energy and cost savings, as well as a reduction in the amount of waste generated. It might even lead to leaving the subgrade material in place through selective mining. For this purpose the development of ore-grade analyzers to quantify the metal and mineral contents in the rock faces would be extremely useful. The ore-grade analyzer must have both real-time analysis and communication capability so operations could be adjusted. Similarly, in surface mines the down-hole analysis of ore in blast holes could lead to more efficient materials handling by identifying ore and waste constituents.

Equally important to improving the performance of materials-handling machinery will be the development of new technologies for monitoring equipment status and for specific automation needs. In addition, for underground applications the interruption of the line of sight with satellites and thus the impossibility of using the GPS means a totally new technology will have to be developed for machine positioning.

Transporting ore for processing can take considerable time and energy and can contribute significantly to the overall cost of production in both surface and underground mining operations. An area for exploratory research should be downstream processing while the ore is being transported. For certain processes transport by conveyer-belt systems and hydraulic transport through pipelines would allow for some processing before the ore reaches the final process mills. Physical separation processes, such as those outlined later in this report, and leaching with certain chemical agents are the most likely processes that could be integrated with transport.

The initial transport of materials is currently done by powered vehicles. In underground mining the use of diesel-powered loading and hauling equipment presents both safety and health challenges. Electric equipment has similar disadvantages, even though it is cleaner and requires less ventilation, because power transmission and cabling for highly mobile equipment complicates operations. Equipment powered from clean, onboard energy sources would alleviate many of these health and safety problems. Research could focus on powering heavy equipment with alternative energy sources, such as new-generation battery technology, compressed air, or novel fuel-cell technology. The development of such technologies may have mixed results from an environmental standpoint. On the one hand, a reduction in the use of fossil fuels would have obvious benefits in terms of reduced atmospheric emissions. On the other hand, the manufacturing and eventual disposal of new types of batteries or fuel could have environmental impacts.

Mining Systems

The industry needs improved overall mining systems. Alternative systems may bear no resemblance to existing systems, although they may be innovative adaptations of the productive components of existing systems (e.g., the deployment of rapid mine-development procedures, truly continuous mining methods, continuous haulage systems, more effective ventilation procedures, and rapid isolation techniques to enhance health, safety, productivity, and resource recovery). From technological and management perspectives several characteristics of a mineral enterprise must be taken into account. Each mineral deposit has unique geological features (e.g., location and physical,

mineralogical, chemical characteristics) that have overriding influence on technical and economic decisions. For example, the environment of an underground mine is totally enclosed by surrounding rock. Because mine development is an intensive cash-outflow activity, the current long lead times must be decreased through new technologies.

The problem of low recovery from underground mines is well documented. In underground coal mining the overall recovery in the United States averages about 55 percent; average recovery from longwall mines is about 70 percent (Hartman, 1987). Technology for mining thin coal seams (less than 1 meter thick), particularly thin-seam longwall technology, would be beneficial. In view of the extreme difficulties for workers in such a constricted environment the technology for thin-seam longwalls must include as much automation, remote control, and autonomous operation as possible. Successful longwall and continuous coal mining technology might be adapted to the mining of other laminar-metallic and nonmetallic deposits. Potential problems to be overcome will include the hardness of the ore, the rock conditions and behavior, and the abrasive nature of the mined materials.

Underground mining of thick coal seams (more than 6 meters thick) also presents numerous problems. Current practice is to extract only the best portion of the seam with available equipment. In some cases coal recoveries have been as low as 10 percent. In addition to the sterilization of the resources this practice has created problems of heating and fire. Research should focus on equipment and methods specific to mining thick seams. Hydraulic mining may have potential applications for thick seams. The technical feasibility of hydraulic mining is well established, but equipment and systems that can operate in more diverse conditions will have to be developed. Like the mining of thick coal seams, other mining methods also leave a relatively high percentage of the resource in the ground. Therefore, research could focus on secondary recovery methods (i.e., returning to mined areas to extract resources still in the ground). The petroleum industry has successfully developed secondary recovery methods; steam, carbon dioxide, and water flooding are commonly used to drive oil to the wellheads.

In-situ mining (discussed in more detail later in this chapter) has been remarkably successful for several metallic and nonmetallic deposits. The application of this technique to the secondary recovery of mineral resources is another area for research. Extensive trials on in-situ gasification of coal have been conducted by a number of agencies worldwide, including DOE and the former USBM. In-situ mining has also been attempted for retorting oil shale. The potential benefits of the in-situ gasification of energy resources include reduction of mine development and mining and more efficient use of resources that are otherwise not economical to mine (Avasthi and Singleton, 1983). However, substantial technical problems, including such environmental issues as groundwater contamination, must first be addressed.

