NATIONAL CONCERNS AND TECHNICAL CHALLENGES

Today we are faced with growing competition for nonrenewable raw materials and fuels and with low standards of living in much of the world. The latter is an old problem, but it is reemerging in a new setting that features prominently the aspirations of the developing countries, concern for the environment, and the scale of international human activities. These difficulties, in consequence, are attracting more and more attention, both in the U.S. and abroad, shifting to a degree the emphasis on national defense and political prestige toward more civilian-oriented goals and concerns.

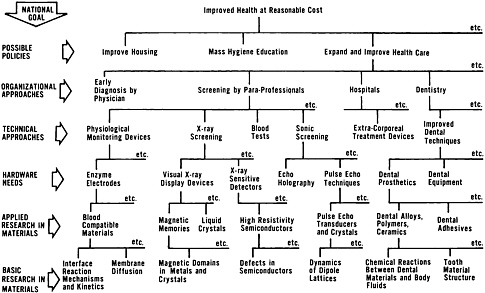

Materials science and engineering can help meet the technical challenges of these growing concerns. The relationship between materials research and development and one such concern, health services, is shown in a general way in the partial “relevance tree” of Figure 9. The existing and potential utility of materials research and development in solving a range of other real-life problems will be evident in our discussion of opportunities in materials research (page 97). In addition, we have examined the diverse technical challenges of the country’s current concerns from two vantage points: challenges in the materials cycle, and challenges in specific areas of national concern, including a priority analysis based on questionnaire replies.

Challenges in the Materials Cycle

Materials science and engineering, by providing options at the various stages in the total materials cycle, can exert direct, if not

FIGURE 9

PARTIAL RELEVANCE TREE FOR HEALTH SERVICES

The relevance tree shown here for health services and materials is not comprehensive, but illustrates the use of the technique for relating national or other broad goals to pertinent needs in research. Additional pathways between basic research and broad goals have been omitted for the sake of simplicity. Also omitted is the time scale: research on materials, for example, might not begin feeding information upward for 10 years or more.

always immediately visible, effects in the problem areas reflected by national concerns. It can help to slow and sometimes to halt the growth in demand for certain raw materials and fuels. It can help to move hardware technologies in directions that raise living standards at home and abroad. It can help to reduce deleterious effects on the environment to acceptable levels. And it can help to achieve these goals in a manner consistent with a sound U.S. balance of trade.

Exploration. The sensing, information-processing, and transmitting functions of orbiting earth-resources satellites and lunar rovers were made possible by progress in development of electronic and structural materials. Comparable technology could be developed for exploring the ocean floor. For more traditional types of prospecting, instrumental methods should progress rapidly as more is learned of the “signatures” of complex natural materials.

Mining. Ores and minerals, in the future, probably will have to be mined in more hostile environments at less accessible sites. (Manganese and other metals, as well as phosphates, for example, are available on the ocean floor.) Working conditions often may be impossible for human operators. To tap the resources available from ultradeep mines or below the ocean floor will require a new technology, “robotics.” In essense, robotics will involve solid-state electronic sensing and information-processing equipment coupled to servomechanical mechanisms that can operate under extreme conditions. The advent of novel equipment of this kind likewise will benefit conventional mining operations. Plasma and rocket-nozzle technology, for instance, has proved useful in

drilling the hard, iron-bearing taconite—which has largely succeeded the heavily depleted high-grade domestic iron ore that was long the mainstay of the nation’s steel industry.

Extraction. We need very much to find new means of extracting basic materials from ores of progressively lower grade and from low-grade wastes, processes that are more efficient, that cost less, consume less energy, and cause less pollution. Aluminum already is being extracted from the abundant anorthosite (in the Soviet Union) as opposed to the conventional source, the high-grade but less plentiful bauxite. Under development in the United States are two new aluminum processes: one reduces by about a third the energy required to produce aluminum from alumina by electrolysis; the other produces aluminum in several (nonelectrolytic) steps, starting with various sources of the metal—not only bauxite, but low-grade alumina-bearing minerals and even clay. The large piles of blast-furnace and open-hearth slag in the Mid-west are potential sources of manganese and phosphate. Longer-range possibilities include simultaneous extraction—perhaps at very high temperature—of several materials from “ores” like granite, which contains all the elements necessary to a modern industrial society. For higher-value materials, study seems warranted on electrostatic, electrophoretic, and other novel methods of separation.

Renewable Resources. Considerable scope exists for expanding the range of materials obtained from renewable resources. Wood and vegetable fibers might become important sources of primary organic chemicals, although they are not economically competitive today. Means of

“cracking” the lignin molecule, the binding material in trees, could make organic chemicals available from about 25 million tons of lignin disposed of annually in this country in wood wastes with only minor recovery of values. The utility of renewable resources in general might be extended by a variety of methods: better chemical means of recovering basic materials; control of physical properties by chemical or radiation treatment; genetic modification during growth; new ways to make composite materials of natural products; and improved methods of protecting and preserving structural materials made of natural products.

Resource Substitution. The substitution of plentiful for less-plentiful resources is likely to become an especially important task for materials science and engineering in the future. A material may be substituted for another of the same class, as when aluminum replaces copper in electrical conductors, or for one of a different class, as when polyethylene replaces galvanized steel in buckets. We will need substitutes for certain metals that have unique and important properties but threaten to become critically scarce in the not-so-distant future. These include gold, mercury, and palladium. The nation’s balance of trade would benefit from substituting manganese for nickel as a stabilizer in stainless steels and substituting domestic ilmenite for imported rutile as a source of titanium.

Even metals and alloys used widely in structural applications may offer broad scope for substitution by other alloys or ceramics based on substances more abundant in nature. The most common substance

in the earth’s crust is silicon dioxide. It is a basic constituent of glasses, which are remarkably versatile materials used hardly at all in proportion to their potential abundance. The properties of glass include excellent corrosion resistance and very high intrinsic strength. Aluminum and magnesium—though the energy cost of obtaining them is relatively high—are plentiful and display useful properties. These include, especially, the high ratios of strength to weight so important in engineering applications.

Processing, Manufacturing. Widespread opportunity exists for new processing and manufacturing techniques that waste less material and use less energy than do current methods. More processes are needed that lead directly from liquids and powders to finished shapes, thereby avoiding, for metals, the ingot and hot-working states. Such processes in general cost less and consume less energy than do the cold-forming and machining required to shape bulk solids. Industry already shapes liquid or powders in many cases: manufacture of float glass, slip casting or compacting of intricate shapes, die casting and plastic molding, and hot forging of sintered metals.

