5

Implementing Emission Controls on Stationary Sources

INTRODUCTION

Stationary emission sources are divided into two categories in the Clean Air Act (CAA): major stationary sources (also called point sources) and area sources (see Box 5-1). Both contribute significantly to air pollution in the United States, and the CAA has contained provisions to regulate and control emissions from many of these sources for over three decades.

In principle, stationary sources can be controlled through the imposition of a design standard or a performance standard applied to individual facilities or through the imposition of an overall cap on a specific industry or segment of sources (see Box 5-2). The CAA applies these controls through a variety of programs that generally fall into five categories:

-

Permits and standards for new sources or major modifications of existing sources (for example, the new-source review [NSR], New Source Performance Standards [NSPS], and prevention of significant deterioration [PSD]).

-

Technology-based standards for emissions reduction in a class of existing facilities (for example, the reasonably available control technology [RACT] requirements for nitrogen oxides [NOx], the acid rain NOx provisions, and the maximum achievable control technology [MACT] for hazardous air pollutants).

-

Cap-and-trade provisions (for example, the acid rain sulfur dioxide [SO2] program of the CAA Amendments of 1990).

|

BOX 5-1 The regulations and controls on stationary sources in the United States have generally been designed to focus on two types of stationary sources:

Major stationary sources (such as factories and electricity-generating facilities) are defined as single sources with emissions exceeding a threshold level that depends on the pollutant. This threshold is generally 100 tons/yr for criteria pollutants and their precursors; however, the threshold for Pb is 5 tons/yr. For the most severe O3 nonattainment areas, the threshold for VOC can be as low as 10 tons/ yr. For serious CO nonattainment areas, the CO threshold is 50 tons/yr. The reporting requirements for major stationary sources are more detailed than those for area sources (65 Fed. Reg. 33268 [2000]). One important distinction between major stationary and area sources is the method used to estimate and control their emissions. Major stationary sources are inventoried individually and their emissions are generally controlled through a permitting process that requires specific regulatory review of each individual facility. Area sources, which are generally widely dispersed sources arising from relatively small industrial and business facilities (for example, agricultural fields and small copying and printing shops) or from application and use of consumer products (for example, architectural coatings), are inventoried and regulated collectively. |

-

Other trading and voluntary mechanisms (for example, pollution prevention programs and the U.S. Environmental Protection Agency’s [EPA’s] Project XL).

-

Regulations on area sources (for example, consumer product specifications).

In addition to those programs, which either provide permits for, or mandate changes in, new and existing facilities and products, the CAA Amendments of 1990 also established the Title V operating permit program, which requires comprehensive operating permits for large stationary sources to record all operating requirements for a facility as a basis for tracking compliance.

Each of these programs is discussed below. This discussion is then followed by a summary of the strengths and weaknesses of the various programs and the lessons to be gleaned for future approaches to air quality management (AQM).

|

BOX 5-2 Traditionally, stationary sources have been regulated through the imposition of emission standards or limitations. The CAA defines such a standard or limitation “as a requirement established by the State or the Administrator which limits the quantity, rate, or concentration of emissions of a source to assure continuous emission reduction, and any design, equipment, work practice or operational standard promulgated under this Act.” Although many specific programs regulate stationary sources in the CAA, the basic approaches that have been adopted to achieve emission reductions fall into three broad categories: technology specification standards (or design standards), performance standards, and the newer use of cap-and-trade requirements. A design standard mandates that a set of design or technological options (for example, installation of particle traps in smoke stacks) must be adopted by the managers of the regulated facilities to meet emission targets. Although this approach has the potential to achieve substantial reductions in air emissions, it has been criticized as being overly inflexible and cost-ineffective. For example, even though there is often a substantial disparity in the marginal costs of emission reductions among facilities affected by the same technology standard, technology-specification standards do not allow market forces to use this disparity to minimize the overall costs of the desired level of emission reductions (Hahn and Stavins 1992; Stavins 2002). Moreover, because firms must use the technologies specified in the standard, the approach does not encourage individual firms to pursue ways to reduce emissions through potentially more effective alternative technologies and front-end process adjustments. In contrast to a design standard, a performance standard simply specifies a maximum allowable rate of emission from a given type of source or facility, and the managers of the facility are free to choose any combination of technologies and operational practices to meet the standard. In principle, this approach provides an individual facility with greater flexibility to discover the most cost-effective way to meet the emission standard. Although the flexibility exists in theory, in practice the performance standard is normally set at the level that can only most readily be achieved by a known technology. Thus, unless readily available alternatives can meet the standards to the satisfaction of the regulators, there is likely to be a tendency for facilities to default to the known technology, thus also limiting the achieved by selection of parameters within that technology (for example, size of options for the affected industries. In that case, the necessary level of control is the control technology and flow rates of reactants). The performance standard can set different degrees of control for different sources—low-emission sources may have a lower control requirement than high-emission sources. However, regulators faced with setting a performance standard often compromise, setting a standard at a lower level than the one that can be achieved by many facilities so that the facility with the largest uncontrolled emissions will not face an impossible task of control. As a result, marginal costs of emission reductions often continue to vary substantially among facilities. Further, once a performance standard is achieved at a facility, there is little incentive to discover more efficient ways of achieving the same or greater emission reduction, |

|

and, most important, there is no mechanism for a company to profit from innovations that achieve emission reductions beyond the standard. The choice between a design and a performance standard is often made as part of a rule-making process. In some cases, such as fugitive emissions, it is simpler to set a design standard because of the complexity of measuring the actual emissions. However, design standards do not provide the same limit on emissions that performance standards do; they simply provide a reduction over a set of baseline emissions. In either case, the standards are related to the output of the facility. Performance standards are usually expressed in such terms as pounds of pollutant emitted per million British thermal units of fuel heat input. In these cases, the actual amount of emissions is permitted to increase as the amount of fuel is increased. In response to the limitations of both design and performance standards, a new approach (a market-based approach) based on cap and trade has emerged in the last decade. In this approach, each source category (or every source) in a given geographic area has its total emissions of a particular pollutant capped at a level below its current level, and each individual source is assigned an emissions allotment consistent in the aggregate with the overall emissions cap. The novel aspects of this total-emissions-based performance standard are (1) that it does not presume any particular technology or emissions standard for the sources, and (2) that it allows market forces to minimize costs and reward innovation. Each facility is allowed to achieve the required reductions in a variety of ways, including conventional pollution control, process change, and product substitution, as well as purchase of reductions at a more economical rate from other facilities that have exceeded their reduction target. Even with a cap-and-trade standard, an emission limit must be set that is based on feasible control technology or process operations. However, the ability to trade removes one of the problems faced by regulators when dealing with a range of existing sources. A greater control requirement can be set, and companies that cannot easily meet the requirement can trade emission-reduction credits to comply with the cap-and-trade requirement. There are challenges in applying this emission-control mechanism in every situation, as discussed later in this chapter. The mechanism does, at least in theory, offer the possibility of achieving substantial reductions while allowing individual sources to minimize costs and optimize efficiency. |

PERMITS AND STANDARDS FOR NEW OR MODIFIED MAJOR STATIONARY SOURCES

The CAA mandates that the states implement and EPA oversee permit programs to control and regulate pollutant emissions from major stationary sources in National Ambient Air Quality Standards (NAAQS) attainment and nonattainment areas. Under these programs, each new major stationary source of air pollutants must apply for a permit before beginning construction and, within the permit application, demonstrate that the new facility will meet appropriate emission-control standards. In recognition of the substantial costs of retrofitting, existing stationary sources are required

by federal law to undergo the permitting process only when nonroutine modifications are planned that will result in a significant increase in pollutant emissions from that source.1 The program for nonattainment areas is described in Part C of Title 1 of the CAA and that for attainment areas in Part D of Title 1. In the CAA, the program is the NSR in nonattainment areas and the PSD in attainment areas. Although NSR is often used generically for both types of programs, there are some differences, so the discussion below uses the CAA’s terms.