A long-standing need of the hardrock mining industry is continuous mining. Currently, only tunnel-boring machines and some prototype road headers have been shown to be capable of mining hardrock. The use of tunnel-boring machines in some mining operations has been limited because they are not very mobile, are difficult to steer, and are completely inflexible in terms of the shape of the mine opening. Tunnel-boring machines are being used more often for mine entry, as in the development of a palladium-platinum mine in Montana. Prototype mobile mining equipment for hardrock was demonstrated in Australia, but production rates were lower than expected, and numerous failures occurred. The solution to this problem will depend largely on the development of advanced cutting technology for hard rock, as well as ways of incorporating new cutting concepts into a mining system that would provide efficient continuous mining with a lower thrust requirement and maximum flexibility. New control systems might incorporate sensor feedback from the cutting head so machine parameters could be adjusted for maximum efficiency. Similar concepts are currently being used in the hydrocarbon drilling industry.

Mining systems that make a clear break with present systems, such as the chemical and biological mining of coal, should also be investigated. In-situ chemical comminution might be possible if the solid coal could be reduced to fragments by treatment with surface-active compounds, such as liquid or gaseous ammonia, and transported to the surface as a suspension in an inert gas. The literature on the biosolubilization of coal and the aerobic and anaerobic conversion of coal by microorganisms and enzymes has been evolving for some time (Catcheside and Ralph, 1997). Biodegradation of coal macromolecules could potentially convert coal carbons to specific, low-molecular-mass products. Research will be necessary to determine the basic mechanisms, as well as to develop conceptual schemes that would make biodegradation cost effective. For all in-situ mining concepts the obvious environmental benefits of limiting surface disturbances and waste generation must be weighed against the potential of adverse impacts on groundwater quality during operation of the mine and upon its closure. Research on chemical or biological mining of coal must also include evaluations of environmental risks posed by reagents and process intermediates.

Improved Machine Performance

Mining depends heavily on mechanical, motor-driven machinery for almost every aspect of the process, from initial extraction to transport to processing. Improving the performance of machinery (thus reducing down time), increasing the efficiency of operation, and lowering maintenance costs would greatly increase productivity. The development and application of better maintenance strategies and more advanced automation methods are two means of improving machine performance.

In recent years new concepts of providing maintenance

for large fleets of vehicles, especially vehicles in remote or difficult-to-access areas, have emerged primarily as a result of research sponsored by the U.S. Department of Defense (DOD) and equipment manufacturers. Mining operations are also often conducted in remote locations where access to spare parts and large maintenance facilities may be difficult. Current research has focused on the development of sensor systems that can be incorporated into large vehicles and heavy machinery to monitor continuously the “state of the health” of the vehicle. When problems are detected, the vehicle monitoring system can transmit data directly to a monitoring station at a large repair facility where the problem can be diagnosed, and repair packages can be prepared and shipped to the field before the equipment actually fails. Additional research into sensors, software, and communications could focus on adapting this concept to a variety of mining situations. Leveraging ongoing DOD programs could have substantial payoffs in terms of reduced down time, reduced volume of spare parts stored on site, and lower repair costs.

Better automation and control systems for mining equipment could also lead to large gains in productivity. Some equipment manufacturers are already incorporating human-assisted control systems in newer equipment, and improvements in man-machine interfaces are being made. Additional research should focus on alternatives, however, such as more autonomous vehicles that have both sensor capability and sufficient processing power to accomplish fairly complex tasks without human intervention. Tasks include haulage and mining in areas that are too dangerous for human miners. Semiautonomous control methods should also be explored, such as “fly-by-wire” systems in which the operator’s actions do not directly control the vehicle but give directions to a computer, which then decides how to accomplish the action. A good example of this technology is currently being used in large construction cranes; the motion of the crane to move a load from one location to another is controlled by the operator through a computer, which controls the rate of movement of the crane in such a way as to minimize the swing of the load. This technology has considerably improved safety, speeded up cycle time, and enhanced energy conservation in the motion of the crane.

Recommendations

Substantial research and development opportunities could be explored in support of both surface and underground mining. The entire mining system, including rock fracturing, material handling, ground support, equipment utilization, and maintenance, would benefit from research and development in four key areas:

-

fracture, fragmentation, and cutting, with the goal of achieving truly continuous mining in hardrock as is done with coal

-

small, inexpensive sensors and sensor systems for mechanical, chemical, and hydrological applications

-

data processing and visualization methods (especially taking advantage of advanced, parallel-computing architecture and methods) that would provide real-time feedback

-

automation and control systems (especially for mining equipment used in hazardous areas).

