4

Soldier Energy Sinks

This chapter describes power demand characteristics of the electronics needed for soldier applications—the soldier power sinks. It discusses both low-power and high-power electronics applications (the latter include laser designators, microclimate cooling, and exoskeletons) in the regimes specified in the task statement. The chapter concludes with observations on the impact of Army logistics on the selection of power solutions for the soldier.

As has been discussed, the energy-consuming hardware used in soldier applications can be roughly divided into two categories: the silicon circuits for computation and communications and the highly specialized sensors and transducers for the weapon systems. The total power demand of the soldier system is now more or less equally distributed between these two categories if the duty cycle is taken into account.

LOW-POWER ELECTRONICS TECHNOLOGY

Communications and computation circuitry both make use of silicon integrated circuit technology, which is being driven by market requirements to be ever more energy efficient. But there are major differences in the degree to which communications and computing can exploit commercial advances to reduce power requirements. The challenge for military communications and computation circuitry applications is how best to capitalize on commercial advances.

The exponential growth that has characterized improvements in commercial processor performance may dramatically slow over the next 10 years. (See the section “Commercial Trends” in Chapter 5.) In fact, the energy efficiency of the best-performing processors has begun to decline as they move into a power-limited operating regime. This is so because the impossibility of removing the heat that is created by the processor at the highest possible clock rates and voltages by means of heat sinks makes it impossible to exploit the peak performance of these processors. While it is believed that the soldier requirements are well below this limit, it is important to be aware of the limitations of the technology, which will become more severe with time.

There is a hierarchy of computation architectures for each computation application. For signal processing (video compression, data communications) the energy efficiency can vary over many orders of magnitude. In order of energy efficiency, the least efficient are standard microprocessor architectures (even with power optimizations such as X-scale). Specialized processors that can implement signal processing functions can be up to 10 times more efficient. Field-programmable gate arrays are even more energy efficient since they can implement highly parallel solutions. If full flexibility is not required, then application-specific integrated circuit (ASIC) solutions can be employed; these provide another order of magnitude improvement in efficiency.

HIGH-POWER APPLICATIONS

Specialized applications such as weapons, infrared sights, laser designators, the exoskeleton, and microclimate cooling require individual consideration. These applications in most cases depend on nonsilicon technology and are highly specialized for their function. Case-by-case investigation of the systems used for each application is needed to identify the devices that consume the most energy and therefore present the best opportunities for power reduction.

Laser Designators

Laser designators represent a unique power demand that can be many times greater than that of other electronics for the Objective Force Warrior (OFW). Systems now available to special operations forces operate at system voltages of 18 to 30, with a standby mode that draws 10 W and an active mode requiring 180 W. The active mode could last as long as 10 to 40 seconds, and specifications indicate that the battery complement required is five BA 5590/U lithium or

four BB 590 NiCd batteries. Because these requirements are far in excess of the other OFW requirements, the energy efficiency of such systems should be of special interest to the Army. Power requirements for new laser designating devices could easily override other considerations and control the selection of a centralized energy source for the soldier system.

The Army did not provide its concept for fielding the devices, and the power demands were not included in the power allocation for the OFW. Clearly, reducing power demand should be a major consideration in designing laser designators. The committee expects that the energy efficiency of such devices can be improved, but it did not know enough about such devices to recommend specific improvement techniques.

Microclimate Cooling Systems

Although soldier microclimate management efforts have been under way since the early 1990s, they remain in an early stage of development. Specifications, including duty cycles and energy use data, for the many prospective systems being contemplated by the Army vary considerably, and the committee was unable to determine whether the solutions proposed are particularly energy efficient. In this report, the committee does document its observations on the preliminary design information provided by the Army program manager (Masadi, 2003). A variety of system approaches—from ice cooling systems to vapor compression and absorption refrigeration—have been tried.

The basic difficulty with management of the dismounted soldier’s microclimate is the large power requirement for such an effort. A dismounted soldier doing very light work such as guard duty has a work rate between 100 and 175 W. Light work such as cleaning a rifle has a work rate of 125 to 325 W. Moderate work such as foxhole digging has a work rate between 325 and 500 W. Heavy work such as emplacement digging has a work rate above 500 W. Since the human body is on the order of 18 percent efficient, these work rates would require cooling rates five times greater.

