9

Sustainable Development: Role of Industrial Water Management

Bhasker Davé

Ondeo Nalco

INTRODUCTION

Sustainable development is a development path that can be maintained indefinitely because it is socially desirable, economically viable, and ecologically sustainable. Economically viable sits at the top of the pyramid in Figure 9.1 because it a very important factor in an industrial environment. Highly sustainable development in industry works only if the company can still make a profit. In other words, there is no such thing as a “golden subsidy.”

Key Drivers for Sustainability

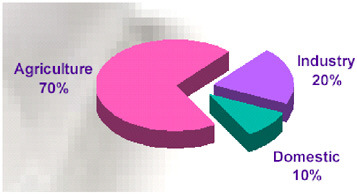

Global freshwater consumption quadrupled in the last 50 years. In 2000, there were 5,000 km3 of fresh water used. Sector withdrawals are shown in Figure 9.2, with 70 percent going to agriculture, 20 percent to industry, and 10 percent to domestic uses.

However, in looking more closely, water usage varies

FIGURE 9.1 The three points of sustainable development.

FIGURE 9.2 Global water withdrawal by sector. SOURCE: Igor A. Shiklomanov, State Hydrological Institute, St. Petersburg, Russia, and UNESCO, Paris (1999).

considerably between developed countries and developing countries. The water demand for the top four industrialized countries (United States, France, Germany, and Canada) shown in Table 9.1 is significantly higher for industrial than agricultural use. In India, China, and Brazil, large centers of development, water use varies considerably from that in the industrialized countries. For India and China, respectively, 93 percent and 87 percent of the fresh water used is in agriculture, whereas industrial uses are very small, with 4 percent for India and 7 percent for China. However, these countries are now going through an explosion of industrial growth. The gross domestic product (GDP) of China is growing 8-9 percent a year and India’s GDP is growing 7 percent a year. Such growth will no doubt have a significant impact on water use. If world water use doubles, where is the fresh water going to come from? As the rest of the world is striving to be “developed,” how will the increased freshwater demand for industrial use be satisfied? Industrial water management is going to be a very critical issue in making development sustainable.

TABLE 9.1 Comparison of Water Usage for Developed and Developing Nations

|

|

Domestic Use (%) |

Industrial Use (%) |

Agricultural Use (%) |

|

Canada |

11 |

80 |

8 |

|

United States of America |

12 |

46 |

42 |

|

France |

16 |

69 |

15 |

|

Germany |

14 |

68 |

18 |

|

Brazil |

43 |

17 |

40 |

|

China |

6 |

7 |

87 |

|

India |

3 |

4 |

93 |

|

SOURCE: Food and Agriculture Organization (1999) AQUASTAT estimates. |

|||

Industrial Perspective

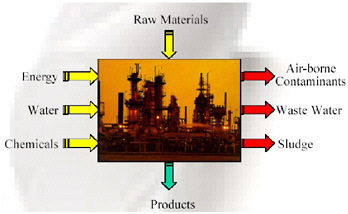

Figure 9.3 shows some very generic input-output for a given industrial site. The three major imported resources are energy, water, and chemical entities, and the undesirable outputs are airborne contaminants, wastewater, and sludge. Therefore, from an industrial perspective sustainable growth goals include reducing both resource consumption (e.g., water) and harmful environmental impacts, while increasing profitable growth.

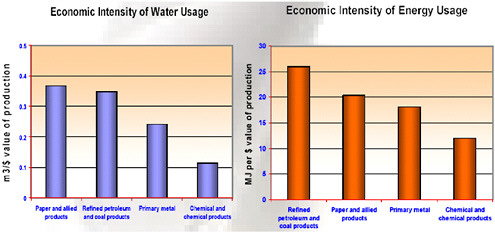

In looking at the economic intensity of water and energy for different industries, pulp and paper and petroleum refin

FIGURE 9.3 Industrial inputs and outputs.

ing are the largest users of water and energy in the manufacturing sector (Figure 9.4). The numbers shown represent cubic meters of water used per dollar value of the product output. For energy, the units are megajoules (MJ) of energy used for every dollar of product made.

