CHAPTER 4

NATIONAL OBJECTIVES AND THE ROLE OF MATERIALS SCIENCE AND ENGINEERING

INTRODUCTION

The Nature of National Goals

There are different kinds of national goals. Some are ultimate objectives of society and are as old as the Constitution and its amendments. These goals define the kind of society we try to be, but they are not, as a rule, reducible to tasks for science and engineering. “Life, liberty, and the pursuit of happiness” are objectives that can be and are advanced by achievements in science and technology, but one would find it hard to derive from them specific programs in MSE. We may call them aspirations, principles, concepts, ideals, or goals, if we like.

Below this towering top comes a layer of other comprehensive national goals that embraces and defines areas of endeavor. Provision of free education for all is an old one; free medical care for the aged a more recent one While subject to change in detail, these are nonetheless continuing objectives, but, in any hierarchy of goals, they still lie above those that are more directly related to technological or materials tasks.

Moreover, one does well to think of a wide spectrum of kinds of goals as well as of a ranking. Various types of goals in the science and technology field alone are, for example—

Large, discrete tasks of social utility (e.g., model cities, urban mass-transportation systems)

Complex, open-ended programs (e.g., weather prediction, oceanographic program)

Large research tasks, with likely social utility (e.g., Apollo, Mohole)

Large fundamental research tasks of uncertain outcome but great social utility (e.g., nuclear fusion, nuclear propulsion)

Correction of social deficiencies (e.g., poverty, genetic defects)

Improvement of productive performance (e.g., reduction in mortality, increased man-hour productivity)

Specific inventions (e.g., aircraft-noise suppressor, alternative to internal combustion engine)

etc. etc.

Similar diversity exists along other classes of goals, i.e., one can distinguish between social goals, goals of scientific understanding, goals associated with pragmatic application of knowledge, and surely others.

Anyone searching for a repository of national goals or anything approaching it will be disappointed. Some goals are so persistent and fundamental that they are built into the conscience of the nation and of every citizen. The various “freedoms,” both from and to, are of that kind. Others are implied in the structure of American society. Easing of upward social mobility, for example, would be hard to identify in any piece of legislation, yet it is undoubtedly a pervasive goal. So is increased man-hour productivity. These are canons by which we live and act.

As one leaves the loftier goals and focuses more on the recent past, it becomes easier to identify specifically formulated goals; this is largely because they cannot be taken for granted, are not “self-evident,” but arise out of changing perceptions, as crystallization of widely-felt needs, as responses to events, or sometimes as “brainchildren” of illustrious citizens. In short, as the level of aggregation drops, the degree of specificity increases. As a result, one can ascertain and assert more forcefully that a goal does in fact exist, and one can more easily link the likelihood of its achievement to activities in MSE.

A useful distinction can be made between goals that have been formulated at some level of government—usually at the federal level—and are embedded in a piece of legislation, an Executive Order, a regulation, and those that rest on a less conspicuous basis, yet partake of the nature of national goals. The “conquest of polio” as compared with the “conquest of cancer” serves to illustrate the difference. The latter is an organized and specifically financed societal goal embedded in a federal statute. The fight against polio, supported financially largely by the annual “March of Dimes,” undoubtedly was as much the expression of national desire, but its implementation was diffuse, unstructured, and left to individual initiative and excellence.

In the category of the less articulate, an interesting national goal and of significance to MSE is one that might be called “economic strength.” While there exists a whole fabric or arsenal of laws designed to facilitate the smooth functioning of the economy (to strengthen competition, safeguard the sanctity of contracts, minimize labor disputes, encourage inventiveness, etc., etc.) one can point only to a single piece of legislation that sets up “economic strength or (disregarding recent misgivings as to its validity) “growth” as a national goal. That legislation was the Employment Act of 1946, which was aimed at establishing “maximum employment, production and purchasing power” as a national goal, or as a trinity of goals.

Only once in recent times has there been a governmental attempt to formulate specific national goals as guides to policy. That was under the Eisenhower Administration, when it adopted the recommendations of the Presidential Commission on National Goals. A different approach was taken by President Nixon when he set up in the Executive Office a “goals research staff” intended to be a permanent feature but disbanded after it had

rendered its first report to the nation. The chapters of that report, issued July 4, 1970, are entitled “Population Growth and Distribution,” “Environment,” “Education,” “Basic National Science,” “Technology Assessment,” “Consumerism,” “Economic Choice and Balanced Growth,” and “Toward Balanced Growth.” Obviously, these are not goals. Rather, the topics suggest that in the process of selection, the Staff tried to determine in what areas conflicts would in the future have to be resolved, objectives established, and debates carried on.

Given the difficulty of defining goals and finding documentary support, the multiplicity of types of goals, their changing nature and stress, and COSMAT’s reluctance to consider itself appropriately composed for conducting an exercise in determining comprehensively what the nation’s goals seem to be, we have chosen a more modest way for evaluating the relationship between goals and MSE. We have selected some areas of national concern that affect all citizens in their daily lives and some that affect the nation’s fate as a whole, and have endeavored to show how needed advances can be assisted by contributions from MSE. We have concentrated on areas where (a) the materials aspect is, if not critical, at least obvious, (b) the contributions that materials advances might make are more easily demonstrated. Change is also a characteristic of the goals of interest to the materials community: change in the priorities among goals and changing emphasis within each. Changing priorities show up clearly when we consider either federal funding alone, overall public spending, or expenditures as reflected in the Gross National Product. Trends within broad goals are discussed extensively in the balance of this chapter.

Limiting our review of federal spending to the recent past, we can clearly identify a number of trends in the allocation of funds (see Table 4.1). Defense, space, and international affairs, in which grouping the first accounts for the lion’s share, declined from 62 percent in 1955 to 37 percent in 1972, though absolute amounts for the same period rose from 42 to 86 billion (current) dollars. The relative decline was due mainly to the continuing and rapid rise in outlays aggregated under the generic term “Income Maintenance;” this item rose from 15 to 85 billion dollars over the same 17-year period and is now about equal to the defense/space/international affairs group in magnitude. Income maintenance comprises above all social security, welfare, and veterans pay, but also includes access to medical care and education.

In relative terms, investment in human and physical resources has risen even more rapidly, as have housing and community development. There are important differences, however. For one thing, the absolute amounts involved are much smaller. Secondly, in the case of investment in physical resources (commerce, transportation, natural resources), growth has been discontinuous; a jump occurred in the second half of the 1950’s, and relative outlays have been on a plateau since. Thirdly, by way of contrast, in the case of housing and community development, the rise has been very recent. Only in the area of investment in human resources has there been a steady absolute as well as relative upward movement in federal spending, mostly in the field of education (Medicare outlays in this auditing scheme are carried under “income maintenance”).

Federal outlays, of course, constitute only a portion of public spending. State and local government expenditures account for the balance. These have

Table 4.1 Changes in Federal Budget Outlays,a 1950–1972, Selected Fiscal Years

|

Category |

1955 |

1960 |

1965 (Percent) |

1970 |

1972 |

|

Defense, space, international |

61.7 |

53.6 |

49.6 |

44.3 |

36.6 |

|

Income maintenance |

22.0 |

26.7 |

29.0 |

32.4 |

36.2 |

|

Investment in human resourcesb |

2.2 |

2.5 |

3.2 |

5.8 |

6.2 |

|

Investment in physical resourcesc |

2.3 |

6.4 |

7.8 |

5.7 |

6.4 |

|

Housing and community development |

0.7 |

0.8 |

1.0 |

2.7 |

3.5 |

|

Net interest on debt |

6.9 |

7.5 |

7.3 |

7.3 |

6.2 |

|

Other |

4.1 |

2.5 |

2.1 |

1.8 |

5.0 |

|

|

100 |

100 |

100 |

100 |

100 |

|

Source: Setting National Priorities—the 1972 Budget, Brookings Institution (1971) p. 13. a Not adjusted for sales of assets b Education, training, health c Commerce, transportation, natural resources |

|||||

risen more rapidly than federal funds: from not quite 40 billion (current) dollars in 1955 to 132 in 1969 (the most recent year for which published data permit these comparisons to be made). Put differently, state and local expenditures have advanced from 36 to 43 percent of total governmental expenditures between 1955 and 1969, with schools, highways, and welfare accounting for the bulk of state and local outlays. If one then aggregates public expenditures at all levels of government, it turns out that in 1969, defense and international affairs for instance, accounted for 27 percent (as against the more than 40 percent in the federal picture), and education for over 16 percent (compared to about 6 percent under the total “investment in human resources” item in the allocation of federal funds). Going beyond public spending, Table 4.2 presents society’s total expenditures in the 1960’s, cast in terms of specified national goals as patterned by a continuing study of the National Planning Association. Significant features of the presentation are the slower than average rise of national defense, agriculture, international aid, housing, and R&D. On the uptrend side are social welfare, education, transportation, health, natural resources, and private plant and equipment. By and large then, the picture parallels the one portrayed by the changes in public spending, except that all spending for housing is down, while governmental spending is up.

