3

AEA SILVER II™ Technology Package

DESCRIPTION OF THE PROCESS

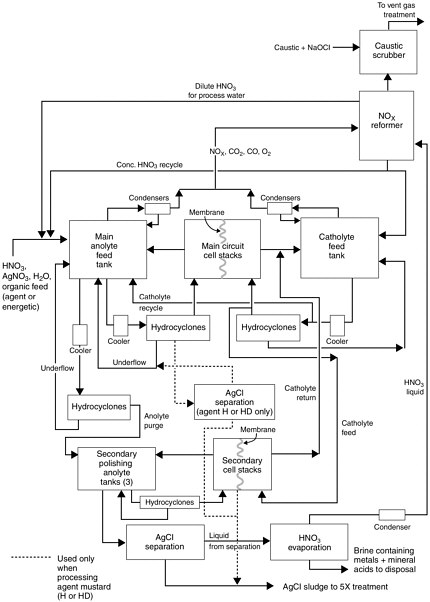

The AEA Technology (AEA) SILVER II™ technology is based on the highly oxidizing nature of Ag2+ ions, which are generated by passing an electric current through a solution of silver nitrate in nitric acid in an electrochemical cell similar to those used in commercial electrochemical processes. The electrochemical reactions used in the SILVER II™ technology belong to a class of chemical processes collectively known as mediated electrochemical oxidation (MEO). MEO processes have been offered as an alternative to conventional incineration for destroying hazardous wastes. Because they are also relatively new in development and application, experience with these processes is limited (Chiba et al., 1995).

Detailed descriptions of AEA’s original total system solution and its unit operations were provided in the original ACW I Committee’s report (NRC, 1999) and the ACW II Committee’s report on Demo II testing (NRC, 2001b). This report provides an update reflecting major changes in the process identified by the technology provider team (consisting of AEA Technology and CH2MHILL) based on prior testing results and on EDS II tests and studies.

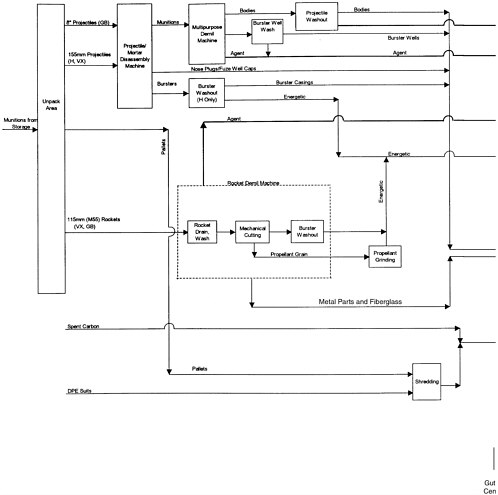

Figure 3-1 shows a block diagram of the overall process for the current AEA SILVER II™ total system solution. The first step in the system is a modified reverse-assembly process in which the energetics, agents, and metal parts are separated. Energetic materials are removed, reduced in size, and prepared as a slurry in water before further treatment. The agent and energetics are then destroyed in separate electrochemical processing units. Metal parts and fuzes are thermally decontaminated to a 5X condition in a metals parts treater (MPT). Dunnage and DPE suit material are decontaminated to a 5X condition by a dunnage treatment system (DTS) that is similar but not identical to the continuous steam treater (CST) in the Parsons/Honeywell WHEAT1 technology package proposed for disposing of the mustard agent munitions at Pueblo Chemical Depot (NRC, 2001a). Silver, water, nitric acid, and NOx are recovered, converted to reagents, and reused in the process. Other solid, liquid, and gaseous effluents from various process units are collected, separated, treated, and tested to prepare them for safe discharge from the plant. Table 3-1 summarizes key plant performance requirements used in developing the SILVER II™ technology package.

The following sections recap briefly the sequence of process steps beginning with munitions disassembly and ending with treatment of various waste streams for final disposal. They are derived from the complete description of the AEA technology proposed in the EDP

TABLE 3-1 Key Plant Performance Requirements for SILVER II™ Technology at Blue Grass Army Depot

|

Parameter |

Quantity |

|

Total processing period |

2 years (730 days) |

|

Peak energetics throughput (lb/hr) |

287.8 of M28 propellant (equivalent to 12.8 M55 rockets/hr) |

|

Peak agent throughput (lb/hr) |

166.7 of mustard agent (equivalent to 14.3 155-mm projectiles/hr) |

|

Destruction efficiency (%) |

|

|

Agent feed |

99.9999 |

|

Energetics feed |

99.999 |

|

Electrolyte composition |

|

|

Anolyte nitric acid |

8 M |

|

Anolyte silver |

0.5 M |

|

Anolyte steady-state TOC |

3,000 mg/L in agent and energetics, main or primary circuit, 3,000 to <1 ppm in agent polishing or secondary circuit, 3,000 to <10 ppm in energetics polishing or secondary circuit |

|

Catholyte nitric acid |

6 M |

|

Catholyte silver |

1 M |

|

SOURCE: Adapted from AEA (2001a). |

|

submitted to PMACWA for a full-scale pilot plant at Blue Grass Army Depot (AEA, 2001a), and they highlight changes from earlier reports of the ACW I and II Committees.

Disassembly of Munitions

Munitions Unpacking

Unpacking of the munitions is performed in the unpack area (UPA), which is the same as that in the Army’s baseline incineration system design (NRC, 1999).

Projectile Processing

The AEA technology package uses the baseline system projectile mortar demilitarization (PMD) machine with modification for burster and agent washout (AEA, 2001a). After removal of the nose closure, fuze adaptor, and fuze cup, the burster tube is removed from the agent cavity and transferred to the burster washout machine (BWM), which uses high-pressure water to remove the energetic material from the burster tube. Water is added to the resulting slurry as it is drained to achieve an energetic concentration of 20 weight percent. The slurry is then pumped through an inline static macerator and into a buffer storage tank for the SILVER II™ energetics destruction system.

The agent is then drained from the projectile and the cavity washed out with a water spray. The amount of drained agent is measured and sent to the buffer storage tank for the SILVER II™ agent destruction system. The burster tube and other projectile metal parts are placed in a bin for transport to the MPT for 5X decontamination.

Rocket Processing Line

The rocket dismantling machine (RDM) proposed by AEA is based on the baseline system design but has significant modifications, including these:

-

a modified punch-and-drain station having a hollow top punch to allow water or low-pressure steam to wash out gelled or viscous agent

-

a tube-cutting machine to cut the rocket in its shipping tube into four segments after removing agent

-

a water jet washout station to wash energetic materials out of the burster tube

-

a mechanical extractor to remove the propellant grain in one piece for subsequent size reduction in a propellant grinder (AEA, 2001a)

Tests to demonstrate the operability of these modifications would be done at the vendor’s plant prior to shipment or during systematization of a constructed facility using the SILVER II™ technology.

Each rocket in its shipping and firing tube is manually removed from its storage pallet in the UPA and transferred to a metering device to ensure that it is oriented with the warhead assembly heading first into the explosion containment vestibule (ECV). The metering

device feeds each rocket into the ECV and from the ECV into the RDM. Two clamps on the RDM engage and grip the rocket tube near the fuze and near the connection between the bottom of the warhead and the top of the rocket motor, as in the baseline configuration. Once gripped in place, the rocket is punched once on top and twice on the bottom, and the agent drains through the two bottom punches to the agent weigh tank. Hot water or low-pressure steam is then passed into the agent cavity through the hollow top punch to wash out additional agent and minimize agent loading in the metal parts treater (MPT). The agent that drains from the cavity through the two bottom punches is pumped to the agent weigh tank and then to the agent buffer storage tanks before it is fed to the agent SILVER II™ processing system. Rinse water or steam/ condensate and residual agent go directly to a buffer storage tank for the SILVER II™ process (AEA, 2001a, 2001b).

When processing GB rockets, the agent weigh tank control system provides a signal indicating the quantity of agent drained from the warhead. If less than a certain minimum percentage of the agent has been drained, the GB is assumed to be gelled or crystallized inside the warhead. Then, low-pressure, saturated steam (15 psig and less than 249.5°F) is fed through the punch head to rinse out the residual agent. When processing VX rockets, after draining the agent, low-pressure water is fed through the punch head to rinse residual agent out of the warhead.

