APPENDIX F

COST-EFFECTIVENESS OF MOBILE SOURCE NON-CMAQ CONTROL MEASURES METHODOLOGICAL ISSUES AND SUMMARY OF RECENT RESULTS

Michael Q. Wang, Center for Transportation Research, Argonne National Laboratory

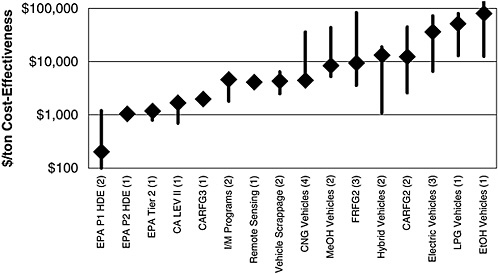

Government agencies and private organizations often use cost-effectiveness, calculated in dollars per ton of emissions reduced, to determine which control measures should be implemented to meet overall emission reduction requirements for a given region. Different studies may, however, yield significantly different, sometimes contradictory, cost-effectiveness results for the same control measures. The results differ because studies might use different calculation methodologies or make different assumptions about the values of costs and emission reductions. In 1997, the author conducted a study to examine some of the methodological issues involved in calculating the cost-effectiveness of mobile source control measures. In that study, ways were proposed to deal with such methodological issues as using user costs or societal costs, using costs at the manufacturer or the consumer level, determining baseline emissions, using emission reductions in nonattainment or in both nonattainment and attainment areas, using annual or pollution-season emission reductions, considering multiple-pollutant emission reductions, and applying emission discounting.

The Transportation Research Board (TRB) of the National Research Council commissioned the author to conduct a study to reexamine mobile source control cost-effectiveness. Findings of this commissioned study are presented. In particular, mobile source control measures adopted for the near future in the United States were evaluated. Among them are the following:

-

The California low-emission vehicle (LEV) II program,

-

The federal Tier 2 light-duty vehicle (LDV) emission standards,

-

The federal Phase 1 heavy-duty engine (HDE) emission standards,

-

The federal Phase 2 HDE emission standards,

-

The California Phase 2 reformulated gasoline (RFG),

-

The California Phase 3 RFG,

-

The federal Phase 2 RFG,

-

Alternative-fueled vehicles (AFVs) [including vehicles fueled with compressed natural gas (CNG), liquefied petroleum gas (LPG), ethanol (EtOH), methanol (MeOH), and electricity],

-

Hybrid electric vehicles (HEVs),

-

Inspection and maintenance (I&M) programs,

-

Old vehicle scrappage programs, and

-

Remote sensing programs of detecting and reducing vehicular emissions.

The conclusion is that except for AFVs, these control measures generally have emission control costs below $10,000 per ton of emissions reduced.

INTRODUCTION

Motor vehicle emissions contribute significantly to urban air pollution problems in the United States. Consequently, control measures ranging from vehicle emission standards to measures of controlling travel demand have been adopted or proposed to help solve U.S. air pollution problems. Among the many programs of reducing mobile source emissions, the U.S. Congress established the Congestion Mitigation and Air Quality Improvement (CMAQ) Program to reduce traffic congestion and improve air quality.

The CMAQ program was designed to provide federal financial support to local areas to introduce control strategies primarily related to transportation demand-side management. With direction from Congress, TRB established a CMAQ evaluation committee to examine the effectiveness of the CMAQ program. The evaluation committee commissioned the author to evaluate the cost-effectiveness of non-CMAQ mobile source control measures. Findings of the commissioned study are documented in this report.

The scope of the study was limited to summarizing and reconciling the results of past studies on mobile source emission control cost-

effectiveness; cost-effectiveness estimates were not conducted by the author. There are two reasons. First, different studies use different methodologies and parametric assumptions concerning control costs and emission reductions for given measures. Though these differences undoubtedly reflect the uncertain nature of the given measures, they also reflect institutional positions on methodological issues. A particular study by this author, however objective, would certainly not cover the wide spectrum of various institutional positions. Second, it was initially thought that the conducting of new control cost estimates by the author could be more time- and resource-consuming than summary and reconciliation of completed studies. However, the path with the original study scope actually showed that the latter approach has been more time- and resource-consuming.

Mainly because of regulatory requirements, various government agencies have been conducting cost-effectiveness analyses for emission control programs. In theory, agencies should use the results of cost-effectiveness analyses to determine which control measures should be adopted for achieving given air quality goals. On the other hand, private organizations have been calculating cost-effectiveness in counterbalancing governmental agencies’ results and positions. There is no formal protocol for governments and industries to follow in conducting cost-effectiveness estimates. Different studies may use different methodologies and different assumptions concerning the values of costs and emission reductions, and they may consequently yield significantly different control cost results. Although an attempt is made to reconcile differences in cost-effectiveness methodologies among studies, parametric differences concerning costs and emission reductions between studies are essentially left intact. In this way, results from various studies are converted into the same or a similar methodological basis, but the results of an individual study are maintained by keeping that study’s parametric assumptions. If parametric assumptions in completed studies were changed to reflect this author’s beliefs, the results from those studies would essentially be those of this author, not those of the original investigators.

This report is organized in six sections. In the first, the mobile source control measures that were evaluated in this study are presented. The key methodological issues involved in calculating mobile

source cost-effectiveness are discussed in the second, and ways to deal with these issues are proposed. In the third section, cost-effectiveness results from studies completed in the past several years are summarized, and the adjustments to be applied in this study to the original studies to make results of past studies comparable are presented. Control cost-effectiveness of the mobile source control measures evaluated in this study are then summarized. General conclusions concerning mobile source emission control cost-effectiveness are presented in the fifth section. In the last section, an appendix to the main body of this report, stationary source control cost-effectiveness is summarized as a way to put mobile source cost-effectiveness results into perspective.

NON-CMAQ MOBILE SOURCE CONTROL MEASURES INCLUDED IN THIS STUDY

The 1990 Clean Air Act Amendments (CAAA) specified control measures to reduce mobile source emissions. In particular, the CAAA directed the U.S. Environmental Protection Agency (EPA) to establish new, stringent vehicle emission standards, establish fuel (gasoline and diesel) quality standards, require use of alternative transportation fuels, and implement other control measures such as vehicle I&M programs. Because of the CAAA, various mobile source control measures have been adopted and proposed. Table F-1 summarizes mobile source control measures already in place or to be in place soon.

Control measures in Table F-1 that have already been implemented include the following:

-

The federal Tier 1 LDV emission standards,

-

The California LEV I program,

-

The federal oxygenated fuel requirement,

-

The California Phase 1 RFG,

-

The California Phase 2 RFG,

-

The California low-sulfur (LS) diesel requirement,

-

The federal Phase 1 RFG,

-

The federal Phase 2 RFG, and

-

The federal LS diesel requirement.

TABLE F-1 Mobile Source Emission Control Measures in Place or to Be in Place

|

Control Measure |

Targeted Pollutants for Reductionsa |

Implementation Year |

Remark |

|

Vehicle Emission Standards |

|

|

|

|

Federal Tier 1 LDV standards |

HC, CO, NOx, and PM |

1994–1996 |

49 states |

|

Federal Tier 2 LDV standards |

HC, CO, NOx, and PM |

2006–2009 |

49 states |

|

Federal Phase 1 HDE standards |

NOx and PM |

2004 |

Nationwide |

|

Federal Phase 2 HDE standards |

NOx and PM |

2007 |

Nationwide |

|

CA LEV I program |

HC, CO, NOx, and PM |

1996 |

CA, MA, NY |

|

CA LEV II program |

HC, CO, NOx, and PM |

2003 |

CA, NY |

|

Fuel Quality Standards |

|

|

|

|

Oxygenated fuels |

CO |

1992 |

Some states |

|

CA Phase 1 RFG |

HC, CO, NOx, and air toxics |

1991 |

CA |

|

CA Phase 2 RFG |

HC, CO, NOx, and air toxics |

1996 |

CA |

|

CA Phase 3 RFG |

HC, CO, NOx, and air toxics |

2003 |

CA |

|

CA low-sulfur diesel |

HC, CO, NOx, and SOx |

1993 |

CA |

|

Federal Phase 1 RFG |

HC, CO, NOx, and air toxics |

1996 |

Some areas |

|

Federal Phase 2 RFG |

HC, CO, NOx, and air toxics |

2000 |

Some areas |

|

Federal low-sulfur gasoline |

HC, CO, NOx, PM, and SOx |

2004–2006 |

49 states |

|

Federal low-sulfur diesel |

HC, CO, NOx, and SOx |

1993 |

49 states |

|

Other Control Measures |

|

|

|

|

Use of alternative fuels |

HC, CO, NOx, PM, SOx, and air toxics |

Varied |

Some areas |

|

I&M programs |

HC, CO, and NOx |

Varied |

Some areas |

|

Remote sensing programs |

HC, CO, and NOx |

Proposed |

Some areas |

|

Old vehicle scrappage |

HC, CO, and NOx |

Varied |

Some areas |

|

Gasoline station Stage II control |

HC |

Varied |

Some areas |

|

Note: LDV = light-duty vehicle; HDE = heavy-duty engine; LEV = low-emission vehicle; RFG = reformulated gasoline; I&M = inspection and maintenance; HC = hydrocarbon; CO = carbon monoxide; NOx = nitrogen oxides; PM = particulate matter; SOx = sulfur oxides. a These are pollutants targeted by a given program. In some cases, a program reduces emissions of other pollutants besides the targeted pollutants. |