Integrated Water Management

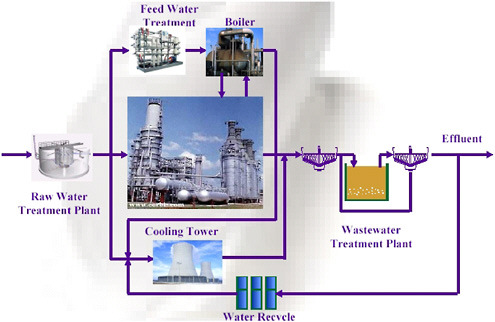

It is important to look at the manufacturing system in its entirety to address water resource management issues (Figure 9.5). Water is typically used in three main areas: manu-

FIGURE 9.4 Water and energy use.

FIGURE 9.5 Integrated water management.

facturing process, cooling water, and feedwater for the boiler system to generate steam. Typically, there is also raw water treatment, especially when surface water is being used; wastewater treatment, which includes removing solids; and biological treatment.

Integrated water management entails evaluating and optimizing all of the resources used for an entire site. Some of the water flows are shown in Figure 9.5. For example, the condensate from the process flows back into the boiler for the recovery of heat and water. The boiler blowdown or the effluent of the whole plant could also be used as a cooling tower.

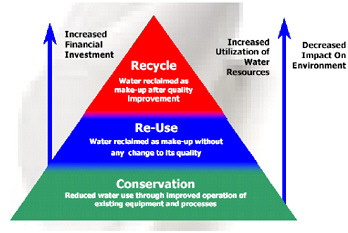

WATER RESOURCE MANAGEMENT

Figure 9.6 shows the hierarchical approach that Ondeo Nalco has developed to address water resource management. The foundation of this approach is conservation, or reducing water use through improved operation of existing equipment and processes. This could mean understanding and preventing scale, corrosion, and microbial formation. Reuse deals with understanding the water quality requirements for the water demand and matching the wastewater from one area as makeup for another area. For example, boiler blowdown could potentially be used as a cooling tower makeup. On top of the pyramid is the recycle option, where chemical sciences currently make a significant capital investment. There is a high level of resource utilization and risk of contamination, but the risk decreases any impact on the environment.

FIGURE 9.6 Water resource management and the Advanced Recycle Technology (ART™) services pyramid.

FIGURE 9.7 Water process management.

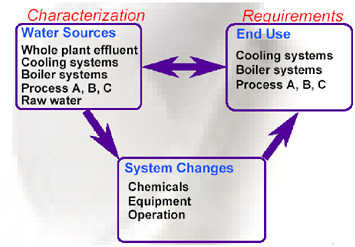

Water Process Management

A key part of water process management is characterization from a chemical science point of view (Figure 9.7). For example, efforts are being made to recycle centric water from polyvinyl chloride (PVC) manufacturing. PVC manufacturing actually uses deionized water in the suspension polymerization process. In fact, for every pound of PVC produced, a pound of deionized water is used only once and then discharged.

One of the greatest concerns about recycling this water is the presence of residual chemicals left over from various stages of the production process. Typically, a free-radical scavenger called a “shortstop” is used to increase the polymerization reaction. If the shortstop remains in the water and ends up in the front of the batch reaction, it can potentially cause problems. Concentrations as low as 50 parts per billion (ppb) of shortstop in water used for the suspension polymerization process can have a detrimental effect on product quality and productivity.

Another example comes from the pulp and paper industry where, during the pulping process (especially mechanical pulping), a significant amount of organics from wood goes into the water and can potentially cause a problem in the papermaking process. It is difficult to measure these contaminants and to know whether they will be harmful to other processes.

Water quality requirements are important for the cooling water system, the boiler feedwater, and the manufacturing process. The water quality requirements, however, are not very clear, and even the people who manufacture do not know the exact quality requirements. Identifying water quality requirements is very important for the manufacturing process since matching them utilizes conservation and reuse approaches that end up being very cost-effective for managing water on an industrial site.

However, when the water system changes, three major components have to be addressed: chemicals, equipment, and operation. By changing the chemistry it is possible to handle the chemical contaminants. For example, a trash-resistant polymer has been developed so that more organics can be handled in the papermaking process and still produce highquality product. The other important aspects of the system are the equipment and the operation. For example, bringing in sensor technology and automating water treatment will make the process more viable because it will improve the reuse and recycling of the water and decrease the amount of harmful contaminants produced.

