1

High-Performance Fiber Technology

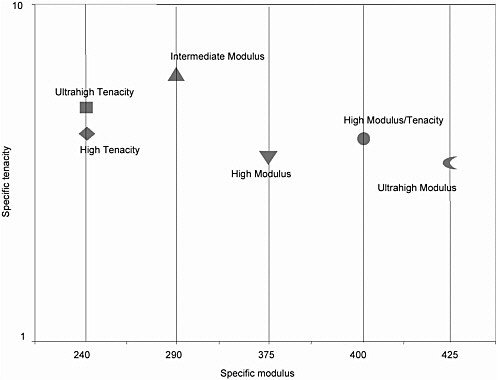

High-performance fibers are those that are engineered for specific uses that require exceptional strength, stiffness, heat resistance, or chemical resistance. There exist a wide variety of fibers with widely ranging properties; Figure 1.1 compares some of the different optimized categories. These fibers have generally higher tenacity1 and higher modulus2 than typical fibers. In the larger fiber market, such high-performance fibers are generally niche products, but some are produced in large quantities.

Glass is the oldest high-performance fiber, one that has been manufactured since the 1930s. Today's glass fibers can be found in such end uses as insulation, fire-resistant fabrics, and reinforcement for fiberglass composites such as bathtub enclosures and boats. In addition, continuous filaments of optical-quality glass have revolutionized the communications industry in recent years.

Carbon fiber is one of the most important high-performance fibers for military and aerospace applications. Carbon fiber is engineered for strength and stiffness, but variations differ in electrical conductivity, thermal, and chemical properties. The primary factors governing the physical properties are the degree of carbonization (or the carbon content, usually greater than 92 percent by weight), the orientation of the layered carbon planes, and the degree of crystallization.

Commercial carbon fibers are made by extrusion of some organic precursor material into filaments, followed by a carbonization process to convert the filaments into carbon. Different precursors and carbonization processes are used depending on the desired product properties. Precursor fibers can be specially purified rayon, pitch, or acrylics. The precursor fiber may also be converted into fabric form, which is then carbonized to produce the end product.

High-performance organic fibers have also become very important in recent years. Aramids are among the best known of the high-performance, synthetic, organic fibers. Closely related to the nylons, aramids are polyamides derived from aromatic acids and amines. Because of the stability of the aromatic rings and the added strength of the amide linkages, aramids exhibit higher tensile strength and thermal resistance than the aliphatic polyamides (nylons). The para-aramids (p-aramids, based on terephthalic acid and p-phenylenediamine, or p-aminobenzoic acid, exhibit higher strength and thermal resistance than those with linkages in the meta positions of the benzene ring. The greater degree of conjugation and more linear geometry of the para linkages, combined with the greater chain orientation derived from this linearity, are primarily responsible for the increased strength. The high impact resistance of the para-aramids makes them popular for “bullet-proof” body armor. For many less demanding applications, aramids may be blended with other fibers.

CARBON FIBERS

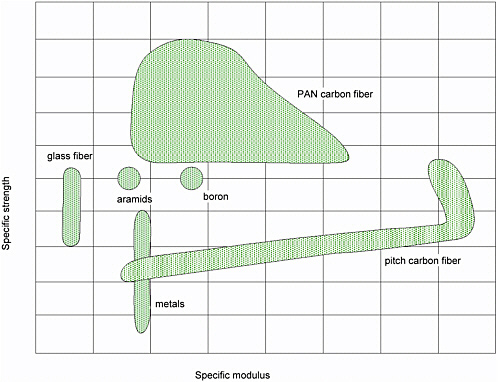

In the 1950s, it was recognized that materials that combine light weight, high strength, and high stiffness are needed to produce ultralightweight structures.3 Carbon fibers were developed to fill this need. Carbon fibers are typically produced by high-temperature processing of one of three types of precursor fibers: polyacrylonitrile (PAN), pitch, or rayon. Depending upon the type of precursor and processing method, the finished carbon fiber has somewhat different properties. Figure 1.2 compares some of the properties of pitch-based and PAN-based carbon fibers. Typically, PAN-based fibers have a higher specific strength and lower specific modulus than fibers made from pitch or rayon; pitch-based fibers have lower electrical resistivity and higher thermal conductivity. In general, PAN-based fibers are less expensive than pitch-based or rayon-based carbon fibers.

FIGURE 1.1 Relative properties for the different categories of high-performance fibers.

