E Mobile Non-Stockpile Systems

This appendix reviews the two mobile non-stockpile facilities proposed for treatment of NSCWM—the Rapid Response System (RRS) and the Explosive Destruction System (EDS).

RAPID RESPONSE SYSTEM

The Rapid Response System (RRS) occupies three trailers: an operations trailer, a support trailer, and a utility trailer. The operations trailer contains the process equipment and instrumentation. The support trailer contains spare equipment and supplies. The utility trailer carries electrical generators to allow the system to operate without commercial or host power when needed. For a more complete description of the RRS equipment and operations, see Rapid Response System Test Report (U.S. Army, 2001a).

Chemical agent identification sets (CAIS) were produced in large quantities (approximately 110,000) and in various configurations from 1928 through 1969. The configurations included the following:

-

sealed Pyrex tubes or ampoules containing chemical agents (e.g., H/HD, HN, and L) and industrial chemicals (e.g., cyanogen chloride, phosgene, chloropicrin, and chloroform)

-

glass bottles containing neat (pure) mustard agent

-

“sniff sets”—widemouthed glass jars containing H/HD or L adsorbed on granular charcoal

The reagents employed in the RRS for the destruction of the various agents and industrial chemicals found in CAIS are as follows:

-

Red process. For use on HN-1, H/HD, and L in chloroform solution, it employs dichlorodimethylhydantoin (DCDMH) in chloroform, t-butyl alcohol, and water.

-

Blue process. For use on H/HD, it employs DCDMH in chloroform, t-butyl alcohol, and water.

-

Charcoal process. For use on HN or H/HD adsorbed on charcoal, it employs DCDMH in chloroform.

-

Charcoal-L process. For use on L adsorbed on charcoal, it employs DCDMH in chloroform, t-butyl alcohol, and water.

The deployment time for the RRS is 2 weeks. The RRS can treat one PIG1 of CAIS per day. Adding transportation and set-up time, a site with one PIG could be dealt with in 6 weeks. This does not include the paperwork and other actions connected with removing the treatment residues from the site, which could add 2 weeks to the schedule.

Following their recovery, CAIS may be stored for only 90 days without a RCRA permit. After that, they must be moved to a permitted storage facility. The RRS was initially permitted under a RCRA permit by the state of Utah to conduct a test program with both simulants and chemical agents at the Deseret Chemical Depot.

A full-scale prototype was designed and assembled. The state of Utah approved a testing program to qualify the process, and 33 of the 60 sets of CAIS stored at Deseret were destroyed during the program. The operation was carried out

successfully and is documented in detail (Rapid Response System Operations Approval In-Process Review (IPR) Package, January 29, 2001). The treatment goal was to reduce agent concentration to less than 50 ppm. This goal was met, with most residue containers having agent concentrations of less than 1 ppm. The operations were then converted to a production mode, and the remainder of the CAIS, more than 1,200 items, was destroyed. A final report will be issued by the Army contractor, SAIC. Only one negative incident was reported to the committee. When a container was opened, a small quantity of chloromethane was released and passed through all of the filters into the containment building. The source of the chloromethane is unknown. An evaluation of the safety and environmental performance of these operations was published in 2001 (Mitretek, 2001). It notes that poor analytical quality control data resulted in a decision to postpone shipment of the waste drums with decontaminated liquid or solid wastes to TSDFs pending resolution of the issue. These issues were resolved, and the wastes were disposed of at commercial TSDFs (U.S. Army, 2001a, 2001b).

After the Deseret campaign, the RRS was moved to Huntsville, Alabama, for modifications by the contractor. These include increasing the capacity of the electrical power supply system and reconfiguring the system, done in response to a failure of the uninterruptible power supply during operations in Utah. The RRS will then be dispatched to the following locations (in the expected deployment sequence): Fort Richardson, Alaska; Camp Bullis, Texas; Redstone Arsenal, Alabama; and Pine Bluff Arsenal, Arkansas. Operations at Fort Richardson will fall under the existing CERCLA action at that site, without further permitting under RCRA. Drafting of the RCRA permit applications for Camp Bullis, Redstone, and Pine Bluff has started. The Pine Bluff application was to be the template for the others. The Army expects that the order of deployment will be determined by the order in which the permits are approved. Ultimately, the plan is to make Pine Bluff Arsenal the home base of the RRS, where crews will be trained and local CAIS will be destroyed when the RRS has not been dispatched elsewhere.