After the agent is washed out, the rocket is rotated 90 degrees about its longitudinal axis to minimize leakage of liquid remaining in the cavity. The rocket is then advanced to the rocket cutting station, where it is clamped into the rocket rotator head and then rotated about its longitudinal axis. The first of three tube cutters cuts through the firing tube and rocket body and separates the fuze from the rocket, exposing the top of the burster well cavity. The severed fuze and associated firing tube section are dropped through a chute and conveyed to a bin for transport to the MPT. A power lance with high-pressure (~15,000 psig) water flowing from multiple nozzles is used to wash the explosive from the burster tube as the remaining section of the rocket in its firing tube is rotated. The washed-out energetic material is pumped through an inline macerator to form a slurry and collected in a tank and mixed with additional water to reduce the energetics content to 20 weight percent. The slurry is then sent to the energetics buffer storage for the SILVER II™ process.

Additional tube cutters then cut the warhead and the fin assembly from the motor casing. After both of these cuts have been made, the motor casing is moved to another station, where the attached antiresonance rod assembly is removed from the propellant grain. The antiresonance rod assembly and igniter are then transferred into a metal parts bin for transport to the MPT, and the motor casing section is moved to another station, where the rolled edge on the casing is expanded. A pusher assembly then forces the propellant grain from the motor casing, and the grain drops into the propellant grinder hopper. The warhead, fin assembly, and motor casing, along with associated firing tube segments, are dumped into a metal bin via the collection chute and conveyed to the MPT for 5X decontamination.

Preparation of Energetic Materials for the SILVER II™ Process

Slurries of energetic materials from two sources are treated in the SILVER II™ process: the explosive in the rocket and projectile burster tubes (which may be either Composition B or tetrytol) and the ground-up M28 propellant grain in the rocket motors.

The propellant grain is transferred through two interlocked blast gates into the grinder, where it is ground up under water to produce a slurry with particles having a maximum dimension of 1/4 inch. The slurry is discharged through a pipeline in a manner that limits the content of the pipe to no greater than 20 weight percent propellant. The energetics slurry then flows into the energetics slurry feed tank (AEA, 2001a).

The uniformity of the energetics slurry, which may at times be combined propellant and explosive, is assured by using a high-shear vortex mixer and a conventional stirrer in the energetic slurry feed tank. The high-shear vortex mixer completes the size reduction of the energetics from burster washout and propellant grinding in preparation for SILVER II™ treatment. The stirrer ensures that all the slurry in the tank passes through the mixer head. The feed tank and slurry piping are trace-heated to prevent cold spots and precipitation or plate-out of energetics materials (AEA, 2001a).

The energetics slurry is transferred from the energetics slurry feed tank into the anolyte feed tank through a hydrocyclone. The concentration of the energetics in the hydrocyclone underflow is nominally 40 weight percent. This underflow drains into the anolyte tank. The overflow, depleted in energetics, goes to a second hydrocyclone. The underflow from the second

hydrocyclone, still containing substantial quantities of energetics, returns to the energetics slurry feed tank. The overflow from the second hydrocyclone goes to the propellant grinder, where it makes up part of the water needed to slurry the incoming propellant grains.

Preparation of Agent for SILVER II™ Treatment

The recovered agent from the projectile and rocket processing lines is pumped to the agent feed system, consisting of a tank and a pump (not shown in Figure 3-1). Dilute nitric acid (HNO3) from the NOx reformer is added to the agent tank depending on the water volumes. (Water additions and other reagent additions achieve an 8 M HNO3 concentration and a 0.5 M AgNO3 concentration for the anolyte feed stream.) An agitator is provided to ensure homogeneity of the contents. The tank is maintained at a slight negative pressure relative to the Category A area2 by venting to the anolyte offgas condenser. A nitrogen blanketing system is provided, with a regulator set at a slight negative pressure.

Treatment of Agent and Energetics by the SILVER II™ Process

Overall Chemistry

The SILVER II™ process is based on the highly oxidizing nature of Ag2+ ions in an aqueous HNO3 solution. Ag2+ ions are among the strongest oxidizing agents known. HNO3 is also a strong oxidizing agent and contributes to the overall destruction process, although the amount of HNO3 that reacts appears to be less than 5 percent of the reaction required for total destruction (AEA, 2001b).

In each of the SILVER II™ cells, a pair of electrodes (anode and cathode) is housed in a compartment within the cell. A semipermeable membrane is placed between the electrodes. The membrane maintains electrical continuity between the electrodes and prevents mixing of the anolyte and catholyte solutions. The electrochemical cells operate at 190°F and essentially atmospheric pressure. Direct current is applied to the electrochemical cells at a potential of 2 volts, resulting in an electrochemical reaction that generates Ag2+ ions.

Since the Ag2+ ions simply mediate the reaction process, the overall reaction across the anolyte and catholyte is essentially the reaction of the organic feed with nitric acid, forming NOx, water, CO2, and inorganic acids:

Organic (anolyte) + HNO3 (catholyte) → CO2 (anolyte) + H2O (catholyte) + inorganic acids (anolyte) + NOx (anolyte and catholyte)

Ag2+ ions generated at the anode react with the water and HNO3 of the anolyte solution to form a range of radicals (e.g., OH•, NO3•) that in turn oxidize the organic material in the anolyte solution completely and irreversibly to carbon dioxide, some nitrogen oxides (NOx from the direct reaction with the acid, which proceeds to a moderate extent), inorganic ions, additional hydrogen ions (H+), and small amounts of carbon monoxide. Ag2+ can also react directly with water in the anode compartment to form oxygen gas. Both Ag+ and cationic impurities in the anolyte can migrate across the membrane to the catholyte compartment. To balance the electrochemical reaction in the anolyte, there is a corresponding cathode reaction that involves reducing nitric acid to nitrous acid, which in turn partially decomposes to NOx gases and water. The water balance is complex and involves two countercurrent fluxes. Water is transferred across the membrane from the anolyte to the catholyte in the form of hydrated protons generated as a product of the anode reaction. Water also flows in the opposite direction from the cathode compartment to the anode compartment owing to the lower acidity (higher water concentration) in the cathode compartment. A more detailed discussion of the SILVER II™ reaction chemistry is given in the ACW I Committee report and is not discussed further in this report (NRC, 1999).

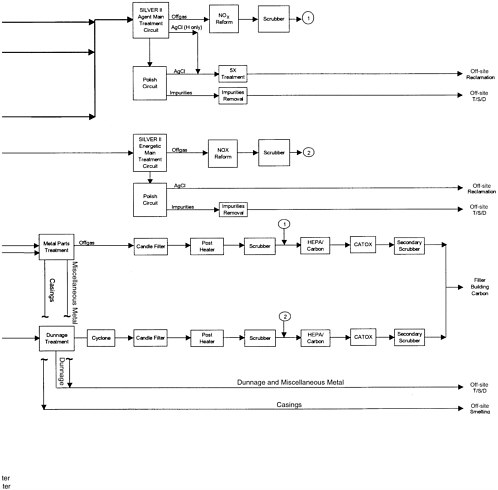

A summary block flow diagram depicting the SILVER II™ systems applicable to the processing of both agent and energetics is given in Figure 3-2. The flow circuit for AgCl separation (shown by dotted lines) is used only when processing H or HD, which contain chlorine. As shown in Figure 3-2, the SILVER II™ systems incorporate internal recycle streams: (1) from the NOx reformer to replenish nitric acid lost from the anolyte and catholyte solutions and (2) from the catholyte circuit to return silver ions, unreacted organic

material, and mineral acid ions that have crossed the membrane from the anolyte to the catholyte circuit. There is also an anolyte purge stream to the impurities removal system (IRS).3 The anolyte purge stream is processed by the IRS in a batchwise sequence through SILVER II™ electrochemical cells in a polishing circuit, where remaining organics are destroyed. After polishing, the purge stream content undergoes AgCl precipitation and separation using hydrocyclones and a centrifuge. The liquid from AgCl precipitation is then sent to an HNO3 evaporation operation for recovery of the nitric acid and to concentrate the impurities in the evaporator bottoms or brine stream. Batchwise processing of the anolyte purge stream is accomplished by collecting the stream in one of three tanks and then processing the contents of that tank through the preceding three steps. The contents collected in each of the other two tanks are similarly processed in sequence.

Process Outputs

Solids. Treatment of mustard agents by the SILVER II™ process results in the precipitation of silver chloride, which, if not removed, could cause cell plugging. This precipitate is removed from the main circuit in a slurry underflow from hydrocyclones in the anolyte feed stream circuit. Subsequently, this slurry is dewatered in a centrifuge to approximately 50 weight percent AgCl, with the remainder of the slurry consisting of water, nitric acid, silver nitrate, and trace amounts of other materials in the anolyte loop.

