Development of Clean-Coal Technology

HONGGUANG JIN, RUIXIAN CAI, and BAOQUN WANG

Institute of Engineering Thermophysics

Chinese Academy of Sciences

Clean-coal technology has attracted worldwide attention since the 1980s. China, which ranks first in the world in terms of coal production and consumption, included clean-coal technology in its national sustainable development plan in the 1990s. Clean-coal technology could lead to revolutionary changes in the development of key industries in China, specifically the electric-power industry and the chemical industry.

The Chinese electric-power industry has grown rapidly in recent years. Total installed capacity of electric power is now 350 gigawatts (GW), and this figure is expected to rise to 1,100 GW by 2030. Coal-based power generation will account for about two-thirds of that amount. With current technology, coal consumption is not very efficient and causes serious pollution. Improving the thermal efficiency of power plants by adopting clean-coal technology could go a long way toward addressing both problems.

The most damaging pollutants from coal combustion are sulfur dioxide (SO2), nitrogen oxides (NOX), carbon dioxide (CO2), and particulate matter (PM). China has successfully reduced emissions of SO2 and NOX and decreased PM from power plants. But controlling CO2 emissions and mitigating their greenhouse effect is still one of the most serious environmental challenges facing China, as well as the rest of the world. Up to now, there have been three main approaches to controlling greenhouse gas emissions: (1) improving the energy efficiency of power plants; (2) switching to fuels that produce less CO2 per unit energy; and (3) using renewable and/or nuclear energy.

Separation and sequestration technology is still not considered by many scholars to be an economically and/or technologically viable solution to the CO2

problem. A major difficulty in capturing and sequestering CO2 is the huge volume of the gas stream. Fossil fuels (especially coal) produce a significant amount of carbon per unit energy; thus, a lot of CO2 must be captured. If the CO2 is diluted by nitrogen, the volume may be two or three times as large. Recovering this large volume of gas places a huge burden on the system in terms of the high cost and the large amount of energy consumed in the separation process. The significant energy required for CO2 separation (e.g., steam or refrigeration) greatly reduces the net energy output and efficiency of the power plant. After separation, the CO2 must be compressed, cooled to a liquid, and transported long distances to a storage area underground or in the ocean. Fully one-third of the energy produced might be consumed in the compression process. Overall, recovery of CO2 by coal-fired power plants is technologically complex and lowers the efficiency of coal conversion. In the long run, CO2 capture technology will have to be integrated with thermal physics systems and chemical engineering systems, which will require some technological breakthroughs.

Current clean-coal technologies all offer opportunities for capturing CO2. These include integrated gasification combined-cycle (IGCC) technology, integrated internal and external coal-fired combined-cycle technology, and coal-based polygeneration systems. These three technologies, as well as a coal-based energy network suitable for China, are discussed below.

INTEGRATED GASIFICATION COMBINED-CYCLE SYSTEM WITH CO2 RECOVERY

IGCC, a relatively new technology, has drawn worldwide attention because it increases efficiency, reduces pollution, and requires less water than current systems (DOE, 1996). Dozens of IGCC demonstration plants have been established or are being established in the United States and Europe. China is beginning to carry out research on IGCC techniques, including gasification, gas purification, gas turbines, and heat-recovery systems, and is considering establishing its first 300–400 megawatt (MW) IGCC demonstration plant in Yantai.

The inherent advantages of IGCC in reducing pollution are indisputable. Waste emissions (SO2, NOX, and PM) from IGCC are lower than from a pressurized, fluidized-bed combustor combined-cycle plant or a pulverized coal-fired power plant with flue-gas desulfurization. The most distinctive characteristic of IGCC is the generation of a concentrated stream of CO2 with no dilution by nitrogen; pre-decarbonization is also feasible in the IGCC system.

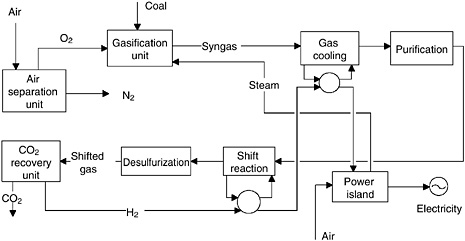

The two critical technologies for IGCC with CO2 recovery are gasification and water-shift reaction (Figure 1). The synthesis gas (syngas) from the gasifier contains a large portion of CO, which is converted to CO2 and H2 through a water-shift reaction:

CO + H2O → CO2 + H2

FIGURE 1 Schematic diagram of pre-decarbonization in IGCC. Source: Doctor et al., 1996.