Background

Since 1970, the CAA has required EPA to promulgate NSPS for major and minor sources on a category-by-category basis. NSPS are national emission standards that are progressively tightened over time to achieve a steady rate of air quality improvement without unreasonable economic disruption. In recognition that the 1970 goals for attainment of air quality standards would not be met and that some attaining areas required measures to prevent conditions from worsening, NSR procedures became applicable to major stationary sources in nonattainment areas and in PSD attainment areas with the 1977 CAA Amendments.

The NSR provisions required that major new sources in nonattainment areas be constructed only if they created no net increase in emissions. That requirement was intended to ensure that major new or modified stationary sources of air pollution within nonattainment areas did not inadvertently undermine the state implementation plans (SIPs) that had been developed for those areas. To accomplish that, NSR requires that new and modified facilities use control equipment that has the lowest achievable emission rate (LAER) and that those facilities obtain an “emission offset” to offset the increase in emissions anticipated from the proposed construction or modification. As discussed in more detail below, the offset is actually required to be greater than the emissions increase from the proposed project to ensure progress toward attainment.

The PSD program for attainment areas was designed to do the following:

-

Maintain public health protection in areas that already meet the NAAQS.

-

Reduce the total amount of emissions entering the atmosphere and thereby provide general protection from public welfare damage and the impacts of pollutant transport.

-

Protect visibility.

-

Counteract the unintended incentive given to industries from the NSR program to relocate to less developed states and thereby avoid NSR permitting requirements.

PSD, like NSR, requires new and modified facilities to meet emission-control standards, although PSD standards need not be as restrictive as those for NSR. Moreover, PSD does not require emission offsets.

NSR and PSD Requirements

Applicability

NSR and PSD apply to major new stationary sources and major modifications of existing stationary sources. However, the definitions of these terms differ somewhat for the two programs:

-

NSR applies only to criteria pollutant emissions and their precursors from major or modified sources. In most nonattainment areas, a major source for the purposes of NSR is a source that has the potential to emit 100 tons or more per year of any criteria pollutant. For ozone (O3) nonattainment areas, the definition of “major stationary source” includes smaller sources in areas of more severe nonattainment and sources with the potential to emit as little as 10 tons per year of NOx and VOCs in extreme nonattainment areas.

-

PSD generally defines a major source as one that produces 250 tons or more per year of any pollutant. However, 28 specific source categories are identified in the CAA for which the PSD definition of a major source is broadened to include sources that produce 100 tons per year or more of any pollutant.2 A major modification is one that produces a “significant increase” in emissions as defined by PSD regulations (40 CFR 52.21(b)23).

The CAA indicates that existing facilities undergoing modifications that significantly increase pollutant emissions shall be subject to NSR or PSD review through the permitting process. The CAA also identifies the net emission increases for each of a series of pollutants that triggers such review. To implement this requirement, EPA developed rules to determine whether a proposed modification would result in a net increase in emissions. That determination involves prescriptions for estimating the present-day baseline emissions and the projected future emissions. In addition, EPA’s rules exempt routine maintenance and repair activities from the definition of a modification that can trigger NSR or PSD review. EPA also exempts modifications that cause de minimis, or insignificant, emission increases. For a modification to trigger NSR or PSD review, an emission increase must exceed a “significant level” specified by EPA. That level varies by pollutant and attainment status of the area. As discussed later in this section, EPA’s rules and regulations have been the subject of much debate and litigation and have been changed from time to time by EPA to reflect changes in policy priorities within the Executive Branch.

To implement the provisions, EPA usually delegates permitting authority to states or local districts. However, before such a delegation is made, the state or district must demonstrate that its permitting process is substantially the same as that used by EPA.

Operation

The operation of NSR in nonattainment areas and PSD in attainment areas is conceptually similar. Major new or modified sources undergo a preconstruction review to qualify for a permit that allows the construction or modification to proceed. The new construction or modification must use stipulated control technology. However, the control technology requirements are different in attainment and nonattainment areas. Sources subject to NSR in nonattainment areas are required to use control equipment that provides the LAER and those subject to PSD in attainment areas are required to use best available control technology (BACT). Section 171(3) of the CAA defines LAER as the most stringent emission limitation based on either (1) the most stringent limitation in any SIP for that class or category of source or (2) the most stringent limitation achieved in practice for a certain class or category of source. Section 169(3) of the CAA defines BACT as an emission limitation based on the maximum degree of reduction of each pollutant subject to regulation under the CAA emitted from any major emitting facility, which the permitting authority, on a case-by-case basis, determines is achievable for such facility. The authority is required to take into account energy, environmental and economic impacts, and other costs. Thus, the emission

limitations required under BACT can be less stringent than those under LAER.

In determining the specifics of a BACT requirement for a facility, EPA and the states must also ensure that the facility does not exceed the NSPS. In practice, NSPS, which are determined once and are changed only if the regulation is fully revised, serve as the minimum level for BACT and LAER determinations.

In nonattainment NSR, offsets are required to bring about a net decrease in emissions in the area. The size of the offset relative to the anticipated increase from the new or modified source varies from 1.1:1 for non-O3 nonattainment areas and marginal-O3 nonattainment areas to as much as 1.5:1 for extreme-O3 nonattainment areas (see Box 3-3 in Chapter 3). The offsets must be reductions that would not otherwise occur (for example, as a result of other SIP activities) and can be obtained from new emission controls on, or shutdowns of, other facilities and sources. They must be real, permanent, and enforceable. In principle, offsets provide an incentive to try innovative control technologies. In practice, offsets are usually obtained by shutting down other facilities.

Offsets are not required in PSD permits. However, any emission increase after the use of BACT is limited to a fixed amount from all new facilities in the area. The amount of the increase allowed under PSD regulations, called the increment, is defined in terms of ambient air concentration and depends on the pollutant and the class of the area affected. National parks, wilderness areas, and similar sensitive areas are identified as Class I areas. Most areas are Class II. The regulations also define a Class III area, for which emission limits are more lenient than those for Class I and II areas; however, no areas have been designated Class III. The increments for various pollutants are shown in Table 5-1 for each area class.

PSD permit applications are also required to analyze the effects of the source on visibility, soils, and vegetation; the economic growth likely to result from the new source; and the effects of this new growth on the new emissions. When a Class I area is affected by the source, the federal land manager for that area must play a role in the permit process. According to PSD regulations, the manager can provide an analysis showing that there is an “adverse air quality impact” on the Class I area, even if all other permit requirements are met. In such cases, the manager can recommend that the permit not be issued, and the permit may be denied.

Issues with the Application of NSR and PSD

NSR and PSD have been a positive force in AQM in the United States. NSR has provided a mechanism for economic development and new con-

TABLE 5-1 Allowable Concentration Increments (micrograms per cubic meter) for Prevention of Significant Deterioration (PSD)

|

Pollutanta |

Measurement |

Increment in Areas That Are |

||

|

Class I |

Class II |

Class III |

||

|

Particulate matter (PM10) |

Annual arithmetic mean |

4 |

17 |

34 |

|

|

24-hr maximum |

8 |

30 |

60 |

|

Sulfur dioxide (SO2) |

Annual arithmetic mean |

2 |

20 |

40 |

|

|

24-hr maximum |

5 |

91 |

182 |

|

|

3-hr maximum |

25 |

512 |

700 |

|

Nitrogen dioxide (NO2) |

Annual arithmetic mean |

2.5 |

25 |

50 |

|

aPM10 is particulate matter with an equivalent aerodynamic diameter of 10 micrometers or less. SOURCE: Clean Air Act, Section 163. |

||||

struction to proceed in nonattainment areas while maintaining progress toward NAAQS compliance. Moreover, both NSR and PSD have mandated the use of modern, clean technologies and practices in new facilities and in modified existing facilities throughout the nation. The application of BACT in conjunction with the requirements for NSPS has encouraged, indeed required, the continual development and application of new technologies that are more cost-effective, cleaner, or both. However, NSR and PSD have some limitations as well. Some of the more prominent aspects are discussed below.