The SILVER II™ polishing circuits for both agent and energetics systems continuously produce a larger stream of AgCl than what is produced in the main circuit when H or HD feeds are being processed. It should be noted that essentially all silver in the main circuits from processing any agent or energetics is eventually removed in the AgCl precipitation step following the polishing of agent and energetic anolytes. In this operation, hydrochloric acid (35 weight percent) is added to the feed tank containing the polished anolyte to form a slurry that contains AgCl precipitate. The slurry is passed through a hydrocyclone and the underflow is sent to a centrifuge for dewatering to approximately 50 weight percent AgCl. The hydrocyclone overflow of the slurry consists of water, HNO3, trace amounts of other materials in the anolyte loop and about 2 percent unreacted silver nitrate. The AgCl sludge is then combined with AgCl sludge from the main circuit when processing H or HD feeds. This resulting sludge stream is then washed with 18 percent NaOH to neutralize the remaining acid. The neutralized sludge is then thermally treated to a 5X decontamination level in an enclosed auger heated by hot oil. The 5X silver chloride is sent to an off-site silver reclaiming contractor, which then returns the silver to the plant for preparing silver nitrate makeup.

The liquid overflow from the hydrocyclones and the AgCl centrifuge in the polishing circuit is sent to an evaporator for recovery of HNO3, which is condensed from the overhead vapor stream and pumped to the NOxreformer. AEA states that the evaporator is expected to recover approximately 70 percent of the HNO3 in the evaporator feed for subsequent recycling to the reformer (AEA, 2001a). The recovery percentage will vary depending on the amount of metals present as impurities in the feed and the final concentrations of metal and sulfuric, phosphoric, and hydrofluoric acids. For agent feed streams, the concentration of acids other than nitric places a limit on the evaporator operation, because carryover of these other acids in the evaporator vapor may occur. Energetic feed streams have no S, P, or F, and the acidic recovery is limited only by the solubility of iron and aluminum nitrates in the strongly acid evaporator bottoms. The bottoms containing mineral acids and metals are then treated, tested for agent, and prepared for off-site disposal.

Liquids. Liquid effluents are expected to be limited to excess concentrated HNO3 of undefined purity that will be produced when processing energetics.

Gases. The anolyte offgas from the primary and polishing systems contains O2, CO2, and NOx and is saturated with water vapor and HNO3 at 176°F. Small, variable amounts of CO are also formed from the oxidation, the amount depending on the organic feedstock. Most volatile organics from decomposition of feed material are expected to be condensed with water and acid vapor in the main and polishing circuit offgas condensers. These anolyte offgas condensers from the main and polishing circuits are cooled with chilled water to operate at 91°F and 40°F, respectively. The condensates are returned to the anolyte in the main system.

The offgas from the catholyte feed tank contains O2

(sparged into the catholyte feed tank for use in the NOx reformer), plus NO and NO2, and is saturated with water vapor and HNO3 at 176°F. This offgas first passes through a condenser to recover water and acid, which is returned to the catholyte feed tank. The anolyte and catholyte offgas streams are combined downstream of their respective condensers and flow to the NOx reformer to produce concentrated nitric acid. Offgas from the reformer system is scrubbed with NaOH/NaOCl solution to remove unreacted NOx. The scrubbed NOx reformer offgas, which contains CO2, volatile organic compounds (VOCs), and small amounts of CO, flows to the gaseous effluent treatment systems (as shown in Figure 3-1)—of the MPT in the case of agent processing and of the dunnage treatment system (DTS) in the case of energetics processing. There, thermal treatment and CATOX units oxidize the CO and organics. The gaseous effluent treatment systems are described in a later section.

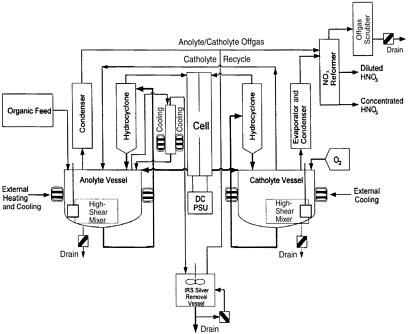

Process Equipment

The electrochemical cell used for the SILVER II™ process is based on a standard industrial cell design. Detailed discussion of the design, installation, and operation of the cells is provided in the EDP report, Volume 2 (AEA, 2001a).

For a full-scale facility at Blue Grass, the main processing circuits would consist of six operating cell stacks of 48 cells each for agent and six operating stacks of 42 cells each for the energetics. In addition, the SILVER II™ processes for both agent and energetics each have polishing systems consisting of three cell stacks, each configured identically to the main circuit stacks. The total power requirements for the primary (main) circuit and secondary (polishing) cell stacks for both the agent and energetics systems in the AEA SILVER II™ process are given in Table 3-2. In addition to the operating stacks, both the agent and energetics systems have one installed spare cell stack. Five more cell stacks are stored as spares. All operating stacks are connected in series to a single direct current power supply. The cells within each stack are connected in parallel. The installed spare is electrically shorted and isolated from the anolyte and catholyte circuits by valves. Demo II testing established that the electrodes and membranes can operate at a current of up to 2 kiloamperes per electrode pair (AEA, 2000).

The anodes are platinized titanium (titanium plated with 5 microns of platinum); the cathodes are also titanium plated with 2.5 microns of platinum. All gaskets are Viton GF (peroxide grade), and the cell membranes are DuPont Nafion 324. Flow through the cells is in parallel using manifolds with 1/4-inch fluid-flow inlet port orifices to provide equal flow to all cells.

As noted in Table 3-2, the secondary polishing system cells require electrical power at 50 percent of the level of the main circuit cells because the electrochemical organic destruction efficiency (i.e., the fraction of the electric current used to oxidize organics) decreases sharply as the organic concentration is reduced from an initial concentration of ~3,000 ppm to 1 to 10 ppm. The average destruction efficiency of the polishing cells is expected to be 2 to 10 percent, with the main competing reaction being the oxidation of water. Consequently, the offgases from the polishing system cells

TABLE 3-2 Summary of SILVER II™ Plant Electrochemical Cells

|

|

Cell Stack Quantities |

||||||

|

Description |

Power (kW) |

Operating Pressure (psig) |

Material |

Electrode Pairs/Cell Stack |

In Service |

Installed Standby |

In Storage |

|

Agent |

|||||||

|

Primary electrochemical cell |

1,120 |

~0 |

PVDF/Ti/Pt |

48 |

6 |

1 |

3 |

|

Secondary electrochemical cell |

560 |

~0 |

PVDF/Ti/Pt |

48 |

3 |

0 |

2 |

|

Energetics |

|||||||

|

Primary electrochemical cell |

991 |

~0 |

PVDF/Ti/Pt |

42 |

6 |

1 |

3 |

|

Secondary electrochemical cell |

495.5 |

~0 |

PVDF/Ti/Pt |

42 |

3 |

0 |

2 |

|

SOURCE: AEA (2001a), Volume 2. |

|||||||

contain a high percentage of oxygen, which flows to the NOx reformer with the other offgases from the main circuit. This oxygen, along with the oxygen that was sparged into the catholyte feed tank, is used to generate nitric acid in the reformer.

AEA is primarily relying on lining all vessels and piping in the agent SILVER II™ system with polytetrafluoroethylene (PTFE, or Teflon) or PFA for corrosion resistance. To prevent HF from returning to the SILVER II™ system via the nitric acid stream from the evaporator, AEA is evaluating methods of keeping the HF in the liquid phase of the nitric acid evaporator bottoms by using a complexing chemical. The method of trapping the fluoride in the evaporator bottoms had not been selected at the time this report was prepared. Therefore, additional unit operations yet to be defined may be required to deal with this issue.

Processing and Treatment of Metal Parts, Dunnage, and Other Solid Waste

Metal Parts Processing

Metal parts, fuzes, and fiberglass segments of shipping and firing tubes from the munitions disassembly lines, and drums containing particulate matter from the candle filters and cyclones of the gaseous effluent treatment systems are conveyed in bins to one of two MPTs for decontamination to the 5X level. Normally only one MPT is required; however, AEA has identified disposal campaigns where a second MPT would also be used (AEA, 2001a). In the MPT, metal and fiberglass parts are heated to over 1000°F for at least 15 minutes.