Continuous on-line assembly with minimum human intervention, a continuing objective for production lines, is virtually achieved in the manufacture of integrated circuits, where relatively few of the 200 or more processing steps are controlled actively by operators. The approach should be extended to other areas of processing and manufacturing. Some of the greatest savings in production costs and resources probably will result in the long run from greater use of small, on-line computers and robots. This form of robotics mentioned

earlier for mining calls for the imaginative exploitation of a variety of sensing and monitoring devices coupled through minicomputers to control mechanisms.

Environmental Effects. The need to preserve the environment requires continuing development of industrial processes that release fewer harmful effluents or whose effluents can be captured and converted to harmless and preferably useful forms. Some such processes are used widely now. One is the recovery of sulfur from petroleum refinery off-gases. Another is the recycling of the hydrochloric acid that has been displacing the nonrecyclable sulfuric acid in the pickling of steel for cold-forming. The heavy, hard-rubber cases on automobile storage batteries are not reused and often are disposed of by burning; a lighter-weight, reusable plastic case would seem feasible. The metallic salts in polyvinyl chloride film may become an air-pollution hazard when the discarded film is burned, as in an incinerator; alternatives to the salts should be considered. To improve health and safety inside the plant, it is likely that one of the most effective moves will be a wider use of robotics where working conditions are not suitable for humans.

Improved Performance. The purpose of materials science and engineering historically has been to improve performance by modifying existing materials and developing new ones. This activity will remain important. Demand will continue for higher-performance alloys, tougher glass and ceramics, stronger and tougher composites, greater magnetic strengths. But the task grows more complex as performance criteria come to embrace

chemical and biological as well as mechanical and physical properties. Consumers and legislation, furthermore, are calling increasingly for materials and products that are more durable, more reliable, safer, and less toxic. To meet these requirements, a number of complex, materials-related phenomena must be elucidated. They include corrosion, flammability, thermal and photodegradation, creep and fatigue, electromigration and electrochemical action, and biological behavior.

Functional Substitution. Functional substitution offers great opportunity in materials science and engineering. The aim is not simply to replace one material with a better one, but to find a whole new way to do a job. To join two metals, for example, one can develop not just stronger nuts and bolts, but adhesives. Jet engines replace piston engines and propellers in aircarft; telephones replace the mails for transmitting information. Functional substitution can lead to the revision of consumption patterns for materials and energy and, indeed, can inspire the creation of entirely new industries. Widespread use of nuclear of solar energy could yield enormous savings in the transportation of fossil fuels. The transistor started the solid-state electronics industry, which has led to technologies like computers, missile-control systems, and a broad range of industrial, medical, and leisure products. Challenging problems for functional substitution include: developing materials and techniques for new methods of generating and storing electrical energy; and finding functional substitutes and biological materials to replace human organs.

Product Design. The better we understand the properties of materials and how to control them, the more efficiently we can design them into products, providing materials and design specialists work closely together from the beginning of the design and development process. The resulting interplay may change apparent design restrictions radically and achieve more effective solutions to the design problem. Purposeful blending of materials and design expertise, moreover, can contribute significantly to conservation of materials. Appropriate knowledge sometimes allows safety margins to be narrowed without hazard, thus reducing the weight of material needed in the product. Where properties like strength and elastic modulus can be upgraded, the product can be made, sometimes, to contain significantly less material without corresponding loss in performance. An example is the use of textured steel sheet in automobile bodies. Design can also be improved as a result of clarifying the functional requirements of specific parts of a product. If only a surface must resist corrosion, for example, coating or cladding may cost less—and may require less material—than use of corrosion-resistant material throughout.

Recovery, Recycling. Facilitating the recovery and recycling of materials—apart from new approaches to questions like collection and separation—presents broad new problems in product design and materials selection. Product designs should ease dismantling and separation of components, but the rising costs of repair services tend to favor materials and products designed for replacement as whole units rather than for dismantling and repair. These conflicting

pressures will have to be reconciled. Metals like those in a shredded automobile tend to be degraded with each recycle, although they may be quite suitable for applications less demanding than the original ones. The same is true of blended plastics, ceramics, composites, and glass. It is not clear that these problems can be solved without sacrificing performance. We must learn not only to recycle materials more efficiently; we must develop secondary and tertiary outlets for recycled materials whose properties no longer meet the requirements of primary functions. Extractive chemistry and metallurgy will be important in improving recycling processes, but better physical methods of separation are needed, too.

Materials Challenges in Areas of National Impact

Peoples and nations have many kinds of concerns and goals. Some aspirations, like “Life, liberty and the pursuit of happiness,” are not truly reducible to tasks for science and technology. Others, like the desire for a strong domestic economy, clearly call for positive technical contributions. In connection with national concerns of the latter type, we have surveyed a number of specific challenges and priorities for materials science and engineering.

One of our approaches involved a novel questionnaire on Priorities in the Field of Materials Science and Engineering. The questionnaire was designed to obtain both qualitative and quantitative opinions concerning important problems and specialties in materials research. It was sent to nearly 3,000 professionals representing many disciplines and responsibilities. The 555 usable replies were analyzed

in detail to yield, for each of the nine Areas of Impact, a selection of high-priority topics and specialties in applied and basic research in materials. The methodology and illustrative results appear in Appendix A. Among other questions, the respondents were asked to rate, on a five-level scale, the overall importance of materials science and engineering to progress in each of the nine Areas of Impact; some of the results, calculated as explained in Appendix A, appear in Table 13. No attempt was made to rank-order the relative importance of the nine Areas of Impact to the nation.

The scope and nature of materials problems we have discerned in seven of the nine Areas of Impact are highlighted in the following brief descriptions.* Exhaustive treatments are beyond the intent of this summary report, though considerable additional information was obtained from the priority analysis (see Opportunities in Materials Research, page 97).

Needs in Communications

Society continues to demand communications systems of greater capacity, versatility, and reliability for many purposes: telephone; radio and television program distribution; information processing, storage, and retrieval; automatic billing, credit-checking, and other operations of a cashless society; airline and hotel reservations; police and fire departments; aircraft navigation and traffic control.

|

* |

These descriptions do not match precisely the Areas of Impact listed in Table 13. Materials problems in Defense, for example, are documented extensively elsewhere and so are not covered in the section on Space (page 68). |

TABLE 13

Relative Importance of Materials Science and Engineering in Nine Areas of Impact

|

Area of Impact |

Rating Number* |

|

Communications, Computers, and Control |

92 |

|

Defense and Space |

92 |

|

Energy |

90 |

|

Transportation Equipment |

69 |

|

Health Services |

69 |

|

Environmental Quality |

68 |

|

Housing and Other Construction |

67 |

|

Production Equipment |

61 |

|

Consumer Goods |

60 |

|

* Rating numbers were derived from analysis of replies to a priorities questionnaire, using the methodology described in Appendix A. Note that respondents were not asked to rate relative importance of the areas themselves to national or other interests. |

|

These demands on communication systems translate into requirements for transmissions at higher and higher frequencies and for hardware inherently more reliable than the existing terminal, switching, and transmission devices. Implicit in such needs is a variety of problems in electronic, optical, and related materials.

