Appendix G

Hydrogen Production Technologies: Additional Discussion

This appendix discusses in more detail the technologies that can be used to produce hydrogen and which are addressed in Chapter 8. Cost analyses for them are presented in Chapter 5. In this appendix, the committee addresses the following technologies: (1) reforming of natural gas to hydrogen, (2) conversion of coal to hydrogen, (3) nuclear energy to produce hydrogen, (4) electrolysis, (5) wind energy to produce hydrogen, (6) production of hydrogen from biomass, and (7) production of hydrogen from solar energy. The following major sections—one for each of the technologies—include a brief description of the current technology; possible improvements for future technology; refer to Chapter 5 and Appendix E (which presents spreadsheet data from the committee’s cost analyses), where applicable, for the current and possible future costs, CO2 emissions, and energy efficiencies; note the potential advantages and disadvantages of using the technology for hydrogen production; and comment on the Department of Energy’s (DOE’s) research, development, and demonstration (RD&D) plan for hydrogen.

In general, in developing estimates about future possible technologies, the committee systematically adopted an optimistic posture. The estimates are meant to represent what possibly could be achieved with concerted research and development (R&D). But the committee is not predicting that the requisite R&D will be pursued, nor is it predicting that these technical advances necessarily will be achieved, even with a concerted R&D program. Estimates were made of what might be achieved with appropriate R&D.

The state of development referred to as “possible future” technologies is based on technological improvements that may be achieved if the appropriate research and development are successful. These improvements are not guaranteed; rather, they may be the result of successful R&D programs. And they may require significant technological breakthroughs. Generally, these possible future technologies are available at a significantly lower cost than are the “current technologies” using the same feedstocks.

HYDROGEN FROM NATURAL GAS

Compared with other fossil fuels, natural gas is a cost-effective feed for making hydrogen, in part because it is widely available, is easy to handle, and has a high hydrogen-to-carbon ratio, which minimizes the formation of by-product CO2. However, as pointed out elsewhere in this report, natural gas is already imported as liquefied natural gas (LNG)1 into the United States today, and imports are projected to increase. Thus, increased use of natural gas for a hydrogen economy would only increase imports further. As a result, the committee considers natural gas to be a transitional fuel for distributed generation units, not a long-range fuel for central station plants for the hydrogen economy.

Production Techniques

The primary ways in which natural gas, mostly methane, is converted to hydrogen involve reaction with either steam (steam reforming), oxygen (partial oxidation), or both in sequence (autothermal reforming). The overall reactions are shown below:

CH4 + 2H2O → CO2 + 4H2

CH4 + O2 → CO2 + 2H2

In practice, gas mixtures containing carbon monoxide (CO) as well as carbon dioxide (CO2) and unconverted methane (CH4) are produced and require further processing. The reaction of CO with steam (water-gas shift) over a catalyst produces additional hydrogen and CO2, and after purification, high-purity hydrogen (H2) is recovered. In most cases,

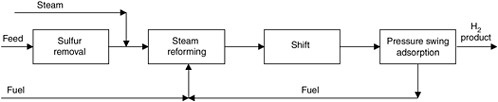

FIGURE G-1 Schematic representation of the steam methane reforming process.

CO2 is vented to the atmosphere today, but there are options for capturing it for subsequent sequestration.

Worldwide production of hydrogen is about 41 million tons per year (ORNL, 2003). Since over 80 percent of this production is accomplished by steam methane reforming (SMR), this method is discussed first.

Steam Methane Reforming

Steam methane reforming involves four basic steps (see Figure G-1). Natural gas is first catalytically treated with hydrogen to remove sulfur compounds. It is then reformed by mixing it with steam and passing it over a nickel-on-alumina catalyst, making CO and hydrogen. This step is followed by catalytic water-gas shift to convert the CO to hydrogen and CO2. Finally, the hydrogen gas is purified with pressure swing adsorption (PSA). The reject stream from PSA forms a portion of the fuel that is burned in the reformer to supply the needed heat energy. Therefore, CO2 contained in the PSA reject gas is currently vented with the flue gas. If the CO2 were to be sequestered, a separations process would be added to capture it.

The reforming reactions are as follows:

CH4 + H2O → CO + 3H2

CO + H2O → CO2 + H2 (water-gas-shift reaction)

Overall: CH4 + 2 H2O → CO2 + 4H2

The reaction of natural gas with steam to form CO and H2 requires a large amount of heat (206 kJ/mol methane). In current commercial practice, this heat is added using fired furnaces containing tubular reactors filled with catalyst.

Partial Oxidation

Partial oxidation (POX) of natural gas with oxygen is carried out in a high-pressure, refractory-lined reactor. The ratio of oxygen to carbon is carefully controlled to maximize the yield of CO and H2 while maintaining an acceptable level of CO2 and residual methane and minimizing the formation of soot. Downstream equipment is provided to remove the large amount of heat generated by the oxidation reaction, shift the CO to H2, remove CO2, which could be sequestered, and purify the hydrogen product. Of course, this process requires a source of oxygen, which is usually provided by including an air separation plant. Alternatively, air can be used instead of oxygen and product hydrogen recovered from nitrogen and other gases using palladium diffusion. POX can also be carried out in the presence of an oxidation catalyst, and in this case is called catalytic partial oxidation.

Autothermal Reforming

As already indicated, SMR is highly endothermic, and tubular reactors are used commercially to achieve the heat input required. When oxygen and steam are used in the conversion and are combined with SMR in autothemal reforming (ATR), the heat input required can be achieved by the partial combustion of methane. The reformer consists of a ceramic-lined reactor with a combustion zone and a subsequent fixed-bed catalytic SMR zone. Heat generated in the combustion zone is directly transferred to the catalytic zone by the flowing reaction gas mixture, thus providing the heat needed for the endothermic reforming reaction. As will be discussed, ATR is used today primarily for very large conversion units. There are several other design concepts that combine direct oxygen injection and catalytic conversion, including secondary reforming.

It has been suggested that methane conversion to hydrogen and elemental carbon might also be an attractive route, but the committee believes that this is unlikely. Such an approach would generate a large amount of carbon by-product,2 and less than 60 percent of the combined heats of combustion of the hydrogen and carbon products is associated with the hydrogen. For this approach to become a viable alternative, uses for large amounts of carbon must be found.

Natural Gas Conversion Today

Steam methane reforming is widely used worldwide to generate both synthesis gas and hydrogen. The gas produced is

used to make chemicals such as ammonia and methanol, to refine petroleum, metals, and electronic materials, and to process food components. More than 32 million tons per year (t/yr) H2 (80 million kg/day) are produced using natural gas SMR. Hydrogen is also made today using partial oxidation and ATR.

The vast commercial experience based on this manufacturing capacity has led to many improvements in the technology, reducing costs and increasing efficiency. Perhaps the most important element is the tubular reactor in which the SMR reaction takes place. Progress has led to higher tube wall temperatures, better control of carbon formation, and feedstock flexibility.3 This progress in turn has led to lower steam-to-carbon ratios and improved efficiency. The water-gas-shift unit has also been improved, and now one-step shift can be employed to replace the former two-step operation at different temperatures. Finally, purification of the hydrogen product has been simplified by using PSA to remove methane, carbon oxides, and trace impurities in a single step. While designs today do not generally include CO2 capture, technology is currently available to accomplish this. Using a commercial selective absorption process, CO2 could be recovered for subsequent sequestration.

Progress has also been made in designing and building larger SMR plants. Currently, single-train commercial plants of up to 480,000 kg H2 per day (200 million standard cubic feet per day [scf/d]) are being built, and even larger plants can be constructed using multiple trains. Units as small as 300 kg/day are also being built.4 In many cases, the units built are one of a kind, with specific features to meet the requirements of a site, application, or customer. At least one company is fabricating commercial SMR hydrogen plants as small as 300 kg/day using components of fixed design, one of the elements of mass production.5

Partial oxidation utilizing natural gas is fully developed and used commercially. In most cases today, commercial units use feeds of lower value than natural gas, such as coal, coke, petroleum residues, or other by-products, because of economics. However, natural gas is a preferred feed for POX from a technical standpoint and can be used to generate hydrogen where competitive.

Oxygen-blown ATR with natural gas is used today in very large units that generate a mixture of CO and H2 for the Fischer-Tropsch process or methanol synthesis. This is attractive in part because the units can produce the hydrogen-to-carbon monoxide ratio needed in the synthesis step. Since the heat of reaction is added by combustion with oxygen, the catalyst can be incorporated as a fixed bed that can be scaled up to achieve further benefits of larger plant size in both the ATR and the oxygen plant that is required. ATR also offers benefits when CO2 capture is included. This is because the optimum separation technology for this design recovers CO2 at 3 atmospheres (atm), thus reducing the cost of compression to pipeline pressure (75 atm).

In summary, all three processes (SMR, POX, and ATR) are mature technologies today for the conversion of natural gas to hydrogen. SMR is less costly except in very large units, where ATR has an advantage. SMR is also somewhat more efficient when the energy for air separation is included. POX has the advantage of being applicable to lower-quality feeds such as petroleum coke, but this is not directly relevant to natural gas conversion.

