1

Summary of the Food Safety and Inspection Service Draft Risk Assessment

The stated purpose of the draft risk assessment prepared by the Food Safety and Inspection Service (FSIS) of the US Department of Agriculture (USDA) is to systematically evaluate and integrate available scientific data and information to

-

provide a comprehensive evaluation of the risk of illness from E. coli O157:H7 in ground beef based on currently available data,

-

estimate the likelihood of human morbidity and mortality associated with specific numbers of E. coli O157:H7 in ground beef servings,

-

estimate the occurrence and extent of E. coli O157:H7 contamination at points along the farm-to-table continuum,

-

provide a tool for analyzing how to most effectively mitigate the risk of illness from E. coli O157:H7 in ground beef,

-

identify future food safety research needs, and

-

assist FSIS in the review and refinement of its integrated risk reduction strategy for E. coli O157:H7 in ground beef (p. 1).1

The attendant model follows each step of the production process, from the prevalence of the pathogen in cattle on the farm to its presence in a single serving of cooked ground beef.

|

1 |

The complete text of the draft risk assessment may be found on the FSIS web site (www.fsis.usda.gov). At the time this report was completed, the URL for the draft was www.fsis.usda.gov/OPPDE/rdad/FRPubs/00-023N/00-023NReport.pdf. |

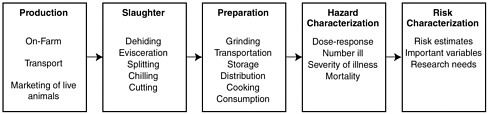

FIGURE 1-1 Risk-assessment structure for E. coli O157:H7 in ground beef. (Reproduced from USDA-FSIS (2001) Figure 1-1.)

This chapter summarizes the content of the FSIS risk assessment as presented in the draft report and is intended as a reference for readers who do not have ready access to that document.2 The draft risk assessment itself is reviewed in the next five chapters and the modeling approach and implementation in Chapter 7.

The model is divided into three exposure assessment modules (Production, Slaughter, and Preparation), a Hazard Characterization Module (also known as dose-response assessment), and a Risk Characterization Module, which estimates the risk of illness from E. coli O157:H7 in ground beef. Figure 1-1 is a graphic representation of those components, which are discussed below.

PRODUCTION MODULE

The Production Module estimates the prevalence of E. coli O157:H7 in live cattle entering US slaughter plants. Prevalence, in this context, is the proportion of a population that is infected. In the model, cattle are divided into two groups: breeding cattle (mature cattle bred to produce milk and calves) and feedlot cattle (steers and heifers specifically intended for slaughter). The distinction is made because breeding and feedlot cattle differ in their slaughter and in the processing and distribution of their meat, and because some evidence suggests that E. coli prevalence varies between the two groups of cattle. About 20% of all cattle slaughtered in the United States are breeding cattle; the remaining 80% are feedlot cattle. Some 15% of beef consumed in the United States is imported from other countries; the model assumes that any E. coli O157:H7 contamination in imported beef would be equivalent to that in domestic beef.

The Production Module is divided into three segments: on-farm, transportation, and marketing of live animals (referred to as slaughter-plant intake in the FSIS draft risk assessment). Those segments, discussed below, represent the three phases that all breeding and feedlot cattle go through before slaughter.

On-Farm Segment

The primary focus of the on-farm segment in the FSIS model is to evaluate the prevalence of E. coli O157:H7 in herds of cattle on the farm before they are sent to slaughter. Cattle are often tested on the farm to determine whether E. coli O157:H7 is present in herds. Fecal testing is used to find infected cattle—cattle whose intestinal tracts are colonized with the E. coli O157:H7 organism. Cattle that test positive for O157:H7 on their hides, hair, or hooves are labeled as contaminated.

Prevalence can be evaluated in a herd in many ways. The four critical inputs to the Production Module are herd prevalence and within-herd prevalence of E. coli O157:H7 for both breeding and feedlot cattle. Herd prevalence is the proportion of herds of a particular type (breeding or feedlot) that have at least one E. coli O157:H7-infected animal; it is assumed to remain constant at a national level. Within-herd prevalence is the proportion of E. coli O157:H7-infected animals in an infected herd.

