CHAPTER FOUR

Energy and Power Materials

CHAPTER SUMMARY

The flow of energy and power forms the lifeblood of military systems. The Panel on Energy and Power Materials was formed to examine advanced materials and processes in this area. Every other panel of the full committee also contributed to identifying challenges to be met in energy and power materials.

DoD needs for energy and power materials are many, among them:

-

Batteries for energy storage, from small portables to large shipboard units,

-

Capacitors for storage and release of pulsed power,

-

Fuel cells for efficient direct conversion of chemical to electrical energy for platform power,

-

Photovoltaics for harvesting energy from the environment,

-

Explosives for enhanced and tailorable lethality, and

-

Microturbines for powering small unmanned aerial vehicles (UAVs).

Because this area is so broad, a comprehensive study was not possible. Instead, the panel identified key materials aspects of each major application and derived broad themes for materials research. Areas identified were those where DoD funding would be needed due to the lack of commercial interest, highlighting differences in commercial and military requirements. Major research themes identified are

-

Nanomaterials science and engineering for control of structure and properties at the nanoscale;

-

Engineering interfaces and surfaces in materials by tailoring material structure to optimize rate and extent of reaction processes;

-

Advanced energy storage and conversion materials;

-

Tools for accelerated, systematic materials discovery, both analytical and experimental, e.g., computational materials science and combinatorial materials science; and

-

Materials as the foundation for systems, based on systems approach to materials in which the entire suite of material properties relevant to a class of applications is identified as early as possible to avoid point solutions.

Successful pursuit of these themes will provide numerous benefits to the DoD, including:

-

Reduced development time and cost;

-

Increased energy density in storage devices, with associated weight reduction;

-

Improvements in lethality of munitions, including increases in range and payload;

-

Practical energy-harvesting devices to allow capture and storage of solar radiation in the battle area; and

-

Reduced weight of energy and power systems, which will reduce soldier and system payload.

Additional information on DoD needs, research themes, and benefits is provided in the body of this chapter and in Appendix D.

INTRODUCTION

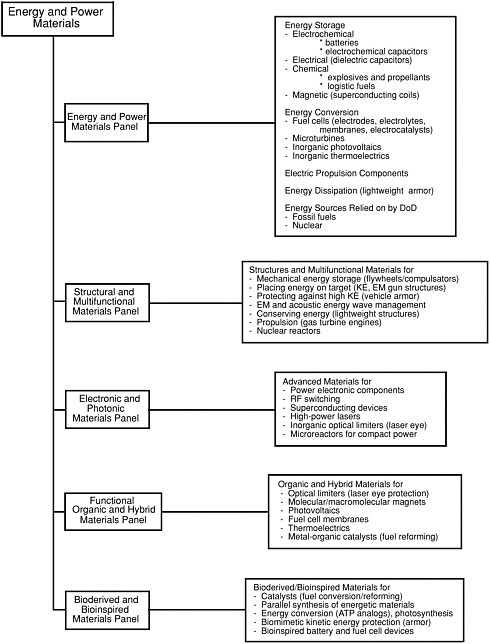

Energy and power are ubiquitous in DoD platforms. To satisfy the broad-ranging charter given to this committee, a separate Panel on Energy and Power Materials was appointed to treat such subareas as batteries, fuel cells, and energetic materials. Other panels addressed specific energy and power areas that fell within their purviews. As an example, biological materials approaches to power and energy (e.g., ATP analogs) were covered by the Bioinspired and Bioderived Materials Panel (see Chapter 7). Figure 4-1 identifies which panels covered which energy and power materials subareas.

Under energy storage, the Panel on Energy and Power Materials examined materials challenges for electrical, electrochemical, chemical, and magnetic storage of energy. This area included materials for improved batteries and for capacitors, both electrical and electrochemical, as well as chemical energy storage in the form of explosives, propellants, and fuels that could provide a significant advantage to the military in 2020. Explosives and propellants are developed almost solely by government entities or their industrial contractors. While the scientific literature was examined, the information available likely reflects work already known to DoD. In this case, the most important contribution of the panel may have been to identify opportunities that are not being pursued aggressively due to limited budgets and a current focus on immediate needs and near-term payoff. Also, while mechanical energy storage (particularly in flywheels/ compulsators) is important to DoD, the associated issues are largely structural (see the work of the Panel on Structural and Multifunctional Materials reported in Chapter 3).

The panel also examined challenges for efficient conversion of energy from one form to another. The most important component in this category, for both small-scale and large-scale energy conversion systems, is the fuel cell. The panel also examined materials for inorganic photovoltaic (PV) devices—organic PV materials were covered by the Functional Organic Materials Panel (see Chapter 6). The Energy and Power Panel also considered the conversion of chemical energy into thrust in very small-scale applications via microturbines, while the Structural Materials Panel addressed materials for larger gas turbine engines.

Materials challenges to fielding advanced weapons, i.e., placing energy on-target, were considered by the panel only in the context of energy storage or conversion, because many of the components of these weapons use materials within the purview of other panels. Materials for advanced high-power lasers, for instance, were addressed within the Panel on Electronic and Photonic Materials (see Chapter 5). Similarly, the problems with materials for advanced gun tubes and for electromagnetic launch rails primarily relate to erosion, wear, and structural integrity, again more aligned with the mission of the Panel on Structural Materials. However, the Panel on Energy and Power Materials did consider the development of materials for energy storage at high levels that might accelerate associated applications.

The need to dissipate concentrated energy and protect systems against its effects is ubiquitous and was addressed by several panels. Materials

challenges for effective kinetic energy dissipation (e.g., novel armor) were addressed by the Panel on Energy and Power Materials (transparent armor and body armor) and the Panel on Structural Materials (integrated structural armor and protection of large platforms). In both cases, information on potential performance improvements from combining new materials with new design approaches was difficult to obtain, because that information was often classified. Materials challenges for hardening against other forms of energy (e.g., acoustic, thermal, radar) are discussed in Chapter 3 in the examination of multifunctional materials.

DoD dependence on natural energy sources was considered, in relation to DoD platforms rather than fixed installations. Accordingly, less emphasis was placed on sources such as water and wind power. Solar energy was recognized as having some potential for use in energy conversion devices for platforms and individuals. The panel did look at materials that could significantly improve DoD’s ability to harvest energy from alternative sources, thereby improving field power-generating capability while decreasing the logistics burden of supporting expeditionary forces. Potential shifts in the reliance of DoD on natural sources such as fossil fuels were examined only briefly because the need for changes in U.S. energy sources, particularly a shift from fossil fuels to more rapidly renew-able resources, has been well documented. If petroleum-based fuel prices were to accelerate dramatically, a substantial U.S. initiative to find and apply alternative energy sources would likely result, with DoD being one major beneficiary. The potential need by 2020 for fossil fuels, as well as future dependence on nuclear power, are also discussed in this chapter.

DOD NEEDS FOR ENERGY AND POWER MATERIALS

Virtually every DoD system requires energy and power to function. Attaining higher energy and power levels in a smaller package is a continual goal in development of new materials, manufacturing processes, and design approaches. Examples are

-

Battery materials (small, ultralightweight power cells to large submarine batteries);

-

Fuel cells (direct conversion of chemical to electrical energy across a range of applications);

-

Capacitors (pulsed power for electromagnetic launch of projectiles, aircraft, etc.);

-

Explosives and propellants (insensitive yet possessing higher energy density);

-

Advanced individual body armor (to offset the increased lethality of individual weapons);

-

Novel power system components (for all-electric weapons platforms); and

-

Components for harvesting energy from the environment (e.g., photovoltaics, thermoelectrics).

These examples are illustrative only; an exhaustive list of energy and power applications would require enumeration of every DoD system.

SPECIFIC AREAS OF OPPORTUNITY

In the sections below, DoD needs for energy and power materials are examined in specific categories:

-

Energy storage,

-

Energy conversion,

-

Electric power generation and transmission,

-

Kinetic energy dissipation, and

-

DoD reliance on energy sources.

