laboratories.

If one focuses primarily on electrical energy, the R&D effort has traditionally been supplied by equipment suppliers and the federal government. Recently the U.S. utilities have considered playing a significantly more active role than they have in the past. A recent report by the Electric Research Council lays out a broad program for utilities, manufacturers, and government.11 The development of better, more reliable materials is an important theme in this report. A clear call is made for additional private, as well as federal, funding to support the work.

Building Materials

Many materials are used in the construction of buildings; these cover the whole spectrum of classes of materials, from low-technology materials, such as wood and concrete, to more sophisticated high-technology materials, such as plastics and composites. To identify materials needs and problems associated with buildings and construction technology, the following list provides a representative sampling of specific problems (prepared by experts in the National Bureau of Standards’ Building Research Division) of primary importance in this area. These are not in order of priority.

Roofing Materials: There have been no recent innovations in this area. This may be partly due to the fact that no performance criteria or standards currently exist for roofing materials. This problem could be further complicated in the future, as there is a shortage of asphalt. It is estimated that 8×109 square feet of roofing material is used per year. Not enough use has been made of plastics or other substitutes.

Plumbing Materials: Plastics are potential replacements for metals. However, here again we need performance criteria and standards for plumbing systems. Additional research is required in the area of plastic pipes and tubings. This problem in the plumbing area has been a subject for comment and criticism by at least one Congressional Committee.

Joining Problems—Adhesives: Here much work is lacking in surface science and the science of adhesion. Adhesive manufacturers will not guarantee their products because not enough is known about the adhesive mechanisms. Current adhesives last only about four years as opposed to the desired 40 years.

Sealants: These are used to provide more-or-less permanent joints between brick walls and ceilings or between marble slabs. Their main purpose is to exclude water and air. They require no structural properties, in contrast to adhesives, which bind one surface to another and must be capable of transmitting stress and strain. Better sealants are needed with greater imperviousness.

Acoustic Materials: Generally speaking, materials with good acoustic absorption do not have good moisture-absorption properties and also present a potential hazard with respect to fire safety. The best acoustic materials are not satisfactory, and further R&D work in this area is necessary.

Solar-Energy and Coating Materials: New materials are required for better solar-energy absorption, and coating transmission and reflectance properties. Current coating materials do not maintain these critical properties over a sufficiently long period of time.

Gasket Problems: This is somewhat related to the sealant problem. However, the gasket is usually coupled into a moving fixture such as a sliding door and may be subject to periodic compression and expansion. The need is for new rubberlike materials with improved resiliency and durability.

Moisture Effects: Moisture is a primary cause of deterioration in almost all classes of building materials, from concrete to metals. We need better materials that will resist the effects of moisture. Degradation of underground insulating materials due to moisture is a particularly serious problem. The corrosion of metals is another serious problem, particularly with respect to the corrosion of air-conditioning cooling towers.

MATERIALS EDUCATION AND RESEARCH IN UNIVERSITIES

Introduction

The marked diversity of the educational backgrounds of the professionals who work in the broad field of materials science and engineering has been emphasized earlier. It will be analyzed further in the final section on manpower of this chapter. The existence of this diversity, which had not been widely recognized hitherto, was identified early in the COSMAT study. Accordingly, it was concluded that a meaningful examination of university education and research in materials should take full account of such activities not only in those university departments that offer materials-designated degrees—such as in metallurgy, ceramics, polymer science, or materials science and engineering—but also wherever else such educational activities occur, i.e., in other university science and engineering departments and in interdisciplinary materials research laboratories.

This section of Chapter 7 describes our examination of that educational scope. Two summary points arising from this examination will perhaps clarify for the reader the wisdom of that broader approach in developing a proper understanding of university activities in materials. First, in the area of education (Table 7.28) for professionals working in the materials field, while the varieties of degree programs and academic institutions are large, formal undergraduate curricula in materials are found to be confined largely to students in the materials-designated departments. Yet, graduates from such departments make up only a fraction of the professional manpower in the materials field. Indeed, in the engineering disciplines alone (almost all of the materials-designated departments are within schools of engineering), the materials-designated bachelor’s degrees are only some 2.5% of the total first-degrees in all fields of engineering, and the master’s and doctorate’s only some 3% and 8% respectively.12

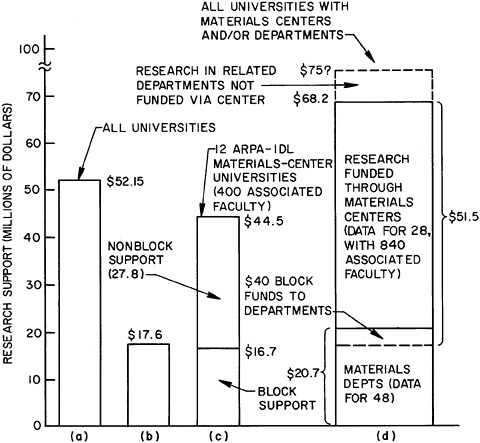

Secondly, the materials research and the related graduate degrees from the materials-designated departments amount, in the early 1970’s, to rather less than half of the materials research and graduate degrees involving faculty and students from other departments, i.e., to less than one-third of the total. In 1971, research support going directly to the materials-designated departments (of which there are almost 100) totaled some $17 million, compared to about $51 million funded to interdisciplinary materials centers and their associated faculty. (Only about one-third was direct or “block” support to the centers; the remainder was direct support to individual faculty members.) Four million dollars of the block support was assigned

TABLE 7.28 Types of Education and Institutions from which Manpower in the Materials Field Is Derived

|

TYPE OF EDUCATION |

|

PRINCIPAL ACADEMIC INSTITUTIONS INVOLVED |

PRINCIPAL USER INSTITUTIONS FOR GRADUATES |

|

I. Terminal B.S. in |

|

State and private universities |

Production & development in materials producing and consuming industries. |

|

a) Met., Cer., Poly. Sci. |

|

|

|

|

and |

|

|

|

|

b) Mech. Eng., Ind. Eng., Civil Eng., Chem. Eng., Physical Sciences |

|

|

|

|

II. Preparatory B.S. in Mat. Sci., Met., Cer., etc. |

? |

State and private universities involved in materials research |

|

|

+ fraction of Physics, Chem., Main Eng. Disciplines |

? |

All research universities |

Graduate schools |

|

a) Headed for advanced degrees in Materials Science. |

|

||

|

b) Headed for advanced degrees in related fields |

|

||

|

III. Terminal M.S. as in I |

|

Major state and private universities |

Development & research in moderate-to-large organizations |

|

IV. Ph.D.’s as in II |

|||

|

a) Mat. degrees in many fields, esp. Mat. Sci. |

Selected universities esp. involved in materials |

Research & development in materials consumer and producer industries, government; university teaching |

|

|

b) All other related depts. |

|||

|

V. 2-yr. Technicians |

State universities, community colleges, other institutions |

Producing industries |

|

to faculty in the materials-designated departments for a total of approximately $21 million. The university materials centers, which were started in the early 1960’s with the formation of interdisciplinary laboratories (known as IDL’s) in 12 universities through the Department of Defense, have increased in number to about 28. In 1971, the original 12 universities received approximately two-thirds of the total direct federal support for all university materials R&D.

The scale of the activities of the materials research centers and their associated faculty, as indicated by the foregoing, merits some discussion of how the centers came into existence, as a precursor to outlining the scope and rationale for the particular analysis of materials activities in the universities which was adopted by COSMAT.

The materials-related disciplines were the focus of the first attempt on the American university campus to create a new style of research organization and to accelerate the processes of academic curricular change resulting from federal recognition of a specific national need. At the time that physical metallurgy and the physics of metals were the principal, and largely separate, areas of materials research at universities in the late 1930’s and 40’s, the concept of task-oriented, closely coupled, interdisciplinary research was being developed in a particular sector of U.S. industry: namely, the research laboratories of the major corporations related to the electronics, communication, and aerospace industries. Such industrial prototypes served as the models for governmentally inspired changes at the universities (although industry had little direct input into the actual formulation of the programs). The federal initiative in the materials research area stemmed from advisory reports which identified the need for increased manpower for such materials research but which also stressed that the university laboratories could not afford the sophistication of industrial research because of the large investments required in equipment and manpower. The Coordinating Committee on Materials Research and Development (CCMRD) proposed specific action to the Federal Council on Science and Technology in 1959. As a consequence, the Advanced Research Projects Agency of DoD developed programs in 12 universities for “Interdisciplinary Materials Research Laboratories.” The AEC supported analogous laboratories in 3 universities, and NASA followed with a smaller program. Subsequently, several universities established similar centers without special or continuing support, so that a total of some 28 materials centers now exist on U.S. campuses. The creation of this system of interdisciplinary materials research laboratories and the strong growth of many of the materials-designated and materials-related departments resulted from federal initiative and from investments of $300—$400 million during the ensuing decade. This effort in the materials field is probably the most widespread and longest established attempt at encouraging interdisciplinary concepts and practices within universities. It has over a decade of history, and now that other fields of similar scope are emerging, an evaluation of MSE in our educational institutions is especially timely for the use of both university administrators and federal officials concerned with research policy.

From the above introductory discussion, it is apparent that an analysis of university education in materials requires a study of the following principal areas:

-

Instructional activities related to MSE, including materials-designated degree programs and educational activities in disciplines related to materials.

-

Materials research, as conducted in the materials research centers and academic departments.

-

Institutional interactions, including the management of materials research and coupling between the universities and industry.