Another variable considered in the on-farm segment of the FSIS model is seasonal variability, the tendency for E. coli O157:H7 prevalence in a herd to increase or decrease with the time of the year. Evidence suggests that there is a high-prevalence season (June to September) and a low-prevalence season (October to May). That is important because increasing the proportion of cattle entering the slaughter process that test positive for E. coli O157:H7 could lead to an increase in its prevalence in ground beef.

Data for the on-farm segment of the model were collected from published research articles that contained information about the prevalence of E. coli O157:H7 in herds on farms throughout the United States. The data were evaluated to estimate the mean and 5th and 95th percentiles of E. coli O157:H7 prevalence. The estimates consistently showed that E. coli O157:H7 prevalence is significantly higher in feedlot cattle than in breeding cattle. An evaluation of herd prevalence and within-herd prevalence in breeding and feedlot cattle did not alter that finding. The findings were consistent whether or not seasonality was considered.

Transportation Segment

The transportation segment considers the transmission of E. coli

O157:H7 among cattle being shipped from the farm to the slaughter plant. There is a potential for E. coli O157:H7 to be transmitted from infected to uninfected cattle or for animals that tested positive for E. coli O157:H7 on the farm to lose the infection en route. Research has not shown any marked increase or decrease in the fecal prevalence of E. coli O157:H7 among cattle that are first tested on the farm before transport and then retested at the slaughter plant. There are no data that document E. coli O157:H7 prevalence on cattle hides at the farm and after transport to slaughter. For those reasons, no effect of transport is included in the model.

Slaughter Plant Intake Segment

All breeding and feedlot cattle are transported to a slaughter plant from livestock markets or farms by trucks. Because breeding cattle are not specifically raised for slaughter, it is not uncommon for them to make their way to livestock markets and then slaughter plants individually rather than in an established herd from one farm. Therefore, it is assumed that the prevalence of E. coli O157:H7 among breeding cattle is independent of that in other cattle that may arrive at the same time. Only in the unlikely event that a large group of breeding cattle (over 40 cows) arrive at a slaughter plant from one farm at the same time would that not be the case.

To model the prevalence of infected breeding cattle in each truckload arriving for slaughter, a Monte Carlo simulation is used. In a Monte Carlo simulation, random values are generated for uncertain variables over and over again to simulate myriad possible outcomes. In the FSIS model, the Monte Carlo simulation is generated from the expected number of cattle (40) in each truckload, herd prevalence, and within-herd prevalence. The technique is also used to evaluate the effect of low- and high-prevalence seasons on the pervasiveness of E. coli O157:H7.

Slaughter-plant intake of feedlot cattle varies from that of breeding cattle. Feedlot cattle are generally transported directly from their original feedlot to the slaughter plant and slaughtered together as a group. Because each truckload of feedlot cattle originate from the same pen in a feedlot, all the cattle on board have the same probability of being infected with E. coli O157:H7. A separate Monte Carlo simulation is generated for feedlot cattle under the assumption that each truckload of cattle originates from an infected or non-infected feedlot based on feedlot prevalence and seasonality.

The inputs generated from these simulations, which provide a prevalence distribution for the number of infected cattle entering the slaughter plant, are used as the starting numbers (inputs) for the Slaughter Module.

SLAUGHTER MODULE

The Slaughter Module estimates the prevalence of E. coli O157:H7 at each step of the slaughter-plant process, starting with live cattle entering the plant and ending with packaged meat product that is ready for shipment. Breeding and feedlot cattle are modeled separately. High- and low-prevalence seasons, representing the times of year when cattle are slaughtered, are also modeled separately. Only cattle that are slaughtered and processed in commercial plants are considered in the model.