Additional information on materials for specific applications is provided in Appendix D.

Energy Storage

In any system, the rates of energy storage and consumption, combined with the total energy available, determine how long the system will be effective, i.e., the system run time. From this standpoint, the ideal system would have an infinite reservoir of energy (or infinite rate of energy storage) and a negligible rate of energy consumption. While real systems never approach these limits, there is nevertheless a continuing drive for approaches that can store large amounts of energy in small packages and use it efficiently. In materials terms, advanced energy storage requires materials having high volumetric and gravimetric energy densities.

Although storing electrochemical energy in batteries may be most familiar, energy can be stored in many forms: chemical (in fuels and

explosives); mechanical (flywheels); electrical (capacitors); thermal (solids, liquids, or gases); magnetic (superconducting circuits); and potential (reservoirs). This report focuses on energy storage in the forms most traditionally associated with DoD platforms and systems.

The future of materials science as it relates to energy storage systems is exciting. For electrochemical systems, advances in nanomaterials can yield ionically conducting electrolytes that can provide both high power and high safety. New discoveries promise high-energy electrode materials and more stable electrolytes that will greatly increase the energy content of current batteries for applications ranging from the dismounted soldier to submarines. Tailored interfaces will increase the lifetime of electrochemical power systems and make them capable of power pulses well beyond what can be delivered today, including in radio burst communication from ground to satellite. Similarly, electrical energy can be stored in dielectric capacitors for use in pulsed power systems for high-energy lasers, railguns, and other advanced weapons.

Materials that are extremely mass-efficient in storing chemical energy are important for DoD. These “energetic materials” will enable the lighter, more lethal force structure envisioned by the Army beginning now and continuing through 2020.1 A driving goal for much of the DoD-wide system transformation is a shift to smaller platforms with increased lethality.2 Higher-energy-density explosives and propellants combined with precision targeting systems translate into smaller warheads, enhanced penetration, longer range, and reduced ammunition logistics support.3 In addition, novel propellant materials may be able to reduce launch signature, thus increasing survivability by reducing detectability.4 This class of materials includes chemical fuels for platform mobility, which now account for some 70 percent of war tonnage shipped to combat locations

(Potomac Institute, 2000) and which are absolutely essential for a wide range of platforms. In addition, energy stored in magnetic fields can reduce the effects of short-term power disruptions. Novel superconducting materials that may increase storage efficiency and decrease the size and complexity of the storage system are discussed later in this chapter.

What energy storage technology will best meet DoD needs? A single answer is not possible, because all power sources have their “sweet spots” (areas of best application), and this panel envisions that a range of energy storage (and conversion) technologies will be important. For example, low-power needs (usually for electronic devices) are optimally met by storage in batteries. Other applications require other technology choices, from storing energy in a highly concentrated, liquid fuel form for use in internal combustion engines to storage in capacitors for high-power directed energy weapons.

The National Academies have published two studies of the use of power sources for defense applications, Energy Efficient Technologies for the Dismounted Soldier (NRC, 1997) and Reducing the Logistics Burden for the Army After Next (NRC, 1999). Both highlight the importance of developing advanced technology for power sources, including batteries, for DoD applications. This study builds on these documents.

The sections that follow discuss novel materials and processes for use in storing energy. Additional information is provided in Appendix D.

Electrochemical Energy Storage

Background: Batteries and Electrochemical Capacitors Batteries and electrochemical capacitors are energy storage devices that convert chemical into electrical energy and are particularly suited to provide the energy to power electrical devices. They cannot be easily replaced, and are very likely to be an essential element in any future military power applications. Their simplicity (no moving parts), reliability, and wide power capability make them attractive as stand-alone power systems or as enabling elements in hybrid power system configurations. Additionally, batteries are the best option for stealthy operation. They produce power with no noise, no heat signature, no intake of oxygen, and no exhaust gas. Special Operations Forces will always need better batteries.

Moreover, while there are more efficient ways to store energy, few other devices can match the attributes of batteries and electrochemical capacitors. Of particular importance is the fact that very few other power sources have a wide enough dynamic range to efficiently deliver power to

follow a dynamic load over three to four orders of magnitude. Several types of batteries have this feature, which is of particular importance in very high power applications and in hybrid power sources (ones that have a tailored power source with a high energy component and a high power component designed to work together for optimum performance).

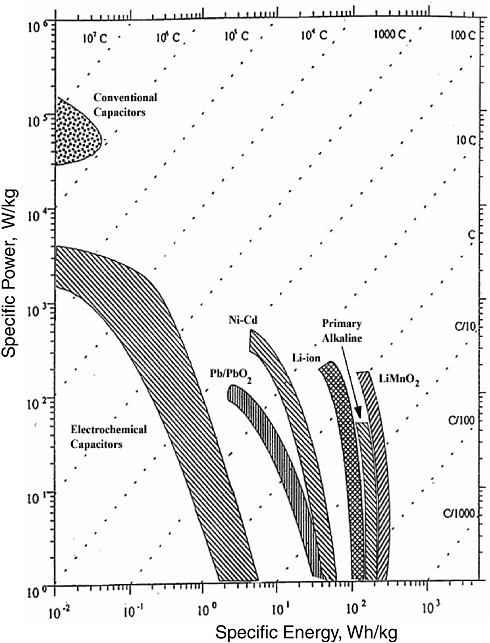

Batteries are electrochemical cells that have two electrodes, an anode and a cathode. During discharge, the anode is oxidized and the cathode is reduced. The electrolyte (solid or liquid) is ionically conductive, allowing ions to be transported between the electrodes. In these systems, the electrons are driven through an external circuit to power electronic devices. Batteries can be disposable (a primary cell) or reusable (a rechargeable or secondary cell). Electrochemical capacitors also have two electrodes separated by a separator having an ionically conductive electrolyte, but their energy can be composed of double layer capacitance (DLC) or it can be stored in Faradaic processes (much like a battery). Either way, they are rechargeable devices designed to have a very high cycle life. Like conventional capacitors, electrochemical capacitors have higher power and lower energy than rechargeable batteries. Figure 4-2 demonstrates the comparison.

DoD system energy and energy storage requirements vary enormously, ranging from tiny batteries to power man-portable communication systems to huge systems to power submarines. Diversity in capacity, physical size, weight and shape, drain rate capability, thermal performance, cycle life, shelf life, and cost make it impossible to define a single optimal battery. The need for a systems approach to finding new materials to match power source to application for DoD will be a continuing theme of this chapter.

Both batteries and electrochemical capacitors can deliver energy over a wide power range, making them well suited to hybrid power systems. A timely example is the hybrid electric vehicle (HEV), which contains both an internal combustion engine (ICE) and a battery pack. The ICE can operate at peak efficiency to charge the battery pack, which in turn provides power for propulsion. Properly designed, one can have the benefits of both systems—the high energy content of a liquid fuel and the high power of a battery.

Military-Unique Requirements There are specific military requirements that limit the use of commercial off-the-shelf (COTS) power sources, among them differences in required power and energy levels, in temperature operating range, in the need for shock resistance, in the requirement

for longevity, and in reliability. Except in HEVs, high-power batteries are generally not needed in the commercial marketplace, and even the HEV is not in a performance realm that can meet future DoD requirements. Operation in a broader temperature range and under more rigorous environmental extremes will be necessary. The military has a greater need for increased shelf life and lower self-discharge rates than typical commercial batteries offer. Furthermore, commercial devices are not held to the same reliability standards as those required by the military.

The reliability driver for commercial power sources is to minimize warranty expenses; the reliability driver for future DoD systems is mission success and soldiers’ lives. Such differences are typified in Figure D-2 on naval batteries (see Appendix D). Materials R&D will be necessary to help fill these gaps.