The MPT is a modified industrial oven with the following four zones:

-

zone 1 for purging air with nitrogen and providing an inert gas barrier for the following zones

-

zone 2 for warming the materials contained in bins to 300°F to volatilize organic materials from the fiberglass and other materials being treated

-

zone 3 for heating the parts above 1,000°F for more than 15 minutes to achieve 5X decontamination

-

zone 4 for cooling and verifying that the parts are acceptable for release

Zones 1 and 4 use inert gas atmospheres and are separately exhausted directly to the carbon filters of the MDB HVAC system. Zones 2 and 3 operate with steam atmospheres and are exhausted through a dedicated gaseous-effluent treatment system to remove entrained water and control the level of trace organics released. (The system is described in a later section.) Steam used in zones 2 and 3 is recirculated through electrically heated exchangers or heaters. The cycle time for each batch is approximately 1 hour to ensure that all of the contents of the metal parts bins reach 1,000°F for 15 minutes and that all organic material in the fiberglass shipping tube segments is decomposed. This thermal treatment also is expected to decompose (possibly through initiation) fuzes and igniters contained in the metal parts bins. Temperature markers4 are placed in each batch to verify that the required time at temperature has been achieved for 5X decontamination. Treated parts are moved to zone 4, where they are cooled and the atmosphere is sampled to verify that the parts are free of agent to the limits established for release off-site. If agent is detected above release limits, the bin is recycled through the MPT. After cooling, the metal parts are sent to a metal parts crusher and then off-site for disposal or recycling.

Dunnage Processing

Wood dunnage, DPE suit material, and spent carbon are treated to the 5X decontamination level using a DTS (AEA, 2001a). The major components of the DTS include the carbon carrier medium silo, the DPE suit shredder, the wood shredder, the feed hopper, and two redundant, full-capacity dunnage treaters. The DTS design is based on a design by Parsons that uses a continuous steam treater (CST) (Parsons, 2001). Wood pallets and DPE suit material are processed in their respective shredders and the shredded material transferred to one of two feed hoppers along with carbon carrier media. The feed hoppers discharge into the dunnage treater through a rotary air lock. Each feed hopper will feed either of the two dunnage treaters. Normally, one dunnage treater is on standby.

Each dunnage treater is a 4-ft-diameter horizontal vessel made of Hastelloy C276 material, within which

is mounted a screw auger to transport wood dunnage, spent carbon, or a mixture of carbon carrier media and either wood chips or shredded DPE suits from one end to the other. The treater is operated under a slight negative pressure, and high-temperature, low-pressure steam sweeps offgases generated by thermal decomposition into the offgas treatment system and contributes to thermal decomposition of the dunnage. The residence time of the dunnage material inside the treater is sufficient to ensure that all of the material contained in the enclosed auger is heated to the conditions required for 5X decontamination. In EDS testing of the CST, residence times of 1 hour were found to be adequate (Parsons, 2001). Actual residence times in the dunnage treater would be determined by using temperature markers during start-up operations. At the discharge end of the dunnage treater, the treated material is discharged through double rotary valves to prevent air backflow into the treater. The treated dunnage drops into a discharge hopper, where it is quenched with a water spray to extinguish any residual embers. Steam generated from the quench water is returned to the dunnage treater as part of the sweep steam. The hopper atmosphere is then sampled to ensure agent levels are below the limits set for discharge. The treated dunnage char is conveyed outside the MDB to a storage silo and transported to off-site disposal.

Each dunnage treater is electrically heated using multiple, equally spaced high-performance mineral-in-sulated band heaters.5 The entire dunnage treater, including heaters, is insulated by ceramic fiber insulation blankets contained within a steel shroud. Since the dunnage treater is operated under only slightly negative pressure, all openings are equipped with seals to prevent fugitive fumes from escaping. The slight negative pressure ensures proper flow of steam and the gases generated in the treater. The dunnage treater operates at temperatures from 1,000 to 1,100°F. Using start-up data from thermal markers, the rotational speed of the screw conveyor or auger is adjusted to provide the residence time required for 5X decontamination. As the screw rotates, the solid material is conveyed through the length of the treater.

Offgases and volatile materials are primarily VOCs, CO, CO2, and H2O generated by thermal decomposition and, to a lesser extent, steam reforming reactions with the dunnage material (Parsons, 2001). When processing DPE suit material, HCl will also be present in the sweep gas stream. The process gases are treated in a gaseous effluent treatment system (described in the following section).

Processing and Treatment of Gaseous Effluent Streams

Two emissions control systems are used prior to discharging the gaseous effluents to the carbon filters in the MDB HVAC system. One emissions control system is provided for the gaseous effluents from the agent SILVER II™ system and the MPTs. The other emissions control system handles gaseous effluent from the energetics SILVER II™ system and the DTS (see the process flow diagram in Figure 3-1). Each system is redundant in that a system is associated with each of the two MPTs and each of the two DTSs in the full-scale design.

The two emissions control systems are very similar. In order of occurrence, the flow paths for both systems contain the following elements. Where an element is unique to one of the systems, it is so noted.

-

Cyclone. The first element in the system for DTS gaseous effluent is the cyclone provided to separate large particulate matter that could rapidly plug the downstream candle filters. This element is not required in the system for MPT gaseous effluent. Separated particulate matter is discharged into a steel container through a rotary air lock. The particulates are processed in the MPT to ensure 5X decontamination.

-

Candle filters. These consist of multiple high-temperature ceramic or sintered-metal candles fitted within a plenum and a nitrogen supply for online periodic back flushing. Captured particulate matter is discharged into a steel container through a rotary air lock. The particulates are processed in the MPT to ensure 5X decontamination.

-

Post heater. Located immediately downstream of the candle filters, a post heater heats the offgas to a temperature of 1,000 to 1,100°F to destroy any agent that might exist in the gaseous effluent. The post heater is designed to provide a minimum residence time of 3 seconds at temperature.

-

Quench elbow and primary scrubber. Here, the gases are scrubbed in a packed tower scrubber for particulates and acid gases, using a scrubber solution with a pH of 7.0 to 8.5. The recirculating scrubber liquor is cooled and, in turn, cools the hot gas from 1,000°F to approximately 60°F.

-

Blowers. Effluent gases in the MPT and DTS trains then flow through positive displacement blowers. Ambient air is added to the streams to provide the oxygen that will be necessary for catalytic oxidation of organic compounds and carbon monoxide. Similar blowers are provided on the offgas streams from the NOx reformers of the agent and energetics SILVER II™ systems so that these streams can be added to the respective MPT and DTS gaseous effluent streams.

-

HEPA filters. A set of parallel HEPA filters removes fine mist, including residual organic aerosols that pass through the scrubber mist eliminator and condensable particulate matter that was not removed in the primary scrubber. At this point in the gaseous effluent system, offgas from the NOx reformers for agent and energetics SILVER II™ systems is added to the offgas from the MPT and DTS systems, respectively. Offgas from the NOx reformer of the agent SILVER II™ system is preheated prior to being added to the MPT gaseous effluent gas stream. These offgas streams increase the gas volume to be treated for the remaining elements of each emissions control train.

-

Carbon filters. For the combined effluent from the NOx reformers of the agent SILVER II™ system and the MPT, three drums of activated carbon, in series, are used to remove any residual agent and PCB vapor. Each of the drums in the filter contains 150 pounds of activated carbon. These filters are not used for the combined gaseous effluent from the energetics SILVER II™ system and the DTS.

-

CATOX preheaters. Each of the combined streams on both systems is heated to approximately 500°F in an electric heater before treatment in the CATOX unit.

-

CATOX unit. Organic vapors and carbon monoxide are destroyed in the CATOX unit of each system using a proprietary precious metal catalyst developed by Engelhard Corporation. The operating range of the catalyst is from 500 to 1,000°F. For maximum destruction efficiency (99 percent) for organic compounds, the catalyst should operate at 900°F.

-

Quench elbow and secondary scrubber. This system is used to remove acid gases formed from the catalytic oxidation of halogenated organic compounds. The operation of the secondary scrubber is identical to that of the primary scrubber with the exception of a recirculation cooler that maintains scrubber exit gas temperature at 120°F. The secondary scrubber has a constant liquid blowdown that is collected in holding tanks and tested for agent prior to release.

-

Blower. Following the secondary scrubber in each system is a blower that is used to maintain negative pressure throughout upstream portions of the gaseous effluent emissions control systems. The blower discharges directly to the MDB HVAC system carbon filters.

Effluent Management

The various processes and streams involved in effluent management include brine from the polishing systems evaporator, scrubber blowdown liquids, concentrated and dilute HNO3, 5X-decontaminated metal parts, fiberglass, dunnage char, and treated process vent gas from the two emissions control systems. Hold-test-release processing is used on all solid and liquid streams (AEA, 2001a). Gaseous effluents, including processing area HVAC air streams and treated process gas, pass through MDB HEPA and activated carbon filters prior to release to the atmosphere.

By-product Recovery

By-product silver chloride from the SILVER II™ process is separated as sludge, decontaminated to a 5X level, and shipped off-site, where it is reduced to silver metal, and returned to the plant for making fresh silver nitrate for the process. Based on material balances provided in the EDP, AEA expects no excess concentrated nitric acid to be produced since it will all be returned to the SILVER II™ processes as makeup acid or used in making fresh silver nitrate (AEA, 2001a).

