The Role of Modeling and Simulation in Extreme Engineering Projects

JON BERKOE

Bechtel National, Inc.

San Francisco, California

Bechtel has constructed a vast array of major plants and infrastructure projects around the world. In the past few years, advanced-technology tools, such as simulations, have increasingly been used to address logistical barriers, schedule constraints, environmental factors, and risk in support of the design and engineering in many projects.

Tools that specialize in modeling physical environments and conditions are particularly useful for many complex projects (e.g., plants and infrastructure). A multidisciplinary approach to analysis and visualization can reduce risk and save money by developing models that simulate the physical environment a component or system may encounter before substantial time and/or money has been invested in the project. In particular, models can be used to investigate safety implications of complex, off-normal conditions that cannot be easily evaluated by the project engineering team.

TACOMA NARROWS BRIDGE MOORING SYSTEM

The towing last July of the first 14,000-ton (12,700-tonne) Tacoma Narrows Bridge caisson to its moored position at the east end of Puget Sound was a historic sight witnessed by hundreds of people. What they didn’t see, however, was the mooring system that restrained the caisson and its west-end counterpart until they took their underwater positions 60 to 70 feet (18 to 21 meters) below the Narrows mud line.

The caisson-mooring system was the result of nine months of design work and close coordination among several engineering teams and individual experts. The system was designed to handle the tidal conditions—8-knot currents and 17-foot (5-meter) tidal fluctuations—while responding to the volatile hydrodynamic zone in the Narrows created by vortex shedding from the existing bridge foundations.

The uniqueness of the project presented the mooring design team with several challenges. Here are some highlights:

-

The new structure will be the longest suspension bridge built in the United States in 40 years. Physical tests of the mooring system were not feasible at a scale that would effectively model the forces on the caissons in the Tacoma Narrows environment.

-

The new bridge foundations will be constructed approximately 80 feet (24 meters) from the existing bridge foundations. (The existing bridge will continue to operate after the new bridge is constructed.) This created extremely tight constraints on acceptable movement of the caissons.

-

The caisson and mooring system will be subject to extreme environmental conditions, particularly tidal fluctuations, in addition to storm surges, wind, and waves. Designing a mooring system with allowances for wide variations in environmental conditions and differing effects on each caisson was perhaps the biggest challenge.

Computational fluid dynamics (CFD)—a computer-based tool for simulating the behavior of systems involving fluid flow, heat transfer, and related physical processes—was used to predict the time-varying loads and moments on the new bridge caissons caused by current flows in the Narrows. To accomplish this, the bathymetry of the riverbed and the designs for the existing and new bridge piers had to be combined into one model; software that used an advanced finite-element-based solver and large eddy simulation proved to be fast and stable. The model showed that CFD results for the loads on the caissons agreed very well with experiment-scale model data from tests carried out at HR Wallingford in the United Kingdom. Using CFD modeling, the designers of the bridge caissons were able to assess risk and gain confidence in design margin, particularly for the “untested” west pier. Based on results of the analytical and physical modeling, Tacoma Narrows constructors selected a two-tiered anchor system with 16 anchors on each level (Figure 1).

CONSTRUCTION OF THE LARGEST NUCLEAR-WASTE PROCESSING PLANT IN THE UNITED STATES

Beside the Columbia River in Washington, 53 million gallons of radioactive waste (60 percent of the nation’s radioactive waste) is stored in 177 underground

FIGURE 1 (Top to bottom) Rendering of the new Tacoma Narrows Bridge positioned next to the existing bridge. Caisson anchor system during installation. CFD analysis plot showing turbulence around two bridge piers subjected to current flow. Plot of the time-varying load components subjected to the caisson during ebb and flood flows. Source: Bechtel National, Inc.

tanks. This waste is a product of 50 years of plutonium production for national defense. The U.S. Department of Energy has commissioned the construction of a vast waste-treatment plant (WTP) to convert this waste into stable glass. The waste in these underground storage tanks is a combination of sludge, slurry, and liquid, which will be transported to a pretreatment facility to be processed in various vessels in preparation for vitrification.