The private consumption sector is of course a vast mix of incommensurables. To get closer to an understanding of its evolution in terms of materials, Table 4.3 presents a breakdown into three major categories.

Perhaps the most interesting feature of Table 4.3 is the relatively rapid rise in expenditures for durables as compared with nondurables and services, though the increase in the last-named category precisely equals that of the entire group (and of GNP as a whole). It suggests that the trend toward services is not nearly as pronounced in private consumer expenditures as in the economy as a whole. With regard to goods, it does indicate that there has been much growth in precisely that segment of private consumption where materials can have their greatest impact: durable goods.

A final comparison, before we draw some conclusions for the impact on the materials community of shifting public-expenditure trends, pertains to the relationship between the funding agency and the consumer of the result of funding. That is, in the case of defense and space outlays, the funder is at the same time the principal, if not the only, consumer of the product arising as the result of the funded expenditures. Such expenditures made, in other words, consitute close to 100 percent of the GNP for that function. In sharp contrast, federal transportation outlays represent only 6 to 7 percent of the output of the transportation industry, and still only 20 percent when state and local expenditures are included. In education and manpower, federal outlays represent a little over 10 percent of the GNP in that segment, but the percentage rises to nearly 90 when state and local expenditures are factored in. The corresponding figures in the health sector have recently run about 25 and 40 percent, respectively. They are lowest of all in housing; whether or not state and local expenditures are included, governmental outlays represent only about 6 percent of the output used.1

Table 4.2 Expenditures for National Goals, 1962 and 1969 (in billions of 1969 dollars)

|

Goal Area |

Expenditures in |

Percent Change, |

|

|

1962 |

1969 |

1962 to 1969 |

|

|

Private consumption |

$418.5 |

$579.6 |

38.5% |

|

Private plant and equipment |

62.0 |

98.6 |

59.0 |

|

Urban development |

84.0 |

94.7 |

11.0 |

|

Housing |

37.5 |

35.4 |

–5.5 |

|

Other urban facilities |

46.5 |

59.3 |

13.0 |

|

National defense |

66.5 |

78.8 |

18.5 |

|

Social welfare |

46.4 |

71.1 |

53.0 |

|

Health |

43.5 |

63.8 |

46.5 |

|

Education |

41.8 |

64.3 |

54.0 |

|

Transportation |

39.3 |

61.5 |

56.5 |

|

Research & development |

21.1 |

26.9 |

27.5 |

|

Natural resources |

7.1 |

10.1 |

42.0 |

|

Agriculture |

8.2 |

7.8 |

–5.0 |

|

Environmental quality |

– |

6.3 |

– |

|

International aid |

6.1 |

5.3 |

–13.0 |

|

Manpower training |

0.1 |

2.0 |

– |

|

GNP |

678.0 |

931.4 |

37.5 |

|

Source: National Planning Association |

|||

Table 4.3 Expenditures for Private Consumption, 1962 to 1969 (in billions of 1969 dollars)

The above sketch suggests four major implications for the materials field. First, those segments of public spending that were prominent in funding R&D have suffered a relative decline. Second, the segment that has increased most in relative importance, i.e., income maintenance, has little direct linkage with materials. Third, those segments that have increased and do have an association with materials problems (housing, transport, etc.) account for only a minor share of the GNP generated in these sectors, i.e. whatever funding is performed will not, as compared with, say, defense, be directly translated into a ready market for the output. Fourth, the rising importance of state and local spending spells a shift to human resource development, prominently education (see above) and thus represents growth in an area in which so far at least materials have not played a key role.

Given the enormous weight of “consumer expenditures” in the nation’s GNP, it is obvious that such inarticulate goals as durability, reliability, performance, safety, low-cost repairability, etc. pose a continuing challenge for MSE. Yet the play of the market is the only mechanism for coupling goals and materials, and as we have pointed out above, it functions far less directly than in areas where the purchaser has a very direct role in the specifications (defense, space etc.). One reason is that often the consumer cannot really specify what he wants, and if he does, his desires may not find a producer responding.

In consumer areas, however, one must be careful not to confuse poor manufacturing practices with unsatisfactory material properties. Not know-what is achievable at reasonable cost, the consumer has a long list of desiderata but he cannot match it with potential solutions. All he can do is test different products offered and proceed by trial and error. Consumer choice is limited by the range of choice presented to him in the market place.

Another poorly articulated goal, moving ever more forcefully onto center stage is materials substitution. Nobody and everybody has responsibility for it. The manufacturer will act on the basis of cost differentials, evaluated in terms of the firm’s profits. The consumer will act in equally narrow terms that include cost and convenience. Society’s interest that ranges from favoring materials with a longer-run supply potential to materials having less noxious environmental impact is basically an orphan, or we should say, has been until recently. In the future, one may expect greater emphasis on substitutions. These substitutions will be (a) the direct substitution of one material for another (aluminum for copper, nickel for silver, polyurethane for cork, etc.); (b) development of new ways to perform the same function (transmitting a telephone signal through transparent fibers in conjunction with light-emitting semiconductor diodes at the transmitting and semiconductor photodetector diodes at the receiving end, or substitution of integrated circuits for transistors and vacuum tubes, or development of wholly new adhesives); and (c) development of substitute technologies that could radically alter the patterns of materials demand (nuclear vs. fossil-fuel power generation, communication through solid-state electronics vs. transportation of people and goods).

Constraints of various kinds will call for much more sophisticated approaches to substitution, and MSE is bound to play a major role in this sphere.

In the balance of this chapter, we attempt to (a) specify some goals in the fields of communication networks, space, electrical power, transportation, health services, the environment, and housing, and then document their evolution by way of governmental pronouncements and actions in various contexts, and (b) illustrate how the achievement of these goals is connected with specific developments in MSE.

The sectors chosen for reviewing the connection between materials research and national goals do not exhaust all segments of economic activity; nor do they cover the broader range that forms part of the materials research priority study described in the next chapter. Specifically, the subsequent discussion omits reference to what are broadly called consumer and producer durables. The reason is simply that one cannot identify anything there that could be regarded as a “national goal” beyond such very loose matters as “competitiveness,” “least-cost production,” etc. Nevertheless, these broad areas do present many important challenges to materials technology and some of these, in the area of defense, the supply of and demand for materials, and automation of industrial processes and methods, are briefly described. This chapter concludes with an overview of goal-oriented materials research opportunities and needs, many of which apply to several economic sectors.