The shifted gas has a high concentration of CO2. For example, for the air-blown IGCC with Kellogg-Rust-Westinghouse (KRW) gasifier, the CO2 mole concentration is about 24 percent (in oxygen-blown KRW IGCC systems it can be as high as 40 percent). By comparison, the flue gas from current coal combustion contains only 5 to 6 percent CO2. Because the volume of the treated gas stream is substantially reduced, the equipment for CO2 separation costs less, and less energy is consumed (Doctor et al., 1996).

A chemical-absorption method using amine solvents, such as mono ethanol amine (MEA) or methyl diethyl amine (MDEA), is commonly used in the capture of CO2 from the IGCC system. Other feasible technologies for large-scale CO2 recovery are hot K2CO3 absorption, Selexol, and low-temperature absorption by methanol. Membrane and membrane-reactor separation methods are now being researched. Energy consumption for CO2 separation by conventional methods in IGCC systems is still rather high, and system efficiency is lowered by about 6 to 10 percent as a result of CO2 recovery. Table 1 compares the effects of CO2 separation methods on the efficiency of the IGCC system. In terms of energy consumption, Selexol is the best option for the recovery of CO2 in IGCC. However, Selexol has some disadvantages, such as expensive solvent and high capital costs for equipment (Doctor et al., 1994).

Current research on reducing energy requirements for CO2 separation in the IGCC system is concentrated in two areas: (1) the oxygen-blown IGCC system and the separation of CO2 and H2; and (2) the selection of a solvent with low energy consumption. In recent years, considerable research has been focused on

TABLE 1 The Effect of CO2 Separation Methods on the Efficiency of the IGCC System

|

Systems/ Parameters |

Base Case |

Selexol |

Hot K2CO3 |

MEA |

Methanol |

|

Net power output (MW) |

454.37 |

380.78 |

328.24 |

310.5 |

269.22 |

|

CO2 emission rate (kg/kWh) |

0.8353 |

0.1559 |

0.1805 |

0.1909 |

0.2037 |

|

Thermal efficiency (HHV %) |

39.62 |

33.42 |

28.87 |

27.33 |

23.76 |

|

Source: Doctor et al., 1994. |

|||||

improving absorption solvents and equipment, and many solvents with low energy consumption and low corrosion rates have been tested and evaluated.

The combination of CO2 separation and clean-energy generation in the IGCC system would provide clean, efficient coal consumption and would greatly reduce the amount of energy consumed during CO2 separation. This integrated system would reduce the intermediate processes of separation, increase the efficiency of the power plant by decreasing the amount of energy consumed during separation, and ultimately create synergy between energy generation and the environment. However, integrating the processes will require a breakthrough in system synthesis. We are currently investigating the integration of a cryogenic air-separation unit into an IGCC system for CO2 separation. The preliminary results show that this would reduce energy requirements for CO2 recovery by one-third compared to the IGCC system using the conventional absorption method by amine solvent.

INTEGRATION OF INTERNAL AND EXTERNAL COAL-FIRED COMBINED-CYCLE SYSTEMS

The commercialization of IGCC depends largely on two factors: (1) thermal performance; and (2) economics. With the development of the advanced gas-turbine engine, the thermal efficiency of IGCC has reached 42 to 45 percent and is expected to exceed 50 percent in the near future. Therefore, high cost is now the biggest obstacle to commercialization of the system. Carbon conversion in IGCC, which usually exceeds 95 percent, requires large equipment and high-temperature materials. Thus, the cost of the gasifier is still prohibitive.

