PANEL MEMBERS

James W. Serum, SciTek Ventures, Chair

Alan Campion, University of Texas, Austin, Vice Chair

Ulrich Bonne, Honeywell Laboratories

Douglas C. Cameron, Cargill, Inc.

Robert E. Ellefson, Inficon, Inc.

E. William Kaiser, Ford Motor Company

John W. Kozarich, ActivX Biosciences, Inc.

Max G. Lagally, University of Wisconsin-Madison

R. Kenneth Marcus, Clemson University

James D. Olson, The Dow Chemical Company

Athanassios Z. Panagiotopoulos, Princeton University

Frank K. Schweighardt, Air Products and Chemicals, Inc.

Gary S. Selwyn, Los Alamos National Laboratory

Michael L. Shuler, Cornell University

Christine S. Sloane, General Motors Corporation

Anne L. Testoni, KLA-Tencor Corporation

Peter Wilding, University of Pennsylvania Medical Center

Submitted for the panel by its Chair, James W. Serum, and its Vice Chair, Alan Campion, this assessment of the fiscal year 2002 activities of the Chemical Science and Technology Laboratory is based on site visits by individual panel members, a formal meeting of the panel on March 12-13, 2002, in Gaithersburg, Md., and documents provided by the laboratory.1

LABORATORY-LEVEL REVIEW

Technical Merit

The mission statement of the Chemical Science and Technology Laboratory (CSTL) is as follows: As the Nation’s Reference Laboratory for chemical measurements, CSTL provides the chemical measurement infrastructure to enhance U.S. industry’s productivity and competitiveness; assure equity in trade; and improve public health, safety, and environmental quality.

CSTL continues to carry out research of excellent technical merit overall. The panel wishes to draw attention here to several outstanding examples:

-

“Ionic liquids” are a class of organic compounds that have been proposed as environmentally friendly solvents for some important industrial processes. This past year, CSTL initiated a program to obtain and disseminate fundamental physical and chemical properties data for some of these compounds in order to facilitate industrial adaptation of these new solvents. The laboratory has anticipated industry need for these data—to the extent that the compounds are not yet available commercially and must be synthesized in-house for study.

-

The laboratory is also continuing work to control and characterize fluid flow in microfluidic devices. This work is noteworthy not only because of its world-class technical merit but also because of the strong industrial involvement in the program and its applicability across a broad spectrum of problems in chemistry, biology, and medicine.

-

Fluorescence spectroscopy is an old “workhorse” technique used in biochemical assays. Despite its long history of use, few standards exist for measuring the intensity of the fluorescent signal, making quantitative assays using this technique unreliable at best. Because of increased use of fluorescent techniques in clinical applications, CSTL is developing standards for these measurements, which will have a significant impact on the quality of clinical measurements made using this technique.

-

CSTL efforts to develop high-throughput characterization of particle properties is not only relevant to industries as diverse as paints and coatings manufacturers and semiconductor manufacturers but is noteworthy for its interlaboratory collaborations.

Several programs were noteworthy for the use and development of cutting-edge technologies. A new primary standard for pressure is under development; it determines pressure by measuring and calculating the dielectric constant of helium rather than by using the mechanical artifacts of existing pressure standards. CSTL work on characterizing degraded DNA samples is pushing forward the state of the art in mass spectroscopic techniques. In work aimed at characterizing “soft” surfaces such as biomaterials and polymers, the laboratory is developing new cluster-ion secondary ion mass spectrometry (SIMS) techniques.

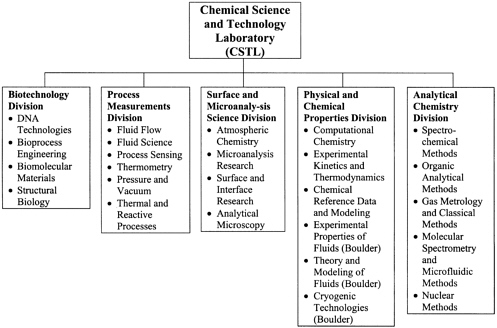

The Chemical Science and Technology Laboratory is organized in five divisions: Biotechnology Division, Process Measurements Division, Surface and Microanalysis Science Division, Physical and Chemical Properties Division, and Analytical Chemistry Division (see Figure 4.1). These units are reviewed in turn under “Divisional Reviews” below in this chapter.

Program Relevance and Effectiveness

The panel found CSTL to be very proactive overall in identifying the customers of its work. In most cases, researchers have a good understanding of how their work meets the needs of those customers. In

FIGURE 4.1 Organizational structure of the Chemical Science and Technology Laboratory. Listed under each division are the division’s groups.

addition to their technical description, all projects presented to the panel had a concise statement of the anticipated industrial use. The panel was pleased to see an increased awareness of customer impact since its last assessment.

Particularly noteworthy for their relevance and effectiveness are the laboratory’s efforts in Standard Reference Materials (SRMs), Standard Reference Databases (SRDs), and international standards activities. These services and activities rarely garner headlines but have a large leverage effect in industry and underpin many critical measurements in the chemical, pharmaceutical, medical, and other industries. For example, the laboratory recently completed a series of SRMs for in vitro diagnostic testing. These SRMs will allow U.S. manufacturers to qualify their products for sale in the European Union. The panel anticipates that the positive impact for U.S. manufacturers will be substantial. NIST-Traceable Reference Materials (NTRMs), discussed in the Analytical Chemistry Division assessment below, have tremendous leverage in the chemical products industry and are also of value to National Laboratories, environmental laboratories, academic institutions, and other industries. Web-based databases are growing in size and number and are improving in quality. The panel is pleased with CSTL efforts in Web-based dissemination and finds that the laboratory’s Web-based dissemination continues to improve in utility and effectiveness. The laboratory has now hired a staff member dedicated to the effectiveness of Web usage and maintenance, which the panel applauds. However, funds are insufficient to maintain and update all of the laboratory’s Web-based tools. The panel is concerned about the utilization of these

databases if CSTL does not take advantage of the opportunity that the Web provides to continually update material. The laboratory needs to develop a strategy to determine how it will utilize its limited resources for Web-based dissemination.

Laboratory Resources

Funding sources for the Chemical Science and Technology Laboratory are shown in Table 4.1. As of January 2002, staffing for the laboratory included 270 full-time permanent positions, of which 232 were for technical professionals. There were also 92 nonpermanent or supplemental personnel, such as postdoctoral research associates and temporary or part-time workers.

The panel observed too many priority projects with subcritical resources devoted to them. It may be that CSTL needs to reexamine its prioritization, either to find additional resources for top priorities that are undersupported or to terminate efforts that cannot be supported effectively. CSTL has also targeted certain areas for strategic program growth. The panel cautions against implementing strategies in these areas too quickly, before the appropriate expertise is in place to launch efforts most effectively. For example, the CSTL program in tissue engineering does not seem to have the complete skill set necessary to meet its goals.

