Appendix B

REMEDIATION CASE STUDIES

Many methods for remediation of contaminated soil and groundwater are characterized by an initial phase of relatively high effectiveness, followed by a prolonged period of much lower effectiveness. This appendix includes case studies that document this system performance over time. These studies can be found in the general scientific literature, as well as in various reports issued by the U.S. EPA, DOE, and other government organizations. The case studies summarized here are all taken from a set of volumes published by the U.S. EPA under the auspices of the Federal Remediation Technologies Roundtable (FRTR). This information is available in hard copy, on CD-ROM, or via the web at http://www.frtr.gov. An attempt was made to balance the quality of the available data with the goal of presenting a variety of remediation technologies and contaminants. Only a very small portion of the information contained in these case studies is presented here.

Pump-and-Treat Systems

City Industries Superfund Site, Orlando, Florida (EPA 542-R-98-014)

This is a former hazardous waste Treatment, Storage, and Disposal Facility where the contaminants of concern include chlorinated solvents and BTEX. Maximum contaminant concentrations detected prior to remediation operation include 1,1-DCE (6,000 µg/l), acetone (146,000 µg/l), methylene chloride (165,000 µg/l), vinyl chloride (2,400 µg/l), and

MIB78,000 µg/l). The pump-and-treat system consists of 13 wells installed across the width of the initial contaminant plume.

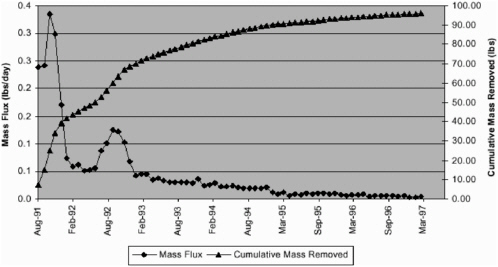

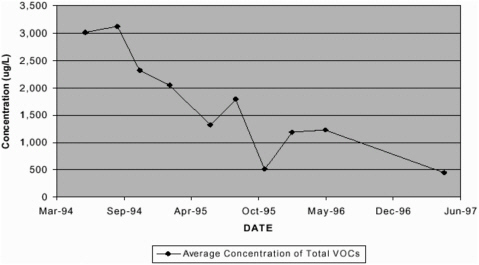

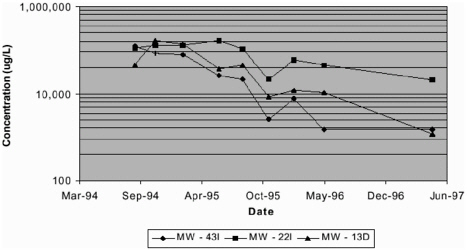

The following figure (Figure 3 in the report) shows the average of the total VOCs in all the monitoring wells at the site. There is a trend of decreasing concentration, but levels of all VOCs remain above cleanup goals. The “tailing” effect is shown more dramatically in the time history of the total VOCs at monitoring wells located in the most heavily contaminated portion of the plume. This figure is also shown below (Figure 6 in the report); note the logarithmic scale for concentration.

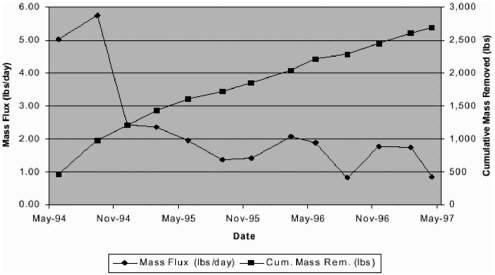

Finally shown is the overall mass removal (daily rate and cumulative removal—Figure 7 in the report). Although the initial mass removal rate is much larger than its value at later times, the rate does not seem to continually decline as observed at many other pump-and-treat sites; that is, the cumulative mass removal seems to continually increase. This is attributed to the relatively homogeneous and high hydraulic conductivity at the site.

Figure 3. Average of Total VOCs in all Monitoring Wells from May 1994 through May 1997

Figure 6. Total VOCs Concentrations in Highly Contaminated Wells, May 1994 through May 1997

Figure 7. Mass Flux and Cumulative Mass Removal, June 1994 through May 1997

United Chrome Superfund Site, Corvallis Oregon (EPA 542-R-98-014)

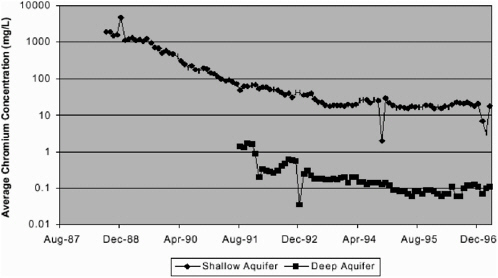

This is an example where the contaminant of concern is a heavy metal rather than an organic compound. The site is a former chrome plating facility that operated from 1956 until early 1985. The site hydrogeology consists of a shallow surficial aquifer about 15 to 18 feet thick, a

relatively thin aquitard, and a deep aquifer about 15 to 25 feet thick. Testing in 1983 to 1984 revealed chromium concentrations up to 3,619 mg/l in the shallow aquifer and 30 mg/l in the deep aquifer. The pump-and-treat system currently consists of nine wells in the upper aquifer and one well in the deep aquifer. This is a subset of the original system which consisted of 23 upper aquifer wells and seven deep aquifer wells; wells were retired from operation as remediation progressed and chromium levels decreased.

