5

Research Opportunities in Environmental Technologies

INTRODUCTION

Chapter 3 identified technologies that would benefit major components of the mining industry in the areas of exploration, mining, and processing. Environmental risks and benefits of some of the technologies discussed in Chapter 3 were also addressed there. This chapter describes research opportunities and technologies that would lessen the environmental impacts of mining.

The creation of large-scale surface disturbances, the generation of large volumes of waste materials, and the exposure of previously buried geologic materials to the forces of oxidation and precipitation are intrinsic to the mining industry and may continue to present complex environmental problems even when the best available practices are conscientiously followed (Chiaro and Joklik, 1998). Even with all of the recent advances in environmental protection, the mining industry still cannot completely and effectively predict, prevent, or treat releases from mine sites during and after operations.

Technologies that predict, prevent, mitigate, or treat environmental problems will be increasingly important to the economic viability of the mining industry. With new and effective environmental technologies new mining operations may be permitted that might otherwise have been rejected because of unacceptable environmental risks. New technologies may also result in reduced costs for environmental compliance and facility closures. Improved environmental technologies related to mine closures have the greatest potential for increasing overall productivity and reducing overall energy consumption because costs of long-term maintenance will be factored into the analysis. Closure procedures usually affect the quality of drainage water from the mine and thus, productive use of the land. Long-term (in perpetuity) treatment of drainage water from mines now requires capitalization by interest-bearing funds. Today, perpetual treatment or maintenance often appear to be economically preferable to expensive permanent treatments. Future technologies that would allow “walk-away” closures by preventing drainage problems would have obvious environmental and economic benefits. Moreover, permanent solutions prevent problems from becoming exacerbated over time rather than simply managing their impacts. The industry now generally recognizes that planning for closure must begin when the mine is in the planning phase.

RESEARCH OPPORTUNITIES AND TECHNOLOGY AREAS

The mining of coal, base and precious metals, and industrial minerals raises several environmental issues. Some are common to all mining sectors; others are specific to one sector or even to one commodity within a sector (Sidebar 5-1). The differences may be attributable to differences in the geologic settings in which the materials are found, differences in the regulatory regimes under which they are mined, and/ or differences in production processes. For example, environmental planning in surface coal mines and surface areas of underground coal mines must meet the performance standards of the Surface Mining Control and Reclamation Act of 1977, which has established standards for closure and reclamation.

Even before the federal law was passed, several coal-mining states, particularly in the eastern United States, had long-standing, mining-specific legislation requiring the reclamation of disturbed lands. As a result of this long history of mandated standards, industry and governmental agencies have made considerable efforts to address the problems specified by the regulations, specifically air quality, water quality, land use, and noise. Industrial-minerals operations in close proximity to communities have been subject to local zoning regulations, which has had a major influence on planning, including environmental planning. Even if the problems facing all mining sectors are similar (e.g., lakes in the final pit, tailing ponds, and waste and spoil piles), the

|

SIDEBAR 5-1 Phosphogypsum Disposal of phosphogypsum is a special problem. The production of phosphate generates 5 tons of phosphogypsum for every ton of phosphate product manufactured. In Florida alone nearly a billion tons of phosphogypsum have been generated. This by-product is generated when phosphoric acid is manufactured using sulfuric acid, an inexpensive reagent. The resulting phosphogypsum must be managed as a waste. Other acids could be used to manufacture phosphoric acid; however, the by-products of these processes are an insoluble calcium salt, which also raises disposal issues. Although potential uses for phosphogypsum have been identified, its use is prohibited by the Environmental Protection Agency because of the presence of radium at a concentration greater than 10 picocuries per gram present in Florida phosphogypsum. Potential uses of phosphogypsum include material for road bases, agricultural fertilizer to supply sulfur and calcium, and a supplement in landfills and sewage treatment plants to enhance the microbial decomposition of organic waste. Research to identify or develop uses for phosphogypsum that contains radium could reduce the amount of material that must be managed as waste, as well as limit its potential environmental impact. Research should also focus on the development of a phosphate manufacturing technology that does not produce phosphogypsum as a by-product. |

magnitude and severity of the problems, and the applicable solutions may not be. Nevertheless, all mining sectors would benefit from new technologies to reduce or eliminate adverse environmental impacts caused by mining operations.

