D Non-Stockpile Facilities

This appendix reviews the two non-stockpile facilities proposed for treatment of NSCWM, the Munitions Assessment and Processing System (MAPS), under construction at Aberdeen Proving Ground, Maryland, and the Pine Bluff Non-Stockpile Facility (PBNSF), proposed for Pine Bluff Arsenal, Arkansas.

MUNITIONS ASSESSMENT AND PROCESSING SYSTEM

The Munitions Assessment and Processing System (MAPS) is a facility developed specifically to destroy explosively configured non-stockpile chemical munitions at the Aberdeen Proving Ground (APG). MAPS has five components: a negative pressure filtration system, an air monitoring system, a glove box, an explosive containment chamber, and a burster detonation vessel. A plan of the facility showing the location of the key components is seen in Figure 2-1.

Description of Main Components

Negative Pressure Filtration System

The filtration system contains carbon filters for removing the contaminants from the building air. This system also maintains the process areas in the facility under negative pressure. Negative pressure is an engineering control that ensures that potentially contaminated building air is not released into the environment.

Air Monitoring System

MAPS contains an array of 15 minicams that monitor the facility air for the presence of chemical agents. These monitors are designed to alert the operators to chemical agent leaks so that appropriate action can be implemented.

Glove Box

The glove box is located in the process room and provides a means of handling the recovered munitions under negative pressure to reduce the risk of chemical agents being released into the process room.

Explosive Containment Chamber

This item is also located in the process room. The explosive containment chamber (ECC) is where the munitions will be either cut or drilled. In the event of an accidental detonation during the cutting or drilling, the ECC is designed to withstand a blast of up to 13 pounds of TNT without a vapor release but is expected to be used to destroy projectiles not exceeding 5 pounds of TNT equivalent.

Burster Detonation Vessel

The burster detonation vessel (BDV) is a commercial detonation vessel used to destroy the empty munition body, fuze, and burster. The BDV contains both the blast overpressure and the metal fragments. The overpressure will be vented to the negative pressure filtration system.

Description of Process

Before any chemical munitions are processed in MAPS, they must be properly identified and their contents verified using approved radiography and nonintrusive characterization technologies. Only after this process has been completed

and the chemical munitions are considered safe will they be processed in the MAPS. MAPS is designed to destroy projectiles as large as 155 mm or having a maximum amount of explosive not to exceed 5 pounds of TNT equivalent, which provides a margin of safety.

When munitions that have been declared safe arrive at MAPS to be processed, they move from the processing room and are placed in the glove box. Any packing material that is around the munitions is removed, and the munitions are then placed onto a drill or cut box. The drill or cut box is then moved to the explosive containment vessel, where the munitions’ chemical fill will be removed by either cutting or drilling a hole into the munitions large enough to allow the chemical fill to drain out. The chemical fill is drained into an approved shipping container that is sent to the chemical transfer facility at APG to be neutralized. The munitions’ bodies are decontaminated and then transported to the MAPS burster detonation unit, where they are detonated. After checking to ensure that the metal debris meets the 3X standard of decontamination, the metal is sent to an appropriate permitted landfill.

PINE BLUFF NON-STOCKPILE FACILITY

The Pine Bluff Non-Stockpile Facility (PBNSF) is currently in the design phase, which is scheduled to run during fiscal years 2001 and 2002. This facility will be designed as a site-specific solution to process the recovered chemical warfare materiel (RCWM), binary chemical weapon components, chemical agent identification sets (CAIS), and chemical samples at Pine Bluff Arsenal. It will have permanent walls, ceiling, and roof, but due to public concerns that this facility might be used to process non-stockpile items not currently stored at Pine Bluff, the equipment inside the building will be modular, skid-mounted, and easily transportable to permit removal after operations have been completed. The non-stockpile inventory at Pine Bluff is listed in Table 1-1. If the workload is broken down by item category, binaries account for 81.7 percent; CAIS, for 10.2 percent; empty ton containers, for 6.3 percent; munitions, for 1.8 percent; and chemical sample containers, for less than 1 percent. The construction of the facility is scheduled to begin in January 2004, with completion by July 2005.