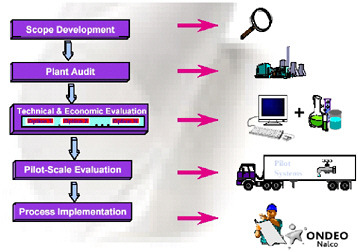

Figure 9.8 shows a five-step approach developed by Ondeo Nalco for site-wide integration of the water resources. The first step is scope development, which involves clearly defined goals and a detailed project plan, including a time line and the resources required. Then a plant audit is conducted to identify best practices. This is where first principles of chemical engineering are applied such as mass and energy balance for the water resources and contaminants. Technical and economic evaluation is then carried out to evaluate different options that might be available. The next step is the pilot study evaluation where the most economically and technically best solution is determined for a given site. Finally, there is process implementation. This is not an additional capital requirement at the site, but often rather the implementation of good ideas.

Advanced Water Chemistry Modeling

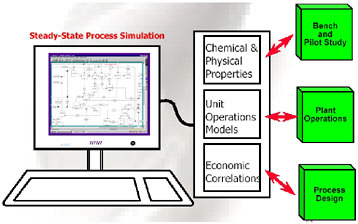

To model a system, a steady-state simulation is assumed. Any given mode will consist of three major components for evaluation: (1) chemical and physical properties, (2) unit operations models, and (3) economic correlation (Figure 9.9). Chemical and physical properties such as mass balance,

FIGURE 9.8 Advanced Recycle Technology services.

FIGURE 9.9 Advanced water chemistry modeling.

air versus water discharges, and effects of pH and temperature, are evaluated. For unit and plant operation, cooling towers, boilers and membrane separations, ion exchange and clarification, and the manufacturing process have to be reviewed. It is necessary to look at the site-wide water management and every place that water plays a critical role. Finally, economic correlations are carried out. Ideally, flow sheeting is performed to utilize available technical merits. Factoring in capital expenditures for the new water treatment equipment and operating expenses also helps the economic evaluation, not just the technical merits.

WATER RESOURCE MANAGEMENT EXAMPLES

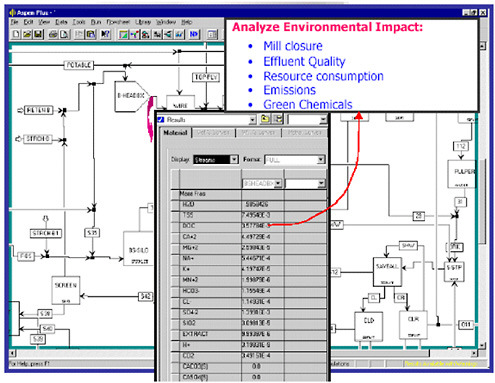

Virtual Paper Mill

In this simulation of an integrated mill, a very small part of the pulp and paper process involving only the paper machine is examined (Figure 9.10). It is a very fairly complex stream or flow sheet that helps to optimize water use in the mill. Typically in the paper machine, the starting rate is for water to be used about 17-25 times before it is discharged. Each component is analyzed for the potential to build up mineral deposits (form scale). Computer modeling is a very good tool because it helps to look at situations under varying conditions.

FIGURE 9.10 Virtual paper machine model.

From a manufacturing point of view, the virtual paper machine is not enough because it cannot determine how water chemistry will affect the product quality. It cannot predict whether the machine will still run at 60 miles per hour or will have to slow down. Therefore, Ondeo Nalco research plays a very important role in helping to better understand the manufacturing process and the role played by water, energy, and fiber. The most critical part here is the ability to look at the impact of this water in different arenas. Equipment, not just chemistry, is also important. It is necessary to look at what equipment can be used.

Recycled Newsprint Facility: Integrated Water Resource Management

At a North American newsprint site the goal was to reduce water demand by 25 percent of the 12 million gallons used per day and to improve fiber recovery. A key aspect of water recovery is that it often leads to improved recovery of other resources. This site also considered using municipally treated wastewater. Contaminant buildup in the system was also an issue. Ondeo Nalco used an integrated approach to look at resource management including the mass and energy balance using computer simulation to evaluate the conceptual designs.

The site discovered it was possible to reduce the water usage in the plant by 33 percent by taking higher-yield fibers. Each percentage on the fiber yield is worth a million dollars per year. The implementation cost is about $2.5 million, with an annual savings of $5.3 million a year. This case shows that it is possible to achieve sustainable development at a reasonable savings.