The power required for microclimate cooling is much greater than the power required for other functions of the dismounted soldier. Because of these excessive power requirements, microclimate cooling for the OFW will be limited to providing ventilation for soldiers clad in protective clothing, whereby a ventilator moves air into and through the soldier’s protective clothing to provide modest improvements in comfort.

This effort is being accomplished in concert with modifications to soldier uniforms that provide passages near the skin in which air can flow to provide evaporation and transport of perspiration. This air movement can be provided with minimum pressure drops for filtering toxic or noxious inputs to the system or modest pressure drops to afford airflow within the soldier’s uniform. For the OFW program, a power budget of 10-12 W has been allocated to accomplish ventilation and cooling tasks. It is expected that a separate specific power source will be provided for the ventilation system.

The present approach is to think of providing soldier microclimate cooling in three variations. The first variation, described in the two preceding paragraphs, is passive cooling designed into a porous uniform. The second variation would provide active cooling by ventilating the soldier’s uniform with continuous airflow from a small fan. The third variation would provide active cooling with a mechanical refrigeration device. The second and third variations are not likely to be available until significant development has been completed. This means that active cooling will not be available until well after the OFW system is completed.

Researchers at the University of Wisconsin surveyed a broad range of possible alternatives for use in active cooling of the dismounted soldier. They also looked at potential power sources for the alternative systems. Their analysis used performance characteristics of large, state-of-the-art, optimized cooling system components, even though such components do not exist on the scale required for individual soldier use. When such components are scaled, there might be significant degradation of system performance.

Vapor compression systems for cooling, which might be made available soonest, were among the most effective. Other systems that might have comparable effectiveness were in early development and had correspondingly low TRLs. The vapor compression systems were projected to be capable of a coefficient of performance of 3.8 and would thus consume approximately 80 W on a continuous basis to handle a modest 300 W body heat load.

Findings

Forced ventilation systems are the most energy-efficient cooling system, but their capabilities are limited. This type of microclimate cooling is only effective under favorable conditions of temperature and relative humidity. Because of the effectiveness of ventilation systems and their modest power requirements (10 to 12 W) they are being developed before active microclimate cooling systems. Even this relatively low power level may require a separate power source, in addition to those sources envisioned for the other soldier electronics.

If active microclimate cooling is to be pursued, much higher power levels will be required. Based on the power demands for microclimate cooling options explored in the University of Wisconsin survey, an energy-dense fueled system will probably be required, even for advanced systems.

Exoskeleton Systems

The Defense Advanced Research Projects Agency (DARPA) is developing an exoskeleton prototype as part of a human performance augmentation program that is focused

on developing load-carrying devices that will increase the speed, endurance, and load-carrying capacity of soldiers in combat environments. This program, like the microclimate cooling efforts, is in its early development phase, and the committee did not analyze the relative merits of solutions on the drawing boards. The committee does, however, document here its observations on preliminary approaches presented to it by DARPA (Main, 2003). Specific target applications include moving heavy loads over rough terrain, bearing heavy weapons or equipment, carrying and powering breaching equipment, and using the exoskeleton as a platform for increased body armor. The vision is to utilize such devices with power supplies that are energetically autonomous of other power sources. Such exoskeleton devices must mimic human motions and provide close human/machine integration. Human/machine interfaces must provide for transparent control of the exoskeleton over extended periods of operation.

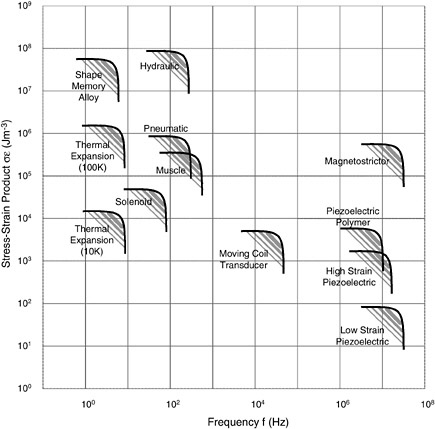

Since the loads carried by rifle-squad personnel during a 72-hr mission are projected to range from 140 pounds for a rifleman to 185 pounds for an antitank specialist, such human augmentation is clearly desirable. Developing augmentation devices that are both compatible with and comparable to human capabilities is a daunting task. Human muscles provide large motions and high repetition rates. Various power sources are compared in Figure 4-1 on the basis of the stress/ strain product capabilities versus their frequency response capabilities.

