5

Technology Overview

The Navy requested an update of previous reviews of innovative technologies for cleanup of groundwater, soils, and sediment (NRC 1994, 1997a, 1999a, 2000). This chapter discusses a variety of innovative technologies the Navy might consider during adaptive site management (ASM), for example, for initial remedy selection, as replacements for existing remedies that have proved to be unsuccessful, or as additions to current remedies to better achieve cleanup goals or reduce cleanup time. Because the Navy defined sediment contamination and solvents and metals in soil and groundwater as its most pressing current problems, the focus is on these types of contamination and on applicable remedial technologies, including the concept of treatment trains designed to meet multiple goals for multiple contaminants. The emphasis is on those technologies showing the greatest promise, particularly those technologies being developed and evaluated by the Department of Defense (DoD) and by the U.S. Environmental Protection Agency (EPA) and its Technology Innovation Office in association with the Federal Remediation Technologies Roundtable (FRTR). Although petroleum hydrocarbon sites remain a significant problem because of their sheer number (as discussed in Chapter 1), they are not the focus of this chapter at the request of the Navy and because their cleanup is generally considered to be well understood.

Both in situ and ex situ technologies can be identified according to applicable contaminant groups. Using the FRTR grouping of contaminants (see Table 1-1), eight contaminants groups—halogenated and non-halogenated volatile organic compounds (VOCs), halogenated and non-halogenated semivolatile organic compounds (SVOCs), fuels, inorganics, radionuclides, and explosives—can be defined and linked to the treatment technologies listed in Table 5-1 in terms of both in situ and ex situ procedures. Contaminants and technologies germane to soils, sediments,

TABLE 5-1 Primary Treatment Technologies

|

In Situ Soil and Sediment |

Ex Situ Soil and Sediment |

In Situ Groundwater |

Ex Situ Groundwater |

|

Biosparging Bioventing Bioremediation Capping Chemical Reduction/Oxidation Dual-Phase Extraction Dynamic Underground Stripping Electrokinetics Hot Air Injection Heating Phytoremediation Soil Flushing (in situ) Soil Vapor Extraction Solidification/ Stabilization Steam Extraction Thermally Enhanced Recovery (e.g., EM, in situ RF, ISTD) Vitrification |

Bioremediation— Composting Bioremediation— Land Treatment Bioremediation— Slurry Phase Chemical Reduction/Oxidation Contained Recovery of Oily Waste Critical Fluid Extraction Cyanide Oxidation Dehalogenation Hydraulic Dredging Incineration (offsite) Incineration (onsite) Landfill Disposal Mechanical Dredging Physical Separation Plasma High-temperature Metals Recovery Pyrolysis Solar Detoxification Soil Washing Solidification/ Stabilization Solvent Extraction Thermal Desorption Vitrification |

Aeration Air Sparging Bioremediation Bioslurping Chemical Reduction/Oxidation Circulating Wells Cosolvent Flushing Dual-Phase Extraction Dynamic Underground Stripping Electrokinetics Hot Water/Steam Flushing/Stripping Monitored Natural Attenuation Permeable Reactive Barrier Phytoremediation Surfactants/Surfactant Flushing Vertical Barrier Wall |

Free Product Recovery Pump and Treat with: Air Stripping Bioreactors Carbon Adsorption Chemical Reduction/Oxidation Chemical Treatment Distillation Electrochemical Treatment Filtration Precipitation Reverse Osmosis Solar Detoxification Solvent Extraction Supercritical Water Oxidation UV/Oxidation |

|

SOURCE: Adapted from EPA (1997a). |

|||

and groundwater can be further categorized according to the purpose of the technology and its relative maturity. Accordingly, as indicated in Table 5-2, screening of potential technologies can be facilitated to assist remedial project managers (RPMs) in selecting a remedial alternative. Each technology is defined in a glossary at the end of this chapter.

Key reference information useful for identifying and selecting technologies and combinations of technologies responsive to cleanup needs has been consolidated into a matrix published elsewhere (EPA, 1997a; http://www.frtr.gov). Other sources of information include technology-specific fact sheets produced by a joint effort between the Department of Energy (DOE) and the Air Force Base Conversion Agency (as well as those from other federal agencies). The objective of these fact sheets is to provide RPMs with information on optimizing cleanup technologies, on presenting multiple lines of evidence about remedy performance, on preparing five-year reviews, on operating remedy demonstrations, and on communicating progress to the public. The FRTR website maintains a database of many remediation technologies, their applications, conditions of use, performance data, and cost (although it is not comprehensive). This database would be even more useful if universities, states, and the private sector were encouraged to submit additional information where appropriate. The lack of a central, comprehensive database is likely to hamper the data analysis exercises (see Chapter 3) that characterize full-scale ASM. In addition, federal facility database systems are aligned to measure progress of the cleanup process (see Figures 1-1 and 1-2) versus measuring cleanup performance—an approach to data collection and analysis that will need to shift in order for ASM to be successfully implemented.

Although site conditions and contaminant sources limit the selection of applicable treatment technologies, most sites can be remediated by three primary strategies—destruction or alteration of contaminants, extraction or separation of contaminants from environmental media, and immobilization of contaminants. Currently, destruction technologies include both in situ and ex situ thermal, biological, and chemical methods. Extraction and separation technologies include thermal desorption, soil washing, solvent and vapor extraction for soils and sediments, and phase separation, adsorption, stripping, and/or ion exchange for groundwater. Immobilization technologies include stabilization, solidification, and containment. Generally, no single technology can remediate an entire site, and the use of treatment trains, sometimes combining in situ and ex situ techniques, is common, as discussed subsequently.

The main advantage of in situ treatment is that it allows remediation

to occur without costly removal of the contaminant source. However, in situ treatment generally requires more time, and there is less certainty about attaining cleanup goals in terms of the extent and uniformity of treatment because of the usual heterogeneity of the source location and problems with treatment verification. In contrast to in situ treatment, the main advantage of ex situ treatment is that it generally requires shorter time periods to complete, and there is more certainty about the extent and uniformity of treatment. However, ex situ treatment incurs costly source excavation/removal and possible permitting and exposure implications. The control and proper disposition of emissions and residuals from ex situ treatment are important considerations that require compliance with permit conditions and the application of best management practices associated with each technology or combination of technologies. It should be noted that disposal actions may also be necessary for such in situ technologies as permeable reactive barriers and phytoremediation. Further discussion of this issue for individual technologies can be found in the references provided in Table 5-2.

Beyond considering the potential advantages and disadvantages of in situ and ex situ technologies, an important consideration in the evaluation of a remedy is the physical/chemical properties and the behavior of the contaminant and its source. For instance, subsurface contamination by nonhalogenated or halogenated VOCs potentially exists in four phases: (1) as vapors in the unsaturated zone, (2) as compounds sorbed on soil particles in both saturated and unsaturated zones, (3) as contaminants dissolved into pore water according to their solubility in both saturated and unsaturated zones, and (4) as a nonaqueous phase liquid (NAPL). The preferred remediation may involve a treatment train approach (e.g., air sparging/soil vapor extraction, liquid-phase carbon adsorption, and catalytic oxidation for nonhalogenated VOCs, or groundwater pumping, activated carbon adsorption with adsorbate reinjection, and offsite disposal of spent activated carbon for halogenated VOCs). In the case of soils or sediments, vapor extraction, thermal desorption, and incineration exemplify a corresponding treatment train.