Water-quality issues related to mine closures are often the most challenging and costly to address for all types of mining. They also present significant opportunities for research that could increase overall productivity. New technologies for managing other materials of environmental concern, such as innovative, cost-effective solutions to managing slimes, could also increase productivity in the mining industry.

Acid-Rock Drainage1

The most common water-quality problem associated with metal and coal mining is the release of metals, acidity, and sulfate from reactive rock surfaces, particularly when pyrite is present (University of California, 1988). Sulfide-containing rock is oxidized when newly fractured rock comes in contact with oxygen, water, and (very often) bacteria. The sulfides are converted to sulfuric acid, which in turn can mobilize a variety of metals (Alpers and Blowes, 1994; Doyle and Mirza, 1990). The most common metals released are iron, copper, zinc, cadmium, manganese, arsenic, antimony, lead, nickel, and mercury. The concentrations of metals vary dramatically with the type of deposit and the environmental factors surrounding the site. The pH of the water can also vary, depending on the amount and type of sulfide minerals oxidized, as well as the amount of neutralization capacity present in the rock. Highly acid-generating rock produces a drainage pH of less than 1; well buffered-rock (e.g., rock that contains calcite or dolomite) may have elevated sulfate concentrations indicative of sulfide oxidation but still retain a near-neutral pH. Metal concentrations, and thus the environmental and health impact of drainage water, depend on the pH. Low pH water (high acidity) has much higher concentrations of metals than near-neutral pH water (low acidity). Some potentially toxic elements, such as selenium and arsenic, are problematic at any pH.

Acid generation is an issue of concern for certain types of coal and hardrock mines (particularly mines that contain high concentrations of pyrite but low concentrations of pH-buffering materials). Problems are most common for reactive waste-rock dumps, although tailings and waste facilities, low-grade ore piles, highwalls, and precious-metal heaps can also generate acids under specialized conditions. Acidic drainage into receiving waters can result in severe impacts to the biological integrity of a stream and can change a diverse, healthy biological system into one in which only less-susceptible organisms can thrive or one devoid of higher organisms.

Prior to planning a mining operation, the potential for acid generation is generally estimated based on cores, drill cuttings, and bulk samples used to characterize the orebody. The characterization of acid-generation potential is critical for constructing waste dumps in a way that minimizes the release of contaminants by oxidation of sulfidic rock. For sites where acid generation is a potential problem, characterization of the rock for contaminant release should be conducted concurrent with characterization of the ore potential. Common tests for acid-drainage potential include acid-base accounting and humidity-cell tests. Both

|

1 |

Additional information on acid drainage can be obtained from Webbased information sources, including the Acid Drainage Technology Initiative (www.mt.blm.gov/bdo/adti), the International Network for Acid Prevention (www.inap.com.au/inap/homepage.nsf), and the Mine Environment Neutral Drainage (MEND) program (mend2000.nrcan.gc.ca). |

methods can underestimate or overestimate acid generation, and continuing research would help to improve the predictions. Predictive tests of acid-rock drainage can be inaccurate if the samples tested do not adequately represent the material that will ultimately be placed on the waste-rock pile or heap. Therefore, careful characterization of the ore and waste rocks is essential.

The preferred technique for managing acid drainage is prevention, which can be effected by several existing methods (Blowes et al., 1995; Lawrence, 1996), including avoidance of acid-generating rock, the addition of inhibitors of microbial oxidation, encapsulation of acid-generating rock in the center of a waste-rock dump that contains mostly neutralizing rock, and the placement of acid-generating rock under water to prevent the rapid transfer of oxygen to reactive surfaces (Steffan et al., 1989). Although each of these techniques has been demonstrated in specialized circumstances, none can be applied in all cases.