Carbon fibers generally are delivered in "tows," or bundles of fibers. These are found in two forms based on the starting precursor: special acrylic fiber (SAF) or textile tow. Textile tow as referred to here is a modified form of an acrylic fiber used in the textile and carpet industry. The world capacity is around 5 billion pounds. It is made as a large-tow material, with 120k to 320k (k = 1,000) filaments that may be split into smaller tows of around 36k. In most cases, a crimp is applied to allow easier handling of the tow. The textile tow is most often piddled into a box containing 300 to 1,000 pounds for shipping. The crimp is needed to keep the piled fiber together in tows.

The SAF tow, conversely, is manufactured solely for conversion to carbon fiber. It can be a compound similar to a textile tow, but it is made on a special spinning line. The filament count ranges from 3k to 24k or larger if required by a specific manufacturing process, such as pultrusion. This fiber is normally provided on a spool without crimp or twist. The conversion process for the two materials is the same except for the feed end and the take-up end of the line. It is more difficult to maintain a uniform tension on the textile tow precursor, which results in the large tow producing a slightly lower tensile strength and greater variability when compared to SAF materials.

PAN-Based Carbon Fiber

More than 90 percent of all commercial carbon fibers are produced by the thermal conversion of PAN precursor fibers. PAN-based carbon fibers are produced in three distinctly separate process steps: polymerization and wet spinning, stabilization, and carbonization.

The precursor used to form PAN-based carbon fibers is a binary copolymer of acrylonitrile with 6 to 9 percent of an acid comonomer.4 Although PAN fibers can be produced by either wet- or dry-spinning processes, wet spinning is used to produce nearly all commercial precursor fibers. The solution used in a wet-spinning process normally consists of from 10 to 30 percent by weight of PAN (or PAN copolymer) dissolved in a polar solvent. This solution is first filtered and then extruded through a thin plate containing thousands of capillaries—termed a spinneret. As the PAN solution is forced through the spinneret capillaries, the shear field tends to orient the solidifying polymeric structure parallel to the direction of flow.

FIGURE 1.2 Generalized specific modulus versus specific strength for several high-performance fibers (carbon, aramid) compared with lower-performing materials (glass, metals). DATA SOURCES: T. Baumeister, 1985. Marks' Standard Handbook for Mechanical Engineers, 8th Edition; J.E. Shigley, 1977, Mechanical Engineering Design, 3rd Edition; BP Amoco and Toray product literature.

As the solution exits the spinneret, it enters a coagulation bath where the copolymer precipitates into filament form. The filaments are made up of a finer structure, termed "fibrils," which run parallel to the filament axis. Various processing parameters, such as coagulation bath temperature, solvent concentration, and degree of stretch, can influence the fibrillar structure and its orientation within the as-spun PAN fiber. In other words, wet spinning yields a precursor fiber in which the PAN molecules are organized into fibrils that, in turn, are generally oriented parallel to the fiber axis. The bundle of filaments (referred to as a tow) is then washed to remove excess solvent and stretched to enhance molecular orientation. This step is essential for producing a final carbon fiber with adequate strength and modulus. Like most polymeric fiber processes, stretching does not greatly increase the crystallinity, which is a maximum of 50 percent, or the molecular order within the PAN fiber; rather, it enhances the axial orientation. This fibrillar network appears to be the precursor of the graphene network that develops during final heat treatment.

The PAN precursor fiber is converted to a carbon fiber in two separate process steps. In the first step, the fiber is heated in air to cross-link the structure. This renders the fiber infusible and inhibits relaxation of the structure during the final heat treatment step. In this step, termed carbonization, a standard-modulus fiber is heated in an inert environment to temperatures approaching 1400°C; higher-modulus fibers may be processed up to 2600°C. This step drives off most of the non-carbon elements, creating a carbon fiber. Since the PAN precursor is approximately 67 percent carbon, it is not surprising that the overall process conversion efficiency for PAN-based fibers (pounds of carbon fiber per pound of precursor fiber) ranges from 50 to 60 percent.