Research Challenges and Materials Opportunities To translate technology needs into materials needs, one must map the system requirements to the materials domain. From a materials perspective, battery performance is dictated by materials selection and stability (Salkind, 1998; Doughty, 1996). Intrinsic properties of the active electrode materials determine the cell potential, capacity, and energy density. The stability of interfaces between reactive materials dictates calendar life and cycle life (in rechargeable systems); safety depends on the stability of materials. Because battery performance depends heavily on tailored stable interfaces, it is here that solutions will be found.

Nanomaterials Nanostructured materials are of wide interest in research programs today. They hold the promise of tailored and engineered materials that were inconceivable a few years ago. Continuing these advances will provide important benefits for power sources if they can be reliably produced and stabilized so that their nanostructure (and associated properties) remain relatively constant over extended use. Specific areas that will benefit are tailored electrode materials and electrolytes.

New processing methods for advanced micro- and nanostructures is one fertile area. While high-power electrodes require high-surface-area materials, processing often does not allow the technology to take full advantage of the material. Nanostructured materials combined with a one-step deposition process or a self-assembly approach to fabricating the electrode may overcome these limitations. Tantalizing initial steps are

already being taken; more effort should be devoted in the next two decades to make such nanostructural processing a reality.

Similarly, thin-film processing techniques have been shown to overcome certain failure mechanisms (using glassy electrolytes to avoid lithium dendrite formation—see below) and have extended the cycle life by over two orders of magnitude (Bates, 2000). Pulsed laser deposition of active materials holds promise (Singh et al., 2000), as do thin-film/thick-film deposition techniques, such as plasma spray and plasma-assisted chemical vapor deposition (CVD). Further extensions of these methods, combined with wholly new approaches, are required. An example is fabrication of the battery layer by layer with solid-state materials. In this approach, the cathode and anode could be surrounded by materials that have, respectively, cathodic and anodic stability. The increase in calendar and cycle life and in high-power delivery could be dramatic.

Tailoring morphology and texture of the electrode material to form high-surface-area composites is another promising area. Mesoporous materials in which nanometer-sized domains are interconnected in a porous electrode can provide up to 100 percent greater capacity than polycrystalline nonporous V2O5 powers, with exceptionally high rate capability (Dong et al., 2000). This is believed to result from increased electrode capacitance, not just larger Faradaic capacity. High-capacity anodes are made from nanostructured alloys or metal/oxide composites. In both cases, large-volume expansion upon charge can be accommodated with in-situ formation of nanostructured electrodes on the first charge, resulting in higher capacity and capacity retention on cycling (Poizot et al., 2000). Nanostructured electrochemical capacitor electrodes providing much higher capacitance (nearly 700 F/g) are also being investigated (Pang and Anderson, 2000). Metal oxides like RuOx have very high capacitance but are quite expensive. Producing other metals with high redox activity in a nanostructured state could heighten capacity and improve volumetric efficiency for supercapacitor electrodes.

Electrolytes for polymer systems have been a huge challenge for technology developers. The “polymer batteries” that are now becoming commercially available employ gel electrolytes that have more in common with liquid electrolyte systems than with true polymer systems. Shape flexibility, lower weight, negligible magnetic signature, and small form factor are important advantages. Nanostructured electrolytes could provide breakthrough technology. For example, organic/inorganic composites hold

the promise of creating new ionically conducting channels in polymer systems that are not limited by the current mechanism responsible for ionic mobility—segmental chain motion in polymers. Self-assembled nanostructures have already been described for use in electrolytes (Bronstein et al., 2001). Improvement in conductivity and transference number have been observed with nanostructured clays in polyethyleneoxide (PEO) (Riley et al., 2000) as well as nanoparticulate oxides in PEO (Croce et al., 1998).

Composites can alter the mechanism of ionic transport, suggesting the possibility of high conductivity, with ionic transport near unity of the “working ion” (e.g., Li+) (Sata et al., 2000). Advances in this area will have application in high-power batteries because they will have low internal impedance and be able to operate over a wide temperature range. For example, if ionically conducting perovskites (like (Li1–xLax)TiO3) could be self-assembled in a polymer film to form ionically conducting channels in a thin-film electrolyte, they might provide room-temperature ionic conductivity as well as serve as a robust separator to enhance safety.

Interface Science Interfaces lead to many problems in batteries and electrochemical capacitors. For example, calendar life deteriorates in lithium ion rechargeable batteries when resistive decomposition products are deposited at the cathode. The power of electrochemical capacitors would improve if the interfaces (where charge is actually stored) were engineered to provide electrochemical stability as well as optimum charge storage. Of major interest to DoD applications would be improved performance at higher frequencies. Little work is now funded on interfacial chemistry as it relates to power sources.

An example of a practical need is stabilizing lithium metal electrodes in rechargeable batteries. The payoff is 2-3 times greater energy density, but the problem is safety. Repeated charging and discharging produces Li dendrites that rob capacity and create a safety hazard by producing a fine pyrophoric Li powder. Tailoring the interface with new additives or by creating ionically conducting nanostructured polymeric or glassy layers on the metal surface could profoundly affect the safety of high-energy-density batteries. Examples are thin oxide layers that are ionically conducting. Currently, lithium phosphorous oxynitride (LiPON) glass is used as the electrolyte for planar batteries. This material can be improved. Other materials might be developed that are ionically conducting like

(Li1–xLax)TiO3 perovskites, that are stable in these environments, and that stabilize the Li surface by forming a graded interface.

New Electrode and Electrolyte Materials Every few years, the materials community is surprised by the discovery of new materials with unexpected properties that prove extremely useful. Examples are high-Tc superconductors and new electrode materials. Research into cathode materials has centered on layered transition metal oxides (e.g., LiCoO2 and related compounds). A new material, LiFePO4, has similar capacity (at low rates) and dramatically improved safety at a fraction of the cost of existing materials, but presently it has very poor electronic conductivity, making it a laboratory curiosity. Investments in new electrode materials will likely yield other new materials with improved performance, new electrolytes with improved conductivity, and new processing techniques (enabling new concepts in microbatteries).

Metal/air and metal/water batteries have some of the highest energy content of any battery systems but materials problems have prevented their widespread use in large applications (Hamlen, 1995). Water management and carbonation of alkali electrolytes remain roadblocks. New polymeric membrane materials that address these problems could have a major impact, as would semipermeable membranes that transport moisture and exclude CO2. Advances in tailored membrane materials and controlled porosity and surface chemistry could be targeted to this application.

Computational and Combinatorial Materials Science “Materials by design” is an appealing approach because it can dramatically shorten the time to develop advanced materials. While it can apply to nanostructured materials, it is a more general concept that may be used to tailor materials microstructure. Therefore, computational materials science should be an integral part of any systematic materials discovery effort. In particular, advanced computational techniques that model performance of materials in active electrochemical environments can point the way to new and potentially revolutionary battery materials.

Similarly, combinatorial chemistry should be employed where possible. It has been used with success in the biological sciences and in drug discovery, and it is appearing in the materials science arena. Initial work is now underway on preparation of alloy anode materials using this approach, but it is limited by the lack of rapid screening techniques. Investments in this area will dramatically shorten the time to realization of

electrochemical materials that can have a beneficial effect on DoD power sources.

Materials for Dielectric and Magnetic Energy Storage

Appendix D summarizes material requirements and prospects for storing electrical energy as separated charge in a dielectric material like a ceramic or a polymer. Compared to other forms of electrical energy storage, such capacitors are lower in energy density but higher in power density, and they are more readily cycled at high frequencies. Pulsed power applications for future DoD systems may require from 0.4 to 40 MJ/discharge, with an average instantaneous power of 0.5 to 7 Gwatt.5

Future ceramic-based power capacitors will require novel formulations and processing methods for tough, defect-free, low-loss ceramic and glasses for use in configurations that are scalable to different sizes to meet different application needs. Recent advanced materials approaches have focused on improved mixed-oxide perovskites, diamond-like carbon, and high dielectric constant ceramics produced using thin-film techniques. Here as elsewhere, computational chemistry, combined with the ability to control structure down to the nanoscale, should pay tremendous dividends. Recently, polymer blends having high dielectric strength and dielectric constant (>8.0) combined with low loss have been produced through physical alloying of polymers. Similarly, PVDF copolymers with nanodomains generated by irradiation have been produced, which suggests the possibility of attaining very high specific energy storage levels (20 kJ/kg) compared to current materials (Clelland et al., 2000).