A similar scenario could be developed for nonhalogenated or halogenated SVOCs. They can occur in the subsurface as vapors in the saturated zone, as contaminants sorbed or partitioned onto the soil or aquifer material in both the saturated and unsaturated zones or on sediments, as contaminants dissolved into pore water in both saturated and unsaturated zones, and as NAPLs. Common ex situ treatment technologies for SVOCs in groundwater include carbon adsorption and UV oxidation. In

TABLE 5-2 Candidate Technologies for Soil, Sediment, and Groundwater Remediation

|

Technologya |

Purposeb |

Target Contaminantsc |

||||||||||

|

a |

b |

c |

d |

e |

f |

a |

b |

c |

d |

e |

f |

|

|

In situSoil and Sediment Remediation |

||||||||||||

|

Bioventing |

X |

|

X |

|

X |

|

||||||

|

Capping |

|

X |

|

X |

|

X |

X |

X |

X |

|||

|

Chemical oxidation/reduction |

X |

|

X |

|

X |

X |

|

X |

||||

|

In situ heating |

X |

|

X |

|

X |

|

X |

X |

X |

|

||

|

Phytoremediation |

X |

|

X |

|

X |

X |

X |

X |

|

X |

||

|

Soil flushing |

X |

|

X |

|

X |

X |

X |

|

X |

|||

|

Soil vapor extraction |

X |

|

X |

|

X |

X |

X |

|

X |

|

||

|

Vitrification |

|

X |

|

X |

|

X |

X |

X |

X |

|

X |

|

|

Ex SituSoil and Sediment Remediation |

||||||||||||

|

Composting |

X |

|

|

|

|

|

X |

X |

|

X |

|

|

|

Confined aquatic disposal |

|

X |

X |

|

X |

X |

X |

X |

||||

|

Hydraulic dredging |

X |

|

|

X |

X |

X |

X |

|||||

|

Incineration |

X |

|

|

X |

X |

X |

X |

X |

|

|||

|

Landfills |

X |

X |

X |

X |

X |

X |

X |

|

X |

|||

|

Land treatment |

X |

X |

|

X |

X |

|

X |

|

||||

|

Mechanical dredging |

X |

|

|

X |

X |

X |

X |

|||||

|

Slurry-phase bioremediation |

X |

X |

X |

X |

X |

X |

|

X |

|

|||

|

Soil washing |

X |

|

X |

X |

|

X |

X |

X |

X |

|||

|

Solidification/stabilization |

|

X |

|

X |

|

X |

||||||

|

Thermal desorption |

X |

|

X |

|

X |

X |

X |

X |

X |

X |

|

|

|

Groundwater Remediation |

||||||||||||

|

Air sparging |

X |

X |

|

X |

|

X |

X |

X |

|

X |

|

|

|

Bioremediation |

X |

X |

X |

X |

X |

|

X |

|

X |

|||

|

Bioslurping |

X |

|

X |

X |

|

X |

X |

X |

||||

|

Circulating wells |

|

X |

X |

X |

X |

X |

|

X |

||||

|

Cosolvents and surfactants |

X |

|

X |

X |

|

X |

X |

X |

||||

|

Dual-phase extraction |

X |

X |

X |

X |

X |

X |

|

X |

||||

|

Dynamic underground stripping |

X |

X |

X |

X |

|

X |

X |

X |

||||

|

Chemical oxidation/reduction |

|

X |

X |

|

X |

X |

X |

X |

X |

X |

||

|

Natural attenuation |

|

X |

X |

|

X |

|

X |

|

X |

|

||

|

Permeable reactive barriers |

|

X |

X |

X |

X |

X |

X |

X |

|

X |

||

|

Phytoremediation |

X |

X |

X |

|

|

X |

X |

X |

X |

|

X |

|

|

Pump-and-treat |

X |

X |

|

|

X |

X |

X |

X |

X |

|

||

|

Steam flushing |

X |

|

X |

X |

X |

X |

X |

X |

|

X |

||

|

Vertical barrier walls |

|

X |

|

X |

|

X |

X |

X |

X |

X |

X |

|

|

aSee Glossary at end of this chapter b(a) Source conversion/removal, (b) plume remediation, (c) containment, (d) remediation enhancement, (e) isolation, (f) pretreatment c(a) Nonhalogenated VOCs, (b) halogenated VOCs, (c) nonhalogenated SVOCs, (d) halogenated SVOCs, (e) fuels, (f) inorganics, (g) radionuclides, (h) explosives d(a) Emerging, (b) innovative, (c) established/conventional SOURCES: Adapted from FRTR (1997, 1998). |

||||||||||||

|

|

Maturityd |

Relevant References |

|||

|

g |

h |

a |

b |

c |

|

|

|

X |

AAEE, 1995, 1997; FRTR, 1998 |

|||

|

X |

|

X |

EPA, 1994; Evanko and Dzombak, 1997; NRC, 1997b, 1999a; EPRI, 1999; McLellan and Hopman, 2000 |

||

|

|

X |

|

NRC, 1997a; EPA, 1998a |

||

|

|

X |

|

Fountain, 1998; FRTR, 1998 |

||

|

|

X |

|

X |

|

Schnoor, 1998; Fiorenze et al., 2000 |

|

|

X |

|

NRC, 1999a |

||

|

|

X |

AAEE, 1997; FRTR, 1998; NRC, 1999a |

|||

|

X |

|

X |

AAEE, 1997; Evanko and Dzombak, 1997; NRC, 1999a |

||

|

|

X |

|

X |

AAEE, 1995, 1997 |

|

|

X |

|

X |

|

EPA, 1994; NRC, 1997b; EPRI, 1999; McLellan and Hopman, 2000 |

|

|

X |

|

X |

EPA, 1994; NRC, 1997b; EPRI, 1999; McLellan and Hopman, 2000 |

||

|

|

X |

|

X |

AAEE, 1994, 1997; FRTR, 1998 |

|

|

X |

|

X |

AAEE, 1994, 1997; FRTR, 1998 |

||

|

|

X |

AAEE, 1995, 1997; FRTR, 1998 |

|||

|

X |

|

X |

EPA, 1994; NRC, 1997b; EPRI, 1999; McLellan and Hopman, 2000 |

||

|

|

X |

|

X |

AAEE, 1995, 1997 |

|

|

|

X |

|

X |

AAEE, 1993, 1997; FRTR, 1998; NRC, 1999a |

|

|

X |

|

X |

AAEE, 1994, 1997; Evanko and Dzombak, 1997 |

||

|

|

X |

|

X |

AAEE, 1993, 1997; FRTR, 1998 |

|

|

|

|

X |

Miller, 1996a; NRC, 1999a |

||

|

X |

|

AAEE, 1995, 1997; FRTR, 1998; NRC, 2000 |

|||

|

|

X |

Miller, 1996b |

|||

|

X |

|

Miller and Roote, 1997 |

|||

|

X |

|

Jafvert, 1996 |

|||

|

X |

|

AAEE, 1997 |

|||

|

X |

|

Fountain, 1998; Balshaw-Biddle et al., 2000; NRC, 1999a |

|||

|

X |

|

X |

|

EPA, 1998a; NRC, 1999a |

|

|

|

|

X |

|

NRC, 2000 |

|

|

X |

|

X |

Vidic and Pohland, 1996; EPA, 1998b |

||

|

X |

|

X |

|

EPA, 1999e; Schnoor, 1998; Schnoor, 2002 |

|

|

|

|

X |

FRTR, 1998; NRC, 1999a |

||

|

X |

Fountain, 1998; NRC 1999a |

||||

|

X |

NRC, 1999a |

||||

soil and sediment, biodegradation, incineration, and excavation with off-site disposal are typical. Associated treatment trains may involve thermally enhanced soil vapor extraction followed by in situ bioremediation for nonhalogenated SVOCs, and excavation, ex situ dehalogenation, soil washing/dewatering and land application for halogenated SVOCs.

Inorganic contaminants such as metals may be found in the elemental form, but more often exist as salts mixed in soil or sediment. The fate of metals depends on their physical and chemical properties, the associated waste matrix, and the environmental phase within which they reside. The most common reservoirs for metals are soil and sediment, and the most common treatment technologies include solidification/stabilization, excavation and offsite disposal, and extraction. Depending upon solubility and mobilization potential, metals may also exist in groundwater, and are most frequently treated by ex situ precipitation, filtration, and ion exchange, although in situ treatment by oxidation/reduction and vitrification has occurred. A representative treatment train may be the combination of electrokinetics and phytoremediation.

OPTIMIZATION OF REMEDIES

Before discussing innovative technologies, it is worthwhile to consider the optimization of existing remedies to make them more efficient and effective. This process can utilize data and information from both routine monitoring conducted during remedy implementation as well as from evaluation and experimentation efforts to better define the site conditions. Periodically reevaluating the entire remedial design to determine whether it should be adjusted is critical because the remedial system is dynamic and will lead to changes in in situ conditions as the remedy is being implemented. As one would expect, optimization is more developed for technologies that have been in use for longer periods, like pump-and-treat.