TABLE 4.1 Sources of Funding for the Chemical Science and Technology Laboratory (in millions of dollars), FY 1999 to FY 2002

|

Source of Funding |

Fiscal Year 1999 (actual) |

Fiscal Year 2000 (actual) |

Fiscal Year 2001 (actual) |

Fiscal Year 2002 (estimated) |

|

NIST-STRS, excluding Competence |

37.9 |

37.7 |

36.9 |

37.7 |

|

Competence |

2.4 |

2.4 |

1.9 |

2.7 |

|

ATP |

3.0 |

3.3 |

3.2 |

2.4 |

|

Measurement Services (SRM production) |

2.4 |

2.2 |

1.9 |

1.9 |

|

OA/NFG/CRADA |

10.9 |

14.2 |

14.3 |

15.4 |

|

Other Reimbursable |

3.4 |

3.4 |

5.8 |

5.1 |

|

Total |

60.0 |

63.2 |

64.0 |

65.2 |

|

Full-time permanent staff (total)a |

276 |

275 |

264 |

270 |

|

NOTE: Funding for the NIST Measurement and Standards Laboratories comes from a variety of sources. The laboratories receive appropriations from Congress, known as Scientific and Technical Research and Services (STRS) funding. Competence funding also comes from NIST’s congressional appropriations but is allocated by the NIST director’s office in multiyear grants for projects that advance NIST’s capabilities in new and emerging areas of measurement science. Advanced Technology Program (ATP) funding reflects support from NIST’s ATP for work done at the NIST laboratories in collaboration with or in support of ATP projects. Funding to support production of Standard Reference Materials (SRMs) is tied to the use of such products and is classified as “Measurement Services.” NIST laboratories also receive funding through grants or contracts from other [government] agencies (OA), from nonfederal government (NFG) agencies, and from industry in the form of cooperative research and development agreements (CRADAs). All other laboratory funding, including that for Calibration Services, is grouped under “Other Reimbursable.” aThe number of full-time permanent staff is as of January of that fiscal year. |

||||

Strategic program goals must be coordinated with a plan for resources, including human resources, in order to ensure that resources are fully leveraged and programs have a sufficient critical mass to be effective. The panel is concerned that CSTL lacks a human resource plan, which would enable better personnel development, succession planning, and acquisition of new skills through hiring or retraining.

The panel recommends that the laboratory utilize a fellowship program for rapid development of the technical expertise needed for growth areas. A program in which NIST researchers spend a period of several months to a year in industry can greatly facilitate bringing new skills into the laboratory. All fellowships awarded must include a clear plan for how the new skills of the awardee will be used once he or she returns to NIST. The program must also be clearly tied to advancement, reward, and recognition to give employees an incentive to participate.

Midlevel managers in CSTL, especially group leaders, are being called on to exercise an increasing number of skills. They generally maintain an active research program while tending to personnel management, leadership of staff, and marketing of programs to industrial customers. Little training seems to be provided to support them in this work. The panel urges a proactive approach to training managers and prospective managers in these areas in order to enable their success. The result should pay off for the laboratory in terms of better coordination of programs, better communications to all levels of staff, and higher overall staff morale.

Facilities for CSTL research have improved greatly in the past 5 years, and the completion of the Advanced Measurement Laboratory (AML) will have a major positive impact. Equipment on hand is generally state of the art, although in some cases the equipment needed to meet goals is not in place. The panel believes that CSTL should clarify its thinking on an in-house microelectromechanical systems (MEMs) production facility. The panel did not see a clear rationale for a decision to procure that capacity in-house versus obtaining it off campus. Because of the high cost of maintaining such a facility, the panel recommends that CSTL and NIST be certain that any make/buy decision on MEMs production take into account the long-term costs of such a facility. The panel is pleased to see that the Hollings Marine Laboratory in Charleston, South Carolina, in which CSTL is a partner with NOAA and state agencies, is being appropriately equipped from the outset.

Laboratory Responsiveness

Clear examples of strong responsiveness to last year’s report2 exist. For example, in response to panel comments, time and funds were reprioritized to increase efforts in international activities and collaborations in analytical chemistry. Some divisions greatly enhanced the usability of their Web-based information, also in response to panel recommendations.

Responses in some areas were not as strong. For example, the panel has pointed out the lack of critical mass in program areas such as atmospheric chemistry. While recognizing that it is difficult to make decisions to redirect resources, some situations have been allowed to linger despite repeated comments from the panel. Such situations are having an increasingly negative impact on the morale of involved staff members.

In general, the panel is satisfied with the CSTL’s response to its 2001 report. It urges the laboratory to try harder to respond to the more difficult recommendations or to provide better explanations for why these recommendations were not acted upon.

MAJOR OBSERVATIONS

The panel presents the following major observations:

-

Chemical Science and Technology Laboratory programs continue to have high technical merit overall.

-

Awareness of customer needs and customer impact is increasing at all levels of CSTL staff.

-

The panel is pleased with improvements made to CSTL use of the World Wide Web. Hiring a staff member devoted to Web utilization and Web-based dissemination is a positive step. A strategy is needed for Web-based dissemination, as databases currently exist that are not kept up to date.

-

CSTL needs a human resources plan that can be integrated with the CSTL strategic plan to account for the training, hiring, and succession planning needed to achieve laboratory goals and objectives.

-

CSTL should utilize industrial fellowships to learn more about its customers and to quickly gain skills necessary to achieve objectives in new and emerging areas. Any plan to place a staff member in industry for an extended period must include a plan for how that person will utilize new skills upon returning to NIST. In order to attract staff participation, industrial fellowships must be tied to advancement, reward, and recognition.

-

More proactive training of group leaders is required to help them achieve success in the multiple roles they are called on to fill in their positions.

-

CSTL should reexamine the rationale for its decision on building a microelectromechanical systems fabrication capacity in-house. If the decision is made to go forward with an on-campus facility, a long-term plan is necessary to provide for the cost of maintaining and utilizing it.

DIVISIONAL REVIEWS

Biotechnology Division

Technical Merit

According to division documentation, the mission of the Biotechnology Division is to advance the commercialization of biotechnology by developing the scientific and engineering technical base, reliable measurements, standards, data, and models to enable U.S. industry to quickly and economically produce biochemical products with appropriate quality control. The Biotechnology Division has four groups: DNA Technologies, Bioprocess Engineering, Biomolecular Materials, and Structural Biology. The division is also evolving a Bioinformatics Group from the Structural Biology Group. The division’s ongoing programs are appropriately aligned with its mission, and the scientific work is of high quality comparable with that at research-oriented universities and in leading industrial laboratories. The division’s challenge is to select those projects that are most critical and that will have the greatest impact on this rapidly growing and changing field.

The DNA Technologies Group carries out research to enhance measurement technologies and to provide SRMs for application in areas related to the detection and characterization of DNA. The group maintains a strong focus on standards development, nucleic acid characterization, and measurement development for the diagnostic and forensic communities. The group’s programs are quite wide ranging and are, in general, of outstanding quality.

The DNA Technologies Group is pioneering the development of SRMs for human identification

and is developing a critical database on short tandem repeats (STRs). The development of these methodologies for human identification is being carried out in collaboration with and with the support of the National Institute of Justice. This research is state of the art and continues to push the technology into new, productive, and high-impact areas. The development of new high-speed matrix-assisted laser desorption ionization (MALDI) time-of-flight mass spectrometric techniques with automated sample preparation is addressing the need for high-throughput analysis of genetic samples. Projects focusing on identification methodologies for the Y chromosome and mitochondrial DNA continue to make impressive progress. The development of Y-STR megaplex assays will greatly increase the acceptance of these identification techniques within the forsenic community. Genotyping of single nucleotide polymorphisms in the Y chromosome and the mitochondrial genome, the development of the prototype Y chromosome standard (SRM 2395), and the enhanced version of the human mitochrondrial DNA SRM 2392 have all progressed well in the past year.

The DNA Technologies Group has also successfully integrated state-of-the-art instrumentation into its programs. One CRADA with a biotechnology company led to the development of rapid capillary electrophoresis (CE) methods for mutation detection. Other work has focused on developing procedures for single-strand conformation polymorphism detection by CE. Another major program has centered on developing methods for detecting and quantifying DNA damage and repair in cancer detection and treatment. Methods have been developed to characterize DNA damage on a molecular scale at levels approaching one base per million using gas chromatography/mass spectrometry (GC/MS) techniques. These methods have been useful in the study of the kinetics and specificity of DNA repair by specific enzymes. Additional studies are concentrated on apoptosis, or programmed cell death, as well as detection of cellular responses to radiation. This work has potentially high-impact value.