|||

Consequently, these measures have become part of the baseline control measures for evaluating new control measures such as CMAQ measures. Thus, these control measures are not, or are less, relevant to the evaluation of CMAQ measures. On the other hand, some measures in Table F-1 are not yet implemented. Furthermore, even though some of the measures are already implemented, their use could be expanded to other regions. Both groups could compete with

CMAQ measures to achieve emission reductions. They are evaluated in this study. Table F-2 presents the control measures selected for evaluation in this study. Each of these measures is discussed below.

California LEV I Program

In 1990, the California Air Resources Board (CARB) adopted the LEV program for the state of California. In 1999, CARB adopted a new LEV program. To differentiate the two programs, the 1990 and 1999 programs are now referred to as the LEV I and LEV II programs, respectively. Because the LEV I program was fully implemented in 1996, it is already part of the baseline control measures. It is presented here to put the LEV II program into perspective.

TABLE F-2 Non-CMAQ Control Measures Selected in This Study and the Nature of Their Impacts

|

|

Travel Response |

Congestion Mitigation |

Emission Reduction |

|

Vehicle emission standards |

|

|

|

|

CA LEV II program |

No |

No |

Yes |

|

Federal Tier 2 LDV standards |

No |

No |

Yes |

|

Federal Phase 1 HDE standards |

No |

No |

Yes |

|

Federal Phase 2 HDE standards |

No |

No |

Yes |

|

Clean conventional fuels |

|

|

|

|

CARFG2 |

Smalla |

No |

Yes |

|

CARFG3 |

Smalla |

No |

Yes |

|

FRFG2 |

Smalla |

No |

Yes |

|

Alternative-fueled or advanced vehicles |

|

|

|

|

Ethanol vehicles |

Smalla |

No |

Yes |

|

Methanol vehicles |

Smalla |

No |

|

|

LPG vehicles |

Smalla |

No |

Yes |

|

CNG vehicles |

Smalla |

No |

Yes |

|

Hybrid electric vehicles |

Smalla |

No |

|

|

Electric vehicles |

Smalla |

No |

Yes |

|

I&M programs |

No |

No |

Yes |

|

Old vehicle scrappage |

Smalla |

No |

Yes |

|

Remote sensing programs |

No |

No |

Yes |

|

a Differences in fuel prices caused by these measures may result in increased or decreased operating costs of motor vehicles, which may cause changes in travel. However, the changes induced by fuel prices are probably small, and virtually all studies ignored such changes in travel. |

|||

Four vehicle types were established under the LEV I program for the purpose of emission regulations: transitional low-emission vehicles (TLEVs), LEVs, ultra-low-emission vehicles (ULEVs), and zero-emission vehicles (ZEVs). Table F-3 presents emission standards for each LEV type. The LEV I program began to take effect in 1994. Together with LEV type-specific standards, the LEV I program established fleet average nonmethane organic gas (NMOG) standards and ZEV sales requirements for individual model years to control the sales mix of these vehicle types. Later, some states in the Northeast adopted part of the LEV I program.

California LEV II Program

In 1999, CARB adopted the LEV II program with more stringent vehicle emission standards and tightened vehicle grouping for emission regulation. Table F-4 presents emission standards under the LEV II program. Relative to the LEV I program, the LEV II program establishes stringent oxides of nitrogen (NOx) emission standards to achieve large NOx emission reductions (see Tables F-3 and F-4). The program establishes a new vehicle type—SULEVs (super-ultra-low-emission vehicles)—with emission standards lower than those of ULEVs. The durability for emission certification is increased from

TABLE F-3 Emission Standards of the CA LEV I Program: Passenger Cars and Light-Duty Trucks with Loaded Vehicle Weight of 0 to 3,750 lb: grams/mile (CARB 1990)

|

Vehicle Type |

NMOG |

CO |

NOx |

PM |

Formaldehyde |

|

50,000-Mile Standards |

|

|

|

|

|

|

TLEV |

0.125 |

3.4 |

0.4 |

N/A |

0.015 |

|

LEV |

0.075 |

3.4 |

0.2 |

N/A |

0.015 |

|

ULEV |

0.040 |

1.7 |

0.2 |

N/A |

0.008 |

|

ZEV |

0.000 |

0.0 |

0.0 |

N/A |

0.000 |

|

100,000-Mile Standards |

|

|

|

|

|

|

TLEV |

0.156 |

4.2 |

0.6 |

0.08 |

0.018 |

|

LEV |

0.090 |

4.2 |

0.3 |

0.08 |

0.018 |

|

ULEV |

0.055 |

2.1 |

0.3 |

0.04 |

0.011 |

|

ZEV |

0.000 |

0.0 |

0.0 |

0.00 |

0.000 |

TABLE F-4 Emission Standards of the CA LEV II Program: Passenger Cars and Light-Duty Trucks with Gross Vehicle Weight of 0 to 8,500 lb: grams/mile (CARB 1998)

|

Vehicle Type |

NMOG |

CO |

NOx |

PM |

Formaldehyde |

|

50,000-Mile Standards |

|

|

|

|

|

|

LEV |

0.075 |

3.4 |

0.05 |

N/A |

0.015 |

|

LEV, Option 1 |

0.075 |

3.4 |

0.07 |

N/A |

0.015 |

|

ULEV |

0.040 |

1.7 |

0.05 |

N/A |

0.008 |

|

ZEV |

0.000 |

0.0 |

0.0 |

N/A |

0.000 |

|

120,000-Mile Standards |

|

|

|

|

|

|

LEV |

0.090 |

4.2 |

0.07 |

0.01 |

0.018 |

|

LEV, Option 1 |

0.090 |

4.2 |

0.10 |

0.01 |

0.018 |

|

ULEV |

0.055 |

2.1 |

0.07 |

0.01 |

0.011 |

|

SULEV |

0.010 |

1.0 |

0.02 |

0.01 |

0.004 |

|

ZEV |

0.000 |

0.0 |

0.0 |

0.00 |

0.000 |

|

150,000-Mile Standards (Optional) |

|

|

|

|

|

|

LEV |

0.090 |

4.2 |

0.07 |

0.01 |

0.018 |

|

LEV, Option 1 |

0.090 |

4.2 |

0.10 |

0.01 |

0.018 |

|

ULEV |

0.055 |

2.1 |

0.07 |

0.01 |

0.011 |

|

SULEV |

0.010 |

1.0 |

0.02 |

0.01 |

0.004 |

|

ZEV |

0.000 |

0.0 |

0.0 |

0.00 |

0.000 |

100,000 miles to 120,000 miles. The LEV II program includes heavy passenger vehicles to avoid an emission regulation loophole for them. The LEV II program allows SULEVs and HEVs to earn partial ZEV (PZEV) credits to meet ZEV sales requirements. The LEV II program will go into effect in model year (MY) 2004.

