11

Manufacturing Globalization at United Technologies Corporation

John F. Cassidy, Jr.

United Technologies Corporation

This paper presents the perspective of a private company, United Technologies Corporation (UTC), on the globalization of manufacturing. It also presents the company’s vision of where things are and how they should be dealt with to ensure economic stability within the United States, as well as growth in manufacturing. UTC provides high-technology products and services to the building systems and aerospace industry throughout the world. UTC’s industry-leading companies are Pratt & Whitney, Carrier, Chubb, Otis, UTC Power, Hamilton Sundstrand, and Sikorsky. Much has been said recently about changes in manufacturing patterns and the effect on the global scene. Globalization has been occurring for decades. Globalized manufacturing will become larger and more volatile through expansion.

METRICS

Metrics are developed to measure changes that are occurring. Figure 11-1 shows that traditional manufacturing countries, such as the United States, Germany, and Japan, had a good annual percentage growth rate in the 1980s and 1990s, while countries such as China and Mexico showed room for increasing growth, especially up to 2002. It can be argued that the rate of growth will always look much larger for countries that are starting out at a low level, when compared to more established countries. However, the overall rate of growth looks promising for countries such as Mexico and China and it would appear that countries such as Germany and Japan are in serious trouble. The United States has an expanding albeit smaller manufacturing base. Other nations are growing faster, but this need not be a major concern if the United States can maintain its pace of growth.

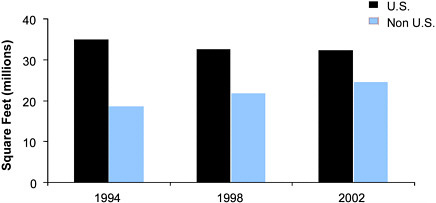

It is important for companies to determine what to do with metrics once they are developed. It has been said that it is a matter of changing the definitions to meet the changing markets. UTC believes that understanding the data and solving the fundamental problem are more important than focusing on definitions. Figure 11-2 provides a good example of this issue. Between 1994 and 2002, UTC had a large presence in the United States. Value produced went up in the space created or allotted for manufacturing in the United States. The rest of the world shows a larger increase over the years, but the reason for this is infrastructure. As a global company, UTC wants to be there in other parts of the world to make ourselves successful. So depending on how you look at it one can say that the productivity in the United States is still very high despite increasing growth outside of the country.

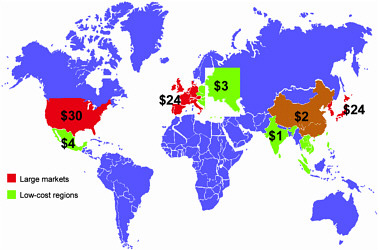

In this global market, UTC has approximately 90,000 employees involved in various manufacturing activities, from receiving orders to shipping product. Overall, UTC has $28.4 billion in annual revenue with about $10.4 billion of buy and $9.7 billion of operations value-added. UTC has 57 million square feet of manufacturing area divided among manufacturing facilities in 28 states and 36 countries. For a company of this nature, one of the largest issues is wages. Figure 11-3 shows the vast differences in wages around the world. China, although

currently on the low end of wage levels, is in a category by itself because it also represents a large market. China recently became the world’s largest market for air conditioners. China is a country in which the market will expand and in which there will be manufacturing jobs without the need to cross boundaries.

There are concerns that globalization of manufacturing causes the loss of jobs and is counterproductive to the local economy. UTC believes that nothing could be further from the truth. Global manufacturing enables engineering and manufacturing responsibilities to be distributed in such a way that the product is built efficiently. For decades, United Technologies has engineered and manufactured products in Europe and Asia. In recent years virtually all markets around the world demand that products be engineered to meet local requirements and preferences. Currently United Technologies has 125 engineering centers in the United States, Europe, Australia, Asia, and South America. The non-U.S. activities leverage the primary work done in the United States and create export sales. Last year United Technologies exported $3 billion of goods and services while its imports totaled $500 million.

An example of the advantages of global manufacturing is UTC’s purchase of PZL-RZESZÓW (Poland), which has been part of Pratt & Whitney-Canada for 27 years. When UTC won a $1.8 billion contract to build F16 jet engines over a period of 10 years, it bought PZL-RZESZÓW and created a lower cost source location. It became a privatized manufacturing arm of UTC, manufacturing some parts of the F16 engines, among other things. Without this investment, UTC would not have been manufacturing this product. The domestic manufacturing locations (e.g., Connecticut, Georgia, and Maine), where other parts of the F16 engine will be built, would not have been manufacturing them either. Rather than focusing on individual pieces of the overall manufacturing scheme, it is important to understand and visualize the whole picture and the total flow of the manufacturing process.

Previously, it was believed that products made outside the United States were lower cost

FIGURE 11-1 Average annual percentage growth in manufacturing for five countries in the periods 1980 to 1990 and 1990 to 2000. SOURCE: The World Bank 2002 World Development Indicators. Available at http://www.worldbank.org/data/.

because they were of inferior quality. At PZL-RZESZÓW a bevel gear for the PT6 turbo engine is made; this same bevel gear is also made near Montréal. The main difference is the price, with the one made in Canada costing $921 and the one made in Poland costing $256. In order to succeed, UTC must take into account this price differential.

Other ways of dealing with this price differential include a renewed commitment to increase productivity. This should not be done by focusing on a specific fix-all manufacturing cell, but rather by adjusting to corresponding issues. It is important to be careful, because if a cell becomes too efficient, then inventory overflow occurs. Inventory begins to pile up because the downstream process cannot accept it.

An example where UTC has increased productivity by an overall investigation of a process is the wiring harness assembly. A value-stream map was used in an end-to-end approach, to become more efficient and increase the drive for manufacturing. Initially, this was a slow process with a total cycle time of 403 days and a processing time of 30 days. After using the value-stream map, the total cycle time was cut down to 21 days and the total processing time down to 18 days. By methods such as this one, it is possible to remain competitive in the global manufacturing arena.

CONCLUSIONS

In 1997, Peter F. Drucker said:

In a transnational company, there is only one economic unit, the world. Selling, servicing, public relations, and legal affairs are local. But parts, machines, planning, research, finance, marketing, pricing, and management are conducted in contemplation of the world market…. national boundaries have largely become

FIGURE 11-2 Millions of square feet of manufacturing area in the United States and abroad. SOURCE: Census Bureau, Department of Commerce.

FIGURE 11-3 Manufacturing direct labor cost (in billions of U.S. dollars) in different parts of the world identified as having a large market, low labor cost, or both. SOURCE: United Technologies Corporation.

irrelevant.1

His statement fits well with the theme of this paper. A company must have a vision of a global market, as well as maintaining productivity in the United States. In order to compete with the $2 per hour wages found in other parts of the world, the bar must be raised for the United States by creating new products and markets that do not yet exist and educating the workforce. As an example of new product/market creation, UTC has 250 fuel cells providing electricity around the world. These fuel cells have 250 kilowatts of power and a lifetime of 40,000 hours. By creating a supply chain around this product, the cost of the unit can be decreased. As an example of the importance of educating the workforce, UTC pays for any employee to attend school on any subject, in addition to giving them a bonus when they complete a degree. This system creates incentives and motivation for individuals to excel, as well as creating loyalty to the company. In the long run, this makes for a more productive and efficient company capable of competing in the global manufacturing market.