Complexity and Inefficiency

The NSR- and PSD-permitting processes have become complex and time consuming, especially if there are disagreements between the permit seeker and the permitting agency. The ever-growing nature of the process is illustrated by EPA’s documentation describing NSR and PSD regulations, manuals, and guidance. About 30 pages in length in the early stages of the program, the documentation now exceeds 1,000 pages and is contained in numerous documents with which permit applicants and writers must be familiar (EPA 2002k). Representatives of industry complain that the process fosters inefficiencies and unduly discourages economic growth and innovation (NAM 2002). The process as currently organized can lead to conflicts between the goal of implementing improved emission-control technology as quickly as possible on the basis of BACT or LAER requirements and the need for firms to know what control technology will be required for new construction or modifications to existing facilities. Because of the lengthy time required to complete a permitting process and the rate at

which control technologies are developing, the BACT or LAER requirements for a given project could change between the time that a project is proposed and the time that it is permitted.3

Older, Dirtier Facilities Remain in Operation

When the NSR and PSD programs were enacted, Congress did not require that emission controls be placed on any existing facilities, in effect “grandfathering” these facilities, although the provisions left open the possibility that controls could be required on these older facilities as part of a SIP filed in a nonattainment area.4 Such facilities were expected to reach the end of their operating lives about 30 years after their initial construction. Experience over the past 25 years, however, shows that older high-polluting facilities throughout the nation have continued to operate with minimal modernization or have undergone so-called lifetime-extension projects. These projects have been able to maintain the economic viability of the facilities well beyond their initial design lifetime without triggering NSR or PSD review and the addition of modern emission-control technology (see Box 5-3). In addition, placing controls on such facilities as part of a SIP has proved politically difficult. Facility owners and operators can demonstrate that the cost per ton of controls on such facilities, assuming a short remaining lifetime, is much greater than the equivalent cost for new facilities. Some maintain that the onerous nature of the NSR and PSD permitting process contributes to this state of affairs by raising bureaucratic hurdles against new construction. Others argue that industry keeps old facilities operating, sometimes unlawfully, to avoid the NSR and PSD requirements to use clean technologies, as discussed further below.

|

BOX 5-3 When the CAA Amendments of 1970 were written, it was assumed that electric power plants would be decommissioned when they completed their expected functional lifetime. Instead, many older power plants have received extensive maintenance to extend their operation and remain in use. Although no specific exemption was created for these facilities, their extended operation amounts to a de facto grandfathering, and that term is commonly used to describe facilities with little or no emissions control that continue in operation well beyond their original expected lives. Table 5-2 provides a breakdown by vintage of NOx emission rates for coal-fired power plants operating in 1999 in pounds per megawatt hours (the amount of NOx emitted per unit of electricity generated) and the percent of total NOx from coal-fired boilers emitted by each vintage. The table indicates that some facilities have remained operational long after their expected 30-year lifetime and that these older facilities emit NOx at a much higher rate than newer facilities. They also emit a disproportionately large fraction of NOx relative to the power they produce, as indicated in the far right column of the table. Substantial reductions in emissions from coal-fired power plants could be obtained by retrofitting plants or by replacing them with newer coal-fired or gas power plants. Although there are reasons for focusing regulation primarily on new facilities or major modifications—most notably the relatively lower cost to incorporate control technology in the planned construction—the net effect of de facto grandfathering of facilities can be a substantial source of emissions. The use of a total cap on emissions with emissions trading can provide a monetary incentive for older facilities to reduce emissions. (See discussion on advantages and challenges of such programs later in this chapter.) |

TABLE 5-2 NOx Emissions from Coal-Fired Boilers in 1999 by Vintage

|

Power Plant Vintage |

Avg. NOx Emission Factors (lb/MW-hr) |

% of Coal-Fired Electricity Capacity |

% of Coal-Fired Electricity Generation |

% of Total NOx Emitted |

% of NOx Emitted per % of Electricity Generated |

|

Pre-1950 |

7.44 |

1 |

0.4 |

0.6 |

1.50 |

|

1950–1959 |

5.97 |

15 |

12.9 |

14.9 |

1.16 |

|

1960–1969 |

5.95 |

20.6 |

18.8 |

21.6 |

1.15 |

|

1970–1979 |

5.37 |

37.6 |

38.6 |

40.1 |

1.04 |

|

1980–1989 |

4.09 |

23.5 |

26.6 |

21.1 |

0.79 |

|

1990–1999 |

3.55 |

2.4 |

2.6 |

1.8 |

0.69 |

|

Abbreviation: lb/MW-hr, pound per megawatt-hour. SOURCE: Data from Burtraw and Evans 2003. |

|||||

Definition of Significant, Nonroutine Modification

Probably the most controversial aspect of the NSR and PSD programs is the set of rules, regulations, and guidance that EPA developed to determine whether a proposed modification to an existing facility would result in a significant net emissions increase of any regulated pollutant under the Clean Air Act and thus trigger NSR or PSD review. These requirements have been subject to considerable debate and litigation. EPA has always used a number of factors in determining whether physical changes in a plant constitute routine maintenance. Owners of sources have complained that the agency has not consistently applied those factors over time as Administrations have changed. Environmental groups have desired stricter rules and have claimed that owners of older high-polluting plants have thwarted Congress’s intention by improperly labeling lifetime-extension projects as routine, thereby avoiding the requirement to meet PSD or NSR emission standards. This viewpoint was supported by the U.S. Court of Appeals of the Seventh Circuit in its landmark 1990 decision in the case of Wisconsin Electric Power Company (WEPCO) versus EPA. The court ruled that the “massive” overhaul of an existing WEPCO facility could not be exempted as routine maintenance. However, the WEPCO decision was viewed by EPA as an isolated case and did not substantially change its policy concerning lifetime-extension projects. Such a change did appear to occur in the late 1990s when EPA asked the Justice Department to file lawsuits against seven utilities that had completed lifetime-extension projects on numerous power-generating plants without submitting NSR or PSD permit applications.

Reforming NSR

Since the early 1990s, EPA has discussed potential reforms for the NSR permitting process. The goal of these reforms is to make permit applications more straightforward and certain for the applicants, while continuing to provide the environmental protection required by the CAA. In 1996 and 1998, EPA published formal notices of proposed changes in NSR and PSD (61 Fed. Reg. 38250 [1996]; 63 Fed. Reg. 39857 [1998]). However, these proposals were never finalized.

The national energy policy enunciated by the Bush administration in 2001 called for another review of NSR and PSD, and in June 2002, the review recommended several changes to NSR that were substantially different from the NSR reforms proposed (by the Clinton administration) in 1996 and 1998. These new rules modify the requirements for NSR on an existing facility and will generally make it easier for projects to be undertaken at existing facilities without triggering NSR. A description of the new

NSR rules is available in the Federal Register (67 Fed. Reg. 80186 [2002]; 68 Fed. Reg. 61248 [2003]).

