Panel III

SBIR at NASA

Moderator:

Duncan T. Moore

University of Rochester

Dr. Moore said that he was publicly known as a university professor, and also for his government service at the White House during the last years of the Clinton administration. Fewer people knew that he had started a small business using SBIR money, he said. Nonetheless, he suggested that his experience might illustrate a complexity that should be taken into account during the SBIR evaluation.

Technology at the Mercy of the Market

In 1970 he began doing research in the field of gradient index optics, or GRIN. The techniques of GRIN can make light travel by a curved path through optical materials, which reduces the number of lenses required in complicated optical systems. He said he had believed that “by 1975 everyone in the world would be using gradient index optics.” The basis of that belief, and of others with whom he worked at Western Electric, in Princeton, New Jersey, was the then-rapid development of picture phones. It was widely accepted that picture phones would be in widespread use, and in order to make that possible, the industry was going to need more lenses than would be easily available.

However, picture phones did not emerge as anticipated, and the projected need for GRIN optics receded. In 1980, Dr. Moore started a company with the goal of commercializing some of the gradient index materials, and he received an SBIR award from the National Science Foundation. The objective of the company was to make axial gradients, and the theory, which had been proved in practice, was that the technology would halve the number of lenses needed for any complicated lens system, such as a camera or spotting scope.

The company had a contract with Olympus to start manufacturing, but a change in the market altered the plans. While it was true that the technology would reduce the lenses by a factor of two, the company still had to be able to make one GRIN lens for less than the cost of making two regular lenses. In the end, the economics of the technology fell short.

Turning “Failure” into “Success”

An evaluation of the SBIR done in 1990 might have judged the company a failure. However, the story did not stop there. In 1992, Dr. Moore was asked to make a new type of disposable endoscope—a device to see inside the body, often for the purpose of performing minimally invasive surgery. This request, too, was accompanied by an unexpected economic context. In the economics of lens manufacture, the cost of large lenses is very high; as size diminishes, costs drop until they reach a minimum for lenses of around 5 millimeters in diameter. For lenses smaller than 5 mm, polishing became hard to control and costs began to rise again. The company developed a new technique, however, by which it was able to make smaller-diameter lenses more cheaply. By this method, a 1-mm GRIN optic, for example, was about eight times cheaper than a 2-mm optic. So in 1996 the company was able to introduce the first “borescope,” which is today a commonly used device for seeing inside many materials and structures. The first such device was made to look not inside the body, but inside machines. Dr. Moore’s company is now the largest manufacturer of borescopes in the United States.

Finding Success Depends on When it is Measured

In terms of the SBIR program, he said, “if we hadn’t done the earlier work that ‘failed,’ we couldn’t have gone to the next step and ‘succeeded’.” He said that this is one of the reasons an assessment would be complex. “Innovation does not follow a linear model,” he said. “It stops and starts.” He judged that if his research project had been part of a large company, it would have been killed in 1990 and the technology abandoned. “But when you’re a small company,” he said, “you only have one technology. You figure out how to make it work or you go out of business.” Since then, his company had gone up and down in terms of sales and people, but it was now very successful.

He concluded by saying that the story of his company should alert the study panel to the need to pay careful attention to the location of each company on its own particular “time line.” He said that if a company could be evaluated more than once as it developed, the study panel might detect the kinds of fluctuations experienced by his own company.

ACHIEVEMENTS, OPPORTUNITIES, AND CHALLENGES

Robert L. Norwood

NASA

Robert Norwood, Director of NASA’s Commercial Technology Program, began by introducing the new mission and vision recently developed at NASA and the NASA SBIR program.

NASA’s Mission and Vision

The new vision is:

-

To improve life here;

-

To extend life to there;

-

To find life beyond.

The new mission is:

-

To understand and protect our home planet;

-

To explore the universe and search for life;

-

To inspire the next generation of explorers …as only NASA can.

This mission and vision, he said, would be expressed shortly in the form of a new agency strategic plan.

Dr. Norwood offered a general introduction to the agency. NASA is organized under five “enterprises”: Space science, earth science, biological and physical research, HEDS (human exploration and development of space), and aerospace technology. His own organization, the Commercial Technology Program, and the SBIR program are part of the Aerospace Technology Enterprise, which is charged not only with developing technology for the world of aeronautics, but also with providing most of the R&D for the other four enterprises.