Federal Tier 2 LDV Standards

In early 2000, EPA adopted the Tier 2 emission standards for passenger cars and light-duty trucks (LDTs) (EPA 2000a). The CAAA established Tier 2 vehicle emission standards, but the adopted Tier 2 emission standards are much more stringent than the CAAA-specified Tier 2 standards. Table F-5 presents EPA’s Tier 2 standards for vehicles at 100,000 miles (another set is established for vehicles at 50,000 miles). A distinguishing feature of the Tier 2 program is that it establishes different vehicle bins to allow automobile makers to certify vehicles with flexibility, as long as a corporate average NOx emission standard

TABLE F-5 Federal Tier 2 LDV Emission Standards: Fully in Effect in MY 2009 for Vehicles up to 10,000 lb Gross Vehicle Weight Rating: grams/mile at 100,000 miles (EPA 2000a)

|

|

NMOG |

CO |

NOxa |

PM |

Formaldehyde |

|

Tier 1 Emission Standards |

0.31 |

4.2 |

0.60 |

0.10 |

N/A |

|

Tier 2 Emission Standards |

|

|

|

|

|

|

0.156/0.230 |

4.2/6.4 |

0.60 |

0.08 |

0.018/0.027 |

|

|

0.090/0.180 |

4.2 |

0.30 |

0.06 |

0.018 |

|

|

Bin 8b |

0.125/0.156 |

4.2 |

0.20 |

0.02 |

0.018 |

|

Bin 7 |

0.090 |

4.2 |

0.15 |

0.02 |

0.018 |

|

Bin 6 |

0.090 |

4.2 |

0.10 |

0.01 |

0.018 |

|

Bin 5 |

0.090 |

4.2 |

0.07 |

0.01 |

0.018 |

|

Bin 4 |

0.070 |

2.1 |

0.04 |

0.01 |

0.011 |

|

Bin 3 |

0.055 |

2.1 |

0.03 |

0.01 |

0.011 |

|

Bin 2 |

0.010 |

2.1 |

0.02 |

0.01 |

0.004 |

|

Bin 1 |

0.000 |

0.0 |

0.00 |

0.00 |

0.000 |

|

Note: N/A = not applicable. a A corporate average NOx standard of 0.07 grams/mile will be fully in place by MY 2009. b The high values apply to heavy light-duty trucks, while the low values apply to light light-duty trucks. c Bins 10 and 9 will be eliminated at the end of MY 2006 for cars and light light-duty trucks and at the end of MY 2008 for heavy light-duty trucks. |

|||||

of 0.07 g/mile is met. Also, instead of applying separately to passenger cars, light-duty trucks 1, and light-duty trucks 2, the Tier 2 standards apply to all three types together (with a transition period in which heavy light-duty trucks are subject to less stringent standards). The Tier 2 standards will begin to be implemented in MY 2004 and will be fully in place by MY 2009. Besides establishing vehicle tailpipe emission standards, EPA requires gasoline sulfur content to be reduced to 30 ppm beginning in 2004.

Federal HDE Emission Standards for MY 2004–2006 (Phase 1 Standards)

In 2000, EPA adopted the final HDE emission standards for nonmethane hydrocarbon (NMHC) and NOx for MY 2004–2006 (Table F-6) (EPA 2000b). The so-called Phase 1 HDE standards require

TABLE F-6 Heavy-Duty Engine Emission Standards: g/bhp-hr, Lifetime of 8 Years (EPA 2000b)

|

|

NMHC |

NOx |

NMHC + NOx |

CO |

PM |

|

MY 1998-2003 standards |

1.1/1.3/1.9a |

4.0 |

N/A |

15.5 |

0.10 |

|

Phase 1 HDE standards: MY 2004 and later |

|

|

|

|

|

|

Diesel-Cycle HDE: Option 1 |

N/A |

N/A |

2.4 |

15.5 |

0.10 |

|

Diesel-Cycle HDE: Option 2 |

<0.5 |

N/A |

2.5 |

15.5 |

0.10 |

|

Otto-Cycle HDE: Option 1 |

N/A |

N/A |

1.5/1.0b |

15.5 |

0.10 |

|

Otto-Cycle HDE: Option 2 |

N/A |

N/A |

1.5/1.0c |

15.5 |

0.10 |

|

Otto-Cycle HDE: Option 3 |

N/A |

N/A |

1.0d |

15.5 |

0.10 |

|

Note: g/bhp-hr = grams per brake-horsepower-hour; N/A = not applicable. a These standards are for Otto-cycle light HDEs (8,500 to 14,000 lb gross vehicle weight rating), diesel-cycle HDEs, and Otto-cycle heavy HDEs (greater than 14,000 lb gross vehicle weight rating), respectively. b These standards are for MY 2003-2007 and 2008 and later, respectively. c These standards are for MY 2004-2007 and 2008 and later, respectively. MY 2004-2007 heavy-duty vehicles are required to be certified with vehicle-based standards as well as with the engine-based standards in this table. d This standard applies to MY 2005 and later. |

|||||

significant reductions in NOx emissions by HDEs. In addition to these standards, EPA established new testing procedures and required onboard diagnosis systems for HDEs.

Federal HDE Emission Standards for MY 2007 and Later (Phase 2 HDE Standards)

EPA recently adopted the Phase 2 HDE standards for MY 2007 and later (Table F-7) (EPA 2000c). To help HDE manufacturers meet the Phase 2 HDE emission standards, EPA requires diesel fuel with a sulfur content limit of 15 ppm, compared with the current limit of about 340 ppm. The LS diesel fuel requirement could go into effect in June 2006.

California Phase 2 and 3 RFG

In 1992, California began to require use of the so-called Phase 1 reformulated gasoline (CARFG1). CARFG1 had the following composition requirements: a maximum aromatics content of 32 percent by

TABLE F-7 Federal Phase 2 HDE Standards (EPA 2000c)

volume, a maximum sulfur content of 150 ppm by weight, a maximum olefins content of 10 percent by volume, and a maximum temperature of 330°F for 90 percent distillation of gasoline (CARB 1991).

In 1996, California began to require use of the Phase 2 RFG (CARFG2). Table F-8 presents composition requirements of CARFG2. Under the CARFG2 requirement, gasoline producers are allowed to certify gasoline by meeting either the specified composition requirements (Table F-8) or predetermined emission reduction requirements with any alternative gasoline reformulation formula. Emission performance of a given alternative RFG formula would be simulated with CARB’s predictive model.

In 1999, because of concern about underground water contamination by methyl tertiary butyl ether (MTBE), California Governor Gray Davis issued an executive order to ban use of MTBE in California’s gasoline beginning in 2003. Subsequently, CARB adopted the Phase 3 RFG (CARFG3), to go into effect beginning in 2003 (Table F-8). The differences between CARFG2 and CARFG3 are (a) elimination of MTBE and (b) reduction of gasoline sulfur content limit from 30 ppm to 15 ppm.

Federal Phase 2 RFG and Tier 2 LS Gasoline

The CAAA required use of RFG in some of the nation’s worst ozone nonattainment areas. The so-called federal Phase 1 RFG (FRFG1) took effect in January 1995. Gasoline producers could certify FRFG1

TABLE F-8 Composition Requirements of CARFG2 and CARFG3 (CARB 1999)

with specified composition requirements or by meeting emission reduction goals. The FRFG1 composition requirements were a maximum benzene content of 1 percent by volume, a maximum aromatics content of 25 percent by volume, and a minimum oxygen content of 2 percent by weight. The FRFG1 emission reduction requirements were a reduction of volatile organic compound (VOC) emissions by 16 percent (northern regions) to 35 percent (southern regions) and a reduction of air toxic emissions by about 15 percent, all relative to conventional gasoline (CG) (EPA 1994). The reduction for VOC emissions is the combined reductions of exhaust and evaporative emissions by LDVs.

EPA established the Phase 2 RFG (FRFG2) requirements through emission reduction standards: a reduction of 27.5 percent in VOC emissions in southern regions and 25.9 percent in northern regions, a reduction of 20 percent in air toxic emissions, and a reduction of 5.5 percent in NOx emissions, all relative to CG. EPA allows gasoline producers to use its Complex Model to determine emission reductions of a given gasoline reformulation formula. FRFG2 began to be introduced into the worst ozone nonattainment areas in 2000. Its use has been expanded into other areas.

In early 2000, EPA adopted the final rule of Tier 2 vehicle emission standards (EPA 2000a). Together with vehicle emission standards (see Table F-5), the Tier 2 rule establishes a gasoline sulfur content limit of 30 ppm. In contrast to FRFG1 and FRFG2, which were required only for the worst ozone nonattainment areas, the Tier 2 LS gasoline will be required nationwide beginning in 2004, except for California, where CARFG3 will be in effect. Since the Tier 2 LS gasoline is an integral part of the Tier 2 program, the LS gasoline will be evaluated together with the Tier 2 emission standards in the section on the review of past studies.