The new rules promulgated by the Bush administration have been controversial. Some states, local governments, and environmental groups have argued that the new rules do not adequately address the problem posed by older, grandfathered facilities (see Box 5-3). On the other hand, affected industries generally welcome the rule changes as improving the flexibility for permit reviews, providing certainty for decisions concerning routine repairs and maintenance, and ultimately making it easier to improve the efficiency of existing facilities and limit their pollutant emissions. The committee did not assess the potential impacts of these new rules. In the Consolidated Appropriations Resolution for federal fiscal year 2003 (Public Law 108-7), signed by the President in February 2003, Congress called for an independent evaluation of the impacts of the revisions to the NSR program by the National Research Council. The evaluation will be carried out by a different committee.

OTHER TECHNOLOGY-BASED STANDARDS IMPOSED ON MAJOR FACILITIES

In addition to the requirements for new and modified emission sources, the CAA contains explicit requirements for the imposition of emission-based standards and emission reductions on specific types of sources regardless of whether they are new or being modified. Examples of these requirements are reasonably available control technology (RACT) within nonattainment areas, and maximum achievable control technology (MACT) for major sources of hazardous air pollutants (HAPs). The Acid Rain Program in the 1990 CAA Amendments focused primarily on the SO2 cap-and-trade program but also included more modest and more traditional controls for reduction of nitrogen oxide (NOx) emissions from existing facilities.

Reasonably Available Control Technology

Beginning with the CAA Amendments of 1977, nonattainment areas have had to apply RACT to all major sources in their areas as part of their attainment-demonstration SIPs (see Chapter 3). RACT is determined by EPA through a process of developing control technique guidelines (CTGs) that take into account cost as well as other factors for each of a number of industrial facilities. To date, EPA has promulgated over 60 CTGs. RACT is generally implemented in each state in accordance with the CTGs. In some cases, states have gone beyond the CTGs in their RACT rules.

The Acid Rain NOx Provisions

To address the problem of acid rain, Congress included provisions in the CAA Amendments of 1990 that were designed to reduce emissions of SO2 and NOx (see Chapter 2). The SO2 provisions, which are described in detail in the following section, set a goal for reduction of emissions by 10 million tons and then set specific caps on allowable emissions from individual facilities to achieve that goal. Unlike the SO2 provisions, the 1990 CAA Amendments set a target reduction of 2 million tons of annual NOx emissions and relied on the promulgation of emission standards on specific facilities to attain the reductions. The requirements were implemented in two phases. Starting in January 1996, Phase I required use of low NOx burner technology in tangentially and dry-bottom-wall coal-fired power plants, producing reductions in emission rates of about 40%. Phase II, which began in 2000, extended emission standards to more types of coal-fired power plants. Though generally prescriptive, the program did allow some flexibility. Companies were able to average emission rates for commonly held facilities, but intercompany trading was not allowed. Facilities that did not achieve the standard after making specified investments could appeal for alternative emission limits. The imposition of Phase I of the Acid Rain Program’s NOx performance-oriented emission standards has substantially decreased the emission rates of the affected facilities.

Maximum Achievable Control Technology

As discussed in Chapter 2, the CAA Amendments of 1990 required EPA to establish emission standards that “require the maximum degree of reduction in emissions of the hazardous air pollutants … that the Administrator determines is achievable” for sources that emit more than 10 tons per year of any listed HAP or 25 tons per year of a mixture of HAPs. In response to that mandate, EPA established standards of maximum achievable control technology (MACT) for relevant HAP sources. In principle, the standards are performance standards, because each facility is only required to match the emission rate obtained using the MACT standard, and it may use any technology. However, the manner in which MACT standards are promulgated provides an incentive for companies to opt for the sanctioned technology and thus may ultimately have the affect of a design standard (see Box 5-2).

The 1990 CAA Amendments specified that the HAP standards covering 25% of the identified categories of emission sources be issued by 1994; another 50% by 1997, and the remaining 25% by 2000. However, this schedule has not been met. The promulgation of these standards has been delayed considerably from its original time frame, proving to be a source of

criticism (Williams 2003) and litigation (Sierra Club v. U.S. Environmental Protection Agency, No. 02-1135 [DC Circuit]). As of February 2003, EPA had promulgated 79 MACT standards, affecting 123 source categories (T. Clemons, EPA, Washington, DC, personal commun., March 31, 2003). In May 2003, EPA indicated that it fully expects to finalize all MACT standards by the time states would be required to set MACT limits on a facility-by-facility basis according to Section 112(j), as amended (EPA 2003b). This section, referred to as the “MACT hammer,” requires states to set MACT standards by facility-specific permit limits if EPA fails to set standards within 18 months of the statutory deadline.

Implementation of MACT standards developed so far is estimated to have already reduced HAP emissions by about 25% (EPA 2001a). Presumably, even larger reductions will be achieved when the program is fully implemented. The use of standards that directly (through a design standard) or indirectly (through a traditional performance standard) mandate the installation of specific pollution control technologies appears to have resulted in substantial reductions in pollutant emission rates (see Chapter 6). However, these technology-specific approaches have some deficiencies (see Box 5-2). They are not set up to minimize costs across all companies who must comply, nor do they provide an incentive for creative problem solving within companies that can result in the development of new, more efficient approaches to reducing emissions.

EVALUATION OF TRADITIONAL CONTROL PROGRAMS FOR MAJOR STATIONARY SOURCES

Although the technology-specific control programs have considered a range of pollutants from the start, consideration has been segmented by the programs, such as NSPS, MACT, RACT, NSR, and PSD, at federal and state levels operating on different time frames and under different levels of stringency. The result has been to make it difficult for any one facility to implement multipollutant controls in a systematic and cost-effective fashion.

Perhaps most important, older plants have not had to make emission reductions in many cases, and the emissions from these older facilities provide a substantial contribution to the emission inventories of some pollutants (see Box 5-3). This situation has been caused by (1) a complex system of requirements for new, modified, and existing facilities that has provided incentives for not retiring or modifying facilities; (2) RACT and other rules that have either been less stringent than originally intended or not been energetically enforced by some states; and (3) the relatively high cost of retrofitting, thereby providing an incentive for operators facing cap and trade to purchase reduction allowances from others who can make the reductions less expensively (see cap-and-trade discussion below).

In addition, there are several concerns regarding HAP emission controls. First, there is a concern that MACT standards stifle the development of pollution prevention technologies (for example, product substitution and reformulation) that are more cost-effective than the predetermined control technologies that are the basis for the standards. Such development is encouraged in the 1990 CAA Amendments. Second, there is a question of whether the MACT hammer requirement of Section 112(j) of the Clean Air Act will need to be imposed. This requirement has been especially challenging for mercury emissions (see Box 5-4). Third, there is the challenge of compliance monitoring and enforcement for HAPs. Continuous emission monitors do not exist for most of them, and substantial contributions from fugitive emissions and temporary excursions from normal operating conditions (“upsets”) are likely. Finally, questions remain concerning HAP con-

|

BOX 5-4 The CAA treats HAPs from electric utility steam-generating units (EGUs) differently from HAPs emitted by other sources. Instead of subjecting EGUs to the generic regime for HAPs regulation, the CAA requires EPA to conduct a study of the potential hazards from utility air toxics and to determine whether regulation is “appropriate and necessary.” In December 2000, EPA completed the study and made the required determination, concluding that regulation of HAPs from coal-and oil-fired EGUs is necessary and that mercury is an air toxic of most serious concern. A subsequent report by the National Research Council indicates that an estimated 60,000 newborns are at risk each year for adverse neurodevelopmental effects from in utero methyl mercury exposures (NRC 2000a). EPA established a subcommittee of the CAA Advisory Committee to advise it on setting the standards for HAP emissions from EGUs. The advisory group met for well over a year but was unable to reach consensus on a number of key issues. Notwithstanding the difficulties, however, a settlement agreement in a court case set the schedule for EPA to promulgate the HAP regulations for EGUs. The schedule called for EPA to propose a rule by December 2003 and finalize the rule by December 2004. On December 15, 2003, EPA proposed two alternatives for controlling emissions of mercury from EGUs.a One alternative would require utilities to install controls known as maximum achievable control technologies (MACT) under section 112 of the CAA. The other alternative is to create a market based cap-and-trade program, which would require a revision of EPA’s December 2000 finding that it is “appropriate and necessary” to regulate HAPs emissions from EGUs using the MACT standards. Given this schedule for rule promulgation, the CAA requires compliance by December 2007, although the Bush administration has indicated that it may extend the compliance date by 1 year. |

trol following MACT. As discussed in Chapter 2, the 1990 CAA Amendments require EPA to establish additional emission standards following an assessment of residual risk. Questions also remain about the science behind residual risk assessments: the adequacy of emission inventories and dispersion and exposure models, the need for more timely updates to EPA’s Integrated Risk Information System (IRIS), the uncertainty in dose-response relationships, and the lack of information on some health outcomes.