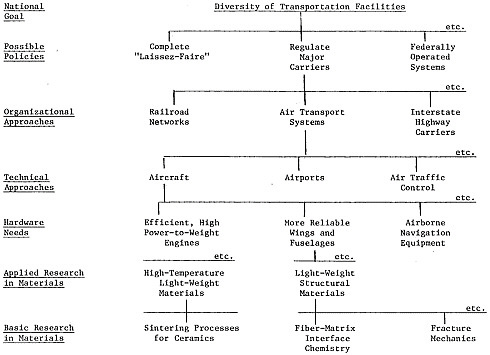

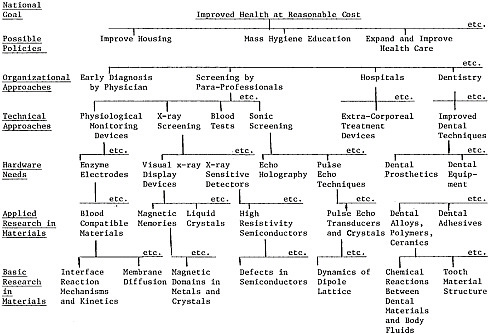

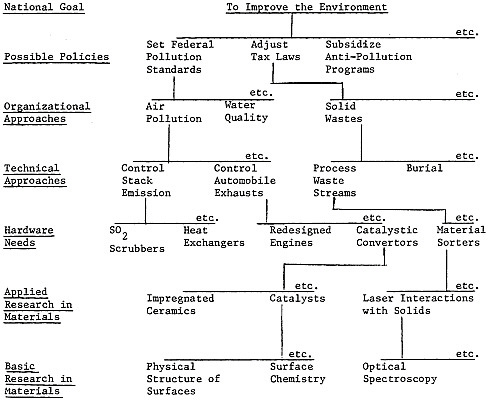

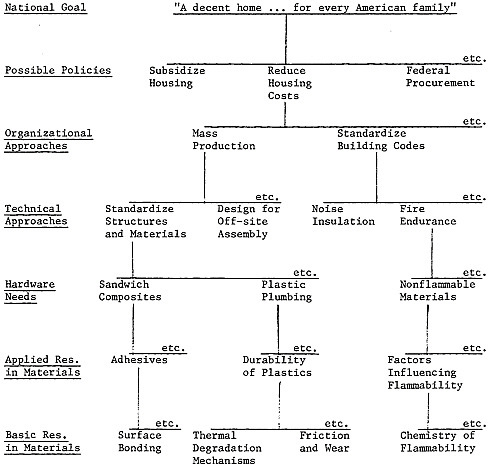

The Relevance-Tree Approach

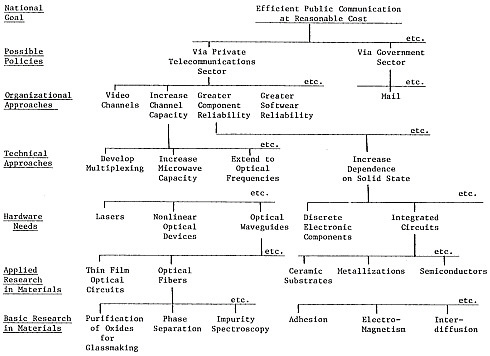

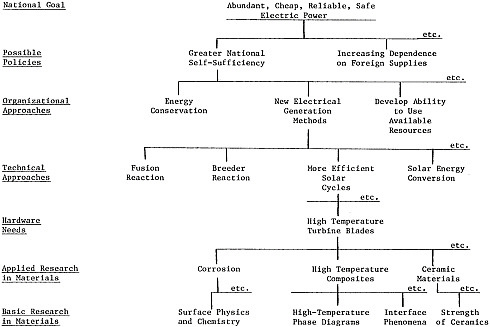

The approach to the identification of critical materials needs has generally been a “shredding out” of specific materials problems and tasks from the more broadly formulated goals; often referred to as the relevance-tree technique. For example, one may derive from the goal of abundant, reliable, low-cost, and environmentally acceptable electric power the route, among others, of controlled thermonuclear fusion and, by an extension of the process, the requirement of a material with specific tolerance for radiation damage.

According to Jantsch2, technology transfer occurs vertically via at least eight levels. At each level, there can also be horizontal transfer. These are summarized in Tables 4.4 and 4.5 where some examples are also given. The eight levels represent progressively increasing (or decreasing) “levels of aggregation” —moving upwards in the tree involves embracing increasing breadth of techniques and technologies in order to achieve the desired social or economic objective.

Vertical transfer can be up or down. When upwards, the science and engineering can be regarded as creative in that it creates new technologies, new functions, and new opportunities for society. When downwards, the science and engineering can be regarded as responsive in that it is responding to perceived societal needs.

Table 4.4 Illustrative Levels in a Relevance Tree (after Jantsch)

|

|

Technology Transfer Level |

Horizontal Transfer |

Vertical Transfer |

|||

|

Direction of Progress |

|

|

8. |

Society |

Ethical Constraints on Social Goals |

Implications of Communications for Society |

|

Impact Levels (Outside Materials Science and Engineering |

7. |

Social Systems |

Technical Air Program for Developing Countries |

Defense and Other Natural Aspects of Commications |

||

|

6. |

Environments |

Invasion of Other Industrial Sections |

Communications Sector of Industry |

|||

|

5. |

Applications |

Demand for Auxiliary Support Systems |

Market for Communications Systems |

|||

|

|

|

4. |

Functional Technological Systems |

Diffusion of Existent Technology |

Solid-State Communication Systems and Functional Sub-Systems |

|

|

Development Levels (Within Materials Science and Engineering) |

3. |

Elementary Technology |

Merger of Discrete Technologies |

Integrated-Circuit Technology, etc. |

||

|

2. |

Technological Resources |

Fructification of other Fundamental Technological Research |

Diffusion Techniques Planar Techniques, etc. |

|||

|

1. |

Scientific Resources |

Empirical Postulation of a Scientific Theory |

Recognition of the Natural Phenomenon of Semiconduction: Majority and Minority Carrier Concept, etc. |

|||

Table 4.5 Example Programs Displayed According to Relevance Trees (after Jantsch)

|

Example 1 (Exploratory, creative, creates opportunities) |

Example 2 (Normative, responsive, responds to needs) |

|

|

8. |

World-wide instant communication, artificial organs for man, etc. |

Space as an environment to benefit man, space as challenge, etc. |

|

7. |

Technological gap between countries, extension of defense and space strategies, support for development of artificial organs, etc. |

National space program |

|

6. |

Changing relationship between systems and components manufacturer (growing together), diversification into medical electronics, city-building, hospital management, etc. |

Planetary mission |

|

5. |

Applications to new tasks, incentive for mass production, market strategy, business cycles for rate of successive and related innovation |

Nuclear rocket propulsion |

|

4. |

Low-cost high-reliability electronic systems increase in capacity for volume and mass unit, etc. |

Nuclear-thermal propulsion unit, nuclear-electric (for example, ionic) propulsion system |

|

3. |

Integrated circuits, number of component functions accommodated, frequency, power dissipation, feasible reject level for mass production |

NERVA-type or SNAP-type nuclear reactor technology, gaseous nuclear fuel technology, thermionic technology, metal vapor turbine cycles, etc. |

|

2. |

Level of microminiaturization feasible with current and future techniques, limits of molecular engineering, high-frequency potential, etc. |

Three-fold specific impulse by use of hydrogen as propellant in connection with nuclear external heating, continuous low-thermal acceleration by electric propulsion, etc. |

|

1. |

Quantum electrodynamics, quasi-particles, etc. |

Conditions for and energy yield of nuclear fission, thermodynamic superiority of low molecular-weight gases, ionization potentials, zero-gravity in orbit (for low-thrust spiralling out), thermionic principle, etc. |

|

Example 3 |

Example 4 |

Example 5 |

|

|

8. |

Abundant power |

Eliminate poverty |

Eliminate poverty |

|

7. |

Power Network system |

Increase exports |

Population control |

|

6. |

Thermonuclear power |

High-technology, e.g. computers |

Distribution of birth-control techniques to public |

|

5. |

Plasma containment |

Large-scale memory |

Birth-control techniques |

|

4. |

Large superconducting solenoid |

Bubble-domain memory system |

Pill |

|

3. |

Cryogenics |

Integrated circuitry |

Drug manufacture |

|

2. |

Superconducting alloy metallurgy |

Garnet crystal growth |

Biochemical synthesis |

|

1. |

Physics of superconductivity |

Cooperative behavior of magnetic lattices |

Biochemistry |

Jantsch labels levels 1 through 4 in Tables 4.4 and 4.5 as Development Levels, being mainly technical in nature and resulting at the 4–5 boundary in a functional technological system. Levels 5 to 8 are labelled Impact Levels, being mainly segments of society which are affected by the results of the science and engineering. MSE is clearly most immediately associated with levels 1 through 4. In its creative mode, the output of MSE is a new functional technological system. In its responsive mode, society has perceived a need for a functional technological system which MSE should help produce.

The relevance tree should also be interpreted on a suitable time scale. It takes time for progress upwards through the various levels to occur. Basic research on materials, for example, might not begin feeding information upward for 10 years or more.