The following figures (Figures 2, 3, and 4 from the report) show (1) the time history of the average chromium concentration measured in the extracted groundwater and the mass removal rate and cumulative mass removed for the (2) upper and (3) lower aquifers. The figures show that the system removal rate has decreased over time. Cleanup goals for the site are 10 mg/l for the upper aquifer and 0.1 mg/l (the MCL) for the lower aquifer. These goals have been met at 11 out of 23 wells in the upper aquifer and at six out of seven deep aquifer wells.

Figure 2. Chromium Levels in the Groundwater as a Function of Time

Groundwater Containment at OU1 Area A, Shaw AFB, SC (EPA 542-R-98-012)

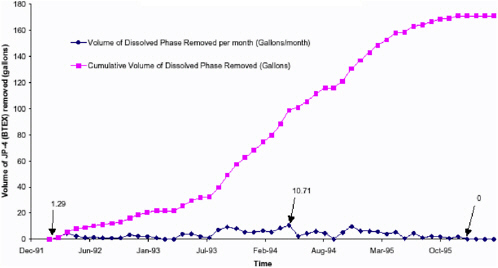

This case study is similar to the Pope Air Force Base case study described in Chapter 3, and it includes a more detailed economic analysis of remediation system cost performance. At this site there is an estimated 400,000 gallons of JP-4 free product, with an extensive dissolved-phase groundwater plume. As part of an Interim Response at Area A, a groundwater containment and free product recovery system were installed. The groundwater containment system consisted of nine recovery wells and a groundwater treatment system.

The performance of the containment and free product removal systems are shown below (Figures 17 and 18, respectively, from the report). It can be seen that both systems eventually reach a point where removal rates are negligible. The free product system also exhibits an early period of low removal rate; the reasons for this are not explained in the report.

Figure 17

Monthly & Cumulative JP-4 Removals vs. Time Dissolved Product (BTEX) OU1 Area A, Shaw AFB

Figure 18

Monthly & Cumalative Volume of JP-4 Recovered vs. Time OU1 Area A, Shaw AFB Free Product

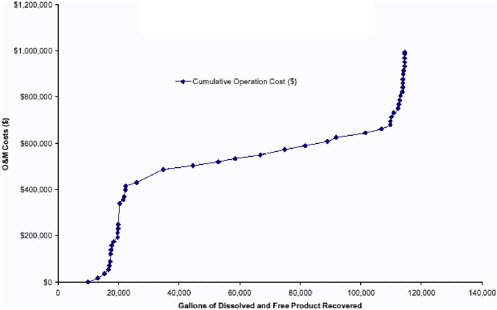

Data were also available on monthly operations and maintenance costs at this site. Combining this data with the removal information gives the graph shown next (Figure 19 from the report). This figure shows the relationship between pollutant removal and cost and again is a dramatic display of how the marginal cost of removal (slope of the curve) increases over time. (The large marginal costs at the start are due to the low effectiveness of the free product recovery system at early time, as previously mentioned in relation to Figure 18). In November 1996 the containment and recovery system was shut down because the operating objectives were no longer being met.

Figure 19

Cumalative O&M costs vs. Volume Recovered Dissolved and Free Product OU1 Area A, Shaw AFB

Soil Vapor Extraction (SVE) Systems

Sacramento Army Depot Superfund Site, Burn Pits OU (EPA 542-R-98-013)

As part of regular operations at the Sacramento Army Depot, a variety of wastes were generated. The Burn Pits Operable Unit was the location of two rectangular trenches constructed in the late 1950s and used intermittently as incineration pits until 1966. Materials reportedly buried and/or burned in the pits included plating shop wastes, oil and grease, batteries, and construction debris. Studies in 1981 revealed that groundwater under a portion of the Depot was contaminated, and the most likely source of contamination was identified as the burn pits.