Because the very grouping of activities entitled materials science and engineering is only somewhat more than ten years old, comprehensive statistics, data, evaluations, and even a definitive list of the departments or degree programs proved to be unavailable. Accordingly, several questionnaires were designed to obtain the necessary data on materials-related university research and educational activities. (In interpreting this information, care has been taken to try to recognize the inevitable shortcomings of data-gathering for a new area where common definitions are not yet adequately established.) The four questionnaires that were adopted and the relevant response characteristics were as follows:

-

Questionnaire to all departments in the U.S. granting materials-designated degrees regarding their undergraduate and graduate teaching and research activities. The responses (72 out of 112 questionnaires sent) cover the institutions granting 95% of all doctorates in such departments.

-

Questionnaire to all departments granting degrees in fields related to MSE, i.e., Chemistry (64%), Physics (70%), Geology (45%), Chemical Engineering (42%), Civil Engineering (33%), Electrical Engineering (53%), Mechanical Engineering (42%), which were listed in the top two categories of the Roose-Anderson report evaluating graduate departments.13 (Shown in parentheses are the percentage of responses in the various fields.)

-

Questionnaire on the research activities of all the formally designated interdisciplinary materials research centers in the country. Twenty-eight such centers were located (100% response).

-

Questionnaire seeking individual opinions of the effectiveness of materials centers from a set of senior university, governmental, and industrial representatives in the materials field. The set used was the membership of COSMAT, its panels, the membership of the National Materials Advisory Board, and the Chairmen (only) of the NMAB major committees for the last decade. (About 40% response)

Samples of the questionnaires are provided in Appendix 7A.

Before proceeding with the analysis of the response data based on the above questionnaires, we shall sketch some historical highlights of materials education in the U.S.

Some Historical Highlights of Materials Education in the United States

A broad perspective of education in the materials field is aided by recognition of the sequence in which the use of the major classes of materials must have developed. If prehistoric times are considered, there is no doubt that man’s dependence on, and hence his concern with, polymeric materials (natural fiber and wood for clothing and shelter) far predates his use of any other type of material, including ceramics (Stone Age) and metals (Bronze Age). Formal education in the science and engineering of any of these materials could not, of course, develop until science and engineering themselves took form in comparatively recent times. Yet, it is interesting to note that many pure sciences were born out of applied science; materials technology was in many ways the precursor of much physical science just as the beginnings of chemistry were grounded in extractive metallurgy. The formation of disciplines within the materials family undoubtedly arose in an order dictated by many factors, but one may speculate that foremost among these were the complexity of the chemical manipulations required to isolate useful materials, and the urgency with which they were needed.

If this is so, the reasons for the preoccupation of materials-science education with metals become clear. Most metals, as used, are nearly pure elements or relatively simple mixtures of them, at least up to very recent times. The processes needed to produce them from their naturally-occurring ores are also simple, again with some notable exceptions such as the electrolytic production of aluminum. The interest of the alchemists in precious metals must have contributed much to the early stages of the science of metallurgy. Additionally, the accessibility of metals, the relative ease with which they can be processed, and their serviceability in answering man’s needs for materials provided the impetus for the early development of the science and engineering of metals, which we now call metallurgy.

Ceramics, on the other hand, are both more complicated chemically and much less tractable. The need for these materials was great in certain areas related to metals processing, such as the refractory materials used to line furnaces or molds. Therefore, a limited portion of the science and engineering of ceramics grew up concurrently with the rise of metallurgy. Other parts of the empirical approach to manipulating brick, clay, sand, and cement chiefly into construction materials developed as a specialized branch of chemistry or chemical engineering. However, the basic science of ceramics has been some two or three decades behind that of metallurgy, principally because of the greater variation of ceramic structures on the atomic scale.

In striking contrast, organic polymers or macromolecules are materials of enormous chemical complexity, whose basic long-chain nature was still in doubt even in the 1920’s. Thus, polymer science and engineering has of necessity developed even more recently, and education in this field came after the systematization of metallurgy and ceramics.

Hence, it is not surprising that the first of the several materials disciplines to advance to the point where separate educational programs and curricula could develop was metallurgy. With the increased tempo of technological advances together with the proliferation of scientific and engineering knowledge, and the consequent need for specialization, formal education in MSE began in separate departments or subdepartments (often within chemistry or chemical engineering) or in schools of mining or mineral products in the early years of the present century. The early departments were also concerned to a lesser extent with nonmetallics, for the reasons cited above.

The Morrill Act of 1862 establishing the Land-Grant Colleges for training to meet society’s obvious needs in “Agriculture and the Mechanic Arts” was a landmark which signalled the beginnings of the great State universities of the U.S. Because of their mandate to supply manpower to the developing materials-industrial base of the nation, these institutions were to produce a large percentage of the trained materials specialists of the country—from the Colorado School of Mines to the State Universities of Michigan, Illinois, Ohio, and Pennsylvania. Other early materials departments were closely associated with specific local industries in which their graduates expected to find employment. Thus, well-established departments of metallurgy grew up in the major centers of the steel and nonferrous industries (Lehigh in Bethlehem, Carnegie-Mellon in Pittsburgh, Case Western Reserve in Cleveland, Illinois Institute of Technology in Chicago). In some of the earlier departments to be formed, the faculty took a national rather than local view of the industry which they were serving. They developed close associations with some of the major metal industries across the country. Notable in this group were Columbia and Yale. One of the few examples of a department being established because of the needs of a metals-consuming industry is that of Rensselaer Polytechnic Institute near the main plant of the General Electric Company in Schenectady.

Some of the early departments of metallurgy had some faculty who specialized in ceramics. As the science of ceramics developed, the subgroups within metallurgy departments which were concerned with this subject tended to expand and in some cases to separate themselves from the parent department. Before the Second World War, some 16–20 such groups existed. However, in those states where the refractory, whiteware, glass, and related industries were important, the ceramics section or departments tended to grow parallel to the metallurgy effort and sometimes in competition with it, e.g. at the Universities of Illinois, Ohio State, and Penn State. About a half-dozen institutions carried on a very large fraction of the nation’s education in ceramic science and technology (including, in the case of Alfred University, some work on the aesthetic and artistic development of these materials).

The early educational efforts related to polymers were largely descriptive rather than scientific, since they predated the development of polymer science and engineering. Courses in the technology of polymeric materials were developed as long ago as 1908 for the paper industry, and subsequently in the 1920’s and 1930’s for the textile, rubber, and paint and varnish industries. Emphasis on plastics per se came later still, for these are largely synthetic materials whereas the above-mentioned industries were originally based entirely on naturally-occurring polymers. It was not until the late 1930’s that the research on polymerization, carried out

chiefly in industrial laboratories, provided a sound basis for the science of synthetic polymers. Organized curricula treating polymers as a science developed only after the Second World War, by which time the dependence of industry on polymeric materials was firmly established; for example, in electrical insulation for radar and television use, and rubbers for seals, gaskets, hoses, and tires. Most of these curricula have remained within the parent departments (again usually chemistry or chemical engineering) with a few notable exceptions. The first separate effort to achieve prominence was at the Polytechnic Institute of Brooklyn, with others formally organized more recently (chiefly after 1960) in the Universities of Akron, Case Western Reserve, and Massachusetts, and informally at Rensselaer Polytechnic Institute and at various industry-oriented institutions such as paper and textile institutes. In general, these departments or subdepartments concerned with polymeric materials have had little or no connection with the older metallurgy/ceramic departments. Starting in the 1960’s, however, departments which grew out of metallurgy and aspired to cover materials more broadly have added courses in ceramics and polymers to their curricula.

The materials departments established before 1930 were often associated organizationally or conceptually with chemistry or chemical engineering and most of the faculty were drawn from those backgrounds. In a few places, the organizational link with chemical engineering has been maintained, as for example at Syracuse University. Yet, for the most part the academic development has not remained closely associated with the development of chemistry, and in some instances (e.g. at the University of Michigan), a long-standing link with chemical engineering has been severed. Once formed, the materials departments have tended to be little influenced by the parent chemical discipline. Moreover, after 1930 a major change occurred. The advances in solid-state physics started to exert a much greater influence on the content of curricula in materials. The flowering, first of metal physics and then of semiconductor physics, provided a great challenge for, as well as a great impact on, pedagogy in the materials field. Since 1960 the trend towards higher-bandgap materials has further emphasized physical inquiry on ceramic or semi-insulator materials. Most of the groups concerned with polymers also started, as stated earlier, in chemistry or chemical engineering departments; they, too, have been absorbing more from the discipline of physics in recent years.

Developments within materials departments have also been influenced, to a large extent, by the changes in general attitude and approach to undergraduate and graduate education in engineering. All of the early programs were designed to produce a qualified and professional metallurgist or ceramist at the bachelor’s level. Many of the graduates of such programs went directly into industry and were expected to be useful engineers very shortly after graduation. The early graduate programs were designed to lead to the doctorate and from the beginning had a strong science orientation. One trend in engineering generally over the last ten years has been to push the primary professional qualification to the master’s level. The undergraduate degree has, therefore, tended to become a more general type of education and a suitable basis for further work in a variety of professions. To some extent, the development of materials-degree programs along these lines has lagged behind those in other areas or engineering; there remains a strong inclination

for such departments to seek accreditation for their respective bachelor’s degrees as the first professional qualification.

Let us now turn to describing the materials teaching and training activities associated with:

-

Degrees carrying the formal designation of materials science and/or engineering, or any one of the material classes (metallurgy, ceramics, polymer science); and

-

Degrees in all the materials-related sciences and engineering disciplines.