As can be seen in Figure 4-1, human muscle provides a combination of high-frequency and high stress/strain activity.

FIGURE 4-1 Comparison of various means of exoskeletal actuation on the basis of stress/strain product capabilities. SOURCE: Main, 2003.

If an exoskeleton device is to improve on human performance, it must match the range of speed capabilities and provide load-carrying capabilities in excess of human muscle capabilities. Figure 4-1 compares various means of exoskeleton actuation and indicates that hydraulic actuation systems provide the best approach. The actuation capabilities must then be combined with a power source of appropriate specific power and energy.

In 1994, the Prospector VI workshop (AUSRI, 1994) considered most forms of electrically driven actuation and concluded that hybrid power and energy sources, generally a high specific battery combined with an electrochemical capacitor, offset many of the problems of high-maintenance hydraulic systems. The workshop did not, however, consider specific exoskeleton applications where bandwidth and stress-strain product were figures of merit.

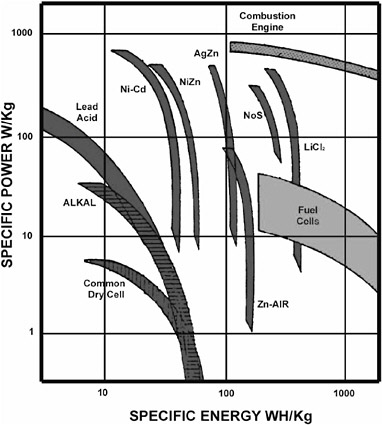

Choices for the power supply to such exoskeleton devices are limited to those of extremely high specific power and specific energy. The generalized Ragone plot in Figure 4-2 show that combustion engines are the most viable candidates. Thus, a combination of an engine-driven hydraulic compressor and hydraulic actuators could provide the energy levels and the frequency response required for exoskeleton operation. The DARPA program manager indicated that the size, weight, and inertial characteristics of electrical actuators that would be needed to provide equivalent energy levels for these devices would be too great. If one reviews the capabilities of electrohydraulic and electromechanical

FIGURE 4-2 Generalized Ragone plot of different power sources. Only engines have both the high specific energy and high specific power needed for exoskeletal devices. SOURCE: Main, 2003.

actuators in a recent NASA review of actuation systems, one draws a similar conclusion (Merryman and Hall, 1996).

Problems remain with the application of hydraulic power. If one sizes a hydraulic system for maximum output in terms of power and frequency response, large energy losses may occur in the control valves when the system is operating at low energy output. In electrical systems such problems are handled with pulse-width modulation of actuators. To minimize losses in energy and thus excessive heat loads in hydraulic systems operating over a wide range of loads and speeds, it would be necessary to modulate system pressures as a function of system output requirements. At present, controls and devices for such flow modulation appear not to be available. It is unclear whether such an actuation system could be created along with a load-following energy source.

Findings

To significantly enhance individual soldier capabilities, exoskeleton systems will require power systems with output in excess of 150 W. Such systems will require fuel-converting power sources with the power density and size of the best small engine power sources available today. These power sources must be integrated into efficient hydraulic actuation and control systems.

The need to function over a range from high to low will require the development of load-following systems and control technologies not available today. The efficiencies of present hydraulic systems peak at the highest output rates and fall drastically as work output falls, yielding low system efficiencies. To make these exoskeleton approaches viable, some load-following approach must be developed to overcome these problems.

BATTLEFIELD LOGISTICS

Choices for power solutions must be compatible with the Army’s logistical and operational systems. In fact, it is unlikely that this study would have been commissioned were it not for the Army’s concern about the logistics of soldier power. This section focuses on what is needed beyond hardware to provide power on the battlefield. It considers such things as the weight carried by dismounted soldiers engaging in multiple operational scenarios; how to transport the batteries, energy-producing fuels, or other consumables to the soldiers when needed; and the costs of acquiring and supporting the energy sources appropriate to different power demands.

