Page 10

2

A Compelling Case for the Integration of Commercial and Military Manufacturing

Several factors point to a compelling need for DOD to adopt ICMM as a routine way of doing business for the production and life-cycle support of DOD weapons system components, assemblies, and subsystems. Key factors are the importance of sustaining technological superiority, a declining production base for new weapons, and advantageous trends in the commercial manufacturing sector.

Today, military decision makers are unsure of who our future enemies will be, as well as when, where, and under what environments and rules of engagement future conflicts will take place. To respond to these uncertainties, a flexible and responsive industrial base will be critical. Our military decision makers today are trapped in an acquisition strategy that depends on an industrial base that cannot respond quickly enough to meet the demand for new and modified military systems expected to result from the stepped-up tempo of future military operations. Rapid and reliable access to the products and services of the commercial industrial base and use of commercial practices could make acquisition more responsive to the current environment. A robust implementation of ICMM can change our military acquisition capability from one of long cycle times producing technological marvels whose need and costs have to be predicted 15 to 20 years in advance to a capability that flexibly responds to changing threats.

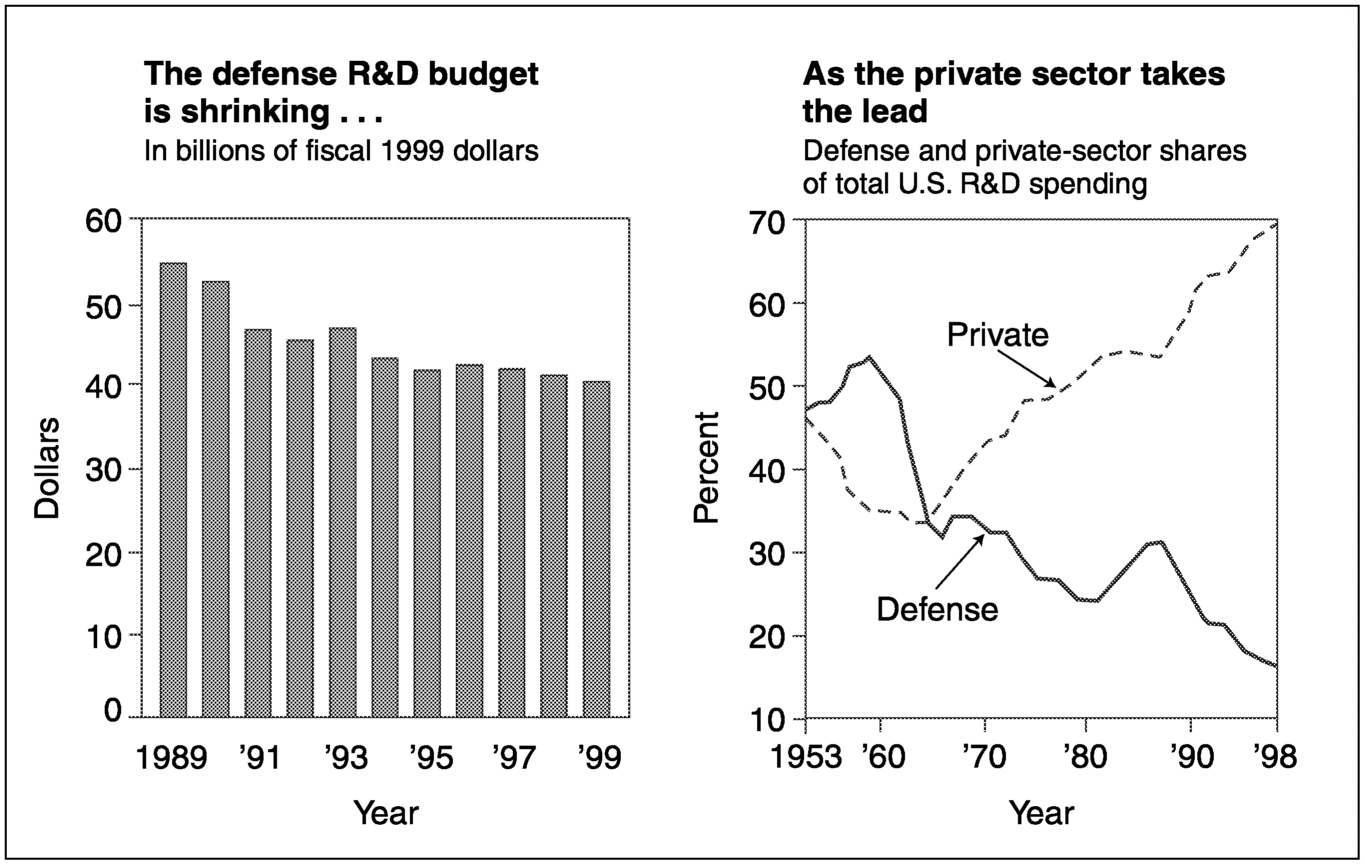

Technological superiority underpins our military strategy. Today, however, the commercial sector leads the military industrial sector in developing and adopting new technology, particularly for electronics components. The overall lead of the commercial sector is illustrated in Figure 2-1.

Page 11

FIGURE 2-1 Defense vs. private R&D funding. From USD(AT&L) (2001), which assembled data from many sources. The sources here are the U.S. Office of Management and Budget and the National Science Foundation.