Instructional Activities

In every field of technology, the contribution of universities to society is educated manpower. Correspondingly, the field of materials draws on the products of the universities’ instructional activities from several disciplines and in two major categories: (a) those departments or degree programs which are formally designated as materials (i.e. materials science, solid-state science, materials engineering, metallurgy, ceramics, polymer science and/or engineering) and hence, are wholly dedicated to the field; and (b) the materials-related disciplines which also contribute in a substantial way to the development of the field, but each of which is only partly concerned with materials as such. Corresponding data from a wide variety of university and manpower statistics (from the National Science Foundation, Engineering Council for Professional Development, Engineering Manpower Commission, the National Academy of Sciences) have been analyzed in addition to the new data obtained from the COSMAT questionnaires in order to develop the following account.

Materials-Designated Departments

In Table 7.29 are listed 89 U.S. universities with their degree programs designated as in the materials area. The degrees include metallurgy, metallurgical engineering, ceramic engineering, metallurgy and materials science, solid-state science, materials science, and polymers. Of these 89, at least 45 have graduate or undergraduate programs with the word materials in the title, as part of a phrase such as materials science, materials engineering, solid-state science (taken to be equivalent to materials science). There are 31 programs with titles involving only metallurgy, though 8 of the 14 materials and solid-state science programs have evolved from those in metallurgy. In contrast, there are only 14 degree programs in ceramics and 4 in polymerics (not including degrees in chemistry with specialization in polymers), in spite of the current wide use of the latter materials.

These program titles have changed significantly in the last decade; in 1960, there were virtually no programs with the word materials in the title. Table 7.30 lists the titles existing in 1964 and 1970 as simple evidence of this change.

TABLE 7.29 Materials-Designated Degree Programs+

G=Grad; U=Undergrad; B=Both; #=Also has interdisciplinary research center

|

|

CERAMICS |

METALLURGY |

POLYMERICS |

MATERIALS (Departmental) *denotes hybrid title, usually with Met. |

MATERIALS (Interdiscip.) |

PART OF LARGER UNIT++ |

|

Akron # |

|

|

G |

|

|

|

|

Alabama |

|

B |

|

|

|

|

|

Arizona |

|

B |

|

|

|

|

|

Brooklyn Polytech. |

|

B |

|

|

|

|

|

Brown # |

|

|

|

|

|

B |

|

California, Berkeley # |

|

|

|

B |

|

|

|

California, Los Angeles |

|

|

|

B* |

|

|

|

California State Polytech. College |

|

B |

|

|

|

|

|

California, San Jose |

|

|

|

B |

|

|

|

Carnegie-Mellon |

|

|

|

B* |

|

|

|

Case Western # |

|

|

G |

B* |

|

|

|

Chicago # |

|

|

|

|

|

|

|

Cincinnati |

|

|

|

B |

|

|

|

Clemson |

B |

|

|

|

G |

|

|

Cleveland State |

|

B |

|

|

|

|

|

Colorado Mines |

|

B |

|

|

|

|

|

Columbia |

|

|

|

|

|

B |

|

Connecticut # |

|

B |

|

|

|

|

|

Cornell # |

|

|

|

B |

|

|

|

Delaware |

|

U |

|

|

|

|

|

Denver |

|

|

|

G* |

|

|

|

Drexel |

|

B |

|

|

|

|

|

Florida |

|

|

|

B* |

|

|

|

Georgia Tech |

B |

G |

|

|

|

|

G=Grad; U=Undergrad; B=Both; #=Also has interdisciplinary research center

|

|

CERAMICS |

METALLURGY |

POLYMERICS |

MATERIALS (Departmental) *denotes hybrid title, usually with Met. |

MATERIALS (Interdiscip.) |

PART OF LARGER UNIT++ |

|

Grove City |

|

U |

|

|

|

|

|

Harvard # |

|

|

|

|

|

B |

|

Idaho |

|

B |

|

|

|

|

|

Illinois Chicago Cir. |

|

|

|

B* |

|

|

|

Illinois, Urbana # |

B |

B |

|

|

|

|

|

Illinois Tech. |

|

|

|

B* |

|

|

|

Iowa State |

B |

B |

|

|

|

|

|

Kentucky |

|

|

|

B* |

|

|

|

Lafayette |

|

U |

|

|

|

|

|

Lehigh # |

|

|

|

B* |

|

|

|

Marquette |

|

|

|

|

B |

|

|

Maryland |

|

|

|

G* |

|

|

|

Massachusetts # |

|

|

G |

|

|

B |

|

M.I.T. # |

G |

G |

|

B* |

|

G |

|

Michigan |

|

|

|

B* |

|

|

|

Michigan State |

|

|

|

B* |

|

|

|

Michigan Tech. |

|

B |

|

|

|

|

|

Minnesota |

|

|

|

|

|

B |

|

Mississippi State |

|

|

|

B |

|

|

|

Missouri-Rolla # |

B |

B |

|

|

|

|

|

Montana College Min. Sci. |

|

B |

|

|

|

|

|

Nebraska |

|

|

|

|

|

B |

|

Nevada |

|

B |

|

|

|

|

|

New Mexico Institute |

|

|

|

|

|

B |

G=Grad; U=Undergrad; B=Both; #=Also has interdisciplinary research center

|

|

CERAMICS |

METALLURGY |

POLYMERICS |

MATERIALS (Departmental) *denoted hybrid title, usually with Met. |

MATERIALS (Interdiscip.) |

PART OF LARGER UNIT++ |

|

New York State, Alfred |

B |

|

|

|

|

|

|

New York State, Stony Brook |

|

|

|

G* |

|

|

|

New York University |

|

|

|

B* |

|

|

|

North Carolina State |

U |

|

|

B* |

|

|

|

North Carolina University # |

|

|

|

|

|

|

|

Northwestern # |

|

|

|

B |

|

|

|

Notre Dame |

|

|

|

B* |

|

|

|

Ohio State |

B |

B |

|

|

|

|

|

Oklahoma |

|

B |

|

|

|

|

|

Oregon State |

|

B |

|

G* |

|

|

|

Penn State # |

B |

B |

U |

|

G |

B |

|

Pennsylvania # |

|

|

|

B* |

|

|

|

Pittsburgh |

|

|

|

B* |

|

|

|

Princeton |

|

|

|

|

G |

|

|

Purdue # |

|

|

|

B* |

|

|

|

Rennselaer Poly. # |

|

|

|

B* |

|

|

|

Rice # |

|

|

|

B* |

|

|

|

Rochester |

|

|

|

|

G |

|

|

Rutgers |

B |

|

|

|

|

|

|

So. California # |

|

|

|

B* |

|

|

|

South Dakota Mines |

|

B |

|

|

|

|

|

Stanford # |

|

|

|

B |

|

|

|

Stevens |

|

B |

|

|

|

|

G=Grad; U=Undergrad; B=Both; #=Also has interdisciplinary research center

|

|

CERAMICS |

METALLURGY |

POLYMERICS |

MATERIALS (Departmental) *denoted hybrid title, usually with Met. |

MATERIALS (Interdiscip.) |

PART OF LARGER UNIT++ |

|

Syracuse |

|

|

|

|

G |

|

|

Tennessee |

|

|

|

|

|

B |

|

Texas |

|

|

|

|

|

B |

|

Texas (El Paso) |

|

B |

|

|

|

|

|

U.S. Naval Acad. (Post Grad) |

|

|

|

|

|

B |

|

Utah # |

|

B |

|

B* |

|

|

|

Vanderbilt |

|

|

|

B* |

|

|

|

Virginia |

|

|

|

B |

|

|

|

Virginia Polytech. |

B |

|

|

G* |

|

|

|

Washington # |

B |

|

|

|

|

|

|

Washington State |

B |

B |

|

|

|

|

|

Washington University St. Louis # |

|

|

|

|

G |

|

|

Wayne State |

|

B |

|

|

|

|

|

West Virginia |

|

|

|

|

|

B |

|

Wisconsin, Madison # |

|

B |

|

|

G |

|

|

Wisconsin, Milwaukee |

|

|

|

B* |

|

|

|

Yale |

|

|

|

|

|

B |

|

Youngstown U. |

|

|

|

B* |

|

|

|

+ These data are combined from reports of ECPD, the Engineering Manpower Commission, NSF Report 71–27 and J.Nielsen’s Education Yearbook. ++ Programs are typically combined with Chem. Eng. (Ch), Mech. Eng. (Mech) or part of a goal, Engineering (Eng) or Applied Physics (AP) degree. |