The RRS is intended for use on multiple items of CAIS. If only one or two items are found at a site, the SCANS system, under development, would be used. The cost of transporting the RRS to a treatment site can be substantial and could have an impact on the Army’s disposal decisions. It might be cost effective to use SCANS for a much larger number of items, as previously discussed. A summary of the costs involved with the permitting, transportation, and operation was previously published by this committee (NRC, 1999, p. 79). The costs for the Fort Richardson cleanup were estimated as follows:

|

Obtaining a RCRA permit |

$250,000 |

|

Transportation of the equipment from Utah to Alaska |

33,000 |

|

Transportation of personnel to Alaska 55 days of operation |

172,000 |

|

Labor |

457,000 |

|

Materials and equipment |

228,000 |

|

Management, engineering, other |

250,000 |

|

Allocation of construction costs, |

|

|

Other indirect |

400,000 |

|

Total |

$1,790,000 |

Of interest is the use of SCANS instead of the RRS. SCANS is under development and would be more efficient for dealing with individual CAIS items, although it will not be able to open a PIG to remove individual CAIS items.

EXPLOSIVE DESTRUCTION SYSTEM

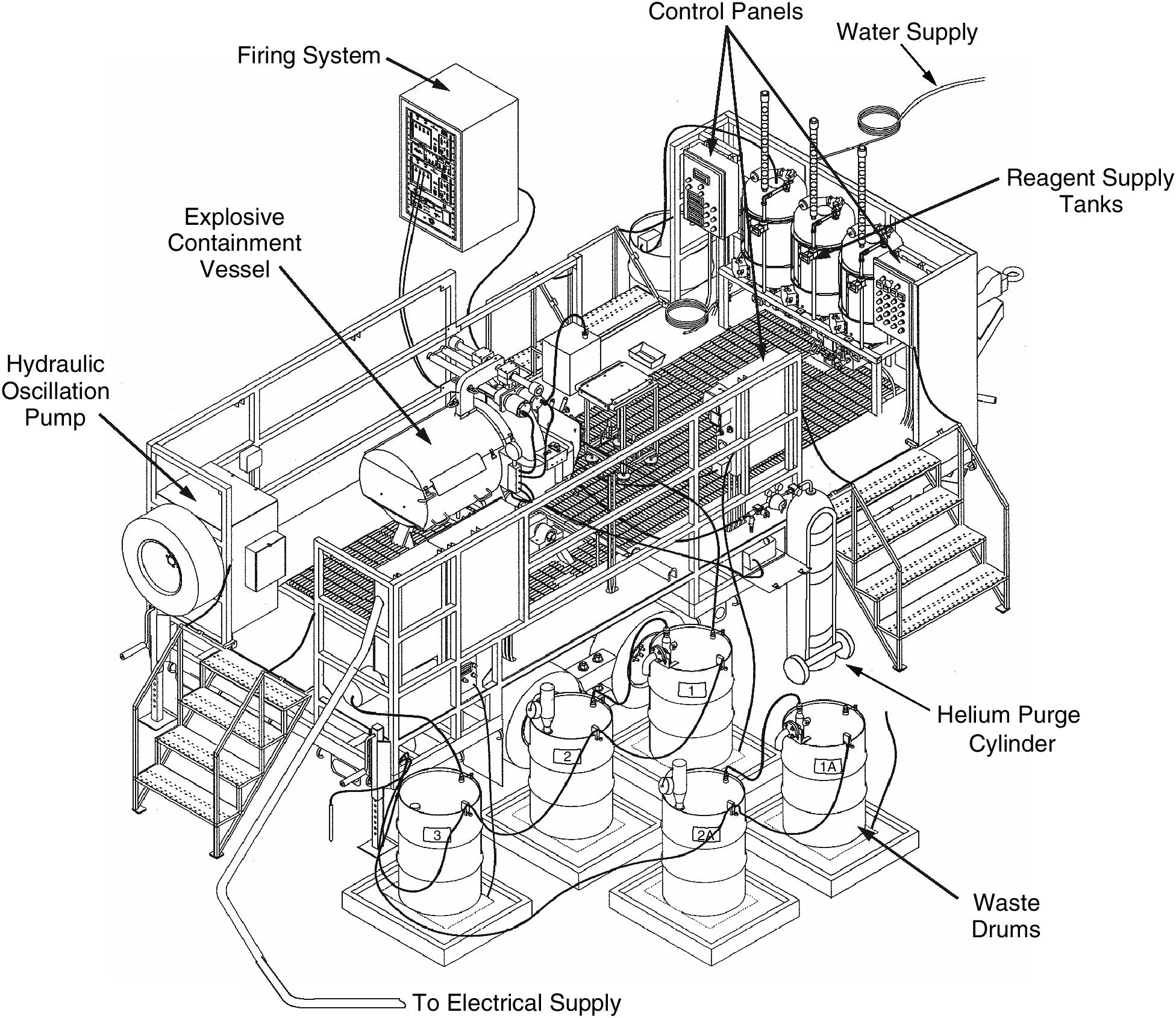

The Explosive Destruction System, Phase 1 (EDS-1) is a trailer-mounted mobile system intended to destroy explosively configured chemical warfare munitions that are deemed unsafe to transport or store routinely. The EDS can also be used to destroy limited numbers of chemical munitions, with or without explosive components, when the quantity of these munitions does not require the use of other destruction systems. A detailed description of the EDS and its operation is found in NRC (2001). A schematic view of the EDS-1 is shown in Figure E-1.

The heart of the EDS-1 is a 6.5-cubic-foot (189-liter) explosion containment vessel mounted on a 20-foot-long flatbed trailer. The vessel is fabricated from two 316 stainless steel forgings and is designed to contain detonations of up to one pound (0.45 kg) of TNT equivalent. The explosion containment vessel contains the explosive shock, fragments, and chemical agents during the munition opening process and also serves as a processing vessel for subsequent neutralization of the chemical agent and energetics within the munition.

The EDS-1 has an inside diameter of 51 cm and is designed to handle three common munitions: a 75-mm artillery shell, a 4.2-inch mortar, and a Livens projectile. It has been used to dispose of a 4-inch Stokes mortar and a M-139 bomblet, as well as nonexplosive cylinders.