As the specifics of the generally formulated or implied goals are modified, so the MSE tasks will vary. In the case of health, there seems to have taken place a shift from conquest of specific diseases or disturbances to delivery of care for large numbers. In the case of energy, we see emphasis on such items as the breeder reactor and on conversion of coal to gas or liquid form. Once these are commercially feasible, emphasis may change again, this time perhaps to such long-run concerns as minimizing the ejection of heat into the atmosphere and, therefore, to the potential of solar energy. Yet, the national goal of abundant, low-cost, reliable, and environmentally sound energy is unlikely to change. Thus, what follows deals generally with goals that may be assumed to be prominent for some time but the specifics of which are subject to modification.

TELECOMMUNICATION NETWORKS

The Nature of Telecommunications

In the broad sense, telecommunications (TC’s) are all-pervasive. TC’s transmit information in the form of electrical signals from one place to another. The information may be speech, or numerical data, or radar signals, or television pictures, or facsimiles, or signals from sensors such as seismographs, electrocardiographs, heat, pressure- and light-sensitive devices.

TC’s impinge on virtually every aspect of life—on work, on pleasure, on health, on business and commerce, on transport, on family. Materials can be ordered by telephone, medical doctors consulted, and business carried on in a very different way from that which preceded the large use of telephony. International communications have shrunk distances, brought families closer together, allowed television viewing of events as they occur the other side of the world. The impact of television has been profound on the economy, the dissemination of news, and the social patterns of life. Similarly, the impact of computers and their interconnection through telephone and data networks is immense—an example from common experience is the vast improvement in air-travel reservation procedures and in seat assignments occasioned by the use of computers coupled to a nation-wide, and in some cases, international communications network.

TC’s are the nervous system of a nation. They are vital for its everyday activity, as has been recognized by Japan which has afforded them top priority in its development plans for the 1970’s. TC’s, along with computers, have had an impact on man’s information-handling tasks and capacities which compares with the impact that the steam engine and other motive powers had on man’s physical tasks and capacities.

The opening paragraph of the final report of the President’s Task Force on Communications Policy (Rostow Report, August 14, 1967) aptly states this theme: “Few technological changes have had so profound an effect on the human condition as the development of telecommunications. Man today lives in a maze of electronic signals; it is certain that their influence on the quality of his environment will be even more important in the future than is the case today.”

The same report goes on to state: “The essential goal of national policy, in our view, is an optimal rate of improvement in our telecommunications capability, based on progress in science, technology, and the arts of management, and addressed to the growing needs of its users.” This is a rather vague definition as definitions of national goals go, but it is indicative of a growing awareness in the late 1960’s that the nation should develop a coherent policy for the telecommunications field.

One of the reasons why national goals for telecommunications have seemed less urgent than they might have been lies with the structure of the nation’s telecommunications network and the way it is managed. The U.S. is the only country in which the operation of the telecommunications network is not the direct responsibility of the government. Instead, it has been left to private enterprise to develop in response to customers’ needs, although under the close and continuous monitoring and regulation provided by the Federal Communications Commission (FCC) and various other state and local utility commissions. In many ways it can be said that the U.S. has found an ingenious compromise between the extremes of outright nationalized industry and private monopoly. The FCC is the instrument designated by Congress to exercise regulatory powers over communications carriers. As such it is the prime agency for formulating and implementing policy for TC.

The major portion of the nation’s TC network is operated by the Bell System which has, as its corporate policy, enunciated by A.T. and T. President W.S.Gifford in 1929, “the best possible telephone service at the lowest cost consistent with financial safety.” In view of the position of the Bell System, it might not be inappropriate for us to regard this objective as in lieu of a national policy statement concerning the TC network.

In recent years, however, the FCC has followed a course designed to temper the dominant position in TC held by the Bell System. Though the TC network is often described as a “natural monopoly,” the FCC is seeking ways to open it up to a greater number of private companies to share in providing the increasing scope and diversity of communications equipment and sources. The resulting arguments over whether the public interest is really best served by a fragmented network and industry or a unified one are outside the scope of this present study.

The issue of the Bell System is, however, an especially poignant one for the modern field of MSE. It can be fairly stated that the field got a big impetus with the discovery of the transistor at Bell Telephone Laboratories

in 1947. In retrospect, it can be seen that the solid-state electronics industry which followed is what is responsible for the great diversity of communications equipment and the highly increased competition the Bell System now faces.

Dimensions of the Telecommunications Sector

TC systems are made up of three principal classes of equipment: terminal (both for sending and receiving), switching, and transmission. Some of the more common types of equipment that are used in these systems are listed in Table 4.6.

There are over 120 million telephones in the US today, close to two million non-broadcast stations authorized, and over 25,000 broadcast services. A recent study3 projected the number of telephones for 1985 as 220 million, plus 3 million picturephones (about two-thirds of which will be used mostly for data or information services), and about 8 million data terminals connected to public and other networks.

TC’s are a major factor in the national economy. According to Clay T. Whitehead, Director, Office of Telecommunications Policy,4 during the past 20 years the communications industries’ contribution to the national economy increased by over 500%, a growth rate almost double that of the economy as a whole and substantially in excess of the rates of such important segments as transportation and trade. The Bell System alone has been responsible for a major share of the nation’s business expenditures for new plant and equipment, 10 billion dollars in 1970 (about 12% of the nation’s total) compared with approximately 6 billion dollars for transportation and 2 billion dollars for mining, and it employs about 1,000,000 people.

In addition to these indirect effects of communications on the economy, the direct impact is substantial by virtue of the size of the industry. The Bell System alone, for example, accounts for 15% of the domestic copper consumption and is the largest single consumer of polyethylene.

Dependence of TC’s on Hardware and Materials

TC’s have become one of the most sophisticated forms of high technology, although a person using a telephone may be less conscious of the hardward than when he uses a car or an aeroplane. But advances in TC technology more often than not result from, or depend strongly upon, advances in materials technology. Some examples will help illustrate the point:

Table 4.6 Types of Equipment in Telecommunications Systems

|

Terminal Equipment (Sending and Receiving) |

|

|

Telephones |

Computers |

|

Television cameras |

Medical sensors |

|

Television receiver |

Industrial sensors |

|

Alphanumeric displays |

|

|

Switching Equipment |

|

|

Relays |

Electronic switches |

|

Ferreeds |

Memory devices |

|

Transmission Equipment |

|

|

Wire |

Coaxial cable |

|

Radio and antennas |

Microwave waveguide |

|

Microwave and antennas |

Satellites |

|

Undersea cable |

|

The first successful transatlantic telegraph cable (1866) rested on the solution of the hitherto unknown problems of making, laying, and splicing cables that would be sufficiently robust and durable in the ocean environment.

Transcontinental telephone service opened (1915) only after ways had been found to build repeater amplifiers in order that intelligible voice communication could be carried this great distance. These, in turn, required the development of both high current-density oxide cathodes to replace the inadequate metal filaments of early vacuum tubes and a new magnetic material, permalloy, for the loading and inductance coils.

Radio relay systems in telephone networks made their appearance after World War II. The successful design of special high frequency tubes essential for this system was only made possible through the development of improved ceramic insulators (steatite) which had low loss at high frequencies and high temperatures—a development which required special attention to material purity and reproducibility of processing cycles to achieve the necessary control of microstructures.

But it was the discovery of the transistor at Bell Labs in 1947 that really opened the era in which materials technology became inextricably interwoven with advances in TC technology. Practical tansistors called for hitherto unheard of achievements in material (germanium and silicon) purity and perfection—landmark feats were the invention of zone refining and techniques for crystal growing. Since then, a steady stream of advances in solid-state electronic-materials technology (controlled alloying, diffusion, epitaxial growth, oxide masking, thermocompression bonding, etc.) has kept expanding the capability and capacity of electronic components and TC’s. The center of the stage is held at present by the integrated circuit (IC), a supreme achievement of MSE in which physics, chemistry, and metallurgy have been combined with electronic design and engineering to produce, via a procedure which involves hundreds of carefully controlled materials-processing steps, a complex functional piece of material—a material which, when it is energized, performs desired electronic functions such as amplification, memory, logic, calculation, etc., with a long-term reliability that would be virtually impossible using earlier discrete component technologies.