A Record of Decision (ROD) for the Burn Pits OU was signed in 1993. In addition to soil excavation and institutional controls, the ROD required SVE for all soils in the area containing VOCs. The SVE system used was a special patented fluid injection/vapor extraction system, that included both injection and extraction wells to produce relatively larger

subsurface pressure gradients and higher flow rates of extracted vapors than would be achieved using conventional vapor extraction technology. The SVE system was operated from May 1994 to January 1995 and again from March 1995 to September 1995, for a total of 347 days of run time.

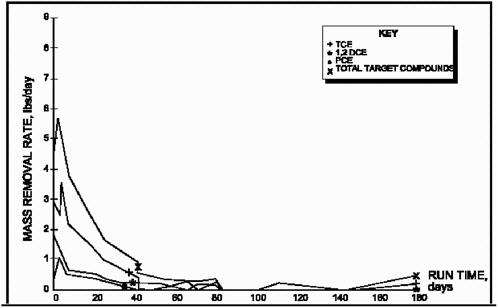

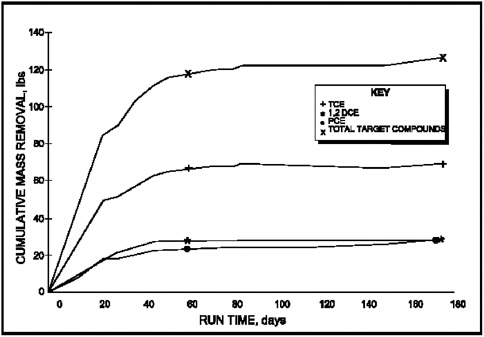

The mass removal rate and cumulative mass removal of TCE, PCE, and 1,2-DCE for the first six months of operation are shown in the figures below (Figures 7 and 8, respectively, from the report). Again, these figures demonstrate typical “tailing” behavior; for example, the mass extraction rate decreased from an average of 4 lbs/day during the first 20 days of operation to less than 1 lb/day after 40 days of operation. More than 80 percent of the total mass was removed during the first 42 days of operation. Soil borings collected in September 1995 after the system was shut down confirm that the average concentrations of each of the three target compounds were less than the cleanup standards set in the ROD.

Figure 7 Mass Removal Rates of TCE, PCE, and 1,2-DCE

Figure 8 Cumulative Mass Extracted of TCE, PCE, and 1,2-DCE

Intersil/Siemens Superfund Site, Cupertino, CA (EPA 542-R-98-012)

At this site, TCE contamination of soil and groundwater was caused by leaks and spills of solvents used in semiconductor manufacturing. In order to address soil contamination, an interim SVE system consisting of four vertical extraction wells began operating in May 1988, and as part of the final remedy specified in the ROD this system was expanded in May 1991 to include three additional wells.

The mass removal rate over time is shown below (Figure 2 in the report). It can be seen that the removal rate for TCE decreased from approximately 15 lbs/day to less than 0.5 lbs/day from May 1988 to December 1992. The system was shut down in August 1993, after determination that the remedial goal of 1 mg/kg total VOCs had been satisfied.

Figure 2. SVE Total System Removal Rate and Cumulative Removal Mass of TCE (May 1998 - Dec 1992)

Thermal Processes

Broadhead Creek Superfund Site (EPA 542-R-98-013)

This is the site of a former coal gasification plant that operated from 1888 until 1944. Coal tar from these operations was disposed of in open pits. Free phase coal tar was identified at the site, in addition to soil and groundwater contamination with PAHs, other SVOCs, VOCs, and metals. An enhanced thermal recovery process was selected for removal of free-phase coal tar from the subsurface soils. The Contained Recovery of Oily Waste (CROW)TM process was used; this involves injection of hot water to decrease coal tar viscosity and recovery of the water and coal tar via extraction wells.

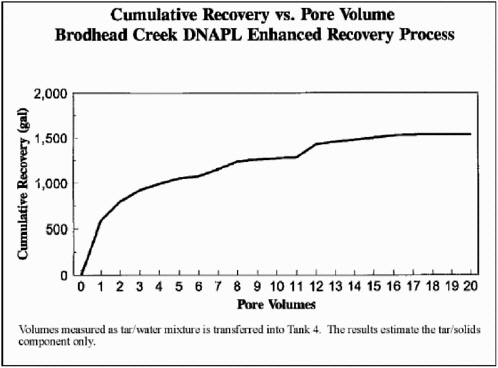

It is much more difficult to estimate recovery for this process than for conventional pump-and-treat and SVE processes. Nevertheless, an estimate of the cumulative recovery as a function of pore volume is given in the graph below (Figure 4 from the report). It can be seen that the majority of the coal tar recovered occurred in the during the early stage of operation; for example, approximately half the coal tar was recovered in

Figure 4. Estimated Cumulative Recovery of Tar Over Life of Project

the first three pore volumes, while an additional 17 pore volumes were required to recover the second half. The CROW TM system was in operation from m December 1994 until June 1996, when the EPA determined that the performance standard had been met.