Existing communications technology relies heavily on electromechanical and reed-contact relays, wire and cable, and microwave radio transmission. These technologies operate under the traditional pressures to reduce costs while increasing reliability. Newer technologies rely heavily on solid-state electronics, particularly integrated circuits. Solid-state electronics, the basis of modern computer and communications systems, is inherently far more reliable and versatile than vacuum-tube devices. Progress in communications also requires the development of cheaper long-distance, broad-band transmission. Involved here will be further advances in microware transmission, including the use of satellites and waveguides, and optical communication technologies. Also necessary will be new switching methods that take advantage of the memory and logic capabilities of integrated circuits, magnetic-bubble and charge-coupled devices, and minicomputers. New customer services will call for cheap, reliable visual displays and data terminals to replace the more cumbersome cathode-ray tube and tele-typewriter. In this vein, the recently developed charge-coupled devices seem especially promising for solid-state television cameras and display systems.

In traditional equipment, there is steady progress toward economizing on materials through miniaturization and by developing

substitutes from cheaper materials. The development of textured spring alloys, for example, has contributed to the miniaturization of electromagnetic relays; ferromagnetic alloys in miniature reed switches have led to compatibility between the fast-switching capabilities of modern electronics and the slower-switching operations of electromechanical equipment; new plastics have been developed for wire insulation that can withstand exposure to various working environments; and, in the substitution area, the price of copper has stimulated the development of aluminum wire and cable together with suitable connection technology. An increasingly pressing problem is to find substitutes for palladium in electrical contacts and for gold in thin-film circuits.

Solid-state electronics is a pace-setter in the materials field for ultimate control over material quality, since electronic properties are so sensitive to impurities and defects. The need for quality control is particularly severe in the manufacture of integrated circuits and optical devices, especially as the dimensions of such devices become smaller and smaller. Critical, too, are advances in the photolithographic-polymer mask process used to lay down circuit pathways. The beams of light employed for this purpose are very close to the maximum possible definition, so that further substantial miniaturization of the circuits, an important factor in cost reduction, is not feasible. For this reason, the semiconductor industry is developing electron-beam lithography processes, which promise ultimately to reduce the size of integrated circuits from 100th to 1,000th the size of those possible with current methods. Critical to the electron-beam approach is the synthesis of

improved mask and lithography materials and better understanding of the physical interaction between such materials and electron beams.

For transmission, especially in conduits under city streets, optical waveguides will permit great savings in space as contrasted to copper or aluminum wire and, at the same time, considerably greater channel capacity. Here, again, a critical need is close control of the composition and structure of the glass fibers involved. Optical communications systems, in addition, will require considerable materials work to develop reliable terminal device arrays. These arrays will comprise a hybrid technology—integrated optics—optical devices like light-emitting diodes, lasers, photodetectors, and optical waveguides driven or controlled by silicon integrated circuits.

Needs in Space

Steady improvement in the performance of materials is required to meet this country’s current and projected priorities in space, which fall into three general areas: manned space flight, space science, and space applications. With the successful completion of the Apollo program, the manned space flight effort will emphasize the earth-orbiting Skylab and the earth-to-orbit Space Shuttle. The space science programs, likewise, will concentrate more on exploration of the earth’s environment, the solar system, and beyond, using a variety of spacecraft and missions: the Orbiting Solar Observatory, the High Energy Astronomical Observatory, the Mariner missions to Venus and Mercury, the Pioneer missions to the vicinity of Jupiter, and the Viking Mars orbiter and lander. Space applications involve near-earth satellites for

meteorology, communications, navigation, geodesy, and earth-resources surveys. Typical unmanned, earth-orbit spacecraft are the Nimbus weather satellite and the Earth Resources Technology Satellite.

An important requirement of the Space Shuttle is a thermal protection system that can be reused about 100 times. One aspect of this problem is that the craft’s payload, and thus the cost of launching 1 pound of payload into orbit, is very sensitive to the weight of the thermal protection system. The leading candidate materials for the system are rigidized ceramic-fiber insulations protected with a ceramic coating. These materials are simple, light-weight, highly-efficient thermal insulators. They should survive repeatedly, without significant loss in performance, the maximum expected surface temperatures caused by aerodynamic heating during normal reentry. Should the ceramic insulations meet unexpected difficulties, however, other thermal protection materials must be developed as backups. These include superalloys, coated refractory metals, and ablators.

The Space Shuttle and other spacecraft will require materials that provide better mechanical properties per unit of weight. The same need applies to space payloads. These requirements call for greater use of alloys and composites having high ratios of strength to weight and of stiffness to weight. As the vehicles move deeper into space, they will require materials that resist radiation and extremes in temperature more effectively than do those now available. Improved surveillance and communications satellites demand optical materials of increased integrity, and mirrors that maintain their shape indefinitely (e.g., that have a near-zero coefficient of thermal expansion).

Research on lasers must be continued to realize the potential of such devices in communications. Materials with novel and superior electronic and optical properties are required for improved sensing devices or instruments. In particular, high-reliability sensors for earth-orbital spacecraft offer the benefits of rapid, continuous observation, greater freedom from weather disturbances, large-area scans for regional synthesis, better-quality data, reduced data-acquisition time, and lower cost. Finally, long-lived materials with extreme service capability are needed for advanced batteries and power-generation systems.

Needs in Electrical Energy

Electrical generating capacity in the United States has doubled every decade since about World War I. There seems little doubt that demand for power will continue to grow, and that measures to safeguard the environment and conserve fuels will raise the cost of power. This will intensify the mounting pressure to generate, transmit, store, use, and conserve electricity more efficiently, and it is here that materials science and engineering becomes essential.

Energy-related materials problems range in difficulty from those of coal-gasification processes, which are perhaps not crucial, to the uncertain but probably exceptional demands that will be imposed by thermonuclear fusion processes. Discussed here are some selected materials needs in superconductors for generators and transmission lines; in high-temperature gas turbines; in magnetohydrodynamic generators; in breeder reactors; in solar-energy conversion; and in materials and devices for storing electrical energy.