But the IC is not-the end of the long series of innovations that can be traced to the transistor discovery. Semiconductor technology stirred intensive R&D in other areas of solid-state science, and in 1958 there occurred another discovery, or invention, that is likely to be of enormous importance to TC’s in the future, the laser. Because their operating frequencies (optical) are so much higher than radio and microwave frequencies, lasers offer the prospect of the vastly greater numbers of communication channels that may be needed in the future as demand for communications continues to increase. The laser has, in turn, stimulated materials research aimed at a whole new family of optical devices—oscillators, amplifiers, modulators, memories, holography, photochromicity, visual display devices, deflectors, etc. Optical transmission lines based on ultra-pure glass fibers and integrated optical circuits are currently receiving heavy emphasis in order to complete the arsenal of components for a complete optical TC technology to supplement existing microwave and older technologies where traffic demands are sufficiently great.

Another, rather different measure of the interplay between materials

technology and TC’s is provided by the familiar telephone handset itself. It utilizes 42 of the 92 elements provided by nature (See Table 4.7); it contains among other things, 35 types of metals and alloys, 14 types of plastic, 12 varieties of adhesives, and 20 different semiconductor devices.

The increasing demand for TC’s can only be met by continuous heavy investment in R&D aimed at finding new and better devices, improved switching and transmission methods, and better materials. The communication system to support the high volume of communications projected earlier will undoubtedly be materials-based; whether the transmission is by wire, radio, coaxial cable, microwave relay or satellite, by waveguide operating at millimeter wave frequency or by glass fibers using laser sources and various optical circuit devices based upon new materials discoveries; whether the switching is by electromagnetic relays, ferreeds, vacuum tubes, transistors, or opto-electronic devices; or whether the information storage is by magnetized wires or tapes, ferrite cores, integrated circuits, holography or photochromicity. (It would be physically impossible to meet today’s demands with yesterday’s relays and wire-based technology—the materials and power requirements alone would be prohibitive.) Present TC technology, now based very much on microwave frequencies and solid-state devices such as integrated circuits, may well have to be extended to optical frequencies in order to keep up with future requirements.

A feature of telephone-network planning is the systems approach in which new techniques have to be added to, or adapted to, existing networks. It would be far too costly to rebuild the whole network each time a new TC technology comes along. This implies, in turn, that all the devices and components in the network must be operationally compatible with one another, and must be chosen so as to optimize the overall performance of the network.

Whatever the technology, because of the vast amount of capital equipment needed nationwide, durability of the hardware and the reliability of its performance must be of the very highest standards.

All the above factors combine to place real pressures on MSE. In the past, these pressures have been repeatedly met through developments in materials and device technology. Many of these achievements, some examples of which are given in Tables 4.8 and 4.9, have gone on to have very significant impact in areas outside TC’s as well.

Government Involvement in Telecommunications

Playing such a vital role in the nation’s economy and welfare, yet tending by its very nature to be a monopoly (as with utilities, one does not have a choice between two separate telephone systems), the communications field is closely regulated by the government, principally through the Federal Communications Commission.

Some major events in the evolution of the federal government’s involvement with communications are as follows:

|

1910 |

Man-Elkins Act; jurisdiction of interstate and foreign telephone and telegraph service given to the Interstate Commerce Commission. |

Table 4.7 Elements in the Telephone Handset

|

Name |

How Used |

|

Aluminum |

metal alloy in dial mechanism, transmitter and receiver |

|

Antimony |

alloy in dial mechanism |

|

Arsenic |

alloy in dial mechanism |

|

Beryllium |

alloy in dial mechanism |

|

Bismuth |

alloy in dial mechanism |

|

Boron |

Touch-Tone dial mechanism |

|

Cadmium |

color in yellow plastic housing |

|

Calcium |

in lubricant for moving parts |

|

Carbon |

plastic housing, transmitter steel parts |

|

Chlorine |

wire insulation |

|

Chromium |

color in green plastic housing, metal plating, stainless steel piece parts |

|

Cobalt |

magnetic material in receiver |

|

Copper |

wires, plating, brass piece parts |

|

Fluorine |

plastic piece parts |

|

Germanium |

transistors in Touch-Tone dial mechanism |

|

Gold |

electrical contacts |

|

Hydrogen |

plastic housing, wire insulation |

|

Indium |

Touch-Tone dial mechanism |

|

Iron |

steel, magnetic materials |

|

Krypton |

ringer in Touch-Tone set |

|

Lead |

solder in connections |

|

Lithium |

in lubricant for moving parts |

|

Magnesium |

die castings in transmitter, ringer |

|

Manganese |

steel in piece parts |

|

Mercury |

color in red plastic housing |

|

Molybdenum |

magnet in receiver |

|

Nickel |

magnet in receiver, stainless steel parts |

|

Nitrogen |

hardened heat-treated piece parts |

|

Oxygen |

plastic housing, wire insulation |

|

Name |

How Used |

|

Palladium |

electrical contacts |

|

Phosphorus |

steel in piece parts |

|

Platinum |

electrical contacts |

|

Silicon |

Touch-Tone dial mechanism |

|

Silver |

plating |

|

Sodium |

in lubricant for moving parts |

|

Sulfur |

steel in piece parts |

|

Tantalum |

integrated circuit in Trimline set |

|

Tin |

solder in connections, plating |

|

Titanium |

color in white plastic housing |

|

Tungsten |

lights in Princess and key sets |

|

Vanadium |

receiver |

|

Zinc |

brass, die casting in transmitter, ringer |

Table 4.8 Summary of Some Major Achievements in Telecommunications Technology and Related Materials Achievements

|

Year |

TC Achievements |

Related Materials Technology Achievements |

|

1844 |

First domestic telegraph cable. |

|

|

1866 |

First successful transatlantic telegraph cable. |

Fabrication, laying, splicing of durable underwater cable. |

|

1877 |

First domestic telephone service. |

|

|

1915 |

First transcontinental telephone service. |

Oxide cathodes for vacuum tube amplifiers. Permalloy (nickel-iron) for loading coils. |

|

1927 |

Negative feedback amplifier enabled multiplexing. |

Quartz crystal piezoelectric filters. Modulators made from copper oxide varistors. |

|

1929 |

Coaxial cable carrier system for broadband transmission. |

Eventually made efficient, in 1939, through first application of polyethylene as a dielectric with low loss at high frequencies. |

|

1947 |

Transistory discovery, and beginning of solid-state electronics. |

Semiconductor verification and crystal growth. |

|

1948 |

Microwave radio relay system. |

Low-loss ceramic (steatite) insulators. Ceramic ferrites for isolators, circulators. |

|

1956 |

Transoceanic Telephone cable. |

Copper-beryllium repeater housings. Ultra-long life dielectrics and insulators. |

|

1958 |

Laser invented— offers prospect of increased bandwidth. |

Growth of suitably-doped refractory oxide crystals—ruby, sapphire led to demonstration of laser in 1960. |

|

1960 |

Electronic switching systems. |

Initially based on vacuum tubes, subsequently on solid-state electronics and integrated circuits. |

|

Early ‘60’s |

Millimeter wave system. |

Development of ultra-straight waveguide tubing and joining techniques. |

Table 4.9 Summary of Some Materials Innovations in TC Technology

|

Material or Process |

Category |

Applications in Telecommunications |

|

Metals |

||

|

Molybdenum Permalloy |

High permeability Magnetic alloy |

Loading coils; high frequency transformers and inductance coils; telephone relays and coils |