The use of electromagnetic fields to structure composites that contain micron and submicron particles should also be examined. This approach has already resulted in materials with unusual properties. Simulations of materials made using this principle have shown that field-structured dispersions of high-dielectric-constant nanoparticles of uniform size possessing organic capping layers may greatly increasing the dielectric constant of composite polymeric thin film.6 Whether this approach improves upon or detracts from other properties essential to power capacitors remains to be determined. Also, though the material properties of numerous potential high-dielectric-constant materials have been evaluated in the laboratory, few have been evaluated as part of a system or subsystem,

where questions about how material properties translate into device performance could be answered relatively inexpensively and straightforwardly.7 This subsystems-level examination should be considered as it would provide DoD the ability to identify potential capacitor material candidates rapidly and with greater precision than is now possible.

Magnetic storage is another way to ensure a ready reservoir of energy. Commercially available superconducting magnetic energy storage (SMES) systems can instantaneously release stored electrical energy to mitigate short power outages or voltage sags, whether AC or DC. The current systems are large and located in fixed installations or sized to fit into the trailer of an 18-wheeler. Materials advances in high-Tc superconducting materials will enable these to operate at temperatures above 77 K, permitting a switch from liquid helium to the more readily available liquid nitrogen. Miniaturization of high-power conversion systems using advanced materials combined with smaller cooling systems will lead to SMESs that are more easily deployed, providing stable, highly reliable, and readily available power for sensing, control, communication, and data processing on the battlefield or on board all-electric ships. To take advantage of these capabilities, materials R&D effort should concern itself first with increasing the Tc and Jc of HTS ceramics and ceramic composites; increasing processability of these new materials while decreasing their cost; exploring higher Tc and Jc of MgB2 and its alloys; and using combinatorial experiments to identify new HTS materials.

Chemical Energy Storage

“Energetic materials” is a collective term for military high explosives, propellants, and pyrotechnics; it is often used as a synonym for “military explosives” (DoD, 1999). In this chapter, this definition is expanded to include chemical fuels, such as diesel and jet fuel—an important class of materials for powering military platforms. Other fuels, including options for use in fuel cells, are discussed in the section on materials for energy conversion.

Whereas chemical fuel development has been led largely by commercial firms, development of explosives and propellants has been funded almost exclusively by the military, and information about it is often closely controlled. The panel used information obtained from unclassified govern-

mental sources, publications appearing in the scientific literature in specific subareas, such as nanotechnology. The panel notes that research in explosives and propellants has concentrated on insensitive munitions over the years and that funding for new materials has not kept pace with the potential for improvement. DoD has recognized this with the recent formation of the Advanced Energetics Initiative, designed in part to rectify this imbalance. Appendix D provides some background information on development of explosives and propellants and their potential for improvement. The remainder of this section discusses the associated research opportunities.

Propellant and Explosive Materials DoD needs energetic materials that are insensitive (i.e., resistant to accidental explosion) and that offer higher energy densities and the ability to tailor energy release for different uses. Tools exist that can speed the development of energetic materials while reducing the cost and time-intensive testing necessary to verify their performance. These include (1) computational materials science in materials design to help identify promising new molecules and formulations; (2) novel syntheses, including the use of combinatorial chemistry for materials discovery; (3) improved processing methods; (4) new characterization techniques; and (5) advanced modeling techniques to predict the effects of testing. These are key enabling tools referenced repeatedly in the panel’s deliberations.

Because this study was not classified, it may not take into account areas known to DoD that have high promise. Key materials-related research areas identified by the panel as having high promise are

-

High nitrogen/polyatomic nitrogen energetic molecules,

-

Nanotechnology for energetics,

-

Reactive intermolecular materials, and

-

Nuclear isomers.

Polyatomic nitrogen compounds have the potential to yield propellant materials with double or triple the specific impulse Isp of hydrazine, and also have potential for enhanced explosives.8 These compounds include

unusual nitrogen complexes, such as N5+AsF6− salt, that yield energy by producing nitrogen molecules. The synthesis of this compound, which is stable but produces high heat of formation, was announced in 1999 but it needs additional work to bring it to reality.9 The real payoff, however, may be the discovery of additional molecules of this family. For example, salts employing polyatomic species that include N4 or N8 ions might allow for a 5-6 times reduction in mass for the same payload mass in missiles, making for huge increases in performance. However, proof of concept would require considerable cost and time to demonstrate, to be followed by development of practical processes for processing these materials in quantity.

Nanoscale aluminum powders produced by such processes as gas condensation are now becoming available in commercial quantities; they make it possible to tailor propellant burn rate, allowing for increases in projectile range or in super-thermite reaction velocity.10 Burn rate increases of 30-fold over standard composite rocket propellants have been identified, and more advanced nanocomposites are possible. Although the outcome is still limited by thermodynamics, intimate mixing at the nanoscale may lead to a 40 percent increase in energy density over currently used materials. This should provide higher payload and perhaps decrease munition sensitivity.

Of particular interest in nanocomposite energetic materials are factors like nanoparticle size, size distribution, morphology, surface chemistry, and composition. These variables have all been shown to be important in determining mechanical, barrier, and other properties of nanocomposites (Kornmann et al., 1998; Messersmith and Giannelis, 1995) and will likely control the contributions of nanoscale components in energetic materials as well. However, any effort to examine nanocomposites for energetic materials will likely require sorting through the materials currently used in propellants at larger sizes as well as examining a myriad of alternatives for combination at the nanoscale. Such an effort could benefit greatly from computational materials science and combinatorial chemistry techniques.

While many explosive molecules are intramolecular materials, metastable intermolecular composites (MICs) are clusters of reactant materials

that are in close proximity at the nanometer scale but that are constrained from reacting until they are triggered.11 The focus in MIC materials has changed from thin films in contact to powders. These materials, which include metals reacting with metal oxides (e.g., Al fuel with MoO3 as an oxidizer) are of potential value for both explosives and propellants, in part because the reaction rate is tunable over several orders of velocity because it is possible to vary the intermolecular separation distance of reactants. MICs have the potential to release perhaps twice the specific energy of common explosives like TNT or HMX while providing extra margins of safety because they are insensitive to impact or electrical charge. The potential to tailor reaction rate in propellants or pressure pulses in explosives offers great benefit. MICs are the focus of current interest within DoD and DOE, but without additional resources payoff is unlikely until the midterm.

The panel was asked to identify revolutionary technologies where possible. One such area may be nuclear isomers, though it may take decades for them to be demonstrated successfully, if they can be. Nuclear isomers are nuclides that have the same mass number and atomic number but occupy different nuclear energy states (McNaught and Wilkinson, 1997). These long-lived nuclear excited states could result in high-energy, clean-gamma-ray bursts for a variety of applications; emission is “clean” because energy is released by spindown of the nucleus, with no residual radioactivity.12 In addition to energetic materials, potential applications include satellite power, space propulsion, gamma-ray lasers, and other pulsed power uses. The specific energy is potentially 105 times as great (GJ/ gm, with MJ output pulses) as traditional chemical fuels, yielding enormous payoffs. Much of the research required lies in the realm of nuclear physics and involves studies of x-ray-induced decay, energy release, and isomer lifetimes. However, the participation of radiochemists, materials scientists, and engineers is likely to be necessary to help transform the basic physics research into practical, self-contained DoD systems.

Logistic Fuels An overriding fuels technology concern for the military is logistics. Fewer fuels simplify the logistics burden and improve the ability

to rapidly and flexibly provide energy to the system that most requires it— ideally all military systems would run on a single fuel. Many current military propulsion systems have been designed to use a variety of petroleum-based fossil fuels, such as jet fuel (e.g., JP-5 or JP-8) and diesel. These fuel families are well-established in military applications and supported by a strong logistics infrastructure.