The above four areas represent a very broad summary of technology advances that would greatly enhance productivity and safety in mining. A more detailed breakdown is provided in Table 3-2.

IN-SITU MINING

In-situ mining is the “removal of the valuable components of a mineral deposit without physical extraction of the rock” (Bates and Jackson, 1987). In-situ leaching is a type of in-situ mining in which metals or minerals are leached from rocks by aqueous solutions, a hydrometallurgical process (American Geological Institute, 1997). In-situ leaching has been successfully used to extract uranium from permeable sandstones in Texas, Wyoming, and Nebraska, and in-situ leaching of copper has been successfully demonstrated in underground copper mines in Arizona, where prior mining has created sufficient permeability for leaching solutions (lixiviants) to contact ore minerals (Bartlett, 1992, 1998; Coyne and Hiskey, 1989; Schlitt and Hiskey, 1981; Schlitt and Shock, 1979). As used in this report the term in-situ mining includes variations that involve some physical extraction.

In-situ leaching involves the injection of a lixiviant, such as bicarbonate-rich, oxidizing water (with added gaseous oxygen or hydrogen peroxide) in the case of uranium, into the ground to dissolve the metal. The metal is then recovered from the solution pumped to surface-treatment facilities. In-situ leaching technologies are based on geology, geochemistry, solution chemistry, process engineering, chemical engineering, hydrology, rock mechanics and rubblization, and petroleum engineering (Wadsworth, 1983).

Related extraction techniques, herein lumped into the broad category of in-situ mining, include: (1) extraction of water-soluble salts (e.g., halite mined to produce caverns in salt domes in Gulf Coast states); (2) brine extraction (pumping of brines to the surface to remove valuable, naturally dissolved materials, such as lithium in Clayton Valley, Nevada, and zinc from geothermal brines in the Salton Sea in California); (3) sulfur extraction using the Frasch process (wherein hot, high-pressure water is injected to melt sulfur, which is then pumped to the surface, as in west Texas and off-shore Louisiana); (4) bore-hole mining (whereby material is removed by breaking rocks with water jets or other techniques and pumping a slurry of water and broken rock to the surface, an experimental process that was tested on

TABLE 3-2 Opportunities for Research and Development in Mining

|

Look-Ahead Technologies • seismic methods and alternatives, such as electromagnetics and ground-penetrating radar • combinations of sensing methods to provide wider ranges of application and better resolution • processing algorithms that take advantage of current parallel-processing technologies to provide real-time visualization ahead of the mine face • visualization of data extended to suit the particular needs of the mining application • ore-grade analyzers to quantify metal and mineral contents • down-hole analysis with analyzers for ore and waste interfaces |

|

Cutting and Fragmentation • cutter designs that optimize fragment size to minimize dust, move materials, and minimize processing • hardrock cutting methods and tools with lower thrust requirements • improved blasting methods for better control of fragment sizes and more precise rock movement • improved explosive tailoring and timing • blasting technology for the preparation of in-situ rubble beds |

|

Ground Control • procedures for ground-control design and effective monitoring and prediction systems for operational ground control • field characterization to determine properties of intact rock and the collective properties of the rock mass • integration of the automatically monitored data (such as data from a seismic and/or other geophysical data acquisition network) into the design of mine structures • approaches to facilitate real-time analysis and interrogation of data with 3-D models • modeling methods that address stochastic features and coupled systems |

|

Materials Handling • a truly continuous haulage system that advances with the cutter-loader • automated roof bolting that can be integrated with the cutting and hauling functions • advanced technology for the integration of location sensors, obstacle-detection sensors, travel-protection devices, automatic controls, and communication tools • technologies for monitoring the operational status of autonomous operations • methods of achieving downstream processing while ore is being transported • alternative energy sources, such as new-generation battery technology, compressed air, and novel fuel-cell technology |

|

Mining Systems • innovative mine development schemes to reduce lead times and enhance recovery rates • mining technology—equipment and mining systems—for problematical deposits (e.g., technology for mining thin coal seams, particularly thin-seam longwall mining, and equipment and methods for mining thick coal seams) • adaptation of longwall and continuous coal mining technology to the mining of other laminar metallic and nonmetallic deposits • continuous hardrock mining with new cutting concepts incorporated into a continuous mining system • in-situ gasification of energy resources to address technical problems and environmental issues • exploration of chemical and biological mining of coal to determine basic mechanisms and develop mining-system concepts • secondary recovery methods for mining |

|

Improved Machine Performance • development of sensors, software, and communications for mining situations • new alternatives for man-machine interfaces • semiautonomous control methods, such as “fly-by-wire” systems • more autonomous vehicles that can perform complex tasks without human intervention or oversight |

phosphate rock in Florida, uranium-rich sandstones in Wyoming, and bituminous sands in California); and (5) in-situ gasification of coal and in-situ retorting of oil shale (described in the previous section on mining).