Future Natural Gas Conversion Plants

Given the current interest in possibilities for a hydrogen economy and the current commercial need for hydrogen, significant effort is being focused on improving natural gas conversion to hydrogen. Improved catalysts and materials of construction, process simplification, new separations processes, and reactor concepts that could improve the integration of steam reforming and partial oxidation are being investigated. Catalytic partial oxidation is also under consideration. Since steam reforming and partial oxidation are mature technologies, the primary opportunities for improvement involve developing designs for specific applications that are cost-effective and efficient.

Several thousand distributed generators will be needed for the hydrogen economy, and it should be possible to lower the cost of these generators significantly through mass production of a generation “appliance.” Such appliances may be further improved by tailoring the design to the fueling application. For example, hydrogen would likely be stored at roughly 400 atm, and to the extent that the conversion reactor pressure can be increased, hydrogen compression costs would be reduced and efficiency improved. For distributed generators incorporating POX or ATR, suitable cost-effective methods for hydrogen purification need to be developed. Alternatively, in such cases there are potentially attractive opportunities to recover the oxygen needed with membranes and thus to lower the cost.

Other concepts are also in the exploratory research stage. These involve new or modified ways of providing the endothermic heat of steam reforming or utilizing the heat of reaction in partial oxidation.

New, lower-cost designs for distributed generation probably can be advanced to the commercial prototype stage in the next 5 to 7 years. Some of these improvements could be applicable to large plants.

Economics

The committee undertook cost studies as described elsewhere (in Chapter 5 and Appendix E) to identify the areas

TABLE G-1 Economics of Conversion of Natural Gas to Hydrogen

|

|

Plant Size (kilograms of hydrogen per stream day [SD]) and Case |

|||||

|

|

1,200,000a |

24,000b |

480c |

|||

|

|

Current |

Possible Future |

Current |

Possible Future |

Current |

Possible Future |

|

Investment (no sequestration), $/kg/SD |

411 |

297 |

897 |

713 |

3847 |

2001d |

|

Investment (with sequestration), $/kg/SDe |

520 |

355 |

1219 |

961 |

— |

— |

|

Total H2 cost (no sequestration), $/kg |

1.03f |

0.92f |

1.38 f |

1.21 f |

3.51g |

2.33g |

|

Total H2 cost (with sequestration), $/kge |

1.22 f |

1.02 f |

1.67 f |

1.46 f |

— |

— |

|

CO2 emissions (no sequestration), kg/kg H2 |

9.22 |

8.75 |

9.83 |

9.12 |

12.1 |

10.3 |

|

CO2 emissions (with sequestration), kg/kg H2 |

1.53 |

1.30 |

1.71 |

1.53 |

— |

— |

|

Overall thermal efficiency (no sequestration), %h |

72.3a |

77.9a |

46.1 |

53.1 |

55.5 |

65.2 |

|

61.1 |

68.2 |

43.4 |

49.0 |

— |

— |

|

|

aIncludes compression of product hydrogen to pipeline pressure of 75 atm. bIncludes liquefaction of H2 prior to transport. cIncludes compression of H2 to 400 atm for storage/fueling vehicles. dIncludes estimated benefits of mass production. eIncludes capture and compression of CO2 to 135 atm for pipeline transport to sequestration site. fBased on natural gas at $4.50/million Btu. gBased on natural gas at $6.50/million Btu. hBased on lower heating values for natural gas and hydrogen; includes hydrogen generation, purification, and compression, and energy imported from offsite, as well as distribution and dispensing. |

||||||

that could have the greatest impact on the introduction of hydrogen fuel. For hydrogen production from natural gas, plant sizes of 1,200,000 kg per stream day (kg/SD), 24,000 kg/SD, and 480 kg/SD were studied (see Table G-1).6 For each plant size, a current case representing what can be done today with modern technology and a future case representing what might be possible in the future were included. The possible future case for the 480 kg/SD plant includes the estimated benefits of mass production. For the two larger plants, options were included to capture CO2 and to compress it to pipeline pressure (75 atm) for sequestration offsite. Capture was not included for the smallest plant, since the cost for collection of CO2 from distributed plants was considered to be prohibitive, in that forecourt sequestration of CO2 added $4.40/kg H2 to the cost (DiPietro, 1997).

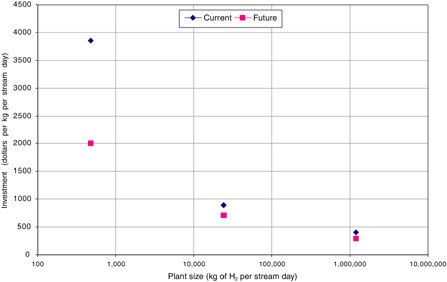

As shown in Table G-1, current investments vary with plant size, from $411 to $3847/kg/SD as size is decreased from 1.2 million to 480 kg/SD. While improved technology visualized in the possible future cases lowers investment by 20 to 48 percent, plant size has a more pronounced effect (see Figure G-2). For the two larger plants, CO2 capture increases investment by 22 to 35 percent.

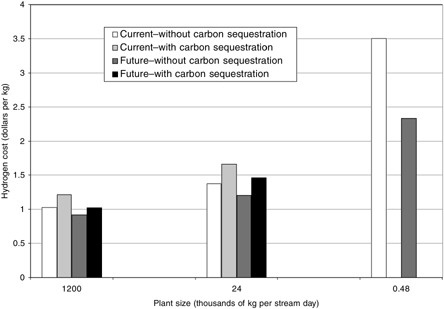

As illustrated in Figure G-3, hydrogen cost7 in the largest plant with no CO2 capture is $1.03/kg of hydrogen with current technology and $0.92/kg with future technology. This cost increases to $1.38/kg and $1.21/kg in a midsize plant, and to $3.51/kg and $2.33/kg in the smallest plant. CO2 capture adds 11 to 21 percent, depending on the case. Table G-1 shows overall thermal efficiency8 for the largest plant to be 72.3 to 77.9 percent without CO2 capture (for current and possible future technology, respectively), and 61.1 to 68.2 percent with CO2 capture (for current and possible future technology, respectively). Efficiency for the smallest plant is 55.5 to 65.2 percent.9 Without capture, the CO2 emissions are 8.8 to 12.1 kg CO2 per kilogram hydrogen. Capture lowers these emissions to 1.3 to 1.7 kg CO2 per kilogram of

FIGURE G-2 Estimated investment costs for current and possible future hydrogen plants (with no carbon sequestration) of three sizes.

FIGURE G-3 Estimated costs for conversion of natural gas to hydrogen in plants of three sizes, current and possible future cases, with and without sequestration of CO2.

hydrogen. Emissions and thermal efficiency estimates include the effects of generating the required electricity offsite in state-of-the-art power generation facilities with 65 percent efficiency with 0.32 kg CO2/kWh of electricity.

The DOE states that its goal by 2010 is to reduce the cost of the distributed production of hydrogen from natural gas and/or liquid fuels to $1.50/kg (delivered, untaxed, without sequestration) at the pump, based on a natural gas price of $4/million Btu (DOE, 2003a). The committee’s analysis indicates that this goal will be very difficult to achieve for the distributed-size hydrogen plants and will likely require additional time. The possible future case for distributed generation, which already incorporates the estimated benefits of mass production of SMR units, yields a hydrogen cost of $1.88/kg with $4/million Btu of natural gas. Achievement of the DOE goal would require additional thermal efficiency improvements and investment reductions. The goal could be met if, for example, the SMR thermal efficiency were further increased from 70 to 80 percent (excluding the compression of product hydrogen to storage pressure) and the SMR investment was cut by 35 percent, assuming that the benefits of mass production have been appropriately included. The committee did not study the likelihood of achieving these additional improvements. It is also important to note that the committee’s cost estimates are based on the assumption that distributed generators operate throughout the year at 90 percent of design capacity. As a consequence, units would have to operate at or near design capacity 24 hours per day, or else the actual cost of hydrogen from such units would be higher than calculated.10 Achieving a 90 percent capacity factor would require careful integration of the design rate of the hydrogen generator, hourly demand variations at fueling stations, and onsite storage capability.

The committee believes that there is considerable uncertainty regarding the future cost of hydrogen from small hydrogen plants. This uncertainty is further increased by the need for high reliability and safe operation with infrequent attention from relatively unskilled operators (i.e., customers and station attendants). In the committee’s view, the DOE program should address these issues on a priority basis, as discussed below.