This panel clearly recognizes that new electrochemical propulsion and a power system employing fuel cells are in various stages of design and development, and believes development as outlined in the Energy Conversion section below is essential for DoD applications in 2020. However, this panel also believes that jet fuel and diesel fuel will continue to power most military platforms in 2020 because they have established themselves as workhorse fuels and because of the cost and time required for propulsion system redesign to enable other fuels.

Improvements to today’s logistic fuel technology are expected to be largely evolutionary. An exception may be the use of microscale process intensification in which a large number of microelectromechanical systems (MEMS) devices or mesoscale processors are used in parallel to improve yield, reduce emissions, provide more rapid heat and mass transport, enhance reaction rate, and improve safety. Additional details on the rationale for these conclusions, together with discussion of potential evolutionary improvements, are provided in Appendix D.

Energy Conversion

Conversion of energy from one form to another is of paramount importance to the future of DoD. Many types of devices can be envisioned that allow this interconversion. Foremost among these is the fuel cell, which directly converts chemical into electrical energy. Because there is no combustion, the fuel cell is not limited by the Carnot cycle and therefore offers the potential for very high efficiencies. Materials challenges for fuel cells were of major interest to the panel. Other areas of energy conversion that were examined were MEMS devices for use in microturbine-based systems, and inorganic thermoelectric and photovoltaic materials. For the sake of brevity, discussion of these latter areas is limited to Appendix D, which also contains an expanded section addressing fuel cells.

The panel notes that materials for energy storage and conversion in this chapter are discussed without regard to the specific hardware configuration adopted. Such devices could ultimately appear in entirely new forms

such as integration into (or with) textiles, and the form is largely a processing issue. Also, as discussed earlier and as shown in Figure 4-1, organic photovoltaic and thermoelectric materials were of interest to the Panel on Functional Organic and Hybrid Materials (see Chapter 6).

Fuel Cells

Each of the services has a vision for an all-electric future. The Army has considered electric ground vehicles whose propulsion and drives are combined with an electric or electrothermal weapon system. The Air Force and Navy have promoted visions of the all-electric aircraft and the all-electric ship (see Appendix D). Because fuel cells output electrical power directly, they will be critical to implementing this vision. In addition, fuel cells can be implemented in a distributed way, increasing the combat robustness of the power supply.

While civilian and military fuel cells face some similar development challenges (cost, lifetime, fuel flexibility), military applications place unique demands on fuel cells. For shipboard applications, the fuel cell must be highly tolerant of saline and humid environments and possess high shock resistance; in submarines, fuel cells must be equipped not only with a fuel supply but also with an oxidant supply; for large-scale power needs, military fuel cells would ideally be compatible with diesel fuels such as JP-8 and JP-3, whereas for small-scale, single-soldier applications, rapid startup and high energy and power densities are of paramount importance. It is unlikely that any single fuel cell system will meet the needs of all military platforms, much less both civilian and military applications.

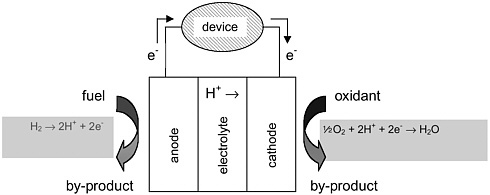

Background Fuel cells are devices that, using as their input some type of chemical fuel, output electrical power. The principle of operation of a fuel cell is illustrated in Figure 4-3 and elaborated upon in Appendix D. The fuel cells developed over the past few decades are differentiated essentially by the type of electrolyte they employ, which in turn determines the temperature at which the fuel cell can be operated. Usually, for reasons of efficiency, higher temperature operation is preferred, but for portable (intermittent) power applications, lower temperature operation is preferred.

Fuel cells offer several attractive features. In particular, (1) they exhibit very high efficiencies, easily 45 percent for high-temperature fuel cells, and even greater efficiencies in hybrid systems; (2) they offer the potential for very high energy and power densities, because they operate on hydrocarbon fuels; (3) they are easily scaled without significant loss in performance

FIGURE 4-3

Schematic of a fuel cell. The overall chemical reaction is H2 + 1/2O2 → H2O. Anode and cathode reactions given are appropriate only for proton-conducting electrolytes. The reactions would be modified for electrolytes with different mobile ions, but the general principle is unchanged.

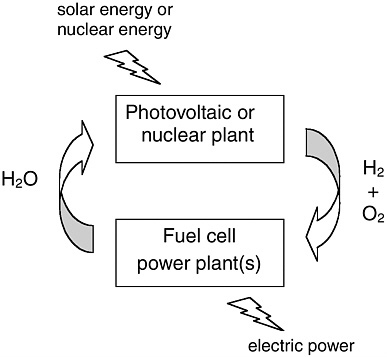

parameters to a wide range of power demands; (4) they are nonpolluting (ultralow NOx and SOx emissions); (5) they can be implemented in a distributed, modular fashion, resulting in a power generation system that is robust under combat conditions; and (6) they can be operated in a closed-cycle system that uses as input solar or nuclear energy and uses fuel cell waste products to generate chemical fuels for reuse in the fuel cell (see Figure 4-4). This latter mode of operation may be particularly advantageous in future military operations, in which shipboard-based nuclear energy and high-efficiency photovoltaic devices could be used to reduce DoD reliance on increasingly scarce fossil fuels. Using electricity to produce hydrogen and oxygen that are then consumed to generate electricity in a fuel cell would reduce its round trip efficiency compared to a battery system (which could also be recharged using this approach). There are applications in which the higher energy density of a fuel cell system may be needed.

Table 4-1 provides information on types of fuel cells and gives conservative values for fuel cell operating conditions; laboratory work to extend the operating envelope to lower temperatures continues. Each of the types listed in Table 4-1 has been demonstrated in complete fuel cell systems, with alkali fuel cells (AFC) and phosphoric acid fuel cells (PAFC) being the

FIGURE 4-4

Fossil-fuel-independent power generation in a fuel cell.

most mature technologies, and solid oxide fuel cells (SOFC) and polymer electrolyte membrane fuel cells (PEMFC) the most recent.

Research Required to Meet DoD Needs The panel addressed the breakthroughs needed in fuel cell research to meet DoD needs within the context of three topical areas: electrolytes, electrodes and electrocatalysis, and fuels and fuel cell system design. It should be noted, however, that advances in one component or aspect will dramatically affect the others. For example, novel electrocatalysis methodologies may simplify system design. A systems approach is therefore essential. Appendix D provides a more detailed technical discussion of research opportunities in the three areas, including an enhanced discussion of ion transport.

Electrolytes A key limitation of performance for all types of fuel cells is the resistance of the electrolyte. Exploratory synthesis of new solid-state electrolyte materials, guided by computational materials science and

TABLE 4-1 Fuel Cell Types and Selected Features

|

Type |

Temperature (°C) |

Fuel |

Electrolyte |

|

Polymer electrolyte membrane fuel cell (PEMFC) |

70-110 |

H2, CH3OH |

Sulfonated polymers (Nafion™) |

|

Alkali fuel cell (AFC) |

100-250 |

H2 |

Aqueous KOH |

|

Phosphoric acid fuel cell (PAFC) |

150-250 |

H2 |

H3PO4 |

|

Molten carbonate fuel cell (MCFC) |

500-700 |

Hydrocarbons, CO |

(Na,K)2CO3 |

|

Solid oxide fuel cell (SOFC) |

700-1000 |

Hydrocarbons, CO |

(Zr,Y)O2–δ |

enhanced by combinatorial approaches, is thus an area ripe for revolutionary fuel cell advances for future defense needs. Solid state conductors of either oxide ions or protons with conductivities of ~10−3 S/cm at temperatures between 25 and 500°C and sufficient mechanical and chemical integrity would completely alter the fuel cell landscape.