Standardization

Enhanced electronics equipment and weaponry make the dismounted infantry soldier a formidable fighter, but the logisticians who support the soldier must now add electric power to the other essentials—ammunition, food, and water—that must be supplied to the battlefield. Complicating the issue, they must provide and support a growing variety of power sources.

In this, standardization is a logistician’s friend. While the military standard for form, fit, and function is the BA5590 lithium battery, the most-used battery is a commercial AA cell. This stems from the obvious fact that the commercial battery can be found around the globe, even when the supply system falls short; they are so ubiquitous that they can be bought in stores on the economy or mailed from home.

Standardization extends to tactics, techniques, and procedures, as soldiers from the Ranger Regiment, Light Infantry divisions, Airborne and Air Assault divisions, new Stryker brigades, and Future Combat Systems will all be expected to fight dismounted from their diverse platforms. Fully training these individuals in all the complex skills needed in modern warfare becomes increasingly challenging. Therefore, while systems providing power and energy to the fully dismounted soldier must emphasize energy efficiency, the electronics equipment cannot be radically different from that employed by mounted soldiers in the armored, mechanized, Stryker, and other brigades.

It is much more difficult to deal with a multiplicity of parts or systems performing similar functions. Individual soldiers and units are less likely to run short of needed supplies when these supplies are fewer in type and larger in quantity. This means that minimizing the variety of batteries and other power sources should remain an important objective. Similarly, efforts should be made to minimize the need for specialized fuels.

The cost of providing disposable batteries has already grown burdensome and can only grow more so. Beyond the direct cost of batteries procured for combat is the even larger amount required for training. Training and fighting with a rechargeable power source, such as a rechargeable battery or a fuel cell hybrid, could reduce costs, but the Army prefers to train as it will fight and fight as it has trained.

By experience, the Army’s operational ideal power source would be a single battery, lightweight and disposable, not harmful to the environment, able to withstand the rigors of combat without endangering soldiers, and capable of providing power for all soldier electronics. This fact must be kept in mind when considering alternative power sources.

Operational Considerations

The Lead Technology Integrator (LTI) for the Objective Force Warrior-Advanced Technology Demonstration (OFW-ATD) Program is integrating its prototype to support six operational scenarios (Erb, 2003). Modifying any of them would require justification and approval from the Army Training and Doctrine Command (TRADOC). While developers must have scenarios against which to be measured, the diversity of missions given to dismounted soldiers virtually

assures that large standard deviations will exist. Simulations of operations, along with real-world measurements, may narrow these modeling deviations, but there will always be a broad spectrum of operations to be considered.

Military tactics, techniques, and procedures influence soldier power requirements on the battlefield. For example, soldiers do not have identical power needs. There are also organizational and hierarchical limitations on the use and placement of recharging facilities as well as limitations on taking full advantage of the most energy-efficient technologies.

The Army provides its soldiers with equipment that has been tested to assure reliability, and it builds redundancy into the supply system. Unfortunately, the contingencies of warfare often reduce planning time and can result in a “come as you are” fight. At this point, the electronics used and the loads necessary to support them will be determined by the equipment on hand. This makes open architectures and versatile power sources desirable.

In general, the electronics equipment and the power sources for the dismounted soldier should be engineered together as a system capable of performing with high reliability and human-factored to minimize interference with all conceivable postures and positioning. Equipment must emphasize small and light construction, preferably modular (i.e., capable of being included or discarded without adverse impact on other components of the soldier system). Not least, by design it should provide for graceful degradation, so that soldiers are not faced with all-or-nothing situations on the battlefield.

Mission Duration

The Army wants its dismounted soldiers to be capable of operating at least 24 hr without having to replace any power sources. It also wants the means to transport and sustain power sources for 72-hr operations.

An important major lesson that has been learned in Operation Iraqi Freedom is that just-in-time logistics resupply may not be able to keep up with the rapid tempo of military operations. Reliable delivery of consumables to every small unit every 24 hr was not achieved and appears unlikely to be achieved during this or similar engagements in the future.

The initial OFW concept envisions a rechargeable power solution, and soldiers will have to be trained to recharge in combat. To be effective, soldier power solutions must both reduce the logistics burden and be adaptable to combat operations.

