have more severe consequences. Severe damage of the pool wall could potentially result from several types of terrorist attacks, for instance:

-

Attacks with large civilian aircraft,

-

Attacks with high-energy weapons.

-

Attacks with explosive charges.

The committee reviewed two independent analyses of aircraft impacts on power plant structures: A study sponsored by EPRI completed in 2002 provides a generic analysis of civilian airliner impacts on commercial power plant structures (EPRI, 2002). A study in progress by Sandia National Laboratories for the Nuclear Regulatory Commission examines the consequences of an aircraft impact on an actual BWR power plant.

The EPRI and Sandia analyses used different finite element and finite difference codes that are in common use in research and industry.15 Both sets of analyses attempted to validate the codes against physical tests, such as the Sandia “slug tests” that impacted water barrels into a concrete test wall at high speeds. EPRI’s analysis used a Riera impact loading condition, which models the aircraft impact on a rigid structure and is a slightly conservative assumption because the structures are in fact deformable. The Sandia analysis was carried out on powerful computers that allowed the aircraft to be included explicitly in the calculations.

The committee also reviewed the preliminary results of Nuclear Regulatory Commission studies on the response of thick reinforced concrete walls such as those used in spent fuel pools to attacks involving simple explosive charges and other high-energy devices. The details of the analyses were not provided and therefore could not be evaluated quantitatively. However, some of these preliminary results are described in the committee’s classified report.

The results of these aircraft and assault studies are classified or safeguards information. The committee has concluded that there are some scenarios that could lead to the partial failure of the spent fuel pool wall, thereby resulting in the partial or complete loss of pool coolant. A zirconium cladding fire could result if timely mitigative actions to cool the fuel were not taken. Details are provided in the classified report.

3.3.2 What would be the Radioactive Releases if a Pool Were Drained?

There are two ways in which an attack on a spent fuel pool could spread radioactive contamination: mechanical dispersion and zirconium cladding fires. An explosion or high-energy impact directly on the spent fuel could mechanically pulverize and loft fuel out of the pool. This would contaminate the plant and surrounding site with pieces of spent fuel. Large-

scale offsite releases of the radioactive constituents would not occur, however, unless they were mobilized by a zirconium cladding fire that melted the fuel pellets and released some of their radionuclide inventory. Such fires would create thermal plumes that could potentially transport radioactive aerosols hundreds of miles downwind under appropriate atmospheric conditions.

The Nuclear Regulatory Commission is now sponsoring work at Sandia National Laboratories to improve upon the analyses in NUREG-1738 (USNRC, 2001a), and in particular to obtain an improved phenomenological understanding of the thermal and hydraulic processes that would occur in a spent fuel pool from a loss-of-pool-coolant event. The committee received briefings on this work from Commission and Sandia staff during the course of this study. Additionally, the committee received a briefing from ENTERGY Corp. staff and its consultants under contract to analyze and understand the consequences of a loss-of-pool-coolant event in a spent fuel pool in a PWR plant.

The Sandia analyses were carried out on the reference BWR described in Section 3.1. Sandia’s analysis of a PWR spent fuel pool had only just begun by the end of May 2004 and has not yet yielded any results. The committee had less opportunity to examine ENTERGY’s approach and results. Because of these limitations, the committee was unable to examine in any detail the effects of the differences between BWR and PWR pools and fuel, except as noted with respect to their locations relative to grade.

The analyses were carried out using several well-established computer codes. The MELCOR code, which was developed by Sandia for use in analyzing severe reactor core accidents, was used to model fluid flow, heat transfer, fuel cladding oxidation kinetics, and fission product release phenomena associated with spent fuel assemblies. This code has been benchmarked against data from experiments (e.g., the FPT experiments on the Phébus test facility, and the VERCORS, CORA, and ORNL VI experiments)16 that involve zirconium oxidation kinetics and fission product release. However, none of the experiments was designed to simulate the physical conditions in a spent fuel pool. Many of the phenomena are not significantly different in a reactor core and in a spent fuel pool, but a few important differences, particularly concerning fire propagation from hotter fuel assemblies to cooler fuel assemblies and nuclear fuel volatilities, warrant more detailed analyses or further experiments. In principle, MELCOR can perform “best-estimate” calculations that address a range of accident evolutions, accounting for temperature, availability of oxidizing air and steam,17 and speciation and transport of radionuclides.