Once a munition is placed inside the explosion containment vessel and its hinged door is closed and secured with clamps, shaped charges are used to open the munition and detonate any explosives within it. Chemical reagents are then introduced to treat the chemical agent within the munition until agent quantities are reduced to acceptable levels. The liquid neutralent is then treated as a hazardous waste and disposed of.

Prior to placing the munition in the EDS containment vessel, it is placed in a fragment suppression system (FSS) consisting of two steel half-cylinders, one above and one below the munition. The FSS reduces the velocity of small fragments in order to protect the wall of the EDS containment vessel. A steel support connected to the bottom half-

FIGURE E-1 Diagram of the EDS-1 vessel on its trailer. SOURCE: U.S. Army (2001c).

cylinder centers the munition in the FSS and provides shock absorption to protect the lower part of the EDS vessel. Additional protection is provided by a steel block placed beneath the bottom half-cylinder (to protect the lower EDS vessel wall from gas jets from the detonations) and end plates hung on the ends of the FSS cylinder to absorb shock and protect the ends of the EDS vessel. In effect, the munition in the EDS is double wrapped, inside the fragment suppression system as well as in the EDS itself.

The FSS is also used to mount and properly locate the charges used for detonation in the EDS. These are a linear shaped charge that cuts open the munition and exposes its contents for chemical treatment and conical shaped charges that detonate the burster inside the munition. Either one or two conical shaped charges, depending on munition size, are positioned above the munition in the FSS.

After unpacking the munition, it is placed in the FSS. The linear shaped charge is attached to the bottom half-cylinder and the conical shaped charges are attached to the upper half-cylinder. Detonators are then attached to the charges and shorted for safety. The FSS is then placed inside the EDS vessel using a loading table.

Following preparation of the door sealing surface and installation of a new O-ring, the EDS door is closed and a leak test conducted. Detonation then takes place and reagent is pumped into the EDS vessel to treat the chemical fill. Reagents used in the EDS include 22 percent aqueous sodium hydroxide for phosgene, 90 percent MEA/water for nitrogen mustard (HD), and 45 percent MEA/water for the nerve agent GB. Reactions take place at low temperatures and pressures.

Following treatment of the chemical munition or item, the EDS vessel is rinsed, cleaned, and inspected. This in

cludes inspection of the sealing surface and the EDS door as well as replacement of the all-metal seal that contains the detonation and the O-ring seals that provide an airspace used for helium leak detection.