Table F-9 presents typical characteristics of CG, FRFG2, and Tier 2 LS gasoline.

Federal LS Diesel Requirement

In October 1993, EPA began to require use of on-road diesel fuels with a sulfur content limit of 500 ppm. Because of that requirement, the average sulfur content of current on-road diesel fuel is about 350 ppm

TABLE F-9 Typical Characteristics of CG, FRFG2, and Tier 2 Low-Sulfur Gasoline (EPA 1994; EPA 2000a)

|

|

CGa |

FRFG2b |

Tier 2 LS Gasolinec |

|

RVP, summer (psi) |

8.9 |

6.7 |

NS |

|

Sulfur content (wt. ppm) |

339 |

150 |

30 (max. 80) |

|

Benzene content (vol%) |

1.53 |

0.68 |

NS |

|

Aromatics content (vol%) |

32.0 |

25 |

NS |

|

Olefins content (vol%) |

9.2 |

11 |

NS |

|

200°F distillation (%) |

41 |

49 |

NS |

|

300°F distillation (%) |

83 |

87 |

NS |

|

Oxygen content (wt%) |

0.4 |

2.26 |

NS |

|

Note: CG = conventional gasoline; RVP = Reid vapor pressure of gasoline; NS = not specified. a From NRC (2000). b Based on representative input parameters to EPA’s Complex Model for simulating emission performances of FRFG2. c From EPA (2000a). |

|||

nationwide, except for California (EPA 2000b). Before October 1993, the sulfur content of diesel fuel was about 3,000 ppm (EPA 2000b). In 2000, EPA adopted the Phase 2 HDE emission standards. Together with HDE standards (see Table F-7), EPA requires that the diesel sulfur content be limited to a maximum level of 15 ppm effective in June 2006 (EPA 2000c). The LS diesel requirement will be evaluated together with the Phase 2 HDE standards in the section on the review of past studies.

Alternative-Fueled Vehicles

Both the CAAA and the 1992 Energy Policy Act called for use of AFVs to achieve emission and energy benefits. Although there are a significant number of LPG vehicles, ethanol flexible-fuel vehicles (FFVs), and CNG vehicles, use of AFVs has not reached the level that some envisioned in the early 1990s. AFVs account for only 0.2 percent of the 210 million on-road motor vehicles in the United States (Table F-10). The lack of fuel distribution infrastructure for alternative fuels is one of the many difficulties that AFVs must overcome. The so-called chicken-and-egg problem between vehicle availability

TABLE F-10 Number of AFVs in Use in the United States (EIA 2000)

|

AFV Type |

Total Number in 2000 |

|

LPG vehicles |

270,000 |

|

CNG vehicles |

101,990 |

|

E85 FFVs |

30,020a |

|

M85 FFVs |

18,730 |

|

Electric vehicles |

7,590 |

|

LNG vehicles |

1,680 |

|

Total |

430,010 |

|

a In 1997, some automobile makers began to include E85-fueling capability in certain model lines of their vehicles. These vehicles are capable of using any combination of E85 and gasoline. These vehicles, whose number is large, are not included by the Energy Information Administration. |

|

and adequate fuel infrastructure and the cost of alternative fuels are the major reasons why use of AFVs has not been widespread.

Nonetheless, efforts to overcome the difficulties associated with introduction of AFVs are continuing. As emissions of conventional vehicles become increasingly difficult to control, AFVs could play an important role in solving transportation energy and air pollution problems, especially if the price of crude remains at a high level.

In addition to AFVs, both the public and the private sectors are actively investing in R&D of advanced technologies such as HEVs, direct-injection engines, and fuel-cell vehicles (FCVs). These technologies can improve vehicle fuel economy significantly and can directly or indirectly reduce vehicle emissions.

Vehicle I&M Programs

The CAAA required ozone nonattainment areas to implement I&M programs to control on-road vehicle emissions. With an I&M program, vehicles are brought to inspection stations to undergo emission testing. If a vehicle fails the emission test, it must be fixed, with some exceptions. Emission reductions by I&M programs come from three sources: (a) repairs of failed vehicles, (b) good maintenance of on-road vehicles by vehicle owners, and (c) early retirement of dirty vehicles. I&M programs can be centralized or decentralized (depending on

where the emission tests are conducted), basic or enhanced (depending on test procedures and program stringency), and annual or biennial (depending on testing frequency). While most states have adopted a uniform I&M program statewide, California has designed its I&M program (or the smog check program, as it is called in California) with different features for different California air basins (CAIMRC 2000).

Researchers have evaluated the Arizona I&M program (Harrington et al. 1999; Harrington et al. 2000; Ando et al. 2000). They summarized several key issues in evaluating I&M programs. First, the repair durability of an I&M program is a key factor determining its emission reductions. Second, in calculating I&M cost-effectiveness, both monetary and nonmonetary costs (such as drivers’ time to and from I&M stations) must be taken into account. Third, emission cut points of an I&M program need to be determined at an optimal level. If the cut points are not stringent enough, the amount of emission reductions is limited. If they are too stringent, the cost of overall emission reductions is high. Fourth, newer vehicles with such devices as onboard diagnosis (OBD) systems may limit the emission benefits associated with I&M programs, since in-use emissions of these vehicles are better controlled by OBD systems.

Old Vehicle Scrappage

Old vehicles, especially vehicles equipped with less advanced emission control technologies, can experience high emission deterioration over their lifetime. Air regulatory agencies have allowed some local air districts and private companies to claim emission reduction credits through the scrappage of old vehicles, which is accomplished by offering financial incentives to owners of old vehicles. Dill (2001) summarizes various vehicle scrappage programs in the United States and in some other countries. While old vehicle scrappage programs can be very cost-effective, by how much they can reduce emissions remains to be seen, especially in the future, when old vehicles may deteriorate less rapidly.

Remote Sensing Programs

In recent years, I&M programs have been criticized for their inability to target potentially dirty vehicles for testing. In order to catch high-

emitting vehicles, I&M programs require almost all vehicles to go through emission tests, which can increase the costs of I&M programs considerably. In addition, since vehicle owners can anticipate the timing of emission tests, they can arrange temporary fixes for their cars in order to pass I&M tests, leaving the vehicle emission problems unsolved.

To compensate for the weaknesses of I&M programs, the use of remote sensing programs to replace or supplement I&M programs in identifying superemitting vehicles has been proposed. With a remote sensing program, remote sensing devices can be set along the roadside. When vehicles pass the site, X rays from the devices can measure the emission concentration from vehicle tailpipes, and video cameras can record vehicle license plate numbers. Thus, superemitting vehicles can be identified.

However, emissions measured for a vehicle by remote sensing devices are a snapshot of emission performance of the vehicle during a trip. To be representative, remote sensing sites need to be carefully selected. The potential superemitters identified by remote sensing devices usually need to go through laboratory emission tests for further confirmation. Thus, a remote sensing program could complement an I&M program in identifying superemitters.

METHODOLOGICAL ISSUES IN MOBILE SOURCE COST-EFFECTIVENESS CALCULATIONS

Cost-effectiveness, presented in dollars per ton of emissions reduced, for emission control measures is often used by regulatory agencies, industries, and public interest groups in determining which control measures to adopt to meet given air quality goals. In fact, estimation of cost-effectiveness is usually required by law. In theory, cost-effectiveness is calculated for each control measure, and control measures are adopted, starting with the lowest-cost measures and proceeding to higher-cost measures, until a predetermined air quality goal is achieved. However, it is questionable whether this is actually carried out in such a way. Often, cost-effectiveness results are used for political, not scientific, debates on air pollution control.

Calculating cost-effectiveness appears simple and straightforward— total cost is divided by total emissions reduced. However, in calculat-

ing values for costs and emission reductions of control measures, researchers may assume different values for cost items and for emission reductions, consider different cost items, and include emissions of different pollutants in different locations and during different seasons. Thus, biases could be introduced into cost-effectiveness results. Considering different cost items and including different pollutants in different locations and different seasons make studies fundamentally incomparable. In this study, these differences are referred to as methodological differences. Comparison of fundamentally different studies is like comparison of apples and oranges. It is flawed and meaningless. On the other hand, use of different numerical values for cost items and emission reductions could reflect the nature of uncertainties in predicting these values. These differences represent varied views of cost reductions and emission improvements of given technologies over time. They are referred to in this study as technical differences (or parametric assumptions). Comparing studies that have the same fundamental basis but different parametric assumptions helps one understand the uncertainties involved in cost-effectiveness estimations as well as the potential for technological improvements in cost reductions and emission benefit increases of a given control measure.