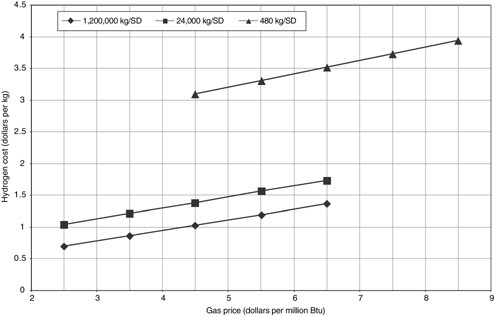

Hydrogen cost using steam methane reforming is sensitive to the price of natural gas, as shown in Figure G-4. Based on current technology cases, an increase in natural gas price from $2.50 to $6.50/million Btu increases hydrogen cost by 97 percent in a 1.2 million kg/SD plant and by 68 percent in a 24,000 kg/SD unit. For the 480 kg/SD unit, an increase from $4.50 to $8.50/million Btu raises hydrogen cost by 28 percent. These numbers highlight the importance of focusing research on improving efficiency in addition to reducing investment.

TABLE G-2 U.S. Natural Gas Consumption and Methane Emissions from Operations, 1990 and 2000

|

Consumption/Emissions |

1990 |

2000 |

|

Natural gas consumption (Tcf)a |

18.7 |

22.6 |

|

Methane emissions (Gg)b |

5772 |

5541 |

|

aSee EPA (2002). bU.S. Department of Energy, Energy Information Sheets, “Natural Gas Consumption,” May 12, 2003, Washington, D.C. |

||

Other Environmental Impacts

Natural gas is lost to the atmosphere during the production, processing, transmission, storage, and distribution of hydrogen. Since methane, the major component of natural gas, has a global warming potential of 23,11 this matter deserves discussion.

Methane is produced primarily in biological systems through the natural decomposition of organic waste. Methane emissions include those from the cultivation of agricultural land and the decomposition of animal wastes. The Environmental Protection Agency (EPA) estimates that 70 percent of methane emissions result from human activities and the balance from natural processes.12 Less than 20 percent of total global emissions of methane are related to fossil fuels, including natural gas operations (IPCC, 1995). The EPA reports that 19 percent of the anthropogenic emissions of methane in 2000 came from natural gas operations, and 25 percent of that came from distribution of natural gas within cities, primarily to individual users (EPA, 2002).

Perhaps the most compelling statistic is that between 1990 and 2000, methane emissions from natural gas operations decreased even though natural gas consumption increased (Table G-2). Clearly, improvements are being made to reduce losses from natural gas operations. For example, the EPA says that a voluntary program with industry, the Natural Gas STAR Program,13 has reduced methane emissions by 216 billion cubic feet (Bcf) since its inception in 1993.

As already pointed out, the advent of hydrogen-powered cars would increase natural gas consumption significantly.

|

10 |

Based on the committee’s model, a reduction of on-stream time from 90 to 70 percent would increase the cost of hydrogen in a 480 kg/SD unit by 11 to 15 percent. |

|

11 |

The Intergovernmental Panel on Climate Change (IPCC) has defined global warming potential as follows: “An index, describing the radiative characteristics of well mixed greenhouse gases, that represents the combined effect of the differing times these gases remain in the atmosphere and their relative effectiveness in absorbing outgoing infrared radiation. This index approximates the time-integrated warming effect of a unit mass of a given greenhouse gas in today’s atmosphere, relative to that of carbon dioxide” (IPCC, 2001a). |

|

12 |

See Environmental Protection Agency (EPA), “Current and Future Methane Emissions from Natural Sources.” Available online at http://www.epa.gov/ghginfo/reports/curr.htm. Accessed December 10, 2003. |

|

13 |

Information on the U.S. Environmental Protection Agency’s STAR Program is available online at http://www.epa.gov.gasstar/. Accessed November 15, 2003. |

FIGURE G-4 Estimated effects of the price of natural gas on the cost of hydrogen at plants of three sizes using steam methane reforming. Costs based on current technology. NOTE: SD = stream day.

However, this increase would not necessarily increase losses from the natural gas system.

Advantages and Disadvantages

There are several advantages to generating hydrogen from natural gas. Feedstock availability is quite widespread, since an extensive pipeline distribution system for natural gas already exists in the United States and natural gas is available in most populated areas of the country. Further, there is extensive commercial experience, and natural-gas-to-hydrogen conversion technology is widely used commercially throughout the world and is at an advanced stage of optimization in large plants. If centralized, large-scale natural gas conversion plants are built, CO2 can be captured for subsequent sequestration, although its separation and capture are probably not economically feasible with small, distributed hydrogen generators. Furthermore, the committee believes that small-scale reformers at fueling stations are one of the technologies most likely to be implemented in the transition period if policies are put in place to stimulate a transition to hydrogen for light-duty vehicles.

The primary disadvantages of using natural gas are that it is a nonrenewable, limited resource, and increasing amounts are projected to be imported in the future to meet U.S. market needs—which runs counter to the DOE’s goal of improving national security. Also, natural gas prices are volatile and are very sensitive to seasonal demand. Over the past 12 months, for example, the price has varied from $2.70 to more than $9.50/million Btu,14 and there has been an upward trend in the U.S. wellhead gas price since 1998. This variability becomes even more important given that SMR economics are sensitive to natural gas price.

Research Needs and the Department of Energy Program

Distributed generation of hydrogen from natural gas in fueling facilities could be the lowest-cost option for hydrogen production during the transition. However, the future cost of this option is uncertain, given the technical and engineering uncertainties and special requirements that demand priority attention in the DOE program, as it is advanced by contract research organizations.

Distributed generation of hydrogen as envisioned has never before been achieved because of two particular requirements: (1) the mass production of the thousands of generating units, incorporating the latest technology improve-

|

14 |

See NYMEX Henry-Hub NATURAL GAS PRICE, available online at http://www.oilnergy.com/1gnymex.htm#year. Accessed December 10, 2003. |

ments, needed to meet demand, minimize cost, and improve efficiency; and (2) unit designs and operating procedures that ensure the reliable and safe operation of these appliances with only periodic surveillance by relatively unskilled personnel (station attendants and consumers). Currently, there is a market for such units in the merchant industrial sector, which accounts for about 12 percent of the total hydrogen market in the United States (ORNL, 2003). It is clear that the DOE must provide the impetus for the program.

In contrast, centralized generation of hydrogen in one-of-a-kind, medium-sized and large plants is widely practiced, and as a result there is extensive commercial experience in this area. Given the commercial market for hydrogen, the committee believes that suppliers will continue to search for ways to improve the technology and make it even more competitive for medium- and large-scale plants.

Publications from the DOE hydrogen program indicate that the program on distributed generation will include demonstration of a “low-cost, small-footprint plant” (DOE, 2003a, b). However, it is not clear whether the program gives priority to distributed generation or includes an effort to demonstrate the benefits of and specific designs for mass production in the specified time frame of the program. The needed designs would involve concomitant engineering that would create designs for manufacturing engineering, to guide research and to prepare for mass production of the appliance, and would also develop a system design for a typical fueling facility, including the generation appliance, compression, high-pressure storage incorporating the latest storage technology, and dispensers. With today’s technology, such ancillary systems cost 30 percent as much as the reformer. The committee believes that these costs can be reduced by over 50 percent and that efficiency can be improved through system integration and the incorporation of the latest technology. Compression and high-pressure storage are examples of systems in which significant improvements are expected.

The DOE hydrogen program is positioned to stimulate the development of newer concepts, such as membrane separation coupled with chemical conversion, and this seems appropriate to the committee. However, most of the effort in this area appears directed toward POX and ATR. The committee believes that SMR could be the preferred process for this application, and that it should also be pursued in parallel with the effort involving POX and ATR.

HYDROGEN FROM COAL

This section presents the basics of making hydrogen from coal in large, central station plants. The viability of this option is contingent on demand for hydrogen large enough to support an associated distribution system, a large resource base, competitive uses of coal, the environmental impacts of production and transportation, and the technologies and the associated costs for converting coal into hydrogen.

Many of the issues and technologies associated with making hydrogen from coal are similar to those of making power from coal. These subjects are closely linked and should be considered in concert—particularly with respect to clean coal technologies. These technologies will be required for making hydrogen, and they also offer the best opportunity for low-cost, high-efficiency, and low-emission power production. The lowest-cost hydrogen coal plants are likely to be ones that coproduce power and hydrogen.15

Coal is a viable option for making hydrogen in large, central station plants when the demand for hydrogen becomes sufficient to support an associated, large distribution system. The United States has enough coal to make hydrogen far into the future. A substantial coal infrastructure already exists, commercial technologies for converting coal to hydrogen are available from several licensors, the cost of hydrogen from coal is among the lowest available, and technology improvements are identified that should reach future DOE cost targets. The major consideration is that, because of the high carbon content in coal, the CO2 emissions from making hydrogen from coal are larger than those from any other conversion technology for making hydrogen. This underscores the need to develop carbon sequestration techniques that can handle very large amounts of CO2 before the widespread implementation of coal to make hydrogen should occur.

Coal Transportation

If coal is to be a major source for future hydrogen production, the infrastructure for delivering it to the future hydrogen plants will need to be expanded enough to handle these future requirements. Based on the assumptions used by the committee, the current production and delivery infrastructure capacity would need to be increased by 11 percent to meet the 2030 hydrogen demand, and by 57 percent to meet the 2050 hydrogen demand. Coal is a viable option for making hydrogen in large, central station plants when the demand for hydrogen becomes large enough to support an associated transport, storage, and distribution system.