COMPLIANCE ASSURANCE FOR TRADITIONAL CONTROL PROGRAMS

EPA and the states rely on two primary means to ensure compliance with the emission-control requirements described in the previous sections: on-site inspection and compliance monitoring. To facilitate these efforts, the 1990 CAA Amendments enacted provisions for the Title V operating permit program, which was designed to record all relevant requirements and conditions in one document and to provide a fee structure for the states to provide resources to support the compliance efforts. The following sections discuss the Title V program, the means to ensure compliance (on-site inspections and compliance monitoring), and the challenge of off-normal emissions.

Title V Operating Permit Program

Operating permits for major stationary sources are required under Title V of the CAA. The Title V permit lists all the control requirements for a particular source to provide the necessary information for inspectors to verify compliance. In addition, the Title V permits are public documents allowing public review of source-emission data and control requirements. The 1990 Amendments of the CAA set forth a schedule that called for all

Title V permits to be issued by November 1997. The Title V permits can play an important role in limiting emissions. Emission standards are usually written in terms of some unit related to production (for example, pounds of emission per million British thermal units [Btu] of heat input). The actual emissions depend on the capacity of the unit and the hours of operation. Operating permits can place limits on those factors, thus providing an effective limit on the emissions rate from a source.

Before the Title V provisions, permit programs in different states and local districts varied in their requirements. State and local air pollution control officers were concerned about the Title V program during enactment and during promulgation of the rules, although they ultimately supported the program. Some permitting agencies thought that the final EPA

regulations implementing the Title V provisions were overly concerned with details. Agencies with already strong permit programs thought that the Title V regulations increased the complexity of the permitting process without improving the overall results. These agencies believed that the regulations were not sufficiently flexible to allow for effective local options.

One important element of Title V amendments was the provision that permitting agencies could collect fees for their costs associated with the permitting system. These fees have provided a useful source of income to agencies that allows them to develop a more effective permit program.

EPA data show that 36,953 stationary sources were potentially subject to the Title V requirements (EPA 2003j). Of these, 17,998 received revised permits that limited their operating hours or emissions below the level that classified them as stationary sources. Such sources, known as synthetic minors, became exempt from the Title V requirements, because they were no longer major stationary sources. Of the remaining 18,955 major stationary sources, only 14,247, or 75%, have received a permit as of September 30, 2002. The EPA inspector general issued a report in 2002 that examined the reasons for delays in the issuance of these permits (EPA 2002f). These reasons included delays in the promulgation of the initial EPA regulations for state and local Title V permit programs, delays in the EPA approval of proposed permit programs, and longer times required for review and approval of permits. There was also some confusion about the monitoring requirements for sources that were included in Title V. The delay in issuing guidance for specific monitoring requirements in the Title V regulations was also cited as a reason for the delay in the implementation of the Title V program.

The complexity of the effort required to issue these permits was underestimated at the time the 1990 CAA Amendments were passed. Sources and state agencies had to pay more attention to emission data, which were not accurately recorded for many sources, to ensure that sources were properly classified as major or synthetic minors. In some cases, the sources and the permitting agencies had to determine which of several contemporaneous requirements to include in the permit.

Part of the complexity is due to the nature of large stationary sources. Such sources have many emitting units that must be considered separately in the permit for the source. An example of a complex permit is one granted to an oil production company in California. This Title V permit, available on the ARB web site, contains 1,460 pages to describe the conditions applied to all the permit units in the source (CARB 2003b).

Overall, despite these difficulties, the Title V program has improved the application of operating permits nationally and given enforcement staff a better understanding of the specific requirements for individual permit units at a source.

Government On-Site Inspections of Stationary Sources

Inspections by government officials (or government contractors) are a fundamental component of compliance assurance for stationary sources (EPA 1992). EPA and state inspectors typically conduct two kinds of inspections: “routine” inspections, which are not based on any suspicion of violation, and “for-cause” inspections, which target a particular facility because of suspicions that it is noncompliant. Inspectors conducting routine inspections observe visible emissions; examine data on control devices and operating conditions for comparison with those specified in the facility’s permit; and review records and log books on the facility’s operations (GAO 2001a). During a for-cause inspection, the inspector typically focuses on identifying possible sources of the emissions causing the inspection and specifying appropriate corrective action. The inspector is free to investigate other possible violations that he or she observes.

Federal and state inspectors perform over 17,000 routine inspections per year (GAO 2001a). In 1999, 88% of the 17,812 facilities routinely inspected by EPA and state officials were reported to be in compliance with permit requirements (GAO 2001a). However, a General Accounting Office report (GAO 2001a) concluded that routine inspections at large air-pollution-emitting facilities fail to detect significant noncompliance with permit requirements that can be revealed by more intensive but rarely undertaken investigations. In intensive investigations of three industries conducted by EPA, 75 of the 96 facilities investigated were not in compliance with their permit requirements (GAO 2001a).

Compliance Monitoring of Stationary Sources

In addition to government inspections, compliance can be assessed through monitoring. Because of the limited enforcement resources available to state and federal agencies, most compliance monitoring is done by the individual companies themselves pursuant to state and federal legal requirements and various permit conditions. A variety of approaches for compliance monitoring are accepted by the nation’s AQM system. These include (1) emissions estimation models, which do not actually monitor emissions directly; (2) periodic source testing; (3) parametric emissions monitoring (PEM); (4) continuous emissions monitoring (CEM); and (5) remote sensing.

Emissions Estimation Models

This approach makes use of the same method as that used in the development of emission inventories (discussed in Chapter 3), in which emissions are estimated as the product of an empirically derived emission

factor and a facility-specific activity factor. Because this method does not involve any measurements of actual emissions from the facility, it is not strictly speaking a form of monitoring. Nevertheless, given the high cost and unavailability of other monitoring methods, many of the regulated facilities in the United States rely on this method to calculate permit fees and report facilitywide emissions to agencies that develop the areawide and nationwide emission inventories. As discussed in more detail in Chapter 6, because this method assumes that emission controls placed on a facility are effective, it is not a scientifically robust way to document independently the success of AQM in reducing pollutant emissions.

Periodic Source Testing

This method uses periodic emission measurements to assess emissions from a facility. Such an approach certainly provides a more accurate assessment of emissions at the time of the test than that from an emissions estimation model, but it is still limited by the need to extrapolate from the measured emissions (made under specific conditions) to the total emissions. Thus, the validity of periodic source tests depends on the accuracy of the data from the tests, the representativeness of the conditions during the tests, and the validity of the model used to extrapolate. Because such testing has to be prescheduled, periodic emission measurements are likely to be conducted during optimal conditions that are not necessarily reflective of conditions over the long run (GAO 2001a).