To summarize different studies and compare them meaningfully, methodological differences among them need to be reconciled. On the other hand, different studies with a similar, if not the same, methodological basis may have different parametric assumptions concerning the costs and emission reductions of the control measures under evaluation. The original parametric assumptions in individual studies can be kept when comparing different studies, so each original study is still maintained as an independent study.

In calculating cost-effectiveness, one must explicitly or implicitly take positions on methodological issues. Readers often fail to pay attention to methodological differences among studies when citing results from different studies, either because they are not fully aware of the methodological issues involved or because the methodologies applied in cited studies are not explicitly presented. Three past studies discussed key methodological issues for mobile source cost-effectiveness calculations (Lareau 1994; Hadder 1995; Wang 1997).

In this section, an update from Wang (1997) of implied meanings of and appropriate solutions to nine methodological issues involved in estimating mobile source cost-effectiveness is presented. Some general guidelines are then proposed to adjust existing studies to make them comparable.

Table F-11 summarizes the nine methodological issues to be discussed in this section and the ways that are proposed here to address these issues. In the section on the review of past studies below, various completed studies are reviewed, and the proposed ways are used to adjust the original results of the completed studies. Since some of the reviewed studies were conducted in certain ways and lacked necessary data for adjustments, this study departs from the theoretically sound or complete ways on (a) program versus component cost-effectiveness, (b) emissions in nonattainment and attainment areas, (c) annual versus seasonal emissions, (d) user versus societal costs, and (e) estimated versus actual emission reductions.

Determination of Baseline Emissions and Emission Reductions of Control Measures

Calculation of emission reductions by a given control measure requires determination of baseline emissions from which the control

TABLE F-11 Nine Methodological Issues for Mobile Source Cost-Effectiveness Issue

|

How the Issue |

Should Be Addressed |

How the Issue Is Addressed in This Study |

|

Baseline emission determination |

Considering already adopted control measures |

Considering already adopted control measures |

|

Multiple air pollutants reduced to be included? |

Yes |

Yes |

|

Emission discounting? |

Yes |

Yes |

|

Program or component cost-effectiveness? |

Depending on study scope |

Program |

|

Include emissions in attainment areas? |

Yes, but with discounting |

No |

|

Annual or seasonal emissions? |

Seasonal emissions |

Annual emissions |

|

User or societal costs? |

Societal |

User |

|

Manufacturer or consumer costs? |

Consumer |

Consumer |

|

Estimated or actual emission reductions? |

Actual |

Estimated |

measure reduces emissions, since the amount of emission reductions by the measure is highly dependent on the quantity of baseline emissions. Usually, the higher the baseline emission quantity, the higher the reduction in emission quantity by a control measure. Obviously, the control measures assumed in baseline emission calculations are critical to determining the quantity of baseline emissions. Yet, sometimes it is unclear which measures should be considered as baseline control measures. For example, past studies that evaluated RFG emission reductions assumed Tier 1 vehicles, Tier 2 vehicles, or California LEV types as baseline vehicles. On the other hand, in estimating the cost-effectiveness of vehicle emission standards, past studies assumed CG or RFG to determine emission reductions of vehicle standards. It is proposed here that, in evaluating a given control measure, all the control measures that have already been adopted be considered for baseline emission calculation. In practice, because most cost-effectiveness studies are conducted for future years, it may not be clear which control measures will be adopted. Care must be taken in addressing future baseline control measures.

Considering different control measures in baseline emission calculations can result in very different control costs. For example, Lareau (1994) estimated the cost-effectiveness of vehicle emission standards and RFG with various baseline cases. He showed widely different cost-effectiveness results under different baseline cases.

Some control measures may be integrated to achieve emission reductions. An example is California’s LEV program, which includes both vehicle and fuel requirements. The integrated measures should be evaluated as a complete program, not as separate components. EPA’s Tier 2 LDV standards and the LS gasoline requirement are summarized together in this study, since the two together form the Tier 2 program. Similarly, EPA’s Phase 2 HDE standards and the LS diesel requirement are summarized together. See the section on the review of past studies for these two programs.

If it becomes necessary to separate some measures from others within an integrated program to evaluate the program’s components, the measures of interest can be evaluated with or without other measures to be considered as baseline control measures, depending on which will be implemented first. In some past studies, although

some control measures were considered in baseline emission calculations, they were not considered in baseline cost calculations. Such inconsistencies must be avoided.

In estimating baseline mobile source emissions, most past studies used either CARB’s EMFAC model or EPA’s MOBILE model. Until the mid-1990s, there were concerns that both EMFAC and MOBILE might have underestimated actual on-road emissions significantly. However, since then, improvements have been made in both models to better predict vehicle emissions. Nonetheless, these models still have problems in accurately estimating the emissions of certain groups of vehicles and the emission reduction effects of certain control measures.

Emission reductions by vehicle control measures are often estimated with limited vehicle emission testing. Emission testing results are usually generalized to estimate the effects of implementing a given control measure in broad vehicle fleets. Large uncertainties exist in the generalization because (a) baseline control technologies in emission testing could be different from those in applicable fleets and (b) tested control measures could be different from adopted control measures.

Multiple-Pollutant Emission Reductions

Most mobile source control measures usually reduce emissions for more than one pollutant. However, a single cost-effectiveness value is usually estimated to compare a variety of control measures. Several approaches have been used in past studies to deal with the multiple-pollutant issue. The first approach combines emission reductions of all the affected pollutants with weighting factors. Two methods can be used to determine weighting factors of individual pollutants. The first is based on contributions of individual pollutants to a given air pollution problem (such as the urban ozone problem). For example, some early 1990s studies used weighting factors of 1, 1/7, and 1 for hydrocarbons (HC), carbon monoxide (CO), and NOx, respectively, on the basis of their contributions to urban ozone formation. In some recent studies, the weighting factors for these three pollutants have been changed to 1, 0, and 1, respectively. The second method determines weighting factors on the basis of damage values of individual

pollutants. The damage value of a given pollutant is estimated, in theory, by the modeling of air quality and human exposure, evaluation of health effects, and valuation of health and other effects (McCubbin and Delucchi 1999).

The first method is rough but simple. The second is theoretically correct and complete, and it should be used to the extent possible. Weighting factors based on damage values of individual pollutants were used in this study.

Because emission damage values are determined by many factors such as time and location of emissions, there are great uncertainties in emission values. To address the uncertainties, three sets of weighting factors are used in this study (Table F-12). The base case weighting factors assume that the damage value of NOx emissions is four times that of VOC emissions. This is primarily based on the ozone formation contributions from the two pollutants in many areas. The equal weighting factors treat NOx and VOC emissions the same, the treatment used in many past studies. For example, Hahn (1995) used both the base case weighting factors and the equal weighting factors in his calculations of mobile source cost-effectiveness. Under the NOx-important weighting factors, NOx emissions are assumed to be eight times as damaging as VOC emissions. This reflects the contribution of NOx emissions to both ozone formation and secondary particulate matter (PM) formation. For example, McCubbin and Delucchi (1999) showed that NOx emissions could be eight times as damaging as VOC emissions, considering both ozone and PM health effects.

All three sets assume a zero weighting factor for CO emissions. This means that CO emission reductions are discarded in the adjust-

TABLE F-12 Weighting Factors of Three Pollutants to Combine Their Emissions

|

|

VOC |

CO |

NOx |

|

Base case weighting factors |

1 |

0 |

4 |

|

Equal weighting factors |

1 |

0 |

1 |

|

NOx-important weighting factors |

1 |

0 |

8 |

ments made in this study, which reflects the recent trend that CO air pollution has become of far less concern in most U.S. areas.

