Plant operators must show that of the four safety trains (each train contains 50 percent of the safety system) at the plant, at least two will survive such a crash. The crash parameters (e.g,, aircraft type, speed, and angle) have been established by RSK. The crash parameters have been published and the public knows about them. Each plant must perform an independent analysis of each reactor building. Sometimes two separate analyses have to be provided for the same site if there are two or more reactors with different designs.

In 1998, the German government decided to phase out nuclear energy. Commercial nuclear plants will be allowed to generate an agreed-to amount of electricity before shutdown. Currently, the Lingen and the Neckarwestheim-2 plants have the highest remaining electricity production allowance and will be shutdown in 2021 or 2022, should no revision of this political decision be implemented.

C.2 SPENT FUEL STORAGE

Until recently, all spent fuel at German plants was stored in the reactor pools until it could be sent to Sellafield (U.K.) or La Hague (France) for reprocessing. In the 1980s, plants began to re-rack their spent fuel pools to increase storage capacities (the older German nuclear plants were designed to contain one full reactor core plus one third of a core). Regulators became concerned that the emergency cooling systems were not sufficient to handle the increased heat loads in spent fuel pools from this re-racking. Some plants added additional cooling circuits to address this concern. Only one power plant (an older plant at Obrigheim) has wet interim pool storage in a bunkered building.

A discussion of alternative spent fuel storage options began in 1979. A reprocessing plant had been proposed at Gorleben that would have had several thousand metric tons of pool storage. The German government concluded that while there were no major technical issues for reprocessing, wet fuel storage was a potential problem because cooling systems could be disrupted in a war. GNS decided to shift from wet to dry storage for centralized storage facilities.

There are two centralized storage facilities in Germany: Gorleben and Ahaus. Gorleben is designed to store vitrified high-level waste from spent fuel reprocessing and spent fuel from commercial power reactors. Ahaus is designed to store spent fuel from test reactors and other special types of fuel. Ahaus currently stores 305 casks of reactor fuel from the decommissioned Thorium High Temperature Reactor, three casks of PWR spent fuel from the Neckarwestheim site, and three casks of BWR spent fuel from the Gundremmingen site. The latter shipment produced large public demonstrations and required the deployment of 35,000 police officers to maintain security.

At the end of 2001, the German utility companies and the German federal government agreed to avoid all transport of spent fuel in Germany because of intense public opposition. The German government recently passed a law making it illegal to transport spent nuclear fuel to reprocessing plants in France and the United Kingdom after June 30, 2005. However, there is no legal restriction concerning the transport of spent fuel from power reactors to other destinations (e.g., to dry storage facilities). The government and power plant operators have negotiated an agreement to develop dry cask storage facilities at each of the 12 nuclear power plant sites to avoid the need for offsite spent fuel transport.

These dry cask storage facilities are to be constructed by 2006. They are licensed to store fuel for 40 years.

There are three dry cask storage facility designs in Germany:

-

WTI design: The walls and roof are constructed of 80 and 50 centimeters, respectively, of reinforced concrete.

-

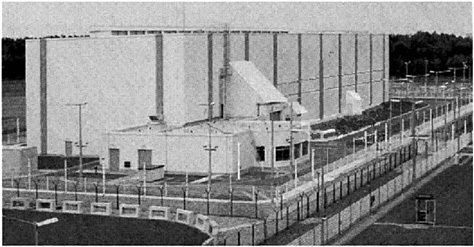

STEAG design: The wails and roof are constructed of 1.2 and 1.3 meters, respectively, of reinforced concrete. This design is used at the Lingen Nuclear Power Plant dry storage facility visited by the committee (FIGURE C.2).

-

GNK design: This is a tunnel design and is under construction at the Neckarwestheim nuclear power plant.

The use of reinforced concrete in these facilities was originally intended for radiation protection and structural support, not for terrorist attacks.

In 1999, RSK issued guidelines for dry storage, which were released in 2001 (RSK, 2001). Licensing a dry storage facility in Germany requires several safety demonstrations and analyses. As part of the licensing procedures for a storage facility, the license applicant must do independent calculations that demonstrate how the building features meet the safety standards and the design basis threat. This threat includes an armed group of intruders and the impact of a Phantom 2 military jet. It also includes a shaped charge. The scenario of a deliberate crash of a large civilian airplane has been considered and analyzed as part of the recent licensing of onsite dry storage facilities but is not established as part of the design basis threat. There are public hearings during which the license applicant explains the safety features of the storage facility. The public is aware of the design basis threat, and it is provided with the results of the analysis but not with the details.

FIGURE C.2 Dry cask spent fuel storage building at the Emsland Nuclear Power Plant located near Lingen, Germany.

SOURCE: RWE Power.

There are six temporary (i.e., five- to seven-year) storage facilities in use at reactor sites until these dry cask storage facilities become available. The casks in these temporary storage facilities are stored horizontally and are protected by concrete “garages” designed to withstand the impact of a Phantom military jet.

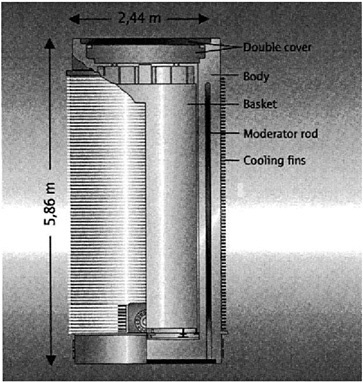

Spent commercial fuel is stored in CASTOR® casks (FIGURE C.3) that were originally designed and developed by the German utility-owned company GNB.2 These casks can store either PWR or BWR spent fuel assemblies. The design consists of a ductile cast iron cylindrical cask body with integral circumferential fins machined into the outer surface to maximize heat transfer; inside, the spent fuel assemblies are inserted in a borated stainless steel basket. The cask has a double-lid system that is protected by a third steel plate. The cask complies with the international regulations of the International Atomic Energy Agency (IAEA) as a type B(U) package.

Spent fuel is typically cooled for five years in a pool before it is put in dry cask storage; some other custom-made cask designs can hold fuel that has been cooled for shorter (minimum two years) or longer times depending on the fuel characteristics and fuel burn-up. Current fuel burn-ups in Germany (52 to 55 gigawatt-days per metric ton) are similar to those in the United States.

FIGURE C.3 Typical features of a CASTOR cask used at the Lingen Nuclear Power Plant.

SOURCE: RWE Power AG Lingen Nuclear Power Plant.