The vision and mission of NASA, said Dr. Norwood, pervade many aspects of the SBIR program. One is investing in technology in collaboration with others—in this case, with small business. Another is to invest in new technologies that have the potential of bringing technical solutions to NASA. These objectives are part of a larger suite of R&D activities in which NASA seeks collaborations to make new technology more useful internally and to carry technology to commercial partnerships outside the agency.

He said that NASA had committed itself to a new emphasis on education, and was contemplating a new organization within the agency dedicated to education. NASA worked with many academic institutions, and the SBIR program was

strengthened when NASA contributed to the nation’s human resources in science and technology.

Tying the SBIR to Enterprise Needs

NASA’s technology strategy was closely coordinated in a “one-NASA framework” of strategic enterprises, and the SBIR and STTR activities were aligned with the technology needs of the enterprises. Several years ago NASA made a strategic change so that the content of each SBIR solicitation would be closely tied to enterprise needs. The enterprises and the respective offices at the ten NASA centers were responsible for writing the contents of the solicitation. This was to ensure that when responses came back from the small business community, the technologies they proposed would accurately reflect the interests of the enterprises. This would increase the likelihood that the technologies NASA supported would find internal applications.

Even though the agency had a one-source selection authority, a team had been formed so that all the enterprises and the centers contributed formal recommendations about which proposals to select. The work of this team tied the priorities of the enterprises more closely to the selection process.

The Agency’s Strategic Approach

Overall, the agency’s strategic approach had several main elements:

-

Cultivate innovative solutions: One objective of the Commercial Technology Program was to establish partnerships with all segments of industry, including large, medium, and small enterprises. The SBIR was the principal mechanism for linking with the small business community.

-

Leverage existing commercial networks to assist small businesses: NASA maintains a network of commercialization offices throughout the United States and tries to leverage that network in support of the SBIR program. The offices include technology incubators and regional technology transfer centers, some of which were refocused last year specifically to help the SBIR program arrange business services and find partners in the investment community to help move companies into Phase III.

-

Maximize the potential for commercial success: The commercial technology offices train NASA scientists and engineers to work with both the non-aerospace industry and small businesses. The agency also uses the benefits of partnerships, cooperative agreements, and other business assets in NASA.

-

Communicate with the business community: NASA Tech Briefs reach well over 500,000 readers. The agency also communicates its needs to the

-

high-technology community through Innovation magazine, Spin-off magazine, and other publications.

Narrowing the Time Gap

One complaint about the SBIR program is the long time gap between Phases I and II. In one innovation that has narrowed that gap, NASA had recently finished implementation of a paperless documentation system, spanning all activities from solicitation, development, and publication through the contracting process. The system, called Electronic Handbooks, was designed to speed data collection, improve management processes, and to make that data accessible to more people. Data could also be sent to and from reviewers more quickly through electronic means.

Speeding Technology Toward the Marketplace

Another change, made in 1995, was intended to increase the rate at which SBIR research was translated into the marketplace. This was done primarily by two mechanisms to evaluate the commercialization potential of Phase I proposals: (1) through evaluation by an internal group of NASA experts who were asked to judge the technical merit of projects, and (2) through evaluation by an external group of business executives and university professors at business schools who were asked to judge commercial merit. For Phase II proposals, NASA added a request for applicants to draw up a business plan showing how the technology might succeed in the marketplace.