In-situ leaching has many environmental advantages over conventional mining because it generates less waste material and causes less surface disturbance (no mill tailings, overburden removal, or waste-rock piles). The major environmental concern is postmining water quality. For example, in the case of uranium, concentrations of uranium and its associated radioactive daughter products and, in some cases, potentially toxic elements, such as arsenic and selenium, could be elevated. Site reclamation has been successful at several south Texas sites where in-situ leaching of uranium was first undertaken in the 1970s. In-situ uranium leaching also has advantages in terms of health and safety because the leaching process selectively removes uranium and leaves most of the dangerous radioactive daughter products in the

ground. In addition, little heavy machinery is required to remove the large volumes of rock that would have been processed in a conventional mining operation.

With in-situ leaching low-grade uranium deposits (with approximately 0.1 percent U3O8) can be mined; these grades are considerably lower than typical grades in the unconformity-type uranium deposits currently mined in Saskatchewan, Canada (with grades on the order of 4 to 20 percent U3O8 [Dennis Stover, vice president, engineering and project development, Rio Algom Mining Corporation, personal communication, June 14, 2000]).

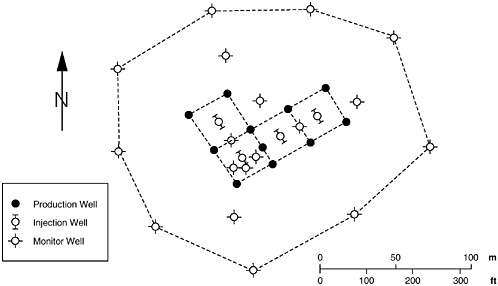

In-situ leaching of uranium typically involves the development of a well field with five-spot injection and production wells (Figure 3-8), four production wells on the corners of a square, and one injection well in the center. Monitor wells, used to monitor fluid flow and containment, are distributed around the periphery of the injection-production well field. Because development of the mine depends heavily on drilling and completion of the well field, improvements in drilling efficiencies (faster and cheaper drilling) would clearly increase the productivity of in-situ mining. With directional drilling, particularly when coupled with sensors on or near the drill bits and controls on water pressures along the length of horizontal segments of holes, lixiviants could be placed more directly in contact with ores (in the middle of the ore bodies).

In-situ leaching of uranium is currently limited to low-grade deposits in highly permeable (hundreds to thousands of millidarcies), essentially horizontal sandstones. Well completions are similar to water wells, with casings perforated in the permeable, ore-bearing aquifers. The use of polyvinyl chloride casing, which is considerably cheaper than steel or stainless steel casing, currently limits depths of economical drilling to within 270 meters of the surface (Dennis Stover, vice president, engineering and project development, Rio Algom Mining Corporation, personal communication, June 14, 2000). The development of inexpensive casing that could withstand higher pressures would expand the resource base to include known deposits at greater depths.

Noninvasive techniques (techniques that do not require drilling holes into the ground) that detect hydrologic inhomogeneities, such as clay lenses that are barriers to fluid flow in sandstones and that determine hydrologic properties (transmissivity, permeability) would greatly improve hydrogeologic modeling and well-field design. Cross-borehole tomography (e.g., three-dimensional seismic or other geophysical imaging similar to magnetic resonance imaging in medicine) is one promising technology. Increased computational speed and greater storage capacity would also improve hydrogeological modeling. Well-field operations can be further improved with the development of in-stream chemical sensors for the major constituents (lixiviants, elements being mined, and elements of environmental concern, such as arsenic, selenium, molybdenum, and vanadium in the case of sandstone uranium deposits).