PAN-based precursor fibers continue to be produced using fundamental technology developed in the 1960s. Since then, fiber properties have improved significantly. Tensile strengths have more than doubled, from 2.8 GPa (400 kpsi) to more than 5.5 GPa (800 kpsi), and fiber with 290 GPa (42 Mpsi) has

been introduced.5 Until the 1980s, special acrylic fiber (SAF) precursor was used for nearly all PAN-based carbon fibers. This precursor fiber is produced in tow sizes of 3,000, 6,000, and 12,000 filaments and is normally supplied on spools without applying a crimp or twist. However, the emergence of non-defense, non-aerospace markets increased the demand for fibers with acceptable properties at a lower price. This led, in part, to the introduction in the early 1990s of large PAN staple tows as precursor material that contains up to 320,000 individual filaments. These large staple tows, originally developed for the textile industry, must be crimped in order to be handled effectively, but this allows the manufacturer to increase the throughput of fiber, resulting in a lower-cost product. However, the defects inserted by crimping, as well as the difficulty in maintaining uniform tension, small oxygen concentration gradients, and a uniform temperature profile, result in carbon fibers from the large textile tows having slightly lower mean strength and greater strength and stiffness variability compared to SAF-based materials.

Pitch-Based Carbon Fiber

Like PAN-based carbon fibers, the peculiarities of pitch-based fibers are the direct result of the precursor and the process used to convert it to fiber form. In this case, the precursor is mesophase pitch, a liquid crystalline material consisting of large polynuclear aromatic hydrocarbons derived from petroleum or coal. The first commercial mesophase precursors were produced by Union Carbide using a thermal polymerization process.6 The precursors were prepared by thermally polymerizing (using an inert gas sparge) a highly aromatic isotropic pitch feed at temperatures of 400 to 410°C for as long as 40 hours. The shear forces during extrusion and subsequent drawing produce a filament with high molecular orientation in the direction of the fiber axis. This orientation is maintained during oxidation and high-temperature carbonization. Carbon fiber can be produced in this way with a variety of strength and flexibility characteristics.

Mitsubishi Gas Chemical Company commercialized a process that uses a strong Lewis acid catalyst (hydrogen fluorene-boron fluorene, HF-BF3) to catalyze a pure chemical feed, such as naphthalene or methylnaphthalene, to a 100 percent mesophase product. The use of HF-BF3 has been shown to greatly reduce the molecular weight distribution of the mesophase product compared to that produced by thermal polymerization.7

ConocoPhillips also developed a process for producing a mesophase carbon fiber precursor.8 The extraction step removed the smaller disordering molecules and concentrated the higher-molecular-weight material. The higher-molecular-weight fraction was then converted to 100 percent mesophase by multiple, brief, heat treatment steps. The final product consisted of a high-molecular-weight mesophase containing a small fraction of solvent that effectively served as a plasticizer.

The mesophase products resulting from these three processes differ considerably; for example, each process yields a product with a different molecular weight distribution (the averages range from 800 to 1,200 daltons) and a different concentration of aliphatic side chains on the individual mesophase molecules. Consequently, their viscosity characteristics differ and their rate of stabilization differs as well. Nevertheless, all of these mesophase products reach a viscosity of approximately 200 pascal-seconds, well below their degradation temperature, allowing them to be melt-spun into fiber form. Also, although somewhat irregular, all of the individual mesophase molecules are disk-like in shape.

In the melt-spinning process, the solid feed is melted and forced through a spinneret. As the molten precursor exits these holes, it is simultaneously quenched by the surrounding atmosphere and drawn down by the take-up device, forming solid fibers. At first glance, this would appear to be a relatively simple process; however, the results are extremely sensitive to small changes in process conditions. Under typical process conditions, the tensile stress on mesophase fibers is about 20 percent

of that required to break the fiber.9 (In comparison, during melt spinning the tensile stress developed within a nylon fiber is less than 1 percent of the breaking strength of the filament.) This greater tensile stress in the mesophase fibers is a direct result of two peculiarities of mesophase: its highly temperature-dependent viscosity and the brittle nature of as-spun mesophase fibers.

Because their viscosity is highly temperature dependent, mesophase pitch fibers draw down and cool very quickly during fiber formation. In fact, at typical melt-spinning conditions, mesophase fibers are already 100°C below their glass transition temperature by the time they are 2 cm from the spinneret. As a result, they can break easily during spinning and are extremely difficult to handle before they are carbonized. Although the rheology of mesophase makes control of the melt-spinning process more difficult, its liquid crystalline nature gives this precursor structural advantages compared to polymeric precursors such as PAN.

The pitch precursor fiber is converted to a carbon fiber in two separate process steps. Like PAN precursor fibers, the fiber is initially heated in air to cross-link the structure. This renders the fiber infusible and inhibits relaxation of the structure during the final heat treatment step. However, the pitch fiber (unlike the PAN fiber) is extremely weak at this stage, which makes it difficult, if not impossible, to pull it through the oxidation oven (the technique used in PAN-based carbon fiber process). This problem has led to alternate oven designs and advanced fiber-handling techniques.