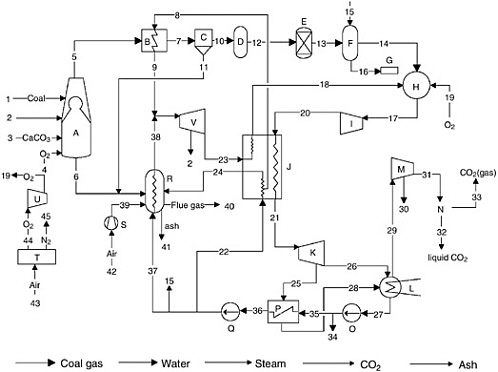

We have proposed a partial-gasification IGCC that integrates internal and external coal-fired combined-cycle systems in a novel power-generating system (Figure 2). This system contains three main “islands”: partial gasification of coal and purification (A–F); internal-fired gas-turbine cycle (H–K); and external-fired

FIGURE 2 Diagram of integration of internal and external coal-fired power-generation combined cycle. A = gasifier. B/P = heat exchanger. C = dust collector. D = hydrolyzer. E = dry desulfurizer. F = washer. G = sewage disposal. H = combustor. I = high-temperature gas turbine. J = reheater. K = low-temperature gas turbine. L = condenser. M = CO2 compressor. N = refrigerator. O/Q = pump. R = semi-coke boiler. S = air blower. T = air separation unit. U = O2 compressor. V = high-pressure steam turbine. Source: Gao et al., 2002.

steam-turbine cycle (O–S, V). The associated units are an air-separation unit (T) and a CO2 recovery unit (M–N). The partial-gasification island provides raw coal gas to the internal-fired gas-turbine cycle and semi-coke to the external-fired steam-turbine cycle, respectively.

In the internal-fired gas-turbine cycle, the raw coal gas is combusted with O2, and the thermal energy released is used to heat the combustion-gas stream (mainly water vapor), thus maintaining a high cycle efficiency. Because the main components of the combustion product are steam and CO2, the turbine exhaust can reach vacuum status, taking full advantage of the low temperature of exhaust in the Rankin cycle. CO2 is separated in the process of condensing the exhaust gas.

In the external-fired steam cycle, high-pressure water is heated to high-pressure steam by the heat recovered from the semi-coke, the reheater, and the high temperature of raw coal gas in the heat exchanger. The high-pressure steam generates energy in the steam turbine (V), and the steam exhaust enters the combustor (H) through the reheater (J).

This novel system, which uses water vapor as the working fluid and a combination of internal and external coal-fired systems, is characterized by high inlet temperature and low discharge pressure. The system has two main advantages over an IGCC system: (1) because partial gasification of coal does not require complete carbon conversion, the gasifier can be substantially smaller; and (2) the temperature for partial gasification is lower than for IGCC; therefore, the equipment is less expensive.

The net efficiency of the novel system is 45.4 percent at an inlet temperature of 1,300°C; the efficiency of IGCC is 45 percent under the same conditions. In addition, the new system recovers about 41 percent of liquid CO2 simultaneously. By integrating partial coal gasification, advanced thermal cycles, and CO2 separation, the novel system is more efficient, more environmentally friendly, and has a better economic profile than an IGCC system.

INTEGRATION OF CO2 SEPARATION AND CLEAN-ENERGY GENERATION BASED ON A POLYGENERATION SYSTEM

Coal gasification is a central technology for both the electric-power industry and the chemical industry. The coal-based polygeneration system, which uses coal gasification and generates syngas, has broad industry applications. The most important feature of polygeneration is the production of methanol, dimethyl ether (DME), and Fischer-Tropsch (FT) liquids, such as FT diesel from syngas.

A polygeneration system can generate various products with high added value, especially clean energy and fuels. In the near term, the products of a polygeneration system could serve a wide range of energy needs with extremely low levels of air pollution. The principle of polygeneration is to integrate and optimize different technologies by compensation and to reduce both the cost of production and pollutant emissions.

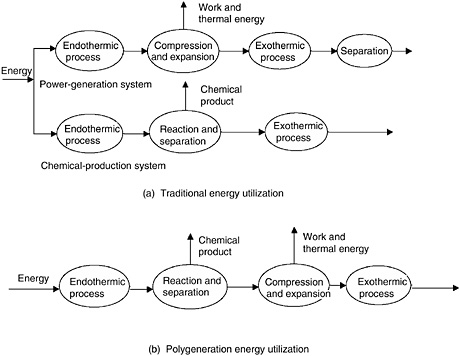

FIGURE 3 Principles of the polygeneration concept. Source: Gao et al., 2002.