INFORMATION USED IN DEVELOPING THE ASSESSMENT

Engineering Design Package

On December 15, 2001, AEA Technology/CH2M Hill issued a final draft of the EDP for a full-scale pilot plant implementing the SILVER II™ technology package at Blue Grass Army Depot (AEA, 2001a). The EDP includes technical descriptions and data, drawings, a preliminary hazard analysis, and cost and schedule analyses. It has been used as the primary source of information for this assessment. Other EDP-related documents used in the assessment include the initial draft of the EDP and the study plan for the EDS submitted by AEA (AEA, 2001b, 2001c).

Overview of Engineering Design Studies and Tests

The Demo II testing phase of the ACWA program for the AEA technology package was conducted between February and October 2000. The Demo II testing confirmed the ability of the core process of the SILVER II™ technology to destroy both energetic and agent materials (AEA, 2000). Although the overall Demo II testing was deemed successful, areas were identified that required further testing prior to progressing to a full-scale pilot plant design.

TABLE 3-3 EDS Tests and Studies Used for SILVER II™

|

Title |

Organization and Report Number |

|

Engineering tests |

|

|

Propellant grinding test |

Eco Logic, Inc., no report number, November 5, 2001 |

|

M28 and Comp B SILVER II™ processing trials |

AEA, 20/3034/13/006 |

|

DMMP (agent simulant) 500-hr run SILVER II™ processing trials |

AEA, 20/3034/13/006 |

|

Laboratory-scale tests |

|

|

High-shear mixer trials for the 12-kW SILVER II™ plant |

AEA, 20/3034/002 |

|

Hydrocyclone trials for the 12-kW SILVER II™ plant |

AEA, 20/3034/001 |

|

FM01 SILVER II™—organic transfer |

AEA, 20/3034/007 |

|

Fluoride mobility report |

AEA, 20/3034/011 |

|

Fluoride removal system |

AEA, 20/3034/009 |

|

Cell membrane life tests |

AEA, 20/3034/13/004 |

|

Investigation into the 12-kW SILVER II™ plant membrane failures |

AEA, 20/3034/13/005 |

|

Silver recovery from silver chloride |

AEA, 20/3034/13/003 |

|

Evaporator trials for the full-scale SILVER II™ EDP plant |

AEA, 20/3034/13/008 |

|

CST/CATOX testing |

Parsons, CW7/I&T/737204EDS |

|

Desktop studies (literature surveys) |

|

|

Water jet cutting and burster washout for chemical agent munitions |

El Dorado Engineering, Inc., no report number, December 3, 2001 |

|

Literature review on energetic slurry concentrations and handling |

El Dorado Engineering, Inc., no report number, August 21, 2001 |

In April 2001, AEA issued its study plan for the EDS II program (AEA, 2001c). This plan set forth a detailed test program to provide the additional information required to enable the SILVER II™ technology to progress to a full-scale pilot plant design stage. The test program also assumed that the results of EDS tests conducted by other technology providers in the ACWA program could be used where appropriate. Table 3-3 lists all tests and studies pertinent to AEA’s SILVER II™ technology package.

The EDS II test program includes testing and design studies needed for a preliminary design of a full-scale pilot plant, a preliminary hazard analysis, development of a full-scale cost estimate, and a schedule for construction and operation of a facility employing the AEA technology.

The test program consisted of two discrete packages (AEA, 2001c):

-

Engineering tests. These tests demonstrated the operation of modifications to the existing energetics feed system and SILVER II™ plant to eliminate the operational problems discussed in AEA’s final report for Demo II (AEA, 2000). They also demonstrated the long-term operation of a 12-kW SILVER II™ system on feeds of agent simulant and energetics.

TABLE 3-4 AEA 12-kW SILVER II™ Tests

|

Feed |

Total Quantity (kg) |

No. of Tests |

Test Duration |

Description |

|

TBP/OK |

30 |

Chemical systemization |

4 days |

Liquid, easily pumpable, not water-miscible |

|

DNT |

83 |

Energetic systemization |

7 days |

Granular form, slurried, 20 wt% w/water |

|

Composition B |

60 |

1 workup |

5 days |

Granular form, slurried, 20 wt% w/water |

|

Composition B |

123 |

1 |

259 hr |

Granular form, slurried, 20 wt% w/water |

|

Composition B/M28 |

23/113 |

1 |

Included in 259 hr above |

Granular form, slurried, 20 wt% w/water |

|

DMMP (agent simulant) |

156 |

1 |

500 hr |

Liquid, easily pumpable, not water-miscible |

|

SOURCE: AEA (2001d, 2001e). |

||||

-

Laboratory-scale tests and desktop studies. These activities provided data needed to complete a full-scale design for the EDP for a facility at Blue Grass Army Depot.

Summaries of the tests and studies performed and used in the development of the final EDP for AEA’s SILVER II™ technology package are discussed in the following sections.

Engineering Tests

Propellant Grinding Test

Specific objectives and results of propellant grinding tests performed in support of the EDS II program for the Eco Logic technology package are discussed in detail in Chapter 4. The description of the tests and the committee’s evaluation of the results presented in Chapter 4 are also applicable to the use of this unit operation in the SILVER II™ technology package.

Long-Term 12-kW Testing on Feeds of Energetics and Agent

The EDS II test program for the 12-kW SILVER II™ plant involved the operation of two campaigns, the first to destroy Composition B and then a mixture of Composition B and M28 propellant and the second to destroy the agent simulant dimethylmethylphosphonate (DMMP). For the EDS II tests, the 12-kW plant used in Demo II tests was upgraded to incorporate lessons learned from Demo II and demonstrate proposed solutions for problems that were encountered during Demo II. A summary of EDS II tests using the 12-kW system is given in Table 3-4, and the test setup for this system is shown in Figure 3-3. Subsequent to authorizing the tests listed in Table 3-4, PMACWA authorized a demonstration of tetrytol destruction using the EDS II equipment and operating conditions. Tetrytol destruction had been problematic in prior Demo II tests. Results were not available at the time this report was prepared.

SILVER II™ Processing Trials with M28 Propellant and Composition B

The EDS II test objectives for the energetics feed system were to design, build, and test a system that allows consistent operation of the SILVER II™ plant, including the following (AEA, 2001c):

-

dispensing known volumes of energetics slurry with up to 20 percent (by weight) solids into the SILVER II™ anolyte feed tank

-

monitoring the level of the energetics slurry within the feed tank

-

operating the energetics system for long periods with limited maintenance

-

verifying that the slurry is homogeneous and that stratification does not occur

The EDS II test objectives for the Composition B/ M28 propellant destruction campaigns were these (AEA, 2001d):

-

Verify long-term, continuous operability, reliability, and maintainability (i.e., operation of the full length of the test without unintended shutdown)

FIGURE 3-3 AEA 12-kW SILVER II™ test setup for EDS II. SOURCE: AEA (2001d).

-

of the SILVER II™ system as proposed for the full-scale version.

-

Demonstrate that organic materials, silver, acid, and water in the catholyte circuit can be effectively managed over prolonged operational periods.

-

Demonstrate that process impurities that build up in the anolyte circuit can be effectively managed over prolonged operational periods.

-

Determine the cell current efficiency to be used in the full-scale design.

-

Verify that system modifications (i.e., high shear mixers and hydrocyclones) effectively treat organic material.

-

Demonstrate that the impurities removal system (IRS) design for the 12-kW plant is applicable to the full-scale design and develop the data necessary for the design of the full-scale IRS.

-

Confirm and supplement Demo II process effluent characterization.

-

Determine impact of operations on materials of construction to be used in a full-scale system— for example, PTFE- and PFA-lined piping.

-

Validate the ability of the SILVER II™ unit operation to achieve a destruction and removal efficiency (DRE) of 99.999 percent for Composition B—cyclotrimethylenetrinitramine (RDX) and trinitrotoluene (TNT).

-

Demonstrate the operation and performance of key process components for future scale-up, including instrumentation, valves, pumps, electrochemical cells (electrodes and membranes), the full-height NOx reformer, and the offgas scrubber operating in conjunction with the NOx reformer.

-

Demonstrate the ability to recycle, reuse, or dispose of nitric acid.

-

Characterize gas, liquid, and solid process streams of the SILVER II™ process for selected chemical constituents and physical parameters and for hazardous and toxic compounds.