Parametric Emissions Monitoring

Parametric emissions monitoring (PEM) applies computer models to data gathered from the source on various operating parameters—such as temperature, pollutant flow rates, and oxygen levels—to estimate emissions continuously, thereby providing a continuous record of a facility’s compliance status (GAO 2001b). Two categories of PEMs have been developed: (1) those that apply first principles (for example, thermodynamics or the ideal gas law) to calculate emissions from operating parameters; and (2) those that predict emissions based on a profile of a source’s pattern of past emissions (developed using neural networks or regression) as related to the operating parameters. The first approach is limited by assumptions needed to solve the complex equations involved, and the second depends on the facility and the sensors behaving in a way consistent with the historical data (EPA 2000c). EPA enforcement officials consider parametric procedures to be generally less accurate than either CEM systems discussed below or periodic source tests. Nevertheless, source facilities are allowed to use PEM to demonstrate compliance with emission standards if the monitoring of the

process and the pollution-control-device operating parameters indicate that the facility is operating within a permitted range (40 CFR § 64.3). A common approach to determining compliance is a combination of PEM and periodic testing.

Continuous Emissions Monitoring

A CEM system includes all equipment necessary to determine the rates of pollutant emissions, either by taking measurements within the stack or by extracting a sample from the stack for analysis, and to record the emissions on a continuous basis (Schwartz et al. 1994). CEM is potentially the most accurate method for measuring emissions and ensuring compliance. It is also the most expensive and the most technologically and operationally demanding. CEM systems that meet the requirements for regulatory purposes are available for carbon monoxide (CO), hydrogen chloride (HCl), NOx, SO2, carbon dioxide (CO2), and oxygen (O2), opacity, total reactive sulfur, hydrogen sulfide (H2S), and volatile organic compounds (VOCs) (NRC 2000c; GAO 2001b; EPA 2003k). Instruments to monitor emissions of mercury, multiple metals, particulate matter (PM), and total nonmethane hydrocarbons continuously are being developed (Hunter et al. 2000; NRC 2000c; Seltzer 2000; GAO 2001b; Mitra et al. 2001). Extractive methods to measure several pollutants at once with Fourier transform infrared (FTIR) spectroscopy and gas chromatography (GC) are also available but not yet used in a regulatory setting, despite the availability of reference spectra for 100 of the 189 HAPs listed in Title III of the 1990 CAA Amendments (EPA 2003l).

CEM systems provide only a few percent of all determinations of stationary-source emissions for compliance purposes. Such systems are required by EPA for only a limited number of source categories; these include new waste incinerators, some chemical plants and petroleum refineries, utilities and large boilers subject to the Title IV acid rain emissions-trading program, and as a condition to consent decrees in enforcement actions (NRC 2000c; GAO 2001b). In all, about 6,750 CEM systems are in use in the United States (GAO 2001a). About 80% of those measure CO, opacity, NOx, and SO2, and less than 1% measure hydrocarbons and air toxics (GAO 2001b).

EPA enforcement officials in general find CEM systems preferable to parametric monitoring, and somewhat preferable to periodic source monitoring (GAO 2001b). EPA has, however, been reluctant to require regulated sources to install CEM technologies “because of time and resource constraints in issuing new rules, as well as the perception that advanced monitoring technologies are too expensive” (GAO 2001b). Companies have been reluctant to use CEM technologies because they are expensive

and their use might reveal additional violations (GAO 2001b). The vendors of CEM technologies are likewise reluctant to put resources into more research unless they have some assurance that EPA will require companies to install them (GAO 2001b). At the same time, EPA must be confident that potentially expensive CEM technologies will work over the long haul before it prescribes their use. Thus, the relevant actors find themselves in a cycle in which promising monitoring technologies are not developed or implemented (see discussion on advances in environmental instrumentation in Box 7-5 in Chapter 7).

Remote Sensing

Remote-sensing techniques quantify the concentrations of gases and particles emanating from a source by measuring the spectral properties of light waves that have interacted with these gases and particles. Remote sensors can be deployed at surface sites in the vicinity of a source, on aircraft, or even on satellites. They are particularly useful for detecting leaks or “fugitive” emissions, because they allow a large area to be rapidly sampled. Remote sensing has not been used widely for routine compliance monitoring (EPA 1992), although a recent report prepared for EPA identified several remote-detection technologies (see Chapter 7, Box 7-5) that, if used instead of portable monitors, could drastically reduce the costs of such programs (ICF 1999).

Off-Normal Emissions

A basic assumption underlying technology-based standards (which include EPA’s NSPS, LAER, BACT, RACT, MACT, and most SIP requirements) is that a well-operated and maintained source can achieve a specified emission standard or limit under all expected operating conditions by using control equipment that has been shown through a performance test to be capable of achieving that limit (62 Fed. Reg. 54900 [1997]). Emission-control technologies, however, are not perfect, and even the most advanced technology may experience off-normal conditions that cause emissions to spike upward. An agency seeking to regulate the emissions from a facility through the application of emission-control technologies has two alternatives: (1) set a lenient emission standard so that a facility can be expected to remain in compliance 100% of the time, including during off-normal conditions; or (2) set a stringent standard and allow for “upsets” or “excursions” in emissions during off-normal conditions identified in the relevant permits and compliance monitoring regulations. For the most part, EPA has elected the second option, often permitting an operating-emission range for a source. Determination of whether a source is in compliance then depends on the

number and severity of emission excursions and “the particular circumstances at the source” that resulted in the excursions (62 Fed. Reg. 54900 [1997]). Although operationally efficient, this approach has some negative aspects. If a facility is allowed an unknown number of emission excursions of unknown magnitude, how can the citizens living and working in the vicinity of the plant be assured that their health is being adequately protected? Likewise, how can the operators of the plant determine when an excursion is sufficiently severe to warrant radical corrective action?

CAP-AND-TRADE PROVISIONS FOR MAJOR STATIONARY SOURCES

Starting in the 1980s, air quality managers began exploring the use of market-based approaches to pollution control. This shift was motivated in part by the belief that market-based approaches would help level out the marginal costs of emission reductions among the affected facilities, dramatically reducing the overall costs of control. It was also believed that market-based approaches would provide greater incentive to innovate, which could in turn contribute to further cost savings and perhaps even greater emission reductions. Another distinct advantage of many market-based approaches is that they place a definite limit, or cap, on the aggregate emissions from a particular type of source or even from all sources of a pollutant. As a result, target emission levels are maintained even while economic and population growth continues.

The most commonly known market-based approach is a cap-and-trade program in which discrete emission quantities, such as a ton of a pollutant, are traded among sources. Trading takes place under an aggregate emission cap set by the regulating agency, presumably based on a determination of the maximum level of emissions consistent with protecting human health and welfare. Cap-and-trade programs have been shown to be effective at achieving emission reductions at much less cost to the regulated facilities than traditional technology-based or performance-oriented standards. However, there are potential disadvantages, some of which are discussed in more detail at the end of this section.

The Acid Rain SO2 Emissions Trading Program

Emissions trading programs were first used in the United States during the 1980s (see Box 5-5); however, the best-known program is that involving the trading of SO2 emissions from electric utilities in the Acid Rain Program (Title IV) of the 1990 CAA Amendments. As discussed in Chapter 2, the goal of this program was to cap nationwide SO2 emissions from electric utilities at 8.9 million tons beginning in 2000.