The DNA Technologies Group also houses the NIST/National Cancer Institute (NCI) Biomarker Validation Laboratory (BVL), part of NCI’s Early Detection Research Network (EDRN). The BVL validates biomarkers of early cancer detection and cancer risk, supports the development and implementation of high-throughput biomarker analysis, and collaborates with Network Clinical and Epidemiology Centers (NCECs) in technology transfer. The panel was impressed with the accomplishments of the past year, including validation analysis of fluorescence in situ hybridization (FISH) for cancer risk analysis; technical improvements in polymerase chain reaction (PCR) DNA sequencing technology for analysis of mitochondrial DNA base mutations for lung cancer; and the development of capillary electrophoresis methods for analysis and quantification of telomerase. The work is cutting-edge and of high impact.

The Bioprocess Engineering Group develops measurement methods, databases, and generic technologies related to biomolecules and biomaterials in manufacturing. The group, which consists of 12 researchers, has activities in eight areas: (1) fluorescence intensity measurements, (2) biothermodynamics, (3) biotech grain testing, (4) quantitative PCR reference materials, (5) chorismate pathway enzymology, (6) biocatalytic hydroxylation/epoxidation, (7) bioelectrochemistry, and (8) DNA separations. The quality of the group’s work is high, and its activities and accomplishments are clearly presented in a useful and well-designed Web site.

The Structural Biology Group participates in the Center for Advanced Research in Biotechnology (CARB), a joint NIST/University of Maryland (UMD) research center located on the Shady Grove campus of UMD about 4 miles from NIST. Scientists at CARB develop and apply measurement methods, databases, and state-of-the-art modeling methods to advance the understanding of protein structure/function relationships. Current programs in x-ray crystallography, biomolecular nuclear magnetic resonance (NMR) spectroscopy, protein folding, computational chemistry and modeling, and mechanistic enzymology are outstanding. The NIST component of CARB has succeeded in attracting

several first-rate young investigators who have nicely blended their NIST-focused programs into the academic culture that they share with their UMD colleagues. The result is a stimulating research environment that maintains the mission-oriented flavor critical to NIST programs. Notable programs include research on the biothermodynamics of protein/protein and protein/nucleic acid interactions, single-molecule measurements, studies on computational molecular evolution, and the development of cell membrane hybrid bilayers for a high-throughput screening assay for membrane receptors. In addition, ongoing work on the x-ray and NMR structures of proteins and nucleic acid is of high quality.

The newly evolved Bioinformatics Group has four major projects: the Protein Data Bank (PDB), the Biomolecular Crystallization Database (BMCD), the Bioinformatics Software Resource (BISR), and the HIV Protease Structural Database (HIVDB). The PDB is a major national and international resource and a very visible success for NIST. The goal of the BISR is to create a database of commercial and noncommercial bioinformatics software. The panel was gratified to learn that the group has developed educational and outreach materials for high schools and has hired high school students to work in the laboratory. Overall, this group is making exceptional contributions to bioinformatics. Hiring and retention are continuing challenges for the group owing to a high demand for such skills in the biotechnology and pharmaceutical industries. The group currently consists of approximately 10 people.

The Biomolecular Materials Group builds on its skills in surface science, optics, biophysics, and chemistry to support research in protein structure/function relationships, biopolymer transport processes, biosensors, molecular recognition, protein/lipid and protein/protein interactions, mechanism of protein adsorption, and tissue engineering. The panel was very impressed that the group was awarded two NIST Competence programs with funding through FY 2007. The first, Single Molecule Manipulation and Measurement (SM3), is a collaboration between CSTL, EEEL, ITL, and PL. This program builds on the group’s historical strengths. Research planned in single-molecule force metrology and single-nanopore-based analyte sensors is particularly noteworthy. The second, Metrology for Tissue Engineering: Test Patterns and Cell Function Indicators, involves collaboration with MSEL. The tissue engineering effort is newer to this group. This program focuses on the use of indicator cells to evaluate cellular response to exposure to a new biomaterial. While most of the group’s efforts are understaffed in comparison with the potential of the research problems, the addition of more staff to the tissue engineering effort is particularly critical. At the time of the panel’s visit, a search was under way for a postdoctoral associate. Filling this position with an appropriately trained individual will be important to ensure rapid progress. The group is well situated to make contributions to these exciting and rapidly evolving research areas with its strong intellectual leadership and first-rate science and technology.

Program Relevance and Effectiveness

The Biotechnology Division has selected a wide range of exciting emerging research areas that will be critical to the nation’s future industrial competitiveness and safety. The division is well positioned to support efforts in genomics, proteomics and structural biology, tissue engineering, standards for genetically modified crops, and characterization and manipulation of single molecules such as DNA. As a whole, the division has selected a very appropriate set of research areas to which to apply its limited resources. The panel and the division both recognize that the range of potential issues in biotechnology is vast and that the potential number of customers for the division’s work is in the thousands. Since all of these issues and many potential customers cannot be served by a group of the division’s size, the prioritization of research problems is critical. The panel concurs with the priorities chosen by the division.

The division demonstrated its ability to respond to customer needs on an emergency basis in its response to the fall 2001 terrorist attacks. The DNA Technologies Group has developed new techniques

to permit identification of persons from highly degraded DNA and is assisting agencies that are using these methods to help identify victims of the World Trade Center attacks.

The Biotechnology Division is by nature cross-disciplinary and has strong international connections. The two Competence awards to the division promote cross-division and cross-laboratory collaborations and communications. The interaction with CARB also promotes an externally oriented perspective. The Protein Data Bank is an international effort. The division is a coleader of the Consultative Committee for the Amount of Substance Biometrology Working Group. This activity involves about 30 countries. Division scientists played an important role in the recommendations of the International Union for Pure and Applied Chemistry (IUPAC) for differential scanning calorimetry measurements. Division staff members played leadership roles in the Second International Conference on Oxidative Stress and Aging, sponsored by the Oxidative Stress and Aging Association.

The division makes substantial use of the Web to disseminate information. It maintains four major databases: the Protein Data Bank (a research collaboratory for structural bioinformatics), the Biological Macromolecule Crystallization Database (SRD 21), the Short Tandem Repeat DNA Database, and the Thermodynamics of Enzyme-Catalyzed Reactions Database (SRD 74). These databases are important resources for scientists worldwide. Some units (e.g., the Bioprocess Engineering Group) have made significant improvements to their Web sites in the past year.

The panel notes that the research in the division aligns well with three strategic focus areas identified in the NIST strategic planning process: health care, nanotechnology, and knowledge management. The central focus of the division is closely related to health care. The SM3 program has necessitated the division’s development of expertise in nanotechnology. The division’s bioinformatics programs are an important example of knowledge management.

The panel reviewed the division’s responsiveness to prior reports. The primary challenge to the division’s ability to maintain relevance and responsiveness to customers is that of maintaining and developing critical mass in emerging areas. This challenge requires the division to reassess research priorities constantly and to encourage staff development in new areas. The panel has seen clear evidence of strategic planning and of reprogramming, particularly in genomics and proteomics, nanotechnology, and tissue engineering. The panel also expressed concern last year about maintaining the proper balance between STRS monies and funding from other sources. While some increase is seen in the use of other funding, particularly with the DNA Technologies Group, the panel believes other groups could benefit from a higher proportion of outside funding. It is difficult to change this balance rapidly.