The weighting factors in Table F-12 indicate that combining different pollutants essentially converts emissions of other pollutants to VOC-equivalent emissions (since the weighting factor for VOC is always 1). Thus, calculated values based on these weighting factors are in terms of dollars per VOC-equivalent ton. This is the case in many past studies. Dollar-per-ton results can be very different if a different pollutant is used as the basis for the tonnage reduction. For example, if emission reductions in VOC-equivalent tonnage are converted into NOx-equivalent tonnage, the total tonnage becomes smaller and the dollar-per-ton cost becomes larger. Many studies did not explicitly state the underlying pollutant for the tonnage reduction, even though a conversion was conducted.

The second approach to multiple-pollutant emission reductions is to allocate the total cost of a control measure to each pollutant affected. To do so correctly, engineering analysis of the effort spent to control each pollutant could be conducted, and the total cost could be allocated according to the control effort for each pollutant. However, in reality, it is generally impossible to precisely allocate the aggregate effort to individual pollutants. Often, a shortcut for this approach is to divide the total cost evenly among all the pollutants. This is crude and usually is not correct.

The third approach is a hybrid system to combine emissions of some pollutants and to subtract the monetary values of emission reductions of other pollutants from the total cost of a control measure. Usually, one or more primary pollutants are selected for evaluation. The cost for controlling the primary pollutants is the net of the total control cost, subtracting the monetary values of emission reductions for other pollutants. Lareau (1994) used this approach to calculate VOC control costs for different control measures. EPA (2000a) used this approach to evaluate its Tier 2 vehicle emission standards (as described later in the section on review of past studies).

The fourth approach is a hybrid system of the first and second approaches discussed above. First, the total control cost is allocated to individual groups of pollutants. Then, within each group, emissions of pollutants are combined together with their weighting factors. For

example, in evaluating CARFG2, CARB (1991) first allocated 20 to 50 percent of RFG costs to air toxic reductions. Then, CARB combined total emissions in HC + CO/7 + NOx + SOx (where SOx represents sulfur oxides) to calculate dollar-per-ton costs for this group.

One way or another, emission reductions of all pollutants affected should be taken into account in calculating cost-effectiveness. Ignoring emission reductions for some pollutants results in upward-biased control costs.

Emission Discounting

Motor vehicles usually last for more than 10 years. While vehicle initial costs occur when vehicles are built or sold, operations and maintenance (O&M) costs occur over the vehicle’s lifetime. In calculating cost-effectiveness of motor vehicles, future O&M costs are usually discounted to present costs to reflect the fact that future dollars are worth less than present dollars. Then, vehicle initial costs and the discounted O&M costs are added together to represent total vehicle costs. In fact, discounting future costs is a standard practice in evaluating costs of given projects. If real-term dollars are used in cost estimates, the discount rate adopted should be a real-term discount rate. If current-term dollars are used in cost estimates, the discount rate adopted should be a current-term discount rate to reflect both inflation and the loss of investment opportunity. The current-term discount rate is usually about 10 percent, and the real-term discount rate is 3 to 6 percent.

Although costs are indisputably discounted, vehicle life-cycle emissions are estimated in some studies to be the straight sum of annual emissions, without discounting (some of these studies are reviewed later in this report). Some researchers have argued that because emissions are in physical terms rather than in monetary terms, emissions do not need to be discounted.

However, cost-effectiveness analysis provides useful information only in the broad perspective of cost-benefit analysis. Cost-effectiveness analysis serves as an approximation of cost-benefit analysis. In this context, the cost of a measure is the dollars spent on the measure, and the benefit is the emission reduction achieved by the measure. Both costs and emissions should be discounted (Schimek

2001). This is especially important in comparing measures whose emission reduction profiles over time are different. Emission discounting is the theoretically correct way to conduct cost-effectiveness analysis. In fact, regulatory agencies, such as CARB and EPA, use emission discounting in their cost-effectiveness analyses.

Because there is no inflation effect on physical units such as emissions, a real-term discount rate should always be used for emission discounting, regardless of which rate—real-term or current-term—is used for cost discounting. Some researchers may argue that a negative, rather than a positive, rate should be used for emission discounting. Use of a negative discount rate means that future emissions are worth more than current emissions. The rationale is that the current generation has some control of emissions for future generations, but future generations have no control over the current generation’s actions. Assigning a higher value to future emissions helps limit the consequences of the current generation’s actions for future generations. In this way, use of a negative discount rate seems to be intended to address the issue of equity among generations. However, discounting of mobile source emissions is usually applicable for the lifetime of a motor vehicle, which is about 15 years. Intergenerational inequity rarely exists over a 15-year period. In addition, cost-effectiveness analysis is usually intended to address issues associated with economic efficiency, not those associated with social equity. Positive discount rates for emissions are appropriate for mobile source cost-effectiveness analysis.

Alternatively, one could annualize the vehicle initial cost over the vehicle lifetime. For a given year, the total cost is the sum of that year’s O&M cost and the annualized initial cost. By taking into account the estimated annual emission reduction for that year, cost-effectiveness can then be calculated for that year. The lifetime average cost-effectiveness of the vehicle is the average of cost-effectiveness of individual years. In this way, the sometimes controversial emission discounting practice can be avoided.

The emission discounting method and the cost annualization method give similar results in practice. That is, in order to obtain correct cost-effectiveness results, emissions need to be discounted or costs need to be annualized. Table F-13 shows emission control

TABLE F-13 Dollar-per-Ton Cost-Effectiveness Calculations: Straight Sum of Emissions, Sum of Discounted Emissions, and Annualized Costs

|

Age |

Annual Miles |

Tier 1 Gasoline Cars with Conventional Gasoline (Estimated with EPA’s MOBILE5b) |