After systemization, a test run of approximately 145 hours was made on Composition B using a slurry feed control system specifically designed for the demonstration test. A radar level probe successfully monitored the level in the feed system after optimizing the amount of surfactant added to wet the Composition B while avoiding foaming of the slurry. No foaming occurred during the treatment of the mixed energetics, so no surfactant was added. Subsequently, a test run of approximately 145 hours was made on a mixture of Composition B and M28 propellant similar to that expected when processing the energetics from rockets.

During both tests, the chemical environment within the anolyte and catholyte circuits was successfully maintained by using the catholyte-to-anolyte recycle system and by periodically purging a stream of anolyte to simulate operation of the IRS.

The hydrocyclones and high-shear mixers operated throughout the testing. During energetics destruction, no deposits of crystalline material or flow blockages were observed with the hydrocyclones and high-shear mixers in place.

Plant maintenance during the tests was limited to correcting a few small leaks. At the end of the Composition B part of the run, a transmembrane breach occurred as a result of membrane shrinking and tearing. This was remedied by using a membrane soaking solution that contained aluminum nitrate to preshrink the membranes prior to placing them in the cell. No further transmembrane breaches were experienced in the remaining runs with energetics.

The offgas system performed within specification. The postreformer NOx level was around 2,000 ppm, while the plant offgas NOx level was less than 100 ppm for the Composition B part of the run and around 400 ppm when mixed energetics feed was used.

Based on the test runs, AEA concluded that catholyte-to-anolyte recycle and periodic removal of an anolyte purge stream (to simulate IRS operation) controlled the anolyte acid concentration, as well as the catholyte silver and organics concentrations. The catholyte silver ion concentration was held at the target 1 M level proposed for the full-scale system.

Accidental operation with an anolyte total organic concentration (TOC) of 6,000 mg/L (rather than the intended 3,000 mg/L) during a test run of Composition B oxidation demonstrated an electrochemical efficiency of approximately 70 percent versus the target 40 percent. This is consistent with the behavior of the plant during the oxidation of M28 propellant in Demo II. The committee notes that other research in mediated electrochemical processes has shown that the coulombic or electrochemical efficiency of the process is directly proportional to the concentration of the material being oxidized and rapidly decreases as the destruction approaches 100 percent—that is, as the concentration of oxidizable material becomes very small (Chiba et al., 1995).

The high-shear mixers and hydrocyclones in the anolyte and catholyte circuits, along with trace heating and elimination of dead legs, successfully maintained the particulate energetics in the anolyte and catholyte circuits in a finely divided state. AEA concluded that this result confirmed the ability of SILVER II™ to handle solids at its design loading (AEA, 2001a). However, AEA also noted that the small particle size resulted in inconclusive performance results for the anolyte hydrocyclone. Therefore, some uncertainties still exist with regard to successful demonstration of solids handling.

There was no accumulation of metals in either the anolyte or catholyte circuits when a spike of metals was fed with the M28 propellant to simulate particles from antiresonance rods. AEA attributes this success to the use of the catholyte-to-anolyte recycle and the anolyte purge operation. Lead, present in M28 propellant as lead stearate (approximately 0.5 weight percent), was oxidized to lead oxide (PbO2) and did not accumulate in solution. Lead oxide was found on the electrode surfaces and as a deposit in the bottom of the cell cavities (AEA, 2001d). A demonstration test successfully removed the lead oxide using an offline formic acid wash of the cell electrode cavities. This is the planned approach for removing accumulating lead oxide. No lead material balance was provided.

The NOx reformer operated for most of the run with a bottoms composition in the boiler reasonably close to the target 60 weight percent acid used in the full-scale EDP design. The offgas scrubber NOx was typically less than 100 ppm during the Composition B phase of the run but somewhat higher during the Composition B plus M28 phase. Based on the available analytical data, the most abundant organic breakdown product from Composition B was trinitrobenzene. Alkyl nitrates were found at a low ppm level in the plant offgas and the scrubber liquor, as was observed during previous trials.

The committee notes that trinitrobenzene is an energetic material and that safety considerations warrant a thorough understanding of the expected quantity and location of this material.

DMMP 500-Hour SILVER II™ Processing Trials

The objectives of trials with the agent simulant DMMP were similar to those with energetics (AEA, 2001e). The trials did not simulate the conditions associated with fluorine- or chlorine-bearing agent feeds. Shortly after beginning the DMMP trial, breaches of the membrane were again experienced. Investigation of these breaches is discussed in detail in reports prepared by AEA and Arthur D. Little Corp. (AEA, 2001f; ADL, 2001). The basic causes of failure (discussed in more detail in a later section on cell membrane failure analysis) were these:

-

membrane contact on the cathode surface when the formation of a gas, possibly from decomposition of the hydroxylamine in the membrane material, causes it to swell

-

holes in the membrane caused by arcing from dendritic silver crystals growing on the catholyte electrode (the silver deposition was believed to be caused by low nitric acid concentration, which had dropped to approximately 1 M, in the catholyte solution during the test)

AEA subsequently implemented the following corrective actions:

-

installation of spacers between the membrane and cathode to provide greater separation between the membrane and the cathode

-

monitoring of nitric acid concentration as well as total acid concentration in the catholyte, and control of the nitric acid concentration in the 6 M to 8 M range

-

pressure control to ensure that electrolyte pressure in the cathode space is higher than in the anode space

With these corrective actions in place, the DMMP run was completed without any further interruption, and test results were within expected parameters. Using normal feed concentration and rundown operations, agent simulant destruction to the required 99.9999 percent was completed.

A PTFE-lined pipe was placed into the anolyte loop to demonstrate the resistance of PTFE (Teflon), a material of construction to be used in the full-scale system, to electrolyte corrosion attack. This pipe was removed and inspected at the end of the DMMP run. Visual inspection showed no evidence of corrosion of the pipe or damage to the liner integrity. This test verifies the suitability of using PTFE lining in SILVER II™ systems processing energetics and DMMP but not the reliability of the array of connections required when using this material in a full-scale plant.

Laboratory-Scale Testing

High-Shear Mixers

During Demo II operation of the 12-kW SILVER II™ plant, problems were experienced with the buildup and handling of solids in the anolyte circuit of the plant (AEA, 2000). The solids were both parent material and intermediate products from the destruction of energetics. Although all of the energetics tested (M28, TNT, and tetrytol) exhibited this problem, it was most pronounced during the processing of tetrytol, when a lowering of the feed rate became necessary to reduce the risk of plugging the process piping. The reduced feed rate and organic inventory led to reduced plant efficiency and destruction rate. As a result, PMACWA required EDS II tests to determine a suitable design for a high-shear mixer to size-reduce solid organic material, primarily from M28 propellant, in both the anolyte and catholyte circuits of the 12-kW SILVER II™ plant. The EDS II test objectives for the high-shear mixers were as follows (AEA, 2001g):

-

Demonstrate that the mixers will size-reduce the crystalline solids that caused most of the operational difficulties in the plant during the Demo II tests.

-

Demonstrate that the mixers will operate without operational difficulties with a slurry that contains M28 propellant.

The high-shear mixers must operate in the presence of energetics and energetic breakdown products and in the highly acidic conditions that are present in the anolyte and catholyte feed tanks of the energetics SILVER II™ plant. Most of the typical industrial solid-liquid mixers were found to be unsuitable for this application. However, tests were conducted using equipment supplied by a high-shear mixer manufacturer, Maelstrom, and included two generic types of high-shear mixers and a high-shear agitator blade. The two types of high-shear mixers were an integral pump mixer and a fluid distributive mixer, also called a high-shear

vortex mixer. Both mixers subject the process fluid-solid mixture to high shear to produce a slurry, but the method by which they do so is different. Based on results of these tests, only the high-shear vortex mixer would meet operational goals.

High-shear vortex mixers were installed in the anolyte and catholyte feed tanks for the EDS II tests of the 12-kW SILVER II™ plant and performed well during the tests with Composition B and M28 propellant. AEA reported that the initial test showed that high-shear vortex mixers would effectively size-reduce the particles of Composition B and M28 propellant (and any other crystalline energetic particles that may have formed) and also provide bulk agitation (AEA, 2001a). AEA has also included conventional stirrers in all full-scale pilot plant feed tanks to further assure bulk agitation since the mixer head is small (18 inches in diameter) compared with the head in the full-scale vessel (10 ft in diameter) (AEA, 2001h). The full-scale mixing configuration has not been demonstrated. AEA also noted that the physical properties of energetics slurry could cause operational difficulties, with safety implications for equipment if unprotected, close-tolerance rotating parts were to come in contact with the slurry. Mixer design specifications address this requirement.