Experiential Optimization

As discussed in Chapter 2, the term “optimization” is used here to mean any adjustment in a single remedy to make it more efficient or cost-effective to implement. To distinguish it from mathematical optimization, the report further defines “experiential optimization” to mean remedy adjustments such as eliminating redundancy, replacing over-

designed components with appropriately sized ones, or relocating or adding some components. In this approach, the technical staff responsible for operation of the remedial system evaluates all components of system design and determines, using engineering judgment, whether any components are redundant, overdesigned, or poorly located and whether additional components are needed. Table 5-3 summarizes examples of experiential optimization for a variety of remedial systems, including soil vapor extraction, air sparging, bioventing, bioslurping, in situ chemical oxidation, reactive permeable barriers, light nonaqueous phase liquid (LNAPL) free product recovery, dense nonaqueous phase liquid (DNAPL) removal and containment, groundwater extraction for hydraulic containment, groundwater extraction for mass removal, and groundwater monitoring. The table entries specifically address optimizing existing remedies and do not include changes to alternate remedies. Additional detail can be found in NAVFAC (2001). These examples demonstrate that a good deal of engineering judgment and expertise are required to implement the suggested schemes. Seventeen case studies mentioning the use of optimization in revising cleanup strategies can be found at the FRTR website (http://www.frtr.gov), although information is not provided on how the optimization was carried out.

Mathematical Optimization

In the peer-reviewed, archival literature, optimization of a remedial scheme is defined more restrictively to mean mathematical simulation of subsurface fluid flow and/or transport coupled with a linear, nonlinear, or dynamic programming algorithm to predict an optimal configuration or management of remedial system components. Formal mathematical optimization of any remedial system is theoretically possible but in practice has principally been applied to pump-and-treat systems.

EPA has recently begun to promote the use of formal mathematical optimization coupled with groundwater modeling for pump-and-treat applications as a potential means to save funds and energy (EPA, 1999a). EPA (1999a) presents a screening model that allows a user to make a rapid determination of whether additional expenditure on a mathematical optimization is worthwhile. In cases where many wells are pumping at a significant rate, where an optimal strategy is not obvious, or where the cost of additional wells is insignificant in comparison to the total amount currently being expended on pumping/energy costs, the screening model will usually indicate that an optimization exercise is worth pursuing. In a

second volume (EPA, 1999b), EPA provides details of how mathematical optimization of a groundwater pump-and-treat situation can be accomplished. The user of the available software should have access to or should be able to construct a groundwater model of the site, and in addition be able to understand and implement the optimization algorithms suggested by EPA. The level of technical competence of the user is presumed to be relatively high.

Typically, pump-and-treat systems are designed based on experience and are adapted to site-specific conditions by carrying out field-scale pilot tests. To assist in the design process, users can use 2- or 3-dimensional numerical groundwater models (e.g., MODFLOW; McDonald and Harbaugh, 1996) to predict groundwater flow paths and hydraulic head distributions at a field site in response to imposed injection or withdrawal stresses, given that site lithology is adequately characterized in terms of spatially varying soil and rock permeabilities. This allows the user to answer questions regarding the number of wells to install and the effects of well placement and pumping rates on the movement of water through the saturated zone. It is possible to find an efficient design by simulating a number of combinations of well numbers, well placement, and injection or withdrawal rates to achieve either desired hydraulic containment or water removal.

However, the best design may not be found by such an iterative procedure. There are many possible combinations of design parameters, and identification of a best set of choices for test simulations may not be readily apparent for heterogeneous soils and complicated site boundary conditions. A more advanced level of design technology that builds on the numerical simulation approach is formal optimization of the design variables, where the best combination is found by mathematical techniques used in the field of operations research (e.g., Bradley et al., 1977; Gill et al., 1981). To optimize pump-and-treat design, mathematical programming algorithms can be coupled with a 2- or 3-dimensional groundwater flow model defining the physical system to determine the optimal set of design parameters for achieving pumping or injection objectives. This approach is the topic of EPA’s recent set of reports (EPA, 1999a,b) and is also the subject of textbooks written within the last decade (e.g., Gorelick et al., 1993; Ahlfeld and Mulligan, 2000).

Optimization as a formal mathematical methodology that can be used to improve system performance has been in use for some time. Indeed, a literature review reveals that the concept of coupling simulation and optimization models dates back to 1958 (Lee and Aronofsky, 1958) and has been applied in the areas of petroleum and gas production, water supply,

TABLE 5-3 Summary of Experiential System Optimization of Certain Remedies

|

Technology |

Component Evaluated for Optimization |

Recommended Action |

Justification |

|

Soil Vapor Extraction |

Characterization of subsurface heterogeneity |

Check for level of detail of characterization |

Improved detail will aid in better placement of extraction well screens |

|

3D distribution of vapor monitoring probes |

Check for adequate number of vapor monitoring points |

Improved placement/numbers will aid in determining adequacy of (1) volume of influence of vacuum system and (2) air flow velocities |

|

|

Flow rates at extraction wells |

Determine mass removal from each well; decrease flow from unproductive wells and increase flow to more contaminated areas |

Improve distribution of total energy used for vacuum application |

|

|

Continued high contaminant concentration in vapor |

Check for unidentified or uncontrolled source areas |

Presence of continuing source area will extend cleanup times |

|

|

Economics of aboveground vapor treatment system |

Check treatment efficiency |

Lower vapor concentrations may cause change in existing treatment efficiency; switching of treatment technology as vapor concentrations get lower could generate cost savings |

|

Technology |

Component Evaluated for Optimization |

Recommended Action |

Justification |

|

Soil Vapor Extraction (con’t.) |

Location/activity of extraction wells |

Conduct equilibrium tests by shutting off all wells for 3– 6 weeks |

Rebounding will occur in hot spots; focus additional contaminant removal on these locations |

|

|

Vertical location of extraction intervals |

Vertical profile testing to determine air flow rates and contaminant concentration with depth |

Determine location of unproductive screened intervals that can be packed off; also want to avoid extracting water from wells that are too close to water table |

|

Air Sparging |

Zone of influence |

Check for design zone of influence. If not being achieved, increase air flow to injection wells or install additional wells outside current zone of influence; evaluate system for short-circuiting |

Design zone of influence needs to be achieved to attain cleanup goals |

|

|

Increasingly high injection pressures required to maintain flow |

Check wells for plugging; redevelop or replace affected wells |

Cleanup will not be achieved or will be delayed if injection wells are plugged. |

|

|

Control of sparging vapors |

May need to install SVE system |

Need to keep sparging vapors from migrating to undesirable areas |

|

|

Slope of contaminant concentration as a function of time |

Check for target slopes; if slopes are too shallow, increase airflow to injection wells; install additional wells; evaluate system for short-circuiting; identify uncontrolled source area; evaluate alternative technologies |

Desire to reduce cleanup times |

|

|

Asymptotic contaminant concentrations due to desorption or diffusion limitations |

Pulse injection wells, install additional wells in contaminated areas, or evaluate alternative technologies |

Desire to reduce cleanup times |

|

Bioventing |

Percent oxygen in soil gas |

Adjust air flow and blower pressure to achieve at least 5% oxygen in soil gas |

Permeability of soil dictates combination of pressure and air flow required to force air into the pore space |

|

|

Excessive air flow |

Reduce air flow until oxygen is between 5% and 15% |

Can achieve energy efficiencies by replacing oversized blowers with properly sized blowers |

|

|

When to stop clean up |

In-situ respiration testing |

Measured rate of biodegradation is indicator of low hydrocarbon supply |

|

Technology |

Component Evaluated for Optimization |

Recommended Action |

Justification |

|

Bioventing (con’t. ) |

Radius of influence |

Check to see whether radius is as designed. Increase air flow, install additional wells, evaluate for short-circuiting |

Desire to achieve design radius of influence to effect desired cleanup |

|

|

High contaminant concentrations |

Excavate hot spots or evaluate alternative technology |

Concentrations may be too high for microbial activity to be effective |

|

LNAPL Free Product Recovery |

Recovery options |

Conduct pilot baildown tests, limited pump down tests, and vacuum-enhanced recovery tests |

Free product recovery is usually on the order of not more than 10% |

|

|

Declining recovery rate |

Check to see if well screens are clogged |

Lower recovery will extend cleanup times |

|

|

Ratio of fuel to water pumped |

Check placement of pumps in wells; check to see if pumping rate is greater than necessary |

If ratio is too low, recovery time will be extended |

|

|

Radius of influence or containment of free product |

Increase pumping rates or install downgradient interceptor trenches |

Incomplete containment of free product will increase cleanup times |

|

DNAPL Containment |

Detail of site characterization |

Tightly spaced soil borings; partitioning tracer test |

Guidance for locating DNAPL |

|

Bioslurping |

Declining recovery rate over time |

Check for biological fouling or mineral buildup at well screen |

Lower recovery rate will extend recovery time and increase costs |

|

|

Design recovery rate never achieved |

Check well development and well screen locations |

Inability to meet design recovery rate will extend recovery time and increase costs |

|

|

Location of suction tubes |

Check to make sure suction tubes intersect free product |

Tubes located above the water table will cause groundwater mounding; tubes too far below the free product will expend energy pumping excessive groundwater |

|

|

Vacuum rate |

If vacuum rate is below design rate, check for short-circuiting and proper sizing of vacuum pump |