Return on Investment

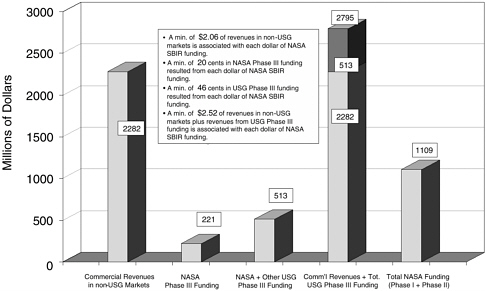

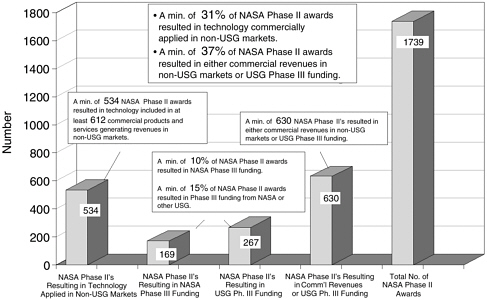

In 1996, a year after that change in emphasis, NASA surveyed all of its SBIR programs from 1983-1996. The survey included all 1,739 Phase II awards and the 800-900 firms that received them. The response rate was 84 percent; the assessment was conservative, making the assumption that non-respondents had achieved nothing. For commercial awards (no revenue from government sources), NASA received a minimum of $2.06 for every dollar it had invested in Phase II projects (see Figure 4).

Another finding was that a minimum of 31 percent of Phase II awards resulted in technology that was commercially applied in non-U.S. government markets (see Figure 5).

Dr. Norwood commented that while these figures sounded impressive, he had nothing to compare them to: “I don’t know if they are good or bad. Hopefully this study will lead us to an assessment at the national level about whether these are good numbers, because I don’t know what the rest of the industry does.”

Opportunities for the Study

He reviewed some of the opportunities presented by the study—a “unique opportunity for a national program assessment. This study can form a basis for assessing how we evaluate high-tech business and how it contributes to the nation.”

For example, can the SBIR play a key role at the national level? Again, he said, this is not known. From the information heard so far from the Department of Defense and from the National Institutes of Health, however, he hoped that this study would “help us understand how to do a better job of integrating technologies into the national storehouse” of knowledge.

Dr. Norwood said he would like to know how SBIR companies compared with other companies in the same technology industries. He would also like to be able to identify themes for program improvements to help guide changes in the SBIR program. During the 20 years since the legislation was passed, he said, we have moved through a generation of new techniques; the economy is different, and the people running the economy are different. The challenge is to adapt the program to all these changes so it is more relevant today.

Challenges for the Study

One challenge facing the study panel, he said, is the question of metrics. “I hope we don’t throw up our hands and say it’s too difficult to do.” He said that he would like the panel to propose some national-level metrics and then to discuss them in light of each agency’s mission and congressional guidelines.

He then listed other challenges for the study:

-

SBIR and other industry sectors: We need to better understand how agencies can better integrate SBIR programs with companies of medium and large size and with industry at the national level. “It doesn’t seem to make sense,” he said, “to have a program of $1.3 billion working ad hoc. Are there techniques we’re not seeing that might be helpful?”

-

SBIR and other government programs: He suggested exploring new relationships between SBIR and other agencies, given the large number of federal and state efforts focused on R&D.

-

SBIR and the academic community: The separate STTR program is focused on the academic and not-for-profit research community. Should this program be independent from SBIR, or might there be advantages to a merger?

-

SBIR and the venture community: Can we take advantage of the presence of several representatives from the venture capital community on the committee to seek ways to collaborate? The investment community is expert at starting businesses and moving them into the market place; the SBIR

-

wants to do the same thing. Just from the “selfish viewpoint” of the agency, he said, NASA can benefit by buying technologies that advance the agency’s mission. In some cases, the agency may be able to buy a technology from a company more cheaply in the marketplace than it could develop it internally. NASA would not be a major customer for these technologies, but if the agency worked more closely with the venture community, it might happen more often than it does at present.

-

A collaborative model for SBIR: The program had worked for 20 years by funding individual companies. Industry was exploring more partnerships today between firms whose missions complemented one another. Could that work for the SBIR? Rather than limiting Phase II awards to single grants of $750,000, would it be more productive to support teams of firms with larger budgets?

Dr. Norwood closed by saying he hoped the study panel would have time to consider such possibilities, along with its more traditional evaluation activities.

DISCUSSANTS

David H. Finifter

The College of William and Mary

Dr. Finifter, who had participated in the SBIR Fast Track evaluation and a study for NASA Langley Research Center, used the analogy of fruit to illustrate the many dynamic components of the SBIR program. He said that while fruit is good in general, it comes in many forms—apples, oranges, bananas, and strawberries. To understand how good fruit is, one has to understand the different kinds. The SBIR, he said, is a diverse and dynamic component of the R&D investment of the U.S. government and the U.S. economy.