Thus far in-situ leaching in pristine formations (where the rock matrix has not been modified prior to leaching) has been economically successful only in the highly permeable

FIGURE 3-8 The design of an in-situ well field in Highland Mine, Wyoming. The drawing shows the locations of wells used to inject lixivants, wells from which uranium-rich solution is pumped (production wells), and wells used to monitor fluid flow and containment. SOURCE: Adapted from Staub et al., 1986.

sandstones in which some uranium ores are found. Although lixiviants are available to leach various copper oxide and copper sulfide minerals, attempts at in-situ leaching of copper in pristine formations have not been very successful because the lixiviants have not been able to adequately contact the ore minerals in the rock. At the San Manuel in-situ operation in Arizona, recovery rates from caved areas already mined have been on the order of only 50 percent over five years (Sharon Young, consultant, Versitech, Inc., personal communication, June 14 2000). The most successful in-situ copper leaching has been in ore bodies that had been previously mined; after the high-grade ores were removed open stopes remained with rubble of lower grade wall rock that could be contacted by lixiviants. New technologies for the in-situ fracturing or rubblization of rocks could be extremely beneficial. Increasing permeability in the rocks to allow lixiviants to contact ore minerals is the biggest challenge for the in-situ leaching of metals. One promising approach to increasing permeability, as has been done for copper, is to rubblize rock during conventional mining, thereby taking advantage of the open spaces already created.

Lixiviants are available for leaching not only uranium and copper but also gold, lead, and manganese, to name a few. Nevertheless, cheaper, faster reacting lixiviants would increase production and could also increase the number of metals that could be considered for in-situ leaching. At the same time, lixiviants that suppress the dissolution of undesirable elements, such as arsenic and selenium, which have geochemistries that are significantly different from uranium, would be helpful, as would additives that lower concentrations of those elements during reclamation. Better thermodynamic and kinetic data on important solid phases and aqueous species would facilitate the search for better lixiviants and additives to promote the precipitation or adsorption of undesirable elements. Confinement of lixiviants and mobilized metals to the mining area is another major challenge.

Bore-hole mining has much the same appeal as in-situ leaching because it also tends to minimize the surface footprint of the operation. The biggest challenge for bore-hole mining is the development of tools that can break or cut and remove rock tens of meters beyond the well bores. Various technologies can be envisioned for accomplishing this task; some, such as flexible cutters that can move out from the bore hole in various directions, may require the development of other tools, such as sensors that can distinguish ore from waste rock.

Recommendations for In-Situ Mining Technologies

Many areas offer opportunities for research and technology development in in-situ mining and related approaches to direct extraction (Table 3-3). The chief hurdle to using in-situ leaching for mining more types of mineral deposits is permeability of the ore. The uranium deposits for which in-situ leaching has been successful were located

TABLE 3-3 Opportunities for Research and Technology Development in In-Situ Mining

|

In-Situ Well-Field Operations • rock-fracturing and rubblization techniquesa,b • directional drillingb • more efficient drillingb • casing for depths below 270 meters • hydrogeologic modelingb • tomography between bore holesb • sensors for monitoring groundwater and operational controlsb • new mining technologies for increasing permeability for in-situ leaching, particularly of base metals |

|

Bore-Hole Excavation • extending of rock fracturing or cutting to tens of meters beyond well boresb • sensors for assaying samples without removing themb |

|

Hydrometallurgical Advances • development of lixiviants and microbiological agentsa,b • suppression of undesirable elements in solutionb • additives that precipitate or enhance adsorption of elements of concern during restoration of groundwater qualityb • thermodynamic and kinetic datab |

|

aHigh priority. bTechnologies with applications in other areas of mining and other businesses, such as environmental restoration of metal-contaminated sites. |

in exceptionally permeable sandstones. However, ore minerals in the most permeable parts of rock formations are unusual; many metallic ores and industrial-mineral deposits are not highly permeable. Technologies that could fracture and rubblize ore in such a way that fluids would preferentially flow through the orebody and dissolve ore-bearing minerals (although this would be difficult in competent rocks with high compressive strengths) are, therefore, a high priority need for in-situ mining.

For some commodities, such as phosphate rock and coal, removal through bore-hole mining of the entire rock mass without dissolving specific minerals may be an alternate approach. New technologies that would extend rock fracturing and cutting to tens of meters beyond well bores, while maintaining control of the direction of cutting to stay within the orebody or coal seam and avoid removing waste rock, would make bore-hole mining more attractive.

Key environmental and health concerns raised by in-situ leaching are the possibility of potentially toxic elements being brought to the surface or mobilized into groundwater. For example, selenium, arsenic, molybdenum, and radioactive daughter products of uranium are concerns in mining sandstone-type uranium deposits. Therefore, the committee also rates as a high priority development of lixiviants and microbiological agents that can selectively dissolve the desired elements and leave the undesired elements in the rock.

The closure of in-situ leaching facilities raises an additional environmental concern, especially in the copper industry where large-scale in-situ leaching of oxide ore bodies