U.K. Petroleum Refinery: Water Audit Uncovers Saving Potentials

The next example is from the petroleum refinery industry. The goal here was to look at reducing the total cost of operation especially from a water resource point of view. In looking at benchmarking, almost two times as much water is used in the processing of crude compared to the industry standard. By applying the integrated resource approach at the site, the best practice alone saved 450 m3 per hour, which resulted in a savings of about 2,000 gallons of water per minute. This is a good example of what can be achieved by implementing best practices. Overall, saving 1,000 m3 per hour brings the refinery close to the industry average. It will save about $2.7 million just by preventing a leak and doing the blowdown control. Looking at the alternative source for makeup water can provide another 1 million dollars in condensate return, and returning condensate to the boiler leads to energy and water savings worth $1.2 million. By implementing a site-wide approach of water and energy resource management, it is possible to give money back to the manufacturing sector.

Green Chemistry: ULTIMER® Coagulants and Flocculants

The better reuse of wastewater involves removal of suspended solids, which typically requires coagulation and flocculation. These processes are often used in a variety of industrial and municipal wastewater areas. Water-soluble polymers are used for flocculation in sludge water, and Nalco is one of the largest manufacturers of this liquid water-soluble polymer.

When liquid water-soluble polymer is used, the liquid part is typically oil. The polymer is a discontinuous phase made in the continuous phase of oil. When this liquid is used in wastewater treatment, the oil is actually there to carry the polymer, after that it has no use. Oil is there only to control viscosity. It is thus a manufacturing issue. Nalco has built a patented technology of liquid dispersion polymers, so that now the polymer is actually in a solution of ammonium sulfate that is also surfactant free. In fact, the salt used is the by-product of other manufacturing processes. Thus, waste is being taken from one industry used for Nalco raw material. There is complete elimination of oil and the surfactants, which makes transportation easier because the product is also free of volatile organic compounds, environmentally benign, and easier to handle. This product won a Presidential Green Chemistry Challenge Award in 1999.

Green Chemistry: Lazon® Biocides

Microbial activity in recycled water is a critical issue. Using chlorine as a biocide often leads to formation of potentially harmful by-products. Green biocides, based on hydrogen peroxide and other nonhalogenated compounds, have been created that can maintain residual toxicity for bacteria, but do not create any organic by-product contamination The environmentally friendly end products are listed in Table 9.2. The green biocides have also shown improved control of microbes.

Automation and Cooling Water

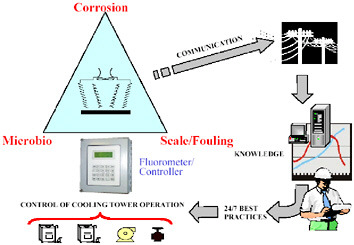

The Erin Brockovich, Pacific Gas & Electric, story helped bring to light the issue of chromate use in industry cooling towers. Using chromate at pH 6 inhibits corrosion, scale, and microbial buildup. Chromate has many benefits, but it is

TABLE 9.2 Green Chemistry and Lazon Biocides

|

Green Biocide |

End Products |

|

Glutaraldehyde |

Carbon dioxide and water |

|

Hyrdrogen peroxide |

Oxygen and water |

|

Ondeo Nalcon Lazon® technology—multicomponent, nonhalogenated, oxidizing biocide |

Carbon dioxide, water, and oxygen |

FIGURE 9.11 Automating the cooling water “triangle.”

not a sustainable solution. Chromate has been found to be very harmful to humans exposed to air emissions from cooling towers. The blowdown from the cooling tower is supposed to be a zero liquid discharge, but the rubber linings can give out and this is what led to the aquifer contamination that Erin Brockovich identified.

Since chromate cannot be used now, new solutions are needed. Automation today plays a key role (Figure 9.11). For example, a fluorometer can be utilized to monitor microbial activity in cooling towers. If microbial activity is found, as signaled by a change in fluorescence, a biocide will be used on an “as-needed” basis. The system can also measure corrosion and scaling in real time. Therefore, if people use more dirty water in the cooling tower, they are taking more risk, but by bringing the right chemistry and automation, they can manage the risk more effectively.

TRASAR® for Reverse Osmosis (RO) Scale Control

The TRASAR system (Figure 9.12) accurately measures the concentration of antiscalant in either the feed or the concentrate streams. The system utilizes fluorescence technology to enable the scale inhibitor chemical feed to be maintained at the prescribed dosage. The RO TRASAR technology ensures that the desired dosage is maintained at all times.