||||||

TABLE 7.30 Materials-Designated Departmental Title Changes from 1964 to 1970

|

A. U.S. Schools with Metallurgy Faculties |

||||

|

Departmental Title |

1964 |

|

1970 |

|

|

Mining and Metallurgy |

1 |

|

– |

|

|

Mining and Metallurgical Engineering |

3 |

|

– |

|

|

Mining Engineering and Metallurgy |

1 |

|

1 |

|

|

Mining, Metallurgical, and Petroleum Engineering |

1 |

|

1 |

|

|

Mining, Metallurgical, and Mineral Engineering |

1 |

|

1 |

|

|

Mining, Metallurgical, and Ceramic Engineering |

– |

|

1 |

|

|

|

7 |

|

4 |

|

|

Minerals and Metallurgical Engineering |

1 |

|

– |

|

|

Mineral Technology |

1 |

|

1 |

|

|

Mineral Engineering |

– |

|

1 |

|

|

Metallurgical and Mineral Engineering |

– |

|

1 |

|

|

|

2 |

3 |

|

|

|

Ceramic and Metallurgical Engineering |

1 |

|

– |

|

|

Metals and Ceramic Engineering |

1 |

|

1 |

|

|

|

2 |

|

1 |

|

|

Metallurgy |

9 |

|

7 |

|

|

Metallurgical Engineering |

21 |

|

13 |

|

|

Physical and Engineering Metallurgy |

– |

|

1 |

|

|

Institute for the Study of Metals |

1 |

|

– |

|

|

Metallurgy and Materials Science |

2 |

|

7 |

|

|

Metallurgical Engineering and Materials Science |

1 |

|

2 |

|

|

Metallurgy and Materials Engineering |

1 |

|

2 |

|

|

Metallurgy, Mechanics, and Materials Science |

1 |

|

1 |

|

|

|

36 |

|

33 |

|

|

Materials Science and Engineering |

1 |

|

2 |

|

|

Materials Science and Metallurgical Engineering |

– |

|

3 |

|

|

Materials and Metallurgical Engineering |

– |

|

1 |

|

|

Materials Science |

4 |

|

6 |

|

|

Materials |

– |

|

2 |

|

|

Materials Engineering |

1 |

|

3 |

|

|

|

6 |

|

17 |

|

|

Carry Forward |

|

53 |

|

58 |

|

A. U.S. Schools with Metallurgy Faculties |

||||

|

Departmental Title |

1964 |

|

1970 |

|

|

Carried Forward |

|

53 |

|

58 |

|

Chemical Engineering (with materials) |

10 |

|

10 |

|

|

Mechanical Engineering (with materials) |

4 |

|

6 |

|

|

Engineering (with materials) |

2 |

|

4 |

|

|

|

16 |

|

20 |

|

|

Total Departments: |

|

69 |

|

78 |

|

Total Associated Metallurgy/Materials Faculty: |

522 |

|

758 |

|

|

Total Associated Metallurgy/Materials Graduate Students: |

1583 |

|

2222 |

|

|

Total Associated Metallurgy/Materials Seniors: |

864 |

|

851 |

|

|

B. U.S. Schools with Ceramics Faculties |

||||

|

Departmental Title |

1964 |

|

1970 |

|

|

School (College) of Ceramics |

2 |

|

2 |

|

|

Ceramic Engineering |

7 |

|

6 |

|

|

Ceramic Technology |

1 |

|

– |

|

|

Mineral Engineering |

1 |

|

– |

|

|

Mineral Technology |

– |

|

1 |

|

|

|

11 |

|

9 |

|

|

Ceramic and Metallurgical Engineering |

1 |

|

– |

|

|

Materials Program |

1 |

|

1 |

|

|

Metals and Ceramic Engineering |

– |

|

1 |

|

|

Mining, Metallurgical, and Ceramic Engineering |

– |

|

1 |

|

|

Metallurgy and Materials Science |

– |

|

1 |

|

|

Materials Science and Engineering |

– |

|

2 |

|

|

Materials Engineering |

– |

|

2 |

|

|

Engineering |

– |

|

1 |

|

|

|

2 |

|

9 |

|

|

Total Departments: |

|

13 |

|

18 |

An overall description of all the materials-degree programs at U.S. universities is given in Table 7.31. It is striking that, in view of the changing titles of the programs discussed above, there appear to be only a very few (less than 10) really new programs. Not all of these are interdisciplinary in nature, and most of them are small. In general, the constraints of the university structure make it easier to modify existing programs than to start new ones, and it is more difficult to operate in an interdisciplinary fashion than within existing departmental frameworks. Nevertheless, two or three strong new interdisciplinary programs have emerged. Other points to note are the frequency (55%) of cases in which the graduate enrollment is larger than the undergraduate; the predominance of metallurgy backgrounds among the faculties; and the concentration in industry as the first employers of graduates with advanced degrees.

While new programs typically appear to lean towards science, more program titles contain the word engineering than science in cases where only one of these words is mentioned. Curricula in metallurgical or ceramic engineering are among those with the largest undergraduate enrollments in any of the MSE programs (“engineering” in this context usually means a concern with the technology of the production and application of a designated class of material together with some understanding of the science relevant to the technology). In these programs, there is frequently considerable emphasis on laboratory courses and nearly all of them contain a project or dissertation requirement in the final year. However, the laboratory courses in the junior years tend to be traditional and the final-year projects are often small laboratory experiments reflecting the scientific, rather than the engineering, interests of the supervisor. Relatively few projects were discovered which were intended to give the senior student a realistic experience of modern problem-solving design engineering. At the graduate level, few of the materials-designated programs seem to have a substantial engineering or technology content; more often they can be described as applied-science-oriented. Less than a dozen D. Eng. or equivalent doctoral degrees have been awarded in materials in any recent year, the Ph.D. and Sc.D. being overwhelmingly more popular where there is a choice. Similarly, where a department offers both science and engineering options, the latter is typically less popular and may amount to only a paper exercise. It also seems more difficult to design engineering courses which deal with all types of materials rather than just one. These characteristics of the curricula are significantly at variance with the emphasis being sought by some industrial employers.

The distribution of faculty in materials departments among the full, associate, and assistant professorships as a function of departmental size is similar to that in other departments of science and engineering schools. The proportion of tenured faculty also appears to be in the expected range. In the majority of departments, a high percentage of the faculty members have Ph.D. degrees.

Table 7.32 shows the relation between graduate faculty and postdoctoral staff for materials-designated departments compared to that of all physical sciences and all engineering. Although intermediate, the proportion of postdoctorals in materials is closer to that in the sciences than in engineering, again reflecting the strong science orientation of the graduate materials programs.

TABLE 7.31 Data on Materials-Designated Degree Programs (Listed in order of average number of Ph.D.’s/yr)