The DNA Technologies Group has maintained high external visibility and programmatic relevance, as evidenced by the high level of external funding it has received to support its programs. Such funding has positive aspects, since it requires the group to maintain a high degree of customer responsiveness. The group is well positioned to respond to customer needs in genomics and proteomics. However, given the general manpower and resource constraints that it is facing and its deep commitment to several key external programs, the group may be spreading itself too thin and may not be able to mount the kind of program needed in proteomics. The leadership of the group and the division must carefully assess priorities and resource distribution to assure that key programs are adequately supported. The group should also develop a plan that prioritizes proteomics efforts consistent with ongoing commitments and the current expertise base.

The Bioprocess Engineering Group has made significant contributions in each of its eight areas but is spread too thin for a group of 12. The panel recommends its reducing the number of project areas and aligning better with the NIST Strategic Focus Areas of health care, nanotechnology, and knowledge management. One promising area that would draw on the group’s strengths is the characterization of

complex, heterogeneous proteins such as the glycosylated protein drugs being developed by the pharmaceutical industry. Currently, the Bioprocess Engineering Group does not rely on outside funding for any projects. Increasing the amount of outside funding to around 20 percent could allow the division to increase the number of researchers on each project and would demonstrate external buy-in to projects. The group’s biotech grain testing and quantitative PCR reference materials projects are areas of growing importance in the food and agriculture industries; such testing and standards are important for regulatory compliance, human health and safety, global trade, and identity preservation of crops. This effort is highly responsive to NIST customer needs and has resulted in CRADAs with seed companies. The number of people working on this project in the Bioprocess Engineering Group has doubled, from one to two, since last year, but is still understaffed relative to its full potential. The Bioprocessing Engineering Group should continue to strengthen its interactions with the DNA Technologies Group to further leverage its efforts.

The Bioprocess Engineering Group continues to deliver high-quality thermodynamics data, as evidenced by the recent publication of thermodynamic quantities for the ionization reactions of biological buffers. The group has also released thermodynamics software. However, the software requires Mathematica, a program that is widely available in academia and in engineering groups in industry but not commonly used by biologists. For the use of its biothermodynamics data, the group should consider developing software that is built on more commonly used software such as Excel or that can be used directly via the Internet.

The relationship to CARB is a critical issue for the Structural Biology Group. The University of Maryland began the CARB collaboration more than 10 years ago. In the panel’s judgment, the NIST and university cultures have been integrated successfully. The current group of NIST investigators at CARB has straddled both cultures effectively. Young NIST investigators are competitive with the best young academic faculty nationwide. However, with regard to manpower and resources, the NIST component of CARB appears to be at a crossroads. NIST manpower levels at CARB are at or near their lowest point, and the division is clearly concerned about NIST’s commitment to rebuilding its presence at CARB in light of flat budgets and decreasing permanent positions. This situation is exacerbated by the fact that another expansion of CARB has been planned, and it is not clear to the Structural Biology Group if NIST will commit the kind of resources needed to maintain a robust presence relative to its UMD peers. CARB has been an important and successful collaboration for NIST, but a clear strategic vision needs to be articulated for the NIST role in the future of this institution. The ongoing search for a new CARB Director also contributes to staff anxieties over the future.

Despite these uncertainties, the Structural Biology Group is expanding its interactions with industry in the vibrant biotechnology sector found in the Washington, D.C., area. A new CRADA with MedImmune was established to undertake a thermodynamic characterization of monoclonal IgM using calorimetric methods. Another new CRADA with Genetics Institute, Inc. explores biophysical and crystallographic attributes of thioredoxin fusion peptides and proteins.

The Bioinformatics Group faces several challenges in maintaining program relevance and effectiveness. The PDB project, an important and high-impact resource for the molecular biology community, will be challenged to keep up with the large number of new protein structures that will be generated by large-scale proteomics projects. The BISR project has the worthy goal of creating a database of commercial and noncommercial bioinformatics software. The panel suggests that one way to strengthen and grow this effort is to convince the key bioinformatics journals to require that software mentioned in publications be archived in such a database. As part of the HIVDB project, the Bioinformatics Group is developing tools for structural-based queries for drug interactions. The panel was impressed with the initial progress of this effort and recommends that feedback from industrial medicinal chemists be

incorporated into the query tools. The panel also recommends that the drug interaction database be extended beyond proteases to other proteins such as protein kinases. Overall, this group is responsive to a wide range of users and has a strong customer-service orientation.

The Biomolecular Materials Group is very forward looking, and its targeted technologies are just emerging in the industrial sector; the two recently funded NIST Competence programs mentioned above confirm the potential relevance of its efforts. Because of the emerging nature of the technology it is working on, this group has fewer obvious links to industrial firms. However, its projects have explicit relevance to tissue engineering firms and to regulatory agencies such as the Food and Drug Administration (FDA). The SM3 project is addressing issues that will be needed in biomicroelectromechanical systems (bioMEMs) projects. Efforts to validate new methods for characterizing nanopores with “molecular rulers” and for DNA sequencing are also important. The research on high-density biological arrays has clear relevance to high-throughput proteomics and to biohazards detection, both of which are critical research areas that would benefit greatly from improved detection techniques. The relevance of this group’s work to supporting critical emerging technologies is high. However, the panel would like a better understanding of how the group will actively link its contributions to customers.

Division Resources

Funding sources for the Biotechnology Division are shown in Table 4.2. As of January 2002, staffing for the division included 37 full-time permanent positions, of which 32 were for technical professionals. There were also 24 nonpermanent or supplemental personnel, such as postdoctoral research associates and temporary or part-time workers.

The availability of adequate human resources remains the critical resource issue for the division. Funding and personnel numbers estimated for 2002 are up by about 8.5 percent compared with those for

TABLE 4.2 Sources of Funding for the Biotechnology Division (in millions of dollars), FY 1999 to FY 2002

|

Source of Funding |

Fiscal Year 1999 (actual) |

Fiscal Year 2000 (actual) |

Fiscal Year 2001 (actual) |

Fiscal Year 2002 (estimated) |

|

NIST-STRS, excluding Competence |

6.5 |

6.5 |

6.6 |

6.9 |

|

Competence |

0.8 |

0.8 |

0.4 |

1.0 |

|

ATP |

1.7 |

1.9 |

1.3 |

0.7 |

|

Measurement Services (SRM production) |

0.1 |

0.0 |

0.3 |

0.2 |

|

OA/NFG/CRADA |

1.7 |

2.2 |

1.9 |

2.8 |

|

Other Reimbursable |

0.1 |

0.3 |

0.2 |

0.2 |

|

Total |

10.9 |

11.6 |

10.7 |

11.8 |

|

Full-time permanent staff (total)a |

37 |

35 |

32 |

37 |

|

NOTE: Sources of funding are as described in the note accompanying Table 4.1. aThe number of full-time permanent staff is as of January of that fiscal year. |

||||

2001. The panel is pleased to note this slight growth. The rapidly changing nature of research opportunities in biotechnology will always challenge the division to assemble the critical mass of human resources needed to attack these emerging opportunities. As a whole, the division has managed its resources well. However, expertise in plants, animal cell culture, and tissue engineering is rather minimal for supporting the aspirations of the division and the needs of its customers. The panel appreciates the difficulty of expanding core personnel in the current fiscal environment, but human resources are the primary limitation for the division (also, see the discussion on manpower levels at CARB in the preceding subsection, “Program Relevance and Effectiveness”).

The division lost two staff members in bioinformatics in the past year. NIST can expect significant competition for personnel in bioinformatics. Many organizations in the Washington, D.C., area can pay people with these skills much more than government agencies can. The growth of the local biotech industry and the expansion of the Howard Hughes Medical Foundation will mean a highly competitive local job market in biotechnology. As the economy recovers, this competition will only intensify.