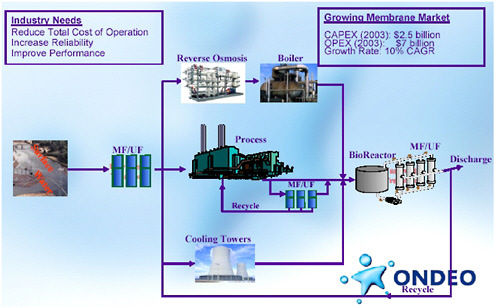

TWENTY-FIRST CENTURY INDUSTRIAL WATER MANAGEMENT

Figure 9.13 shows what industrial water management will look like in the twenty-first century. Some of the items shown are already happening; for example, RO is the main choice for the boiler feedwater system. Also, microfiltration (MF) and ultrafiltration (UF) clarification membranes are used in the manufacturing process.

FIGURE 9.12 TRASAR for RO scale control.

In wastewater treatment, a membrane bioreactor is combined with the clarification membrane. This produces half the amount of sludge and more than 95 percent removal of the biological oxygen demand (BOD). High BOD is typical of polluted water. Very high quality water is generated that can be recycled back to the cooling tower or to the RO system.

For surface water, 50 percent of the new industrial water treatment in Europe is now based on membrane technology. The total growth in the industrial segment this year is about $2.5 billion in capital sales of membrane technology in industrial water, excluding municipal use. The operating cost to the customer in the manufacturing sector is $7 billion, and the growth rate is about 10 percent annually. In looking at industrial needs, it is important to reduce the total cost of operation, improve the liability, and improve the performance.

SUMMARY

Industrial water management is a very critical component of sustainable development. An integrated approach to industrial water management can actually provide a cost-effective solution; chemistry, equipment, and operations, especially automation, play a significant role. Chemical

FIGURE 9.13 Twenty-first century industrial water management and the role of membrane separations technology.

sciences should look at this tier as an opportunity for new business, especially the membrane separations equipment area. There is tremendous growth to be made here, and it will play a very critical role going forward in industrial water management.

DISCUSSION

Microbial Monitoring

Dick Carlson, of San Diego County, was looking at the use of recycled water for cooling towers. He said that one of the concerns of recycled water is the growth of bacteria that lead to Legionnaires’ disease. He wanted Dr. Davé to discuss more about using the Ondeo Nalco technology to monitor biological contaminants in real time.

Dr. Davé responded that they can monitor on-line microbial activity in the cooling water system, but the process does not distinguish between Legionella and other organisms. It measures total microbial activity in the system through a technology based on fluorescence. There is a fluorescence moiety that reacts with enzymes in the bacteria by oxidizing and changing the fluorescence properties.

Industrial Reuse of Water

Vasilios Manousiouthakis, of the University of California at Los Angeles, stated that it is important to have some metrics for the source water, whether it is renewable or nonrenewable. This may not be a concern here in the United States, but it is a concern in many parts of the world where fossil water is being extracted at very high rates. This water is not renewable, and it is important that industry is aware of this particular issue and is not tapping into nonrenewable water. He asked about the rate of reuse in the United States. It was mentioned that industrial use is around 46 percent, and he wondered how much of that water is being reused today by industry.

Dr. Davé replied that a significant part of that water is not being reused because the largest consumers in the industrial segment (power generation, manufacturing, and mining) are actually the power generation segment. Most of the power generation uses water once through the system. Of the 46 percent, a significant portion is actually power generation.

He continued to explain that the world is very connected. For instance, the outbreak of severe acute respiratory syndrome (SARS) is not a Chinese problem but a world prob-

lem affecting our economy. There is interconnectedness and it is necessary to take a more global view of the total cost and impact on the environment.

Integrated Source Approach for New Facilities

Dan Askenaizer, of Montgomery, Watson, and Harza, was curious about whether industrial clients building new facilities are requesting that an integrated resource approach be incorporated up front in the design of this new facility.

Dr. Davé said that it is not the normal or standard practice. It occurs more on a sporadic basis, especially by the people who are putting in a new desalination plant in a refinery. In one case, resource management was implemented from the design phase because the cost of water was very high. They actually built a desalination plant along with the refinery so they had an integrated approach.