|

STUDENTS |

|

FACULTY |

||||||||||||||||||||||

|

|

First employers of 1971 M.S. + Ph.D. graduates |

|

Field (%) |

|||||||||||||||||||||

|

No. Jr-Srs (av.) |

No. Grad. Stud. (av.) |

Total Students (av.) (Upperclass + Grad) |

No. BS/yr (av. 5 yrs) |

No. MS/yr (av. 5 yrs) |

No. Ph.D. (av. 5 yrs) |

Total No. Degrees (av. last 5 yrs) |

% Industry |

% Government |

% University |

% Other |

Postdoctoral |

Total Faculty |

FTE Faculty |

Tenured |

% with Ph.D.’s |

Materials Sci. |

Materials Eng. |

Metallurgy |

Ceramics |

Polymerics |

Chemistry |

Physics |

Engineering |

Other |

|

37.8 |

146 |

184 |

14.6 |

12.4 |

29.8 |

57 |

75 |

3 |

17 |

5 |

4 |

30 |

28 |

21 |

97 |

– |

– |

56 |

10 |

– |

17 |

17 |

– |

– |

|

74 |

146 |

220 |

35.4 |

14.6 |

24.6 |

75 |

53 |

7 |

28 |

12 |

24 |

37 |

28 |

27 |

95 |

8 |

– |

22 |

8 |

5 |

24 |

14 |

8 |

8 |

|

49 |

115 |

164 |

27.4 |

16.0 |

16.8 |

60 |

73+ |

3 |

18 |

6 |

10 |

21 |

21 |

15 |

95 |

– |

– – |

70 – |

20 – |

– 40 |

– 30 |

10 20 |

– 10 |

– – |

|

49.6 |

97 |

147 |

24.6 |

14 |

14.8 |

53 |

72 |

16 |

12 |

– |

2 |

22 |

18 |

12 |

100 |

6 |

15 |

30 |

6 |

8 |

10 |

8 |

5 |

5 |

|

14.2 |

89 |

103 |

5.2 |

7.6 |

14 |

27 |

35 |

7 |

43 |

– |

16 |

17 |

17 |

15 |

100 |

13 |

– |

47 |

6 |

12 |

6 |

12 |

6 |

– |

|

– |

104 |

104 |

7.8 |

3.8 |

13.4 |

25 |

85 |

10 |

5 |

– |

7 |

16 |

16 |

12 |

94 |

7 |

14 |

44 |

14 |

– |

7 |

14 |

– |

– |

|

75 |

86 |

161 |

32.2 |

15.6 |

13.0 |

51 |

71 |

19 |

10 |

– |

NA |

27 |

16 |

22 |

88 |

8 |

– – |

53 – |

– 50 |

– – |

7 8 |

20 8 |

20 8 |

– 17 |

|

125 |

87 |

212 |

25.2 |

17.8 |

12 |

55 |

70 |

8 |

22 |

– |

37 |

22 |

7 |

20 |

100 |

– |

– – |

46 – |

– 78 |

– – |

15 11 |

8 11 |

23 – |

– – |

|

1 |

81 |

82 |

1.6 |

16.6 |

11.8 |

30 |

40 |

50 |

10 |

– |

9 |

15 |

13 |

13 |

100 |

20 |

– |

20 |

– |

7 |

20 |

33 |

– |

– |

|

53 |

68 |

121 |

26.6 |

21.0 |

9.8 |

57 |

85 |

4 |

4 |

7 |

6 |

20 |

9 |

16 |

100 |

7 |

3 |

4 |

2 |

0 |

1 |

1 |

0 |

2 |

|

56 |

26 |

82 |

26.4 |

3.6 |

8.6 |

39 |

84 |

9 |

7 |

– |

2 |

11 |

9 |

6 |

80 |

– |

– |

– |

70 |

– |

– |

20 |

– |

10 |

|

32.4 |

47 |

79 |

25.4 |

17.8 |

8.0 |

5 |

165 |

15 |

20 |

– |

1 |

15 |

15 |

10 |

86 |

7 |

– |

62 |

– |

– |

14 |

17 |

– |

– |

|

13.8 |

56 |

70 |

11.4 |

5.8 |

8.0 |

25 |

58 |

6 |

24 |

12 |

10 |

13 |

13 |

9 |

92 |

74 |

– |

46 |

– |

– |

8 |

30 |

12 |

– |

|

11.4 |

52 |

63 |

5.8 |

4.8 |

7.6 |

18 |

49 |

3 |

45 |

3 |

8 |

13 |

13 |

11 |

100 |

8 |

– |

76 |

– |

– |

8 |

8 |

– |

– |

|

87 |

55 |

142 |

41 |

18.4 |

6.2 |

66 |

80 |

15 |

5 |

– |

3 |

18 |

16 |

16 |

55 |

– |

– – |

63 – |

9 71 |

– – |

– – |

9 14 |

9 – |

– 14 |

|

23 |

29 |

52 |

9.6 |

9.0 |

6.0 |

25 |

60 |

10 |

15 |

15 |

4 |

15 |

13 |

14 |

93 |

7 |

– |

40 |

13 |

13 |

13 |

7 |

7 |

– |

|

39.4 |

53 |

92 |

16 |

16.8 |

5.6 |

38 |

62 |

8 |

15 |

15 |

2 |

16 |

15 |

10 |

91 |

38 |

– |

31 |

– |

– |

– |

13 |

19 |

– |

|

16.8 |

41 |

58 |

6.0 |

6.0 |

5.2 |

17 |

38 |

21 |

18 |

23.3 |

50 |

18 |

17 |

12 |

90 |

– |

– |

40 |

10 |

– |

10 |

20 |

5 |

15 |

|

55.8 |

60 |

116 |

24.2 |

9.8 |

4.6 |

39 |

70 |

10 |

20 |

– |

3 |

14 |

13 |

55 |

76 |

– |

– – |

44 – |

– 67 |

– – |

– – |

14 16 |

14 16 |

– – |

|

15.6 |

30 |

46 |

– |

9 |

4 |

13 |

65 |

1 |

5 |

26 |

4 |

27 |

27 |

15 |

80 |

– |

4 |

67 |

– |

15 |

7 |

– |

4 |

– |

|

– |

17 |

17 |

– |

4.4 |

3.6 |

8 |

|

|

|

|

0 |

12 |

6 |

7 |

92 |

– |

– |

75 |

– |

8 |

8 |

8 |

– |

– |

|

|

24 |

24 |

12.2 |

2.4 |

4.2 |

19 |

44 |

21 |

35 |

– |

6 |

10 |

10 |

7 |

100 |

– |

– |

2 |

– |

1 |

3 |

3 |

– |

1 |

|

23.8 |

17 |

41 |

|

3.0 |

3.4 |

6 |

73 |

0 |

20 |

– |

2 |

7 |

9 |

6 |

100 |

17 |

– |

83 |

– |

– |

– |

– |

– |

– |

|

|

32 |

32 |

13.2 |

7.6 |

2.6 |

23 |

75 |

20 |

– |

5 |

20 |

11 |

10 |

7 |

100 |

– |

– |

– |

– |

– |

33 |

33 |

33 |

– |

|

26.4 |

29 |

55 |

20.8 |

5.8 |

2.6 |

29 |

75 |

10 |

15 |

– |

4 |

14 |

10 |

4 |

86 |

36 |

– |

55 |

– |

– |

– |

9 |

– |

– |

|

54 |

27 |

81 |

1.4 |

8.2 |

2.6 |

12 |

30 |

14 |

37 |

19 |

2 |

13 |

13 |

12 |

85 |

16 |

– |

56 |

7 |

– |

7 |

7 |

7 |

– |

|

2.8 |

9 |

12 |

6.6 |

0.4 |

2.4 |

9 |

|

|

|

|

3 |

4 |

4 |

4 |

100 |

1 |

– |

3 |

– |

1 |

– |

– |

– |

– |

|

13 |

15 |

28 |

5.6 |

2.8 |

2.0 |

10 |

39 |

9 |

48 |

4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

11.6 |

15 |

27 |

2.6 |

3.2 |

2.0 |

8 |

67+ |

13 |

20 |

– |

0 |

7 |

6 |

7 |

86 |

– |

– |

– |

100 |

– |

– |

– |

– |

– |

|

STUDENTS |

|

FACULTY |

||||||||||||||||||||||

|

|

First employers of 1971 M.S. + Ph.D. graduates |

|

Field (%) |

|||||||||||||||||||||

|

No. Jr-Srs (av.) |

No. Grad. Stud. (av.) |

Total Students (av.) (Upperclass + Grad) |

No. BS/yr (av. 5 yrs) |

No. MS/yr (av. 5 yrs) |

No. of Ph.D./yr (av. 5 yrs) |

Total No. Degrees (av. last 5 yrs) |

% INDUSTRY |

% GOVERNMENT |

% UNIVERSITY |

% OTHER |