Most bulk coal transportation is by rail, with trucks used for local transport. For reasons of economics, most of the world’s coal consumption is in power plants located nearby coal mines, which minimizes the necessity for long-distance transportation. More than 60 percent of the coal used for power generation worldwide is consumed within 50 km of the mine site. In the United States, the average distance that coal is shipped by rail is farther, at about 800 miles. That distance has increased in recent years owing to the move toward greater use of coals with lower sulfur content (found mainly in the West) to meet sulfur oxide emissions standards in plants located mainly in the South and the East. As coal is currently shipped over great distances in the United States,

delivery to broad geographic areas should not be a barrier to the use of coal to make hydrogen for at least the next 30 years, since demand will not be much different from current trends.

Environmental Impacts of Coal Consumption and Transportation

Using more coal to produce hydrogen will have a number of environmental consequences. Coal mining itself causes numerous environmental issues, ranging from widespread land disturbance, soil erosion, dust, biodiversity impacts, waste piles, and so forth, to subsidence and abandoned mine workings. Once coal has been extracted, it needs to be moved from the mine to the power plant or other place of use.

The main pollutants resulting from conventional combustion of coal are sulfur oxides (SOx), nitrogen oxides (NOx), particulates, CO2, and mercury (Hg). SOx is dealt with through lower-sulfur-content coal as well as flue gas desulfurization (FGD). Approximately 30 percent of U.S. coal power generating equipment had some sort of FGD or SOx reduction technology at the end of 1999, according to data gathered by DOE’s Energy Information Administration.16 Newer processes for power generation, such as integrated gasification combined cycle power generation, which involves a conversion rather than a combustion process, is more effective at reducing criteria pollutants than existing pollution control technologies are (East-West Center, 2000).

Potentially the most significant future issue for coal combustion is CO2 emissions, since on a net energy basis coal combustion produces 80 percent more CO2 than the combustion of natural gas does, and 20 percent more than does residual fuel oil, which is the most widely used other fuel for power generation (EIA [2001], Table B1). Likewise, the CO2 emissions associated with making hydrogen from coal will be larger than those for making hydrogen from natural gas. Using currently available technology, the CO2 emissions are about 19 kg CO2 per kilogram of hydrogen produced, compared with approximately 10 kg CO2 per kilogram of hydrogen manufactured from natural gas.

Atmospheric emissions from coal-fired generating plants are of concern to various bodies—national (criteria pollutants [CO, particulates,17 O3, NO2, SO2, and Pb], are defined and regulated by the EPA under the National Ambient Air Quality Standards) and international (greenhouse gases, considered under the UN Framework Convention on Climate Change, are mainly CO2, CH4, N2O, hydrofluorocarbons, perfluorocarbons, and SF6). Since the 1970s, the U.S. electricity industry has made considerable progress in reducing SO2, NO2, and particulate emissions, despite a large increase in coal consumption, through the use of FGD, filtration, electrostatic precipitators, and selective catalytic reduction (SCR). To the extent that new emission control technologies can be applied to existing plants and that new generating technologies can be used, further progress is expected in overall emissions reductions (Ness et al., 1999).

Current Coal Technologies

Conventional coal-fired power generation uses a combustion boiler that heats water to make steam, which is used to drive an expansion steam turbine and generator. Various designs of coal combustion boilers exist, the most modern and efficient of which use pulverized coal and produce supercritical (high-pressure/high-temperature) steam. Overall efficiencies are typically in the 36 to 40 percent range. Although a staple for power generation for decades, this conventional combustion technique is not suitable for making hydrogen. Hydrogen-making technologies employ a conversion process rather than a combustion process. These conversion processes, such as gasification, are suitable for making power and/or hydrogen.

Clean Coal Technologies

Clean coal technologies use alternative ways of converting coal so as to reduce plant emissions and increase plant thermal efficiency, leading to an overall cost of electricity that is lower than the cost for electricity from conventional plants. Systems under development include low-emission boiler systems (LEBSs), high-performance power systems (HIPPSs), integrated gasification combined cycle (IGCC), and pressurized fluidized-bed combustion (PFBC) (Ness et al., 1999). The goal is to attain thermal efficiencies in the 55 to 60 percent range (higher heating value [HHV]) (Ness et al., 1999). With the exception of the IGCC systems, all of the others rely on increasingly sophisticated emissions control systems; IGCC uses a different conversion system to reduce emissions at the outset. It is this gasification technology that is best suited to making hydrogen from coal.

Gasification Technology

Gasification systems typically involve partial oxidation of the coal with oxygen and steam in a high-temperature and elevated-pressure reactor. The short-duration reaction proceeds in a highly reducing atmosphere that creates a synthesis gas, a mix of predominantly CO and H2 with some steam and CO2. This syngas can be further shifted to increase H2 yield. The gas can be cleaned in conventional ways to recover elemental sulfur (or make sulfuric acid), and a high-concentration CO2 stream can be easily isolated and sent for

disposal. The use of high temperature and pressure and oxygen minimizes NOx production. The slag and ash that is drawn off from the bottom of the reactor encapsulate heavy metals in an inert, vitreous material, which currently is used for road fill. The high temperature also eliminates any production of organic materials, and more than 90 percent of the mercury is removed in syngas processing. Syngas produced from current gasification plants is used in a variety of applications, often with multiple applications from a single facility. These applications include syngas used as feedstock for chemicals and fertilizers, syngas converted to hydrogen used for hydro-processing in refineries, production, generation of electricity by burning the syngas in a gas turbine, and additional heat recovery steam generation using a combined cycle configuration.

There are currently at least 111 operating gasification plants running on a variety of feedstocks. These include residual oils from refining crude oil, petroleum coke, and to a lesser extent, coal. The syngas that is generated has typically been used for subsequent chemicals manufacture; making power from IGCC systems is a more recent innovation, successfully demonstrated in the mid-1980s and commercially operated since the mid-1990s. Gasification is, therefore, a well-proven commercial process technology, and several companies offer licenses for its use.

Oxygen-Blown Versus Air-Blown Gasification

Gasification plants exist that use either air-blown or oxygen-blown designs. Air-blown designs save the capital cost and operating expense of air separation units, but the dilution of the combustion products with nitrogen makes the separation of CO2, in particular, a much more expensive exercise. In addition, the extra inert nitrogen volume going through the plant increases vessel sizes significantly and increases the cost of downstream equipment. Oxygen-blown designs do not introduce the additional nitrogen, so once the sulfur compounds have been removed from the syngas, what is left is a high-purity stream of CO2 that can be more easily and cheaply separated. Because of the need to consider CO2 capture and sequestration for future hydrogen generation plants, only oxygen-blown designs are feasible for consideration.

Estimated Costs of Hydrogen Production and Carbon Dioxide Emissions

Most gasification plants produce syngas for chemical production, and often for steam. IGCC plants then burn the syngas to produce power. The flexibility to polygenerate multiple products to suit a given situation is one of the strengths of the gasification system. Thus, relatively few gasification plants are dedicated to producing hydrogen only (or indeed any other single product). The future large-scale hydrogen generation plant will likely also generate some amounts of power because of the advantages provided through polygeneration. It is necessary therefore to preface any remarks concerning the costs of producing only hydrogen or the costs of sequestering CO2 with this caveat.

All of the technology needed to produce hydrogen from coal is commercially proven and in operation today, and designs already exist for hydrogen and power coproduction facilities. However, technology advances currently in development will continue to drive down the costs and increase the efficiency of these facilities. Hydrogen-from-coal plants combine a number of technologies including oxygen supply, gasification, CO shift, sulfur removal, and gas turbine technologies. All of these technology areas have advances under development that will significantly improve the plant’s capital and operating costs and thermal efficiency. Examples of these pending technology advances include Ion Transport Membrane (ITM) technology for air separation (oxygen supply); advances in gasifier technology (feedstock preparation, conversion, availability); warm gas cleanup; advanced gas turbines for both syngas and hydrogen; CO2 capture technology advances; new, lower-cost sulfur-removal technology; and slag-handling improvements.

It is estimated that today a gasification plant producing hydrogen only would be able to deliver hydrogen to the plant gate at a cost of about $0.96/kg H2 with no CO2 sequestration. If CO2 capture were also required, it would cost $1.03/ kg H2. This pricing reflects costs for producing hydrogen from very large, central station plants at which hydrogen will be distributed through pipelines. In these plants a single gasifier can produce more than 100 million scf/day H2. It is envisioned that a typical installation would include two to three gasifiers.

The economics of making hydrogen from coal is somewhat different from that for making it from other fossil fuels, in that the capital costs needed per kilogram of produced hydrogen are larger for coal plants, but the raw material costs per kilogram of produced hydrogen are lower. Coal is inexpensive, but the coal gasification plant is expensive. If the coal price is changed by 25 percent, the hydrogen cost is changed by only $0.05/kg. If the cost of the plant is changed by 25 percent, the hydrogen cost is changed by $0.16/kg. This should lead to a very stable cost of hydrogen production that can be lowered through future improvements in technology.