To accomplish the emissions reduction, Congress established a national cap on SO2 emissions from electric utilities and authorized EPA to allocate an annual emissions allowance to each of the affected electricity-generating facilities. The allowance assigned to each utility is based on its historical rate of resource consumption (expressed in units of equivalent million British thermal units of energy contained in the fuel used annually) and entitles the holder to emit a specified amount of SO2 in the year the allowance was issued or in any later year. If the initial allocation does not cover the desired emissions for a given utility, that utility has a variety of options. It can reduce its emissions to the allowable amount internally through the use of technologies to capture emissions before they escape to the atmosphere (for example, scrubbers), the use of renewable or alternative clean technologies, and conservation and pollution prevention (for example, the use

|

BOX 5-5 Emission-Reduction Credit Programs Emission-reduction credit (ERC) programs implemented in the 1980s were the first emission-trading programs in the United States. These programs generally were organized around measuring and trading of emission rates rather than discrete units of emissions and shared some of four characteristics: (1) offsets, or emission reductions at existing facilities that must be obtained by new facilities in areas that fail to attain NAAQS; typically, the emission reductions at existing sources must be greater (usually by a factor of 1.3:1or more) than the new emissions; (2) bubbles, or average emission rates over several facilities in a region; (3) netting, which applies to expansion within a facility at existing sources; and (4) banking, which refers to intertemporal trading; banked credits are typically lost if a plant shuts down. The first-generation ERC program yielded about $10 billion of savings in capital costs but still yielded far less than the expectations of economists (Tietenberg 1990; Hahn and Hester 1989a,b). One problem with the ERC program was the relatively high transaction costs associated with trades. State regulators also wavered in their commitment to the program. That undermined the willingness of parties to engage in trading (Liroff 1986). A final failing of the ERC program was that it translated an existing prescriptive program into a trading program without any associated gains for environmental quality. Hence, the program was perceived as solely in the interest of business, resulting in widespread mistrust on the part of environmentalists and some regulators (Hahn and Stavins 1991). Lead Phase-Out The phase-out of lead (Pb) in gasoline affected emissions from mobile sources (Nussbaum 1992). It was implemented at refineries, however, and thus |

|

affected stationary sources. Unleaded fuel was mandated to be available beginning in 1974, but implementation was eventually postponed until 1979. The maximum allowable Pb was reduced to a maximum of 1.1 gram (g) per gallon (gal) by 1982, to 0.5 g/gal by 1985, and to 0.1 g/gal by 1986. To achieve this phase-out, a program of “interrefinery averaging” was initiated on a quarterly basis from 1983 to 1986. Banking across quarters was allowed as the average allowable Pb content was reduced. Several hundred refineries, representing about half of all refineries affected by the phase-out, participated in the trading program. Savings amounted to about 20% of program costs (EPA 1985). The trading program enabled political support for the Pb phase-out to take shape. There is also compelling evidence that the trading program accelerated the process of technological change that lowered costs, an important lesson for other regulatory programs (Kerr and Newell 2001). Chlorofluorocarbon Phase-Out The Montreal protocol and international agreement to protect stratospheric O3 required national reductions in use and eventual phase-out of chlorofluorocarbons (CFCs) and halons, gases that cause depletion of stratospheric O3. The trading programs to achieve these reductions were implemented nationally (with the exception of trading within the European Union). The trading program implemented in the United States was innovative because, under Title VI of the 1990 CAA Amendments, it recognized that different chemicals had different O3-depleting potentials (ODPs), and the chemicals were assigned different weights, depending on their ODPs. Subsequently, this program was supplemented by a tax on virgin CFCs. The tax was introduced principally to capture the profits that accrued to holders of permits that were created by the scarcity of permits. Ultimately, the tax may have been the most effective instrument in the CFC phase-out in the United States. |

of low-sulfur fuels). The utility can also elect to meet its emission allocation in part or in whole by purchasing additional allowances from others with a surplus. In exchange for the flexibility given to emission sources to meet their emission allocations, each source was required to install CEM systems and report emissions to EPA on a quarterly basis. EPA is responsible for managing an allowance tracking system and for ensuring compliance with the program. Failure to comply results in a $2,000 per ton fine and a requirement to reduce emissions the next year by an additional ton for each excess ton of SO2 emitted.

Congress designed the SO2 trading program to be implemented in two phases. Phase I began in 1995 and affected electricity-generating facilities with a capacity of 100 megawatts (MW) or greater and with an emission rate of 2.5 pounds or more of SO2 per million Btu of heat input (GAO

2000). Phase II began in January 2000 and expanded to include all electricity-generating facilities over 25 MW. At the beginning of the Phase II program, annual electric utility emissions of SO2 were capped at 9.2 million tons. By 2010, the cap is scheduled to drop to 8.95 million tons, which will be equivalent to a 10-million-ton or a 50% reduction in emissions from electricity generation when compared with those in 1980.

Economic and Emissions Performance of the SO2 Trading Program

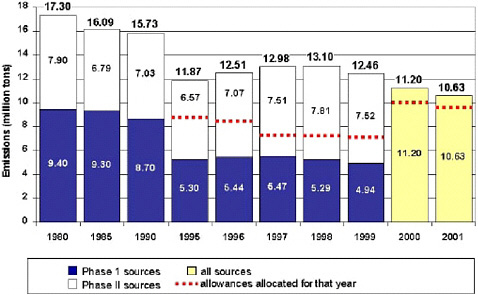

The SO2 emissions trading program provided the large reductions in SO2 emissions from stationary sources and at much less estimated cost than would have been obtained from traditional technology-based control strategies (GAO 2000). EPA reported that all companies maintained compliance from the inception of the program through 2000; some noncompliance occurred in 2001 apparently as a result of simple and small accounting errors (EPA 2001d). A decrease of 3 million tons of SO2 was seen in the beginning of the program (EPA 2001d), and the total achieved reductions from Phase I was approximately 22% over the base allocations (see Figure 5-1). The beginning of Phase II saw an additional 1-million-ton decrease in SO2, bringing the nationwide total emissions to 11.2 million tons. This

FIGURE 5-1 SO2 emissions from electric utilities in the United States from 1980 to 2001. The emission reductions between 1990 and 1995 are attributable to actions taken to implement the acid rain section of the CAA 1990 Amendments and have been documented by continuous emission monitors. SOURCE: EPA 2002l.

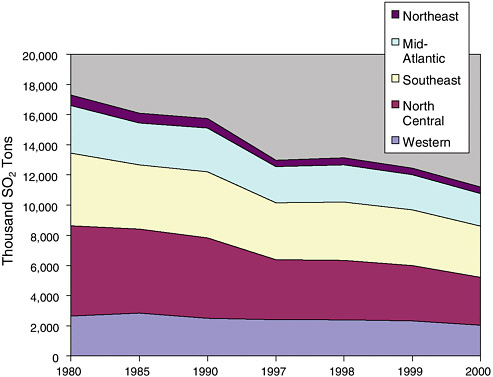

total was slightly higher than the cap for the year 2000, as sources began drawing on their banks of unused emission allowances accumulated from overcontrol during Phase I, but the total was still lower than that during any year of Phase I. A detailed discussion of the spatial pattern of these reductions is included later in this chapter.

