Sequestration via Injection of Carbon Dioxide into the Deep Earth

FRANKLIN M. ORR, JR.

Stanford University

We have a number of alternatives for dealing with large quantities of carbon dioxide (CO2) in ways that do not put it into the atmosphere. We know, for example, that oil and gas reservoirs store carbon on geologic time scales— millions of years. If we start with the premise that geologic formations can store carbon on this scale, then we can conclude, I think, that the possibility exists of putting large quantities of carbon back into such formations and leaving it there for long periods of time.

The question is whether we can take advantage of this possibility. We do have some technologies already in place that are capable of injecting CO2 into geologic formations. The engineering issues associated with oil and gas recovery and sequestration are closely linked, and a considerable body of engineering expertise already exists. I will discuss three alternatives for injection sequestration: (1) oil and gas reservoirs; (2) coal beds; and (3) deep saline aquifers.

We already have the technology to inject CO2 into oil and gas reservoirs. We also have technology available for recovering methane in coal beds, and we know how to inject CO2 into deep aquifers that contain salt water. If we can resolve safety issues and accurately predict the long-term fate of the injected CO2, it may be possible to store large quantities of CO2 in geologic formations.

But, as we approach the entire problem of atmospheric CO2, we are not likely to find a single solution. Moreover, the volume of atmospheric CO2 is enormous—gigatons per year. In other words, to make a difference, we must be able to store, say, a billion tons of CO2 per year. That would require us to store something in the neighborhood of 25 million barrels of CO2 per day under typical reservoir conditions. We now move about 75 million barrels of liquid petroleum

around the planet every day, as well as large amounts of natural gas. So we already move large quantities of fluids, but the volume of CO2 would be very large. We are going to need many options, the ones already mentioned and many we have not yet thought of. We must plan to develop a portfolio of responses.

An obvious possibility that goes with storing CO2 in geologic formations is to inject the CO2 to recover oil and gas. CO2 is already being injected into oil-and gas-bearing formations to displace the oil and gas from porous rocks into wells where it can be recovered. That is a very different concept from inject-and-forget storage. With recovery, we actively displace oil from one spot to another, and there is field evidence that this can be done with reasonable efficiency.

In the mid-1990s in the United States, there were 66 projects involving injection of high-pressure CO2 to recover oil. Most of the injected CO2 is recovered from underground formations in the Four Corners area and transported by pipeline to west Texas, where it is injected to recover oil in the carbonate oil fields north of Midland. The amount of CO2 injected is a small fraction of the total amount of CO2 emitted in the United States, however, about 0.50 percent of current U.S. fossil-fuel emissions. In addition, these projects do not sequester atmospheric CO2 because they use natural CO2 tapped from underground. However, one project in Canada uses CO2 recovered from a coal-gasification plant to recover oil in a nearby field. It is also true that options for recovering natural gas have not been as well explored as options for recovering oil.

If CO2 were abundantly available, it would be much more widely used for oil recovery because it is a very efficient agent for recovering oil. The primary limit on CO2 injection for oil recovery is the availability of CO2. If sufficient volumes of injection gas were available, it could be used in a very wide range of reservoir situations. The reason it is not used this way now is entirely a consequence of availability.

The effectiveness of CO2 as an oil-recovery agent is attributable to the phase equilibrium of CO2 with oil. CO2 dissolves in oil, and components in the oil transfer into the CO2-rich phase. The resulting mixtures can then displace oil efficiently in the zones swept by the injected CO2. The efficiency of the displacement process is often limited, however, by reservoir heterogeneity—that is, the natural variability of the rocks. CO2 has low viscosity and finds easy flow paths through the reservoir rocks. In a displacement from an injection well to a production well, the injected gas flows preferentially through high-permeability flow paths. One of the limits in this setting is the fraction of the reservoir’s volume that can be swept without recycling major amounts of CO2.

Gravity segregation of the injected CO2 can also be important. If there is reasonable vertical permeability, the injected CO2 can flow upward to create a thin tongue of low viscosity under shales or other barriers to vertical flow. Once these zones of fast flow have connected the injection well to the production well, surrounding zones of less rapid flow are invaded more slowly. Considerable effort has been expended to reduce the amount of CO2 required to recover oil. If

the objective were to store the maximum amount of CO2, the design constraints would be different.

Unfortunately, oil and gas fields are not necessarily located near the places where CO2 is produced. Thus, another factor that becomes significant in sequestration is transportation costs, which could make this method of storing CO2 inefficient in some parts of the world. It can be a good solution for places where appropriate geological formations are not far from the CO2-generating sources.

A key factor will be accurate prediction of displacement performance. If monitoring and permitting are important issues, then predicting where the fluids will go in the subsurface and determining where they have gone will be issues for consideration. We will have to learn how to monitor storage projects at reasonable cost.