In the final heat treatment step—termed carbonization—the fiber is heated in an inert atmosphere to temperatures as high as 3000°C. This drives off most of the non-carbon elements, creating a highly oriented carbon fiber with truly graphitic crystallinity. Since the mesophase precursor is approximately 90 percent carbon, the overall process conversion efficiency for pitch-based fibers (pounds of carbon fiber per pound of precursor fiber) can be much greater than PAN-based carbon fibers. However, the brittle nature of pitch fibers leads to increased breakage during processing, often lowering the actual process conversion.

Since the first development of mesophase precursors, researchers have recognized that melt-spun mesophase fibers can develop remarkably high elastic moduli. This is a direct result of the transverse microstructure and axial molecular orientation created as the liquid crystalline precursor flows through a capillary and then is extended during fiber formation. Unless relaxation occurs during thermosetting, the transverse microstructure and axial orientation are merely perfected during carbonization. The transverse microstructural texture of early commercial mesophase carbon fibers was either radial or flat layer. Thus, in the transverse direction the graphene layer planes fan out from the center of the fiber, and in the axial direction the layer planes tend to align parallel to the fiber axis.

Mesophase pitch-based carbon fibers with radial and flat-layer transverse textures readily develop three-dimensional crystallinity. Although this structure makes these pitch-based carbon fibers more flaw sensitive than PAN-based fibers with their more random, filament structure, it gives them superior lattice-dependent properties (modulus and thermal conductivity).

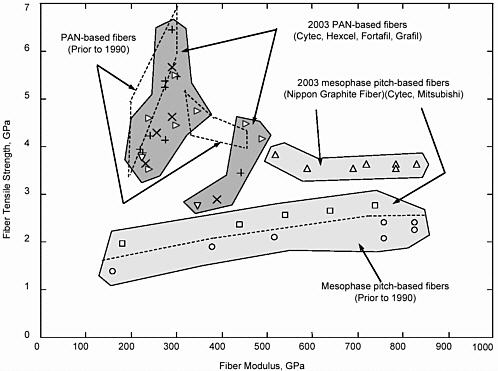

Figure 1.3 shows that prior to 1990, PAN-based carbon fibers were characteristically high strength but low modulus, whereas pitch-based carbon fibers were high modulus but low strength. Since then, manufacturers have discovered that they can disrupt flow during extrusion and create mesophase precursor fibers with random transverse textures. This disrupted texture mimics the filament texture of PAN-based fibers by reducing flaw sensitivity. This, in addition to developing purer mesophase precursors, has allowed the introduction of new varieties of pitch-based carbon fibers with improved tensile strengths.

Similarly, manufacturers such as Cytec have begun using improved mesophase precursors and linearizing the transverse texture during extrusion to create new varieties of pitch-based carbon fibers with thermal conductivities that are at least three times that of copper.10 Most agree that these highly ordered textures can be produced only by using a liquid crystalline precursor. Thus, this new product may represent the natural niche for mesophase pitch-based carbon fibers.

Rayon-Based Carbon Fibers

Rayon was the original precursor for carbon fibers. Like PAN, rayon precursor fibers are solution spun, then stabilized and carbonized to form carbon fibers. High tension is often applied during the final step (termed stress graphitization) to increase the modulus and strength of rayon-based carbon fiber. The solution spinning process gives rayon-based carbon fibers a crenulated cross section, a peculiarity that appears to improve the performance of carbon-carbon composites. Stress graphitization and the low carbon content of the precursor account for the high cost of this type of carbon fiber.

FIGURE 1.3 Improvement of the mechanical properties of commercial PAN-based and mesophase pitch-based carbon fibers from the period prior to 1990 to 2003. DATA SOURCES: Historic and current corporate product literature.

Rayon-based carbon fibers are used predominantly for ablative applications such as reentry vehicle nosetips, heat shields, and solid-rocket motor nozzles and exit cones. These applications require high thermal resistance but relatively low strength. The tensile strengths of these fibers vary from 345 to 690 MPa (50 to 100 kpsi) and the tensile moduli range from 20 to 55 GPa (3 to 8 Mpsi). Because of their relatively low tensile strength and high cost, rayon-based carbon fibers have been largely supplanted by PAN-based carbon fibers.11