It is too soon to forecast the materials requirements of a fusion power system, which should offer cheap, clean, and practically unlimited energy. The scientific feasibility of the process has yet to be fully demonstrated and, if it is, engineering feasibility is unlikely to be shown before the end of this century. The fusion reaction would occur at hundreds of millions of degrees in a plasma confined by a magnetic field, no known material being up to the task. A gas-containment vessel and other components will be needed, however, and it must be assumed that the materials used will have to cope with intense heat and radiation, in particular, extremely high-energy neutrons.

Superconductors. Superconductors are materials that lose their electrical resistance below a characteristic and, thus far, very low transition temperature. The alloy with the highest known transition temperature found yet becomes superconducting at only 23.2º above absolute zero or about 250ºC below freezing. Known superconductors must thus be cooled cryogenically using helium or hydrogen liquids.

Despite the costs and engineering problems of cryogenic cooling, superconducting alloys may allow the efficiency of conventional electrical generators to be increased and their size reduced. Size and efficiency depend in part on the intensity of the magnetic field that can be produced by a given volume and weight of electrical conductor. Superconductors like niobium-tin yield very high magnetic fields; progress is being made with this approach, but difficult fundamental and engineering obstacles remain. At some point, moreover, extensive high-power experiments will have to be done on full-scale generators, which are very expensive to build and evaluate.

Superconducting cable may ultimately reduce the cost of transmitting large amounts of power underground. The passage of direct current through superconductors generates essentially no heat, which would avoid the problems of dissipating heat in confined spaces. The hope is that, when transmitting very large blocks of power, the resulting savings would more than offset the cost of cryogenic cooling. Super-conductors with higher transition temperatures than those now available are desirable. Even small increases in transition temperature can improve the economics of cryogenic cooling. Whether significant improvement is possible, however, cannot be predicted, since we still know too little of the fundamental relationships of the composition, structure, and properties of superconductors.

High-Temperature Turbines. Electric utilities have turned significantly to generating electricity with gas turbines, which can be obtained and brought on-line quickly, to make up shortages caused by delayed additions of nuclear and sometimes conventional generating capacity. The thermal efficiency of the turbines, however, is only 25 to 30 percent when operating on natural gas at about 870ºC. If the temperature can be raised to between 1,100º and 1,300ºC, an overall efficiency of 40 to 45 percent is predicted to be possible. The key to achieving such efficiency will be new or improved materials for the turbine parts, heat exchangers, and related apparatus. These materials must be strong and readily fabricated and, at the required temperature, must resist oxidation, impact, and thermal fatigue. It would be advantageous, too, if they could withstand the abrasive gas produced by burning pulverized coal,

thus making the latter technology more attractive. Such conditions cannot be met even by the most sophisticated alloys developed for turbine blading, so that ceramic materials will be necessary. Those being studied include silicon nitride, silicon carbide, and composites of silicon carbide or aluminum oxide fibers in a metal matrix. Selection of the optimum materials must await more comprehensive knowledge of their properties and performance.

MHD Generator. In the magnetohydrodynamic (MHD) generator a hot conducting gas replaces the rotating generator of conventional equipment. In either case, a magnetic field induces current in the conductor moving through the field. In the MHD device, current generated in the gas by passing it through a transverse magnetic field is drawn off by electrodes inserted into the stream. An MHD generator should achieve a thermal efficiency of 50 to 60 percent, but the materials problems are unusually severe. Current thinking envisions zirconium oxide for the electrodes, and aluminum, zirconium, and magnesium oxide for the burners. The conductive gas could be combustion gases from coal, seeded with potassium sulfate and maintained at 2,000º to 2,400ºC. We know far too little to be able to predict the behavior of this combination of materials at the temperatures involved. Reliable design criteria and materials selection will come only through coordinated materials research and engineering in several areas.

Breeder Reactor. Development of commercial breeder reactors, which may be the best hope for a relatively nonpolluting, long-term power supply, is a major interdisciplinary task. The fuel elements alone present

formidable materials problems (and coping with radioactive wastes is not the least of many other difficulties). Probably they will resemble today’s power-reactor fuel elements, which are thin-walled tubes, about 4 meters long, filled with uranium dioxide pellets. The breeder reactor, however, probably will use uranium-plutonium oxide pellets as fuel.

Effective fuel-element design requires that a number of characteristics of the pellets be clarified. These include elastic and plastic deformation, fracture, corrosion, effects of change in system composition, diffusion, and crystal defects. Such characteristics will be modified in complex ways, moreover, by radiation damage and large temperature gradients. Obtaining the needed understanding of the properties of this new fuel will occupy many scientists and engineers for several years, but the work is essential if breeder reactors are to be operating commercially by 1990, the current target in this country.

Solar Energy. Solar energy is chemically and thermally nonpolluting, and a number of approaches to harnessing it are being explored. These include conversion to electricity, directly or by steam turbine or other types of generators; heating and cooling homes and providing domestic hot water; and extracting energy from sun-powered phenomena such as winds and thermal gradients in the oceans. Progress in materials is important to such schemes. To convert sunlight to electricity, for example, requires large arrays of efficient, low-cost solar cells or collectors. Existing materials cannot fully meet the requirements.

The present silicon solar cells are effective in the space program, but widespread conversion of sunlight to direct current requires

more practical devices. The highest efficiency achieved yet is 18 percent— 4 to 5 percent above the best previous level—in a gallium arsenide cell; also under study is cadmium sulfide. Silicon, whose conversion efficiency is about 11 percent, remains the only cell material available commercially. The efficiency of solar collectors can be raised by coatings that absorb the sun’s energy much more readily than they re-emit it. Collector coatings may have to function at perhaps 500ºC, however, to improve the thermal efficiency of the system, and existing coatings may not be sufficiently stable. Molten salts, which are candidates for storage media, will cause corrosion problems in piping and containment vessels. Another scheme is to use wind-generated electricity to electrolyze water to hydrogen and oxygen, which could be stored and recombined at will in an energy-producing fuel cell. Materials problems here include fuel-cell catalysts and hydrogen embrittlement in piping. The latter problem could be serious in the proposed “hydrogen economy,” in which hydrogen would be a major fuel.

Energy Storage. Environmental concerns have prompted new efforts to develop inexpensive, reliable, nonpolluting means of converting and storing energy. Among the possibilities are improved electrochemical devices: fuel cells, primary cells (flashlight battery), and secondary cells (storage battery). Each of these converts stored chemical energy to electrical energy upon demand. The secondary cell, when recharged, converts electrical energy to chemical energy, stores it, and reconverts it to electrical energy upon demand.