The most common method of treating acid drainage is lime precipitation (Kleinmann, 1997). Lime is added to the acidic water and aerated to oxidize soluble ferrous iron to ferric iron, which then precipitates as iron oxide or oxyhydroxide. As the pH is raised, other metal oxides can also be precipitated. The technology for lime treatment of acid drainage, which is reasonably mature and widely utilized, requires the continuous delivery of lime. Unfortunately, the process also generates a calcium-sulfate/iron-oxide sludge that, depending on the concentration of metals and acidity, can pose significant problems. Even if the chemical composition of the sludge is not a concern, this large volume of material can be very difficult to handle.

Other methods of treating acidic drainage, including direct electrowinning of concentrated waste solutions to remove certain metals (an emerging technology), reverse osmosis, and ion-exchange technologies, can be used under certain conditions although at present, few of them can compete with lime precipitation. Because acid management is a significant problem in many mines, additional cost-effective methods for treating these fluids are very much needed. For example, if new regulations stipulate that sulfate must be below 500 mg/L, lime precipitation will not be effective. Processes that recover contaminants in a form that can be beneficially used would be particularly attractive.

One promising option that could be used either alone or in combination with lime precipitation is sulfate-reducing bioreactors (Kleinmann and Hedin, 1993; Lawrence, 1998). For this treatment an acclimated biological reactor is fed a variety of alcohols, sugars, other organic substrates, or hydrogen to supply reducing equivalents for the bacteria, which are usually a Desulfovibrio species. Sulfate is reduced to hydrogen sulfide, which then precipitates divalent metals as metal sulfides. Like lime precipitation, this treatment creates a sludge (metal sulfides) that is reactive and must be managed to keep it in a chemically reduced state. If the metal sulfides are allowed to reoxidize, the resulting sulfuric acid and metals can again be released. Bioreactors have been used successfully in a variety of pilot plants, as well as for low-volume (1–50 L/min) flows from acidic seeps. The cost of this option can be either competitive or less expensive than lime precipitation because bioreactors can be operated without electricity, and gravity is used for flow systems.

Passivation technologies that can coat pyrite surfaces to prevent oxidation are also under development. At least three patented methods of passivation are being evaluated. The alkaline-permanganate treatment involves rinsing pyrite surfaces with a potassium permanganate solution at pH >12 (Marshall et al., 1998). This technology was developed by the DuPont Corporation and recently donated to the University of Nevada. The permanganate oxidizes the pyrite and immediately lays down a mixed iron-oxide/manganese-dioxide coating that is remarkably stable. The silica microencapsulation technology of KEECO utilizes an alkaline solution of silicate to cover the reactive pyrite surfaces (Mitchell et al., 2000). The Envirobond treatment uses a separate proprietary process to form a stable, insoluble compound with pyrite surfaces (Gobla et al., 2000). Phosphate coating uses a soluble form of phosphate that coprecipitates with iron oxide to form a stable surface coating on the pyrite. In silicate coating, basic solutions of silicates are allowed to cover pyrite and form a stable silicate surface on the reactive rock. Further development will be necessary to determine how long any of these methods will last, as well as the costs of treatment and, if necessary, retreatment. The economic viability of these methods is still unproven and will have to be compared to continuous treatments in terms of environmental impact and long-term stability.

Closure and Reclamation of Dump-Leaching and Heap-Leaching Operations and Tailings Impoundments

Upon the cessation of production, dump-leaching and heap-leaching piles and tailings impoundments must be closed in an environmentally sound manner. In the basemetal and precious-metal mining sectors and in some types of industrial-minerals operations these piles and tailings can present potential environmental risks. Depending on the chemical characteristics of the wastes and reagents used, as well as on atmospheric precipitation rates, piles and tailings may contribute poor-quality seepage or runoff to surface and/ or groundwater through the release of residual solution or from infiltration of or contact with atmospheric precipitation. The released solution may be acidic (as discussed above) or may contain cyanide or other contaminants, such as selenium, sulfates, radionuclides, or total dissolved solids. Waste piles are also subject to erosion, which potentially contributes sediments directly to surface waters. Over time, erosion may lead to structural instability and potential catastrophic failure. Moreover, waste piles remain as unproduc-tive disturbances on the land unless the land is reclaimed for postmining use.