The second possible area for geologic CO2 sequestration is in coal beds. About 5 percent of the natural gas produced in the United States is methane that comes from coal beds. The fact that methane is found in coal is well established and has been a problem for coal miners. Most methane is adsorbed on the surfaces of coal particles. CO2 also adsorbs on coal particles, and it does so more strongly than methane. Suppose we injected CO2 and the CO2 then adsorbed on the coal surface, displacing some of the methane. We could then use the fracture network of the coal to transport the methane to wells where it could be taken to the surface. This adsorption behavior has been studied for some time now. Coal surfaces could adsorb about twice as much CO2 as methane.

Thus, coal beds might be used as chromatographs. Here is how that would work. Starting with a coal-bed concentration high in methane, we could inject a mixture of CO2 and nitrogen, producing a separation so that the nitrogen is forced out first. The CO2 would then be trapped, while the methane was recovered. To pursue this technique, we will have to have better ways of predicting flow behavior—sorting out the adsorption details, studying what happens to fracture permeability as the CO2 adsorbs, and determining the state of stress in the reservoirs. We will also need broader brush techniques so we can select appropriate coal seams. In addition, we will have to look more carefully at the long-term fate of adsorbed CO2.

Methane is adsorbed on coal surfaces for geologic periods of time, so it is possible that similar long-term storage of CO2 is possible. Coal-bed dewatering and water disposal issues will also be important, and we should not discount them. To move other fluids, we will have to displace water and dispose of it properly. The effect of these procedures on aquifers will also have to be taken into account.

One test of this method is under way in the Four Corners area using CO2 from the same pipelines that carry natural CO2 to west Texas. In the test, CO2 has been injected for a considerable time with minimal breakthrough, but serious problems with water and water handling have been encountered. There is a lot more to be learned in this area.

The third possible method of CO2 sequestration is injection in aquifers. For the sequestration of large amounts of CO2, we require large volumes of porous rocks, typically sandstones and carbonates. Many are not oil and gas reservoirs but contain salt water, and these porous formations could be used to sequester CO2. The big difference between an oil and gas reservoir and an aquifer is that, in an oil and gas reservoir, we know there is a seal—a geologic formation with some combination of impermeable rocks that traps the oil or gas. With an aquifer, that is not necessarily the case. Moreover, not much money has been spent to delineate aquifers in the same detail that oil and gas reservoirs have been delineated. The immediate problems in aquifer formations are the significant uncertainties in the geometry, extent, and flow properties (permeability distribution.) Similar uncertainties pertain to characterizating oil and gas reservoirs, but much more information is available.

One aquifer injection project is under way in Norway where a high tax on carbon makes it cheaper for companies operating there to reinject CO2 than to emit it into the atmosphere. This test involves the injection of about a million tons per year of CO2 into an aquifer.

CO2 injection into aquifers, of course, creates interesting geochemical problems. CO2 displaces water relatively inefficiently. It also dissolves in both brine and fresh water making an acid capable of dissolving carbonate rocks. There are also other potentially problematic mineral interactions, some of them long-term problems.

The injection technology required is essentially the same as the technology for injecting CO2 into oil reservoirs. For aquifers, however, permitting and monitoring are certain to be larger issues than they are for oil and gas reservoirs. In addition, we have not yet sorted out the long-term geochemical questions.

Let’s turn now to verification and monitoring. It is easy to figure out how much CO2 we put into the ground. The oil industry does this all the time using injection metering. But monitoring where the CO2 goes next is a different story. In settings where there is some production, where fluid is removed from the reservoir, we can immediately find out where the CO2 has gone by looking at the composition of the fluids produced. But in large-scale aquifer storage, immediate tracking is less likely to be available. The cost of monitoring will very likely limit aquifer storage to experimental situations.

Monitoring could be based on seismic information, both time-lapse and cross-well data. It may also be possible to obtain information passively by listening with down-hole sensors. Now that sensors are becoming cheaper, it is possible to equip a set of wells with sensors and listen to them all the time for changes in an aquifer or reservoir. It is also possible that other electrical methods or synthetic-radar aperture methods could be used.

CO2 poses unique safety questions. Although it is not flammable, it is an asphyxiant, and it is relatively dense. If it leaks at the surface and there is little wind, it pools, creating a dangerous area that could suffocate people who

inadvertently venture into it. This is not a theoretical problem. Just such an accident occurred in west Texas in the mid-1970s, when a leak occurred in a surface facility during the night. The leaking gas also contained hydrogen sulfide—a lethal mixture. Four people were killed when they drove into the area and were rapidly overcome. We must address these safety issues very carefully.

We already deal with related issues in large-scale engineering systems. For example, we transport natural gas around the country in large pipelines that present fire and explosion hazards that do not exist for CO2. The greatest risk is probably in well-bore failures. When we inject CO2, we want it to go all the way to the formation and not depart en route. It will take some effort to understand how to achieve that. But these kinds of problems are addressed all the time in industry, and I think they can be dealt with in this instance.

A more serious problem may be long-term subsurface reservoir leakage. Information about the integrity of the geologic seal will be vital. We know that changes in geologic stress can damage the seal above an oil reservoir over the lifetime of the reservoir. In aquifer settings, there are more uncertainties than in oil reservoir settings.