Electrochemical devices potentially could replace the internal combustion engine in automobiles. Research in this area has produced promising secondary cells that include the sodium-sulfur battery announced several years ago. The anode in this device is liquid sodium; the cathode is liquid sulfur (in contact with carbon felt). The main innovation in the battery is the solid-state electrolyte, beta-alumina. It allows unusually high transport of sodium ions, which diffuse through it to produce electric current when the battery is connected to an external load. The cell is recharged by reversing the process.

The sodium-sulfur battery, though a significant development, is not well adapted to vehicle propulsion. Its operating temperature is high, around 300ºC, and metallic sodium would be hazardous in a crash. Many other materials are being studied for use as electrodes and electrolytes in electrochemical devices. The beta-alumina, for example, only suggests a crystallographic structure that should be explored for other solid-state electrolytes. The ultimate material, if there is one, probably will be found in quite different classes of structures.

Needs in Transportation

Advances in transportation in this country are hampered primarily by social, political, and economic factors. But while materials are not limiting, they do present important opportunities and problems. Transportation systems consume enormous amounts of metals, concrete, plastics, and other commodities; in the federal highway system, maintenance costs for bridges alone are estimated at $6 billion over the next decade. In such a context any technical advance can affect costs markedly. More specifically, the automobile industry faces

immediate materials difficulties induced not only by rising costs and competition, but also by safety and emission standards. Improved materials, in addition, would facilitate progress in mass-transit systems, marine transportation, and aircraft.

Automobiles. The sheer size of the automobile market makes its materials needs critical. A weight increase of 1 pound per vehicle adds 5000 tons annually to the industry’s consumption of materials. Automotive transportation accounts for about 45 percent of all United States transportation expenditures and 84 percent of total passenger-transportation costs. The passenger car is used for 82 percent of commuting to work, and city streets are estimated to handle more than half of the vehicle miles traveled nationally. Pressure is rising to reduce the reliance on the automobile, particularly in cities, but the change seems unlikely to come rapidly.

In few industries is competition among materials as fierce as in the automobile industry, which converts some $5 billion in materials annually into 10 million vehicles and will struggle to lop pennies from the manufacturing cost per car. The competition is being intensified by vehicle safety and emission standards. New equipment mandated into autos in 1971–76 includes bumper systems, safety devices, emission controls, and heavier suspensions and body components to support the extra weight. These changes could increase the weight of a typical passenger car by 10 percent or more. Greater weight requires more power and thus control of a higher level of emissions. Reduction

in weight, consequently, has become a major design problem, along with safety and emission standards, and each of these problems is materials-intensive.

Meeting safety standards will require additional structural members, which is prompting research on more effective use of high-strength steels and on the light metals, aluminum and magnesium. For a high-integrity safety car, steel may be too heavy to use in the large number of structural members required for good energy absorption. Aluminum would be the natural successor, although steel honeycomb could be competitive if its fabrication costs were reduced.

High-strength, low-alloy (HSLA) steels are prime candidate materials for reinforcing ultrasafe passenger compartments. A return to the separate reinforced frame will require more steel, some of it probably HSLA. More steel will be needed also in door safety beams, double roofs, and bumper systems. With proper design, however, new high-strength steels could help to reduce weight. If a part now made of carbon steel sheet can be made 15% thinner, for example, it can usually be made of currently-available HSLA steel—to have the same functional strength at the same cost but with less weight.

Among the emission-control problems is the need to find durable materials that will last for the 50,000 miles required for auto-exhaust systems. The only proven materials for this use, muffler stainless steel, contains about 11 percent chromium, of which the United States has no domestic supply. The consequent increased demand for chromium in exhaust systems may require materials substitutions in other uses.

Severe difficulties exist with catalytic emission-control systems, as indicated by the one-year delay granted recently by the Environmental Protection Agency for meeting the 1975 standards. Catalysis, as mentioned earlier, seems not to be the best long-term solution to the emissions problem, but the possibility of at least interim use has stimulated a considerable effort on catalytic materials. Platinum, the best material available now, would have to be largely imported, and spent auto catalyst probably would have to be regenerated and recycled. Other catalysts tested thus far are less effective than platinum and may be simply inadequate.

To hold down costs the automobile industry, among other measures, is working on more efficient processes, such as high-speed induction sintering of powdered metals, continuous casting or electro-forming of metal sheet and strip, and reuse of plant scrap in manufactured products. Research is likely on more quantitative means of evaluating the acceptability of materials during production—as in the melt, ingot, or powder stage—to reduce the processing of rejectable materials. Expanded research is in prospect on joining, particularly the use of adhesive bonding and inertial and electron-beam welding in large-volume production. Already well established is the effort to reduce materials consumption by sharper design and improved functional characteristics.

Mass Transit. The main structural requirements of mass-transit systems can be met, in general, by state-of-the-art materials, although stronger, more durable light-weight structures are important for transit

cars as well as for autos. Many improvements are needed in specialized subsystems: electrical controls, storage-battery components, electro-deposited finishes, and nonsmoking, self-extinguishing polymers. Lower-cost electrical insulations are desired, for example; present resin systems require considerable tailoring to achieve the best combination of dielectric strength, life, flammability, and smoke behavior.

An important area is the development of solid-state power components. As the speeds and power of rail vehicles increase, the trend in propulsion will be toward greater electrification and alternating-current traction motors. The related component problems lie in three areas:

-

Energy transfer—as from the power system grid to the moving vehicle and in reverse for braking, the latter being particularly significant for cooler subways.

-

Conversion of power on board the vehicle for various purposes—power either transferred from the grid or generated on board.

-

Propulsion units—either alternating current rotation motors for driving wheeled vehicles or linear motors for driving air-cushioned or magnetically levitated vehicles.

Marine Transportation. Among important materials problems in marine transportation is corrosion resistance in propulsion systems. The relative availabilities of various fuels are somewhat uncertain in the future, but it must be assumed that the cheapest residual oils will be used in marine machinery: boilers for steam turbines, marine diesels,

and gas turbines. The materials problems involve hot corrosion in the presence of salt-containing air, sulfur, and some components of ash, like sodium and vanadium. Ash deposition is also harmful. These difficulties are being explored by the U.S. Maritime Administration in cooperation with marine equipment suppliers. Further in the future will come materials bottlenecks in nuclear propulsion. Current work on both land-based and sea-going reactors should provide at least partial solutions in this area.