Many factors influence whether E. coli O157:H7 will end up in the final meat product. Even if cattle begin the slaughter process infected or contaminated with E. coli O157:H7, it will not always be found in the meat after processing. Contamination or decontamination can occur at any step of the slaughter process. Therefore, one must take many other factors into account when evaluating the presence of E. coli O157:H7 during the slaughter process, including the status of the cattle entering the slaughter plant, the type of processing plant, the type of equipment used and procedures followed within the plant, and the efficiency of the decontamination and sanitation processes.

In the model, the slaughter process is divided into seven steps: the arrival of cattle at the slaughter plant, dehiding, decontamination after dehiding (first decontamination), evisceration, second decontamination, chilling, and carcass fabrication. Those steps are detailed below.

Arrival of Live Animals

Cattle arrive at slaughter plants by truck from farms and livestock markets. After arrival, they are placed in holding pens at the plant until they are led to slaughter. The model does not provide any information about the level of E. coli O157:H7 transmission that occurs in the holding pens at the plants. The estimated prevalence of E. coli O157:H7 in each truckload of arriving cattle—calculated in the Production Module by the type of cattle and the season—serves as the initial set of inputs for the Slaughter Module.

The model estimates the prevalence of E. coli O157:H7 in processed meat after slaughter on the basis of prevalence in each truckload of cattle arriving at the plant. To determine the amount of processed meat that will come from each truckload of cattle, some assumptions are made. For each truckload of cattle, a total carcass weight is estimated. The carcass weight is the weight of an animal after it has been killed and its hide has been removed. Average carcass weights have been determined for each type of cattle: breeding cattle (dairy cattle and calves) and feedlot cattle (steers

and heifers). Summing the average carcass weights based on the distribution of cattle in each truckload results in a total carcass weight per truckload. The average truckload is assumed to be 40 cattle.

Once the carcass weight has been estimated, further calculations are used to establish how much of the carcass will be processed as distinct cuts of meat and how much will be trim, the meat product from which ground beef is eventually made. Trim is made up primarily of muscle and fat; it is the remainder after the cuts of meat have been removed from feedlot cattle. In breeding cattle, trim is the primary product after deboning of the carcass. Trim is removed from each carcass and combined into 2,000-pound combo bins during the slaughter process. Combo bins are typically large cardboard boxes lined with plastic that are used to collect meat trim. The percentage of each carcass that amounts to trim is calculated as a percentage of the total carcass weight for each cattle type. The number of live cattle necessary to fill one combo bin is called a lot in the FSIS draft report.

To summarize, the goal in this first step of the Slaughter Module is to estimate the number of trucks per lot. That is calculated by using the type of cattle in the truckload to determine the average carcass weight and the amount of trim from each carcass. From those data, the number of animals needed to fill one combo bin (one lot) is determined on the basis of a truckload of 40 cattle. By using the final outputs of the Production Module as the inputs in the Slaughter Module, the prevalence of E. coli O157:H7 in each lot can now be determined on the basis of calculations from each truckload of cattle entering the slaughter plant.

Knock Box and Stunning (Not Modeled)

Cattle entering the slaughter plant are channeled into the “knock box,” where they are stunned. After stunning, the animals are chained to an overhead conveyer rail by one hind leg. Before moving on the conveyer to the main floor of the slaughter plant, an animal’s throat is slit and the animal is bled. Although cross-contamination can occur during this part of the slaughter process, it is not included in the model, because data on hide contamination, the most likely contamination in this part of the slaughter process, are lacking.

Dehiding

In the next step of the process, the animal is moved to the main floor of the slaughter plant, and the dehiding process begins. To remove the hide from the animal, thus creating a carcass, the horns, hocks (joints of leg to foot), and udder are removed. The head is skinned and the hide is

cut down the midline, legs, and front shanks and rolled up over the carcass.

There are many opportunities for contamination to occur during the dehiding process. If the hide is intact before dehiding, E. coli O157:H7 contamination is limited to the surface of the hide and the feces. Once the hide is removed, the sterile muscle and fat on the carcass are exposed to microbial contamination. Contamination of the carcass can occur directly from its own hide or feces (self-contamination); from other infected carcasses via clothing, gloves, knives, or machinery in the plant; and through the release of aerosols from contaminated carcasses during the dehiding process.