Dismounted Soldier Load

At every level of operation the Army seeks to plan as far ahead as possible. This is true at all levels—fire team, squad, platoon, and company. Capable leaders in disciplined units will tailor the loads that their soldiers carry to best perform the anticipated mission; it is these leaders who ultimately decide how much weight is enough. If mobility and endurance are expected to be high priorities, loads will be lighter. In more static situations, they might be heavier.

In scenarios describing future operations, power sources account for a relatively modest percentage of soldiers’ loads: Weapons, ammunition, water, protective armor, and special-purpose gear form the lion’s share of the weight of the gear. Nevertheless, it is the responsibility of all who provide equipment to the dismounted soldier to make each item as small, light, and user-friendly as possible.

The committee was amazed to learn about the physical loads—at times in excess of 100 pounds—that were actually borne by dismounted soldiers in Afghanistan (Erb, 2003). These loads did not include weight that would be added by the LW ensemble.

Army concepts for the future LW assume that LW effectiveness and survivability will depend on situational awareness, communications, and special-purpose equipment and on weapons that depend heavily, and in some instances almost totally, on reliable power. For example, missions lasting 24 hr will require the soldier to carry a certain weight of primary batteries to provide this power. Barring resupply, longer 72-hr missions would require at least three times as much battery weight; this additional weight is heavy enough to subtract substantially from the amount of mission equipment that can be carried.

There will be times when missions last longer than anticipated or when resupply is delayed, and it will then be necessary for the soldier to make do. Two important capabilities are needed and should be part of any power solution: reliable indicators for energy remaining in the power sources and provision for graceful degradation, which will enable a soldier to minimize all but the most essential power consumption needed to complete the mission.

Perhaps the clearest indication that graceful degradation is needed is the desire expressed by soldiers that individual weapons have a separate power source rather than being tethered, with or without wires, to the LW ensemble. Regardless of what else happens, soldiers want to be able to fight and to defend themselves.

Recharging on the Battlefield

Dismounted units in any active state will need either a new supply of disposable batteries or a recharge of rechargeable ones frequently—OFW scenarios suggest as often as daily. However the recharge solution adds complexity. Instead of delivering fresh batteries and departing, soldiers manning forward supply vehicles will have to collect discharged units and provide for their renewal, either on board the vehicle or at a location further back. Recharging at the

small unit’s location virtually dictates the presence for a time of a charger-carrying vehicle, possibly a small robotic vehicle. While locating such battery rechargers on vehicles or in forward locations is a worthy approach, one must recognize that they could then become choke points that diminish a small unit’s operational flexibility.

User/Developer Interface

Open and thorough interaction between user and developer is important in defining and developing any new Army system. This is especially so for a recharging system that will necessitate changes in training and doctrine. TRADOC, which represents the Army’s combat units, legitimately wants the best that can be provided and will ask for it. However, user/development interaction is especially important in soldier systems, where the weight is so critical and where seemingly small changes in requirements can cause large increases in weight.

Acquisition Planning

The Department of Defense (DOD) acquisition system is so cumbersome that it is difficult if not impossible to match the rapid development of electronics and devices in the commercial sector. Slow development cycles, often coupled with the need for backward compatibility with earlier systems, drive the Army toward evolutionary rather than revolutionary approaches to development. This militates against special-purpose development and qualification, because by the time a revolutionary product is completed, it is one or more generations out of date.

Army dismounted infantry and special operations forces (SOF) have power/energy requirements (environmental, duty cycle, power levels) that cannot always be satisfied by equipment in commercial use. The Army and DOD then have no choice but to develop their own sources or adapt commercial ones. The cost of doing so becomes a serious factor.

Solutions appropriate for SOF, with their smaller structure and unique ability to provide logistics for targeted missions, are not necessarily appropriate for all dismounted soldiers. The number of non-SOF dismounted infantry is substantially larger, and they require more standardized items.

Energy-efficient electronics and reduced consumption of energy are less important to mounted (armored and mechanized infantry) soldiers, who are less dependent on portable electronics. There is little incentive to reduce power demand if better performance can be achieved using non-portable electronics without concern for weight. For example, it is likely that radios developed for dismounted soldiers and SOF will continue to have quite different designs and require separate development and testing.