Hydrocyclone Trials for the 12-kW SILVER II™ Plant

As part of the EDS II laboratory-scale tests, trials were performed to determine the optimum hydrocyclone geometry for removal of solids from both the anolyte and catholyte circuits of the 12-kW SILVER II™ plant (AEA, 2001i). The trials established and demonstrated a hydrocyclone geometry capable of removing the simulated energetic material to a satisfactory level, less than 100 microns. In addition, the trials showed that the titanium hydrocyclones that had previously been installed on the 12-kW plant during Demo II for silver chloride removal could remove simulated energetic material after minor modification and reconfiguring. The simulant for the trials was chosen to closely mimic the behavior of the energetics to be processed.

Specific test conclusions by AEA are the following:

-

The existing titanium hydrocyclones, modified to incorporate a 14-mm vortex finder6 and a 6.4-mm underflow spigot, are suitable for the particle removal duty specified for a SILVER II™ facility at Blue Grass.

-

The existing titanium hydrocyclones are close in design to the units to be provided by the Mozley Company for a full-scale facility in multiple parallel flow units (sometimes called “multiclones”). Therefore, the results for the titanium system are anticipated to be similar to those for the Mozley units.

The flow rate to the hydrocyclones for the full-scale SILVER II™ unit, based on a 14-mm vortex finder and a 6.4-mm underflow spigot, would need to be approximately 3.2 m3/hr at a pressure of around 3.5 bar. This flow rate should be sufficient to achieve the overflow flow rate of 1.8 m3/hr required to feed the SILVER II™ cells. As noted previously, the hydrocyclones used in the 12-kW energetics and agent simulant trials for EDS II handled solids at the planned design loading (AEA, 2001a).

The committee notes that the laboratory tests established operating parameters for hydrocyclone operation that involve careful control of pressures and flows to achieve desired separation efficiencies. No tests were performed to demonstrate the robustness of hydrocyclone operation during the pressure and flow swings that might be expected during normal operations of a full-scale facility.

Organic Transfer Across Cell Membrane

The objectives of this laboratory-scale test were to quantitatively assess the rate and determine the mechanism of transfer (diffusional versus electrochemical) of organics and their breakdown products across the membrane (AEA, 2001j). For the test, a small, laboratory-scale SILVERII™ plant was constructed at Aberdeen Test Center at Aberdeen Proving Ground, Maryland, to accomplish the following:

-

Determine which species move across the membrane for a given substrate and their rate of transport.

-

Optimize the chemistry for the destruction of specific organic feeds to achieve maximum current efficiency.

The equipment included an Imperial Chemical Industries FM01 test cell that had been modified to en-

able it to treat mixtures containing energetic solids. The test cell contained platinized titanium electrodes and a Nafion N324 membrane and operated at a current density of 500 mA/cm2. These parameters are used in the 12-kW pilot plant system as well as in the full-scale design.

The coulombic efficiencies for the destruction were calculated to be as follows (figures in parentheses include the total rate of destruction when direct chemical oxidation by HNO3 is included):

-

Composition B, 62 percent (63 percent)

-

Composition B/M28, 78 percent (78 percent)

-

DMMP, 26 percent (29 percent)

As can be seen, the Ag2+ is responsible for most of the destruction; direct reaction with the HNO3 is a minor contributor for these organic materials.

The tests demonstrated that diffusion is the most likely mechanism for transfer of energetic organic species across the membrane from the anolyte to the catholyte chamber. Both the parent species in Composition B (TNT and RDX) as well as a TNT breakdown product, trinitrobenzene (TNB), move to the catholyte. Under operational conditions that provided a processing efficiency of approximately 80 percent for the energetics mixture, the rates of transfer were TNT = 2.6 g/hr/m2, TNB = 0.6 g/hr/m2, and RDX = 1.4 g/hr/m2.

The tests also demonstrated that the movement of metals and other ionic species could be estimated from knowledge of the system chemistry and the appropriate ionic mobilities. Table 3-5 gives typical transfer rates for concentrations of 0.5 moles/L of feed.

TABLE 3-5 Typical Transfer Rates for Concentrations of 0.5 Moles/L of Feed

|

Parameter |

Value |

|

Current |

5 kA |

|

Area |

1 m2 |

|

Fe3+ |

2.8 moles/hr |

|

Al3+ |

2.4 moles/hr |

|

SO42 |

0.033 moles/hr |

|

PO43 |

0.012 moles/hr |

|

SOURCE: AEA (2001m). |

|

Fluoride Transport Test

Agent GB contains fluoride. During SILVER II™ processing, the fluoride in GB is converted into HF. The ability of the HF to migrate through the plant is a factor in the selection of materials for different sections of the plant. A series of 8- and 72-hour tests were carried out in a laboratory SILVER II™ setup using the FM01 cell to confirm how fluorine moves around the plant, especially across the cell membrane and in the gas phase under different operating conditions. The tests, performed in a matrix of current “on,” current “off”, “silver present,” and “silver absent,” could be replicated. In each set of conditions, the change in concentration of fluoride with time in the anolyte and catholyte feed tanks and in the offgas was tracked after the introduction of sodium fluoride—equivalent to 0.1 M in the anolyte solution—at the beginning of each run (AEA, 2001k).

Test results showed that in both the 8-hour and 72-hour tests the concentration gradient caused a small diffusion of F (possibly as HF) through the membrane from anolyte to catholyte. Comparison of these results with runs using applied electric current showed the transfer flux is enhanced significantly by the electric field (possibly H2F+). However, even at the end of the 72-hour runs, the concentration of fluoride in the catholyte was no more than 0.01 M. In all of the runs, barely any fluoride was detected in any of the offgas scrubbers. This indicates that any HF in either the anolyte or catholyte offgas was returned in the condensate from the offgas condensers fitted to each of the anolyte and catholyte feed tanks.

The most significant test result was severe corrosion of the titanium anode. Based on inspection of the anodes after 8 hours of testing, it was concluded that attack in the presence of fluoride was occurring through imperfections in the platinum coating, undercutting it and causing it to spall off. As a consequence, the titanium was left exposed for corrosion during the 72-hour runs. The presence of silver is believed to enhance the titanium corrosion—possibly through local deposition and redissolution in nitric acid.

To address the imperfections of the anode coating, new Pt coating methods are being investigated by the electrode suppliers to improve deposition and eliminate pinholes. Also, no evidence of corrosion was observed during GB treatment in Demo II tests with the 2-kW SILVER II™ pilot plant, which is constructed of glass (AEA, 2000). AEA has indicated that the ability

of F complexation with Si, A1, Ti, and Zr to reduce corrosion of the electrodes should also be investigated.

AEA also concluded that the agent offgas/scrubbing systems could be fabricated from stainless steel, while the agent anolyte and catholyte circuits should be lined with materials resistant to corrosion by free fluoride, e.g., PTFE or PFA.

Fluoride Removal System Test

In addition to the preceding fluoride transport tests, laboratory-scale tests were conducted to investigate the possibility of containing or removing fluoride from the system to allow more economical materials of construction to be used in the design of the full-scale plant (AEA, 2001l). A series of nine tests was to be conducted to obtain kinetic data on the use of calcium as an agent for fluoride removal from the GB simulant, fluorophosphoric acid. Data were to be obtained for the hydrolysis reaction under acidic, neutral, and alkaline conditions.

No test data were available at the time this report was prepared. However, the fluoride transport test results discussed previously confirm the need to consider some form of removal or complexation of fluoride.

Cell Membrane Life Tests

Tests on the lifetime of cell membranes were performed to provide design, testing, and operations data for a full-scale SILVER II™ plant (AEA, 2001m). The test objectives were these:

-

Confirm the selection of membrane and gasket material for a full-scale facility.

-

Estimate membrane and gasket life.

The test of membrane lifetime consisted of a single test of 95 days cumulative duration on a laboratory-scale SILVER II™ plant. Two grades of Nafion membrane and four grades of Viton gaskets were tested for the full test period. Worst-case conditions, defined as exposure to the highly oxidizing conditions of SILVER II™ operating in the absence of an organic feed, were used. These conditions correspond to operation in continuous rundown or polishing mode and expose the membrane to the highest concentration of Ag2+. Analysis of the test data shows that the grades of membrane and gaskets currently used in the 12-kW pilot plant have a lifetime of at least 95 days under the conditions of this test.

The committee notes that the analysis of the cell membrane failure that occurred in the 500-hour DMMP (discussed in the next section) suggests that the cell membrane tests did not represent worst-case conditions for membrane life under actual operating conditions and that limited credence can be given to the conclusions from this test (AEA, 2001k). It also notes that in the absence of organics, parasitic oxidation of water may offset the Ag2+ attacks that were anticipated in this test.