Mining facilities currently address the closure of dump-leaching and hepa-leaching sites in a number of ways. Diversions are used to prevent run-on of precipitation. In the gold industry, heaps are rinsed or fluids recirculated until cyanide in the effluent is reduced to an acceptable level. Spent ore and tailings may be recontoured to limit erosion and enhance long-term structural stability. Cover material may be placed on the surfaces both to inhibit infiltration (and thereby limit leaching) and to provide a medium for plant growth. Alternatively, wastes may be directly vegetated with the addition of soil amendments. In the last decade a number of facilities have run cattle-feeding operations on closed tailings impoundments to create a soil and promote plant growth.

Although existing technologies have been successful, each has limitations. Diversion structures require periodic maintenance to continue to function effectively. Rinsing is typically effective for cyanide, but if contact with air and water is not limited, sulfidic waste materials can continue to oxidize and release contaminants through infiltration of precipitation and subsequent leaching. Covering with soil is a proven technique for revegetation but is only practical if soil is readily available. If no soil was salvaged prior to construction (e.g., at older sites that predated a regulatory requirement of stripping and stockpiling soil for future reclamation), providing a soil cover for a heap or tailings impoundment often requires the creation of an additional disturbance. Moreover, the excavation and placement of large volumes of soil can be costly. A more serious problem, however, is that, regardless of the effectiveness of soil cover as a plant-growth medium, it may not effectively eliminate long-term acid generation and leaching of contaminants.

Ideally, closure technologies for dumps, heaps, and tailings impoundments must be cost effective, require little or no maintenance, limit or reduce the infiltration of precipitation as necessary to control seepage, and must be capable of supporting diverse vegetation. Designs for covers or caps on mine wastes should maximize evapotranspiration in areas of limited precipitation. In areas where precipitation exceeds evaporation cover technologies must seal the surface of mine wastes to prevent the continued oxidation of sulfides and the infiltration of water. Techniques that establish and maintain chemically reducing conditions and thereby immobilize metals should also be investigated. Techniques for the insitu destruction of cyanide mine wastes should be researched to reduce the time and fresh water required to decommission precious-metals heap-leaching facilities.

Pit Lakes

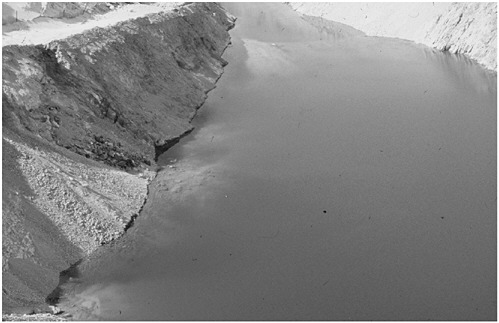

Open-pit mines that penetrate the water table are “dewatered” to maintain dry working conditions during their operational life. (Underground mines commonly require dewatering as well, but postmining recovery generally returns the groundwater to nearly the same conditions as before mining.) When operations cease and pumping stops, the pit begins to fill (Figure 5-1). The quality of the pit water and

FIGURE 5-1 Photograph of pit lake. SOURCE: Glenn Miller.

its potential for adverse impacts on the environment depend on the pit geology and geochemistry, area hydrogeology, and the presence of exit pathways for the pit water. Sulfide materials in the pit walls and floor of base-metal and precious-metal mines begin to oxidize during the mine’s operational phase. As the water level rises in the pit and contacts these areas, the acid generated by this oxidation may lower the pH of the pit lake (see above discussion of acid rock drainage). Although the acidification of the pit water can be severe, the rate of oxidation of wall rock decreases once a pit fills with water and the sulfides are no longer exposed to oxygen.

If the acidity and metal levels of the resulting pit lake are not neutralized and buffered by alkaline minerals within the pit, they may pose a threat to the health and safety of humans and wildlife. The rising pit water may encounter other permeable strata or old underground mine workings that may provide conduits for the poor-quality water to enter other aquifers, which can result in discharges to surface drainages.