Industrial Base Issues

Maintaining suppliers, particularly suppliers of special-purpose power sources that have no commercial counterparts, will require effort. For example, small fuel-cell systems will continue to be viewed as special-purpose items until a design concept resolving all fuel issues is agreed upon. Even then, the relatively small quantities needed by dismounted soldiers limit the Army’s procurement leverage and will continue to affect the amount of attention that can be paid to energy efficiency in adapted commercial designs. Fortunately, there is increasing interest in the commercial world for energy efficiency in small devices, and the Army must take advantage of commercial-off-the-shelf (COTS) opportunities that develop.

Energy efficiency was not an important factor in developing the original prototype for the LW ensemble. The OFW-ATD now appears to recognize its importance and must follow through with its choices of electronics. In acquiring electronics for the dismounted soldier, the Army needs to recognize that appropriate incentives will be necessary to encourage the development and use of low-power technologies and designs.

OFW Operational Assumptions

The Army apparently has made a rational decision to use OFW-ATD to provide near-term operational capabilities that can help to overcome past LW shortcomings. The program is fast-paced and resources are focused on quick iterations and results. While this is commendable, it means that OFW is not currently structured to advance the development of LW-unique technologies. One aspect of this that affects the power source solution is the emphasis placed on 24-hr vs. 72-hr mission lengths. The assumption that resupply will occur at least once a day may not be valid. The 72-hr mission requirement should drive the power source solution, but it is not being emphasized. Either the scope of the OFW-ATD Program must be increased or a separate effort must focus on the lengthier mission requirement.

Near-Term Considerations

Many considerations are involved in choosing between primary and rechargeable batteries for operational use. Primaries are attractive. As described in Appendix D, they have higher energy densities than their rechargeable counterparts. They are disposable after use and thereby lighten the soldier’s load. Their principal drawback is affordability. Rechargeables are now used in training, because the cost of using disposables increased significantly as battery usage grew. The Army recognized that it could not sustain this peacetime expense.

Rechargeable batteries offer an attractive near-term solution. Their life-cycle costs are far more affordable, the

weight and volume that the logistics system must bring to forward positions are reduced substantially, and the risk is low. Moreover, the supply line is radically shortened; no longer is there a need to reach back to the continental United States for battery resupply. A fully recharged battery is as close as the nearest recharger, which may be on the soldier himself, on a vehicle in the squad, or within his unit.

The additional jet propellant 8 (JP-8) required to fuel rechargers is minuscule compared to amounts already in-theatre for vehicles and other engines. However, a decision to rely on rechargeable batteries also brings disadvantages and burdens. Less energy can be stored in a rechargeable than in a primary battery of equal weight. Rechargers in different configurations will introduce additional items of equipment that must be proliferated and supported in forward areas. These, as well as the batteries being recharged, will necessitate additional vehicles and possibly additional personnel. Vehicles such as the high-mobility, multipurpose wheeled vehicle (HMMWV, or Humvee) presently in use have preexisting priority weight and volume claims, and their alternators are ill-suited for supporting repeated recharging requirements. Unmanned robotic ground vehicles, which are scheduled to arrive on the scene, may provide at least part of the solution.

A seemingly attractive near-term solution to further reduce risk is to stockpile primary batteries for use only in emergency and combat situations, using rechargeable batteries for training. Field training exercises usually last 3 days or less, and recharging during most training could be handled administratively. This solution avoids the requirement for a fully developed recharger support structure for both training and combat operations.

However, another risk is introduced. Experience during the early weeks of Operation Iraqi Freedom, when battery stockpiles were almost exhausted, does not inspire optimism that adequate stocks of primary batteries can be procured and rotated during peacetime. If the Army believes it important to have this flexibility, it must develop soldier systems that can safely and easily use primaries and rechargeables interchangeably.

In the near term, there appears to be little risk that two fully functional rechargeable batteries cannot provide adequate power for the 24-hr missions foreseen today. Absent an ability to resupply or recharge during the mission, there is no technology solution that permits accomplishing a 72-hr mission without tripling this load of batteries to six, thereby adding significantly to the soldier’s load.

Findings

Batteries have become critical elements of a soldier’s combat effectiveness, so the Army must make distribution and recharger configuration choices that incorporate redundancy to protect against battle damage and overcome periods of nonavailability, as well as insure against choke points during periods of intense use. A reserve of fully charged batteries will always be a safety valve, with the size of the reserve dependent on the situation.