Postdoctoral |

Total Faculty |

FTE Faculty |

Tenured |

% with Ph.D.’s |

Materials Sci. |

Materials Eng. |

Metallurgy |

Ceramics |

Polymerics |

Chemistry |

Physics |

Engineering |

Other |

|

12.6 |

20 |

33 |

23.6 |

0.4 |

2.0 |

26 |

50 |

– |

50 |

– |

2 |

22 |

14 |

10 |

20 |

2 |

– |

4 |

2 |

1 |

5 |

2 |

– |

– |

|

47.6 |

18 |

66 |

6.2 |

7.8 |

1.6 |

16 |

45 |

22 |

33 |

– |

3 |

10 |

10 |

8 |

90 |

– |

– |

70 |

– |

10 |

10 |

– |

10 |

– |

|

12.6 |

14 |

27 |

14.2 |

4.6 |

1.6 |

20 |

70 |

20 |

10 |

– |

0 |

6 |

4 |

6 |

6 |

– |

– |

83 |

– |

– |

– |

17 |

– |

– |

|

28 |

18 |

46 |

|

8.6 |

1.6 |

10 |

69 |

5 |

26 |

– |

0 |

12 |

8 |

4 |

75 |

– |

– |

25 |

8 |

– |

8 |

17 |

25 8 |

– |

|

26 |

15 |

41 |

11.2 |

2.2 |

1.4 |

15 |

80 |

– |

20 |

– |

1 |

7 |

7 |

5 |

100 |

– |

– |

6 |

1 |

– |

– |

– |

– |

– |

|

|

21 |

21 |

|

6.2 |

0.8 |

7 |

57 |

14 |

3 |

26 |

1 |

10 |

12 |

7 |

70 |

30 |

– |

20 |

– |

– |

10 |

20 |

10 |

10 |

|

114 |

20 |

134 |

48 |

9.4 |

0.6 |

58 |

90 |

– |

– |

10 |

1 |

19 |

15 |

6 |

79 |

21 |

16 |

53 |

5 |

– |

5 |

– |

– |

– |

|

15.4 |

14 |

29 |

5.2 |

3.6 |

0.2 |

9 |

– |

– |

– |

– |

3 |

10 |

10 |

7 |

90 |

30 |

– |

50 |

10 |

– |

10 |

– |

– |

– |

|

40.2 |

24 |

64 |

|

6.0 |

0.1 |

6 |

22 |

22 |

44 |

11 |

1 |

8 |

8 |

1 |

87 |

13 |

– |

13 |

25 |

– |

13 |

25 |

– |

13 |

|

24.4 |

8 |

32 |

|

3.4 |

0 |

3 |

50 |

20 |

20 |

10 |

0 |

5 |

5 |

4 |

100 |

– |

– |

40 |

100 |

– |

– |

– |

– |

– |

|

9 |

2 |

11 |

4.8 |

2.6 |

0 |

7 |

75 |

– |

– |

– |

0 |

3 |

0 |

3 |

67 |

– |

– |

100 |

– |

– |

– |

– |

– |

– |

|

9.6 |

8 |

18 |

3.8 |

2.8 |

0 |

7 |

|

|

|

|

NA |

4 |

4 |

NA |

100 |

25 |

– |

50 |

25 |

– |

– |

– |

– |

– |

|

8.8 |

3 |

12 |

2.8 |

1.6 |

0 |

4 |

80 |

3 |

0 |

– |

0 |

3 |

3 |

0 |

66 |

– |

– |

7 |

– |

– |

– |

– |

33 |

– |

|

17.2 |

16 |

33 |

6.4 |

5.8 |

0 |

12 |

80 |

20 |

0 |

0 |

NA |

8 |

8 |

8 |

90 |

– |

35 |

50 |

15 |

– |

– |

– |

– |

– |

|

13.2 |

2 |

15 |

7.0 |

4.8 |

0 |

12 |

85 |

5 |

10 |

– |

0 |

6 |

5 |

NA |

3 |

50 |

– |

50 |

– |

– |

– |

– |

– |

– |

|

5.4 |

|

5 |

2.4 |

|

|

2 |

|

|

|

|

NA |

22 |

NA |

13 |

100 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

4 |

4 |

3 |

75 |

25 |

25 |

75 |

– |

– |

– |

– |

– |

– |

|

16.2 |

|

16 |

8 |

|

|

8 |

|

|

|

|

1 |

6 |

6 |

5 |

100 |

– |

– |

59 |

– |

16 |

– |

25 |

– |

– |

|

|

|

|

|

|

|

|

|

|

|

|

1 |

14 |

11.5 |

9 |

93 |

– |

9 |

38 |

38 |

– |

– |

15 |

– |

– |

|

18 |

6 |

24 |

4.3 |

|

|

4 |

|

|

|

|

0 |

8 |

8 |

7 |

88 |

20 |

– |

60 |

10 |

– |

– |

– |

– |

– |

|

43.6 |

6 |

50 |

11.2 |

|

|

11 |

80 |

4 |

12 |

4 |

0 |

13 |

7 |

1 |

90 |

30 |

10 |

40 |

5 |

5 |

5 |

5 |

– |

– |

|

A. Totals from COSMAT Returns |

||||||||||||||||||||||||

|

1409 |

1868 |

3292 |

588 |

348 |

259 |

1182 |

|

|

|

|

|

655 |

532 |

|

|

|

|

|

|

|

|

|

|

|

|

B. National Totals (from other sources) |

||||||||||||||||||||||||

|

|

~920 |

~460 |

~270 |

|

|

|

|

|

|

749 |

|

|||||||||||||

|

|

Percentage A/B×100 |

|||||||||||||||||||||||

|

|

64% |

76% |

96% |

|

||||||||||||||||||||

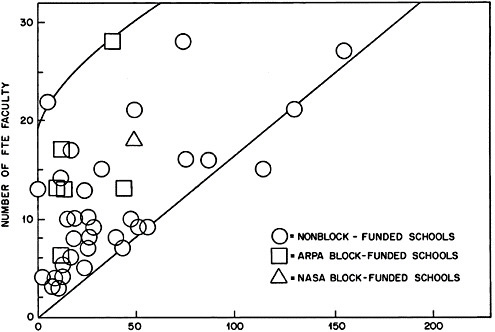

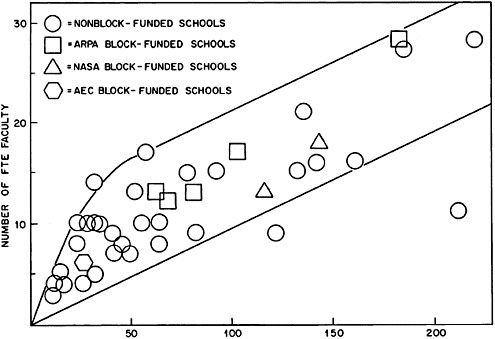

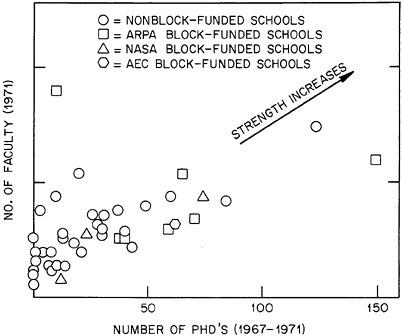

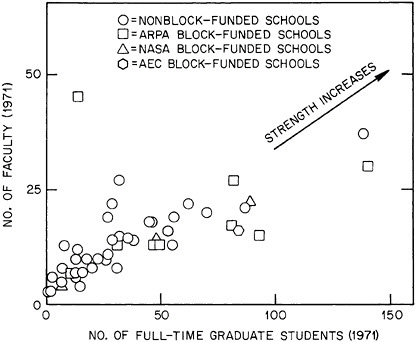

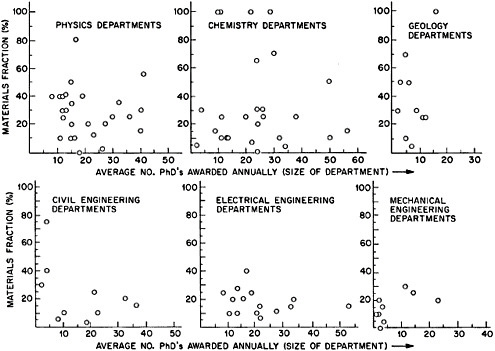

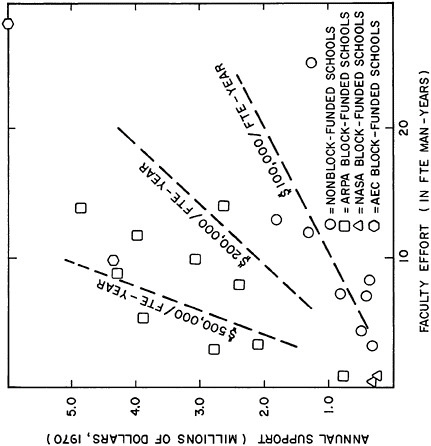

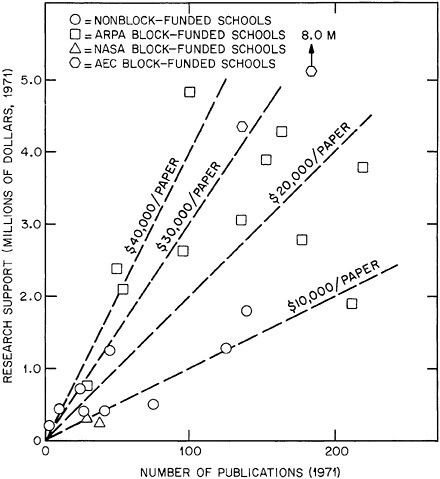

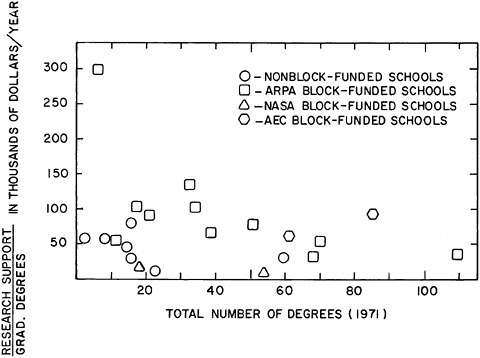

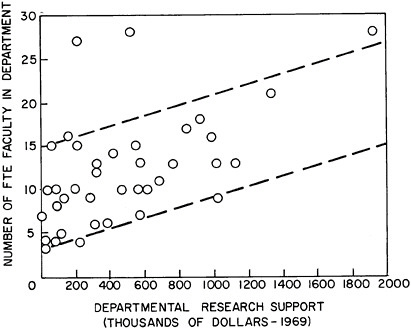

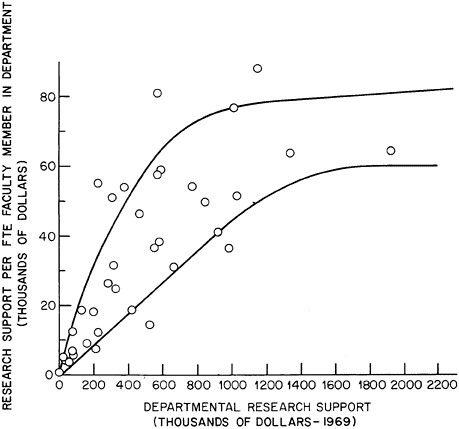

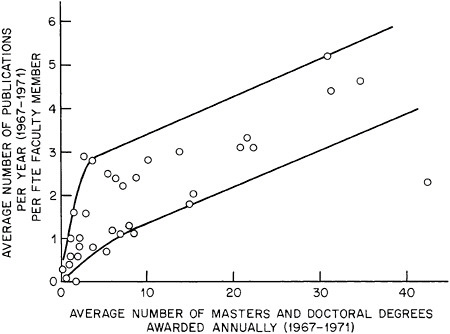

The size range of undergraduate enrollments in relation to the number of full-time equivalent (FTE) faculty in the materials-designated departments is shown in Figure 7.22. The data scatter widely, but the spread is reduced when the combined graduate and undergraduate student enrollment is considered, as in Figure 7.23. The faculty-student ratio is still high, at about 1 to 10 and is rather insensitive to the size of the department. In terms of total number of students, there are two large departments with more than 200 students; 25 departments having between 50 and 200 students; and 20 small departments with less than 50 students.

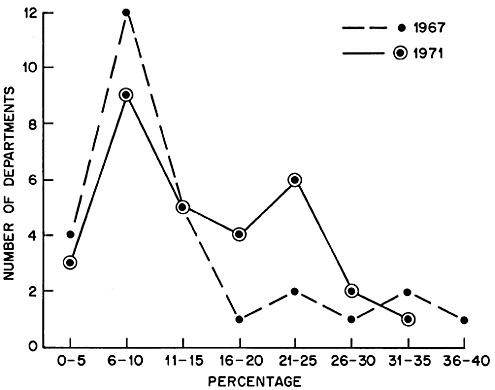

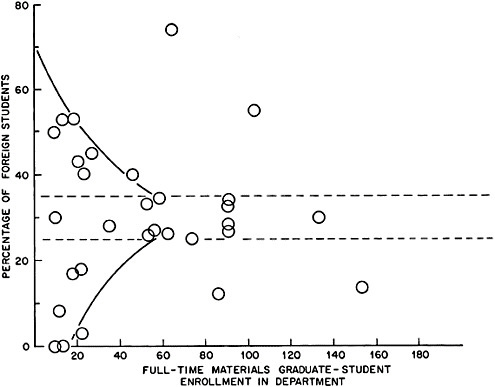

Graduate enrollments in materials-designated departments and their percentages of those for the corresponding engineering schools are shown in Figure 7.24 which indicates that the proportion of materials students has not changed much over the period 1967–1971. The proportion of foreign graduate students (Figure 7.25) is approximately 30% overall, compared to 20% among graduate students in physical sciences, 36% among graduate students in engineering, and 41.6% among materials-designated graduate students, as reported recently (NSF 1971, No. 71–27). In the latter report, only the materials-related fields of mining, agriculture, and petroleum engineering had more foreign graduate students than the materials-designated fields.