The challenge of employing human resources optimally is affected not just by the supply of funds but also by the type of fiscal support currently available in the laboratory. The internal STRS funds do not currently cover the salaries of all of the division staff, which has led to a significant dependence on support from other agencies. Different programs within the Biotechnology Division appear to have different attitudes toward the use of noncore funding and its application to staffing. In some programs, staff aggressively pursue OA funding in order to hire new personnel and expand into new areas. In others, permanent positions are not created unless they can be supported by NIST core money. The former approach embraces risk and increases the potential impact of a group’s work, while the latter allows program managers to be assured that mission-critical activities are sustained and NIST’s customer base will be served. The panel recognizes that both approaches have value, but suggests that modest dependence on external funds be encouraged.

The panel also noted a need for increased computer support and additional disk storage space for the Bioinformatics Group.

Process Measurements Division

Technical Merit

The Process Measurements Division’s mission is to pursue basic research efforts in measurement science; enhance the state of the art in measurement standards and services; provide recommended measurement techniques; standardize recommended practices in sensing technology, instrumentation, and mathematical models required for analysis, control, and optimization of industrial processes; and provide a central, national source for calibration of measurement equipment. The Process Measurements Division has six groups: Fluid Flow, Fluid Science, Process Sensing, Thermometry, Pressure and Vacuum, and Thermal and Reactive Processes.

A core responsibility of the Process Measurements Division is the improvement and dissemination of national measurement standards for temperature, fluid flow, air speed, pressure and vacuum, humidity, liquid density, and volumetric measurements. The division also interacts with its counterparts in other countries and represents the United States at international measurement science conferences. The division’s research currently supports 6 of the 12 major CSTL programs with a broad range of research in new and traditional fields, development of world-class measurement methods, standards, calibration services, and measurement of important physical properties for industry. The division’s efforts are divided among the development of calibrations and reference materials, the development of new mea-

surement methods, and database activity. The division staff balances its activities in order to perform its dual roles of addressing the calibration and reference material needs of customers and advancing the state of the art in measurement science in the fields applicable to the division’s mission.

The panel is impressed by the concentration of measurement knowledge and expertise in this division and by the quality of its work. The technical merit of its work remains high. The panel noted major progress in the development of new cutting-edge measurement technologies and improvements in measurement and calibration uncertainties in flow, pressure, temperature, and humidity. Ongoing efforts in the development of new sensors, measurement methods, and process models show good progress. Some highlights of the division’s work in the past year are presented below.

The division has improved flow measurements in the 1 to 1,600 L/min range with a newly completed, automated pressure-volume-temperature flow accumulator. This improvement reduces the uncertainty of flow calibration results by a factor of 4 relative to the old mercury-sealed calibrator pistons and the still-older bell-prover method, which the division has now phased out. The division’s leadership in the area of flow measurement is evidenced by its staff members chairing the BIPM/CIPM (Bureau Internationale des Poids et Mésures/Comité International des Poids et Mésures) Working Group for Fluid Flow and the Sistema Interamericano Metrología (SIM) Metrology Working Group for Fluid Flow.

In FY 2001, the division participated in four Consultative Committee for Mass and Related Quantities (CCM) Key Comparisons (KCs) and piloted three of them, two to completion of Draft B reports. These two completed comparisons were notable for being the first successful international comparisons in this pressure range (which was due to the division’s innovative transfer standard design) and for being the only CCM pressure comparisons to be completed on time. The division is developing a pressure standard based on the dielectric constant of helium to provide an alternative to the conventional dead-weight methods for intercomparison standards. The division has come to within a factor of 10 of the accepted pressure-sensing uncertainty standard. Before this new standard is available, NIST may need to replace aging piston gauges for the old standard in order to maintain competence for industrial calibrations. In another effort related to pressure gauges, division scientists developed a portable transfer standard using a vibratory/resonant MEMS sensor that achieved impressive performance in terms of sensitivity and stability, as demonstrated with data taken in a NIST-directed international comparison of pressure gauges.

The division has been the pilot lab for the CIPM Key Comparison 3 (K3) covering temperatures from 84 K to 933 K (−189 °C to 660 °C). As the pilot lab, the division has authored a comprehensive report on K3, which was approved by the Consultative Committee on Temperature (CCT) in 2001. This is a major accomplishment in improving the ITS-90 standard in this temperature range and helps establish the equivalence of the measurements performed by various national measurement institutes (NMIs), a resource that is important to industry in international trade. The 8th International Decadal Conference, Temperature: Its Measurement and Control in Science and Industry, is being organized under CSTL’s leadership.

The division completed constant-volume gas thermometry measurements up to 700 °C, demonstrating that the NIST spherical acoustical resonator produces the most accurate thermodynamic gas temperature measurements as a realization of the ITS-90 temperature scale. Work is in progress to improve the accuracy at higher temperatures by comparing acoustic and microwave resonances. The Competence project on Johnson Noise Thermometry, a further effort to develop new, practical temperature standards, has progressed beyond experimental design to the first prototype stage.

The division has collaborated with an ultradry gas manufacturer to demonstrate excellent agreement between atmospheric pressure ionization mass spectrometry and the division’s cavity ring-down

spectrometer (CRDS), measuring less than 10 ppb water vapor as produced by the division’s Low Dew Point generator. A commercial version of CRDS for water vapor measurement at low parts-per-billion levels, a metric required by U.S. industry, is being evaluated by the group in collaboration with the manufacturer.

The division is also developing Evanescent Wave Cavity Ring-down Spectrometry as a diagnostic technique for remote sensing of chemicals. Tests with a broad-spectral-range light source have allowed measurement of water and trichloroethylene. The importance of this technology is indicated by the division’s collaborations in this area with industry, national laboratories, and academia.

A new NIST Competence project on molecular electronics focuses on developing metrology to measure electrical properties of newly conceived molecular circuitry and appropriately aims at establishing metrologies for this new area of study. Another NIST competence project is dedicated to the rapidly expanding field of microfluidics needed in “lab-on-a-chip” applications and is presently measuring flow profiles before addressing sensing approaches. This resonates with the trend of chem-bio, biomedical, and analytical chemistry technologies. The division should lend its standard-setting and fundamental measurement science abilities to this rapidly growing field.

The division has developed three tools pertinent to plasma etch monitoring: radio frequency (RF) waveform analysis; planar, laser-induced fluorescence (PLIF); and neutral mass spectrometry. Analysis of RF as an indicator of plasma state has matured to a level at which the panel encourages testing on plasma etch tools used in semiconductor manufacturing. The division has demonstrated expertise in PLIF, which can provide a spatial map of both ground-state CF and CF2 radicals in a plasma. The division should maintain plasma measurements of the neutral species, using mass spectrometry as a complementary measurement tool for plasma processes.

The division has achieved a detection level in the <1 ppm range using chemical microsensors utilizing MEMs microhotplate technology. This is sufficient sensitivity for detecting many chemical agents without preconcentration, as sought by the Defense Threat Reduction Agency. The division has successfully leveraged its microhotplate as a tool to explore catalytic, doped-metal-oxide, matrix, and thermal cycling approaches to trace gas detection. It has also established strong ties with customers, as evidenced by OA contracts and CRADAs. The panel cannot assess whether the metal-oxide/catalytic hotplate sensor is going to be sensitive and stable enough for the detection of all chemical agents but is impressed by the initiative taken in the division to work on this topic. To make gas sensors viable, the panel believes that a demonstration of stability and sensitivity should be early goals of the effort.