To evaluate contamination during the dehiding process, a transformation ratio is created; it is defined as the ratio of the frequency of contaminated carcasses to the frequency of infected cattle in a lot (as determined in the “Arrival of Live Animals” step). The prevalence of E. coli O157:H7 on carcasses is calculated from data contained in a paper by Elder and colleagues (2000), which are used to estimate the range of carcass contamination during the high-prevalence season. To estimate the lower frequency of contamination during the low-prevalence season, the same data are used, but more uncertainty is introduced into the calculation by creating a “mixture” of the transformation ratio and a uniform distribution, which ranges from near zero to a maximum of the transformation ratio found during the high season.

On the basis of data from research papers and the FSIS national baseline survey of slaughter plants (1994), further calculations are made to estimate the maximum and minimum number of E. coli O157:H7 organisms on a contaminated carcass at dehiding. The results of the calculations provide the basis of modeling the next step of the slaughter process.

First Decontamination

To remove any visible foreign matter after dehiding, one or more decontamination processes may be used to clean the carcass. Large areas of fecal contamination, defined as those greater than 1 inch in diameter, are removed with a knife. Smaller areas of contamination are removed by spot steam vacuuming. Some plants decontaminate the entire carcass with a hot-water rinse or organic acids. No procedure is successful in removing all E. coli O157:H7. Visible contamination can be reduced from the carcass surface with knives and vacuuming, but some bacterial colonies— invisible to the naked eye—will be missed. In addition, cross-contamination from improperly cleaned knives, clothing, and equipment can occur during the decontamination process. Using rinsing during the decontamination process will reduce the E. coli O157:H7 on the carcass but might not

remove all the contamination. To account for any residual contamination after the first decontamination process, the model factors in a variable to represent the reduction of E. coli O157:H7 on the carcass. Three reduction values are represented in the model in a triangular distribution—a minimum, an uncertain “most-likely” value, and an uncertain maximum—to capture the various levels of decontamination success.

Evisceration

In the evisceration step, the carcass is split along the ventral midline, and the gastrointestinal tract and remaining organs (including bladder, lungs, and heart) are removed. Although opportunities for contamination are slight at this stage, it can occur if the intestinal tract is perforated during removal and there is leakage onto the surrounding muscle tissue. The model presumes that if the animal is already infected with E. coli O157:H7 and leakage occurs during evisceration, contamination will occur.

Carcass Splitting (Not Modeled)

During carcass splitting, the carcass is sawed in half, the tail is removed, and excess fat is trimmed away from the sides. Although it is possible for contamination to occur during these procedures, it has not been modeled because there are no relevant data available.

Second Decontamination

The first and second decontamination steps are similar in that knives and spot steam vacuuming are used to remove visible contamination from carcasses. The model assumes that small plants use, in addition, hot-water rinsing, sometimes with organic acids. This rinsing can either reduce the E. coli O157:H7 on the surface or redistribute it over the entire carcass. The effectiveness of rinsing is assumed to be the same as in the first decontamination. The model also assumes that larger plants typically use steam pasteurization during their second decontamination. Although that can be highly effective in reducing contamination on carcasses, studies have shown that variation in the steam-pasteurization process can affect its efficacy. To model the variation, a minimum, an uncertain most-likely value, and an uncertain maximum are used to represent steam-pasteurization efficacy.

Chilling

After the second decontamination, the split carcasses are placed into a blast air chiller for 24–48 hours. The sides of beef are occasionally sprayed with water or in some cases other solutions. After chilling, the sides are unloaded, graded, and sorted. The model accounts for the possibility of growth of or decline in E. coli O157:H7 on the surface of an already-contaminated carcass during the chilling process because of fluctuations in time and temperature. No new contamination is assumed to occur in this step.