Existing technologies to address the issue of pit lakes include predictive modeling, in-situ treatment by lime addition, and continued dewatering of the pit to prevent it from filling with poor-quality water. The accuracy of currently available models in estimating the quality of pit lakes is limited by the lack of data necessary to characterize the complex geology and hydrology typically encountered in mineralized regions, as well as uncertainties in predicting the acid-generation potential of sulfide materials (as discussed above with respect to acid rock drainage) (NRC, 1999b). Current models, therefore, can significantly overestimate or underestimate the occurrence or severity of problems. Research to increase the understanding of the complex hydrology of mines may also help to minimize dewatering requirements.

The addition of lime to acidic pit lakes has successfully returned the water to a neutral pH and reduced metal concentrations. This technology is costly, however, especially for large pits with highly acidic water. Continued pumping of groundwater after operations cease eliminates the formation of a poor-quality pit lake but requires a perpetual, not necessarily productive use of energy and groundwater. In addition, it assumes that the resources (e.g., equipment, labor, finances) will remain available indefinitely. Even then, the oxidation of sulfide materials continues as long as the pit remains dry, which eventually results in more severe acidic conditions in the pit lake if pumping is eventually terminated and the pit fills with water.

The industry needs better and less expensive methods to ensure that the acid and metal contents of pit lakes do not threaten humans and wildlife. With more accurate predictive models for final pit lake quality potential problems could be identified during the mine planning process. If the potential for acid generation within the pit is significant, technologies that can reduce or eliminate the oxidation of sulfides in pit walls and floors would be extremely helpful. Cost-effective technologies are also needed for the treatment of acidic and contaminated pit waters at sites that have already experienced this problem.

Treatment of Nonacidic Waters

Some nonacidic aqueous discharges from metal and industrial-mineral mining operations require treatment to remove certain constituents before the water can be discharged into a stream or lake. Dewatering operations frequently generate very large flows that must be treated to meet rigorous discharge standards. The treatment for these high-volume discharges, which contain low concentrations of certain metals, such as arsenic and selenium, is coprecipitation of the metals with ferric iron followed by filtration to remove the precipitated metals. Although low levels of arsenic can be effectively removed by this technique, low concentrations of selenium are more difficult to remove by coprecipitation. The removal problem is exacerbated if the solution has other constituents that interfere with the selenium-removal chemistry. Treatment by reverse osmosis, a technology with high capital and operating costs, is sometimes necessary.

Some states also have rigorous discharge standards for nitrate. Mine dewatering products sometimes become contaminated with nitrate as a result of contact with blasting agents, and this water must be treated before discharge. Technology for nitrate removal is limited. Biological nitrate reduction often used in other industries has limitations. Water pumped from mines is often cold, which slows the biological reactions, and is usually devoid of the nutrients required for biological activity. This necessitates the addition of expensive food sources for the bacteria.

Tailings are usually managed by evaporation; however, occasionally overflow from tailings dams must be treated before discharge. In gold mining, cyanide recovery or destruction and metals removal are required. Cyanide recovery, which may be desirable because of the high cost of this reagent, is possible using technology based on a sequence of steps involving acidification, stripping, adsorption, and neutralization. Cyanide and metal-cyanide complexes can be destroyed with hydrogen peroxide, Caro’s acid, sulfur dioxide, or by biological means. Following the chemical distruction of cyanide, metals can be precipitated by lime treatment (discussed earlier). When biological treatment is used for cyanide degradation, the resulting nitrate is reduced to gaseous di-nitrogen, and the metals can be removed from the water by binding to the micro-organisms attached to rotating biological contactors.

Better treatment technologies for the effective removal of low concentrations of certain metals, particularly selenium, from large volumes of solution to meet stringent discharge standards, and for efficient cost-effective nitrate removal from aqueous discharges, would be extremely useful.