Operation below design rate will reduce the radius of influence and extend cleanup times |

|

|

Migration of free product |

Check on adequate location and number of recovery wells |

Desire to prevent free product migration |

|

Permeable Reactive Barriers |

Location of monitoring wells |

Need wells upgradient, downgradient, laterally, and within reactive barrier |

Desire for accurate evaluation of system performance |

|

|

Breach of reactive barrier |

Upgrade or reinstall barrier; consider alternative technology; grout any leaks between barrier and funnel walls |

Desire to contain/treat contamination |

|

Technology |

Component Evaluated for Optimization |

Recommended Action |

Justification |

|

In situ Chemical Oxidation |

Radius of influence |

Check against design radius of influence. If radius of influence is below design radius, refine permeability characterization; reassess injection volume of reagent |

Permeability may be too low for reagent to effectively reach contaminant’ inadequate injection volume of reagent will result in incomplete oxidation |

|

|

Chemical concentrations remaining after treatment |

If chemical removal is incomplete or rebounds, check on well locations, volume of chemical reagent, refinement of site characterization, chemistry of aquifer material |

Desire to attain complete oxidation reaction by having all reactant reach contamination and by having minimal interference by reactions with aquifer material |

|

Groundwater Extraction for Hydraulic Containment |

Mapping of dissolved phase |

Check for level of detail of characterization; utilize direct push probes and discrete sampling for additional detail |

Improved level of detail will aid in better placement of extraction well screens |

|

|

Source controls |

Possible addition of source-control well, in situ chemical destruction, or in situ barriers or treatment walls |

Without removal of source, rates of mass removal will become asymptomatic; with source control, volume of water pumped in downgradient areas may be able to be reduced |

|

|

|

Evaluate potential for natural attenuation |

Other source control or mass removal may not be necessary |

|

|

Location of extraction wells, total pumping rates |

Mathematical optimization |

Identify better combinations of pumping locations, rates, and schedules. May be able to achieve objective of plume containment with lower than maximum pumping rates |

|

|

Well design |

Evaluation of well design, construction techniques, well materials |

Possible improvement of system efficiency; identify potential of well clogging if rates have decreased over time |

|

|

Monitoring wells |

Check for adequate number of monitoring wells |

Evaluate whether entire plume is being contained |

|

Groundwater Extraction for Mass Removal |

Extraction rates |

Evaluate mass removal for each location |

Decrease extraction rates at unproductive wells, increase extraction rates in more contaminated areas |

|

|

Pumping rates |

Check on whether contaminant removal is limited by chemical solubility or diffusion; possibly lower or cycle pumping rates |

Pumping rates in solubility-limited and diffusion- limited systems may be too high and ineffective; cost savings can be realized by reducing pumping rates |

|

|

Pumping rates |

Check on whether design rates have been achieved |

Failure to attain design rates may prevent plume containment |

|

|

Location/activity of extraction wells |

Complete equilibrium tests by shutting off wells for three months |

Define hot spots where remediation efforts should be focused |

|

Technology |

Component Evaluated for Optimization |

Recommended Action |

Justification |

|

Groundwater Extraction for Mass Removal (Con’t.) |

Vertical location of extraction intervals |

Complete vertical profile testing |

Identify intervals containing greatest masses of recoverable contaminants; allow determination of unproductive intervals to pack off |

|

|

Map of dissolved phase |

Check to make sure that plume is being contained while being removed; increase pumping rates as needed |

Contaminant plume migration increases plume volume and possible receptor exposure. |

|

|

Location of extraction wells, total pumping rates |

Mathematical optimization |

Find better combinations of pumping location/rates/schedule to increase mass removal and/or decrease cleanup costs |

|

|

Above-ground treatment system |

Evaluate for economic efficiency |

As contaminant concentrations change, an alternate treatment system may be more cost-effective |

|

|

Above-ground treatment system |

Evaluate for design treatment efficiency |

Unit may not be operating properly and could be repaired |

|

|

Above-ground treatment system |

Evaluate monitoring versus maintenance costs |

Dollars spent monitoring maybe better suited to maintenance |

|

|

Above-ground treatment system |

Evaluate pumps and blowers for overdesign |

Potential cost savings as concentrations begin to decrease |

|

|

Above-ground treatment system |

Evaluate cost of remote monitoring vs. onsite labor |

Possible cost savings via remote monitoring |

|

|

Number of wells |

Identify redundant wells for elimination (with regulator) |

Potential cost savings |

|

Groundwater Monitoring |

Frequency of sampling |

Evaluate appropriateness of sampling less frequently based on remediation progress |

Potential cost savings |

|

|

Sampling and analytical protocols |

Ensure that correct protocols are being applied to monitoring well samples |

Potential cost savings if all monitoring wells are not required to undergo same protocols as point-of-compliance wells |

|

SOURCES: Adapted from Air Force (2001) and NAVFAC (2001).p |

|||

wastewater injection, excavation dewatering, and hydraulic containment of groundwater contaminant plumes. The objective functions specified in problem formulations vary widely and have included, for example, maximizing profit, maximizing production, maximizing sum of hydraulic heads, maximizing total injection/withdrawal flow rates, minimizing costs, minimizing difference in desired versus actual production, and minimizing total injection/withdrawal flow rates. For the specified objective functions, decision variables have included flow rates at wells, head or pressure at wells, and well installation (binary or yes/no decision variables). Optimization algorithms that have either been proposed or actually used to solve these problems include linear, quadratic, nonlinear, and mixed linear-integer programs; some algorithms for solving certain optimization problems are widely available as commercial software packages (e.g., Murtaugh and Saunders, 1983, available from http://www.sbsi-sol-optimize.com/Minos.htm; Schrage, 1997, available from http://www.lindo.com).

EPA presents several case studies demonstrating that application of optimization to existing pump-and-treat well fields can save on the order of hundreds of thousands of dollars per site, depending on the objective. If, for example, the objective is plume containment, often it will be found that adequate hydraulic gradients toward the center of the plume can be maintained by reducing the pumping rates of the wells at the site, thereby reducing annual energy costs. In other cases, it can be shown that additional well placement and reevaluation of pumping and injection rates can also save additional dollars beyond the present scenario. A case study of mathematical optimization is presented in Box 5-1.

EPA notes that hydraulic modeling does not address mass removal or desired contaminant concentrations. To model such contaminant concentrations or masses, contaminant transport modeling must be coupled with optimization algorithms. This approach appeared in the literature over 15 years ago (Gorelick et al., 1984) and is now being pursued by EPA. Transport modeling is more complicated in that there are more parameters that need to be specified (dispersivities, sorption coefficients, biodegradation rates) and the process is nonlinear in contaminant concentration.

The principles discussed above can be applied to mathematical optimization of remediation of the vadose zone. An optimization handbook for soil vapor extraction is under development by EPA. A recent discussion of the mathematical approach to optimization of soil vapor extraction system design is provided by Sun et al. (1998).

One deficiency in the use of mathematical optimization not widely

recognized is that rarely is the uncertainty in the predicted optimal scheme quantified. Aquifers are naturally heterogeneous such that the three-dimensional spatial variability of the rock and soil structure can never be known precisely. The uncertainty in the distribution of soil properties affects predictions of flow and transport. To address the issue of uncertainty in groundwater flow and transport modeling, statistical methods are used to generate a synthetic geologic structure between points of observed head/solute concentration, and often Monte Carlo methods are employed to evaluate equally likely realizations of geologic structure that obey the assumed underlying statistical pattern. In this way, the effect of the uncertainty of the inputs (soil/rock hydraulic conductivity distribution) on the outputs (hydraulic head and solute concentrations) is quantified. The practice of quantifying uncertainty in subsurface flow and transport modeling is virtually ignored in the literature on coupling flow and transport models with optimization algorithms for improving well placement/pumping rates. Inclusion of the consideration of uncertainty would provide a range of possible optimal scenarios instead of just one scenario.