Carcass Fabrication

After carcasses are removed from the chiller, they move on overhead rails to the fabrication floor for cutting and deboning. In plants that slaughter feedlot cattle, major and minor (primal and subprimal) cuts of meat are removed from the carcass by slaughter plant personnel with knives. “Leftover” trim, primarily muscle and fat, is separated and collected. Breeding cattle are processed in the same way, but trim is a primary product rather than a byproduct that results from deboning. Once the trim is removed from the carcass, it moves on conveyer belts to combo bins or to vacuum-packaging areas. Trim going to combo bins is packed with dry ice in preparation for shipping. The remainder of the trim is vacuum-packed, packaged in boxes, and chilled at 0°–2°C (32.0°–35.6°F) until shipping.

Although few studies have looked exclusively at contamination that occurs during carcass fabrication, there are many opportunities for E. coli O157:H7 contamination and cross-contamination. Not only can contamination take place as trim from different animals is combined in combo bins, but it can also come from contact with processing and cutting equipment and from workers’ gloves and aprons. And although fabrication areas are kept at a temperature intended to inhibit growth (10°C, or 50°F), higher temperatures can occur that will lead to increases in the growth of E. coli O157:H7.

The model estimates the level of contamination that occurs during fabrication by creating a simulation using the outcomes from the slaughter process and the grinder segment of the Preparation Module (which uses FSIS sampling data). High- and low-prevalence seasons are factored in separately. The model anchors the output of this section to real-world observations by placing bounds on how the generated values are used: if simulation results are too high, they are discarded; if they are too low, contamination is added in the model to reflect contamination during fab

rication. Results from this portion of the model indicate that the fabrication process is critical with respect to E. coli O157:H7 contamination.

Slaughter Module Results

The final outputs of the Slaughter Module—which become the inputs for the Preparation Module—are the distributions of E. coli O157:H7 in the trim in combo bins and boxes at slaughter plants. The distributions take into account the type of cattle being slaughtered (feedlot or breeding) and the time of year when the animals are slaughtered (high- and low-prevalence seasons).

The distributions generated by the Slaughter Module suggest that E. coli O157:H7 contamination is higher in feedlot cattle than in breeding cattle and that the prevalence and levels of contamination found in combo bins and boxes is greater during the high-prevalence season. The model indicates that an average of 6% and 8% of combo bins produced from breeding cattle are contaminated with one or more E. coli O157:H7 organisms during the low and high seasons, respectively; an average of 23% and 43% of combo bins containing meat from feedlot cattle are contaminated during the low- and high-prevalence seasons. The disparity in prevalence between breeding and feedlot cattle is due primarily to variations in their living conditions, feeding practices, and processing before they enter the slaughter plant.

Boxes of processed meat follow the same general pattern of contamination as combo bins. Of boxes generated from breeding cattle, 1–2% are contaminated with at least one E. coli O157:H7 organism during the low and high seasons, respectively. Within boxes of meat trim from feedlot cattle, an average of 6% and 13% are contaminated during the low and high seasons. Although the averages are lower for boxes than for combo bins, the decreases reflect the fact that boxes contain much less trim than combo bins (60 pounds versus 2,000 pounds) and therefore fewer servings. Overall, the risk of consuming contaminated ground beef processed from boxes and combo bins would be roughly equivalent.

PREPARATION MODULE

The Preparation Module estimates the incidence and scope of E. coli O157:H7 contamination in a single serving of cooked ground beef. For the model, ground beef is defined as hamburger patties or formed major ingredients (such as meatballs or meatloaf). Factors examined include handling practices and cooking, the age of the consumer, and the location where

the ground beef is cooked. Cross-contamination is considered to be beyond the scope of the model and is therefore not included.

The Preparation Module is divided into six steps: grinding beef trim, storage during processing by the retailer or distributor, transportation to the home or to a large-scale establishment (termed an HRI for hotels, restaurants, and institutions), storage at home or “away from home”, cooking, and consumption (whose evaluation takes into account the age of the consumer and the location of the meal).