Program Relevance and Effectiveness

The panel is especially pleased with the effort made this year by the Thermal and Reactive Processes Group to contact semiconductor and tool manufacturers to identify metal and dielectric deposition process areas in need of modeling research. Contacts with semiconductor manufacturers identified atomic-layer deposition, plasma-enhanced chemical vapor deposition (CVD), and thermal CVD modeling and measurements for advanced integrated circuit (IC) interconnects as areas in which the division has expertise and equipment to address fundamental issues. The result of this outreach is a redirection of research within this group to metal-organic thermal CVD. Research will investigate the mechanism involved in CVD of metallic thin films. The panel looks forward to further feedback from industry participants on the progress of this work.

The division is continuing its dialog with manufacturers of semiconductor gas mass flow controllers. These companies use the thermophysical property data on reactive process gases to enable more accurate flow-rate calibration. As new data are obtained on these reactive gases, the preliminary results

are posted on the Web with conservative uncertainties until final values are published. This makes rare data immediately available to the user community.

Making at least some of the division’s databases freely available on the Internet boosts NIST’s image in and appreciation from the technical community. It could also spur innovation and trade. The panel recommends continuing this effort. The panel commends the CSTL for providing unfettered access to the gas and liquid property data needed by the semiconductor industry. These databases might be usefully extended to include fluid property data needs for other sectors. Such a proactive approach will add to NIST’s relevance to industry and further its contact and connections with U.S. industry. The panel also commends the division for maintaining a Web page with division results and accomplishments.

The division provides primary calibration of gauges and sensors used for temperature, humidity, pressure, and flow measurements over a wide range of operating parameters. The principal customers of this service are secondary calibration laboratories and industrial users who want fast, low-cost calibrations. The appropriate focus for the division’s calibrations remains high accuracy, including in many cases information feedback on the design or condition of the gauge. The panel encourages continued efforts to automate these primary calibration services and consideration of the viability of lower-cost calibrations, where practical, to help free staff time for the evaluation and analysis rather than using it for data taking.

The division’s work in the measurement of the basic thermophysical properties of gases generates and updates fundamental properties, such as speed of sound, heat capacity, density (equation of state), and viscosity, for a variety of gases needed by the semiconductor industry. Such data enable the prediction of calibration factors for mass flow controllers and for improvement of modeling used for CVD. These data fill an important need in the semiconductor and high-technology industries. Physical properties of hazardous gases heretofore unavailable, with uncertainty ranges of 0.01 to 0.5 percent, are being systematically measured, and preliminary data are being made freely available on the Internet and eventually included in NIST’s physical property data publication series.

The panel encourages the division to benchmark activities as a way to measure performance and progress in pertinent areas. The panel would like to see indicators such as numbers of journal publications, citations of previous work, patents, CRADAs, Web site hits, and other measures of information creation, use, and transfer. Numbers do not tell the whole story of the effectiveness of NIST research, but comparisons of trends over the years can reveal migration of modes of information transfer and can aid researchers and management in evaluating their effectiveness.

Division Resources

Funding sources for the Process Measurements Division are shown in Table 4.3. As of January 2002, staffing for the division included 59 full-time permanent positions, of which 54 were for technical professionals. There were also 15 nonpermanent or supplemental personnel, such as postdoctoral research associates and temporary or part-time workers.

The panel commends the division for its retention rate for postdoctoral researchers over the past 5 years. Retention of postdoctoral fellows provides one good source of qualified researchers to fill permanent CSTL staff positions. The panel would like to encourage the division to perform more benchmarking of its personnel efforts—for example, examining turnover at CSTL compared with that at other government laboratories.

The current economic downturn might provide a special opportunity for NIST to develop further industrial connections. Because many companies that normally operate within the field of use targeted by NIST have surplus employees and yet may not want to lose those well-trained employees perma-

TABLE 4.3 Sources of Funding for the Process Measurements Division (in millions of dollars), FY 1999 to FY 2002

|

Source of Funding |

Fiscal Year 1999 (actual) |

Fiscal Year 2000 (actual) |

Fiscal Year 2001 (actual) |

Fiscal Year 2002 (estimated) |

|

NIST-STRS, excluding Competence |

7.9 |

8.7 |

8.7 |

8.6 |

|

Competence |

0.8 |

0.9 |

1.0 |

1.1 |

|

ATP |

0.4 |

0.5 |

0.7 |

0.3 |

|

OA/NFG/CRADA |

0.8 |

1.0 |

1.6 |

2.7 |

|

Other Reimbursable |

1.2 |

1.1 |

1.1 |

0.8 |

|

Total |

11.1 |

12.3 |

13.1 |

13.5 |

|

Full-time permanent staff (total)a |

59 |

57 |

58 |

59 |

|

NOTE: Sources of funding are as described in the note accompanying Table 4.1. aThe number of full-time permanent staff is as of January of that fiscal year. |

||||

nently, the division might utilize an industrial sabbatical program, following the example of its present academic sabbatical program. In such a program, companies might detail employees to NIST while paying a portion of their salary. NIST would pay the balance of the salary and would gain by the insight and viewpoint provided by these industrial partners and through use of their expertise for NIST projects.

Surface and Microanalysis Science Division

Technical Merit

According to division documentation, the mission of the Surface and Microanalysis Science Division is to serve as the nation’s reference laboratory for chemical metrology research, standards, and data to characterize the spatial and temporal distribution of chemical species and to improve the accuracy, precision, sensitivity, selectivity, and applicability of surface, microanalysis, and advanced isotope measurement techniques. The current mission statement does clearly and concisely define the division’s current role and responsibilities within the CSTL and NIST.

The Surface and Microanalysis Science Division is organized in four technical groups: Atmospheric Chemistry, Microanalysis Research, Surface and Interface Research, and Analytical Microscopy. In addition to the personnel in these groups, the division staff includes two active and one emeritus NIST fellows. The fellows pursue very active research programs and provide mentoring and technical guidance to younger staff across division organizational boundaries. The division is fortunate to have its programs supported by these fellows, productive scientists who are internationally recognized as leaders in their fields.

Several changes were made to division organization in 2001. First, leadership of the Analytical Microscopy Group changed; the former group leader returned to work as a researcher, and another staff member assumed the leadership role. The panel compliments the division on enabling both individuals to fulfill career aspirations and allowing a smooth transfer of responsibility. Second, the Surface and

Interface Research Group, previously called the Surface Dynamical Processes Group, underwent a name change in order to reflect more accurately its current and planned activities.

The organization of the Surface and Microanalysis Science Division has generally enabled the division to respond effectively to the need for programmatic evolution while maintaining logical groupings of expertise by analytical method or class. Technical activities are organized at the CSTL and NIST program level, allowing many opportunities for collaboration across CSTL and NIST. Currently, division projects are aligned in support of CSTL’s 12 programs and play a central role in four: Semiconductor Metrology, Nanotechnology, Chemical Characterization of Materials, and Environmental Measurements. In 2002, the division will be deeply involved in CSTL’s newly defined programs in Biomaterials, Environmental Technology and Systems, Industrial and Analytical Instruments and Services, Microelectronics, and Emerging Technologies.

The technical programs in the Surface and Microanalysis Science Division are of very high quality. Staff continue to receive recognition for their work within NIST and from the larger scientific community and are much sought after as speakers at major international technical symposia, conferences, and workshops. The following section of the report discusses program highlights and issues relating to the projects under way in each of the division’s four groups.