The concept of polygeneration is illustrated in Figure 3. In the traditional method of energy consumption (Figure 3a), the power-generation system is independent of the chemical-production system. Because both systems may have processes for the same purpose, such as separation, this is inefficient. In contrast, in a polygeneration system, the power-generation system and the chemical-production system can be integrated (Figure 3b). Because duplications and overlapping processes can be avoided, less energy is consumed. For example, in a traditional power-generating system, contaminations are separated downstream of the system, an energy-intensive process. In the polygeneration system, the reaction and separation are accomplished in one process; thus, chemical production and power generation form a chain. In short, in polygeneration the energy and material exchanges between the power-generation system and the chemical-production system are interdependent. Although polygeneration could be more complex to regulate, the system has great potential for saving both energy and economic resources.

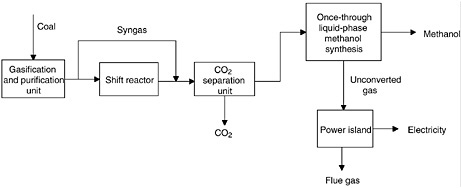

The polygeneration system proposed here integrates CO2 separation and clean energy (e.g., methanol) generation. The system has once-through, liquid-phase methanol synthesis. As shown in Figure 4, syngas from gasification is

FIGURE 4 Simple block drawing of polygeneration system with integration of CO2 separation and clean-energy generation. Source: Gao et al., 2002.

divided into two parts: one part that enters the shift-reaction unit and one that serves as regulating gas. Unlike conventional methanol synthesis, which recycles unconverted gas to increase the methanol conversion rate, the polygeneration system controls methanol synthesis by adjusting the flow rate ratio of the shifted gas to the regulation gas and sends the unconverted-gas stream to the power island as fuel. Both clean energy from methanol and electricity are products of the system.

The optimal methanol conversion rate may not be ideal for the overall polygeneration system, however. Thus, acceptable performance will require optimization of both the production of methanol and the production of electricity. This integration will surely affect the CO2 recovery rate, which is determined by the proportion of syngas sent to the shift-reaction unit.

The integration of CO2 separation and clean-energy generation could lead to an innovative system that meets both environmental and energy-production requirements. The key component of the polygeneration system is the CO2 separation unit. The separation of CO2 from shifted gas changes the proportion of H2 and CO in the feed gas, leading to a suitable concentration of reactants for methanol synthesis. In other words, the separation of CO2 and the generation of methanol can be accomplished simultaneously. Thus, integration of CO2 separation and clean-energy generation eliminates the energy penalty of CO2 separation.

The integrated polygeneration system has a higher efficiency than the IGCC with CO2 recovery system, with the same ratio of CO2 recovery. A comparison of the three systems (Table 2) shows that the thermal efficiency of the integrated polygeneration system is about 5 percent higher than for IGCC without CO2 recovery and 11 percent higher than IGCC with CO2 recovery. In addition, the polygeneration system can recover 56 percent of CO2 at high efficiency. The

TABLE 2 Comparison of the Integrated Polygeneration System, IGCC System, and IGCC System with CO2 Recovery

|

Systems/ Parameters |

IGCC |

IGCC with CO2 Recovery |

Integrated Polygeneration |

|

CO2 recovery (%) |

0 |

58 |

56 |

|

Thermal efficiency (%) |

45 |

39 |

50 |

|

Source: Gao et al., 2002. |

|||

excellent performance of the integrated polygeneration system is attributable to many important features. For example, in the methanol-synthesis process, the cascade use of the chemical energy of syngas increases system efficiency and decreases energy loss from combustion (Gao et al., 2002).

The strategy of the energy industry in China will eventually be to develop a polygeneration system. But for the time being, the power and electricity industry is focusing on the development of a supercritical-steam turbine. Compared with this system, the polygeneration system may require a higher initial investment because polygeneration is a complex system that combines several advanced technologies, including gasification, gas turbines, and high-temperature gas cleanup. However, the efficiency of polygeneration may be as high as 55 to 60 percent if the inlet temperature is 1,500°C. In contrast, the increase in efficiency with the supercritical-steam turbine cycle will be limited to about 45 percent. Moreover, as the advanced technologies mature, there is a good chance that the costs of polygeneration will decrease. In addition, if CO2 is used for enhanced oil recovery and enhanced coal-bed methane recovery, the higher costs could be offset and would not be an obstacle to the spread of polygeneration.