The basic technologies for injecting CO2 already exist. For CO2 sequestration to be practical, however, we will have to put forth significant effort. We must also expect that many approaches will be part of the solution. There will be no silver bullet.

Using Carbon Dioxide to Recover Natural Gas and Oil

GARDINER HILL

British Petroleum Group

Being more of a businessman than an academic, I want to start by talking about the challenge of cost. If you look at carbon dioxide (CO2) capture and storage projects, you see that 75 percent of the cost of a new project is in the capture technology, and 25 percent is in the storage technology. Overall, the cost of capture and storage today are very high. Capture and storage are already used in the food processing industry, so we know it can work on that scale, but cost will remain a big issue. We are looking to find a cost-effective, verifiable, viable way to store at least a million tons of CO2 in reservoirs.

The next challenge we face is health and safety, which we believe must always remain at the top of the agenda. People are right to have safety concerns about the use of CO2. We have to ensure that when we use CO2, when we capture it and store it in geologic formations, we do it safely.

The third challenge we face is environmental. In trying to solve the current environmental problem, we don’t want to create a new environmental problem with the solution we think is appropriate today. We must be mindful of how the world may change in the future.

Another challenge is assurance. If we are putting CO2 into a reservoir, we must be able to ensure that it will stay there for as long as we want it to stay there. That is especially important if money is changing hands in connection with treatment or offsets. People want to be sure that their investments are long term and sensible.

We believe technology is the key to solving the problem, but as other speakers have pointed out, there is no silver bullet. We need a portfolio of options for the most efficient solutions to distinctly different problems. Some technologies

will have to be retrofitted, some will have to be new, some can be used to inject CO2 into oil and gas reservoirs, and some storage may take place in aquifers.

Two other major challenges are scale and time frame. When is action necessary? Many people believe that it is urgent that we act now. But what actions should people or companies take today? What about future uncertainty, given all the uncertainties about the future? What policies might future governments introduce? What incentives or tax situations might be available in ten years? How do we know the actions we take today will be appropriate in the future?

There is a real bias, a strong preference today, for taking preventive action. A number of companies, governments, and academics want to use the time available to us to identify solutions. To that end, a large number of companies are working together, sharing resources and experiences to reduce the risks and costs of finding a solution to the climate problem.

Public/private partnerships, like the CO2 Capture Project, will be very important to the solution, and they represent a great opportunity. These partnerships and cofunding agreements give industry the confidence to move forward. The CO2 Capture Project is taking a distinctive integrated approach to the use of CO2 to recover natural gas and oil and, hence, to stretch our natural reserves. The project is exploring the possibilities in the context of real applications—specific fields and operations where we would like to capture and store CO2.

We know that large-scale storage technologies are not available today. The showstopper to using storage technology could well be the problem of subsurface monitoring. If we don’t handle that correctly, we may not get permission to use capture and storage technology as an option for mitigating against atmospheric CO2 concentrations.

Why are we focusing on capture and storage technology? First of all, capture and storage technology clearly provides an opportunity to add value to the use of CO2. It enables us to reduce CO2 emissions both by attacking a large-scale source of CO2 emissions and by using geological formations as storage. Many energy companies already have large sources of CO2 and sinks. The synergy between sinks and sources could be an advantage in tackling this complex problem.

The CO2 Capture Project has two very simple objectives. First, we want to reduce the costs of CO2 storage through technology development. We hope to achieve a 50-percent reduction in cost for retrofits and a 75-percent reduction in new-build applications. Second, we want to demonstrate to external stakeholders that CO2 storage is safe, measurable, and verifiable. We plan to initiate at least one large-scale application that will be in operation by 2010. For this specific project, however, we will have a proof-of-technology concept by the end of 2003.

Nine companies are involved in the project—BP, Chevron, Texaco, ENI, Norsk, EnCana, Shell, Statoil, and Suncor. It is split into three distinct regions: (1) the United States, which is the largest; (2) Norway; (3) and the rest of Europe. Each region participates in a cofunding arrangement, and the companies share technologies, experience, and learning to avoid duplication and to promote the

development of the technology. The participants put up about 54 percent of the overall funding ($25 million). The U.S. Department of Energy is putting up 21 percent of the total. The European Union and Norway are putting in 12 and 30 percent respectively.

The program is nearing the halfway point. It began in early 2000 with a review and evaluation phase to define the state of the art at that time and to identify the most favorable areas for technology development. Next came an analysis phase to identify the technologies with the greatest chance of meeting program objectives. The program is now in the contract and procurement stage fostering broad technology development. This phase should last until the end of 2003, when a proof-of-concept of the technology will be demonstrated.

We are investigating three types of capture technology. The first is pulse combustion decarbonization to capture CO2 from flue gas. This technology is already in use in the food processing industry, which uses an amine absorption process to scrub CO2 from flue gas and compress it to make it available for geologic storage. The second method is called precombustion decarbonization, which takes fossil fuel, reforms it to make hydrogen and CO2, compressing and storing the CO2 and using the hydrogen to generate power and heat. The third method is called oxyfuels. This method uses fossil fuel in the presence of oxygen to generate water, steam, CO2, power, and heat. Oxyfuels is the least developed and the least understood of the three, but it is important because it captures and separates CO2 from fossil fuels.