A particular example is direct methanol fuel cells (DMFCs). Because of their relative simplicity and minimal auxiliary components, these are considered most suitable for single-soldier applications. In today’s DMFCs, power densities are low because the methanol concentration in the fuel, a mixture of water and methanol, is limited to no more than ~3 percent and the electrolyte is relatively thick. Higher concentrations and thinner electrolytes lead to dangerous levels of methanol crossover (diffusion across the hydrated polymer), which can result in uncontrolled combustion. Zero methanol crossover electrolytes would reduce the amount of unnecessary water carried by the soldier or a supporting robot by a factor of about four while increasing the power density of the fuel cell by at least a factor of two. While civilian applications would also benefit from such electrolytes, the suitability of alternative fuel cell types in many of those applications (e.g., reformate-based PEMFCs) lowers the motivation of the civilian sector to address this challenge.

Electrodes and Electrocatalysis Critical to the function of a fuel cell are the electrodes/electrocatalysts. These components catalyze the electrochemical reduction of oxygen at the cathode and the oxidation of fuel at the anode. Breakthroughs in electrocatalysts would revolutionize fuel cells by giving them fuel flexibility and increasing their power outputs. However, it is not at all clear how such breakthroughs can be achieved, particu-

larly in electrocatalysis of diesel fuels that are of unique importance to the military. The importance of electrocatalysts, combined with the absence of a clear pathway for success, dictate that the military explore a broad range of solutions to improve fuel cell catalysts.

Diesel fuel anode catalysts should be heavily emphasized because these fuels are of lesser interest to the civilian sector. Tools developed in the last few years can and should be effectively leveraged by DoD as part of this effort: (1) combinatorial chemistry methods for quickly finding and optimizing new alloy compositions; (2) computational materials chemistry for guiding exploratory research in identifying new catalysts; and (3) new synthetic methodologies that allow for architectural control of fuel cell electrodes at the nanoscale, potentially enhancing reaction kinetics by dramatically increasing electrode surface area and restricting reactions to confined regions. Though the fuel cell community has yet to take advantage of such advances, it is at the interface between these fields and traditional electrochemistry that the most significant breakthroughs can be anticipated.

Fuels and Fuel Cell System Design It is evident that the choice of fuel is a fundamental question for fuel cell systems. While higher temperature fuel cells can operate directly on hydrocarbon fuels (typically using water to achieve internal reforming), lower temperature fuel cells operate on hydrogen or sometimes methanol. Generating, storing, and transporting hydrogen is a significant hurdle. Hydrogen is typically produced from methane (CH4) or other hydrocarbon fuels in reactors termed “reformers” that yield hydrogen tainted with trace impurities such as CO and H2S. Removing these impurities is of paramount importance for optimal fuel cell performance.

In recent years there have emerged new approaches to generating clean hydrogen from a variety of fuel sources (including coal, which could reduce dependence on imported oil) that warrant further DoD investment. These rely on membrane reactors, which enable the production of high-purity products like hydrogen at rates beyond nominal thermodynamic limits (see Appendix D). Successful operation of membrane reactors requires materials with high hydrogen fluxes, good catalytic properties, and excellent chemical and mechanical robustness. Research in this area is in its infancy, with the majority of work directed at palladium-based membranes and some limited studies of ceramic membranes. Given the potential of such reactors to solve the daunting fuel problem for fuel cells,

additional research on new membranes and nonprecious metal catalysts is warranted.

An entirely different strategy for providing hydrogen for fuel cells is the use of nonconventional fuels, such as ammonia, hydrazine, or sodium borohydrate. As with hydrogen, some other energy source must be used to synthesize these fuels. They offer the advantage, however, of being processable in a closed cycle so that reliance on fossil fuels is minimized. Particularly attractive is sodium borohydrate, which readily reacts with water to release hydrogen. The byproduct, sodium borate, can be regenerated to borohydrate using independent energy inputs.

Storage of hydrogen fuel will be of considerable importance in future military systems. Storage issues related to both conventional approaches (compressed gas, liquid hydrogen) and sorption systems have been identified (Cava et al., 2001; Schlapbach and Zuttel, 2001). Because the former depend on either high pressures or extremely low temperatures, they are problematic for the battlefield environment. Physisorption or chemisorption systems using metallic and intermetallic hydrides (based on light elements like Mg and Al) or possibly carbon-based materials may overcome these limitations and allow for high-density storage of hydrogen. Here, DoD will likely be a beneficiary of commercial work.

MEMS for Energy Conversion

MEMS extend the integrated circuit concept to incorporate electronic, electrical, mechanical, optical, magnetic, and photonic functions into a chip or structure built on a wafer of silicon or other material. An extensive manufacturing base is already available for manufacturing many MEMS devices. Indeed, most of us literally trust our lives to the accelerometer that deploys the air bags in our cars, a MEMS device that has been in mass production for years. MEMS micropower sources (gas turbines, fuel cells) and microchemical processing plants for fuel reforming are the two MEMS technologies that are most relevant to the work of the Energy and Power Panel. The Electronics and Photonics Panel report (Chapter 5) considers other MEMS applications, such as sensors.

Chip-scale microturbine engine hardware (e.g., 21 mm in diameter by 4 mm high) has already been fabricated and is under test. For DoD this technology makes possible sensor-equipped, hummingbird-sized UAVs that could be deployed at the squad level for immediate neighborhood surveillance. Table 4-2 shows comparison between the performance of

TABLE 4-2 Comparison of Initial Performance of Macro Gas Turbines and of a MEMS Microturbine

|

Engine |

JUMO 004 (1939) |

J-85 (1954) |

Demo Micro (1999) |

|

Aircraft |

Me-262 |

T-38, F-5 |

MAV |

|

Engine diameter (in.) |

31 |

18 |

0.8 |

|

Thrust (lb) |

2000 |

2950 |

25 × 10−4 |

|

Thrust/wt |

1.2:1 |

7.3:1 |

5.5:1 |

|

Thrust-specific fuel consumption (lb/hr/lb) |

1.4 |

1 |

1.4 |

|

Turbine inlet temperature (°F) |

1430 |

1715 |

2421 |

|

Overall pressure ratio |

3:1 |

7:1 |

2:1 |

|

SOURCE: Waitz, I., “Micro Heat Engines,” paper presented at the Grand Challenges Workshop, November 16-18, 1999. |

|||

macro gas turbines for aircraft (standard and turbofan) and a micro gas turbine, each at their initial states of development.

The thrust-to-weight ratio and thrust-specific fuel consumption (SFC) of the microturbine are remarkable for a gas turbine with a pressure ratio of 2, especially at this early state of development. Small engines are usually less efficient than larger engines; hot gas leakage is proportionately a higher percentage of total gas flow because tip clearances represent a larger fraction of the blade surface area in small engines. Yet the microengine has a thrust SFC comparable to large engines. The microengine runs uncooled at ~2400°F (1315°C). If it could be made to run hotter, it would be even more efficient, but use of silicon as the engine material limits the turbine inlet temperature (TIT) to ~90°C below the melting point of silicon. The use of alternative materials such as silicon nitride or silicon carbide could increase efficiency by raising the TIT to 1350 or 1375°C (2500 to 2550°F). However, SiC is more difficult to process than silicon. Thus it is encouraging that a SiC MEMS accelerometer for use at moderately elevated temperatures (>400°C) has recently been achieved using standard microfabrication technologies (AFRL, 2001).

MEMS microturbines can also be used for power for the individual soldier and auxiliary power sources. Wafer-level integration of multiple microturbines may enable modular power sources in increments of 40 to 50 W (the power level of one microturbine). Using today’s technology, 100 microturbines could be fabricated within one 6-layer stack of silicon wafers. By 2020, significant size reductions are likely, as semiconductor

fabrication technology continues to reduce feature sizes (currently 0.18 down to 0.13 microns). New thermal managment and heat disipation technologies would promote the longevity and efficiency of these devices and will therefore be critical for their use in the field.