Slurry Management

Large volumes of water slurries containing fine particles are produced by all types of mining facilities. The management of these slurries as they are dewatered and disposed of can present significant environmental issues. In addition to the potential chemical concerns previously discussed with regard to closure and reclamation, management of these materials can present challenging physical problems.

Whether slurries are produced as tailings from milling operations, spoils in coal mining, or as clay slimes in the phosphate industry, they are often slow and difficult to dewater and dry because of their colloidal nature. The large amount of water tied up with these materials can compromise the structural stability of the units used for their management and disposal, and this situation can be exacerbated by continued precipitation. Although safety factors are routinely included in the engineering design of units that manage these wastes, periodic structural failures continue to occur.

Slime management in the phosphate industry is particularly difficult. Despite years of research few advances have been made in the dewatering and drying of these wastes. When sand is available, it can be mixed with the clay, and the mixture discharged into impoundments. These sand/clay impoundments eventually dry and become suitable for pastureland, but the sites are not suitable for construction. In addition, mixing clay slimes with sand is a limited option because sand is not always available.

Research to alleviate these problems should promote the rapid dewatering of mine slurries. Research should also focus on ways to ensure that the disposal units for slurried mine wastes remain structurally stable throughout their operational life and beyond. For slimes in the phosphate industry, the development of an economical method of removing water from the clays at the washer circuit and consolidating the clays rapidly would accelerate the return of slimes-management areas to productive use and might increase the options for postmining uses of these areas.

Methane Gas

Methane gas, inherently associated with coal beds, is released as the coal is mined. Methane is a greenhouse gas that contributes to global warming. Some mines capture the gas in methane drainage systems, but these systems on average recover only about 50 percent of the methane evolved in the mines. In mines containing less methane the majority of the methane is released to the mine ventilation system and emitted to the atmosphere in dilute concentrations with the ventilation exhaust (Kruger, 1994).

Research is needed on better methods of collecting methane in drainage systems in the mine, as well as methods of using the low concentrations of methane in the mine return air. In addition to reducing emissions of greenhouse gases advances in these areas would have the health and safety

TABLE 5-1 Opportunities for Research and Technology Development for Environmental Protection

|

Acid Rock Drainage • identification of potential acid-generating materials • prevention of acid generation (encapsulation of wastes, passivation) • treatment of acidic wastewater |

|

Closure of Dump-Leaching and Heap-Leaching Operations and Tailings Impoundments • cover technologies to promote evapotranspiration, inhibit infiltration, and/or immobilize metals • in-situ destruction of cyanide • alternatives to current production and management of phosphogypsum |

|

Pit Lakes • improved predictive modeling • techniques to eliminate or reduce acid generation in pit walls and floors • treatment technologies for acidic pit water |

|

Treatment of Nonacidic Waters • removal of low concentrations of metals from large volumes of wastewater • removal of nitrate from wastewater |

|

Slurry Management • cost-effective methods of dewatering and consolidating slimes • methods to ensure the long-term stability of disposal units |

|

Methane • improved methods of methane drainage collection and recovery of diluted methane from mine ventilation exhaust |

|

Fine Particulates (PM2.5) • control of emissions of fine particulates |

benefit of limiting dangerous conditions in mines and the economic benefit of producing a valuable commodity.

Fine Particulate Matter (PM 2.5)

Federal air-quality regulations limit the concentration of fine particulate matter (2.5 microns or less) in ambient air (PM 2.5). Although particulates in this size range are emitted from all types of mining operations, industrial-mineral facilities may have the most difficulty meeting this standard partly because they are frequently in urban locations and lack sufficient buffer areas around their mines. The entire mining industry would benefit from control technologies to limit these emissions to acceptable regulatory levels.

RECOMMENDATIONS

The greatest environmental benefits for the mining industry would be derived primarily from advances in the protection of surface and groundwater quality (Table 5-1). Accurate,

real-time methods of characterizing the potential of waste materials to generate acid rock drainage would enable operators to identify potential problems before they develop. Research should focus on improving techniques for managing these wastes to prevent acid generation, including biologic and physicochemical passivation methods to inhibit the oxidation of sulfide materials. Research could also focus on further development and optimization of treatment technologies for acid rock drainage, such as biologic reduction, as well as acid rock drainage associated with the pit lakes.