|

Remendur |

Magnetic alloy |

Fereed relays for electronic switching |

|

Remalloy, Permendur |

Magentic alloys |

Telephone receive diaphragms |

|

Vicalloy |

Permanent magnet |

Twistor memory devices |

|

Cobalt samarium copper alloys |

High strength permanent magnet |

Travelling wave tubes |

|

Alnico |

Permanent magnet |

Telephone ringers |

|

Vibralloy |

Constant modulus alloy |

Frequency-sensitive switches |

|

Textured copper alloys |

Spring materials |

Relay springs, electrical contacts |

|

Pure nickel alloys |

Vacuum tube filaments |

Microwave triodes; submarine cable tubes |

|

High conductivity aluminum alloy |

Electrical conductor |

Exchange area telephone cable |

|

Tantalum, tantalum nitride |

Thin film conductor |

Thin film circuitry; integrated circuits; resistors, capacitors |

|

Lead-antimony |

Soft alloy |

Cable sheath |

|

Copper-beryllium |

Sea-water resistant |

Submarine cable repeater housings |

|

ZAMAK alloys |

Die-casting alloy |

Precision switchgear and handset piece-parts |

|

Laminated sheets of copper and copper-nickel |

Composites |

Laminated coins acceptable to coin telephones |

|

Material or Process |

Category |

Applications in Telecommunications |

|

Plastics, polymers |

||

|

High density polyethylene |

Thermoplastic |

Cable insulation; cable sheath |

|

Long-life polyethylene |

Thermoplastic |

Durable cable sheath |

|

Impregnated, stabilized paper |

Paper |

Pulp insulated cable; metallized paper capacitors |

|

Continuously vulcanized rubber |

Rubber |

Rubber insulated cable |

|

Ceramics and Glass |

||

|

Low-loss steatite |

Ceramic insulator |

Supports in high-power transmitter tubes |

|

High alumina |

Ceramic insulator |

Insulating supports, integrated circuit substrates |

|

Freeze-drying |

Preparation of ceramics |

Improved ceramic composition and structure |

|

Garnets |

Magnetic ceramics |

Microwave, components, filters, isolators |

|

Ferrites |

Magnetic ceramics |

Magnetic memories |

|

Nickel-manganese-cobalt oxide |

Thermistors |

Thermal stability of circuits |

|

Potassium-sodium-niobate |

Piezoelectric ceramics |

Piezoelectric transducers and delay lines |

|

Lead-zirconate titanate |

Piezoelectric ceramics |

Microphone transducers |

|

Ultra-pure glass |

Optical glass |

Optical waverguides |

|

Material or Process |

Category |

Applications in Telecommunications |

|

Crystals |

||

|

Synthetic quartz |

Piezoelectric |

Ultrasonic transducers, frequency standards and filters |

|

Silicon |

Semiconductor |

Junction diodes, rectifiers, Schottky diodes, field effect transistors, solar cells, microwave diodes, transistors; integrated circuits; camera tube targets; charge-coupled shift register and image sensing devices |

|

Lithium tantalate, lithium niobate, barium sodium niobate |

Ferroelectrics |

Ultrasonic transducers, frequency filters; electro-optic modulators; optical harmonic generators; parametric optical oscillators |

|

Gallium phosphide |

Semiconductor |

Light emitting diodes for alpha-numeric displays |

|

Gallium arsenide |

Semiconductor |

Varactor diodes |

|

Mixed III–V compounds |

Semiconductors |

Continuous room-temperature injection laser |

|

Copper oxide |

Semiconductors |

Rectifiers |

|

Zone refining |

Purification process |

Semiconductor devices; integrated circuits |

|

Diffusion |

Doping process |

Semiconductor devices; integrated circuits |

|

Oxide masking |

Control of doping process |

Semiconductor devices; integrated circuits |

|

Epitaxy |

Thin film growth |

Semiconductor and magnetic devices; integrated circuits |

|

Thermo-compression bonding |

Connection technique |

Integrated circuits |

|

Material or Process |

Category |

Applications in Telecommunications |

|

Neodymium-doped yttrium aluminum garnet |

Lasers |

Optical transmission |

|

Substituted rare earth garnets |

Magnetic |

Bubble domain devices |

|

Czochralski growth |

Crystal growing |

Semiconductors, ferroelectrics, garnets |

|

Hydrothermal growth |

Crystal growing |

Quartz, garnets |

|

1912 |

Radio Act of 1912; protects certain radio frequencies for governmental use. |

|

1922 |

Interstate Radio Advisory Committee (IRAC) formed by Secretary of Commerce; to allocate frequencies among various federal agencies that use radio communication. |

|

1927 |

Establishment of Federal Radio Commission; to classify, license, and regulate nongovernment stations. |

|

1934 |

The Communications Act of 1934; creation of the seven-man Federal Communications Commission, an independent agency with regulatory powers over communications carriers that the Mann-Elkins Act had vested in the Interstate Commerce Commission and licensing power over radio communications that the Federal Radio Commission had exercised. |

|

1951 |

Creation by President Truman’s executive order of a Telecommunications Advisor to the President. |

|

1956 |

FCC consent decree which allows the Bell System to retain its manufacturing subsidiary, Western Electric Co. but with the latter allowed to sell only to the Bell System. In addition, all extant patents in 1956 were made freely available to any applicant and all future patents were to be made available on request but at reasonable royalties. |

|

1958 |

Advisory Committee on Telecommunications convened by the Director of the Office of Civil Defense Mobilization. |

|

1959 |

Proposal to set up a five-member special Telecommunications Commission failed to obtain Congressional approval. |

|

1960 |

Task force appointed by President-elect Kennedy recommended transfer of all OCDM telecommunications powers to a new Office for Coordination and Development of Communications Policy within the Executive Branch. |

|

1960 |

FCC allocates frequencies in bands above 890 Mc/s. Customer ownership of private microwave. Previously limited to right-of-way companies (rail, pipeline, public safety) and governmental agencies in addition to communication carriers. |

|

1961 |

Transportation and communications service established; responsible for procuring and promoting economical use of transportation motor equipment, public utilities and communications service in executive agencies. |

|

1962 |

Communications Satellite Act establishes COMSAT, a private corporation to be owned 50% by overseas carriers and 50% by general public. Space and ground segments open to competitive bidding. |

|

1965 |

FCC, regarding ownership of satellite communication ground stations, assigns 50% to COMSAT, 50% to overseas carriers, with COMSAT as manager. |

|

1965 |

FCC in allowing 50%-80% reduction in Bell System rates compared with private microwave tariffs raises question of discriminatory practices. |

|

1966 |

FCC rules satellites should supplement underseas cable facilities and question is raised of whether private entities can build and own specialized satellite systems within the continental U.S. |

|

1966 |

FCC considers interdependence of computer and communications services and facilities, and whether remote data-processing is outside of regulatory control. |

|

1967 |

FCC considers applications by Microwave Communications, Inc. for setting up new facilities in domestic public point-to-point microwave radio service. Consent eventually given. About 1700 station applications pending by mid-1972. |

|

1968 |

“Carterphone decision” on interconnections in which FCC ruled that the Bell System must allow entry and allow customer ownershipe of data modems, private PBX systems, and private point-to-point microwave. |

|

1970 |

National Academy of Sciences reports on study of problems of interconnections and suggests some possible solutions. |

The above partial list of public indicators of shifting emphasis in the general TC sphere gives some hint of the current trends: (a) the increasing diversity and complexity of TC—voice and data communication; satellites versus terrestial and submarine facilities, and (b) the growing fragmentation of the TC business, with increasing numbers of companies offering to provide pieces of the action. It seems that when the increasing complexity of TC’s calls more than ever for a systems approach and the economies of scale to achieve maximum cost-effectiveness (optimum combination from the customer’s viewpoint of quality of service versus cost). It remains to be seen whether the TC sector can continue to be innovative and efficient under the increasing constraints.

Tomorrow’s TC Technologies

The full impact of telephone networks and computers on our pattern of living is still to be felt. Shopping, automatic billing, credit transactions, up-to-date information on sports events or on business, the storage and editing of written texts, translation of letters from or to a foreign language, all can be done by TC’s.

A recent study5 projected the technical evolution of the telephone plant, with widespread installation of such advances as time-division switching, stored-program electronic control, and data-link type signalling channels. Some of the conclusions are given in the following paragraph and Table 4.10.

“Microwave radio will continue to carry the majority of interexchange voice trunks, but the use of satellite circuits and high-capacity waveguide buried transmission systems will increase.

A number of new telecommunications services are likely to be offered in the future, particularly to the home. Prime examples include: plays and movies from a video library, computer-aided school instruction, ‘cashless society’ financial transactions, and facilities allowing executives et al. to work at home rather than commute.

Such new services are unlikely to generate sizable revenues before 1980, but revenues are expected to rise rapidly thereafter, reaching about $9.2 billion per year by 1985 and about $19.7 billion by 1989.”

There is no sign of a slackening demand by society for increased TC capacity, versatility, and reliability. Technologically, these demands translate into needs for communication at higher than ever frequencies and for new hardward inherently more reliable than existing devices. And these demands must be met at prices consumers are willing to pay.