MEMS technology is also being developed for 10- to 500-milliwatt fuel cells and reformers.13 Wafer-level integration of such fuel cells and reformers (both of which could be fabricated on the same wafer) would enable a scaling up of power in increments determined by the replicated devices. The materials issue for this technology is to find a suite of anode, cathode, interconnect, and ion exchange membrane materials that can withstand the highly reactive environments encountered in semiconductor fabrication processing. Other micropower systems, such as chip-level combustors and thermophotovoltaic systems, are also possible. The energy densities of diesel fuel and/or methanol are each at least ten times greater than lithiumion batteries.14 However, to realize this advantage the fuel processors and ancillary equipment need to be simplified and miniaturized. The panel believes that MEMS-based, subwatt microfuel cells may enable the individual soldier to move beyond the limitations inherent in battery-powered communications and sensor systems.

To move advanced MEMS approaches into DoD applications for reliable and durable use in energy and power applications (particularly in dynamic as opposed to static applications), other materials and process issues must be considered. Extension to nanoelectromechanical systems (NEMS) will only add to the difficulties. Therefore, it is essential to understand the phenomena occurring at the micro- and nanoscales, and the differences from conventional phenomena due to scaling factors. Key areas for research are (1) tribology; (2) heat transfer thermal stresses and mechanical properties; (3) corrosion and other environmental degradation modes; and (4) reactions between dissimilar materials at elevated tempera-

tures. All of these must be understood at the micro (0.5- to 5-micron) and nanoscales (10- to 500-nm). Of special importance are differences in physical properties at the nanoscale, where a large fraction of atoms may be in surface rather than volume lattice sites. The panel believes that MEMS for power and energy is an area full of military promise, but it will require significant materials science and engineering support to reach its full potential.

Small Nuclear Power Sources

Small nuclear-power devices are typically implemented as radioisotopic thermoelectric generators (RTGs), beta cells, and similar devices. They rely on the nuclear reaction to produce heat that is converted to electricity by thermoelectrics (RTGs) or direct conversion of radioactive decay particles (beta cells). Output power is a few milliwatts to approximately 1 kW; applications are typically in spacecraft or weapon systems. While the panel did not have sufficient resources to explore this class of nuclear power sources, it did review earlier studies (NRC, 1997, 1999) and other information that suggests that this area should be explored. In particular, a hybrid device made of a small nuclear power source having essentially a constant power output combined with a battery or electrochemical capacitor could be advantageous. While concerns about contamination, toxicity, and environmental acceptability must be addressed, the panel believes that such a device could offer the possibility of a practical, acceptable power source for low-power electronics.

Electrical Power Generation and Transmission for Propulsion and Related Systems

Platform propulsion and support using more electric systems are of central importance to the Army, Navy, and Air Force of 2020. Although the panel did not have sufficient resources to fully identify all the materials challenges in this important area, it identified factors affecting the consumption of, and the benefits to be derived from, increased electric power use for platform propulsion and support over the next 20 years. These factors, which have a multiplier effect, are detailed in Appendix D. Among them are identification of unique DoD benefits as well as discussion of characteristics of materials (e.g., high-temperature superconductors) that will be required to make all-electric/more electric systems a reality.

Kinetic Energy Dissipation and Protection

This section briefly summarizes advanced lightweight armor materials (e.g., body armor) and transparent materials for dissipating kinetic energy. Other areas of energy dissipation (laser, structural armor, etc.) are discussed elsewhere in this report.

The most important asset and most complex system on the battlefield is the individual soldier. Protecting soldiers from fragments and small-arms kinetic energy (KE) threats is perhaps the single most important energy dissipation issue for DoD. With the trend toward a smaller but more capable force, even a relatively small number of casualties may severely degrade mission effectiveness. Because major improvements in armor materials and designs may be classified, highly promising existing and developmental materials and designs may have been omitted in this study, which is limited to unclassified sources.

Lightweight Armor

Three classes of nonstructural armor were considered by the panel: soft (fabric) personnel armor capable of defeating fragments and low KE ball ammunition (presently typified by Kevlar fabric); hard-faced composite light personnel armor for defeating high energy ball and armor piercing (AP) rounds (presently typified by ceramic tiles backed by layers of Kevlar); and transparent armor for face, riot shields, and lightweight vehicle windshields (currently typified by ballistic glass/polymer multilayers).

These engineered systems require trade-offs among such factors as penetration resistance, weight, bulk, deflection, multihit capability, flexibility, comfort, and field durability. Although this deals with materials properties, ballistic performance is in fact a systems property. Projected increases in the ballistic resistance of materials, while important, are unlikely in and of themselves to make dramatic increases (i.e., >100 percent) in ballistic efficiency for all classes of personnel armor. Rather, such materials performance increases will enable improved or innovative designs, which will synergistically leverage the materials property gains to yield dramatic armor systems improvements. The next section summarizes principal conclusions. Potential lightweight armor goals between now and 2020 are discussed in Appendix D.

Soft Fabric—Fragmentation Protection Of the classes of armor considered in this assessment, soft, textile-fiber-based armor for fragment and

low-velocity ball rounds is the best understood from a theoretical basis. Cunniff (1999a) found that, given projected improvements in fiber properties, reductions in areal densities of at least 50 percent for a given threat level are possible by 2020. This increased performance may entail excessive behind-armor deflection, necessitating redesign of the entire soldier protection system to compensate. Introduction of new fibers could provide an impetus if a clear “requirements pull” should justify the cost of new fiber development. Some fiber families (e.g., PIPD) employ rigid rods within the chain combined with strong interchain hydrogen bonding. Continuous fibers based on single-walled carbon nanotubes could be potentially significant if processing can control structure and limit defects. Hybrid yarns employing fibers having complementary characteristics could also provide synergy.

Hard-Faced Protection Against Ball and AP Rounds While the conventional wisdom in hard-faced armor systems is that the thickness of the hard face must be near that of the projectile diameter, recent work on the defeat of ball ammunition has challenged this rule of thumb. Cunniff (1999b) has shown that judicious design can achieve equal protection with less damage by using thinner face plates of the same ceramic. There may also be benefits derivable from engineered nanomaterials for protection against such threats. Withers has tested nanomaterial configurations against ball projectiles and shown potential benefits.15 The wide range of possible nanomaterials and configurations makes this a fertile ground for examination; the challenge is to narrow the range appropriately in order to limit the testing required. Computational modeling could enhance understanding of the behavior of such materials, but a real payoff could be realized if an accurate, small-scale lab test could be developed to predict and supplement results of full-scale configuration testing.

Ceramic-faced armor for personnel protection against AP projectiles dates from the early 1960s with the development of boron carbide/GRP lightweight composite armor (Viechnicki et al., 1991). In general, the material must be harder than the projectile and should have as high an impedance (l=√ρE ) as possible. The most efficient hard-face materials tend to be the oxides, carbides, or nitrides of Al, Si, or B. Currently, B4C

provides the most mass-efficient hard-face material with a density of ~2.5 g/cc. There are presently no known materials that have significantly higher impedance combined with a lower density; the properties of some armor ceramics are shown in Table 4-3.

In the panel’s view, only incremental improvement (<30-40 percent), can be expected in the ballistic resistance of rigid and hard-faced armor systems based on straight materials improvements. Similarly, incremental improvements in design are not likely to yield performance increments of the order of 100 percent. What is required are totally new approaches in armor design that lead to new mechanisms for defeating the more severe small arms threats, such as 0.30 cal AP. Possibilities include projectile tipping or rotating, momentum trapping, and confinement.

Transparent Protection Currently, there are three main developmental transparent armor ceramics: AlON (aluminum oxynitride), spinel (magnesium aluminate), and sapphire (single-crystal aluminum oxide). Sapphire is currently the most industrially available of these materials, and AlON appears to be the most ballistically promising. However, all three materials have a density in the range of 3.6 to 4 g/cc. Even though these materials perform significantly better than glass/polycarbonate laminates, they still have areal densities nearly double those of ceramic-faced opaque armors. It is therefore critical to try to synthesize new transparent ceramics that have densities close to that of boron carbide (2.5 g/cc).