On the storage side, we are looking at the classical geological options— storage in oil and gas recovery infrastructure, storage in depleted oil and gas reservoirs, and storage in coal beds. Gas and coal-bed methane are much less mature options than oil reservoirs but may have considerable potential.

The large-scale use of CO2 to stretch our natural resources began in Texas in 1972. Today there are more than 70 CO2-based projects worldwide, many of them in the United States. In 2001, about 30 million tons of CO2 were injected, producing 180,000 additional barrels of domestic oil a day—a significant achievement. However, only about 7 million tons of that CO2 was man-made; most of it was natural CO2.

Oil and gas reservoirs have a potentially huge capacity to store CO2. A conservative estimate is that 40 to 50 billion tons of CO2 could be stored in oil reservoirs. We are not aware of any CO2 being used to enhance gas recovery, but a number of companies have begun looking into the potential of using CO2 in this way. Under some conditions, using CO2 for gas recovery could be valuable. The CO2 storage capacity in gas reservoirs could be significant—estimates suggest it could be almost double the capacity of oil reservoirs, perhaps as much as 80 to 100 billion tons of CO2.

Coal-bed storage could be very useful as well. There are at least two coal-bed methane projects in the continental United States. Coal beds could have a huge storage capacity, conservatively estimated between 50 and 200 billion tons.

The mechanism for coal-bed storage is actually very interesting because CO2 attaches itself to the surface of the coal and displaces the methane, thus enhancing methane production.

Finally, CO2 might have other uses. Maintenance of reservoir pressure is the most important use. CO2 could be used extensively in oil and gas reservoirs, as well as to offset subsidence. CO2 may also have other industrial uses, such as in the production of carbonate steels.

The CO2 Capture Project is addressing many important questions. What formations are suitable for CO2 traps, and what are their most important properties? How will faults and cap rocks respond, both in geochemical and geo-technical ways, to large quantities of CO2? How would the competence of the cap rock change? How is that change related to reservoir pressure that may vary over long periods of time? How will defaults change over time when they are subject to large concentrations of CO2? What will the chemical reactions and products of rock water and CO2 interactions be? If precipitation reduces the ability of the reservoir to store CO2, what would the impact be on storage efficiency? Would it reduce the actual capacity and volume available and plug up reservoirs and wells?

Furthermore, can we inject CO2 over the long term? Will injection be permanent? How do we define permanent? If injection is not permanent, what leakage rates are acceptable? How might CO2 actually be stored, monitored, and verified? What is the best method of monitoring and verifying costs? The method we typically use today is very expensive and is implemented in a time frame of 50 to 100 years, which could translate into huge long-term costs.

In terms of costs, what are the economic drivers? How long will it be necessary to take those into account? When we develop oil and gas reservoirs, we typically think in terms of 20- and 30-year periods. Now we may be talking about periods of hundreds, perhaps thousands, of years.

In the end, we are looking for geological storage sites and technologies that will be acceptable to the public and to regulatory agencies and that will pose the fewest safety and environmental risks. The CO2 Capture Project has identified a number of gaps in the work that has already been undertaken. The first gap is in cost, which remains very high. Monitoring phases could potentially become very expensive, and individual surveys can run into the millions of dollars. Many surveys over hundreds of years using current methods would add prohibitive costs.

Another topic we identified as very important is risk assessment. This means putting mitigation strategies in place to deal with risks and taking steps to reduce them. Consider the risk of leakage. First, the most likely leakage will occur not at the surface but within the formation, so we will need mitigation strategies to reduce that risk. Leakage into formations might lead to the contamination of drinking water, which could cause serious health problems, especially if

contaminated water leaches through certain minerals or metal lines. Mitigation measures would be necessary to reduce that risk to as low as practically possible.

Long-term monitoring standards are another problem. We are using current tools and practices, but for monitoring to be cost effective and sustainable over a long period of time, we will need new tools and new procedures. And verification will be essential. We must be able to demonstrate that CO2 is going where we say it is going and staying where we said it would stay. If money is changing hands to provide storage, and if carbon credits are offset, the money people must know they are making robust investments. We are not paying for CO2 to leak back into the atmosphere.

The CO2 Capture Project has adopted a whole-risk assessment approach, using safety assessment methodologies and establishing risk assessment frameworks important for public perceptions and public involvement. Monitoring is a major component of risk assessment, and we have monitors in place to tell us the effects of injection properties on reservoirs and cap rocks. We are also looking into novel geophysical techniques to monitor the movement of CO2, such as long-term sealing of wells, which are the most likely sources of leaks. Natural reservoirs have been storing hydrocarbons for geological time frames. When we punch wells into them, we break the integrity of the seal, hence the leakage potential from wells. Integrated simulation is another important tool. Through simulation and modeling of basins, we hope to learn how CO2 might migrate. We can also do verification by using natural CO2 analogs and investigating fracture mechanisms to evaluate seal integrity.