For the foreseeable future, hopes for satisfying these demands are pinned on the continuing development of integrated circuits (inherently far more reliable and versatile than older vacuum-tube technologies), and the development of drastically cheaper long-distance broad-band microwave (particularly beyond 15 GHz), including satellites and waveguides, and optical communication technologies. In parallel with these developments of broad-band transmission capabilities, new switching approaches will be evolved to take advantage of the memory and logic capabilities of integrated circuits, magnetic bubble, charge-coupled devices, and minicomputers to perform message switching with addressed blocks of digitized information. New customer services will call for developments of inexpensive, reliable, visual displays and data terminals (replacing the more cumbersom cathode-ray tube and teletypewriter, respectively). Visual displays capable of capturing and storing a full picture frame for later viewing will be needed as well as cheap means for recording

Table 4.10 Characteristics of New Nationwide Networks that May Have an Impact on the Public Network

|

|

Median Size 5 Yrs. After Emergence (Thousands) |

|

|||||

|

Information Network |

Median Date of Emergence |

(% Probability) |

|||||

|

Terminals |

Locations |

10 |

50 |

90 |

|||

|

1. |

Banking system for cashless society transactions |

1980 |

20 |

10 |

|

x |

|

|

2. |

Stock certificate clearing |

1978 |

5 |

2 |

x |

||

|

3. |

Biomedical network |

1980 |

10 |

5 |

x |

||

|

4. |

Hotel/Motel Reservations |

1975 |

20 |

10 |

x |

||

|

5. |

Police/Crime Prevention |

1975 |

10 |

5 |

x |

||

|

6. |

Education |

1976 |

50 |

5 |

|

x |

|

|

7. |

Post Office |

1985 |

40 |

10 |

x |

|

|

|

8. |

Credit Card Verification |

1967 |

80 |

20 |

|

x |

|

whole video programs. Mobile telephone service is also expected to grow.

These demands for new and improved TC technologies all translate into demands for new and improved solid-state devices and materials. Integrated circuit technology has to be developed further, particularly by reductions in dimensions and by better material composition and microstructural control. Failure mechanisms in all manner of devices under environmental-use conditions have to be elucidated and dealt with. A whole optical communication technology has yet to be developed—the present battery of lasers, modulators, detectors, and so on, impressive as they are individually, have not yet been worked up into an efficient, functioning communication system. Transmission media, particularly optical fibers, have yet to be proven in the field. New terminal-equipment devices, particularly solid-state display devices, are needed. These may be based on liquid crystals, on electroluminescent diodes for alpha-numerics, on bubble domain or charge-coupled devices. Similarly, solid-state cameras are needed—the charge-coupled devices look particularly intriguing for this. To meet all these demands for new devices, new materials will often have to be discovered or developed but perhaps the main emphasis in materials technology will be on processing—improving the ability to control composition and structure, and thereby to build in reliability.

It is hard to visualize the impact that future TC technologies will have on society and the way of life. But imagine what the way of life would be today without the telephone, if every message and discussion now carried on by telephone had to be conducted by mail service. In the future, videotransmission and picturephone terminals, for example, may have a similarly profound effect on society. Communication may become, increasingly, an alternative to travel. Many may even stay at home and communicate to work. The corresponding relevance of materials R&D is illustrated in Figure 4.1.

SPACE AND DEFENSE

U.S. Space Program

“Now is the time to take longer strides—time for a great new American enterprise—time for this Nation to take a clearly leading role in space achievement which in many ways may hold the key to our future on earth.”

John F.Kennedy

State of the Union Address

May, 1961

The space effort of the U.S. had a modest beginning with the work of Robert H.Goddard (1882–1945) who carried on aerospace research involving rockets and balloons prior to World War II. Following the war, the U.S. obtained additional rocket and missile guidance expertise when the German

rocket pioneer, Wernher Von Braun, and his associates were moved by the army to Redstone Arsenal at Huntsville, Alabama where they continued their pioneering aerospace research and development activities. The Soviet Union’s success in orbiting the world’s first satellite in 1957 triggered a surge of public interest and competitive spirit in the aerospace field. This public interest resulted in a series of aerospace projects including Vanguard, Pioneer, and Explorer which were motivated partly by a national desire to demonstrate that this country could match Soviet exploits. Continued public interest in the “race-for-space” with the Soviets was elevated by President Kennedy in 1961 to a national goal of sending men to the moon and return, within the following ten years.

In July of 1958, the National Aeronautics and Space Administration (NASA) was created to conduct this country’s peaceful aeronautics and space programs in accordance with broad national goals laid down by the U.S. Congress. The original Space Act stated, “The Congress hereby declares that it is the policy of the United States that activities in space should be devoted to peaceful purposes for the benefit of all mankind.” These activities include such goals as: “The expansion of human knowledge”; “long-range studies of the potential benefits to be gained and the problems involved in the utilization of aeronautical and space activities for peaceful and scientific purposes”; and “the most effective utilization of the scientific and engineering resources of the United States.”6

During the 1960’s there was assembled, under the leadership of NASA, a very large mission-oriented scientific and technological team, perhaps the largest ever put together: at its peak in 1966, over 400,000 persons were engaged in the space program in government, universities, and industry. They made rapid progress in science and engineering; they devised management systems to handle extremely complex and interrelated problems and programs; and they forced development of newer and faster computers to aid them in their work. This effort required the development of systems which represented a new level of reliability and which worked effectively under severe or difficult operational conditions. Behind these new system developments were many technological advances in the form of (a) new materials with a level and uniformity of properties previously considered impractical to achieve, and (b) new processes and fabrication techniques which worked faster, more reliably, and with greater precision. In fact, the lunar landing timetable necessitated compressing into one decade technological advances that might normally have taken several.

During the 1960’s, the public enthusiastically supported the lunar landing goal; but with the objective achieved in 1969, public backing for continued scientific missions to the moon began to wane, perhaps largely because other national issues such as the Viet Nam war, inflation, quality of life and environment, health, education, and urbanization claimed the increased attention of the nation.

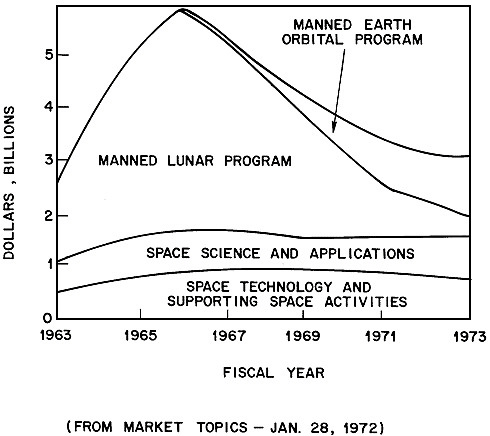

Funding of space activities has been greatly reduced since its peak in 1966, as is indicated in Table 4.11, from a high of 4.4 percent of the total federal budget outlays in FY 1966 to about 1.4 percent in FY 1972. This drop has been due to general budgetary considerations as well as to the fact that there does not now exist a widely-supported national goal in the aerospace field that compares with the well-defined, single objective of the Apollo manned space-flight program.

Projected space programs of the U.S. will be more limited in scope and in cost than Apollo. The preeminence of the Apollo program in the 1960’s and the trend to near-earth programs in the 1970’s is indicated in Figure 4.2. Specifically, major emphasis will be on manned earth-orbital flights, space science and applications R&D activities. The manned space-flight missions will emphasize both the Skylab and Space Shuttle.

The major focus of the orbital-workshop Skylab program will be on (a) studies of the sun, (b) space applications which include surveying earth resources and environmental interactions, (c) the use of the space environment for special processes, and (d) the effects of long-duration space flight on man. The Space Shuttle is regarded as a key element for future space operations in earth orbit. The earth-to-orbit shuttle provides a reusable vehicle for placement, retrieval, and servicing of satellites; short-duration manned and unmanned missions; and delivery of propulsive stages and payloads for high-energy missions. It provides savings in the cost of payloads because of the ability to repair and reuse payloads and because of the relaxation of the stringent weight, size and reliability requirements currently imposed on payload designers.