Operational Characteristics

Deployment Protocol

The deployment protocol calls for seven EDS units to be operational by FY 2007, including three Type 1 and four Type 2 units. Two Type 1 units will be based in APG. One will be on standby for deployment as required to handle emergency situations that require timely disposal of unstable munitions. The other will be used at APG to handle remediation activities at Lauderick Creek. The third Type 1 EDS will be based at Pine Bluff for destroying warfare material recovered at that location.

The EDS developer, Sandia National Laboratories, is also designing and fabricating an EDS Phase 2 (EDS-2). The EDS-2 vessel will be capable of repeated use cycles at 3 pounds TNT equivalent and occasional uses of 5 pounds of TNT, should such a need arise. The frequency of allowable use above 3 pounds has yet to be defined. The EDS-2 vessel will be tested at Livermore Laboratory at more than 5 pounds of TNT equivalent for rating purposes. This larger version of the EDS will be able to dispose of munitions as large as 155-mm projectiles. The Army plans to have four EDS-2 units: two for operations and the other two as replacement units. Developmental testing of the first EDS-2 is planned to take place in Porton Down, United Kingdom, in 2003, followed by operational testing at APG, also in 2003. This unit is to be operational by FY 2004-2005 and available to support emergency response and chemical samples disposal. The purchase of an additional three Type 2 units is planned for FY 2006-2007 as required.

Throughput

Table E-1 presents some approximate EDS processing times for different agent fills. The data were derived from test and deployment results using the EDS system. In addition, there can be 3 hours of heat-up time for hot water rinses.

The best performance at RMA on sarin was destruction of one munition every 2 days. This would roughly be 8-9 hours of processing time on the first day, with the second day devoted to preparing (replacing door seal, charging reagent tanks, etc.) the EDS unit for the next munition.

Secondary Waste Streams

Based on current and expected operation of the EDS, three types of liquid wastes are generated:

-

neutralent, consisting of the initial treatment of agent with active reagent (e.g., MEA) and any subsequent chamber washes with chemical reagent (if used)

-

rinsate, consisting of additional agent treatment with water and chamber washes with water after opening the EDS

-

cleaning solution, consisting of washes (water/detergent) that are made between processing of each munition, and final washes (e.g., water/acetic acid) made after completing a munitions campaign

The expected source and collection of these wastes are presented in Table 2-2.

TABLE E-1 Approximate EDS Processing Time, by Agent

|

Agent Fill |

Treatment Time (hr) |

Rinse Times (hr) |

Total Contact Time (hr) |

|

Phosgene |

1-1.5 |

0.17 |

1.2-1.7 |

|

Mustard |

4-4.5 |

2.25 |

6.3-6.8 |

|

Sarin |

4.25-4.5 |

1 |

5.3-5.5 |

|

SOURCE: NRC (2001). |

|||

REFERENCES

Mitretek. 2001. D. Tripler, K. Raghuveer, R. Rhoads, A. Amr, and J. Miller. Independent Evaluation of the Rapid Response System, Safety and Environmental Performance, Mitretek Technical Report MTR 2001-22. Aberdeen Proving Ground, Md.: Program Manager for Chemical Demilitarization.

NRC (National Research Council). 1999. Disposal of Chemical Agent Identification Sets. Committee on Review and Evaluation of the Army Non-Stockpile Chemical Materiel Disposal Program. Washington, D.C.: National Academy Press.

NRC. 2001. Evaluation of Alternative Technologies for Disposal of Liquid Wastes from the Explosive Destruction System. Committee on Review and Evaluation of the Army Non-Stockpile Chemical Materiel Disposal Program. Washington, D.C.: National Academy Press.

U.S. Army. 2001a. Rapid Response System Test Report. Final. October. Aberdeen Proving Ground, Md.: Program Manager for Chemical Demilitarization.

U.S. Army. 2001b. Non-Stockpile Systems Program, Rapid Response System (RRS) After Action Report. Contract No. DAAA-09-95-D-0001, Task 0019. November. Prepared by Teledyne Brown Engineering.

U.S. Army. 2001c. Emergency Destruction Plan for M139 Bomblets Filled with GB at Rocky Mountain Arsenal, Colorado, using the Explosive Destruction System (EDS). Product Manager for Non-Stockpile Chemical Materiel, Aberdeen, Md. Final Revision 3, January 2001.