Let me summarize what we have done so far. We have completed the review and evaluation phase. In the analysis phase, we reviewed more than 100 technologies and identified 30 key technologies we believe have the potential to meet the program and project objectives. Cofunding is in place, and we have already issued 100 contracts for work on capture and storage technologies. We have participated in some outreach, and we are creating more outreach programs. We are working with academics and nongovernmental organizations to improve public perceptions of this technology, particularly for CO2 storage and CO2 injection into oil and gas reservoirs. We want an open dialogue to gather information to incorporate into our programs. All of the participating companies have endorsed the research and development (R&D) plan, and we have established the project as an integrated international corporation agreement.

What next? As we move through the R&D phase, we will narrow down the number of technologies we are working on, focusing on the ones with the most promise of meeting our objectives. In addition, we are always looking for novel ideas. We will continue to have a constructive dialogue with external stakeholders and work hard to understand the cost levers to meet project objectives. Our goal is to develop technology that gives us options at a cost industry can afford. We are working on economic models to help us achieve that.

In 2003, we’ll be planning how we will demonstrate the technology and determine if it will be appropriate at scale. Our objective is then to make that technology available and put it into general use throughout the industry. Finally, we will continue to share information on our web page at CO2captureproject.org.

Geologic Sequestration of Carbon Dioxide

SALLY BENSON

Lawrence Berkeley National Laboratory

Today I will give you a few examples of the research going on to support the development of geologic sequestration of carbon dioxide (CO2). But first, let’s review our needs. First, we must have a better understanding of technologies for so-called value-added CO2 sequestration—that is, enhanced oil and gas recovery. These technologies could greatly lower the cost of sequestration. A second very important area is the development of reliable, low-cost monitoring technology, not only to monitor where CO2 is going, but also to monitor interactions between CO2 and host materials. Third, we need performance assessment models, basically simulation technologies to help us predict and optimize the important factors in sequestration. Simulation technologies must include: where the CO2 is going; how it interacts with rocks; what geomechanical stresses it places on the system; and whether it interacts with microorganisms. We will need robust simulation tools to enable us to do all of this. Fourth, we will need methods of assessing storage capacity. The storage capacity in oil and gas reservoirs is significant, and the capacity in brine formations is huge. A great deal more work must be done before we can place some bounds on these capacity assessments. Finally, we will need criteria for selecting sites.

The U.S. Department of Energy began its research and development programs in geologic sequestration three or four years ago. As the discussion broadened to include more interaction with industry, environmental organizations, nongovernmental organizations, and other stakeholders, some very pressing issues have emerged. The first of these is that we will need robust performance requirements to enable us to decide whether a site is suitable or not for CO2 storage. We will have to decide what the critical issues are and how to go about

permitting a facility on a solid scientific foundation. Finally, a very important area is risk assessment and mitigation technologies. How do we assess risks in a predictable and repeatable way that the public, regulatory agencies, and project operators will all understand and agree with?

CURRENT RESEARCH

Value-Added Sequestration

The first major area of active research is technologies for value-added sequestration. Enhanced oil recovery is a mature technology, as others have pointed out. In fact, enhanced coal-bed methane production, although a much less developed technology, is also receiving a lot of attention in the industry. Nevertheless, even mature technologies will require more research to assess the best way to use CO2 sequestration.

The idea behind CO2 sequestration for enhanced gas recovery (CSEGR) is to take CO2 separated from a power plant, compress it, and reinject it into a natural-gas reservoir to enhance natural-gas production. This technology is not in use today. In fact, when it was first suggested, the conventional wisdom was that it would not work. Many believed that when the CO2 was put into a gas reservoir, it would mix with the natural gas very quickly. But a number of studies have shown otherwise, so we decided to study it more, in hopes of squeezing out the last bits of natural gas from a depleted reservoir. Natural gas reservoirs are also very attractive targets for CO2 sequestration because they offer known containment and proven isolation for gas in the subsurface geologic environment.

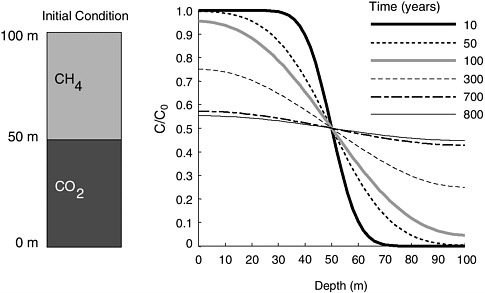

What kind of research is being done on gas recovery? First, research is focused on molecular diffusion between the CO2 injected into the reservoir and the natural gas still present to determine how quickly this takes place. Analytical systems have been developed for studying this question. For example, Figure 1 shows that in a 100-meter-thick reservoir, it would take more than 800 years for the CO2 to mix completely with the methane. This suggests that the engineering process of CSEGR will take place in a much faster time frame. The results of these analyses suggest that natural recovery is worth pursuing.