Part of the engineering challenge is designing a system that can keep solids in continuous suspension during processing while minimizing the risk of mixing-system failure and eliminating the need for maintenance. Pulse-jet mixers (PJMs) are an integral part of the black-cell conceptual design. Black cells—sealed areas of the plant that no human will ever enter—are designed to require no maintenance, no equipment replacement, and no repairs. PJMs are air-driven pumps installed inside stainless-steel tanks that process radioactive waste. Because they have no moving parts, they never require maintenance or replacement. The mixers agitate the radioactive waste and keep it homogenous, which is necessary to achieve the correct blend of waste fed to the melters. The agitation also prevents the formation of gas pockets, thus ensuring that hydrogen gas does not build up.

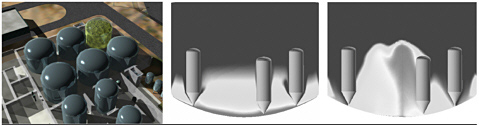

The research program for the project has been focused for nearly three years on testing and evaluating the effectiveness of PJMs. CFD models of all process vessels in the WTP have been developed either to confirm that the PJMs meet stringent mixing criteria, or, if performance is inadequate, to provide insight as to how the systems should be redesigned. State-of-the-art multiphase modeling techniques were used to prove out the basic design for fluidics mixing in the various process vessels. These models include the transient effects of solid-liquid mixing, such as accumulation, non-Newtonian yielding, air sparging, and heat transfer (Figure 2). By using CFD in this way, the project team was able to bypass extensive demonstration tests and keep pace with the plant’s construction schedule.

FIGURE 2 (Left to right) Waste-processing tanks in a section of WTP. A plot taken from a CFD analysis of solids suspension in a vessel using PJMs showing settling during suction. Liftoff during drive. Source: Bechtel National, Inc.

DESIGN OF THE CHERNOBYL NEW SAFE CONFINEMENT

The Chernobyl new safe confinement (NSC) will shield the sarcophagus, or shelter, that was constructed soon after the nuclear accident in 1986 to contain the deadly radioactive materials in damaged Unit 4. Specifically, the NSC is designed to keep radioactive dust in and rain out and to facilitate the deconstruction of the sarcophagus and Unit 4. The NSC is intended to minimize occupational exposure for at least 100 years, with the expectation that improved storage or disposal methods will be available within that time.

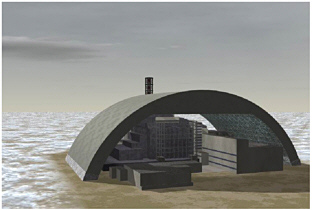

The design team chose a movable, arch-shaped building made of large, preassembled pieces that could be constructed and then slid into place over the Unit 4 shelter (Figure 3). After considering eight initial configurations, the team selected one that met several of its key criteria and then optimized the configuration for chord depth and diameter and section shape. The layer of contaminated topsoil will be removed before construction begins to minimize radiation exposure to workers and schedule risk.

For rapid prototyping, the project team used state-of-the-art computer 3-D animation and virtual reality (VR) development software. The VR team was given a series of hand-drawn blueprints, annotated in Russian, along with ground-level and aerial photographs of the site and video footage of the area. Using the blueprints, they were able to create an accurate 3-D representation of the building exterior. Details of the confinement structure were provided by way of 2-D CAD drawings, which were used as a template to create a 3-D model. The heavily damaged interior was modeled primarily from photographs and video footage. The project team quickly developed 3-D simulations and generated large-scale animations by using distributed-rendering technology. The dynamic

FIGURE 3 Chernobyl NSC conceptual design shows the assembled arch positioned over the existing Unit 4 reactor. Source: Bechtel National, Inc.

view of the NSC construction and operations provided by the simulations greatly facilitated the project review.

SUMMARY

Because the cost of using simulation has decreased dramatically in recent years, it is now typically well within the cost and schedule constraints of many project budgets. Thus, engineering teams can now study the impact of environmental factors, including extreme conditions, from various perspectives. Prototyping the technical and conceptual aspects of projects on the computer early on can minimize many potential downstream risks.

ACKNOWLEDGMENTS

I would like to acknowledge the outstanding work of the engineers responsible for the projects discussed in this paper, including Brigette Rosendall, Kristian Debus, Carl Johnson, Chris Barringer, Martin Melin, and Feng Wen. They, along with their peers in the Advanced Simulation and Analysis Group at Bechtel, continuously strive to achieve success on challenging, schedule-driven assignments.