Grinding Beef Trim

As described earlier, the outputs of the Slaughter Module serve as the inputs for the grinding step of the Preparation Module. Those outputs are the distributions of E. coli O157:H7 in the trim that fills the combo bins and boxes at slaughter plants (taking into account cattle type and season). Each combo bin has a level of “leanness” that is defined by the fat in the animals that contributed to the trim. To produce ground beef with a specific fat content, it is necessary to combine trim from different combo bins. Trim from breeding cattle is routinely mixed with trim from feedlot cattle. In the United States, 60% of trim comes from feedlot cattle (steers and heifers); the remainder comes from breeding cattle (cows and bulls). About 15% of all beef consumed in the United States is imported. Imported beef is either processed separately or mixed with domestic product. The model assumes that contamination in imported meat is equivalent to that in domestic meat.

Trim from combo bins is processed in large commercial facilities. The model combines combo bins of three types of beef trim (from domestic breeding and feedlot cattle and from imported cattle) to represent the mixing that occurs during the grinding process. Grinder loads are presumed to vary in size from the equivalent of 2 to 15 combo bins of trim. If there is any E. coli O157:H7 contamination in a bin before grinding, it is assumed to be distributed throughout the load during grinding. A further calculation is made for retail ground meat that is modeled as coming from one to seven 60-pound boxes of trim.

Once ground beef is processed, it is sold by wholesale distributors to retail establishments (grocery stores, butcher shops, and the like) and HRI that in turn sell it to consumers. Retail operations buy ground beef in “case-ready chubs” (plastic tubes filled with 5–10 pounds of ground beef) and use it directly or mix the processed ground beef with trim produced in house. Generally, HRI use ground beef directly as it comes from grinder establishments.

Storage by Retailer or Distributor, Transportation to Home or HRI, and Storage at Home or “Away from Home”

The next part of the FSIS draft model examines E. coli O157:H7 contamination in beef from the time it is ground until the time it is ready to be prepared for consumption. Various factors can affect how much E. coli O157:H7 growth, if any, occurs during this time: the storage time and temperature (including effects of freezing), the fat content, the strain of E. coli O157:H7, and the packaging.

To model growth of E. coli O157:H7 in ground beef, three assumptions are made.

-

All areas of a product are at the same temperature.

-

All E. coli O157:H7 strains exhibit the same growth characteristics in any ground-beef product.

-

The lag period (the time before cell division) in any stage is affected by temperatures in previous stages.

Information on the time between purchase and cooking and on storage temperatures is used to predict microbial growth or inhibition.

Cooking

The cooking portion of the Preparation Module simulates the effect of cooking on E. coli O157:H7 in ground beef in homes and HRI. The model uses data from a survey of final internal temperatures of cooked product. To determine the effect of cooking on E. coli O157:H7, the model simulates the internal cooking temperature and variables that represent pretreatment storage conditions (time and temperature of storage). Differences in hamburger patty thickness are not explicitly modeled.

Consumption

Three primary types of ground beef are modeled in the consumption portion of the Preparation Module: raw ground beef, hamburger patties and sandwiches, and such products as meatballs and meatloaf whose major ingredient is formed ground beef. Consumption patterns at and away from home and the age of the consumer are factored in. Data for this modeling come from the USDA’s 1994–1996 and 1998 Continuing Survey of Food Intakes by Individuals (CSFII) (Kause, 2001). To calculate the amount of ground beef consumed, the model factors in the three ground-beef options above and uses survey data that indicate the frequency with which meals are consumed at and away from home. That results in two

eating locations and three meal options—a total of six possible combinations for ground-beef consumption. The amount of ground beef in each ground-beef food item is modeled by using CSFII’s recipe files. The model further stratifies the data into four age categories (0–5, 6–24, 25–64, and 65+ years). Of primary interest are the youngest and oldest consumers (0–5 and 65+ years) because these groups are the most susceptible to the ill effects of E. coli O157:H7 contamination.