Cell Membrane Failure Analysis

Repeated membrane failures during the early part of the 12-kW plant 500-hour DMMP run prevented effective control of water balance and levels of silver and organic material in the catholyte system. After laboratory-scale testing from October 11 to October 21, 2001, AEA concluded that the failures resulted from foaming or pockmarks in the lattice structure of the PTFE support in the Nafion membrane and that the pockmarks formed only if the membrane came into contact with the cathode.

The cell in the 12-kW plant was then modified to incorporate a system of spacers between the cathode and the membrane to ensure that the membrane did not contact the cathode. When the 12-kW plant was restarted, the catholyte level had risen more than would be expected during normal process operating conditions after 36 hours of operation. The cell was dismantled and the membrane was found to have small pinholes along the bottom edge. In addition, metallic silver deposits in the form of dendritic silver crystals were found in the cell.

DMMP testing was then stopped until PMACWA was convinced that the failure mechanisms were understood in sufficient detail to ensure that the plant could be operated without future membrane failures. A test program was conducted that looked at the following phenomena (AEA, 2001f):

-

Dendrite growth. Solid silver crystal needles grow on the cathode that can lead to arcing, short circuits, and membrane breach.

-

Foaming of Nafion. The interstices in the Teflon support lattice become discolored and develop pockmarks. This leads to zones of low mechanical stability from which pinholes may form, lead-

-

ing to localized heating, membrane failure, and arcing.

-

Membrane swelling. Such swelling, which is caused by the chemicals present in the anolyte solution, specifically organophosphates such as DMMP, can lead to deformation and mechanical damage as well as contact with the cathode.

Laboratory-scale tests were performed using both an FM01 cell and an ‘H’ cell. The tests show that silver dendrite growth in the catholyte solution is prevalent when the concentration of HNO3 is below 4 M. At concentrations between 4 M and 6 M, dendrite growth occurs at room temperature but is much reduced. It is not visible at elevated temperatures. With HNO3 at concentrations above 6 M, there is no dendrite growth at room temperature. AEA concluded that the concentration of HNO3 in the catholyte must be kept above 6 M to ensure that silver dendrite does not grow. Also, the formation of pockmarks appeared to be eliminated if the membrane was kept away from the cathode.

To validate the findings of the laboratory-scale testing, the 12-kW plant was reconfigured as a 4-kW system, with one operational anode and two operational cathodes. The cell was assembled with spacers between the cathode and the membrane to ensure that under operating conditions, the membrane could not come in contact with the cathode. The cell current was 2,000 A to provide the same current density across the membrane as that for the normally configured 12-kW plant. The catholyte offgas system was modified to provide a back pressure on the catholyte return system; this also had the effect of forcing the membrane toward the anode rather than the cathode. The plant was run in this configuration for 24 hours. Inspection of the membrane after this test showed that the membrane had been in contact with the anode and that there were no signs of silver deposits or damage to the membrane surfaces.

The plant was reassembled in its normal 12-kW configuration with cathode spacers fitted. To provide a worst-case operating condition, the back pressure on the catholyte system was removed so that the spacer was the only mechanism that kept the membrane from contacting the cathode. The plant was run for 24 hours under these conditions, and the cell was dismantled to inspect the membranes. There were no signs of damage to the membrane surfaces and no signs of silver deposits.

Electron microscope examination of a membrane has shown that the pockmarks have largely the same chemical composition as undamaged membrane components but contain a small amount of silicon. Burnt areas around pinholes have appreciable levels of platinum and titanium, which is probably a result of arc damage to the metal surface of the electrode coating. AEA noted that small amounts of this type of damage are of little consequence to the electrode since the electrochemical processes seal any damaged areas by passivation. AEA stated that it is not clear why pockmarks occur with DMMP (an organophosphate) and not with the energetics (AEA, 2001f). AEA has noted that in other electrochemical systems, pinholes can lead to local areas of high current density. This produces a significant amount of ohmic heating and melting, leading to membrane failure. It is unclear if this is a failure mechanism in this application.

The committee notes that the electrode damage may become more severe when feeds containing fluorine and chlorine are processed. In the fluoride transfer test discussed earlier, the titanium electrodes were severely corroded and the Pt coating was pitted or peeling off. This more severe damage would be unacceptable during full-scale plant operation.

AEA concluded from the EDS II tests that all of the mechanisms that can give rise to premature membrane failure had been identified (AEA, 2001f). Subsequent completion of the DMMP 500-hour run without membrane failure appears to validate this conclusion for DMMP operation. Although the DMMP run was successfully completed, it is not certain that other membrane failures will not occur when agent feeds containing fluorine or chlorine are used. Whereas organophosphates can lead to swelling of the membrane by the mechanism previously described, both concentrated acids and multivalent metal ions can cause shrinkage of the membrane. Further, it is not clear that additional membrane failure mechanisms will not be experienced as a consequence of flow and pressure variations in the six cell stacks of up to 48 cells each, recommended for the full-scale facility at Blue Grass.

Silver Recovery from Silver Chloride

These tests were conducted to provide sufficient data to select a silver recovery method (AEA, 2001n). They had three objectives:

-

Demonstrate silver recovery from (contaminated) silver chloride.

-

Determine the levels of impurities in the silver.

-

Characterize the slag for purposes of reuse and disposal.

The tests involved mixing known amounts of silver chloride with sodium hydroxide. The silver chloride was precipitated from a simulated anolyte solution with composition similar to that expected after the anolyte solution has been passed through the polishing circuit of the IRS. Metals in the simulated anolyte solution included Fe, Al, and Cu. The silver chloride/sodium hydroxide mixture was placed in a nickel crucible and then into a furnace heated to 600°C. After termination of the reaction, the crucible contents were quenched in water, washed out with water, and filtered. A silver mass balance was then performed.

The results demonstrated that low-temperature caustic fusion at 600°C is effective in recovering more than 93 percent of the silver with a purity of greater than 99 percent. Furthermore, the silver is recovered in a form suitable for quick reaction with HNO3 to form silver nitrate makeup without a significant amount of metal impurities. The committee notes that the 93 percent yield of silver suggests that 7 percent of the silver is not recovered, and the cost of this unrecovered silver and its disposal via a process waste stream must be considered when calculating the cost of operation. As reported in the EDP, AEA anticipates using off-site reclamation for silver recovery. An evaluation by Ames Goldsmith Corporation, a potential off-site reclaimer, states that 98 percent of the silver could be recovered at a purity level of 99 percent (AEA, 2001a). Thus, the EDP is based on off-site reclamation with a silver recovery of 98 percent.

Evaporator Trials for the Full-Scale SILVER II™ Plant

According to the EDP, a full-scale SILVER II™ plant at Blue Grass would include an evaporator circuit to reduce the volume of waste that arises from metals and mineral acids accumulated in the IRS. (See Figure 3-2 for the location of the evaporator in the IRS.) This test program investigated evaporator operation and selected suitable materials of construction (AEA, 2001o). Specific objectives were as follows:

-

Conduct evaporator tests on a solution that simulates the solution to be evaporated in the full-scale plant for the IRS system.

-

Demonstrate ease of evaporation and recovery of water and nitric acid from simulated feed solutions.

-

Provide stream composition data for the overheads and bottoms streams during the evaporation process.

-

Establish the maximum evaporation ratio (i.e., evaporated quantity/feed quantity) without compromising the pumpability of the bottoms discharge (or impurity) stream and without excessive decomposition of the bottoms stream while minimizing the volatility of any bottoms components (such as HF or HCl) or decomposition of the overheads components.

-

Identify appropriate materials of construction for the evaporator.

The evaporator tests were conducted in a laboratoryscale test setup. The bottoms product after the worst-case volume reduction (70 percent) was found to be similar in density and viscosity to that of concentrated HNO3. No solids and no decomposition were observed after cooling, and AEA expects that the resulting bottoms product after evaporation will not compromise pump operation.

Based on corrosion coupons in place during this test, Inconel 690 was found to be an unsuitable material of construction; however, PTFE-lined metal was suitably resistant to the most aggressive feed solution.

The committee notes that the test solutions fed to the evaporator contained nitric, sulfuric, and phosphoric acids and fluoride for establishing fluoride volatility. No silver or organic carbon was included, although design conditions assume up to 100 ppm total organic carbon and approximately 2 weight percent of the silver since complete silver separation is not expected. Also, some chlorides may be present after separation of the AgCl precipitate in the preceding process step. These low-level concentrations are problematic for good evaporator operation. In particular, foaming may result from the presence of organic materials, and fluorides and chlorides may migrate to the NOx reformer system and pose added materials challenges.

Desktop Studies