Aircraft. In airborne transportation, significant progress can be made by improving the thrust-to-weight ratio of jet engines. The materials with the best potential for achieving this goal are composites. Carbon- or boron-reinforced polymers are the most likely composites for use in low-temperature fans. These materials are quite promising for reducing engine weight. Current research goals are tough, readily processible polymers that can withstand 250ºC. Polymers may be required later for service at 300º to 500ºC, the temperatures that will be encountered in higher-speed, multistage fans. An important backup to the graphite-polymer composites is aluminum reinforced with boron fibers.

Composites for use in the turbine section of a jet engine present still greater difficulties. These materials must be able to operate for thousands of hours at more than 1,000ºC; they must be light, strong, and dimensionally stable and must have excellent oxidation resistance. One possibility is “natural composites” or oriented eutectics, in which the reinforcing and matrix phases are produced automatically in certain favorable cases by carefully controlling the conditions of solidification. These composites promise major advances in high-temperature metals.

Such systems include nickel-base alloys reinforced with tantalum carbide or nickel-niobium (Ni3Nb) and cobalt-base alloys reinforced with tantalum carbide. Turbine materials for operation above 1,300ºC probably will have to be made of coated refractory metals.

Needs in Health Services

Only recently have medical and materials people begun to work seriously together to make or modify materials specifically for medical use. The soft, water-swellable gel, Hydron, resulted from collaboration among polymer chemists and surgeons; ultrapure, medically acceptable silicone rubber came as an industrial response to a medical need. Both materials are for surgical implants. A longstanding effort on biomaterials is the dental-research program of the National Bureau of Standards and the American Dental Association. This interdisciplinary effort has produced improved dental materials, standards, test methods, and instrumentation. Although other such cases exist, the general tendency is still to rely on materials developed first for nonmedical purposes.

Work on biomaterials is not extensive yet, but in the coming decade may become an exciting thrust of materials science and engineering. Good progress, however, will require that several obstacles be overcome:

-

Industrial interest is inhibited by relatively small markets and by shifting national goals in health care.

-

Lack of basic knowledge forces us to rely mainly on empirical solutions to important biomaterials problems.

-

The unusual interdisciplinarity of the field requires new perspectives, particularly in the university sector.

-

Standards and testing capabilities for biomaterials are absent or inadequate.

Small Markets. The markets for surgical and dental supplies in this country in 1970 were each in the range of $250 million to $300 million. These products—e.g., sutures, syringes, and dental cements—are made by aggressive companies with active though highly proprietary development programs. Research on specialized biomaterials, on the other hand, is restricted because of the smaller markets in cardiovascular equipment ($127 million in 1970) and in catheters, artificial organs, and heart-lung equipment (each between $20 million and $25 million). Still, workers in these smaller areas have achieved a degree of success by innovative use of materials like silicone rubber, Dacron, and polyvinyl chloride in heart valves, oxygenators, and vascular (circulatory system) replacements. Industrial titanium, tantalum, vitallium (a cobalt-based alloy), and stainless steel are also used quite commonly in prosthetic and orthopedic devices.

Research in specialized biomaterials is hampered, moreover, by its decline in relative national priority during the past few years. Higher priority now is assigned to improvement in general health-care services. Progress in materials is most likely to contribute to the achievement of this goal when it is translated into markets for medical-service equipment, such as diagnostic and monitoring devices based on fundamental knowledge of the physical and chemical properties of biological substances.

Gaps in Knowledge. A notable gap in basic knowledge is clear in the artificial kidney. After 30 years of steady improvement, development of the device has reached a plateau. Further development is stalled because we know too little of the diffusional and surface properties of polymers to build better membranes and blood-access connectors. The problem has become even more pressing since July 1, 1973, when Medicare began to pay 80 percent of the cost of kidney dialysis after the first three months of treatment.

There are major unknowns in the reactions of blood with surgical implant materials. Nearly all nonliving and many living materials are thrombogenic: they induce blood-cell damage, clot formation, and protein destruction. Studies of surface charge, surface free energy, and similar properties of various materials have turned up few if any correlations. Surfaces containing bonded heparin (an anticoagulant) and aqueous gel surfaces are compatible with blood to a degree, but have yet to be proven clinically. The interdisciplinary approach of materials science and engineering clearly could create a major impact in this area.

New Perspectives. The range of disciplines needed to solve problems in biomaterials calls for new perspectives at the university level. Scientists have shown that, for example, bone will grow comparatively deeply into pores in the surfaces of metals and ceramics when pore diameter is 100 microns (0.004 inch) or more. There is some hope that implants of suitable surface porosity can be firmly and stably grafted to bone in this way. The work, however, requires experts in ceramics, powder metallurgy, orthopedics, and biomechanics. Such a variety of

disciplines means that the team and the funding must be relatively large to ensure significant progress. A situation of this kind is a marked departure for those funding agencies and university administrators who are more accustomed to dealing with academic research focus in units of one faculty member.

Lack of Standards. A major difficulty in biomedical materials is the lack or inadequacy of agreed-upon standards and test methods. The problem is likely to persist so long as evaluation of many of these materials depends on the surgical profession, since the system is not designed to obtain the comprehensive life-test data needed for surgical implant materials. Federal agencies are beginning to encourage their contractors and grantees in biomaterials research and development to adopt the methods of industrial materials science and engineering, including scientific standards of measurement. Lack of basic knowledge, however, often leads to less than adequate test methods. The biomaterials field could be significantly advanced by the establishment of a suitable research center concerned with the evaluation of biomaterials, together with the development of associated test methods and standards.

Despite these growing pains, some activity is under way in biomaterials. Many materials have been screened in the search for non-thrombogenic vascular replacements. The leading candidate materials, thus far, are composite structures of non-thrombogenic hydrogel, carbon, or cell-seeded microfiber surfaces on silicone rubber substrates, and some segmented polyurethanes. Plastics reinforced with glass

fibers are being studied for orthopedic service. A variety of membrane-fabrication techniques are being used, mainly with common materials, to improve the performance of economical oxygenator systems. And a new, still highly experimental use of biomaterials is in biologically active surgical implants. Enzymes bound to the surface of such an implant, for example, may catalyze specific biochemical reactions in the body.

Needs in Environmental Management

Many of the nation’s environmental problems reflect the customary inattention to the materials cycle. Industry, including the materials community, has tended, understandably, to optimize only that segment of the cycle that deals with the incoming material through to the out-going product, especially the parts of that segment where optimization will reduce costs. This approach creates environmental impacts that by now are well recognized. Few would question the need to broaden the span of materials management to the full cycle, from primary resources through disposal and reclamation, including the side effects such as emissions to the environment. Materials science and engineering can do much to ease the transition.