DEVELOPMENT OF A COAL-BASED ENERGY NETWORK IN CHINA

There is no doubt that the strategic goals of future energy development must be compatible with environmental protection and that clean-coal technology with greenhouse gas control will necessarily be accepted by countries that rely on coal for energy. The obstacle to CO2 control with current clean-coal technologies is the high energy penalty in the separation of CO2. Although the capture of CO2 in the IGCC system can reduce the energy penalty to some extent, so far no such system has been developed. Can we create new-generation clean-coal technologies with CO2 capture? Will a breakthrough concept be developed that allows coal-dependent countries like China to produce energy in an environmentally benign way? We have attempted to answer these questions based on our research.

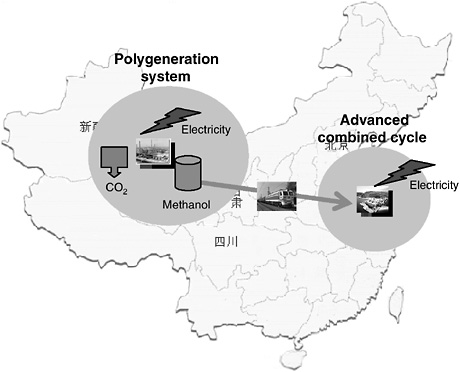

For the purpose of answering these questions, we have proposed a coal-

based energy network (Figure 5). A polygeneration plant built near a coal mine can convert the coal to power and liquid fuels, such as methanol and DME, which can then be transported to urban areas. These liquids can be used as a raw material for chemical synthesis and clean power generation. The captured CO2 can be sequestered or potentially recycled into useful products.

The energy network has several distinctive characteristics. First, it is an environment-friendly system that is highly integrated with emerging technologies, such as polygeneration and clean synthetic-fueled multiutilization systems. By taking advantage of these advanced technologies, the energy network can achieve high efficiency and save resources. Second, the system should contribute to CO2 capture technology because the energy network can capture CO2 without the energy penalty associated with current systems. This means that the efficiency of the energy network with CO2 removal may be even higher than the efficiency of the IGCC system, with or without CO2 capture. Third, the transportation of clean energy requires less energy than the transportation of coal. Finally, the energy network is flexible; it has multi-output upstream and multiutilization of products downstream. Upstream, the polygeneration network

FIGURE 5 Block diagram of coal-based energy network. Source: Gao et al., 2002.

generates both electricity and clean synthetic fuels; the upstream output of IGCC is just electricity, although it has high thermal efficiency. Downstream, clean synthetic fuels have many uses:

-

Power generation. Clean synthetic fuels can be used as fuels in combined cycles. Most clean synthetic fuels are organic; the combustion products are CO2 and H2O, and the CO2 can be easily recovered by condensing the water vapor. Some clean synthetic fuels (e.g., methanol) effectively use low-temperature thermal energy.

-

Fuel-cell vehicles. Clean synthetic fuel of methanol has the potential to be used in fuel-cell vehicles. In the future, the widespread use of fuel-cell vehicles will be an important contributor to CO2 control.

-

Substitute for oil. Methanol, for example, is a high-octane fuel that can replace gasoline in spark-ignition internal-combustion engines. DME can be used as a substitute for diesel oil in compression-ignition engines to improve energy security in China.

-

Material for chemical synthesis. The cost of generating clean synthetic fuels from polygeneration might be much lower than from the traditional chemical system; thus, the cost of products derived from clean synthetic fuels may be competitive.

-

Energy for buildings. Clean synthetic fuels used for central heating systems will require 20 to 30 percent less energy because of higher boiler efficiency.