Sandia calculated the decay heat in the assemblies using the ANSI/ANS 5.1 code based on actual characteristics of the spent fuel (i.e., actual fuel ages, burn-ups, and locations) in the reference BWR pool. Flow and mixing behavior in the pool and reactor building enclosing the pool were modeled using a separate computational fluid dynamics (CFD) code.

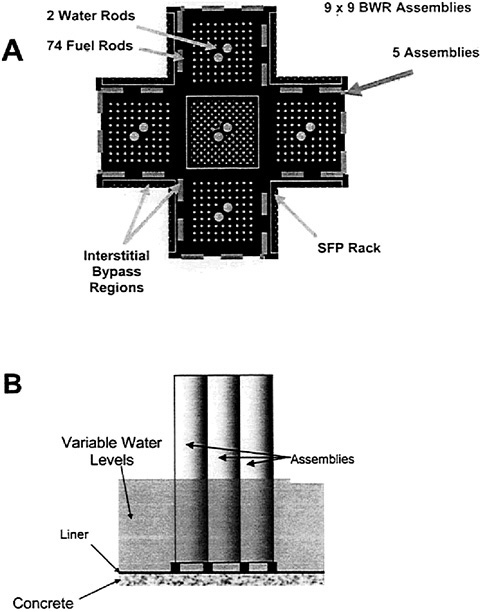

Two types of analyses were carried out. A “separate effects” analysis was undertaken to examine the thermal responses of a spent fuel assembly (FIGURE 3.4) in a

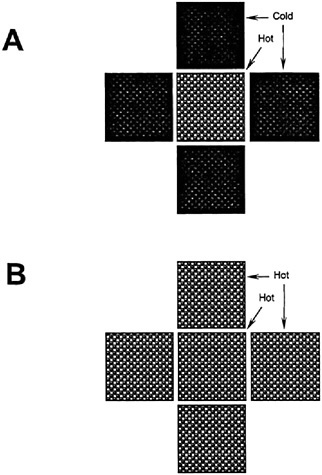

FIGURE 3.5 Two configurations used in the separate effects models shown in FIGURE 3.4: (A) Center hot spent fuel assembly surrounded by four cold assemblies; and (B) center hot spent fuel assembly surrounded by four hot assemblies. SOURCE: Nuclear Regulatory Commission briefing materials (2004).

loss-of-pool-coolant event. This analysis was used to understand how thermal behavior is influenced by factors such as decay heat in the fuel assembly, heat transfer with adjacent assemblies, and heat transfer to circulating air or steam in a drained spent fuel pool. This analysis was used to guide the development of “global response” models to examine the thermal-hydraulic behavior of an entire spent fuel pool.

The separate effects analysis examined the thermal behavior of a high decay-heat BWR spent fuel assembly surrounded either by four low decay-heat assemblies (FIGURE 3.5A) or four high decay-heat assemblies (FIGURE 3.5B). This analysis showed that the potential for heat build-up in a fuel assembly sufficient to initiate a zirconium cladding fire depends on its decay heat (which is related to its age) and on the rate at which heat can be transferred to adjacent assemblies and to circulating air or steam.

In the configuration shown in FIGURE 3.5A, the low decay-heat assemblies act as thermal radiation heat sinks, thereby allowing the more rapid transfer of heat away from the center fuel assembly than would be the case if the center assembly were surrounded by high decay-heat assemblies. The results from this analysis indicate that this configuration can be air cooled sufficiently to prevent the initiation of a zirconium cladding fire within a relatively short time after the center fuel assembly is discharged from the reactor. In the configuration shown in FIGURE 3.5B, heat transfer away from the center assembly is reduced and heat build-up is more rapid. Results indicate that this configuration cannot be air cooled for a significantly longer time after the center fuel assembly is discharged from the reactor,

The global analysis modeled the actual design and fuel loading pattern of the reference BWR spent fuel pool. The pool was divided into seven regions based on fuel age. Within each of those seven regions, the model for the fuel racks was subdivided into 16 zones. The grouping of assemblies into zones reduced the computational requirements compared to modeling every assembly.18 Two scenarios were examined: (1) a complete loss-of-pool-coolant scenario in which the pool is drained to a level below the bottom of spent fuel assemblies; and (2) a partial-loss-of-pool-coolant scenario in which water levels in the pool drain to a level somewhere between the top and bottom of the fuel assemblies. In the former case, a convective air circulation path can be established along the entire length of the fuel assemblies, which promotes convective air cooling of the fuel, in the latter case, an effective air circulation path cannot form because the bottom of the assembly is blocked by water. Steam is generated by boiling of the pool water, and the zirconium cladding oxidation reaction produces hydrogen gas. This analysis suggests that circulation blockage has a significant impact on thermal behavior of the fuel assemblies. The specific impact depends on the depth to which the pool is drained.