Design Concept

The facility will be designed to operate 8 hours a day, 5 days a week. At this time no specific rate has been determined for the disposal of the binaries, the CAIS items, or the chemical samples. The facility will include a munition unpacking chamber, two ECCs, a neutralization trailer, soak tanks, and a secondary waste processor. The secondary waste processors under primary consideration are supercritical water oxidation and plasma arc, with the Army favoring plasma arc at this writing. Outside the walls of the PBSNF will be a detonation chamber, an EDS, and an RRS. When completed and operational, the facility will be able to destroy all items currently stored at Pine Bluff Arsenal.

Process Flow for RCWM

Before any of the munitions are delivered to the facility, they will have been previously assessed by the portable isotopic neutron spectroscopy (PINS) technique, x-rayed where appropriate, and the results reviewed by the Munitions Assessment and Review Board (MARB) to properly identify the contents. Data indicating the presence or absence of explosive and fuze components and the type of chemicals will be provided to the PBNSF operator for each item. The munitions will arrive at the facility overpacked individually in air-tight containers. The following briefly describes the typical process flow for the categories of RCWM to be processed.

Munitions Having Unstable Energetics

The overpacked munitions are removed from storage and transported to the Munitions Warming Area, if necessary, or to the Unpack Area. After visual inspection of the overpack, the munitions are removed from the overpack and a visual inspection is performed. The munitions are then placed in a cradle and an x ray is taken to verify the contents. If a munition has an armed fuze or is determined to have unstable energetics, it is sent outside the facility to the detonation chamber (in this case, an Explosive Destruction System (EDS)) to be processed. In the EDS, a linear shaped charge is placed on the munitions to cut them open and expose their contents for chemical treatment. Conical shaped charges are used to detonate the internal energetic compounds. Once sealed inside the blast chamber, the charges are detonated, destroying most of the energetics and the CW material. The blast chamber is then loaded with neutralizing reagent and the contents are chemically neutralized. The neutralent is sent for secondary waste processing through PBNSF. The chamber is then flushed out with approved rinsates, with the liquid going to secondary treatment as necessary. The metal is immersed in a soak tank, where it is treated to a 3X1 condition before final disposal.