The next question is whether we can show that the injection of CO2 into a reservoir will provide pressure support quickly enough to enhance production. Simulations have shown that pressure support would indeed be fast enough (Plate 1). In fact, it moved quickly enough that natural gas recovery could be increased; at the same time, the plume of CO2 would take about 20 years to move across the reservoir. Moreover, for the first 10 years, methane production could be increased with almost no contamination or dilution by CO2. Thus, total natural-gas recovery from this reservoir could potentially be increased by as much as 30 percent. This was the second critical step in evaluating the feasibility of CSEGR.

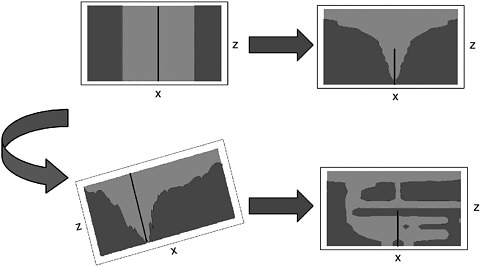

FIGURE 1 Conceptual model and results calculated from a new analytical solution for diffusion of gases with different densities. Source: adapted from Patzek et al., 2003.

Early simulations were highly conceptualized and idealized in many ways. In the next phase, simulations showed what would happen in a real reservoir engineering-type well pattern, the so-called five-spot pattern—the typical way we inject CO2 into a reservoir from which we also want to produce natural gas (Plate 2). When we injected CO2 into the lower right-hand side of this system and produced methane out of the top, we found that the CO2 did not move quickly from the injection well to the producing well. Because CO2 is so much denser than the resident methane, it basically formed a pancake and swept upward through the reservoir. This attribute would be very favorable for CSEGR. This is just one example of the kind of innovative work that may help us develop more options for value-added sequestration.

Monitoring Technology

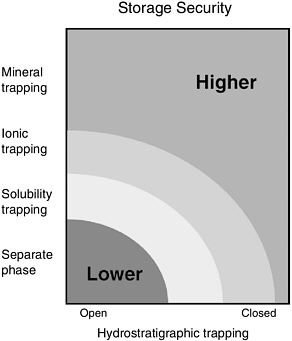

A second focus of research is low-cost, reliable monitoring technology. In Figure 2, monitoring is simulated in the context of the security of geologic storage. When we inject CO2 into a completely closed hydrostratographic trap, we expect the CO2 to be retained in the structure. In that case, the security of storage is very high. The job of monitoring is to show that the CO2 indeed stays in the trap.

Some systems we call open traps. If CO2 is injected into these systems, over very long periods the CO2 may be free to migrate and interact with the rocks. In

FIGURE 2 Conceptual description showing that the security of CO2 storage depends on physical and geochemical trapping.

open-trap systems, the security of storage will depend heavily on the extent of geochemical interactions between CO2 and the host materials. For instance, some CO2 could dissolve into water or oil. In addition, adsorption may occur, for example, onto coal. Finally, there might be mineral trapping, in which case stable mineral phases might be created that would remain underground. We would like to put together a suite of monitoring technologies that can tell us not only about the physical trapping of CO2, which we already understand quite well, but also about the geochemical trapping of CO2.

A pilot project has been conducted along these lines in the Lost Hills Oil Field in California by Chevron and Texaco. In this enhanced oil recovery project, the participants agreed to provide a suite of monitoring wells to determine where the CO2 was going. The goal was to develop complementary monitoring technologies. We decided to look at cross-well seismic imaging, which provides very high-resolution images between the injection and producing wells. We also tried electromagnetic methods, which complement seismic technologies by transmitting information about the saturation of water in the pore bases, a very important piece of information. We also looked at other monitoring technologies, such as high-resolution, single-well seismic monitoring, and we added a suite of tracers so we could begin looking at issues of solubility and mineral trapping (Figure 3).

By the time this project was completed, it had become very challenging,

FIGURE 3 Photograph of the monitoring setup for cross-well seismic tomography at the Lost Hills CO2 injection pilot project.

particularly in light of what we were trying to accomplish. We wanted to measure the saturation of CO2 into the pore spaces. I have come to believe that this is going to be very complicated in mature oil and gas reservoirs, because an oil and gas reservoir has multiple fluid phases present—oil, gas, and water. The presence of multiple fluid phases, particularly the presence of free gas, makes it extremely difficult to track CO2. We are working on methodology for combining multiple geophysical techniques, such as high-resolution electromagnetic and seismic imaging technologies to tell us something about the saturation of CO2 in the formation (Plate 3).

Performance Assessment

We now turn to performance assessment models. How do we predict what will happen when we put CO2 underground? This, I think, is best considered in the context of the security of CO2 storage. We would like to know about where CO2 will migrate, about solubility trapping, and about mineral trapping and absorption in mineral phases.

One of the very practical problems we face is how much CO2 we can store underground and how we can use simulation models to provide information about it. If we inject CO2 into a reservoir, we expect that, because of the low

viscosity of CO2, it will only partially sweep out the pore spaces. In fact, the average saturation of CO2 in a water-filled system may be 30 to 50 percent. We are starting to understand some of the fundamental processes and features we think will be important to determining the most effective use of underground storage capacity.