Tier 2 Vehicle Emission Reductions: |

Discounted Emissions (lb/year) |

Annualized Costs ($/ton) |

|||||||||

|

Grams/Mile Rates |

Emissions (lb/year) |

Emission Reductions (lb/year) |

||||||||||||

|

Exh. HC |

Evap. HC |

CO |

NOx |

HC |

CO |

NOx |

HC |

CO |

NOx |

Combined |

||||

|

1 |

10,768 |

0.254 |

0.280 |

4.019 |

0.305 |

12.7 |

95.3 |

7.2 |

6.3 |

47.7 |

3.6 |

20.8 |

20.8 |

7,096 |

|

2 |

13,808 |

0.354 |

0.289 |

6.184 |

0.437 |

19.6 |

188.1 |

13.3 |

9.8 |

94.0 |

6.6 |

36.4 |

34.3 |

4,059 |

|

3 |

13,061 |

0.449 |

0.300 |

8.232 |

0.561 |

21.5 |

236.8 |

16.1 |

10.8 |

118.4 |

8.1 |

43.1 |

38.3 |

3,428 |

|

4 |

12,354 |

0.539 |

0.309 |

10.169 |

0.679 |

23.1 |

276.7 |

18.5 |

11.5 |

138.4 |

9.2 |

48.5 |

40.7 |

3,044 |

|

5 |

11,688 |

0.888 |

0.415 |

14.509 |

0.940 |

33.5 |

373.5 |

24.2 |

16.8 |

186.8 |

12.1 |

65.2 |

51.6 |

2,265 |

|

6 |

11,056 |

1.218 |

0.517 |

18.616 |

1.188 |

42.3 |

453.3 |

28.9 |

21.1 |

226.7 |

14.5 |

79.0 |

59.0 |

1,869 |

|

7 |

10,458 |

1.530 |

0.616 |

22.501 |

1.422 |

49.4 |

518.3 |

32.8 |

24.7 |

259.2 |

16.4 |

90.2 |

63.6 |

1,636 |

|

8 |

9,892 |

1.825 |

0.712 |

26.176 |

1.644 |

55.3 |

570.3 |

35.8 |

27.6 |

285.2 |

17.9 |

99.3 |

66.0 |

1,487 |

|

9 |

9,357 |

2.104 |

0.805 |

29.652 |

1.854 |

60.0 |

611.1 |

38.2 |

30.0 |

305.6 |

19.1 |

106.4 |

66.8 |

1,387 |

|

10 |

8,852 |

2.368 |

0.896 |

32.940 |

2.052 |

63.6 |

642.3 |

40.0 |

31.8 |

321.1 |

20.0 |

111.8 |

66.2 |

1,320 |

|

11 |

8,373 |

2.618 |

0.985 |

36.050 |

2.240 |

66.4 |

664.9 |

41.3 |

33.2 |

332.4 |

20.7 |

115.8 |

64.7 |

1,274 |

|

12 |

7,919 |

2.854 |

1.072 |

38.992 |

2.417 |

68.5 |

680.1 |

42.2 |

34.2 |

340.1 |

21.1 |

118.6 |

62.5 |

1,245 |

|

13 |

7,492 |

3.078 |

1.156 |

41.776 |

2.585 |

69.9 |

689.4 |

42.7 |

34.9 |

344.7 |

21.3 |

120.3 |

59.8 |

1,227 |

|

14 |

7,087 |

3.289 |

1.239 |

44.409 |

2.744 |

70.7 |

693.2 |

42.8 |

35.3 |

346.6 |

21.4 |

121.0 |

56.7 |

1,220 |

|

15 |

6,704 |

3.489 |

1.321 |

46.899 |

2.896 |

71.0 |

692.5 |

42.8 |

35.5 |

346.3 |

21.4 |

121.0 |

53.5 |

1,219 |

|

16 |

6,341 |

3.678 |

1.402 |

49.254 |

3.036 |

71.0 |

687.9 |

42.4 |

35.5 |

344.0 |

21.2 |

120.3 |

50.2 |

1,227 |

|

17 |

5,998 |

3.857 |

1.480 |

51.483 |

3.170 |

70.5 |

680.2 |

41.9 |

35.3 |

340.1 |

20.9 |

119.0 |

46.8 |

1,240 |

|

18 |

5,674 |

4.027 |

1.556 |

53.590 |

3.298 |

69.8 |

669.8 |

41.2 |

34.9 |

334.9 |

20.6 |

117.3 |

43.6 |

1,258 |

cost-effectiveness results on the basis of a hypothetical case to demonstrate the implications of different methods. As the table shows, while emission discounting and cost annualization give similar results, use of the straight sum of emissions gives much lower dollar-per-ton cost values. That is, the straight sum of emissions underestimates control costs by a large amount. This should be avoided in cost-effectiveness calculations.

The cost-effectiveness of some mobile source control measures is calculated on the basis of annual rather than lifetime emission reductions. Such measures include I&M programs and RFG requirements. The capital costs of these measures are usually annualized. On the other hand, emission reductions from these measures are themselves annual emissions. For the reason stated in the above paragraph, emission discounting is not needed. That is, the cost-effectiveness calculations for these measures are based on annualized costs and annual emission reductions.

Program Cost-Effectiveness Versus Component Cost-Effectiveness

The cost-effectiveness of one component of a control program can be calculated on the basis of the incremental cost of and the incremental emission reductions achieved by the component. Meanwhile, cost-effectiveness can be estimated separately for the entire program. Some researchers maintained that component cost-effectiveness should be estimated to determine the design of a least-cost program. However, components of some control measures may interact with one another in terms of costs and emission reductions. For example, various components and specifications of gasoline may be changed collectively to meet RFG requirements at the least cost. To estimate the actual cost-effectiveness of RFG requirements, collective changes in various components and specifications should be simulated. Otherwise, studies could generate unrealistic results. For example, Sierra Research (1991) estimated the cost-effectiveness of changes in various gasoline components independently and showed very high component cost-effectiveness. Sierra’s component cost-effectiveness results showed that many separable refining steps for producing RFG with emissions lowered further are not cost-effective, being even more costly than Sierra’s cost estimates for federal and

California Phase 2 RFG. Because refiners would not be likely to take the incremental steps as Sierra Research evaluated, those component cost-effectiveness results have less meaning in comparing the cost-effectiveness of RFG with that of other control measures. Nonetheless, the results did indicate that extreme, inflexible RFG requirements could be very expensive.

Component cost-effectiveness results can be helpful in determining the composition of a control program. For example, component cost-effectiveness results for California’s LEV program showed that electric vehicles (EVs) could be very expensive in reducing emissions. While the California LEV program has been relatively successful, California could have used component cost-effectiveness results to decide the fate of the ZEV requirement in the LEV program. On the other hand, program cost-effectiveness is useful in comparing the cost-effectiveness of a designed program with other control programs. This study focuses on program cost-effectiveness.

Emissions in Nonattainment Versus Attainment Areas

In calculating the cost-effectiveness of control measures that reduce emissions in both nonattainment and attainment areas (such as new vehicles to be sold nationwide), some researchers maintain that emission reductions only in nonattainment areas should be considered. This assertion is based on the argument that the purpose of emission reductions is to help meet air quality standards in nonattainment areas. Whether to include emission reductions in attainment areas is especially important in comparing mobile source control measures, because some measures (such as vehicle emission standards) may inevitably be applied to both nonattainment and attainment areas. Other measures (such as RFG requirements and I&M programs), however, can target emissions in nonattainment areas. The latter are more effective than the former in reducing air pollution in nonattainment areas.

Considering emissions only in nonattainment areas implies that emission reductions in attainment areas have no benefits. This may be based on the perception that there are air pollution thresholds below which no air pollution damage occurs and at which air quality standards are set. However, such thresholds may be much lower

than air quality standards or may not exist at all. Emissions cause damage, though less severe, even at lower concentrations. Thus, emissions in attainment areas cannot be ignored completely, although they may be assigned lower values. Furthermore, because emissions can be transported for a long distance from attainment to nonattainment areas, emission reductions in attainment areas could benefit attainment goals for nonattainment areas. Emissions in attainment areas may be discounted on the basis of their damage values and then added to the emissions in nonattainment areas. For example, studies have been conducted to estimate emission values in various areas with different air quality problems (Wang et al. 1994). Emission values estimated for different regions could be used to weight emissions in nonattainment and attainment areas.

To the extent possible, in this study results from past studies are adjusted to include emissions in nonattainment areas only.

Annual Versus Seasonal Emissions

Some researchers, on the basis of reasoning similar to that for using emissions only in nonattainment areas, argue that emissions only during the nonattainment season (e.g., ozone precursor emissions in summer) should be used in calculating cost-effectiveness values. For example, Sierra Research (1994) and Lareau (1994) calculated cost-effectiveness values based on one-third of annual emissions. Use of seasonal emissions is especially important in comparing measures to reduce emissions in the nonattainment season with measures to reduce emissions year-round (the former are more effective in reducing air pollution in the peak season than are the latter). For example, while RFG requirements are enforced in summer to reduce VOC and NOx emissions for ozone attainment, vehicle emission standards reduce VOC and NOx emissions year-round. As for the case of emissions in nonattainment versus attainment areas, emissions in attainment seasons cannot be ignored completely, although they may be assigned lower values. Emissions in attainment seasons may be discounted on the basis of their damage values and then added to the emissions in nonattainment seasons.

The use of emissions in nonattainment areas and during the nonattainment season undoubtedly results in a low level of emission

reductions and consequently high control costs. Comparisons of control cost-effectiveness from studies with different considerations of regions and seasons regarding attainment status may result in incomplete conclusions. In this study, annual emissions are used in order to be consistent with most past studies.

Private Costs Versus Societal Costs

There is no question that costs to users (private costs) should be included in calculating cost-effectiveness. However, societal costs—the costs not paid in markets by individuals, but by society, directly or indirectly—are often ignored. Consumers use private costs to make private decisions, such as buying a new vehicle. On the other hand, cost-effectiveness is intended to help make sound public policies to improve air quality, which is a public good. In designing public policies to address public goods, both private costs and societal costs need to be taken into account. Thus, for a complete cost-effectiveness analysis, societal costs should be included. For example, the use of gasoline incurs costs such as national energy insecurity. In calculating the emission control cost-effectiveness of alternative fuels relative to gasoline, it may be appropriate to include an estimate of the monetary benefit of reducing U.S. dependence on foreign oil by the use of alternative fuels. Such a benefit would be the diminished monopoly power of oil suppliers (Greene and Leiby 1993). Another example involves using transportation control measures to reduce emissions. Transportation control measures can reduce emissions by decreasing vehicle miles traveled, which also reduces the demand for further expansion of transportation infrastructure in the long run. Costs avoided in infrastructure expansion because of reduced vehicle miles traveled may need to be subtracted from the costs of the measures. On the other hand, the welfare loss due to reduced vehicle miles traveled may need to be added to the costs of transportation control measures.

In calculating societal costs, costs transferred in the market from one group to another should not be included, because they are not net costs to society, but the secondary impacts of transfer costs on the economy may be included. Usually, the secondary impacts of transfer costs are minimal. Obvious examples of transfer costs are vehicle registration fees and motor fuel taxes.