Armor Materials Research Needs: Summary Progress in fibers will lead to sizable improvements in soft armor only if DoD takes the initiative to fund new fiber development. Improvements in ballistic performance of ceramics for hard-facing of lightweight armor will most likely be incre-

TABLE 4-3 Properties of Armor Ceramics

|

Material |

Density (g/cc) |

Hardness (GPa) |

Young’s Modulus (GPa) |

|

AlN |

3.2 |

14 |

280 |

|

Al2O3 (90 percent) |

3.6 |

20 |

275 |

|

B4C |

2.5 |

30 |

445 |

|

SiC (sintered) |

3.2 |

27.5 |

390 |

mental (20 to 40 percent range). For opaque lightweight armor, the most promising approach to attain major gains in performance (~100 percent) may be by innovative design. Significant increases in transparent armor performance can be made by implementing systems based on the current generation of developmental materials (i.e., AlON and sapphire), but further advances in the performance of ceramic-faced transparent armors will require new transparent ceramics with a density of less than 3 g/cc (with other properties equal to or better than AlON). Finally, the panel emphasizes that nanomaterials technology should be explored as a potential “paradigm breaker” in light-armor technology.

DoD Reliance on Energy Sources

National energy dependence, particularly with respect to reliance on energy imports, has been the subject of considerable policy discussion for many years. Though this is not a materials development issue per se, the committee agreed that a brief discussion of overall DoD energy usage, dependence on various sources, and issues related to DoD energy dependence through 2020 was desirable. The committee’s conclusion was that, although new approaches to energy harvesting (e.g., photovoltaics) will be combined with increasing use of fuel cells, existing infrastructure makes it likely that current fuels (e.g., JP-8, diesel) and nuclear power (for the Navy) will still make up the bulk of energy sources used by DoD platforms of 2020. Supporting information is given in Appendix D.

RESEARCH AND DEVELOPMENT PRIORITIES

The energy and power area spans numerous applications, device types, materials families, and subspecialties of expertise. Nevertheless, the materials R&D priorities that would most benefit future DoD systems can be articulated in a short list, given below.

Nanomaterials Science and Engineering

A common theme throughout the report of the Panel on Energy and Power Materials is the potential contribution of materials either containing nanoscale components or having structure control at the nanometer scale.

Materials exhibit wholly different properties at the nanoscale, which often translate into radically different macroscopic behavior. Nanostructuring offers a powerful lens through which to both reexamine the vast array of existing materials and to approach new materials.

Nanomaterials science and engineering affect virtually every energy and power area. For batteries, nanocomposite electrolytes could lead to entirely new mechanisms of ionic transport with possibility for very high conductivities. In dielectric capacitors, copolymers with structured nanodomains have the potential that may greatly increase dielectric constants. In energetic materials, nanoscale aluminum powders are already used to tailor burn rate in propellants; engineering of energetic material nanocomposites by controlling such factors as nanoparticle size and size distribution, composition, and morphology may lead to major improvements in these materials. New synthetic methodologies that allow for architectural control of fuel cell electrodes at the nanoscale could enhance reaction kinetics by dramatically increasing electrode surface area and restricting reactions to confined regions.

The use of nanoscale and nanostructured materials spans the entire range of metals, ceramics, polymers, and composites of interest to DoD, and the paybacks are potentially huge. The challenge is to produce nanostructures that have useful material properties in a controlled and reliable manner, while assuring that the structures remain stable over extended use. Accordingly, DoD should continue to support efforts to develop new ways to structure materials and to combine them with other materials at that nanoscale.

Engineered Interfaces and Surfaces in Materials

The importance of engineered interfaces and surfaces in materials arose continually, either directly or indirectly, as the Energy and Power Materials Panel identified materials challenges. Electrochemical capacitors will have improved power density if the interfaces on which charge is stored are tailored to provide electrochemical stability as well as optimum charge storage. Similarly, lithium batteries with interfaces tailored to eliminate pyrophoric dendrites could lead to 2-3 times power density improvements. Advanced approaches for increasing the surface area of intermixed components in energetic materials may be able to significantly raise the energy/mass ratio, leading to smaller projectiles of similar or

greater capability. MEMS devices may be dramatically improved by an enhanced understanding of reactions occurring at surfaces between dissimilar materials at elevated temperatures. DoD should place renewed emphasis on interfaces and surfaces, either separately or under a nanomaterials initiative.

Advanced Energy Storage and Conversion Materials

New materials will be essential in meeting the energy and power needs of DoD in 2020. The largest subarea that can potentially benefit is materials for electrochemical energy storage and conversion for use in batteries, electrochemical capacitors, fuel cells, and fuel reforming. As an example, high-surface-area battery electrodes made using a one-step process may allow full exploitation of the material’s possibilities. Synthesis of new solid-state electrolytes (e.g., perovskite or fluorite oxide conductor) could produce revolutionary advances for the DoD of 2020. For instance, a zero methanol crossover electrolyte would reduce the water requirements for a direct methanol fuel cell by a factor of four while at least doubling the power density, thus greatly reducing the burden of water carried by a dismounted soldier or supporting robot. New electrocatalysts for reforming diesel fuel could have a huge DoD payoff. Similarly, diesel fuel anode catalysts should receive considerable attention, because the civilian sector has little interest in this area, while it is crucial to DoD for reforming logistic fuels.

The panel also suggests that novel energetic materials, including propellants and explosives, continue to be a fruitful area for research for future defense needs. Some of the key subareas of this important category have been highlighted in this chapter.

Tools for Accelerated, Systematic Materials Discovery

Considerable time may separate the discovery and the introduction of a new material, depending on the application area and the forces driving the new material. Structural materials have required on average approximately 20 years for introduction; energetic materials have often taken considerably longer. Traditionally, the development of new materials has relied on the intuition, ingenuity, and knowledge base of experienced

individuals who can extrapolate the properties and structures of existing materials to those of new materials. To be exploited, materials must first be discovered.

To speed the discovery of new materials, the panel emphasizes, tools for accelerated systematic materials discovery and application should be employed to the maximum extent possible. These tools include (1) computational materials science, to assist in analytical design of promising new materials; and (2) combinatorial materials science, to speed the experimental discovery of new materials. The latter is particularly important in those cases where there are few signposts to promising materials, such as fuel cell electrocatalysts, or where it appears desirable to map out possible limits on the material properties of a family of compounds. DoD is already using these tools effectively. This suggestion emphasizes the importance of expanding their use in materials discovery and application, to hasten the discovery and exploitation of novel materials.

Materials as the Foundation for Systems

Materials are the basic ingredients of all DoD hardware systems. They (together with the design) affect system cost throughout the system life cycle in terms of the costs for raw materials, processing and fabrication, assembly, NDI/NDE, repair and maintenance, and disposal. It is axiomatic that much of the cost associated with a system is locked in very early in system development by the materials and design decisions made at that time. It is also clear that many materials scientists often become so strongly associated with a material or family of materials that they become advocates for that material. Similarly, materials and design engineers often become wedded to particular approaches.

During the investigations conducted by the Energy and Power Panel, it was not uncommon to encounter strong advocates for particular materials. Typically, one or more key properties of a material, which happened to be optimized and which made the material a candidate for an application, were cited as evidence for the material’s value in that application. In reality, however, every material has strengths and weaknesses. Virtually every application places multiple requirements upon a given material, making the selection of material a complex tradeoff among different, often conflicting, factors.

Similarly, the cost savings for using a given material in a component were sometimes provided as a “point comparison” with another material, without regard to the contribution of that component to total system cost. Such comparisons provide little real insight. For example, a system (e.g., a fuel cell) is a collection of interdependent components (e.g., anode, cathode, electrolyte), and the introduction of one material into a system has consequences for every other material used in that system in terms of such issues as reactivity, thermal stability, or need for compatibility coatings.