Munitions Having Stable Energetics

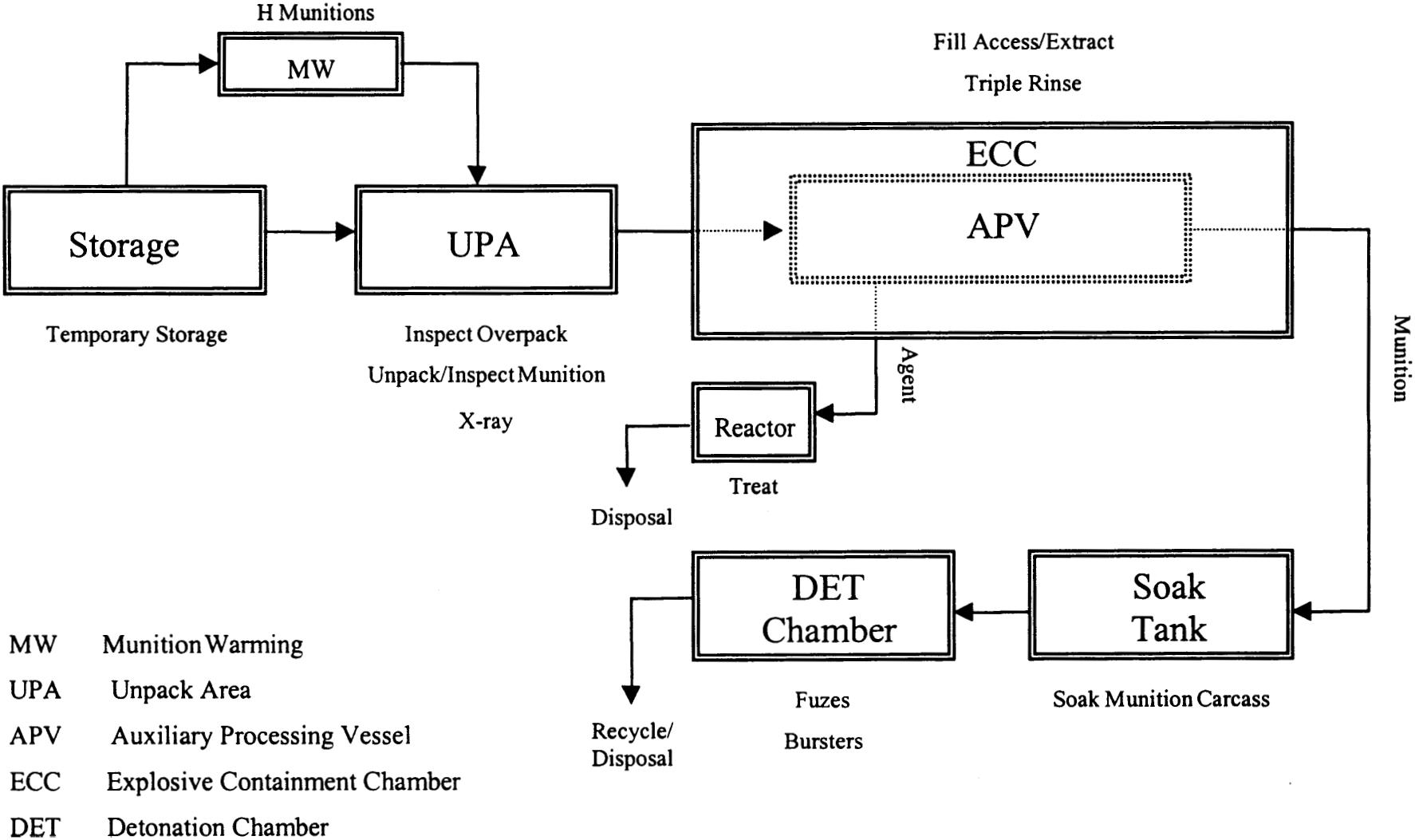

Munitions having stable energetics are treated inside the facility. The munitions are transported to the ECC, where a remotely controlled device punches a hole into the munition, allowing the chemical to drain out. After draining, the ECC is rinsed and the liquid stream produced is sent to the chemical processing trailer, where the primary neutralization operations take place. The liquid waste is then sent to secondary treatment within PBNSF for final treatment. After the munition casing has been adequately rinsed, it is moved to the soak tank for further decontamination. When the munition has been verified to be in a 3X condition, it is loaded into the detonation chamber, located outside the facility, where destruction of the explosive components is accomplished. The detonation chamber can also be used for small NSCM items such as miscellaneous fuzes. The metal is then processed for final disposal, as shown in Figure D-1.