It is also important that CO2 is significantly less dense than the brines that will receive injections. CO2 densities at reservoir depths typically range from 600 to 800 kg/m3. Brine densities will be on the order of 1,000 kg/m3. The density difference leads to strong buoyancy forces that drive the CO2 plume upward to the base of the cap rock. To understand these forces, we need tools to model them.

Because of the natural heterogeneity of all geologic systems, we will need simulation models to predict the influence of this more complex sort of plumbing. We can start with models first developed by the oil and gas industry, then by the environmental cleanup industry, which have been available for decades. We can then modify and enhance these models to simulate geologic sequestration of CO2. We start with a subsurface grid, divide the subsurface into a number of pixels or boxes, and assign physical properties to them. We can then simulate what happens in these systems when we inject CO2. The available simulators cover the full spectrum of physical processes, chemical processes, and geomechanical processes. Although they are not perfect, we are developing the capability to study these issues, particularly for short-term processes. We will also have to understand much longer term processes, particularly the chemical processes that are likely to lead to mineral trapping over very long periods of time.

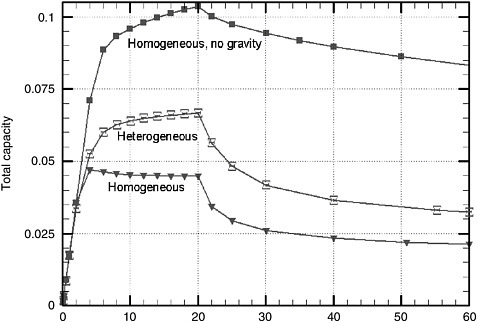

Figure 4 shows how multiphase flow, buoyancy forces, and reservoir influence storage capacity heterogeneity. In Plate 4, the subsurface is assumed to be uniform, with no buoyancy forces. Over a 20-year period, the volume we are studying is swept out by CO2. Plate 5 shows a uniform, three-dimensional model in which gravity plays a role. The CO2 plume forms an upward cone as the result of buoyancy forces. This is likely to be a very important effect that could have a serious impact on our ability to use the full thickness of the brine formations available for sequestration.

In Plate 6, a heterogeneous system with buoyancy, intricate subsurface plumbing has a huge impact on where the CO2 goes. It appears that heterogeneity may help us use the subsurface volume more effectively. This goes against the assumption of most reservoir engineers that heterogeneity is not helpful. In this case, subsurface heterogeneity may actually act like a set of baffles to increase the contact area between the injected CO2 and the rocks and other aspects of the structure, thus helping to counteract the influence of gravity. The influence of gravity can have a severe impact on available storage volume, sometimes even halving it. Evidently, heterogeneities can help mitigate the effects of gravity.

We can also compare the total capacity of the subsurface system as a function of time for these three cases (Figure 5). In a homogeneous reservoir with no

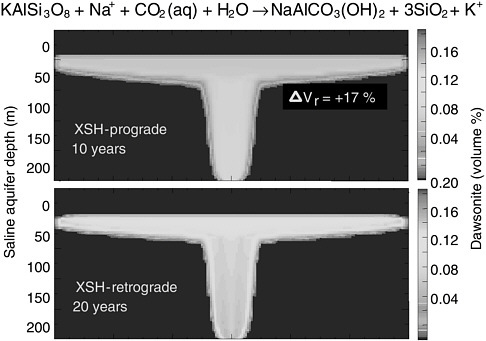

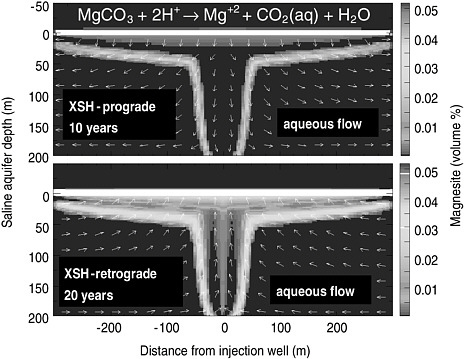

FIGURE 6 Reactive geochemical transport simulation showing the precipitation of dawsonite within the CO2 plume. Source: adapted from Johnson et al., 2001.

buoyancy forces, nearly 10 percent of the volume could be available; buoyancy cuts the capacity nearly in half. The heterogeneous case is midway between the homogeneous reservoirs, with and without gravity. This confirms that heterogeneities do, in fact, make it possible to store more CO2 in the reservoir. After 20 years, when we stop injecting, the CO2 concentrations actually start to decrease. Thus, after CO2 injections stop, factors such as buoyancy forces continue to move CO2 out of the system and upwards, until it either finds a stable trap or returns to the surface.

Further simulations are being developed for geochemical reactions. Scientists at Lawrence Livermore National Laboratory have found that a small degree of dawsonite cementation may occur in the pore spaces, not enough to plug things up, but plugging—trapping CO2 as a mineral—is one more aspect of secure storage (Figure 6). Another interesting simulation shows that carbonate precipitation is unlikely to occur within the plume but will occur in rinds at the edges of the plume (Figure 7).