The Surface and Interface Research Group, formerly the Surface Dynamical Processes Group, conducts theoretical and experimental research into chemical processes at surfaces and interfaces. As with its name, the focus of this group has and will continue to evolve and change. In the past, the group focused almost exclusively on the development and application of molecular spectroscopy to surface reactions; now it is beginning to broaden its work to include the development and use of other surface-sensitive and high-spatial-resolution probes such as near-field scanning optical microscopy (NSOM), atomic force microscopy (AFM) of soft surfaces, and conductance-based scanned probes. The evolving emphasis in this group on the development of novel tools is especially commendable. The group maintains its position as an international leader in sum frequency generation optical spectroscopy (SFG-OS) of surfaces and buried interfaces. The leader of the SFG-OS project received the Department of Commerce Bronze Medal in 2002 in recognition of his seminal efforts in this area.

In FY 2001, the group ended research into reactions of radicals at surfaces. The group performed fundamental measurements of the interactions of ground-state (3P) and electronically excited (1D) oxygen radicals with fused silica. This is a system of strong interest to the semiconductor and biomaterials industries, as oxygen radicals are the key reactive species in oxygen plasma reactors used for resist ashing and surface cleaning in semiconductors processing, and in polymer surface modification for biocompatibility in biomaterials. Fused silica is used for plasma containment, and it is important that the reaction models be known in order to help plasma scientists predict species lifetime and reactivity. It is unfortunate that this important research has been discontinued. The panel suggests that the division establish contact with plasma reactor companies to determine whether the research can be continued with outside resources.

The Surface and Interface Research Group is participating in two new CSTL FY 2001 competence programs: (1) Molecular Electronics and (2) Polymeric Thin Films: A Test Bed for Combinatorial Methods. A primary component of the Molecular Electronics program focuses on new, two-photon and conductance-based scanned probes. The secondary component focuses on ultrafast SFG-OS and theoretical studies of electron dynamics. In the Polymeric Thin Films program, the group will contribute to the development of novel instrumentation for hyperspectral imaging and rapid sample analysis, including nanoscale optical probes for analysis at various wavelengths (ultraviolet [UV], infrared [IR], and microwave). The group has assembled and tested a scanning confocal microscope. The application of these tools to polymeric films, and particularly to rapid sample screening, is noteworthy.

The Surface and Interface Research Group continues its development of nonlinear optical probes and their application to surfaces and buried interfaces, which is of note because these techniques can serve as in situ probes capable of real-time monitoring of processes at the molecular scale. Two National Research Council postdoctoral fellows have worked to take vibrationally resonant SFG-OS past proof-of-principle and into important practical application by studying the formation kinetics of self-assembled monolayers. This method is being applied to study the chemistry of copper electrodeposition in situ.

Members of the Surface and Interface Research Group were recognized by the 2001 CSTL Technical Achievement Award for their paper describing an exciting advancement in ultrahigh-resolution analysis of materials.3 It is applicable to many industrial-relevant systems, including polymer film and semiconductor surfaces.

The Microanalysis Research Group performs research at and beyond the state of the art in techniques for electron and x-ray beam microanalysis applied to understanding the chemical, morphological, and crystallographic properties of materials. The group’s goal is to improve the analytical resolution, sensitivity, accuracy, and precision of measurements made with scanning electron microscopy, electron microprobe analysis, analytical electron microscopy, scanning Auger electron spectroscopy, x-ray fluorescence, and x-ray photoelectron spectroscopy. Members of this group are some of the most influential scientists in their fields; their work is of outstanding quality.

The Microanalysis Research Group continues to pioneer new spectrometers for x-ray microanalysis. Researchers are using x-ray microcalorimeter detectors developed by EEEL in Boulder, Colorado, to study the fundamentals of low-energy x-ray line generation (e.g., L, M, and N lines of medium to high atomic number materials). Data on the absolute energy position and relative line intensities are scarce but are essential to accurate qualitative and quantitative microanalysis. This group’s researchers are uniquely and appropriately situated to advance this work. It will have impact on every industrial and academic group that uses energy dispersive and wavelength dispersive x-ray spectrometry—which takes in nearly every high-tech industry and university in the United States. Many workers in the semiconductor industry are anxiously awaiting commercialization of these microcalorimeter detectors and will shortly thereafter be seeking accurate low-energy x-ray line information. The Microanalysis Research Group is also furthering the commercialization of a new, high-throughput x-ray detector, the low-energy silicon drift detector. The panel believes that this work epitomizes what NIST should be doing—both developing new instruments to enhance metrology and performing measurements for standards.

Researchers in the Microanalysis Research Group are exploring the use of fractal analysis of particle shapes for automatic classification. The work in this area is highly interesting and important to many industries (for example, automotive and semiconductor) and to government agencies (such as the Environmental Protection Agency [EPA] and DOD) that must characterize or identify particles and their sources. The group is approaching this research with sound fundamental principles. The panel recommends that the activity be focused to address first an understanding of the critical parameters of more standard particles, such as those available commercially or through NIST. Ultimately, the goal should be to provide a software tool kit for individuals to use in particle identification. The panel recommends discussions with industry researchers responsible for generating particle-classification algorithms; this will help the group avoid repeating industry’s efforts. The panel encourages the division to continue the

development of such software tools on PC-compatible platforms for easy dissemination to potential customers.

The panel recognizes the quality and relevance of the work that this group is performing in understanding the fundamental science behind measurements of films using cross-sectional transmission electron microscopy (TEM). High-resolution TEM is often used to measure gate dielectric thickness during process development in the semiconductor industry. As films approach monolayers of thickness, accurate understanding of measurement errors and proper measurement methods are essential. This group’s careful research has resulted in new models for building virtual gate dielectric stacks that can then be compared with experimental data for error analysis. The panel encourages the continuation and completion of this work, as it will help scientists at industrial laboratories provide more accurate measurements to semiconductor process development engineers, resulting in higher device yields and performance.

The panel encourages the Microanalysis Research Group to accelerate its focus on measurements of the surface and bulk of silicon-germanium (SiGe) films and substrates, especially with high spatial resolution. The panel recognizes the expertise that this group has in TEM, x-ray spectroscopy, and grazing incidence x-ray photoemission spectroscopy (GIXPS) that is being explored for application to this material system. High-performance microprocessor manufacturers such as Intel, IBM, and Advanced Micro Devices (AMD) are increasingly adopting SiGe substrates and films. Lack of adequate measurement methods is preventing wider adoption of these materials; wider adoption by domestic semiconductor manufacturers would give them a competitive edge in this important market. The panel also encourages the division to continue to expand efforts in high lateral resolution chemical and elemental mapping and characterization of surfaces and interfaces, including the development of new instrumentation and analytical methods. The panel encourages collaboration with other divisions outside of CSTL on these efforts.

The Atmospheric Chemistry Group continues to focus on carbon isotope metrology and on elemental/organic splits in the carbon content of airborne particulate samples. The most confounding aspect of air quality associated with particulate matter continues to be discrimination of the myriad of emission sources responsible for airborne particulate carbonaceous material. The Atmospheric Chemistry Group has appropriately identified two key needs that clearly fall within the NIST mission: SRMs of quantified particulate mixtures from known emission sources, and chemical methods (both physical measurements and data analysis) to profile and distinguish different types of emission sources from atmospheric samples. During the past year, the group has focused on three categories of activity consistent with the high-relevance elements identified in its mission:

-

Providing reference materials to enhance the accuracy and precision of chemical measurements used for compliance with asbestos and air quality regulations. The group’s careful, systematic, and arduous asbestos research is an example of valuable and unique national service consistent with the core NIST mission. The panel recognizes the high quality of expertise applied to produce SRMs for critical certifications of asbestos measurements. In addition, the group released one new standard reference material—SRM 2784, Urban Dust—and four reference materials. However, in the broader mission beyond asbestos measurements, personnel limits prevent the group from moving to research with higher payoffs to address the critical need for reference materials representing mixtures of known and quantified particulate emission sources.