In addition to the CO2 produced from making the electricity consumed in producing hydrogen, CO2 emissions result from the carbon in the coal. The emissions depend on the type and quality of coal, but for typical Western coal with 2 percent sulfur and 12,000 Btu/dry lb, approximately 18.8 kg CO2 are emitted per kilogram of hydrogen produced. With a CO2 capture system in place, it is estimated that this figure could be reduced by as much as 80 to 90 percent, the exact amount depending on capital efficiency and cost-benefit analysis. Although the economics of hydrogen production from coal does vary somewhat with the quality of coal being gasified, essentially any coal can be gasified to produce hy-

drogen. Coals with ash content greater than 30 percent are already being gasified. The main effects of coal-quality variance on hydrogen production are the amount of by-products produced (primarily slag and elemental sulfur) and the capital cost, which would be affected mostly by the amount of additional inert material in the coal that has to be handled. For a gasification plant producing maximum hydrogen from coal, the variance in potential feed coal quality is estimated to produce a variance of less than 15 percent in the amount of CO2 generated per ton of hydrogen produced. The lower-quality coals generate lower amounts of CO2 per ton of hydrogen. Other effects of coal quality are less significant.

Research and Development Needs

In terms of its stage of development, coal gasification is a less mature commercial process than coal combustion processes and other hydrogen generation processes using other fossil fuels, especially in the aspects of capturing CO2 and providing flexibility in hydrogen and electricity production. In that sense the potential for improvement through technology development is significant. The main issues are capital cost and reliability (the latter is usually addressed through including standby equipment). Both are major reasons why IGCC technology has not been widely adopted for power generation, which is a very competitive business. The flexibility to vary between hydrogen production and power production will cost extra capital, which has to be recovered.

For the commercial processes available from several different licensors, the R&D needs should be directed at capital cost reduction, standardization of plant design and execution concept, gas cooler designs, process integration, oxygen plant optimization, and acid gas removal technology. The potential efficiency and capital cost improvements in these areas could combine to lower the overall cost of hydrogen from coal by about 10 to 15 percent from today’s costs. Since many parts of the coal-to-hydrogen process are the same as for coal-to-power processes, similar improvements in power costs from IGCC should be possible. These areas are improvements to existing technology, so they should be able to be achieved in the near term.

The potential also exists for new technologies to make larger improvements in the efficiency and cost of making hydrogen from coal. For new gasification technologies, the best opportunities for R&D appear to be for new reactor designs (entrained bed gasification), improved gas separation (hot gas separation), and purification techniques. These technologies, and the concept of integrating them with one another, are in very early development phases and will require longer-term development to verify the true potential and to reach commercial readiness. Recent studies have indicated that the combined potential of these new technologies could lower the cost of making hydrogen from coal by about 25 percent.

Future Costs

Evolutionary improvements in current technology can lower the cost of hydrogen from coal from the estimated $0.96/kg to about $0.90/kg. The evolution of future costs will be a function of the number of units constructed over time, since each subsequent plant gives an additional opportunity to apply the experience derived from prior plants, as well as economies of scale for process unit production.

The introduction of new technologies can lower costs even further. New gasification technologies along with new syngas cleanup and separation technologies hold potential for further improving efficiencies and lowering the costs of producing hydrogen to about $0.71/kg (see Chapter 5 and Appendix E). Separating and capturing CO2 will increase these costs to $0.77/kg.

Department of Energy Programs for Coal to Hydrogen

The DOE programs for making hydrogen from coal reside in the Office of Fossil Energy and are related to programs to make electricity from coal. The overall goal of the Hydrogen from Coal Program is to have an operational, zero-emissions, coal-fueled facility in 2015 that coproduces hydrogen and electricity with 60 percent overall efficiency (DOE, 2003c). Major milestones for reaching this goal include these:

-

2006—Advanced hydrogen separation technology, including membranes tolerant of trace contaminants, identified;

-

2011—Hydrogen modules for coal gasification combined-cycle coproduction facility demonstrated; and

-

2015— Zero-emission, coal-based plant producing hydrogen and electric power (with sequestration) that reduces the cost of hydrogen by 25 percent compared with the cost at current coal-based plants demonstrated.

To reach these milestones, R&D activities within the Hydrogen from Coal Program are focused on the development of novel processes that include these:

-

Advanced water-gas-shift reactors using sulfur-tolerant catalysts,

-

Novel membranes for hydrogen separation from CO2,

-

Technology concepts that combine hydrogen separation and water-gas shift, and

-

Fewer-step designs to separate impurities from hydrogen.

Associated coal gasification R&D programs in which success is dependent on efficiency improvements and lower cost include these:

-

Advanced ITM technology for oxygen separation from air,

-

Advanced cleaning of raw synthesis gas,

-

Improvements in gasifier design, and

-

CO2 capture and sequestration technology.

Summary

The United States has enough coal to make all of the hydrogen that the economy will need for a very long time, a substantial coal infrastructure already exists, commercial technologies for converting coal to hydrogen are available from several licensors, the cost of hydrogen from coal is among the lowest available, and technology improvements are identified to reach the future DOE cost targets. As such, coal is a viable option for making hydrogen in large, central station plants when the demand for hydrogen becomes large enough to support an associated distribution system.

The key to the efficient and clean manufacture of hydrogen from coal is to gasify the coal first, to produce a synthesis gas—a mixture of hydrogen and CO—and then to further process the CO with water to produce additional hydrogen and CO2.

Combinations of coal gasifiers and gas cleanup processes have been built, tested, and used to produce electric power in the integrated gasification combined cycle (IGCC) process. While IGCC power plants have been built and operated on a commercial scale, further process improvements to lower costs and to improve reliability are both possible and desirable. Accordingly, a number of years ago the DOE initiated a related R&D program called Vision 21, which is up and running and has been reviewed by the National Research Council, most recently in early 2003 (NRC, 2003b). Major aspects of this program will be applicable to making hydrogen from coal and will lead to more efficient and lower-cost hydrogen production designs.

Making hydrogen from coal produces a large amount of CO2 as a by-product. At present, the United States does not restrict the emissions of CO2 from any sources, but it is possible that such restrictions might be invoked in the future. Because of the possible effects of CO2 on global climate change, the government has accelerated R&D aimed at reducing or eliminating CO2 emissions from energy-producing systems, one of these being coal-fueled systems. A part of the Department of Energy’s hydrogen program is aimed at developing safe and economic methods of sequestering CO2 in a variety of underground geologic formations. Indeed, a sequestration R&D program was initiated in the department’s Office of Fossil Energy a number of years ago and is now supported at a significant level. The new coal-based power systems being developed under the DOE’s Vision 21 program are aimed at coupling power plant with sequestration systems.

Beyond the Vision 21 program, the DOE recently announced its intention to proceed with a large, coal-to-electricity-and-hydrogen verification plant with coupled sequestration. This plant, called FutureGen, is now in the early stages of detailed planning. In addition to demonstrating coproduction of electricity and hydrogen with sequestration, the system is intended to act as a large-scale testbed for innovative new technologies aimed at reducing systems costs.

HYDROGEN FROM NUCLEAR ENERGY

Nuclear Power Technology Today

The United States derived about 20 percent of its electricity from nuclear energy in 2002 (EIA, 2003). While no nuclear power plants have been ordered in the United States since 1975, the orders prior to that date resulted in the 103 power reactors operating today. With a total capacity of nearly 100 gigawatts electric (GWe), they constitute about 13 percent of the installed U.S. electric generation capacity. Since their operating costs are relatively low, the existing plants tend to be part of the base load for their owner companies, and their output has been increasing since the late 1980s. The current U.S. plants use water as the coolant and neutron moderator, and they rely on the steam Rankine cycle as the thermal-to-electrical power conversion cycle. Nearly 65 percent of these light-water reactors (LWRs) are of the pressurized-water reactor (PWR) type, and 35 percent are of the boiling-water reactor (BWR) type. The LWR technology has dominated the reactor market and constitutes about 80 percent of the nearly 440 operating plants in the world today. Different technologies have been deployed in Great Britain, which depends mostly on gas-cooled reactors (GCRs) and advanced gas-cooled reactors (AGRs) cooled by CO2 but using an indirect steam power cycle. Canada, India, and a few other countries operate heavy-water reactors (HWRs), also with an indirect steam power cycle.

Other reactor technology options were tested in several countries. These include helium-cooled high-temperature gas-cooled reactors (HTGRs) and sodium-cooled fast reactors (SFRs). However, the operation of these plants did not spur wider market penetration. The HTGR has a significant technical base due to the experience gained from power plants in the United States and Germany and the more recent, smaller test reactors in Japan and China. Coupling gas-cooled reactors to a direct or indirect gas turbine Brayton power cycle can yield thermal efficiencies much higher than the 33 percent of current LWRs. However, there is no experience in gas-turbine powered nuclear plants, since the U.S. and German HTGR plants use an indirect steam Rankine cycle for electricity production.

