21

Turning New Technologies into Products at Sandia National Laboratories

Gregory F. Cardinale

Sandia National Laboratories

Sandia National Laboratories is involved in a wide range of national security research and development projects. Current programs include nuclear weapons fail-safe technologies; nonproliferation and materials control technologies, such as a foam intended to combat biochemical spills and chemical attacks; national infrastructure projects involving water supplies or energy sources, which are easy to contaminate or attack; and projects to prevent the types of disasters that occurred in Oklahoma City, New York, Washington, D.C., and Pennsylvania. The Sandia vision is to help the nation secure a peaceful and free world through technology. When developing technology programs, Sandia explores commercial market opportunities. This paper describes a successful business development and technology transfer case study, the development of extreme ultraviolet lithography (EUVL). It also presents Sandia’s current technology transfer model and a proposed new model. Finally, some venture opportunities with Sandia are discussed.

NEW TECHNOLOGIES

A successful example of Sandia’s business development and technology transfer is the nanolithography program, under which EUVL was developed in collaboration with several semiconductor manufacturers. The nanolithography program is a next-generation lithography cooperative research and development agreement (CRADA). Under the program, Sandia, Lawrence Livermore National Laboratory, and Lawrence Berkeley National Laboratory developed and built a full-field scanning exposure tool capable of printing features less than 100 nm in size.

Nanoscale devices fabricated at Sandia include radio frequency nanoelectromechanical systems (RF-NEMS), nanofluidics, and molecular electronics or “molectronics,” i.e., electronic devices built out of individual molecules. A molecular junction is created by patterning two electrodes with a nanometer-scale gap using the EUVL exposure tool, and then a gold sphere is placed in the inter-electrode spacing. The gap size between the two electrodes is less than 40 nm. The gold sphere is functionalized using wet chemistry with an appropriate solution such as thiol, and the molecule of interest is deposited on the functionalized sphere. By applying an electrical bias to the electrodes, the transfer characteristics of the molecule can be determined. Agglomerates of functionalized gold spheres placed between functionalized, nanometer-scale electrodes exhibit interesting electrical properties.

TECHNOLOGY TRANSFER AT SANDIA

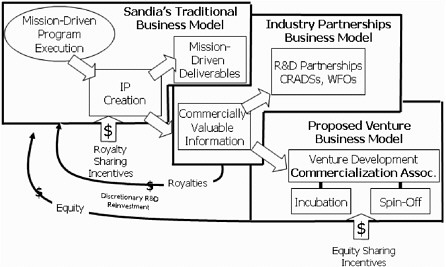

Sandia has traditionally had a business model that was mission-driven, with mission-driven deliverables. In addition, Sandia has participated in research and development

FIGURE 21-1 Three different business models at Sandia National Laboratories. SOURCE: Model developed by Denise Koker, Manager, Business Development, Sandia, Calif.

partnerships with industry. A new business model currently under consideration focuses on the development of incubator-type environments, where technologies can be spun off when appropriate (Figure 21-1). Input from industry will help Sandia make this transition in business models.

Once a market opportunity is identified, several paths can be taken to commercialize a technology: creating a large, multiyear CRADA; evolving from a small business agreement to a strategic partnership with a licensing agreement and CRADA; obtaining a license for a new start-up venture (spin-off); and commercializing stand-alone inventions, from laboratory directed R&D to licensing. These processes have evolved since the Federal Technology Transfer Act was enacted by Congress in 1986 to commercialize government technologies.

Methods of moving ideas into the marketplace have also evolved. Industry generally uses models that are based on customer-driven demand, i.e. filling a market need. Such a model involves the following steps: research and development (R&D); prototyping; pilot production; and volume manufacturing. The model used more frequently at Sandia has the Department of Energy (DOE) as the primary customer. Non-DOE customer needs must be consistent with national security needs. In this model, national security-related products are provided to the government when Sandia’s technology is transitioned to industry. Such a model involves the following steps: Sandia R&D; prototyping; pilot production; commercialization partner (private sector); and volume manufacturing. Under this model, discretionary revenue can be fed back to the laboratory through licensing agreements. The main differences between the two models arise from the fact that Sandia is national security-centric, works with nuclear weapons, has restricted outsourcing policies, and is a not-for-profit organization. Similarities include the R&D programs, generation and licensing of intellectual property, and customer-driven product development.

NEW TECHNOLOGY CHALLENGES

Manufacturability is a major challenge for new technologies, such as microelectromechanical systems (MEMS) and nanotechnology. The MEMS industry has leveraged much of the learning and manufacturing rigor of the integrated circuit industry. The integrated circuit industry’s existing infrastructure (wafer suppliers, overlapping processing foundries, metrology services, packaging) has facilitated MEMS productization. A culture change is still needed, however, among smaller MEMS companies to implement metrology and achieve stricter process control (i.e., six-sigma). In contrast, there exists little or no infrastructure for nanotechnology to leverage. Nanotechnology start-ups may rely on government laboratories, institutes, and universities to serve as foundries until such an infrastructure is developed. Nanotechnology companies may even use MEMS foundries since they are more closely related to nanotechnology and are more flexible than larger, blue chip industries. Nanotechnology foundries or centers may provide a stopgap solution by offering unique capabilities in key process areas such as metrology.

CONCLUSION

Venture opportunities exist between national laboratories and private companies. National laboratories can, for example, be considered as an R&D nucleus. Most national laboratories have state-of-the-art metrology, analytical techniques, unique processing methods, and modeling capabilities that can be exploited by private companies with little initial investment in capital equipment. Specific venture partnership opportunities with Sandia in national-security technologies include microsystems, nanotechnology, chemical/bioterrorism prevention, water surety (plant and point of use), secure communications, and distributed microsensors.