There is no documentation indicating that the Navy has been using the mathematical optimization approach championed by EPA as a method of saving remediation costs for pump-and-treat scenarios. The Navy may wish to consider implementing mathematical optimization for improving the efficiency of pump-and-treat systems and ultimately saving hundreds of thousands of dollars in pumping costs. However, a high level of technical expertise is needed to (1) calibrate a groundwater model to existing site hydrogeology and (2) couple site-specific groundwater modeling results with the mathematical optimization tools available from EPA. This of course requires an investment in personnel resources. The Navy could consider utilizing EPA’s screening methodology (EPA, 1999a) to decide whether a full-blown optimization effort would be economical to undertake. According to EPA, implementation of the screening model costs about $15,000.

***

At the current time, mathematical optimization is readily available only for pump-and-treat remediation schemes, such that experiential optimization will be needed for other remedies. Although few quantitative criteria are available for implementing experiential optimization, checklists provided by, for example, NAVFAC (2001) and the FRTR should be useful until a more complete database of experience is developed.

|

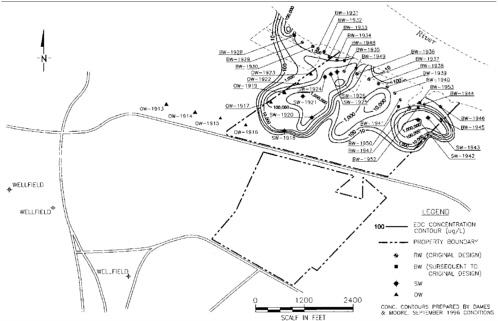

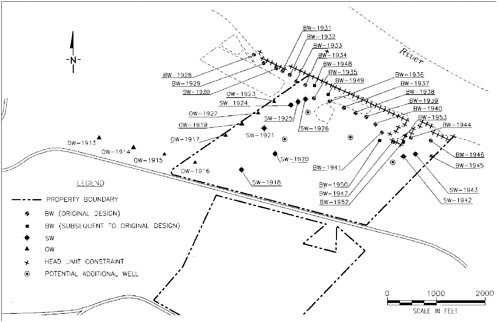

BOX 5-1 Mathematical Optimization of a Groundwater Pump-and-Treat System SOURCE: EPA (1999b). Figure 5-1 illustrates contamination contours of a 1,2-dichloroethane (EDC) plume in a sand, clay, and gravel aquifer, beneath a site adjacent to a river in Kentucky. The saturated thickness of the aquifer varies from 100 feet at the southern border to 30–50 feet at the river. At the time of the study, a pump-and-treat system had been operating at the site since 1992. Twenty-three wells (18 from an original design plus five added subsequent to the original design, all labeled BW on Figure 5-1) had been installed principally for preventing migration of groundwater contaminants to the river, eight (“SW”) wells were installed near the plume centers for the purpose of accelerating mass removal, and eight “OW” wells were installed to prevent plume migration to adjacent properties. The typical pumping rates for the three kinds of wells were 420–580 gallons per minute (gpm), 80–160 gpm, and 25–100 gpm, respectively. A range of pumping rates for each type of well reflects adjustments in the system to respond to variations in the water table elevation caused by variations in the river level. EPA chose this site as a case study for illustrating the application of mathematical optimization because of the large number of existing wells in operation as well as the high annual expense of operation. Contaminants removed from the aquifer were being treated by steam stripping, and the treated water was discharged to the river. The cost of pumping and treatment by steam stripping was on the order of $1.8 million per year in 1999. A screening analysis by EPA (1999a) determined that it would be economically justifiable to expend funds ($40,000) to conduct groundwater modeling and optimization analysis of the current system to see if cleanup objectives could be attained at a lower cost by installing new wells and/or utilizing different pumping rates at existing wells. The screening analysis suggested that a change in pumping rates and/or in the number of wells pumped could save millions of dollars over the planning horizon (20 years), even if new wells costing $20,000 each were added to the system. The goals of the hydraulic optimization were to evaluate the following: (1) the potential for reducing pumping rates at the BW wells with continued prevention of plume migration to the river, (2) the tradeoff between the total number of BW wells operating and the total pumping required for containment, (3) the total pumping required for containment with BW wells pumping only, (4) the pumping required for containment as a function of variation in the hydraulic head constraint required, and (5) the tradeoff between adding SW wells and reducing pumping rates at BW wells. The code used to conduct the optimization was “MODMAN,” consisting of the U.S. Geological Survey groundwater flow code MODFLOW (McDonald and Harbaugh, 1996) coupled with a linear programming algorithm LINDO (Schrage, 1997), to find the optimal set of pumping rates given the physical constraints of the system (EPA, 1999b). The mathematical objective function specified was minimization of the total sum of the pumping rates at the site, which is a surrogate for minimizing costs, since electricity usage is proportional to pumping rate. The annual steam stripping costs were equivalent to about $2000/gpm of water |

|

pumped. The physical characteristics of the hydrogeology are captured by first calibrating the groundwater flow code to the site, and subsequently determining site-specific aquifer responses to unit pumping rates at various locations, which are then built into the coefficients of the specified objective function. (This method of including the physical system characteristics as coefficients in the objective function is termed the matrix-response method, see Gorelick et al., 1993). Physical constraints that were mathematically defined included (1) hydraulic head at locations where hydraulic containment was desired, and (2) maximum desirable pumping rates at each well. In the case of the BW wells protecting the river, a hydraulic head constraint along a line between the river and the BW wells was specified, as shown in Figure 5-2 by the cross marks. The numerical value specified was 0.01 ft lower than the head of the river, in order to guarantee a solution that would contain a hydraulic gradient pointing toward the plume and away from the river at the desired locations.  FIGURE 5-1 1,2-dichloroethane concentrations in September 1996 at a facility in Kentucky. SOURCE: EPA (1999b). |

|

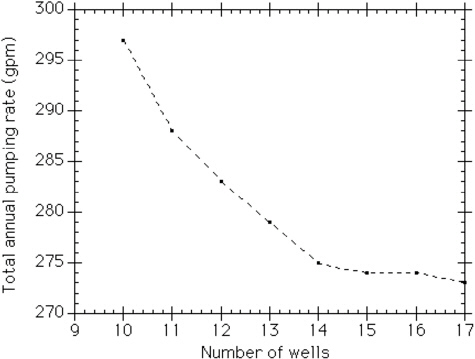

The results of the first two goals of the optimization runs are discussed here. A first set of runs examined whether the pumping rates of the original 18 BW wells could be reduced, holding the pumping rates of the SW and OW wells constant at their original design rates, to achieve the specified hydraulic constraint of 0.01 ft at the noted locations. The optimization algorithm found that only 17 of 18 BW wells were needed, and that the total pumping rate required at these wells to achieve hydraulic containment was 273 gpm instead of the original design total pumping rate of 549 gpm. This scenario resulted in a savings of $552,000 per year in operating costs. Further runs limiting the total number of wells allowed to operate (runs each with a maximum of 10–16 wells specified) indicated that as few as 14 wells could be pumped (275 gpm or a cost savings of $548,000 per year), with a more modest incremental savings as the number of wells was further limited to be as few as 10 (see Figure 5-3). Only when the number of wells was limited to nine was the solution found to be infeasible, that is, the constraints could not be met. If the optimization algorithm had been used in the design  FIGURE 5-2 Hydraulic head constraint locations and potential additional well locations specified in the hydraulic optimization modeling. SOURCE: EPA (1999b). |

PROMISING TECHNOLOGIES FOR THE NAVY’S PRESSING CONTAMINATION PROBLEMS

The following sections describe specific innovative technologies applicable to the types of contamination problems encountered at Navy and other federal facility sites. The discussion includes several technologies because there are more than just two or three that would suffice to cover all of the Navy’s critical problem sites. The innovative technologies for treating solvents in soil and groundwater were chosen because they have recently garnered intense interest from potentially responsible parties (PRPs), including the Navy, and they have proven promising based upon previous applications. Thus, pump-and-treat and other conventional technologies are not included. On the other hand, a broad overview is given of technologies for treating metals sites and contaminated sediment sites that reflects the committee’s professional experience regarding their potential use and efficacy.