A CLEAN SYNTHETIC-FUELED POWER-GENERATION SYSTEM

The clean synthetic-fueled power-generation system is a type of combined-cycle system that would use clean synthetic fuel indirectly. The most significant benefit of such a system is that the clean synthetic fuel could be decomposed into synthesis gas (containing CO and H2) by upgrading the low-temperature thermal energy to chemical energy. Therefore, when the synthesis gas is combusted, the energy output would be higher than from the direct combustion of clean synthetic fuel. A clean synthetic-fueled power-generation system would be much more thermally efficient than a conventional combined-cycle system. At a turbine inlet temperature of 1,300°C, for example, the thermal efficiency of a methanol-fueled power-generation system with intercooling is 60 percent. This is significantly more efficient than the IGCC system without recovery of CO2, which averages 42 to 45 percent, and even more efficient than the present natural-gas combined-cycle system, which averages 55 percent (Jin et al., 2003).

This estimate is based on the subsystems described above. Upstream, the thermal efficiency of a coal-based polygeneration system, with half of CO2 recovery ratio, is 50 percent. Downstream, thermal efficiency could be as high as 60 percent with the methanol-fueled power-generation system. For simplification,

we have assumed the same energy requirements for transporting coal and methanol. Based on these values, the thermal efficiency of the energy network would be 44 percent, with CO2 recovery of 60 percent and a CO2 emission rate of about 0.29 kg-CO2/kWh.

CONCLUSION

An integrated energy network could address the energy efficiency and environmental problems caused by the use of coal in China. In the long term, this energy network would be superior to current advanced power technologies, such as a supercritical power plant. For a supercritical power plant with 60 percent CO2 recovery and 10 percent parasitic losses, the average thermal efficiency would be 13 percent lower than for the energy network with the same coal input. Thus, the integrated energy network would be about 40 percent more efficient. In terms of controlling greenhouse gas emissions, the CO2 emission rate for the supercritical power plant with CO2 recovery of 60 percent is 0.46 kg-CO2/kWh. The CO2 emission rate of the energy network (0.29 kg-CO2/kWh) would be 37 percent lower with the same ratio of CO2 recovery because of the increase in thermal efficiency.

Energy consumption and CO2 emission rates in the energy network could potentially be reduced even further. A rough estimate shows that a 50-percent energy saving would be possible with a higher performance gas turbine and lower energy consumption for methanol synthesis and CO2 recovery. Studies indicate that the price of methanol and electricity would be lower than when methanol is synthesized from natural gas by individual processes. In addition, producing methanol from coal will probably increase the use of natural gas, which currently accounts for less than 3 percent of energy consumption in China.

In conclusion, an integrated energy network would simultaneously save energy and control greenhouse gas emissions in China.

REFERENCES

DOE (U.S. Department of Energy). 1996. The United States of America and the People’s Republic of China Experts Report on Integrated Gasification Combined-Cycle Technology (IGCC). DOE/ FE-0357. Available online at: http://www.lanl.gov/cgi-bin/byteserver.pl/projects/cctc/resources/pdfsprog/clncoalgnrl/M98001976.pdf (accessed May 14, 2004).

Doctor, R.D., J.C. Molburg, P.R. Thimmapuram, G.F. Berry, and C.D. Livengood. 1994. Gasification Combined Cycle: Carbon Dioxide Recovery, Transport, and Disposal. ANL/ESD-24. Argonne, Ill.: Argonne National Laboratory.

Doctor, R.D., J.C. Molburg, and P.R. Thimmapuram. 1996. KRW Oxygen-Blown Gasification Combined Cycle: Carbon Dioxide Recovery, Transport, and Disposal. ANL/ESD-34. Argonne, Ill.: Argonne National Laboratory.

Gao, L., H. Jin, and Z. Liu. 2002. Energy Analysis of Coal-Based Polygeneration System for Power and Chemical Production. Pp. 137–144 in Proceedings of the 15th International Conference on Efficiency, Costs, Optimization, Simulation (ECOS) 2002. Berlin: Technische Universität Berlin, Institute for Energy Engineering.

Jin, H., H. Hong, and R. Cai. 2003. A Chemically Intercooled Gas Turbine Cycle for Recovery of Low-Temperature Thermal Energy. Pp. 1025–1032 in Proceedings of the 16th International Conference on Efficiency, Costs, Optimization, Simulation (ECOS) 2003. Copenhagen: Ikon Document Services.