“High Time” for a Study

Because of the SBIR’s importance, it is “high time, after about 20 years, to do a comprehensive evaluation of the SBIR system of programs,” he said. It is important to examine and puzzle about its basic structure, program missions, and goals; it is also critical to understand the differences across agencies, and how programs are organized, targeted, and managed. One must understand programs at the agency level in order to understand the effects of the program at the national level.

Among the five major SBIR agencies, as well as the five smaller ones, he said, the issues that are critical will vary. In some agencies a major issue will be the comparison between grants and contracts. Other issues to examine will be who identifies the program targets; how much of target selection is mission driven as opposed to market driven; how effective is the agency in identifying and moni-

toring projects for its technical side versus the commercial side. For these reasons, he said, it is appropriate that the study panel was doing its work at the agency level. At the same time, it is critical to remember the national policy questions and “critical at the end of the day to come back to the question of how good is fruit for you.”

Talking to Program Managers

Dr. Finifter said that he had already seen, from DoD, NIH and NASA, that there are many differences within agencies—for example, in how they select, monitor, and “incentivize” contractors. The experience of the DoD Fast Track study, he said, would certainly help the current study panel review methodology and extrapolate it from the agency to the national policy level. In particular, he reported that the Fast Track team had discovered the great value of talking not only to firms but also to program managers and program points of contact in order to understand how the program was implemented. He said that he and a colleague, Robert Archibald, had done an email survey of the technical program points of contact and found that these people “have an understanding of the value of SBIR that others don’t have.”16 The survey had asked the points of contact both to compare, both in an absolute sense and a relative sense, the SBIR with other R&D sponsored by their agency. The response, “somewhat to our surprise,” had been that in both senses the SBIR “holds up pretty well.” He and his colleague gained other insights by looking at firm-level data and case studies. He predicted that “all those things will come out in this study of the agencies,” and could then be aggregated at the national level.

Study the Program “Microscopically”

He said that NASA’s SBIR program is an innovative one, and that he had been impressed while observing it for several years. Its mix of topics varied widely, compared with other agencies and with the overall range of R&D activity of the agency. This range was wide because of the five enterprise levels and the differences across the ten centers. But he said that studying the program “micro-scopically” before going to the macro level was important. “Decisions and feedback are built in terms of how the national program evolved, and it’s important that we understand that as we study the program.”

He then turned to another joint study he had done with Dr. Archibald, this one for the NASA Langley Research Center in Virginia.17 They looked at all of Langley’s SBIR contracts from 1984 to 1995, both Phase I and II, by means of a mail survey. They received over 200 responses and developed the following conclusions:

-

About 36 percent of the Phase II projects had developed a product and/or had sales;

-

28 percent had actual sales;

-

44 percent had some additional investment;

-

46 percent reported that the innovation would reduce costs to users;

-

45 percent had performed basic research leading to publication or technical reports;

-

34 percent had outcomes leading to intellectual property patents or copyrights.

Allowing for Sufficient Risk

Like Dr. Norwood, he confessed to a lack of context for these results: Were they good or bad? A high success rate is gratifying, but a low success rate implies risk, and “we do want to be sure that it’s a sufficiently risky portfolio.” He said that if the program aims too low “we won’t be doing our job as federal portfolio managers.” The question of “how high is high,” therefore, is important to the program and to the study.

He also noted that the measures of success varied by disciplinary area, such as aeronautics, computers, and space science, and by federal policy. He said that the study panel would be able to do some simulations of the effects of SBIR on federal policy, both before and after 1992. He and Dr. Archibald had already found a difference, because in 1992 a greater emphasis was placed on commercialization versus mission-driven research. They had written, for an article forthcoming in the journal Research Policy, that the change in the program in 1992 had come to some extent at the expense of basic research.18 “This,” he suggested, “should be debated in the policy arena.”