Cost issues are not discussed in subsequent sections, primarily because complementary cost data for remediation technologies are not readily available for every type of application. However, a recent cost compendium has been prepared to include current information about the costs of bioremediation, thermal desorption, soil vapor extraction (SVE), onsite incineration, groundwater pump-and-treat, and permeable reactive barriers (PRBs) based upon about 150 projects (EPA, 2001a). The overall findings regarding remediation costs indicated that:

-

correlations between unit costs and quantity of material treated or mass removed were evident for bioventing, thermal desorption, SVE, and pump-and-treat systems,

-

economies of scale were observed for bioventing, thermal desorption, and SVE in that unit costs decreased as larger quantities of soil were treated,

-

costs of technology applications are site-specific and thus are affected by many factors (e.g., properties, distribution, and concentrations of the contaminant; character of treated matrix and hydrogeological setting; market forces; maturity of technology; regulatory requirements; etc.), and

-

some technologies (e.g., PRBs) could not be quantified with respect to cost due to lack of information concerning the longevity of the project, the contaminant quantity treated, and the mass of contaminant removed.

It will be important to the eventual success of ASM (particularly at management decision period [MDP] 3) to have greater understanding of the labor, utility, chemical, and disposal costs of different technologies. Presently, most financial data systems do not break down cleanup costs in this way, such that new budgeting requirements and formats will be needed to produce data that can support ASM.

Technologies for Remediation of Organic Contaminants in Soil and Groundwater

Recalcitrant organic contaminants are found at over 54 percent of all Navy facilities (NRC, 1999b), and are common contaminants at federal facilities in general. As discussed in Chapter 1, they pose significant challenges to site remediation, particular when found in karst and fractured rock environments. Three of the innovative technologies discussed below (in situ chemical oxidation, thermal treatment, and enhanced bioremediation) are broadly classified as source removal technologies because their goal is to reduce substantially the source term (be it solid-bound, free-phase or dissolved contamination). In situ oxidation and thermal treatment in particular are noteworthy for reducing contaminant mass over a short timeframe. Barrier walls, in contrast, are effective primarily for contaminant plume treatment and control. To date, they have been developed for a limited number of organic compounds and metals.

In Situ Chemical Oxidation/Reduction

In situ chemical oxidation/reduction (ISO) is a groundwater remediation technology for toxic organic chemicals that has largely been used for source removal and control. The oxidants most commonly employed include peroxide, ozone, and permanganate. Hydrogen peroxide is capable of directly oxidizing organic contaminants—by free radical formation when ferrous iron is used as a catalyst (Fenton’s Reagent). Fenton’s Reagent oxidation is most effective under very acidic conditions, such that the need for pH adjustment is a disadvantage during the application of the technology. The advantages of peroxide include relatively low regulatory resistance, more field experience than for either ozone or permanganate, and a sparsity of byproducts of oxidation.

Ozone gas also can oxidize contaminants directly or through free

radical formation, and it is the strongest viable chemical oxidant available. Because ozone is a gas, it is most suitable for treating the vadose zone, or possibly contaminant accumulations (e.g., LNAPL) in the capillary fringe. Like peroxide, ozone reactions are most effective in systems with acidic pH, where they proceed with extremely fast, pseudo first-order kinetics. Because of ozone’s high reactivity and instability, it is produced onsite and requires closely spaced delivery points. In situ decomposition of the ozone can lead to beneficial oxygenation and biostimulation, and it is less costly than either peroxide or permanganate. However, because ozone must be applied as a gas, vapor recovery and possible treatment can add to the cost of the technology.

Permanganate is typically provided as a liquid or solid potassium or sodium salt that dissolves directly in the groundwater, and its reaction stoichiometry in natural systems is complex because of its multiple valence states and mineral forms. Depending on pH, the reaction can include direct oxidation or free radical enhanced oxidation. The reactions proceed at a somewhat slower rate than for peroxide or ozone according to second-order kinetics. Permanganate has a lower cost than peroxide and is effective over a broader pH range, and it is more stable than ozone. However, oxidation via permanganate also produces manganese oxide, which can precipitate and potentially cause reduced porosity. Increased dissolved manganese levels are also a regulatory concern, as is the purple color of groundwater containing unreacted permanganate.

The rate and extent of oxidation of a target contaminant are determined by the properties of the chemical itself and its susceptibility to oxidation as well as by the reaction matrix and its conditions (e.g., pH, temperature, oxidant concentration, other reduced compounds, minerals, and free radical scavengers). Generally, the technology is used on chlorinated volatile organic compounds (CVOCs) such as trichloroethylene (TCE) and on petroleum hydrocarbons. The method of oxidant delivery throughout the reaction matrix is of paramount importance; vertical and horizontal injection wells and sparge points with forced advection to rapidly move the oxidant, particularly for peroxide and ozone, into the subsurface are often deployed. Moreover, all three oxidation reactions (Box 5-2) can lead to (1) a decrease in pH if the system is not effectively buffered, (2) genesis of colloids with reduced permeability, (3) mobilization of redox-sensitive and exchangeable sorbed metals, (4) possible formation of toxic byproducts, (5) evolution of heat and gas, and (6) biological perturbations.

|

BOX 5-2 Simplified Stoichiometry for Oxidation of TCE by Peroxide, Ozone, and Permanganate

|

The stoichiometric relationships, like those shown in Box 5-2, can be used to estimate the amount of oxidant that would theoretically be needed to destroy the target contaminant. However, for site-specific oxidant demand estimates, bench-scale treatability tests based on soil slurry systems are often conducted to evaluate the feasibility of in situ oxidation and to calculate potential oxidant loading requirements. Results from slurry systems do not take into account preferential flows that are likely to occur in the subsurface, such that in reality, an excess of oxidant is often applied. Example bench-scale testing results are provided in Gates and Siegrist (1995).

Single, multiple, and continuous injections using recirculation of amended fluid have been used to apply the technology. For single or multiple injections, permanent or temporary injection points are used to deliver an aqueous solution containing the oxidant and any needed catalyst under pressure. The oxidant (and catalyst) concentration, the target pH, the injection well spacing (i.e., radius of influence), the number of injections, and the injection pressure are all important design parameters that can affect cost and performance. The use of recirculation, with injection and extraction wells, is intended to increase subsurface mixing and reaction opportunity, but the costs are likely to be higher. In addition, thin screen intervals at different depths more fully saturate the target zone and reduce the need for vertical migration of the oxidant. High injection pressures may be used to create fractures in tighter subsurface materials and thereby encourage migration and mixing of the reactants. Finally, in some cases, vapor extraction is used in conjunction with oxidation in the vadose zone to relieve off-gas pressure, to encourage oxidant migration, and/or to capture any volatile emissions (ESTCP, 1999). Despite these measures, it should be noted that in situ oxidation reagents, particularly Fenton’s Reagent and ozone, are relatively short-lived compared to the rate of groundwater flow in most aquifers, such that oxidant contact with and treatment of contaminants is not significantly mediated

by groundwater advection and oxidant dispersion. Table 5-4 provides example calculations of the minimum volume of injectant that must be delivered in an active form to achieve cleanup of different target treatment volumes. In summary, significant volumes of liquid oxidants may be required to treat relatively small areas.

Measuring Performance. Performance measurement should be based on multiple lines of evidence. Contaminant concentration changes over time and space are the most common and useful measurement. However, because contaminant concentration reductions can be caused by oxidation, simple displacement, and/or dilution effects, the measurement of geochemical indicators, tracers, and contaminant-destruction byproducts (e.g., chloride), as well as the use of control wells, should be considered. Geochemical indicators such as dissolved oxygen, redox potential, and conductivity (background chloride, etc.) provide an initial geochemical fingerprint that will change if the oxidant is delivered to a specific monitoring location. Tracer compounds that should be considered for the evaluation of oxidant distribution include both visual tracers and a semi-conservative dissolved tracer (i.e., Mn2+, K+, Na+, etc.); bromide and iodide should be considered when applying liquid oxidants like peroxide. The release of halogenated ions, such as chloride or bromide, from target contaminants is a useful line of evidence if original contaminant concentrations are high enough to result in a significant increase in halogen ion concentrations as a result of contaminant destruction. All injection trials should include one or more control wells where water and tracer are injected into a contaminated zone in order to differentiate dissolved contaminant displacement or dilution from destruction.