Most past studies considered private costs only. Consideration of societal costs involves assessment of the societal costs of control measures, which are subject to great uncertainties. Because of limited data, only private costs are considered in this study.

Costs at the Manufacturer Versus the Consumer Level

It is often not clear in a study whether the costs used are at the manufacturer or the consumer level. Even worse, some studies may use manufacturer costs for some cost items and consumer costs for others. This inconsistency within a study must be avoided.

Manufacturer costs are costs to manufacturers, and consumer costs are costs to consumers. The differences between manufacturer costs and consumer costs are caused by marketing and distribution costs and profit margins. Wang et al. (1993a) concluded that for automotive emission control equipment, the markup factor between manufacturing costs and a manufacturer’s charged prices is about 20 percent, and the markup factor between dealer costs and retail prices could be as high as 40 percent. Of course, the markup factors include such transfer costs as manufacturer and dealer profits, as well as real costs, such as division overhead, marketing, and distribution costs. Nonetheless, costs at the consumer level are much higher than costs at the manufacturer level, resulting in control costs calculated on the basis of consumer costs being higher than those calculated on the basis of manufacturing costs. Costs at the consumer level, not the manufacturer level, should be used in calculating cost-effectiveness values.

Estimated Versus Actual On-Road Emissions

Virtually all past studies relied on EPA’s MOBILE or CARB’s EMFAC model to estimate emission reductions. Despite efforts to upgrade and refine MOBILE and EMFAC, neither yet accurately predicts actual on-road emissions. Early versions of the two models tended to underestimate on-road emissions. Underestimation of on-road emissions was caused primarily by off-cycle emissions; activity factors such as cold starts, hot soaks, and multiple-day diurnals; and underrepresentation of superemitting vehicles. Consequently, emission reductions based on MOBILE or EMFAC may have underrepresented actual

reductions, causing higher calculated control costs. To reflect the effect of actual on-road emission reductions on cost-effectiveness, Wang et al. (1993b) established a case of adjusting MOBILE5a-estimated emissions to actual on-road emissions and calculated cost-effectiveness for this case. They showed that adjusting on-road emissions could improve mobile source cost-effectiveness significantly.

Summary

Among the nine methodological issues, some affect completeness and others reflect scope. Consideration of completeness-related issues helps cost-effectiveness studies to be more complete. Such issues include consideration of societal costs, use of costs at the consumer level, consideration of emissions of all pollutants affected, and adjustment for actual on-road emissions. The question for these issues is not whether they should be considered, but rather how they can be considered.

On the other hand, scope-related issues include calculation of baseline emissions, whether to consider attainment-area emissions, whether to consider attainment-season emissions, application of emission discounting, and calculation of program or component cost-effectiveness. Whether these issues should be addressed in one way or the other by a particular study depends on the scope of the study. For example, if the scope of a study is to determine how air quality standards can be met, emissions in attainment areas and seasons may not need to be included; if the scope is to reduce the adverse effects of air pollution, emissions in both nonattainment and attainment areas and in both nonattainment and attainment seasons should be included. If the scope of a study is to evaluate a given control program relative to other control programs, program cost-effectiveness should be calculated; if the scope is to determine the least-cost design of a control program, component cost-effectiveness should be calculated. If cost-effectiveness is calculated as an approximation of the cost-benefit ratio, emissions as well as costs should be discounted; if the scope is to determine the least-cost way of meeting given air quality standards, emissions may not be discounted, because physical units of emissions are the concern. The scope of a

study may reflect one’s belief in the ultimate goal of emission reductions. Scope-related issues may be addressed differently in different studies without sacrificing the completeness of studies. However, when the results of different studies are compared, scope-related issues need to be adjusted so that the results can be compared on the basis of similar scopes.

REVIEW OF PAST STUDIES: KEY ASSUMPTIONS IN INDIVIDUAL STUDIES AND ADJUSTMENTS APPLIED TO THEM

A review of studies on mobile source control cost-effectiveness completed in the past several years is presented in this section. Some past studies evaluated the control measures that are already in place (such as federal Tier 1 LDV standards). Although those studies were reviewed by Wang (1997), they are not presented in this report, since the control measures evaluated in those studies have already become a part of baseline emission control measures and consequently are irrelevant to the evaluation of CMAQ control measures. Only the studies that evaluate the control measures that are proposed or are to be implemented in the near future are included in this section. They potentially compete against CMAQ measures. The following control measures are included in this study:

-

The California LEV II program,

-

The federal Tier 2 LDV standards,

-

The federal Phase 1 HDE standards,

-

The federal Phase 2 HDE standards,

-

CARFG2,

-

CARFG3,

-

FRFG2,

-

AFVs,

-

I&M programs,

-

Remote sensing programs, and

-

Old vehicle scrappage programs.

Descriptions of these control measures were presented earlier. Some of the above control measures were evaluated in multiple studies, others in only one study. This is a problem in summarizing the cost-

effectiveness of a given control measure from different studies. With multiple studies, institutional biases, in addition to parametric assumption differences, are introduced to a control measure. Usually, the more studies conducted for a given measure, the larger the uncertainty range for the given measure. It could be argued that the measures subject to a large number of studies are usually more controversial and less certain than the measures subject to a small number of studies.

Some studies covering mobile source control cost-effectiveness did not conduct original estimates. Instead, they cited or summarized results of other original studies. Nonoriginal studies are not included in this report for the most part.

In reviewing each of the studies, special attention was paid to (a) incremental costs of evaluated control measures, (b) emission reductions for each of the affected pollutants, (c) the magnitude of emission reductions to be achieved by a given control measure (e.g., tons of emission reductions per year), and (d) other details of the control measures. These items, when available from a study, are extracted from the original study and presented here. Some of the items are not used for adjustments applied in this study. However, they could be helpful to the CMAQ evaluation committee, especially when the committee compares a wide spectrum of mobile source and stationary source control measures.

California LEV II Program

CARB (1998) estimated cost-effectiveness of the California LEV II program relative to the California LEV I program. Table F-14 presents CARB’s estimated cost-effectiveness for ULEVII and SULEV—two new vehicle categories under the LEV II program. CARB used its EMFAC7G to estimate LEV II emission reductions.

In this study, three adjustments were applied to CARB’s original estimates:

-

Dollar amounts were converted from a 1998 base to a 2000 base.

-

Emissions were discounted with a discount rate of 6 percent.

-

Reactive organic gases (ROG) were combined with NOx with three sets of weighting factors (see Table F-12).

TABLE F-14 Costs, Emission Reductions, and Cost-Effectiveness of the California LEV II Program (1998 dollars) (CARB 1998)

|

LEV II Vehicle Category |

Vehicle Type |

Incremental Cost ($)a |

Per-Vehicle Emission Reduction over 120,000 Miles (lb) |

Cost-Effectiveness ($/ton) |

|||

|

ROG |

CO |

NOx |

ROG + NOx |

ROG + NOx + CO/7 |

|||

|

ULEVII |

PC |

71.5 |

0.0 |

48.4 |

67.3 |

2,120 |

1,920 |

|

|

LDT1 |

46.2 |

0.0 |

51.5 |

69.3 |

1,340 |

1,200 |

|

|

LDT2 |

184.1 |

2.3 |

171.2 |

159.7 |

2,280 |

2,200 |

|

|

MDV2 |

207.9 |

10.6 |

662.4 |

156.1 |

2,500 |

2,280 |

|

|

MDV3 |

208.9 |

13.3 |

796.8 |

244.0 |

1,620 |

1,120 |

|

|

MDV4 |

134.1 |

11.0 |

78.4 |

94.3 |

2,540 |

2,300 |

|

SULEV |

PC |

131.1 |

5.8 |

205.5 |

81.6 |

3,000 |

2,240 |

|

|

LDT1 |

104.9 |

5.9 |

216.0 |

83.9 |

2,340 |

1,740 |

|

|

LDT2 |

279.4 |

7.7 |

335.7 |

174.4 |

3,060 |

2,640 |

|

Averageb |

All LDVs |

152.0 |

6.3 |

285.1 |

125.6 |

2,311 |

1,960 |

|

a Consumer costs relative to LEV I vehicles. b These are straight averages of the nine vehicle types without considering their sales shares, which are not avail- able. |

|||||||