While the LWR technology dominates the global nuclear energy market, the fuel cycle technology has not had similar unanimity. The United States, Spain, Sweden, and several other countries opted for a once-through uranium-based fuel cycle, in which the used fuel is destined for a geologic repository for highly radioactive waste, after a storage period of a decade or more. France, Germany, Japan, and Russia, among other countries, have preferred to extract and recycle the fissile material in the spent fuel to increase the energy

derived from the fuel and to reduce the volume and toxicity of the waste that will be disposed of in geologic repositories. The U.S. approach is less costly while the supply of inexpensive uranium lasts—which at the current rate of consumption should be for at least 50 to 100 years. When additional fuel material is needed, chemical reprocessing of the used fuel to recycle it can extend the fuel availability to thousands of years—that is when fast reactors, such as the sodium-cooled reactors, would become desirable.

Nuclear Power Technology in the Future

In the past 20 years, several advanced versions of the LWR, collectively called advanced LWRs (ALWRs), have been designed, but only one type has been built: the advanced boiling-water reactor (ABWR), which was built in Japan. These reactors are generally known today as Generation III reactors. Some of these designs have been certified as safe by the Nuclear Regulatory Commission (USNRC), but no orders have materialized for them in the United States. New versions of light-water reactors are now under review for safety certification by the USNRC.

Two versions of the HTGR are being designed by international consortia. One is led by the South African utility, ESKOM, with a direct helium gas turbine power cycle. This reactor builds on the German experience with circulating graphite pebbles containing ceramic-coated oxide fuel microparticles. The fuel is designed to be robust for the temperature range of operation and accidents. The ability of the microparticle fuel to reach very high burnup induced another consortium (Framatome ANP, General Atomics [GA], and Russian collaborators) to design a plutonium consumption reactor. In this case, the microparticles will be housed in stationary graphite blocks, typical of the earlier GA-designed HTGRs in the United States.

In 2002, several reactor concepts were selected by an international team representing 10 countries as promising technologies that should be further explored for availability beyond 2025; these technologies are collectively known as the Generation IV reactors. The goals for the new reactor systems are to improve the economics, safety, waste characteristics, and security of the reactors and the fuel cycle. The emphasis in the development was given to the following six concepts:

-

Very high temperature reactor (VHTR), a version of the HTGR;

-

Supercritical water reactor (SCWR), with a direct power cycle;

-

Fast gas-cooled reactor (FGR), with a direct helium or CO2 gas turbine power cycle;

-

Heavy metal (lead alloy)-cooled reactor (HMCR), with an indirect power cycle;

-

Sodium-cooled reactor (SCR), with an indirect steam power cycle; and

-

Molten salt-cooled reactor (MSR), with a fluid fuel and an indirect power cycle.

It is notable that all Generation IV reactors aim to operate at higher coolant temperatures than those of the LWRs, thereby increasing the efficiency of thermal-to-electrical-energy conversion. The main characteristics of some of the reactors mentioned here and others are given in Table G-3.

Proposed Technologies for Hydrogen Production

Hydrogen can be produced using current reactor technology for electricity for electrolysis (water splitting). Potentially more efficient hydrogen production may be attained by significantly raising the water temperature before splitting the molecules using thermochemistry or electrolysis. Such approaches require temperatures in the range of 700°C to 1000°C. Current water-cooled reactors produce temperatures under 350°C, and cannot be used for such purposes. However, the coolants from several advanced reactor concepts do reach such high temperatures and may be coupled to thermochemical plants (Brown et al., 2003; Doctor et al., 2002; and Forsberg, 2003). A recent experimental helium-cooled reactor at the Japan Atomic Energy Research Institute (JAERI) was built specifically with the goal of hydrogen production. Its desired coolant maximum temperature is 900°C. It started operation in 1999 and is still undergoing testing of its fuels and its operations at lower temperatures.

Another possibility for producing hydrogen is the use of nuclear heat to provide the energy needed for heating in the steam methane reforming (SMR) process, as suggested recently by the Electric Power Research Institute (EPRI) (Sandell, 2003). That too requires high temperatures, above 700°C, for efficiency. Therefore, it must be coupled to a high-temperature reactor. This process reduces but does not eliminate the CO2 emissions associated with conventional SMR. It also reduces the amount of natural gas required for hydrogen production.

TABLE G-3 Nuclear Reactor Options and Their Power Cycle Efficiency

|

Current and Advanced Reactor Type |

Toutlet (°C) |

ηth (%) |

|

Current light-water reactor (LWR) |

280–320 |

32–34 |

|

Advanced light-water reactor (ALWR) |

285–330 |

32–35 |

|

Supercritical water-cooled reactor (SCWR)a |

400–600 |

38–45 |

|

He high-temperature graphite reactor (HTGR) |

850–950 |

42–48 |

|

Supercritical CO2 advanced gas reactor (S-AGR) |

650–750 |

46–51 |

|

Molten salt-cooled reactor (AHTR)b |

750–1000 |

NE |

|

Heavy metal (lead alloy)-cooled reactor (HMCR)a |

540–650 |

NE |

|

NOTE: NE = not evaluated. aOne of the Generation IV reactors. bThe fuel resembles that of an HTGR but with a salt coolant. |

||

The various options for nuclear hydrogen production are given in Table G-4. The basic chemistry, projected efficiency, established experience, and other related issues for each technology option are now briefly addressed.

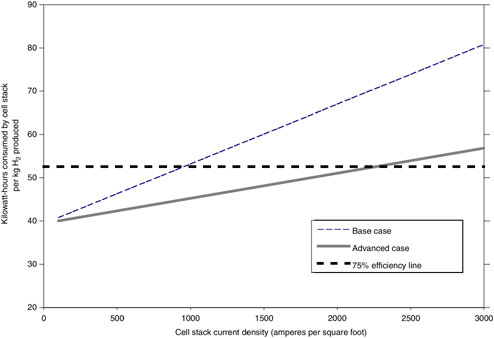

High-Temperature Electrolysis of Steam

The electrical energy demand in the electrolysis process decreases with increasing water (or steam) temperature. While the demand for heat energy is increased, the decrease in the electrical energy demand improves the overall thermal-to-hydrogen heat conversion efficiency. Higher temperatures also help lower the cathodic and anodic overvoltages. Therefore, it is possible to increase the current density at higher temperatures, which yields a significant increase in the process efficiency. Thus, the high-temperature electrolysis of stream (HTES) is advantageous from both thermodynamic and kinetic standpoints. The electrodes of the HTES unit can be made of ceramic materials, which avoids corrosion problems, though hydrogen embrittlement might still be a problem for electrode durability. High-pressure operation would also be preferable, in order to reduce the size of the chemical units and transmission lines.

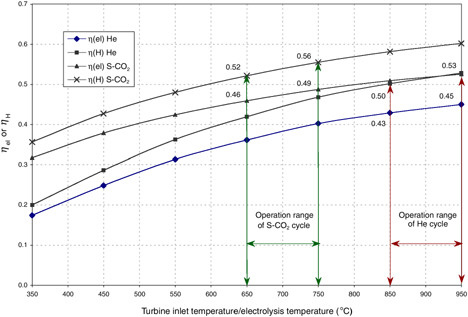

The HTES process is potentially advantageous when coupled to high-efficiency power cycles and can consequently yield high overall thermal-to-hydrogen energy efficiency. The efficiency of hydrogen production via coupling of HTES to either of two high-temperature nuclear reactors is given in Figure G-5 (Yildiz and Kazimi, 2003). One reactor is the gas turbine modular high-temperature reactor (GT-MHR) (LaBar, 2002). The second is an advanced gas-cooled reactor (AGR) coupled to a direct supercritical CO2 power cycle. The cycle was originally proposed for fast reactors (Dostal et al., 2002). The supercritical AGR (S-AGR), also referred to as the S-CO2, necessitates upgrading the AGR design pressure from the current 4 megapascals (MPa) to about 20 MPa, which has not been attempted before in a concrete containment. A reference HTES design called HOTELLY (high-operating-temperature electrolysis) (Doenitz et al., 1988) is chosen as the basis for this example.

Implementation of the GT-MHR-HTES at the temperature of 850°C for the near term appears possible, while achieving temperatures of 950°C and higher might be expected for the years 2025 and beyond. Similarly, for the S-AGR-HTES, the near-term and far-term goals may be 650°C

TABLE G-4 An Overview of Nuclear Hydrogen Production Options

FIGURE G-5 Power cycle net efficiency (ηel) and thermal-to-hydrogen efficiency (ηH) for the gas turbine modular helium reactor (He) high-temperature electrolysis of steam (HTES) and the supercritical CO2 (S-CO2) advanced gas-cooled reactor HTES technologies. SOURCE: Yildiz and Kazimi (2003).