TABLE 5-4 Volumes of Liquid Oxidant required to affect Target Radius of Influence

|

Assumed radius of influence (ft) |

Target or injection well screened interval (ft) |

Volume of aquifer affected (gal) |

Required volume of injectant to achieve assumed radius of influence (gal)a |

Approximate Number of injection wells/acreb |

Approximate Total volume injectant/ acre (gal)c |

|

10 |

10 |

23,500 |

5,900 |

140 |

826,000 |

|

10 |

20 |

47,000 |

11,800 |

140 |

1,652,000 |

|

20 |

20 |

188,000 |

47,000 |

35 |

1,645,000 |

|

50 |

20 |

1,170,000 |

294,000 |

6 |

1,764,000 |

|

aEntries equal Column 3 multiplied by an assumed porosity of 0.25. bNumber of wells per acre is approximated by dividing the surface area of an acre by the surface area coverage of a single well. cEntries equal Column 4 multiplied by Column 5. |

|||||

Although the theoretical stoichiometry of ISO is known, nontarget materials in the subsurface (e.g., natural organic acids, reduced iron and manganese, and sulfides) can all consume oxidant. Moreover, these sources can affect the potential for heat and off-gas generation or foaming and for rebound of contaminant levels caused by diffusion from untreated sources. Thus, data on the concentrations, masses, and fluxes of these materials in the treatment zone are essential to both rational design and measuring performance.

Because most subsurface environments are highly heterogeneous, the effectiveness of injection and/or reinjection needs to be evaluated both at the initial location and at possible new locations. The presence of target contaminants in lower-permeability layers that are adjacent to more permeable, preferential flow paths should be of special concern since oxidant delivery may be incomplete in lower-permeability zones. Thus, performance monitoring should be conducted in unique lower-permeability and/or high organic carbon layers. Likewise, monitoring for contaminant concentration rebound can guide the design of any subsequent remediation strategies by defining the remaining contaminant reservoir that was not treated by ISO. However, such information should be coupled with measurements of soil pore water chloride concentrations during injection to provide supporting evidence of dechlorination reactions and concomitant loss of the contaminant. For such a soil confirmation program to be useful, it needs to appropriately consider potential spatial and temporal variability of contaminant distribution, and recognize the associated mechanisms (e.g., chemical oxidation, volatilization/air stripping/gas phase partitioning, and dilution) of contaminant reduction.

Technology Evaluation. A recent status review of in situ oxidation (ESTCP, 1999) at 42 government (DoD and DOE) and private sites is summarized in Table 5-5. The review was conducted in two phases; phase I consisted of a survey of sites to identify where ISO had been used. The survey involved contacting ISO vendors and reviewing government (DoD, DOE, and EPA) databases and websites to determine current status of the project, scale, contaminants and media, responsible parties and regulators involved, extent of any available site data, and initial response indicating relative success or failure to satisfy facility-specific performance objectives. Accordingly, 19 sites were deemed successful, six failed, and 17 were uncertain. Of the 42 sites, 19 were partially or primarily contaminated with CVOCs, with TCE being the most prevalent

TABLE 5-5 Characteristics of In Situ Oxidation (Phase I) Field Sites

|

|

Number of Sites |

|||

|

Characteristics |

DoDa |

DOE |

Private |

Total |

|

Contaminants |

||||

|

CVOC |

6 |

3 |

12 |

21 |

|

BTEX/TPH |

6 |

- |

13 |

19 |

|

Both |

1 |

- |

- |

1 |

|

Unknown |

1 |

- |

- |

1 |

|

Media Treated |

||||

|

Soil only |

0 |

0 |

0 |

0 |

|

Groundwater |

2 |

0 |

17 |

19 |

|

Both |

10 |

3 |

7 |

20 |

|

Unknown |

2 |

- |

1 |

3 |

|

Oxidant |

||||

|

Hydrogen peroxide |

12 |

1 |

24 |

37 |

|

Potassium permanganate |

1 1 |

2 0 |

1 0 |

4 1 |

|

Ozone |

|

|||

|

Vendor |

||||

|

Geo-Cleanse |

8 |

1 |

4 |

13 |

|

Clean-Ox |

3 |

0 |

13 |

16 |

|

ISTEC |

1 |

0 |

7 |

8 |

|

Other |

2 |

2 |

1 |

5 |

|

Scale |

||||

|

Pilot/Demo Only |

9 |

3 |

15 |

27 |

|

Full Only |

1 |

0 |

4 |

5 |

|

Both |

4 |

0 |

6 |

10 |

|

Outcomeb |

||||

|

Success |

5 |

3 |

11 |

19 |

|

Failure |

6 |

0 |

0 |

6 |

|

Uncertain |

3 |

0 |

14 |

17 |

|

Totals |

14 |

3 |

25 |

42 |

|

SOURCE: ESTCP (1999). aDoD Breakdown: Navy (NFESC) = 5; Corps of Engineers/Air Force = 7; Army (Base Contract) = 2 bOutcome determinations are relative terms based on available Phase I information provided by facility representative (e.g., direct comments or pilot-scale tests that led to full-scale operations). These terms denote the ISO technology’s ability or lack thereof to satisfy facility-specific program performance objectives. |

||||

contaminant of concern. Hydrogen peroxide was used at 37 sites, potassium permanganate at four sites, and ozone at only one site. Five of the 42 were Navy sites.

The results of the Phase I survey were then used to select several

sites for more detailed Phase II evaluation, consisting of a review of available site characteristics, design, and performance data to more fully investigate and understand the site conditions and characteristics, the reasons why ISO was selected, the design parameters and rationale, the cost and performance of ISO under real-world conditions, the reasons for success or failure of ISO to meet the project objectives, and the specified technological concern. The Naval Submarine Base at Kings Bay, Georgia (Box 5-3), and the Naval Air Station at Pensacola, Florida, received such detailed site profiling and evaluation of results. At both of these sites, natural attenuation appeared promising after ISO treatment. The location, area and contaminant of concern, regulatory driver, oxidant, scale, remediation objectives, ability to meet objectives, and follow-up actions for these and the other Phase II sites are summarized in Table C-1 in Appendix C.

Collectively, the experiences with ISO indicate varying degrees of success, largely based on the sufficiency of site characterization and technology deployment. Various key factors have been identified and relate to site characterization needs and design and operational issues. The success of ISO is dependent upon effective contact and mixing with target contaminants, compatible subsurface geochemistry, and the maintenance of sufficient oxidation capacity to overcome oxidant losses from nonspecific oxidation reactions (e.g., reactions with the aquifer matrix and spontaneous oxidant decomposition). Major unanswered issues regarding the technology include:

-

the absence of a well-defined screening procedure to evaluate site-specific geochemical parameters for compatibility with ISO techniques,

-

the lack of properly designed pilot-testing procedures,

-

differentiation between dissolved contaminant displacement and dilution versus treatment,

-

oxidant loss due to consumptive reactions with soils and naturally occurring organic and inorganic materials, and estimations of the amount of oxidant necessary to overcome these losses so as to achieve the desired contaminant destruction,

-

effectiveness of ISO for dissolved versus sorbed contaminants,

-

credible analyses of contaminant rebound effects, and

-

compatibility with anaerobic biodegradation processes.

|

BOX 5-3 In Situ Oxidation for Remediation of Chlorinated Solvents in Soil and Groundwater at Kings Bay Naval Submarine Base, Georgia The site under consideration is a leaking former sanitary landfill, under which a perchloroethylene (PCE) plume has developed that is 120 feet long by 40 feet wide, with a 30- to 40-foot horizon below ground surface (bgs). The plume is moving toward a residential area through sandy soils that have a hydraulic conductivity in the impacted zone of 30 ft/day. The PCE concentrations detected in the landfill source area were as high as 8,500 µg/L, with breakdown products TCE, dichloroethylene (DCE), and vinyl chloride detected at concentrations of more than 9,000 µg/L in groundwater. The remediation strategy chosen was to conduct full-scale in situ chemical oxidation with Fenton’s Reagent (Geo-Cleanse) at 50 percent peroxide and an equivalent volume of ferrous iron catalyst delivered by injection to the subsurface. A total of 44 injection wells (23 in Phase I; 21 in Phase II) were installed at both deep (40–42 ft bgs) and shallow (32–35 ft bgs) depths. Phase I included two injections of oxidants totaling 12,045 gallons (8,257 gallons November 2–21, 1998; 3,788 gallons February 8–14, 1999). Phase II included two additional injections totaling 11,247 gallons (8,283 gallons June 3–11, 1999; 2,964 gallons July 12–15, 1999). The estimated volume of groundwater treated during Phase I was 78,989 gallons (based on treatment volume of 11,778 cubic yards and a porosity of 22 percent). During both phases, the design injection rate of oxidant was 0.2–1 gpm, while air was injected at 3 cfm to disperse the catalysts. Following the in situ oxidation treatment, total VOCs in the primary treatment area were reduced from 9,074 µg/L to 90 µg/L, a 99 percent reduction. Subsequent results have shown that concentrations have remained below 100 µg/L. The natural attenuation capacity of the aquifer is expected to polish residuals outside the source area that are present in concentrations of less than 100 µg/L. Modeling exercises are predicting plume collapse in five years, barring the existence of other source areas outside the primary treatment zone. Based on the apparent success of in situ oxidation, the existing pump-and-treat system was discontinued. |

Accordingly, uncertainties that have emerged during the demonstration and applications have indicated a need to provide comprehensive information on several factors (ESTCP, 1999). First, there must be better delineation of the contaminant’s location and extent and of its sorption potential, particularly for DNAPL accumulations. The degree of soil layering versus the distribution of contaminants is an important parameter to understand because the distribution of oxidants will be limited to more permeable soil horizons unless injection/distribution approaches are tightly controlled. Mass and volume estimates of total CVOCs be-

fore and after treatment are needed to determine the efficacy of natural attenuation, and to be able to estimate the injected fluid volumes of oxidant. Another requirement is vapor monitoring, including detection of potentially explosive vapors in the subsurface, to safeguard against possible health and safety hazards during treatment. The prior consideration of these factors in formulating and optimizing a remedial action plan will enhance the potential success of ISO applications at contaminated sites (NAVFAC, 2001).