The global analysis examined the thermal behavior of fuel assemblies in the pool at 1, 3, and 12 months after the offloading of one-third of a core of spent fuel from the reactor. Sensitivity studies were carried out to assess the importance of radiation heat transfer between different regions of the pool, the effects of building damage on releases of radioactive material to the environment, and the effects of varying the assumed location and size of the hole in the pool wall.

The results of these analyses are provided in the committee’s classified report. For some scenarios, the fuel could be air cooled within a relatively short time after its removal from the reactor. If a loss-of-coolant event took place before the fuel could be air cooled, however, a zirconium cladding fire could be initiated if no mitigative actions were taken. Such fires could release some of the fuel’s radioactive material inventory to the environment in the form of aerosols.

For a partial-loss-of-pool-coolant event, the analysis indicates that the potential for zirconium cladding fires would exist for an even greater time (compared to the complete-loss-of-pool-coolant event) after the spent fuel was discharged from the reactor because air circulation can be blocked by water at the bottom of the pool. Thermal coupling between adjacent assemblies will be due primarily to radiative rather than convective heat transfer. However, this heat transfer mode has been modeled simplistically in the MELCOR runs

performed by Sandia.19

If the water level is above the top of the fuel racks, decay heat in the fuel could cause the pool water to boil. Once water levels fall below a certain level in the fuel assembly, the exposed portion of the fuel cladding might heat up sufficiently to ignite if no mitigative actions were taken. This could result in the release of a substantial fraction of the cesium inventory to the environment in the form of aerosols.

A zirconium cladding fire in the presence of steam could generate hydrogen gas over the course of the event. The generation and transport of hydrogen gas in air was modeled in the Sandia calculations as was the deflagration of a hydrogen-air mixture in the closed building space above the spent fuel pool The deflagration of hydrogen could enhance the release of radioactive material in some scenarios.

Sandia was just beginning to carry out a similar set of analyses for a “reference” PWR spent fuel pool when the committee completed information gathering for its classified report. There are reasons to believe that the results for a PWR pool could be somewhat different and possibly more severe, than for a BWR pool: PWR assemblies are larger, have somewhat higher burn-ups, and some assemblies sit directly over the rack feet, which may impede cooling. While PWR fuel assemblies hold more fuel, they also have more open channels within them for water circulation. The committee was told that as part of this work, a sensitivity analysis will be carried out to understand how design differences among U.S. PWRs will influence the model results.

ENTERGY Corp. has carried out independent separate-effects modeling of a PWR spent fuel pool using the MELCOR code. The analyses addressed both partial and complete loss-of-pool-coolant events for its PWR spent fuel assemblies in a region of the pool where there are no water channels in the spent fuel racks. The analyses were made for relatively fresh spent fuel assemblies (i.e., separate models were run for assemblies that had been discharged from the reactor for 4, 30, and 90 days) surrounded by four “cold” assemblies that had been discharged for two years. In general, the ENTERGY results are similar to those from the Sandia separate-effects analyses mentioned above.

Several steps could be taken to mitigate the effects of such loss-of-pool-coolant events short of removal of spent fuel from the pool. Among these are the following:

-

The spent fuel assemblies in the pools can be reconfigured in a “checkerboard” pattern so that newer, higher decay-heat fuel elements are surrounded by older, lower decay-heat elements. The older elements will act as radiation heat sinks in the event of a coolant loss so that the fuel is air coolable within a short time of its discharge from the reactor. Alternatively, newly discharged fuel can be placed near the pool wall, which also acts as a heat sink. ENTERGY staff estimates that reconfiguring the fuel in one of its pools into a checkerboard pattern would take only about 10 hours of extra work, but would not extend a refueling outage. Reconfiguring of fuel already in the pool could be done at any time. It does not require a reactor outage.