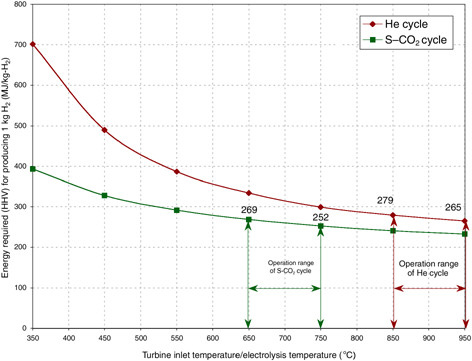

and 750°C, respectively. The thermal energy (MJ) needed to produce 1 kg H2 is presented in Figure G-6.18

Nuclear reactors coupled to HTES are capital-intensive technologies, due to both the nuclear plant and the electrolysis plant. The development of economical and durable HTES unit materials, which can be similar to those of the solid oxide fuel cell materials, can contribute to cost reduction. The development of improved HTES units with low electrode overvoltage at lower temperatures can enable their use with lower-temperature and thereby lower-cost nuclear plants. Improved HTES cell designs are currently being investigated at Lawrence Livermore National Laboratory (Pham, 2000) and Idaho National Engineering and Environmental Laboratory (Herring, 2002). In addition, attaining high power cycle efficiency at the nuclear plant with relatively low temperatures can contribute to cost reduction. Finally, development of economic high-temperature radiation-resistant graphite or ceramic-coated graphite materials for the nuclear plant is needed.

Thermochemical Water Splitting

A recent screening of several hundred possible reactions (Besenbruch et al., 2000) has identified two candidate thermochemical cycles that have the highest commercialization potential, with high efficiency and practical applicability to nuclear heat sources. These are the sulfur-iodine (SI) and calcium-bromine-iron (Ca-Br) cycles. The S-I cycle is being investigated by General Atomics and JAERI. The Ca-Br cycle, which is sometimes called UT-3 to honor its origin at the University of Tokyo, is being investigated by JAERI. Argonne National Laboratory (ANL) is currently working on achieving thermochemical water-splitting processes at lower temperatures than the SI and Ca-Br cycles. ANL has identified the copper-chlorine (Cu-Cl) thermochemical cycle for this purpose (Doctor et al., 2002).

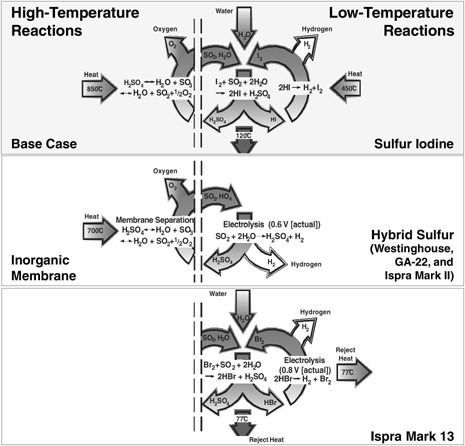

Sulfur-Iodine Cycle and Other Sulfur Cycles The SI cycle has been proposed in several forms. (The SI cycle and other

FIGURE G-6 The energy needs for hydrogen production by the gas turbine modular helium reactor (He cycle) high-temperature electrolysis of steam (HTES) and the supercritical CO2 (S-CO2 cycle) advanced gas-cooled reactor HTES technologies. NOTE: HHV = higher heating value.

sulfur cycles are depicted schematically in Figure G-7.) The most promising form consists of the following three chemical reactions, which yield the dissociation of water (Brown et al., 2003):

A hybrid sulfur-based process does not require iodine and has the same high-temperature step as sulfur iodine but a single electrochemical low-temperature step that forms sulfuric acid. That electrolysis step makes sulfuric acid at very low voltage (power). The low-voltage electrolysis step (low power compared with electrolysis of water) may allow much larger scale-up of the electrochemical cells. (High-voltage systems have high internal heat generation rates that often limit the scale-up of a single cell.) The efficiency of this process is about the same as that of the SI process, but is influenced by the efficiency of the electrical power cycle. It is one of only four processes for which a fully integrated process has been demonstrated in a hood. It is the only process for which a full conceptual design report for a full-scale facility has been developed. Lastly, like the SI process, it has the potential for major improvements.

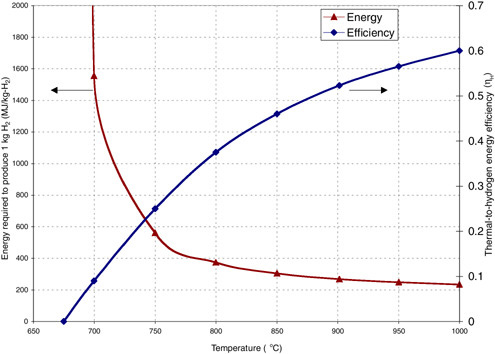

The SI cycle requires high operating temperatures but offers the opportunity for high-efficiency conversion of heat to hydrogen energy, ηH, as shown in Figure G-8. The SI cycle can be coupled to the modular high-temperature reactor (MHR) (a version of the HTGR) (LaBar, 2002). This reactor consists of 600 megawatt-thermal (MWth) modules, which are cooled by helium gas, with high coolant exit temperatures that can provide the necessary heat to the SI reactions. The coupling of the MHR and SI cycle, MHR-SI, provides a large-scale, centralized production of hydrogen.

The MHR-SI is a capital-intensive technology. Future cost reduction can be achieved from high efficiency by devising materials that can withstand higher temperatures. Reactor materials that are temperature-, irradiation- and corrosion-resistant would be needed. Also, possible reduc-

FIGURE G-7 Depiction of the most promising sulfur thermochemical cycles for water splitting. Courtesy of Charles Forsberg, Oak Ridge National Laboratory.

tion in the capital cost may result from improved catalytic materials and higher hydrogen production capacity in each facility.

Calcium-Bromine-Iron Cycle The calcium-bromine-iron (Ca-Br, or UT-3) cycle involves solid-gas interactions that may facilitate the reagent-product separations, as opposed to the all-fluid interactions in the SI cycle, but it will introduce the problems of solids handling, support, and attrition. This process is formed of the following reactions (Doctor et al., 2002):

The thermodynamics of these reactions have been found favorable. However, the hydrogen production efficiency of the process is limited to about 40 percent, owing to the melting point of Ca-Br2 at 760°C (Schultz et al., 2002).

Other Cycles Argonne National Laboratory’s Chemical Engineering Division is studying other cycles like the copper-chlorine thermochemical cycle. The energy efficiency of the process is projected to be 40 to 45 percent (ANL, 2003). This work is currently being investigated only by ANL, at a bench-scale R&D level, and no pilot demonstra-

FIGURE G-8 Estimated thermal-to-hydrogen efficiency (ηH) of the sulfur-iodine (SI) process and thermal energy required to produce a kilogram of hydrogen from the modular high-temperature reactor-SI technology. SOURCE: Brown et al. (2003).

tions have been undertaken. One of the main advantages of this process is that construction materials and corrosion-resistance are more tractable at 500°C than at higher temperatures. Another advantage is that, owing to its relatively low operating temperature, it can become compatible with several current and advanced nuclear reactor technologies.

Steam Methane Reforming

Steam methane reforming (SMR) is currently the main commercial technology for hydrogen production in the United States. The SMR process requires high temperature, and the most common means of providing the heat for the process is through the burning of natural gas in the reforming furnaces, as described in the section “Hydrogen from Natural Gas,” earlier in this appendix.

The SMR process can be coupled to a high-temperature helium-cooled reactor, such as the MHR. The MHR can function as the heat source operating at about 850°C, to replace the natural gas burning. The high operating temperature can enable the process to take place at about 80 percent efficiency. This approach (which might be called N [nuclear]-SMR) reduces the CO2 emissions to the atmosphere by large quantities. Elimination of the natural-gas-burning furnace in this process reduces the CH4 consumption by about 40 percent (Spath et al., 2000), which is parallel to the amount of CO2 emission reduction.

Cost of Nuclear Hydrogen Production Plants

The cost of hydrogen produced by electricity generated from existing nuclear power through water electrolysis is equivalent to using the electricity supplied by the grid for hydrogen production. Today this cost is about a factor of 3 higher than what is achievable by conventional SMR, with natural gas prices at $4.5/million Btu, even when the cost of hydrogen distribution is taken into account. The improved power-cycle efficiencies of the advanced nuclear power plants may bring this cost differential in the future down to a factor of 1.5.

The cost of hydrogen production using the MHR-SMR option is dependent on the cost of natural gas feedstock to the reforming process. However, the cost from MHR-SMR is less sensitive to the cost of natural gas than is conventional

SMR. Hydrogen production cost estimates by EPRI (Sandell et al., 2003) and by the Massachusetts Institute of Technology (Yildiz and Kazim, 2003) indicate that this approach may be competitive with conventional SMR if the natural gas prices go above $6/million Btu. However, their analyses did not include any taxes or fees for CO2 production.