Design considerations include determining the radius of influence of injection wells to ensure adequate contact and the enhancement of mixing to promote contact between oxidant and contaminant. It may be necessary to consider multiple injections into the same or preferably new locations to accommodate matrix heterogeneities and circumvent problems with the development of preferential flow paths and short-circuiting caused by plugging of flow paths. Comparisons of the estimated in situ half-life of the oxidant to the groundwater flow velocity will help determine whether natural or induced groundwater flow can significantly distribute the oxidant. Finally, it will be important to incorporate ISO into an overall site management strategy, particularly at DNAPL sites, where source removal or reduction can be complemented by more cost-effective residuals treatment (e.g., natural attenuation or sparging).

Thermal Treatment

There are three general methods that can be used to inject or apply heat to the subsurface to enhance remediation: injection of hot gases such as steam or air, hot water injection, and electrical resistance heating (Davis, 1997, 1998). Steam, hot air, and hot water injection rely on contact between the injected fluid and the contaminant. Steam injection will displace mobile contaminants in front of the steam as well as vaporize volatile residual contaminants, and therefore can recover volatile and semivolatile contaminants in both the liquid and vapor phases. Hot air injection has been used to recover contaminants only in the vapor phase, and it is applicable to water-soluble volatile and semivolatile organics. Because steam has a heat capacity approximately four times that of air and a heat of evaporation of more than 2,000 kJ/kg, steam is often preferred to enhance the recovery of volatile contaminants and oils in soils and aquifers. However, for contaminants that have a high solubility in water, residual contamination remains after steam injection, unlike with hot air injection. Hot water injection is applicable for contaminants in

the nonaqueous liquid phase, which tend to have low volatility and very low solubility in water, and this is most effective when the nonaqueous phase is present in quantities greater than the residual saturation.

Electrical energy has been applied to the soil in the low frequency range used for electrical power, that is, electromagnetic (EM), alternating current (AC), or resistivity heating, as well as in the radio frequency (RF) range. In each case, electrical energy heats the soil, increases the volatility of contaminants, and may induce the groundwater to boil and form steam (Fountain, 1998). The contaminants are driven out of the source zone by a combination of volatilization and thermally induced vapor-phase transport. Hence, electrical heating is usually coupled with soil vapor extraction (SVE) or steam injection to recover the volatilized contaminants. DNAPLs will be volatilized if the soil is heated to near the contaminant boiling point; the contaminant may also be mobilized by a reduction in viscosity. For semivolatile organic contaminants, higher temperatures (300°–400°C) obtained using RF energy are required to achieve greater removal and transformation efficiencies.

Electrical heating has proved to be effective in sandy media, and it also has a greater potential than steam or hot water injection in less permeable media such as clays. The higher water content generally found in clay will aid in directing the electromagnetic energy to the clay and promotes both a faster heating rate and higher temperatures. RF heating, however, is limited to the unsaturated zone, and for contaminants trapped below the water table, dewatering would have to be conducted prior to electrical heating.

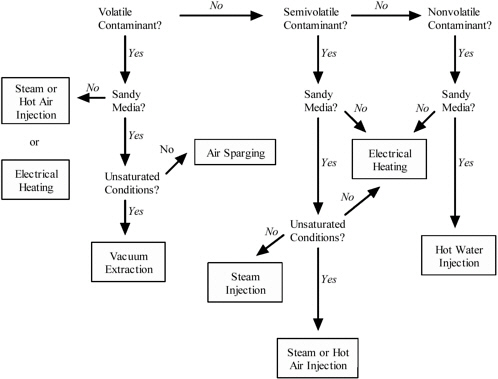

Each of these thermal treatment methods is applicable only to certain types of sites and contaminants. The permeability of the media, the amount and type of heterogeneity, the amount of sorption, and the solubility of the contaminant must all be considered. For example, electrical heating may be favored in low-permeability media and when there is significant heterogeneity. Hot air or RF heating may be more applicable for highly soluble contaminants where drying of the soil may be necessary, and higher temperatures and/or longer remediation times may be necessary when adsorption is significant. Figure 5-4 can be used to determine which of the techniques is most applicable in a given situation; in some cases, more than one technique may be applicable, such that the selected technology is often the least severe in terms of temperature and pressure requirements (Davis, 1997).

A second important point is that each of these thermal treatment

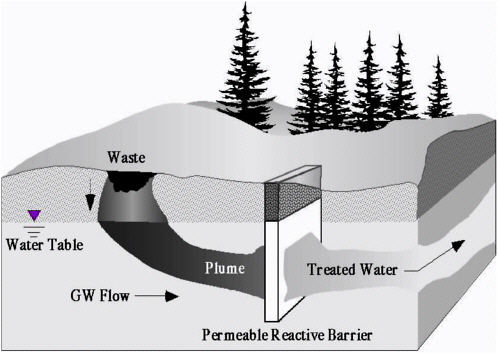

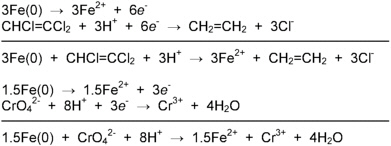

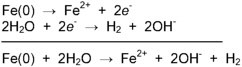

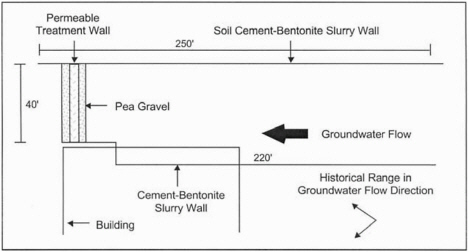

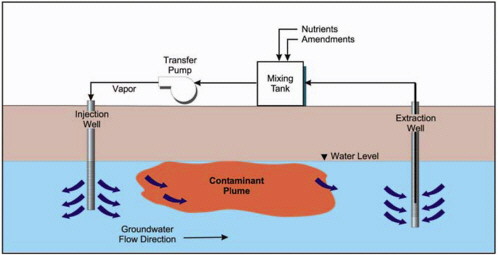

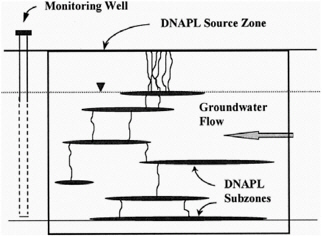

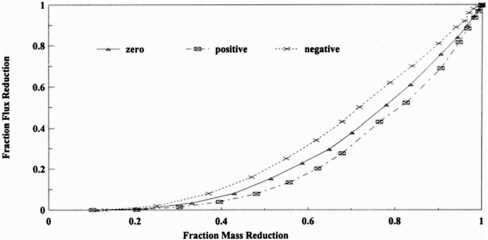

methods is completely dependent on the capture effectiveness of the newly mobilized contaminant. With the possible exception of hot water flooding, all thermal remediation technologies require a highly effective soil vapor extraction system as the ultimate contaminant removal mechanism. The soil vapor capture system must be capable of overcoming condensate formation in situ and in above-ground equipment; it must be capable of fully capturing the “flash” volatilization of heated nonaqueous phase liquid; and, where applicable, it must be designed to effectively capture contaminants mobilized in the saturated zone. Groundwater extraction systems are often used in concert with soil vapor extraction systems at sites where contaminants are present in or adjacent to the saturated zone.