Manufacturing. Knowledge of properties of materials can contribute to the development of manufacturing properties that generate less waste but preserve the functional properties of the materials involved. A general approach mentioned earlier is to shape products directly from fluid (liquid or powder) materials instead of from solids. A more specific example is the printed circuit board, which the electronics

industry makes from a board covered completely by a copper film. The film is etched away chemically to leave copper only along the desired circuit pathways. The process produces, industrywide, more than 5 million pounds per year of dissolved copper in wastes. Most of the metal is recovered, both because it is costly and because otherwise the wastes would present a severe disposal problem. New processes have been devised, however, in which copper is deposited in the first place only along the desired circuit pathways. The circuit pattern is first printed on the board with a special ink or with a polymer coating that can be optically activated and chemically developed in the shape of the pattern. The copper, deposited from a chemical bath, adheres only to the pattern delineated on the board. Both the ink and polymer processes avoid the waste problem and also reduce the costs of starting materials.

Recycling. Materials scientists and engineers can create materials, or combinations of materials, that function as required and, at the same time, are amenable to product designs that facilitate recycling. An everyday instance is the glue used in some types of cardboard boxes. This adhesive gums up the paper-processing step so that the paper in the boxes cannot be recycled economically. Careful study of precisely how glue effects a bond, in terms of its composition and structure, almost certainly would yield an adhesive more compatible with reprocessing. Metals provide a second example. Some alloying substances and coatings degrade the base metal to the point where it cannot be recovered economically from the alloy. Similar problems exist with polymer blends. Materials research should create alternative materials systems that fill the design function at competitive cost and still permit economic reclamation.

Waste Conversion. Wastes can often be converted to useful materials, but the requirements of environmental protection and the related skewing of the traditional economic framework call for more concentrated effort. Examples of potential uses of wastes include the manufacture of brick from fly-ash or coal-ash slag combined with suitable binders. One new method of making brick combines almost any solid inorganic material with a small amount of portland cement and a proprietary chemical accelerator. The mixture is molded at high pressure to give a brick whose properties adapt it to new construction techniques that reduce labor costs.

A waste of unusual potential is lignin, the cellulose-bonding material in wood. Lignin and other soluble components amount to some 55 percent of the weight of the tree. The lignin, about 25 million tons of it annually, is discarded with waste pulping liquor by paper producers. A small amount of lignin is recovered as lignosulfonates, which are used by industry as surface-active agents. An attractive possibility, however, is to employ lignin as a bonding agent in wood products, where it would function as it does in nature.

The ability to use lignin in this way would represent a marked gain, both in conservation of resources and in environmental improvement, but the problem is particularly difficult. It has not responded to concerted scientific attack for some years. New hope lies currently in the use of sophisticated methods, such as high-voltage electron microscopy, to probe the chemical structure of lignin as it exists in the tree. Scientists to date have had to study the compound largely after it emerged from the severe chemical attack of the pulping process.

Organic wastes might provide a raw-material base for biodegradable plastics, although the costs involved are quite unfavorable today contrasted with plastics made from petroleum and natural-gas liquids. Newsprint and waste cotton fabric might be recycled to become a raw-material base for cellulosic plastics. Ethylene, the leading monomer for plastics today, might be manufactured by fermenting sugars or hydrolyzed cellulose to ethyl alcohol, which could be cracked to ethylene.

Packaging. Noteworthy among environmental concerns are packaging materials. Consider the simple beer can, a common element of litter. For economic reasons, producers have shifted from iron-based cans, which rust away eventually, to aluminum cans, which last almost indefinitely. A container material that degrades quickly and naturally could solve the litter problem. It might be costly, on the other hand, and be made from a relatively limited resource like petroleum. Iron or aluminum can be reclaimed without great difficulty, if at some cost, and reclamation is perhaps the pragmatic course at the moment. In any event, the packaging problem illustrates an environmental role of materials science and engineering applied to the materials cycle.

Needs in Housing

The materials-related problems in housing, even those of broad import, hamper progress much less than do legal, economic, and cultural constraints. Easing these constraints was one of the goals of Operation Breakthrough, sponsored by the Department of Housing and Urban Development (HUD). An official of HUD has said of Breakthrough,

“…very little of what we are doing involves basic research or totally new hardware technology.” HUD hoped to “…facilitate the…use of technology which currently exists but has not found extensive use by the housing industry.”

Predicting Behavior. A major bar to the introduction of new materials in housing is the unreliability of short-term tests for predicting long-term behavior such as weathering. A related obstacle is the lack of data on the performance of materials and components in service. Information is scattered and uncorrelated; a sound compilation is not available to the housing industry. Such data are basic, not only to the use of current materials but for developing short-term tests and otherwise predicting the behavior of new materials.

A second general need is a more fundamental basis for predicting the effects of fires in buildings. Laboratory tests have been devised to measure such parameters as speed of ignition, rate of flame spread, smoke evolution, and penetration of fire through walls and partitions, but the validity of these empirical tests is too uncertain. Their frequent appearance in building codes is due largely to the lack of anything better. The peculiar needs of flammability research could be well served by a center devoted to this subject.

Performance Criteria. The estimated 4,000–6,000 building codes in this country impede progress partly because they are out of date and more importantly because they differ among themselves. The resulting effects are to limit both the range of usable materials and the size of their markets; both factors restrict the effort likely to be expended

on new materials. The probable solution is to replace building codes with performance criteria. Such criteria would specify degrees of safety, durability, livability, and the like, but would leave design and materials selection to the engineer. (The National Bureau of Standards developed “guide criteria” in the course of its evaluation of the 22 housing prototypes created by industry under Operation Breakthrough.)

Replacement of building codes by performance criteria is expected eventually to permit the development of modular home-building systems. These could consist of standard components, assembled offsite into a variety of configurations. Offsite manufacture will reduce costs, but perhaps by no more than 20 percent of the cost of the home, including land, financing, and so forth. Performance criteria and testing, however, will help resolve other problems: protecting the public against poorly designed and unsafe structures; establishing standards of construction suitable for Federal Housing Administration mortgages; and developing more livable communities of homes.

Thermal Insulation. The National Bureau of Standards has estimated that energy consumed in residential heating and air conditioning could be reduced, nationwide, by as much as 50 percent from current levels by better insulation and construction. The technology is available, and insulation is being upgraded.

Offsite Assembly. Developments in housing materials will come most likely in response to demands of industrialized offsite assembly processes. A number of laboratories, for example, are seeking materials capable of

joining housing components satisfactorily for long-term service. Other problems include the fire-retardation properties of synthetics, which generally will have to be less expensive before the materials can enjoy widespread adoption in housing. Materials such as gypsum board, plywood, concrete, glass, and aluminum, on the other hand, are remarkably inexpensive and unlikely to be displaced soon in their traditional functions.