Start from the Agency Level

Returning to the analogy of fruit, he reminded his audience that the SBIR should be addressed as a national program, not merely as a collection of apples and oranges. He said that the panel should think of national policy goals as being implemented across multiple agencies and sub-agencies. The panel must produce a clear “bottom line” for Congress, he suggested, while being careful about how it arrives there. Starting from the agency level is the correct approach, he said, combined with sensitivity to the differences across agencies and sub-agencies, as well as differences in the perspective of firms, program managers, and technical points of contact at agencies. He also said that it was important to track variations among types of technologies that had different likelihood rates of commercialization, especially commercialization outside the funding agency. “We have our work cut out for us,” he concluded, “and we look forward to your help.”

Charles Kolb

Aerodyne Research

Dr. Kolb said he would first attempt to describe “what the ideal SBIR project would look like”—one that satisfied the goals of the government, private, and academic sectors—and then make a few “personal and biased” remarks on how to achieve this ideal in some of the NASA programs he had experienced.

High Expectations for SBIR

He said that any SBIR project came with high expectations. “You start off with the fact that the ‘I’ stands for innovation, which means that it has to make a novel, unique, or at least potentially very significant contribution to our nation’s science and technology knowledge base.” For most research proposals to the government, he said, that was the only expectation, and a project that met this expectation was judged successful. The SBIR program, however, brought two additional expectations. The first was that it should generate commercial activity, such as job creation, export sales, and earnings for stockholders. It was expected to make a significant economic impact—something which was not usually expected of a research proposal from a university.

The second additional expectation, he said, was that it advance the mission of the sponsoring agency in some meaningful way—to help NASA or other agency do its job better. So an SBIR project must clear three significant hurdles to be successful, and it must do so for a total investment (Phase I plus Phase II) which is almost always less than a million dollars; in some of the smaller agencies, funding was about a third of a million dollars. This was not a large investment for such high expectations, he said, which presented a question for the study

panel: how fair are these three expectations, and how often must any or all of them be met for the program to be judged a success?

Tech Transfer as Part of NASA’s Mission

At NASA, he said, after a proposal had been funded and presumably cleared the “innovative hurdle,” the agency still had to evaluate the likelihood of commercialization and contribution to the agency mission. He referred to Dr. Norwood’s description of the NASA Commercial Technology Program, and called it “one of the most energetic and comprehensive in the SBIR program.” The CTP also went beyond the SBIR program, he said, in that NASA had for many years tried to stimulate its internal organization to develop technology and apply this development in ways that benefit the nation. Here he referred to the “folklore” about non-stick Teflon frying pans, Tang, and other NASA-generated products that have found wide usage. “In my own view, it’s quite enough that NASA took us to the moon, and helped developed airplanes that are the envy of the world, communications satellites, meteorological satellites, and global change satellites, all of which are extremely important to the economic well-being and future of the country. But NASA also feels it’s part of their mission to spin technology out into the commercial sector.” He said that the SBIR program benefits from this objective, and from the Technology Commercialization Centers, as well as from NASA’s publication of Tech Briefs, Aerospace Innovations, and other communications to the science and technology community.

Taking a slightly different view of what NASA was doing, he called attention to the inherent difficulty faced by a federal agency in guiding projects into the commercial arena. “It’s a little like going to Jamaica to take snowboarding lessons,” he said. “It’s not really what they’re good at.” While the SBIR program is “thorough and energetic, I think most companies realize that it’s up to them to commercialize their technology, not up to NASA.”

How SBIR can Help NASA

Then he focused on how a NASA SBIR award recipient can help NASA with its mission. This is difficult for a large agency, he said, especially one with NASA’s breadth of mission. In NASA this is exacerbated by the relative independence of the ten field centers, or sub-organizations, which do not take naturally to collaboration. A small business applicant for an SBIR award has to sell its idea not only to NASA as a whole; it also has to direct its idea to a receptive center. Even if this happens, the “right” center may or may not be the entity that finally sponsors and monitors the work. “If I want my technology to go to NASA, I have to have a champion inside NASA who’s going to push it,” he said. “He goes to the NASA meeting I’m not invited to where he says, Look, this technology is a better way to do part of our mission.” When things go well, a champion, which ideally is the program manager,

can also make good suggestions about writing Phase II proposals so they are attractive to the center and to NASA in general. When the applicant cannot engage such a person, or the person moves elsewhere before completion of the project, progress may slow. Given the many uncertainties of this kind, he recommended that the study panel look for ways to better transfer technology to the mission agencies in ways that maximize its productivity.