HAZARD CHARACTERIZATION MODULE

The Hazard Characterization Module seeks to characterize the dose-response relationship for E. coli O157:H7, that is, how the amount of pathogen consumed affects the risk of infection, illness, or death. In this context, a dose is the number of E. coli O157:H7 organisms in a serving of ground beef. The response refers not only to the number of people who get ill from consuming E. coli O157:H7-contaminated ground beef but also to the severity of illnesses. Because E. coli O157:H7 infection has the potential to induce serious illness and cause death, it is not possible to conduct dose-response testing on human subjects; the model must rely on information accumulated from other sources to make the calculations in this module.

To determine how many cases of E. coli O157:H7-induced illness occur in the United States annually, information was gathered from the 1996– 1999 Emerging Infections Program, Foodborne Disease Active Surveillance Network (FoodNet). Dose-response estimates are calculated by using the FoodNet data and input from the exposure-assessment modules regarding amounts of E. coli O157:H7 in servings of cooked ground beef. Adjustments are made to account for underreporting and overreporting of infections in the FoodNet data and to ensure that the E. coli O157:H7 dose-response estimates are consistent with those known for other pathogens. Further calculations are used to estimate the number of severe cases of illness from E. coli O157:H7 infection that will result in hospitalization or death and to determine which age groups are most susceptible to infection.

To set the upper and lower boundaries of the E. coli O157:H7 dose-response function, data from similar (“surrogate”) pathogens were used. After evaluation of the availability of data, genetic relatedness, and similarities in transmission, infectivity, and pathogenicity, Shigella dysenteriae 1 was chosen as the upper-boundary pathogen. That is, it was assumed that exposure to a given dose of E. coli O157:H7 was no more capable of causing illness than exposure to an equivalent dose of Shigella dysenteriae 1. Enteropathogenic E. coli (EPEC) was chosen as the lower-boundary pathogen.

A dose-response function for E. coli O157:H7 is then derived by using the upper- and lower-boundary dose-response functions in conjunction

with the estimated number of cases attributed to ground beef and the estimated number of servings contaminated with E. coli O157:H7. Dose and response information from an outbreak of E. coli O157:H7 due to contaminated ground beef is then compared with the derived function to “validate” it (that is, demonstrate that it generated results consistent with an actual event).

RISK CHARACTERIZATION MODULE

The Risk Characterization Module of the FSIS draft model estimates the risk and severity of illness from the consumption of a single serving of E. coli O157:H7-contaminated ground beef. They are calculated for different populations (from individuals to entire communities), exposures (single, per year, or during a lifetime), and population variability (season, age, and where the meal was prepared). To make those estimates, the model combines outputs from the Exposure Assessment and Hazard Characterization modules.

A risk characterization can be used to help to identify the steps in a process that have the greatest influence on the final output and thus highlight where interventions may be most effective. When the risk assessment is final, such analyses will assist FSIS in the review and refinement of its integrated risk-reduction strategy for E. coli O157:H7 in ground beef.

REFERENCE

Elder RO, Keen JE, Siragusa GR, Barkocy-Gallagher GA, Koohmaraie M, Laegreid WW. 2000. Correlation of enterohemorrhagic Escherichia coli O157 prevalence in feces, hides, and carcasses of beef cattle during processing. Proceedings of the National Academy of Sciences 97(7):2999–3003.

FSIS (Food Safety and Inspection Service). 1994. Nationwide Beef Microbiological Baseline Data Collection Program: Steers and heifers—October, 1992–September, 1993.

Kause J. 2001. SAS Analysis of the 1994–1996, 1998 CSFII for Consumption of Ground Beef by Age and Location for the E. coli O157:H7 Risk Assessment. Informational memorandum to Wayne Schlosser through Carol Maczka, Director, Risk Assessment Branch, Office of Public Health and Sciences, Food Safety and Inspection Service, USDA, Washington, DC.

USDA-FSIS (US Department of Agriculture, Food Safety and Inspection Service). 2001. Draft Risk Assessment of the Public Health Impact of Escherichia coli O157:H7 in Ground Beef. September 7, 2001. [Draft report Appendix C dated October 9, 2001; Appendix D undated but released October 31, 2001.]