FIGURE 7 Reactive geochemical transport simulation showing precipitation of calcium carbonate at the edge of the CO2 plume. Source: adapted from Johnson et al., 2001.

Capacity Assessment

The Texas Bureau of Economic Geology has done some interesting work based on an examination of 21 formations and 19 basins in the United States. The study concluded that most of these have viable targets for sequestration. The targets are permeable formations with sufficiently thick reservoirs and thick low-permeability cap rocks. Detailed studies are being done of the Frio formation in Texas, a structure that underlies the Houston area and covers the entire Gulf Coast. The formation has high-permeability sand and very thick cap rock.

We are now beginning a pilot study in the Frio formation. Texas, which is the largest emitter of CO2 in the United States, has a significant interest in this study. The plan is to conduct a pilot injection experiment, injecting about 7,000 tons of CO2 into the formation. The Frio formation offers a very large sequestration target at an ideal depth of about 1.5 kilometers below the surface; the sand thickness varies from 100 to 500 meters; the porosity is about 30 percent. The project will include site characterization, modeling, CO2 injection, monitoring, and data evaluation. We must do these field experiments to make progress.

Performance Requirements

Much more progress has been made in the technology arena than in establishing performance requirements. Not enough work has been done on performance and engineering specifications for geologic storage. How long do we want CO2 to remain underground? What will the requirements be for releases from active and abandoned wells? Will we allow releases from reservoirs? Will we allow surface leakage? What, if any, will be acceptable human and ecological impacts? What about impacts to groundwater? What about induced seismicity? Will it be permissible for a CO2 plume to migrate to an adjacent property, or will that be banned? All of these issues will have huge impacts on the way geologic sequestration actually moves forward.

Another very important question is whether we will use performance-based requirements or a practice-based permitting scheme. One example of performance-based requirements is in the nuclear waste storage industry, which has very basic requirements for storing nuclear waste that limits the permissible radiation dosage the public might receive. To assess the safety of a nuclear waste storage site, engineers work backwards from these requirements through an elaborate set of models that tell them how to design the waste canister and other aspects of the site. In contrast, a practice-based permitting scheme is used in the design of injection wells for the deep injection of hazardous waste. If you conform to the requirements in the way you complete the injection well, you can have a permit. Which style of permitting is more appropriate for CO2 sequestration? This question must be addressed before large-scale sequestration can proceed.

Previous speakers have mentioned risk assessment. Models are now being developed to show migration of CO2 from the storage formation up to the surface. Coupled with atmospheric models, they will help us assess acceptable rates of surface leakage that will not cause unsafe build up CO2.

A large community of researchers is interested in the problems of simulation, and an international effort is under way to bring together teams from all over the world to improve simulation capabilities, as well as to establish some benchmark problems that can be used to demonstrate to the public and the regulatory community that these models are reliable and robust.

REFERENCES

Doughty, C., K. Pruess, S. Benson, S. Hovorka, P. Knox, and C. Green. 2001. Evaluation of Brine-Bearing Sands of the Frio Formation, Upper Texas Gulf Coast for Geologic Sequestration of CO2. Available online at http://www.netl.doe.gov/publications/proceedings/01/carbon_seq/4a2%20.pdf

Doughty, C., S.M. Benson, and K. Pruess. In press. Capacity Investigation of Brine-Bearing Sands for Geologic Sequestration of CO2. In Proceedings of the Sixth International Conference of Greenhouse Gas Technologies. St. Louis, Mo.: Elsevier Science Ltd.

Hovesten, G.M., R. Gritto, T.M. Daley, E.L. Majer, and L.R. Myer. In press. Cross-well Seismic and Electromagnetic Monitoring of CO2 Sequestration. In Proceedings of the Sixth International Conference on Greenhouse Gas Technologies. St. Louis, Mo.: Elsevier Science Ltd.

Johnson, J.W., J.J. Nitao, C.I. Steefel, and K.G. Knauss. 2001. Reactive Transport Modeling of Geologic CO2 Sequestration in Saline Aquifers: The Influence of Intra-aquifer Shales and the Relative Effectiveness of Structural Solubility, and Mineral Trapping during Prograde and Retrograde Sequestration. Available online at http://www.netl.doe.gov/publications/proceedings/01/carbon_seq/P28.pdf

Oldenburg, C.M., K. Pruess, and S.M. Benson. 2001. Process modeling of CO2 injection into natural gas reservoirs for carbon sequestration and enhanced gas recovery. Report No. LBNL-45820. Energy and Fuels 15: 293–298.

Oldenburg, C.M., and S.M. Benson. 2002. CO2 Injection for Enhanced Gas Production and Carbon Sequestration. SPE 74367. Available online at https://speonline.spe.org/mbrservices/ShopperIndex.cfm?RptCategPassed=Web&RptCodePassed=proc

Patzek, T.W, D.B. Silin, S.M. Benson, and G.I. Barenblatt. 2003. On vertical diffusion of gases in a horizontal reservoir. Transport in Porous Media 51(2): 141–156.