The space-science programs reflect emphasis on exploration of the earth’s environment, the solar systems, and the universe through manned spacecraft and related ground-based observations. Typical of the explorer spacecraft in this mission ar the Orbiting Solar Observatory and the High Energy Astronomical Observatory. The latter spacecraft is designed to identify and observe gamma, cosmic and x-ray sources. Both programs involve international cooperation.

Planetary exploration is also emphasized in the space-science programs. Included are (a) the Mariner missions to Venus and Mercury, (b) the Pioneer missions to explore beyond the orbit of Mars, through the asteroid belt and into the vicinity of Jupiter, and (c) the Viking Mars orbiter and lander. Planning is also underway for Mariner-class spacecraft missions to Jupiter and Saturn.

Applications programs will emphasize the continued expansion of the use of near-earth satellites for meteorology, communications, navigation, geodesy, and earth-resources surveys.

A major demonstration of the beneficial uses of space could revive public support for the space program. In particular, the new technology being developed in this program can potentially provide real and lasting solutions to some of man’s social problems. Specific examples include radioactive waste disposal and low-cost electric power through solar-energy conversion.

Table 4.11 Space Research and Technology

|

Fiscal Year |

Space Research and Technology Outlays (in millions) |

Percent of Total Federal Budget Outlays |

|

1973 Estimate |

$3,191 |

1.3 |

|

1972 Estimate |

3,180 |

1.3 |

|

1971 |

3,381 |

1.6 |

|

1970 |

3,749 |

1.9 |

|

1969 |

4,237 |

2.3 |

|

1968 |

4,721 |

2.6 |

|

1967 |

5,423 |

3.4 |

|

1966 |

5,933 |

4.4 |

|

1965 |

5,091 |

4.3 |

|

1964 |

4,170 |

3.5 |

|

1963 |

2,552 |

2.3 |

|

1962 |

1,257 |

1.2 |

|

1961 |

744 |

0.8 |

|

Source: Economic Report of the President, January 1972 Table B-64. |

||

Materials Development and Space Achievements

In general, the achievements in space have not depended upon the use of exotic new materials. Instead, a highly developed and sophisticated systems-engineering approach has been employed in which materials and process capabilities have been pushed to their limits. There are several reasons for this. First, space flights are expensive and require a high degree of reliability for even minimum cost-effectiveness. Thus, it has been necessary and prudent to use materials which were thoroughly tested and characterized. Also, the regard for safety in manned space flights has dictated the need for redundancy wherever possible together with liberal margins-of-safety in design. Specifically then, emphasis has been on materials engineering of a high degree of sophistication rather than on new materials synthesis.

On the other hand, new adaptations of materials already developed exemplify innovative thinking as much as do new syntheses. As an example, the early use of heavy copper heat sinks for re-entry nose cones was a logical and predictable choice at the time, but the succeeding generation of re-entry thermal-protection materials (phenolic-nylon and phenolic-glass) represented a completely different approach. Few individuals involved in polymer development in the early days of the space program would have predicted that these materials with their relatively limited temperature capabilities could be used to protect man and equipment from the severe heat and structural loading environments of entry from outer space.

Similarly, materials such as thermal-control coatings, lubricants, optical materials, adhesives, seals, organic and inorganic structural materials and solar-cell covers have been developed, modified, and/or tailored for the space program. It is interesting that some of these materials were exposed to more severe environments during prelaunch testing than during actual flight. Also, many of the early fears which plagued designers did not materialize. For example, cold-welding in space did not occur nearly as frequently as was expected simply because the tenacious surface gas and oxide films carried along from earth were extremely difficult to remove. That is, exposure of a material to a vacuum environment of less than 10–10 torr does not mean that its surfaces are automatically cleaned.

Evidence that advances in materials, as well as in vehicle design, have been made at a steady pace through the years is attested to by the longer operating lives of spacecraft. Rittenhouse7 made an analysis, covering the launch period from January 1958 to January 1967, of the length of time that some (81) of the U.S. unclassified scientific, weather, and navigational spacecraft have transmitted useful data. Their lives were plotted against the Year of the Space Age, arbitrarily assuming that 1958 was Year 1. It was found that the 90 percent confidence estimate for the lifetime of spacecraft increased from about 1/2 year in 1960 (Year 3) to 2 years in 1966 (Year 9). Extrapolation of Rittenhouse’s data would indicate a 90 percent confidence lifetime of more than 3 years by 1975 (Year 18).

Many of the products, materials, and new fabrication techniques developed for the space program are currently being adopted as new or improved products or processes for home and industry. It is difficult, however, to determine quantitatively the extent to which space-inspired technology is responsible for such developments. This situation results from the fact that the reduction of technological advances to civilian practice is time-consuming and the aerospace industry is only one of a number of sources of new technological knowledge.

The general conclusions to be drawn from a review of the space-technology-stimulated developments involving materials and processes are: (a) the NASA contributions are many, both direct and indirect, and varied; (b) the major effect of the NASA contribution has been to cause the technological advancement to occur at an earlier date than it would have otherwise; and (c) the NASA contributions took place at all levels of technology, including step-changes, incremental advances, and consolidations. From these conclusions, it is apparent that one of the space program’s roles in advancing materials and processes technology has been to create a demand for the technology to fill. By creating this demand and, in some instances, by carrying out the appropriate development efforts, NASA further advanced the technology in the field, resulting in new products and processes.

Material Needs of the Space Program

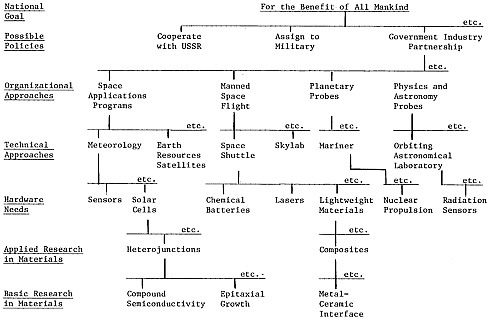

The on-going space program of the U.S. involves three general areas, namely, manned space flight, space science and space applications. Figure 4.3 is a partial relevance tree which helps show the connections between materials and process developments and the goals of this overall space effort.

Some requirements in common with the above three space areas indicate the need for: (a) ongoing research in the laser field if the potential of lasers is to be realized for space communications, power transmission, conversion, and propulsion; (b) materials for use in improved sensing devices and instrumentation for all aspects of the space program [High reliability sensors for earth-orbital spacecraft in particular offer the advantages of (i) rapidity and continuity of observation, (ii) greater freedom from weather disturbances, (iii) large-area views for regional synthesis, (iv) reduced data-acquisition times, (v) reduced costs, and (vi) higher quality data.]; and, (c) materials with long-life and extreme service capability for advanced batteries and power-generation systems, including thermionic, nuclear, isotope, and MHD.

The space-shuttle payload capability, and hence the payload cost, is very sensitive to the weights of the orbiter and booster thermal-protection systems (TPS) and structures. High insulative efficiency, rigidized ceramic-fiber insulations protected with a ceramic coating are currently the leading candidates for the TPS because of their (a) simplicity, (b) low density, (c) capability for repeatedly surviving the maximum expected surface temperatures, and (d) reserve margin. However, other materials such as superalloys, coated refractory metals, ablators, and carbon-carbon materials are being carried as backup materials in case unexpected difficulties should develop with the leading candidates.

Advanced composites also offer the potential for significant weight reduction in the structure of the shuttle vehicles. To achieve the required level of confidence for their use, technological advances are needed in the design of structures to fully exploit their unique properties and in the development of methods for accelerated and proof-testing under simulated heating conditions, chemical environments, and foreign object damage.

A different kind of opportunity for materials research, development and fabrication lies not in the need for, and stimulation of, new or improved materials for the spacecraft, but in the use of the space environment itself for processing the materials, namely, under high-vacuum and low-gravity conditions. Recent analysis8 suggests that technical benefits may result from preparing some materials and products in space. The two classes of materials which appear closest to satisfying the technical and economic constraints at this time are:

Electronic Crystals

Float-Zone-Refined Semiconductors

Solution-Grown Crystals

Biologicals

Vaccines for Human Usage

Cells for Human Usage

Viral Insecticides and Pesticides

It has been estimated that 30 to 50 space shuttle payloads might be generated from these product areas by the year 2000 AD. The total value of the payload could range as high as $1.5 billion.

Some Observations Regarding Materials in Space Technology