Techniques to improve the long-term environmental stability of closed dump-leaching and heap-leaching operations and tailings impoundments are also areas for additional research. The industry particularly needs improved cover technologies that can enhance evapotranspiration in areas of low precipitation, prevent infiltration of precipitation in areas where recharge to mine-waste materials is significant, and/or maintain reducing conditions in order to immobilize metals. The mining industry may also benefit from research being conducted on impermeable caps and other technologies to prevent the release of toxic materials from hazardous and municipal wastes. Research on the in-situ destruction of cyanide could lead to quicker, less water-consumptive methods for closures of precious-metals heap-leaching facilities. Alternatives to the current generation and management of phosphogypsum would also be beneficial.

Although much of the recommended research involves acid rock drainage, other areas for fruitful research are improving technologies for managing nonacidic wastewaters, including effective, low-cost techniques for removing low concentrations of metals, such as selenium, from large volume flows and for removing nitrates from wastewater discharges. The dewatering of phosphate slimes and other slurried mine wastes, as well as the long-term stability of disposal units for these wastes, could also be an area for future research. Development of better techniques for methane recovery from underground coal mines would provide environmental, health and safety, and economic benefits. Research is also needed on technologies to control emissions of fine particulates.

In many respects the technology needs identified in this chapter either represent incremental advances or practical developments of known technologies or build on techniques already known and understood to some degree. The committee believes that research into areas beyond our current understanding, and which may now appear to be infeasible, could lead to innovative solutions to environmental problems facing the mining industry (Sidebar 5-2).

|

SIDEBAR 5-2 Blue Sky Ideas for Research on Environmental Issues • Economical recovery of metallic constituents from acid rock drainage releases, including methods of recovering iron sulfides in a form that could be used as a soil acidifier in agriculture. Technologies that could turn costly waste-treatment projects into economically viable production activities would have significant benefits in terms of resource conservation and waste minimization, in addition to the clear economic benefit of creating a secure and dedicated funding source for the remediation of acid rock drainage releases problems. • Sealing of pit walls to prevent the oxidation of sulfides and the formation of acidic pit lakes. Open-pit mine walls at or above the water level of a pit lake can continue to oxidize and adversely affect the quality of pit water if they contain unbuffered sulfide minerals. Significant technical barriers must be overcome to devise a cost-effective way to seal these rock faces and prevent their long-term oxidation. • Sealing of in-situ mineralized zones to prevent the inflow of groundwater and allow in-situ leaching and complete recovery of solutions without continuous pumping to maintain a cone of depression. The migration of metal-rich leaching solutions beyond the mineralized zone of an in-situ orebody and into the surrounding aquifer is currently controlled by continuous pumping of the groundwater to create and maintain a cone of depression around the operation. The cost of this dewatering activity, as well as the use of the water resource, could be eliminated if the mineralized zone could be sealed in place. Better control of the leaching solution would also provide a significant environmental benefit. • Remote sensing of groundwater quality throughout the operating life of a mine and during the closure and postclosure periods. Groundwater-monitoring programs at mine sites can involve large numbers of wells, require thousands of samples and analyses, and last for decades. Techniques for direct, down-hole measurements and data logging could significantly reduce the cost and human resources requirements of monitoring. • Effective, inexpensive technology for removing low concentrations of contaminants (e.g., selenium, arsenic) from high-flow volumes of water. The cost-effective recovery of low concentrations of potentially toxic large flows would have significant economic and environmental benefits. • Techniques for rapidly developing soils on mine wastes, heaps, and tailings. The direct vegetation of mine wastes, without a soil cover or amendments designed to create a suitable growth medium, may foster some plant growth but can result in the establishment of a monoculture that cannot support complex ecosystems. Research should be conducted to develop cost-effective techniques for creating soil that can support a diverse plant community directly from mine waste. |