The cost of hydrogen production by the nth-of-a-kind of MHR using the SI process was assessed by Brown et al. (2003). The authors considered the cost of producing 800 t H2 per day using heat from four units of 600 MWth, each producing a coolant at 850°C and having an overall efficiency of 42 percent. Starting with an overnight cost of $470/ MWth for the nuclear electric plant, adding a heat exchanger, and replacing the electric generation capacity with a thermochemical plant, the total plant capital cost was found to be about $750/MWth. (A recent review of the costs of nuclear power at recent plants—built in the past 10 years in Korea, Finland, and Japan—finds the overnight costs of plants to be in the range of $530 to $800/MWth [Deutch and Moniz, 2003].) The cost of running the MHR nuclear plant is estimated to be $93.9 million per year and the hydrogen plant to be $50.7 million per year. This resulted in the cost of hydrogen production being about $1.50/kg. However, it is possible to argue that future developments could facilitate reaching higher efficiency in the conversion of the nuclear thermal energy into hydrogen production. Furthermore, larger numbers of units in one place could lead to lower costs; thus, larger plants could be associated with lower plant and operating costs. Using optimistic assumptions about advances in nuclear plant construction and thermochemical plant efficiency, the cost of a 1200 t/day MHR-SI hydrogen plant may be assumed to reach a level of $600/MWth as the technology matures. Including the usual contingency and permitting costs could add about one-third to this cost, thus leading to an effective plant cost estimate of $800/MWth and, assuming a 3-year construction time, the hydrogen production cost would be about $1.60/kg.

Advantages of Nuclear Energy Use for Hydrogen Production

-

Long-term domestic source. Nuclear fuel will be available for a long time in the future, both domestically and worldwide. Its price is not subject to global geopolitical pressures.

-

Carbon implications. If nuclear energy is used in the short term as the heat source in the SMR process, the result would be to reduce CO2 emissions by nearly 40 percent. If one of the water-splitting processes is used, whether via a thermochemical process or an electrolysis approach, there will be no CO or CO2 emissions.

-

Efficiency of the overall process. In comparison with several other sources of hydrogen, the capability of attaining overall thermal-to-hydrogen energy efficiency in excess of 50 percent values by future technologies (e.g., the N-SMR, HTES, SI, and possibly other paths) is one of the advantages of nuclear energy use in hydrogen production. The higher the temperatures that can be achieved for the reactors, the higher their efficiencies.

-

Environmental implication. There are no polluting emissions, or toxic gas, or particulate releases due to nuclear energy use for water splitting as the means for hydrogen production. N-SMR will have CO2 emissions. The water-splitting processes coupled to high-temperature reactors assume complete recycling of all reactants. The volume of waste from the nuclear reactor cycle, while highly radioactive, is confined to small quantities compared with that from several other sources of energy, but it will have high levels of concentrated radioactivity.

Disadvantages of Nuclear Energy Use for Hydrogen Production

-

Efficiency of the conventional electrolysis process. Even though it is a proven and clean technology, the low efficiency of low-temperature electrolysis makes the process uneconomic.

-

Capital cost. Both the new nuclear reactor plants and the hydrogen plants coupled to the nuclear plants are capital-intensive. While the operating costs will be low owing to the expected high thermal efficiencies, the economics of the whole process may be disadvantageous. Capital and life-cycle costs remain high, and plant designs are in need of simplification. Enabling shorter periods of construction and increased factory-based manufacturing of components will also reduce the cost of the plants.

-

Nuclear waste. The nuclear waste disposal scheme remains to be finalized. The Yucca Mountain project in Nevada has made good advances recently, and when licensed it can provide a destination for the spent fuel accumulating at the plant sites. The development of a closed fuel cycle that involves the extraction and use of the fissile contents from the irradiated fuel would reduce the long-lived radioactivity associated with the waste to be sent to the repository.

-

Proliferation. Nuclear-fuel-cycle operations leave open the possibility of improper access to fissile material through theft or diversion. Proliferation can be addressed through near-term measures designed to improve the proliferation-resistance of current nuclear reactor operations and through long-term research to explore proliferation-resistant designs (PCAST, 1999).

-

Public concerns and permitting needs. There is a public perception that nuclear energy and its emissions during normal operations increase radiation risks. There is also some fear of widespread devastation in case of accidents. These concerns would be reduced by the continued safe operation of existing plants and increased safety margins in new plants. In addition, the recent concerns about terrorism may add to the public fear of nuclear plants. The concerns of the public have led in the past to prolonged permitting periods for nuclear plants. Thus, the permitting of commercial

-

nuclear energy may pose a barrier to any expansion of this technology.

Research and Development Needs for Economic Hydrogen Production Using Nuclear Energy

-

A high priority should be given to the development of high-temperature reactors that can provide coolants at temperatures higher than 800°C. This objective seems most readily achievable using the helium-cooled gas reactor technology of HTGRs. The ability of the reactor’s structural materials to operate for a long time at temperatures between 800°C and 1000°C needs to be established. The R&D program should include the following:

-

Qualification of particle fuel materials to operate at the desired high temperatures,

-

Qualification of the irradiation properties of graphite and other structural materials at the desired range of temperatures, and

-

Operation and control of the helium power cycle at very high temperatures.

-

-

The efficiency of thermochemical schemes to accomplish water splitting without any CO2 emissions should be examined at a laboratory scale for the promising cycles, such as the SI cycles. Materials compatibility issues and catalysts to enhance the reaction at lower temperatures should be pursued. Reasonably-sized demonstration plants using the integrated process should be pursued in a few years for the most promising scheme.

-

Development of the high-temperature steam electrolysis process should be pursued. The issues of materials durability, reduction of overvoltages, effects of the operating pressure, and separation of gas products in an efficient and safe manner should be investigated.

-

Development of a supercritical CO2 cycle should be given a high priority. It can be directly used with a CO2-cooled reactor such as the AGR, or indirectly used with the other reactors such as an HTGR. It can be the bottoming cycle for a high-temperature reactor, whose coolant would supply heat at higher temperatures to a thermochemical plant. Demonstration of the thermal conversion efficiency for a moderate-size turbine and compressor (in the MWe range) is needed to validate the cycle thermodynamics.

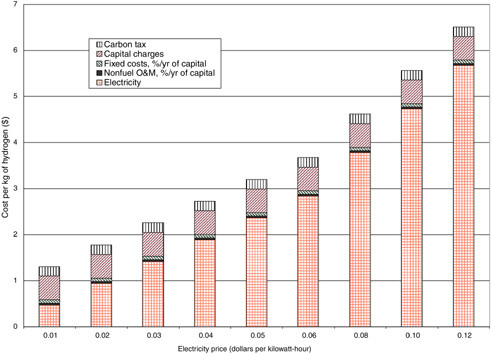

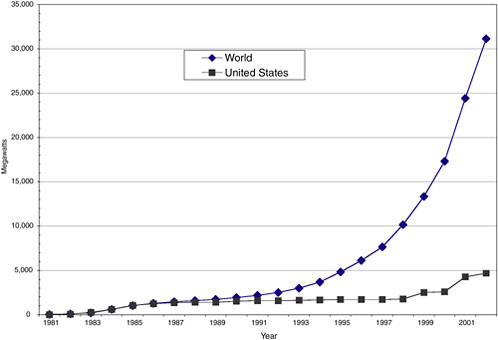

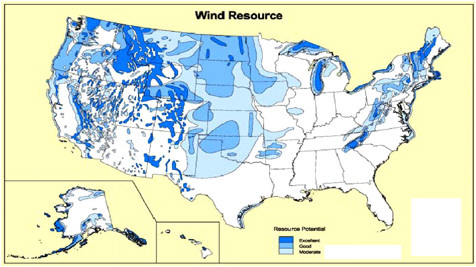

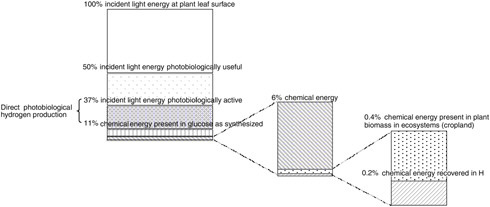

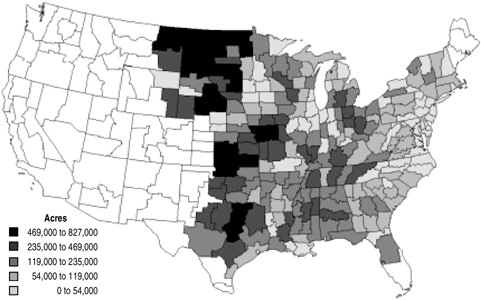

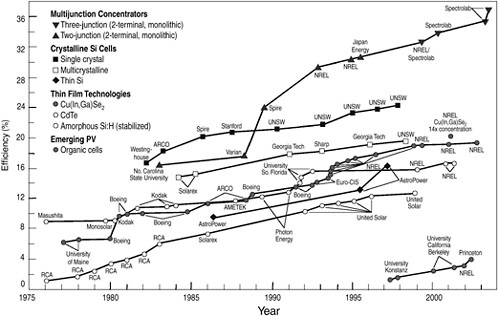

-