Nonexplosively Configured Munitions

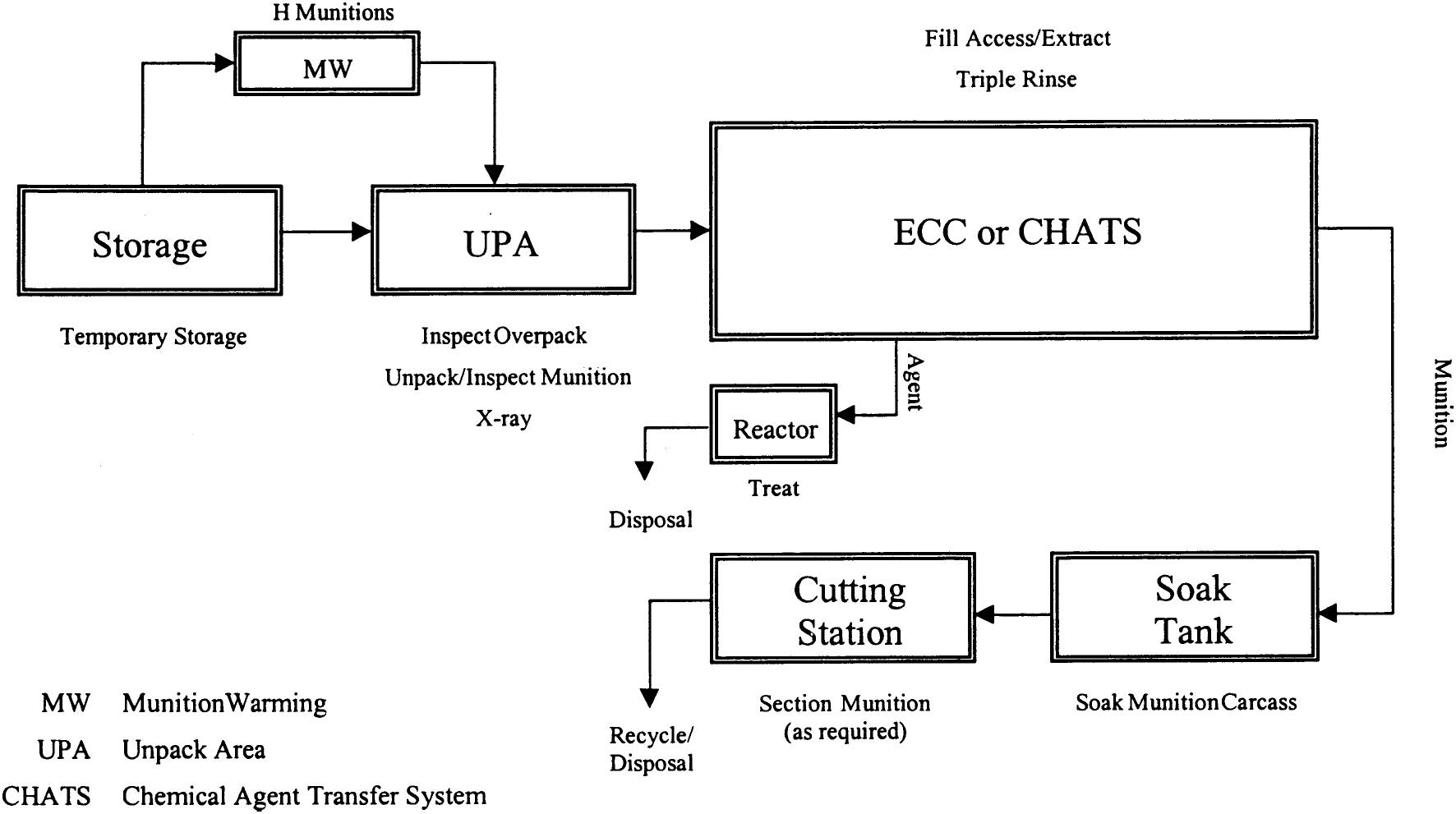

The process for handling nonexplosively configured munitions is very similar to that for handling explosively configured munitions. The current design instructions call for the munitions to be processed in either the ECC or in the Chemical Agent Transfer System (CHATS), which will be designed for operations in a nonenergetic atmosphere. In either case the munition is breached using a remotely controlled operation, the chemical fill verified, and the chemicals drained from the munition are transferred to a secondary treatment facility for final treatment. The main difference is that after the munition is drained, properly rinsed, and soaked, it is taken to a cutting station, where it is cut into various sections. The sections are inspected to ensure they are in 3X condition before being released for disposal. The typical process flow for nonexplosively configured munitions is shown at Figure D-2.

Process Flow for Binaries

The final decision on how to process the binary chemicals has not been made. It is anticipated that binaries will be processed either by a punch-and-drain operation followed by neutralization or by feeding the DF canisters into a system—plasma arc, for example—in a single step.