Rechargeable batteries are a feasible near-term solution for short missions but involve risks that must be mitigated. They should be regarded only as an interim step in an evolving progression. Where possible, the Army should ensure the inclusion of hardware “enablers” in the near term that will facilitate solutions in the long term.

Long-Term Considerations

A hybrid power solution that packages a fuel cell and a rechargeable battery in the soldier’s load offers attractive increases in performance. Figure 3-6 showed that a full 72-hr mission requiring 20 W of average power and 50 W of peak power over 10 percent of the time can be satisfied with a lithium ion rechargeable battery and a direct methanol fuel cell (DMFC). One hundred soldiers operating under these conditions for 72 hours would require approximately 200 liters of methanol (120 kg plus packaging) to replenish their individual fuel cells. Consumption would amount to about two thirds of a liter per soldier per day. For shorter missions, it would be possible and desirable for soldiers to leave their fuel cell behind and rely on embedded and central batteries. With this solution, the need for separate battery rechargers would be eliminated, bringing logistical and operational benefits.

Absent is the ability for the Army to devote substantial resources to maturing the DMFC; it must depend on progress in the commercial market. Fortunately, more than one corporation appears close to offering these devices in the 20-W range for use in portable computers, and the opportunity to exploit COTS may soon arise.

Proceeding with the direct methanol fuel cells used in this example is yet another undertaking that demonstrates the dynamic tension between new technologies with increased capabilities and the logistics systems that must support soldiers in their use of the new capabilities in combat. Technologists are dissuaded from pursuing a promising new opportunity when they have little confidence that it will be incorporated into operational use. Logisticians have little reason to do comprehensive, detailed analyses of the logistics implications, advantages, and burdens of a new technology until they have reason to believe that it will be coming into the force.

While this hybrid approach has the potential to meaningfully reduce the cost, weight, and volume of the logistics chain, its burdens include adding another separate fuel, methanol, to the diesel and JP-8 found in forward combat units. In the near future, the fielding implications of fuel cell hybrid solutions should be examined to include operational benefits, life-cycle costs, and safety and risk.

Commercial investments and applications may make small fuel cells a more acceptable alternative for batteries.

Prototypes have already been demonstrated for use in laptop computers. The Army should be prepared to take advantage of such investments by evaluating the logistical trade-offs involved in fielding nonbattery power solutions. The evaluation should include timelines for the introduction of fueled system alternatives and estimate the consequent reductions (if any) in battery use. This would permit decision makers to make informed judgments on how operational advantages compare to the added burden.

Predictive modeling must play an important part in mitigating risk through analysis of this opportunity. For example, the miniscenario described above was overly simple, taking no account of duty cycles. With predictive models in place, multiple scenarios can be reviewed. Predictive models will be invaluable in examining alternatives, understanding the impacts of unique operations, and narrowing the standard deviations in complex scenarios.

Tethering a single power source to multiple components, such as weapons, sensors, laser designators, and helmets, presents unattractive human factors issues that must be resolved. On the other hand, the attractiveness of a one fuel cell/one battery solution cannot be denied. One way to reap the benefits of both untethered subsystems and a master central power source is to colocate the batteries with the components that require relatively large amounts of power and energy. These could then be tethered to the central source with quick breakaway connectors to permit recharging from the fuel cell during periods of relative inactivity and unhampered action when the need is greatest.

Findings

The one fuel cell/one battery central power approach with satellite rechargeable batteries appears to have great promise. If a detailed analysis justifies its operational value and logistics supportability, it is a candidate for accelerated development.

Hybrids have great potential, both as power sources and, over the longer term, as factors in decisions on centralized vs. distributed power. The packaging of a nonstandard fuel for the fuel cell requires an immediate and thorough analysis of trade-offs. The fuel cell approach can then be pursued in earnest if this screen is passed. To facilitate the analysis, the Army should use predictive modeling to narrow sigmas and evaluate choices.

Efficient fuel cells permitting use of JP-8 or reformed fuels could offer even greater advantages and more relief from the logistics burden, eliminating the need for packaged nonstandard fuels from the supply chain. Combining an air-breathing fuel cell with a rechargeable battery would enable operation in all conditions, but would have to be integrated into a much smaller package than current state-of-the-art to be viable on the battlefield.