-

Providing an analysis of the sensitivity of artifacts in the thermal-optical measurement of elemental/organic carbon ratios to chemical speciation and physical properties of an airborne sample

-

and to temperature-ramp protocols used in the measurement process. This information could provide insights to highlight significant reliability concerns with this commonly used technique. It also might raise awareness of the consequent large uncertainties in emission-source apportionments that are based on its use. The rate of progress on this effort is compromised, however, by personnel limitations.

-

Applying analytical methods to assist specific clients where reliable and conveniently available technical competence is required. Examples include developing a reference protocol to measure gas mask leakage, and application of radiochemical measurements to carbon-date particulate samples from the EPA air quality field studies. These client-oriented projects are executed with competence.

The panel notes that the Atmospheric Chemistry Group has not aggressively pursued novel techniques for isotopic profiling of emission sources, a goal highlighted last year, because of personnel limitations.

The Analytical Microscopy Group conducts research on the chemical and structural properties of matter using ion- and photon-based microscopies. This includes understanding fundamental aspects of the excitation process, quantitation methods, standards development, and commercial instrumentation improvements. This group continues to be a premier source of research and applications for methods such as secondary ion mass spectrometry, laser Raman microprobe, and Fourier transform infrared microprobe. The group’s work on the development of new SRMs for dopant profiling is essential for the semiconductor industry, and NIST researchers are viewed as the international leaders in this field. The panel encourages this work and looks forward to the release next year of the SRM 2133, phosphorus implant in silicon. The panel repeats its suggestion to develop other dopant profile standards of value to industry, such as boron, arsenic, and phosphorus in common metal silicides. The panel was impressed by the SIMS instrumentation that is undergoing installation in this group’s laboratories and looks forward to seeing results from these instruments in next year’s review. In other work, the group is taking a leading role in the investigations of how to perform very shallow depth profiling using time-of-flight SIMS and is developing cluster-ion SIMS techniques that will allow the composition of “soft” surfaces such as biomaterials and polymers to be characterized. The panel looks forward to seeing this work extended to practical materials in the future.

Homeland security has long been a focus of the research of the Analytical Microscopy Group. In past reviews, the panel has commended the high-quality work that this group has done in developing methods for analyzing particles in support of international nuclear safeguarding. The panel recognizes this year’s work to apply autoradiography in order to increase and improve uranium particle sampling throughput by pre-selection. More recent work on developing methods for calibrating gas masks has been performed in collaboration with researchers in the Analytical Chemistry Division and in the Fire Research Division of the Building and Fire Research Laboratory. This interesting activity will continue in FY 2002 and should result in new methods for testing the efficacy of gas masks in the field using particle aerosols. Finally, the division has been assisting in the development of trace explosives detection portals (TDEP) as a method of screening airline passengers for explosives and drugs. The group’s unique knowledge of high-accuracy and high-throughput methods for analyzing particle composition makes it appropriately positioned to drive new methods and standards for accurate screening for security threats. The group’s work on the application of cluster-ion SIMS to studying known explosives will provide TDEP manufacturers with new ways of distinguishing harmful materials from the large background of benign organics.

In collaboration with the Process Measurements and Analytical Chemistry Divisions, the Analytical Microscopy Group released a new series of standards for Raman spectroscopy. This technique, widely

used for the characterization of materials, has lacked a comprehensive set of standards. This work by NIST will enable researchers and instrument manufacturers to have more accurate quantitative information for compositional analysis.

Finally, the panel would like to recognize the extraordinarily high technical quality of the work of the division’s two active NIST fellows. One is the internationally recognized expert in the generation and emission of electrons from solid surfaces under x-ray and electron-beam irradiation. This was tangibly recognized by the outside scientific community in FY 2001 with the American Vacuum Society’s Albert Nerken Award. This fellow’s work is essential to the accurate interpretation and quantitation of x-ray photoelectron and Auger electron spectroscopies (XPS and AES, respectively). Research projects under his direction in FY 2001 have produced key databases or updates: SRD 20 on X-Ray Photoelectron Spectroscopy released version 3.1 in April 2001, and SRD 82 on Electron Effective Attenuation Lengths released version 1.0 in September 2001. He is also active in encouraging young researchers inside and outside of NIST to continue and expand the work in this field. The second fellow is one of the leading researchers in electron microprobe analysis, pioneering the application of new x-ray detector technology on traditional platforms such as high-vacuum, high accelerating voltage SEMs as well as new instrumentation such as variable pressure and low accelerating voltage systems. He has been the driving force behind the implementation of microcalorimeter x-ray detectors on SEMs for small particle analysis; this work is helping to meet an essential need of the semiconductor and other industries dependent upon understanding the composition of extremely small features.

Program Relevance and Effectiveness

The Surface and Microanalysis Science Division uses a variety of methods to ensure the relevance and effectiveness of its programs. It is mapping key activities to the NIST Strategic Focus Areas. For example, nanotechnology is supported by the division’s project on cluster-ion SIMS for high-resolution depth profiling, the Competence program on molecular electronics, and overall general chemical imaging. Support of homeland defense has been an integral part of the division for many years, with projects in forensic particle analysis, quality assurance and control methods for the U.S. Atomic Energy Detection System (USAEDS), gas mask standards, and analysis of explosives particles. The division has new activities in support of health care, including monitoring boron neutron capture chemotherapy using SIMS analysis of tissue samples, drug delivery using nonlinear optical spectroscopy, and nanoscale analysis of compounds of pharmaceutical interest using near-field scanning optical microscopy. The panel recommends that the division perform periodic, perhaps annual, formal comparison of its activities with those occurring in other CSTL divisions, other NIST laboratories, and appropriate domestic universities to ensure that the work is complementary, not overlapping.

Researchers visited or met with many different corporations in FY 2001 to consult on measurement methods, discuss potential collaborations, and gain insight into new work areas. Division researchers interacted with various industries, including the following: chemical (Dow, DuPont, Visteon, PPG); consumer products (Proctor & Gamble); aerospace (General Electric); semiconductor (AMD, Agere, Cirent, KLA-Tencor, SEMATECH); and analytical instrumentation (Noran, Gatan, Photon Imaging, X-ray Optical Systems). CRADAs and consortia are currently in place on combinatorial methods and polymer characterization.

In order for the division to further enhance the effectiveness and relevance of its work, the panel repeats its recommendation that a sincere effort be undertaken to encourage staff members to utilize the NIST Industry Fellows Program. This division plays an important role in providing standard methods and materials to U.S. industry, but most NIST researchers do not have a personal understanding of the

challenges faced by their customers. While interactions in professional societies and conferences and visits by industrial customers provide a limited perspective, nothing can replace having NIST researchers spend even short periods of time at a customer site. The panel recognizes that utilizing the Industry Fellows Program is not always easy, but by being flexible in assignment duration, rewarding researchers for their participation, and setting specific division and CSTL goals for success, the program can be used more successfully. Industry utilizes such programs; CSTL can do so as well.

The division is very visible both nationally and internationally. The professional staff publishes its work extensively in prestigious scientific journals (80 publications in FY 2001); organizes and sponsors conferences and workshops (7 in FY 2001); and presents at major conferences, often as invited speakers (94 presentations in FY 2001). Staff members produce and maintain Web-distributed databases that are widely used by a variety of technical communities. SRD 20 (X-Ray Photoelectron Spectroscopy Database) alone produces more than 30,000 hits per month! The panel commends the division for greatly improving the accessibility and appearance of its Web site.