Microstructure-Dependent Properties of Carbon Fibers

Figure 1.3 shows the trade-off between tensile strength and modulus for each class of fibers and illustrates the improvements in properties of commercial PAN-based and pitch-based carbon fibers achieved during the 1990s. The reason for the significant differences in modulus and strength lies in the structure of the fibers. X-ray studies prove that PAN-based carbon fibers have no long-range, three-dimensional order.12 Instead, PAN-based carbon fibers contain extensively folded and interlinked turbostratic layers of carbon with interlayer spacings considerably larger than that of graphite. As a result, PAN-based carbon fibers have a low degree of graphitization. The turbostratic layers in PAN-based carbon fibers appear to follow the original fibrillar structure of the PAN precursor fiber. Although the turbostratic layers within these filaments tend to be oriented parallel to the fiber axis, they are not highly aligned. In contrast, pitch-based fibers are composed of highly oriented graphene sheets parallel to the fiber axis. Transverse to the fiber axis the sheets can be arranged radially, randomly, or in a flat-layer structure. Pitch-based fibers have a larger crystallite size as well.

Thus, pitch-based fibers have a higher modulus because of the high degree of orientation in the fibers compared to PAN-based fibers. Pitch-based fibers have lower strength because the high degree of graphitization also leads to larger crystallites. Carbon fibers fail due to the failure of internal defects in the form of these crystallites. The smaller a crystallite is, the less likely its failure is to cause catastrophic failure in the fiber.

Recent work indicates that the intercrystalline and intracrystalline disorder characteristics of PAN fibers are also responsible for the superior compressive strength of this type of carbon fiber. Thus, the same fibrillar morphology that disrupts the transverse structure of PAN-based carbon fibers and gives them a higher tensile strength than pitch-based fibers also gives PAN-based fibers superior compressive properties. In other words, polymeric precursor fibers, such as PAN fibers, offer natural advantages when compression properties are critical. Developing superior compressive properties in pitch-based carbon fibers could be much more difficult.

As Figure 1.3 shows, the tensile strengths of pitch-based carbon fibers improved significantly during the 1990s, whereas the strengths of PAN-based fibers, although higher than those of pitch-based fibers, remained relatively constant for two reasons. The obvious reason is that the lower strength of early pitch-based fibers offered more opportunity for improvement. However, the major reason is that pitch-based carbon fiber producers have developed better mesophase pitch precursors and learned how to control the molecular structure of the precursor during fiber formation. The results have been improved properties and potentially lower production costs.

Nevertheless, the natural application of mesophase pitch-based fibers is not in high-strength applications, but in those requiring high thermal conductivity. This is because linearizing the pitch fiber’s transverse structure to produce high thermal conductivity (approximately 100 times greater than PAN-based fibers) is easier than disrupting the structure enough to significantly increase the tensile strength. Furthermore, pitch-based carbon fibers are generally capable of achieving higher moduli compared to PAN-based fibers, making them attractive for stiffness-critical applications such as certain spacecraft components. Thus, for the foreseeable future, it is likely that PAN-based fibers will dominate applications where strength is critical, and pitch-based fibers will dominate applications where heat transfer or stiffness is important.

HIGH-PERFORMANCE ORGANIC FIBERS

The precise definition of high-performance organic fibers is controversial. High-performance functionalities may include high strength, high stiffness, high toughness, damage tolerance, durability, dimensional stability, and flame resistance. Often, more than one of these properties is required in a single fiber. High strength and stiffness require almost perfectly oriented polymer molecules and a fully extended polymer chain. Although this has been recognized since the 1930s, the breakthrough in producing a highly oriented aramid fiber did not occur until the late 1960s and early 1970s when it was discovered that nematic solutions of poly(p-benzamide) and poly(p-phenylene terephthalamide) could be processed into fibers with a highly oriented, extended chain configuration.13

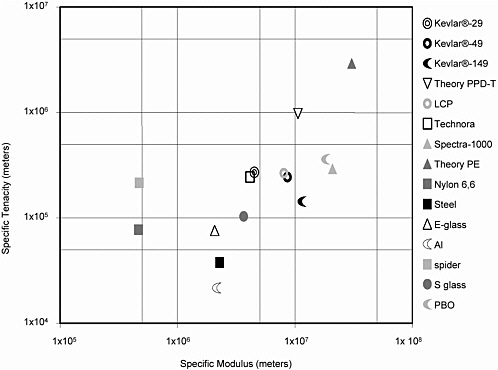

Commercial high-performance organic fibers first became available with the introduction of a meta-aramid (m-aramid) fiber, Nomex, in the second half of the 1960s. Since that time, several classes of fibers have been commercialized. High-strength p-aramid fibers were introduced in the early 1970s, followed by liquid crystalline polyesters (LCPs), high-strength polyethylene, and most recently, the introduction of poly(p-phenylene-2,6-benzobisoxazole), or PBO. A new fiber M5® has entered late development stages. Table 1.1 summarizes properties of existing commercial organic fibers, while Figure 1.4 compares the properties of these fibers with those of other materials. Both strength and stiffness are expressed as specific values and are corrected for density.