Overall, EPA believes that the SO2 cap-and-trade program has produced more reductions more rapidly and at a lower cost than anticipated when the legislation was passed. At the time of its passage, it was estimated that Phase I and Phase II would cost $4.6 billion per year. However, current estimates project total costs at only $1 billion (see Box 5-6). The compliance flexibility allows facilities with high-cost controls to purchase

|

BOX 5-6 The savings obtained in the cap-and-trade program to reduce SO2 emissions from electric utilities appear to have been substantial. At the time of enactment of the program mandated in Title IV of the 1990 CAA Amendments, the costs for the program were projected at $4.6 billion per year. However, as has often been the case for the emission-control programs mandated in the CAA, the actual costs have been substantially less than first projected. It is now estimated that when the bank of emission allowances achieves equilibrium in about 2010, the cost of the program will be just over $1 billion per year. Is that cost a significant savings over the costs of more conventional approaches? The answer appears to be yes, although estimates of the cost savings depend on the baseline against which the program is compared. Compared with programs using performance standards, the emission-allowance trading program is estimated to have reduced implementation costs by 30–50% (Carlson et al. 2000; Ellerman et al. 2000). Compared with a prescriptive technology approach, such as the requirement of scrubbers at a certain class of facilities, the trading-program savings have been estimated to be substantially higher (Carlson et al. 2000). There has been a tendency to overstate the savings of the trading program. That stems from a failure to recognize a trend in the electricity, coal, and railroad industries toward greater use of low-sulfur coal at existing facilities, thus reducing SO2 emissions without new regulations in 1990. The SO2 trading program enabled the industry to capitalize on this trend, however, by making use of the flexibility inherent in permit trading. A program based on the imposition of performance standards also could have taken advantage of the fortuitous trend in the availability of low-sulfur coal (although probably not as thoroughly as a cap-and-trade approach).a A prescriptive program (for example, one that requires the installation of scrubbers) would not have gained a similar benefit. |

allowances from others with low-cost compliance options. A portion of the cost decrease can be attributed to the financial incentive to improve scrubber technology. About 40% of the reductions came from the use of scrubbers. Another important low-cost strategy estimated to be responsible for about 60% of the reductions came from switching to low-sulfur coal—a switch that was greatly assisted by the deregulation of railroad transport, which made western low-sulfur coal cheaper (Ellerman et al. 2000). This particular option for low-cost control may not be available in the trading of every pollutant; however, the potential financial incentives under a cap-and-trade program can be expected to result in the reduction of costs in unanticipated ways.

The features that appear to have contributed to the successful design of the SO2 trading program include large emission reductions, simplicity, effective monitoring, transparency, certain penalties, and the opportunity for banking emission allowances.

-

Substantial emission reductions: The overall cap set by Congress for SO2 emissions represented a 50% reduction in emissions nationwide. Such a large emission-reduction mandate was most likely key to ensuring that trading between regions did not produce spatial pockets of emission increases.

-

Simplicity: The SO2 trading program set a clear aggregate cap on the total annual allocation of emission allowances for all large fossil-fuel-fired electricity-generating facilities and allowed nearly unfettered opportunities to trade or bank emission allowances.

-

Availability of CEM systems: CEM systems have come at a substantial cost and might not have been required technically, because engineering formulas could reliably predict SO2 emission rates from the sulfur content of coal. However, mistrust between environmental advocates and the regulated community led to uncertainty about when and whether post-combustion controls, such as scrubbers, would operate. Compliance assurance under trading required measurement of actual emissions. The technology to do so, as well as the computing capability to process large amounts of emission data, emerged just in time to facilitate the SO2 trading program.

-

Transparency: The electronic allowance tracking system maintained by EPA posts allowance holdings and transactions and emission data in a prompt fashion. The resulting transparency facilitated the simplicity of the SO2 trading program, which in turn contributed to its overall success.

-

Certainty of penalties: Noncompliance triggers a prespecified financial penalty plus the surrender of a number of allowances for a subsequent year.

-

Opportunity for banking emission allowances: This opportunity has contributed greatly to the cost savings of the SO2 trading program (Ellerman et al. 2000). Banking provided a mechanism for firms to insure

-

against adverse conditions caused by fuel markets or their own compliance activities. In addition, it facilitated “buy-in” by some of the regulated parties into the program design, because banking endows them with an asset that is only of value when the program is successful and stable.

NOx Emissions Trading Programs

Regional Clean Air Management

The South Coast Air Quality Management District (SCAQMD) implemented the Regional Clean Air Management Program (RECLAIM) in 1994 to stem the tide of rising industrial emissions in the Los Angeles Basin. RECLAIM was initially designed to control stationary-source emissions of NOx, SO2, and certain reactive organic gases by using cap-and-trade provisions. However, reactive organic gases trading did not function because of the difficulty in establishing a baseline for allocating allowances, and SO2 trading was problematic because of emissions being concentrated at a small number of power-generating facilities. As a result, RECLAIM focused on trading NOx emissions. The program operates under a total emissions cap, which declines at a rate of 5–8% per year. When fully implemented in 2003, overall emissions are expected to be reduced by almost 80%.

The NOx program encountered difficulties because of two unforeseen eventualities:

-

The initial allocation was based on a period of high economic activity. When the economy slowed, companies found themselves endowed with substantial excess allowances. Interyear banking of emission allowances was therefore prohibited.

-

The year 2000 was pivotal for the program because it was the first year when aggregate annual allocations would fall below aggregate emissions, thereby requiring actual sectorwide emission reductions. Unfortunately, most companies had not elected to make investments in control technologies before 2000. At the same time and for reasons unrelated to RECLAIM (for example, deregulation of the electricity market and alleged market manipulation by suppliers), there were widespread problems in electricity distribution in California in the summer of 2000. The summer of 2000 was also unusually hot in California, and that led to a high demand for electricity. The confluence of the factors, along with the absence of a banking mechanism in RECLAIM, created difficult challenges for the program. Electricity demand spiked, and to prevent widespread power disruptions, the participation of power generators in the RECLAIM program was suspended so that these facilities could operate at rates that caused them to exceed their emission allocations.

In addition, EPA recently reviewed the RECLAIM program (EPA 2002m). The lessons EPA derived from RECLAIM for other market-based programs include the following:

-

Market-based programs require substantial planning, preparation, and management during development and throughout the program’s life.

-

Market information is a key factor affecting decision-making at individual facilities.

-

Regulators should strive to create confidence and trust in the market by making a full commitment to the program and ensuring consistency between the market and their policies.

-

Unforeseen external circumstances and policies (such as energy deregulation) can have dramatic impacts on market-based programs. Therefore, these programs must be designed to react quickly and effectively to unforeseen external factors.

-

Periodic evaluation, revisiting of program design assumptions, and contingency strategies are crucial for keeping programs operating effectively.

-

RECLAIM’s experience seems to demonstrate that cap-and-trade programs can work with new-source review. That finding may be a function of the types of sources included or the controls in place at many facilities.

-

Regulators need to have a strong understanding of the regulated facilities and the factors affecting their decision-making.

Since 2000, the SCAQMD has substantially amended and imposed the RECLAIM rules (SCAQMD 2001), and trading prices have returned to pre-2000 levels. At this writing, SCAQMD is actively considering seeking additional NOx reductions from RECLAIM (SCAQMD 2003).

Northeast O3 Transport Region NOx Budget Trading Program

This program was developed by the states of the Ozone Transport Region (OTR) to supplement the NOx emission reductions mandated under CAA provisions for RACT in Title V and the Acid Rain Program of Title IV, which did not adequately address the regional transport of NOx and O3 and the resultant nonattainment of the O3 NAAQS in the region. The OTR mandates the use of a cap-and-trade system involving large stationary sources to reduce NOx emissions during the May-to-September O3 season. It aims to reduce total emissions by 55–65% in the 1999–2002 interval and by 65–75% starting in 2003. The program was initially designed to have two trading zones to avoid possible regional disbenefits of trading but was finally implemented without constraints to maximize cost savings. Interyear banking of allowances is limited in the program through a provision known

as “progressive flow control,” which limits the size of the aggregate bank. (Banking is discussed later in this chapter.)

NOx SIP Call Trading Program

The next bellweather in emissions trading is expected to be the initial implementation of the NOx SIP call trading program in 22 states and the District of Columbia during the 2004 summer O3 season. The program will target large stationary sources of NOx emissions, mostly electricity-generating facilities, by requiring that the affected states revise their SIPs to achieve NOx emission-reduction targets assigned by EPA. EPA will allow, but not require, states to participate in an interstate trading program. This program will subsume the current OTR trading program and is expected to meet or exceed the annual cost of the SO2 Acid Rain Program. The program imitates the SO2 trading program in many respects, but like the OTC program, it has limited opportunity for inter-annual banking of emission allowances.

Cap and Trade in Proposed Multipollutant Legislation