The persistence of familiar housing materials is evident in the mobile home industry. Mobile homes are made in sufficient volume—the number sold in 1972 amounted to 20–25 percent of the housing starts that year—to be well adapted to industrialized assembly. They are not subject to building codes, moreover, and thus offer unusual flexibility in materials selection and assembly techniques. Even so, the industry has not seen the emergence of spectacular new families of materials. Aluminum sheet, hardboard, and the like are in common use. More advanced concepts are found perhaps in bathroom materials, where the traditional cast iron and porcelain have given way largely to reinforced plastics. These are mainly glass-fiber reinforced polyesters with gel coats. They are light and strong and withstand the handling involved in assembly and transportation. On the other hand, they scratch more readily than porcelain, and are subject to cigarette stains and charring although they meet fire safety requirements.

New building materials have appeared in recent years, of course, for applications other than in mobile homes. Prominent among them are polymeric products such as vinyl tile, polymer-paper laminates for

working surfaces, and sealants and gaskets for installing large sheets of glass and prefabricated components. A product specifically of materials science and engineering, polymer latex-modified portland cement, has experienced modest but growing success in the decade it has been on the market, despite its relatively high cost. More recently, a high-strength concrete reinforced with steel or glass fibers has been developed. These newer materials have succeeded as a rule by producing economies, as in assembly or maintenance, that offset their higher initial costs. And since the greatest economies in housing probably will stem from offsite assembly, novel materials seem likely to be tied to that method of construction.

Needs in Consumer Goods, Production Equipment, Automation

In addition to the preceding illustrative studies of materials in seven areas of impact, we have analyzed the qualitative responses to the COSMAT priorities questionnaire in terms of specific research needs in all nine of the areas surveyed. In consumer goods and production equipment, the two areas not covered above, the responses mentioned certain requirements consistently. These include, for consumer goods, greater durability (both physical and chemical), less flammability, and greater safety, reliability, serviceability, and maintainability. A clear need exists also for better tests for these characteristics. Materials problems mentioned consistently for production equipment include longer-lasting, higher-speed machining devices, both metallic and ceramic (e.g., grinding wheels), better joining methods, and greater high-temperature strength.

We have noted earlier the attractive opportunities in a special area of production equipment: automation and robotics. These opportunities exist not only in production and manufacturing, but also throughout the service areas of the economy—mail sorting, billing, typesetting, weather forecasting, health checkups, traffic control. Automation techniques in all of these areas include a common approach: the generation and processing of information to provide or display data in useful forms or to control servomechanisms. Myriad opportunities can be discerned in primary information-generating devices or sensors, which will depend on the nature of the quantity or physical property to be measured, the object to be sensed, or the pattern to be diagnosed. Nearly always these sensing techniques must be nondestructive. They must rely, therefore, on the effects of the interaction of matter with various kinds of radiation—optical, electromagnetic, ultrasonic, and others. Progress in this field clearly will require the most sophisticated knowledge of materials and of spectroscopy in its broadest sense.

The signals generated by the primary sensing device usually must be processed, analyzed, and correlated by a computer or, increasingly, a mini-computer, itself a product of sophisticated materials science and engineering in its integral circuits and memory devices. Once in useful form, the information can be printed out, visually displayed, or used to control a machine or servomechanism. Opportunities for improvement lie both in visual displays and in computer-controlled machines. The latter can range from simple mechanical transducers—to control a valve, for example—to complex robots that can simulate some of the routine actions of human beings.

The development of this type of automation will require new devices, particularly optoelectronic ones, and solid-state electronic circuits with associative memory and learning capability for parallel processing. Especially promising avenues for further research appear to be semiconductor lasers and light-emitting diodes, magnetic-bubble devices, charge-coupled devices, reversible photosensitive materials, liquid crystals, optical modulators and deflectors, and various functional components such as amplifiers, timing circuits, and shift registers. Advances in servomechanism design will call for the combined talents of electrical and mechanical engineers, but often these devices and machines will also place stringent demands on the materials of which they are made, especially when the equipment must work reliably for long periods in hostile environments.

Automation is a very broad interdisciplinary area and is likely to become more so. It combines the knowledge and skills of materials scientists and engineers with those of the information community— mathematicians and statisticians, as well as computer hardware and software engineers. The economic and social implications of switching to automation in a given operation, moreover, can call also for the expertise of economists and social scientists.

Goal-Oriented Materials Research Bearing on Areas of National Impact

COSMAT analyzed several thousand write-in comments from materials professionals to derive a list of goal-oriented research topics that rate high priority in the nine national areas of impact. The topics selected included various properties of materials, classes of materials, processes, and applications (Table 14).

TABLE 14

Goal-Oriented Materials Research

Bearing on Areas of National Impact

|

Analysis of several thousand write-in comments from materials professionals indicates that the topics below rate high priority in research in the areas of impact shown. Where applications are listed, the meaning, generally, is that new materials and processes are needed to advance the application. Communications, Computers, and Control Memories; visual displays, semiconductors, thin films; integrated circuit processes, yields in large-scale integration, component reliability; optical communication systems; defect properties of crystals; chemical and surface properties of electronic materials; purification; crystal growth and epitaxy; joining techniques; contacts; high-temperature semiconductors. Consumer Goods Durability; visual displays; corrosion; mechanical properties; improved strength-to-weight packaging; recyclable containers; high-strength glass; plastics; plastic processing; composites. Defense and Space Mechanical properties; lasers and optical devices; energy sources; heat resistance; corrosion; radiation-damage-resistant electronics; composites; turbine blades; heat shields; thermal-control coatings; nondestructive testing; higher strength-to-weight-ratio materials; reliability; materials for deep-sea vehicles; joining. Energy Battery electrodes; solid-state electrolytes; seals; superconductors; electrical insulators; mechanical properties; radiation damage; high-temperature materials; corrosion; joining; nondestructive testing. Environmental Quality Less-polluting materials processes; pollution standards; recyclability; reduced safety and health hazards; extraction processes; catalysts; secondary uses for discarded materials; sorting processes; nondestructive testing; noise reduction. Health Services Implant materials; membranes; biocompatibility; medical sensors; material degradation. Housing and Other Construction Prefabrication techniques; corrosion; cement and concrete; weatherability; flammability. Production Equipment Friction and wear; corrosion; sensors; automation. Transportation Equipment Corrosion; pollution control; high strength-to-weight ratios; high-strength, high-temperature materials; impact resistance; catalysts; adhesives; superconductors; lubricants. |