DISCUSSION

Reconciling Differing Mission Orientations

Duncan Moore of the University of Rochester, pursuing a point made by the previous speaker, asked Dr. Norwood for advice on handling conflicts that emerge from the differing mission orientations of the 10 NASA centers.

Dr. Norwood offered an explanation of the SBIR selection process without emphasis on conflict. Once the missions are defined by each of the four enterprises, he said, they are further refined into the technical objectives needed to achieve each mission. Those technical needs are then related to the center(s) best positioned to execute them. For example, a new earth science mission would probably require a suite of technologies from the two centers that perform most of NASA’s earth science, Goddard Space Flight Center and Jet Propulsion Laboratory. The enterprise manager would align the needed technologies with the appropriate center(s), and the technical manager at each center would write a solicitation explaining the technical needs. Once those needs were described, the solicitation would return to the enterprise level; the enterprises would review it and send it out as a request for proposals.

When the proposals returned to NASA, they would be evaluated, like every other program, against the mission’s technical needs. The centers would make recommendations and order priorities; the enterprises would review the centers’ response, which would return again to the selection authority. That authority would approve the suite of proposals based on the funding available. Dr. Norwood ended by saying he did not think that conflict was inherent to this process, other than normal collaborative tensions.

Defining Success

Owen Moss of CIIT, Research Triangle Park, North Carolina, said that the symposium had heard good suggestions on how to refine what was already a successful program, and yet he felt that persuading Congress of its value would require more concrete evidence of success or metrics that could measure that success.

More generally, he said, SBIR is one of many agency programs that stimulates and harvests innovation in this country. He suggested that there are thou-

sands of people involved in this process nationwide, at individual organizations and institutes and universities. These people are responsible for intellectual property programs in those places. He said it would be useful to know more about how programs other than SBIR are run and evaluated.

At each institution, for example, the person responsible for intellectual property has to report the number of inventions the program has produced. Out of that number, the program manager chooses a smaller number in which to invest money on patent applications. Of that smaller number, a still smaller number will actually receive patents over a 3- or 5-year period. Those three numbers can be used as concrete measures of annual achievement for the SBIR or any similar innovation program. All of them represent monetary output.

Yet another number could be used to represent intellectual property areas that were commercialized and that generated enough money to pay for the resources invested in them—in other words, those that broke even or better. A still smaller number would represent the quantity of projects that generated huge commercial success.

This process is general and nation-wide, he suggested, and such data are accessible because companies and organizations are proud of their successes, even if they produce just one successful project. In small companies, the rate of success is not high. An intellectual property manager at a company has to accept every project that is proposed and try to move it toward commercialization. He recalled that in the 1980s about one in a hundred patents would pay for themselves, and about one in a thousand would be “big hits.”

The SBIR program, because of its more rigorous selection process and its ability to track projects and promote every innovation, would probably generate better rates of success than most small-business programs. He suggested that it should probably duplicate the success rate of a “reasonable-size company.”

Balancing Technical Merit and Commercial Potential

Charles Wessner thanked Dr. Norwood for his “engaging and open-ended presentation,” and for the series of questions he posed to the study panel. He asked if Dr. Norwood had a suggestion about how NASA balances the number of SBIR projects that have a high apparent potential for product development and commercialization against the number projects that are clearly valuable research questions but which have less apparent potential for commercialization. He also asked whether some of the centers were more research-oriented than others, and whether that affected overall project selection.

Dr. Norwood answered that selection was a heuristic process in which “we try to evaluate on two axes, one on technical merit and another on commercial potential.” He said that NASA tries to maximize both qualities, although the process is primarily a matter of judgment. He said that in all cases the primary objective is to meet NASA’s technical missions. But there are also cases of projects

that seem to have excellent commercial potential and also have the potential to help a NASA mission downstream by providing a commercial source of technology or service. Such a project may receive somewhat higher priority than a project that is purely technical. He repeated that the appropriate enterprise must first approve each project, and then the source selection authority examines the program in toto and asks probing questions about it “in a collaborative and ongoing process.”