Furthermore, our current and potential adversaries have ready access to most commercially available technology-based products, and it is impossible to control the export and diffusion of critical new technologies that feed emerging global commercial markets. In the long range, for example, such new technologies as microelectromechanical devices (MEMS) will emerge from the global commercial industry, and by 2010 the military must be ready to exploit the power of this type of technological advancement ahead of our adversaries. A recent Defense Science Board report on the technology capabilities of non-DOD providers (DOD, 2000a) recognizes the need for DOD to find and acquire commercial technology and to increase its acquisition of technical assistance from sources outside DOD and traditional defense contractors. In limited cases, export controls can slow the movement of these technologies outside our borders, but they cannot stop it.

One clear solution to this military parity issue is for DOD to have direct access to commercial technologies and to adopt them much more quickly than our adversaries. The committee believes that adoption of ICMM as an industrial base strategy can significantly increase the pace of technology insertion and help to sustain technology superiority. Just as the military has become almost totally dependent on the commercial sector for microcircuits, its greater use in future

Page 12

commercial integrated electronic subsystems does not threaten the stability of the military industrial complex. Rather, ICMM is a winning strategy for the military if we can master the issues associated with reducing the lead time to introduce new and updated systems.

The potential for ICMM to benefit life-cycle support of military systems is equally compelling. Military budget constraints through 2010 will severely limit the number and production rate of new platforms (aircraft, ground systems, and ships). Aging military systems and the obsolescence of subsystems and parts will be increasingly common. Subsystem upgrades will solve some of the obsolescence problems and provide new military capabilities. However, even with a robust upgrade program, without ICMM it is unlikely that the military can keep pace with the electronics technology being introduced by the commercial sector on a new product cycle as short as 9 months but not more than 3 years. The commercial industry, driven by competitive pressures, successfully deals with this modernization issue every day, taking a total value perspective. Frequently, commercial products are modernized by either rapid introduction of new models or insertion of product upgrades that are compatible in form, fit, and function. For example, an advanced disk drive for a microcomputer can now be inserted in a plug-and-play environment. In many cases, military systems can be designed in this way. One effort to promote this design approach is the modular open systems architecture (MOSA), promoted by DOD's Open Systems Joint Task Force.

A commercial modernization strategy can be adopted by the military by assigning the defense prime contractors total product responsibility, including product support. The contractors and their commercial subcontractors would be responsible for replacing a product (subsystem) if it fails. During replacement, the contractor could choose to modernize components, if improved parts are available, on a form-fit-function basis. This strategy has been successfully implemented on a few military systems and subsystems (see Chapter 3), and wider adoption of this life-cycle support concept through the use of the commercial manufacturing base can give the military reliable, high-quality systems for the entire life cycle at lower cost.

Some segments of commercial industry are changing to take advantage of contract manufacturing. This is a growing industrial sector, particularly in electronics manufacturing, where the pace of technology advances is rapid and the interdependence of product technologies and manufacturing processes is high (Miscioscia and Libin, 2000). Contract electronics manufacturing is a high-growth sector that is expanding from a build-to-print model to a capability that integrates product design, manufacturing, and product support. DOD contractors are beginning to use these specialized electronics manufacturers, but only to a very limited extent.

A single business model obviously does not fit all of the situations the committee studied. Examples of commercial manufacturing of military electronics include Rockwell-Collins, where a single process concept has been imple

Page 13

mented for design and production of both military and commercial electronic systems in common facilities; 1 M/A-COM, which produces both military and commercial microwave integrated circuits using common processes and facilities; 2 and SCI, a commercial electronic manufacturing service (EMS) company that produces large volumes of commercial electronics assemblies and systems as well as some military products using common processes. 3

Expanded use could be made of contract manufacturers as a new source of competition based on a new model for military electronics design and production. Also, DOD could significantly benefit from access to short-production-cycle capabilities inherent in these specialized manufacturers, the continuing technology refreshment demanded by the commercial marketplace, and the benefits of commercial-scale learning curves that provide reliable, high-quality, competitively priced products.

Finally, expanded adoption of ICMM can lead to significant cost savings. Several examples of implemented ICMM, particularly for electronic systems, clearly demonstrate the potential for very impressive cost savings, sometimes of 50 percent or more. While the examples are not extensive, the cost savings analyses are credible and of such magnitude that profit-on-profit 4 concerns related to the subcontracted work are not significant. While cost savings and the resulting affordability of new systems provide a strong case for ICMM, the more compelling arguments are those regarding technology superiority and access to a flexible and responsive industrial base.

In summary, it is essential that our military be equipped with the latest technology and that the technology be superior to that of our potential adversaries. Further, the unique systems integration capability of the U.S. defense industry can be enhanced through aggressive adoption of ICMM, which will be well worth the sustained commitment of management this adoption will require.

Some military-unique products and technologies cannot be produced by the commercial sector, and a few should not be, due to the need for assured access and security. These exceptions are usually developed through DOD R&D activities, and the ability to acquire these products and technologies while preventing their dissemination to our adversaries must be maintained.

1HermReininga, Rockwell-Collins, Dual Production Experience at Rockwell-Collins, presentation to the committee on January 26, 2001.

2 Jim Fallon and Joe Thomas, M/A-COM, A Common Manufacturing Base for Dual-Use Applications, presentation to the committee on January 25, 2001.

3Steve Werner and Jerry Thomas, SCI Systems, Circuit Board Manufacturing, presentation to the committee on January 25, 2001.

4Profit-on-profit refers to a prime contractor earning a percentage of profit on profit earned by a subcontractor.