The data in Tables 7.33 and 7.34 show the proportion of graduate students by type of support and by the sources of federal support (data derived from NSF 71–27). The proportion of research assistants in metallurgy and materials (56.5%) is the highest in all engineering and in all fields, and the fraction of support from DoD (33.8%) and AEC (21.5%), for graduate students in metallurgy and materials is also higher than for other fields.

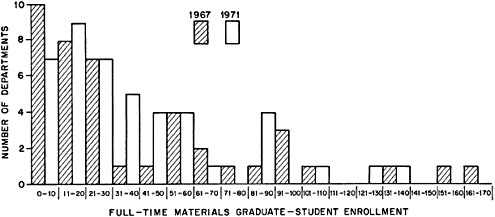

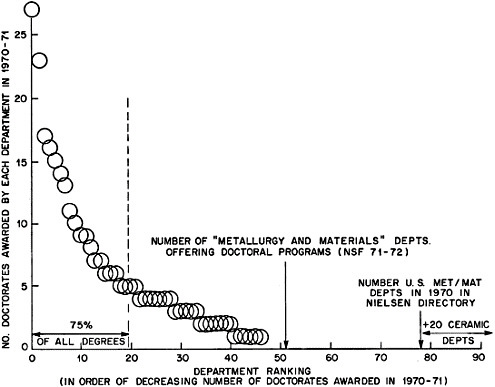

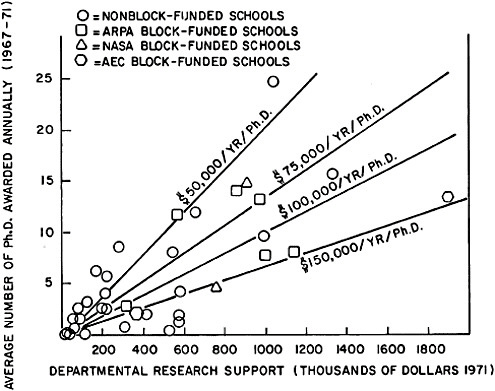

The size distribution of materials-designated departments in terms of number of doctoral degrees granted is illustrated in Figure 7.26. These results (taken from Engineering Manpower Commission, 1971) pertain to a median department size of 21–30 students. Of the 51 departments with doctoral programs in materials, 2 awarded 20%, 8 awarded 50%, and 19 awarded 75%. Over a quarter of the departments graduated 5 or less Ph.D.’s in 1970–71. The questionnaire data on this point (Figure 7.27) indicate an even larger proportion graduated by the larger schools.

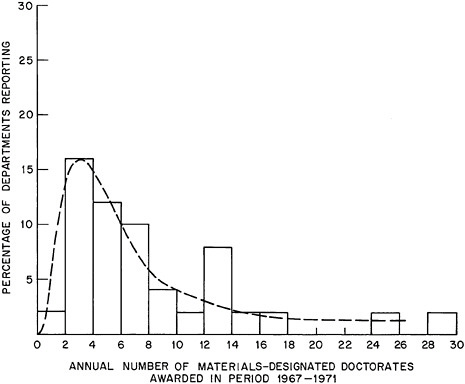

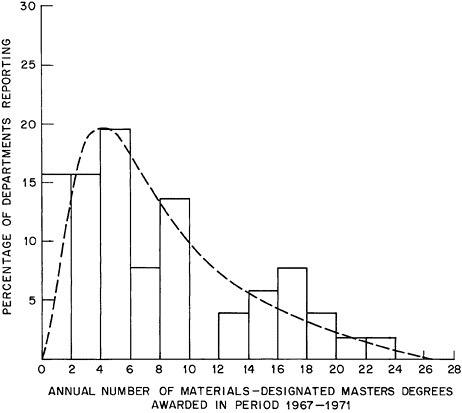

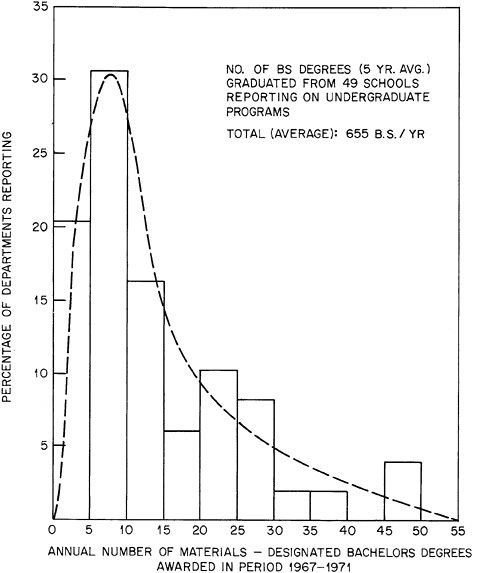

The distribution among materials-designated departments of doctor’s master’s, and bachelor’s degrees awarded is shown in Figures 7.27, 7.28, and 7.29, respectively (Questionnaire data). The distribution of B.S. degrees is similar to that reported in the Nielson Education Yearbook (1969) for the number of senior students in 85 metallurgy departments. Of the 49 departments reporting undergraduate data in the COSMAT questionnaire, 25 graduated less than 10 students per year averaged over the period 1967–1971, whereas two awarded more than 45 B.S. degrees per year and two more between 30 and 40. Among these four, however, there was little correlation between the sizes of the undergraduate and graduate programs, only one department having large numbers in both groups.

Among the departments awarding materials-designated Ph.D. degrees, the largest producer graduated 30 per year on the average, and only two others awarded more than 15 per year. Of the 50 departments reporting, 24 awarded fewer than 6 Ph.D.’s per year, but some of these had relatively large undergraduate enrollments.

TABLE 7.33 Full-Time Graduate Students by Type of Support, 1970

|

|

Fellowship & Traineeship |

Research Assistant |

Teaching Assistant |

Other |

|

All fields (145,970 students) |

27.7% |

21.4% |

24.4% |

26.5% |

|

Engineering (31,491 students) |

23.8% |

30.0% |

14.0% |

32.3% |

|

Metallurgy and Materials (1,836 students) |

20.5% |

56.6% |

10.5% |

12.3% |

|

Physical Sciences (29,522 students) |

20.9% |

30.6% |

36.3% |

12.2% |

TABLE 7.34 Sources of Federal Support for Full-Time Graduate Students, 1970

|

|

Departments of |

|

Department of |

|

Other U.S. Government |

||||

|

|

AEC |

Agriculture |

DoD |

NDEA |

NIH |

Other |

NASA |

NSF |

|

|

All fields (100%) |

5.5% |

2.2% |

10.6% |

9.8% |

24.6% |

3.3% |

4.0% |

27.8% |

12.2% |

|

Engineering (100%) |

6.7% |

0.5% |

24.3% |

6.1% |

8.6% |

1.7% |

8.5% |

26.8% |

16.8% |

|

Metallurgy and Materials (100%) |

21.5% |

— |

33.8% |

4.8% |

4.5% |

— |

5.2% |

24.5% |

5.8% |

|

Physical Sciences (100%) |

13.4% |

0.1% |

12.3% |

7.8% |

10.6% |

1.0% |

5.6% |

41.6% |

7.8% |

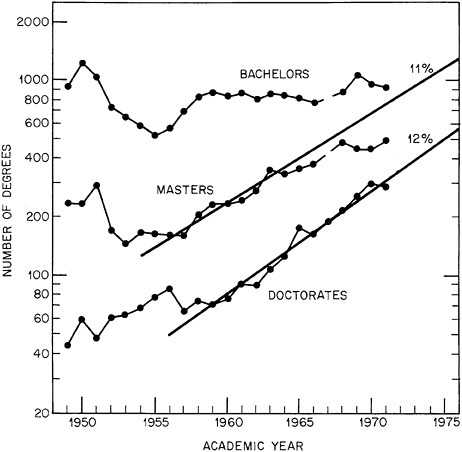

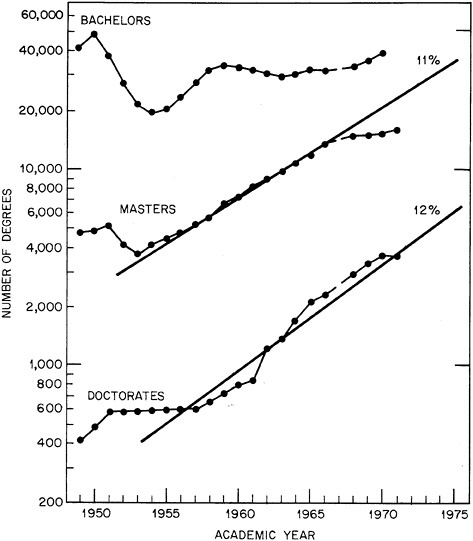

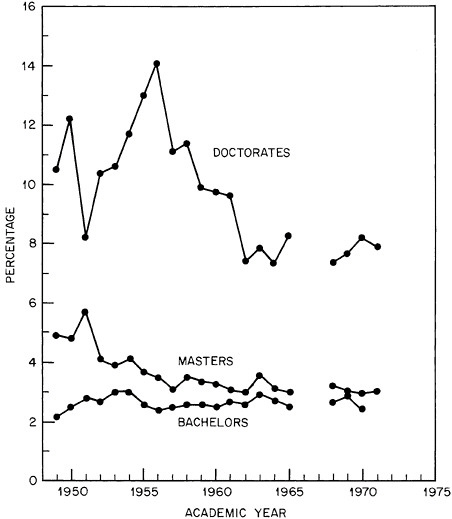

The total numbers of materials-designated degrees are plotted as a function of year in Figure 7.30 (data taken from Radcliffe (1969) and later Engineering Manpower Commission). For comparison, data for all engineering fields are given in Figure 7.31, and the proportion of materials to all engineering degrees in Figure 7.32. The number of bachelors degrees conferred by materials-designated departments has remained at about 2.5% of the total bachelors degrees conferred in all fields of engineering.