Innovative Technologies

There are a number of case studies that considered technologies such as permeable reactive barriers (PRBs), air sparging, and in situ bioremediation, usually in conjunction with pump-and-treat systems. In general, the data for these newer technologies is less developed than for the case studies presented above.

Pump-and-treat and Permeable Reactive Barriers to Treat Contaminated Groundwater at the Former Intersil Site, Sunnyvale, CA (EPA 542-R-98-015)

This is a chlorinated solvent site at the location of a semi-conductor manufacturing facility. A pump-and-treat system operated at the site from 1987 to 1995. The original system was expanded in 1989 and 1991. The mass removal by the pump-and-treat system was steadily declining over time, as would be expected.

Due to the declining efficiency of the pump-and-treat system, in 1993 Intersil examined alternative technologies. The selected technology was an in situ granular iron treatment wall system. The added benefit of this technology is that it would allow Intersil to dismantle the pump-and-treat system and return the property to leasable/sellable conditions.

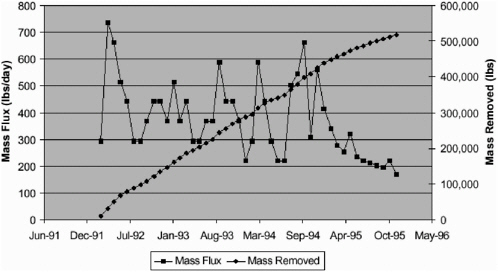

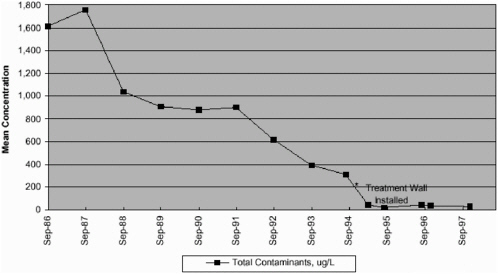

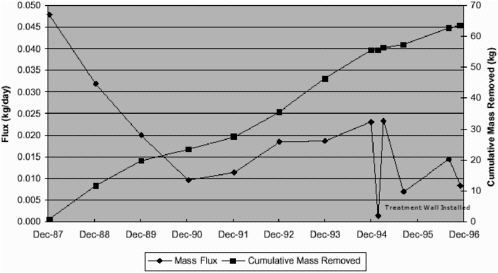

The following figures (Figures 4 and 5 from the report) show the average concentration in monitoring wells across the plume over time, and the mass removal rate. Although it appears that the treatment wall has a lower mass removal rate than the pump-and-treat system, the former technology is passive and should be less costly over the long term. Also, use of the treatment wall had the added benefit of allowing sale/lease of the property. (No information was given whether or not such a transaction has occurred.)

Figure 4. Total Contaminant Concenrations in the Groundwater(1987-1996)

Figure 5. Total Contaminant Mass Flux and Mass Removed as a Function of Time (1987-1996)

Pump-and-treat and In Situ Bioremediation at the French Ltd. Superfund Site, Crosby TX (EPA 542-R-98-015)

This was a former sand mine site that was permitted by the State of Texas to accept industrial waste from 1966 to 1971. The facility’s permit was revoked in 1973 and it was placed on the NPL in 1981. Contaminants of concern in groundwater include benzene, toluene, chloroform, 1,2-DCA, and vinyl chloride.

Active remediation was conducted at the site from January 1992 through December 1995. Initially groundwater extraction and above-ground treatment was used. Then an enhanced in situ bioremediation strategy was instituted. Nitrate and diammonium phosphate was mixed with clean water and injected for 90 days, followed by injection of oxygenated water for 44 months.

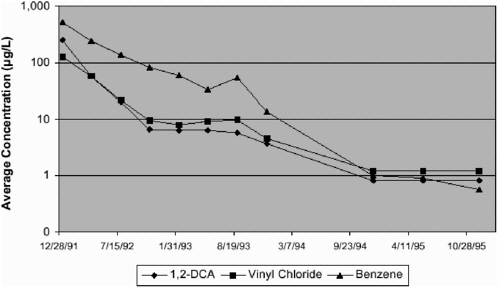

The figures below (Figures 3 and 5 from the report) show the time history of average contaminant concentrations in monitoring wells and the mass removal rate. It can be seen that the contaminant levels are declining. There was no documentation provided regarding what portion of the removal could be attributed to in situ bioremediation.

A modeling study conducted in 1995 demonstrated that natural attenuation would reduce contaminant concentrations below the remedial goals within ten years after shut down of the system. As a result, EPA allowed active systems to be shut down in December 1995.