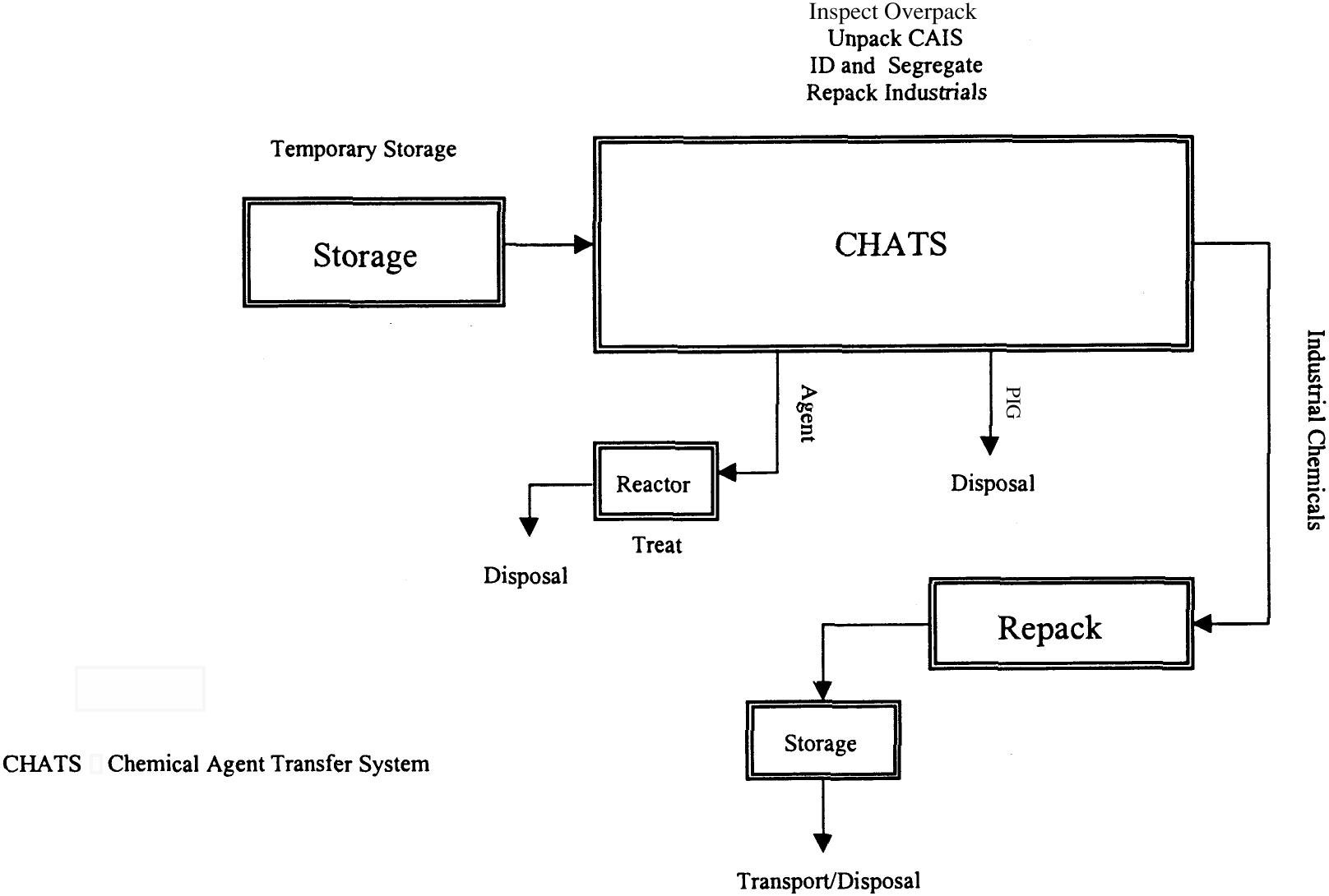

Process Flow for CAIS

The Rapid Response System (RRS) will be set up as part of the PBNSF operation but will be located outside the PBNSF structure and will be used to process all CAIS items. The overpack containing the CAIS is removed from storage and transported directly to the RRS. The RRS contains a series of linked glove boxes designed to remove the CAIS ampoules and bottles from their packages, identify their con

FIGURE D-1 Typical process flow for explosively configured munitions at PBNSF. SOURCE: U.S. Army (2000).

FIGURE D-2 Typical process flow for non-explosively configured munitions at PBNSF. SOURCE: U.S. Army (2000).

tent, crush the bottles, and neutralize the chemical agent. The waste stream produced is sent to the secondary treatment facility within the Pine Bluff facility for final treatment. The RRS provides the majority of the equipment used for this process and is part of the CHATS. The typical process flow for chemical agent detection systems is shown at Figure D-3.

FIGURE D-3 Typical process flow for chemical agent identification sets at PBNSF. SOURCE: U.S. Army (2000).

Process Flow for Chemical Samples

The small amount of CWM in this category will be processed in the PBNSF together with other items having similar chemistry.

REFERENCE

U.S. Army. 2000. Request for Proposal. Pine Bluff Arsenal Fixed Facility (PBA-FF). Solicitation number DAAA09-99-R-0090. October 27. Aberdeen Proving Ground, Md.: Program Manager for Chemical Demilitarization.