The conclusion is clear that the graduate degree output in materials has grown in a manner rather similar to the overall growth in engineering education. There is no evidence in these data for any special increase in materials degree production that reflects the substantial federal block-support of materials centers* during the period since the early 1960’s; in fact, the proportion of “materials” Ph.D. degrees has declined relative to those of all engineering fields since the late 1950’s—see Figure 7.32.

Curricula in the materials field, whether considered at the graduate or undergraduate level, can scarcely be discussed from a unified point of view. They exist as, and can only be described as, groups of curricula in materials science, materials engineering, in metallurgy, in ceramics, in polymerics, etc.

Table 7.35 lists the number of undergraduate curricula accredited by the Engineers’ Council for Professional Development (ECPD) in the materials area. The dichotomy mentioned above can be seen here: It is appropriate to group the “metallurgy and materials” curricula (by name) in a single group (57), and those dealing with ceramics (13) separately. There are no specific undergraduate curricula accredited in the polymer field, but the 19 dealing with mining form a separate group. The universities in which all these curricula exist have been listed in Table 7.29.

The content of undergraduate materials curricula emphasizing metallurgy changed drastically during the 1940’s and 1950’s. Before that time, emphasis

TABLE 7.35 Curricula Data from 39th ECPD Annual Report, 1971

|

The following are the undergraduate curricula accredited in the “materials” area: |

|

|

Ceramic Engineering |

12 (+ 1 option) |

|

Ceramic Science |

1 |

|

|

13 |

|

Engineering Materials |

— (1 option) |

|

Materials Engineering |

4 (+ 1 option) |

|

Materials Science |

3 (+ 1 option) |

|

Materials Science and Engineering |

3 |

|

Materials Science and Metallurgical Engineering |

1 |

|

Materials Engineering |

36 |

|

Metallurgy |

4 |

|

Metallurgy and Materials Science |

6 |

|

Metals Engineering |

– (1 option) |

|

|

57* |

|

Mineral Dressing |

1 |

|

Mineral Engineering |

1 |

|

Mineral Process Engineering |

– (1 option) |

|

Mining Engineering |

17 |

|

|

19 |

|

* Some of these curricula appear in the same department. |

|

had been placed on the extraction and processing of metals, and curricula included courses in ore dressing and the production of iron and steel and of nonferrous metals. The faculty of the early departments had a strong background in chemistry, and attention was given to such subjects as corrosion and oxidation. The change in the 1940–1960 period was marked by a strong expansion of the area of physical metallurgy, and later what might be called a generalized science of materials (although still primarily metals) with a dominant theme of structure-property relationships. In some schools, this shift was nearly complete, with only a remnant interest in the processing of materials. In others, little change took place. Elsewhere, and in most cases, a compromise evolved between the old descriptive program and the more quantitative and analytical materials sciences.

Among materials-designated departments, some graduate metallurgy programs have moved far towards incorporating materials science concepts with emphasis on structure-property relationships. At the present time, several graduate curricula in “metallurgy and materials science” are designed to give a working understanding of solid-state physics and its application to real problems in the manipulation of materials. A fairly common pattern has emerged with core courses in phase transformations, defect theory (sometimes restricted to dislocation theory), thermodynamics of solids, mechanics of solids (quite often described as crystal mechanics), the mechanical behavior of real solids, and the electrical, magnetic, and optical properties of solids. Most graduate programs attempt to insure that the student receives a basic education in quantum mechanics, statistical mechanics, band theory, and related theories of solid-state physics. In only a few instances has an equivalent emphasis been placed in the chemical or preparative aspects such as advanced phase equilibria, solid-state reaction kinetics and mechanisms, crystal growth, elemental analysis. This modest influence of chemistry is in sharp contrast to that of solid-state physics.

Over this period of change, several schools developed graduate programs in mineral processing and extractive metallurgy based primarily on chemistry. The curricula include, heterogeneous equilibria, solution thermodynamics, surface chemistry, reaction kinetics, transport processes, and similar subjects, as they apply to the production and refining of materials, particularly metals. In general, graduate research in these areas has found little federal support, in contrast to the encouragement given to research in materials science.

Some specific metal-production research was federally supported as in the case of AEC funding of studies on nuclear materials. Nevertheless, the general outcome over this period has been the discouragement of research and education at most schools in the actual production and refining of materials in favor of an emphasis on structure-property research.

The effects of the emergence of physical metallurgy, ceramic science, and their successor materials science upon the traditional metallurgy curriculum are more variable at the undergraduate level than at the graduate. Some departments oriented toward the terminal B.S. degree have programs with relatively less physical metallurgy and more process and extractive metallurgy, and with a focus on engineering rather than on theory. This pattern appears to have been influenced by a desire on the part of industry to employ B.S. graduates with fairly specific knowledge in metallurgy, ceramics, or

polymers rather than the more general exposure to all of these areas that constitute some “materials science” curricula. A few departments offer materials science as electives at the undergraduate level, in the junior and senior years. Most departments have continued with a compromise between an experience-intensive descriptive program and the more quantitative and analytical modern materials science.

The shift from descriptive to analytical curricula in the ceramics field has not gone as far as in metallurgy, inasmuch as the quantitative aspects of physical ceramics are just developing. The same is true of polymerics, the latest of the three materials-disciplines to develop. The departments dealing with polymeric and ceramic materials, moreover, are torn between the alternatives of providing bachelor-level technician-engineers for industry, or introducing more materials science in an advanced-degree program but delaying the availability of the fully qualified graduate accordingly. In the polymer field, it seems clear that a terminal bachelors degree is of limited value, whereas in ceramics this may still be otherwise.

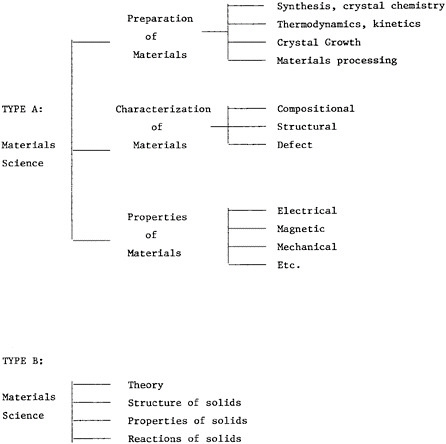

The ten or twelve graduate-degree programs in materials science which are new within the last decade offer an opportunity to discover whether or not a new hybrid “discipline” or unified materials curriculum is emerging. These new curricula have all attempted to restructure the subject matter according to concepts other than the traditional disciplines. Typical sets of subdivisions which have emerged are shown in Figure 7.33.

There appears to be little difficulty in developing a materials science program along patterns similar to those in Figure 7.33, provided that the emphasis is on scientific principles and theory. Questions of the degree to which the individual courses should be applications-oriented rather than basic, and of how the technologies of the different materials should be introduced into the program, are more difficult, and several variations have evolved. Experience shows that it has been easier to design a new materials-science curriculum than to modify an existing one. Frequently such new programs have been able to capitalize on the interdisciplinary nature of the subject matter by using faculty from several departments in a university-wide program.

Some examples of new curricula are described in Appendix 7B. Not all conform to the concepts discussed above. In particular, it appears from a perusal of the curricula in polymer science and engineering that the degree of commonality among metals, ceramics, and polymers is apparently not sufficient to allow an across-the-board treatment of the technology of all three, even in a new program. The covalent carbon-carbon bond dominates the structure-property relationships of polymers to such an extent that major differences between polymers and other materials emerge. Especially at the points in the curriculum where chemistry becomes important, the training needed by a competent polymer scientist-engineer seems to be substantially different from that needed to train scientist-engineers specializing in other materials. To date, possibly because most polymer programs have had a base dominated by chemists and chemical engineers, the materials-oriented polymer degree is the exception rather than the rule.

During the last decade, most engineering schools have considered or implemented an undergraduate survey course in materials as a requirement for all engineers. Various properties, including mechanical, electrical,

magnetic, optical, and chemical, are treated for a variety of materials, with particular emphasis placed on structure-property relationships. Often, a single course is given to students of the various engineering disciplines, rather than separate courses to each. The coverage is usually built predominantly on first-year subjects. Such a course must be limited in depth because of its breadth of subject matter. It is important that this necessary compromise should not isolate the course from the rest of the curriculum, a result which is not easy to achieve. Many schools have begun to regard this initial materials subject as a general materials course, much as the first chemistry subject may be a general chemistry course. The materials relationship to engineering design and practice is also considered significant, although as yet not fully implemented. However, it is remarkable that while most engineering curricula require such a course, virtually none of the science curricula do.