meta-Aramids

meta-Aramid fibers (especially with 100 percent aromatic content) offer very high temperature stability. Homopolymers in this class of materials exhibit a glass transition temperature of 275°C and a melting temperature of 420°C, very close to the decomposition temperature. The high aromatic content is also responsible for excellent performance in flame, leading to an intumescent char with adequate mechanical properties to provide for additional thermal insulation. The thermal stability and fire resistance characteristics of m-aramid fibers make them attractive for application such as protective apparel and hot gas filtration.

FIGURE 1.4 Specific tenacity versus specific modulus for several advanced organic fibers. DATA SOURCE: Composites Design. Available at http://www.carb.com/carbon_comp.html. Accessed September 2004.

These fibers are now also being marketed in paper form, making them attractive for structural applications. m-Aramid-based paper can be saturated with a matrix (e.g., epoxy, phenolic) resin to form composite boards, or it can be converted into honeycomb structures, which find applications in the aerospace, electrical, and electronic industries. For example, Nomex products are used in protective apparel, hot gas filtration, automotive hoses, electrical insulation, aircraft parts, and sporting goods.

para-Aramids

This class of materials has several products differing in the specific chemistries used. The first commercial product (Kevlar) is based on p-(phenylene terephthalamide), which continues to represent the largest global volume. The same chemistry underlies the second-largest-volume product, Twaron. Due to the rigidity of this material it forms anisotropic solutions in its solvent, sulfuric acid. The air-gap spinning process converts the solution into a highly ordered, highly crystalline fiber. This higher rigidity translates into better thermal properties (dimensional stability). Several p-aramid copolymers have been evaluated in the past. As copolymers, they are noncrystalline and can be processed by spinning from organic solvents containing salts with orientation, and thus properties, developed by fiber drawing. Technora represents the only firm that has reached a small commercial scale in the West. Russian scientists had structured their p-aramids (SVM, Armos, Rusar) on a rather expensive monomer diaminophenylbenzimidazole and its copolymers with p-phenylenediamine. This technology while producing slightly better mechanical properties, results in a very expensive fiber (monomer cost, very low productivity spinning processes, and very large energy consumption). Many of these products still do not meet Western standards as far as quality and uniformity are concerned.

p-Aramids, such as Kevlar fibers, are used in thermal-resistant clothing, protective vests and helmets, composites, asbestos replacement, reinforcement for tire and mechanical rubber goods, ropes and cables, and sporting goods.

TABLE 1.1 Mechanical Properties of Some Fibers, Including Projections for M5®

|

Fiber |

Strength (σ) (GPa) |

Failure Strain (ε) (%) |

Modulus (E) (GPa) |

(U*)1/3a (m/s) |

|

PBOb |

5.20 |

3.10 |

169 |

813 |

|

Spectra 1000 |

2.57 |

3.50 |

120 |

801 |

|

600-den.c Kevlar KM2 |

3.40 |

3.55 |

82.6 |

682 |

|

850-den. Kevlar KM2 |

3.34 |

3.80 |

73.7 |

681 |

|

840-den. Kevlar 129 |

3.24 |

3.25 |

99.1 |

672 |

|

1,500-den. Kevlar 29 |

2.90 |

3.38 |

74.4 |

625 |

|

200-den. Kevlar 29 |

2.97 |

2.95 |

91.1 |

624 |

|

1,000-den. Kevlar 29 |

2.87 |

3.25 |

78.8 |

621 |

|

1,140-den. Kevlar 49 |

3.04 |

1.20 |

120 |

612 |

|

Carbon fiber |

3.80 |

1.76 |

227 |

593 |

|

E-glass |

3.50 |

4.7 |

74.0 |

559 |

|

Nylon |

0.91 |

N/A |

9.57 |

482 |

|

M5 conservative |

8.50 |

2.5 |

300 |

940 |

|

M5 goal |

9.50 |

2.5 |

450 |

1,043 |

|

M5 (2001 sample) |

3.96 |

1.4 |

271 |

583 |

|

a U* is the product of fiber specific toughness and strain wave velocity such that the dimensional analysis indicates that V50 velocity of an armor system scales with (U*)1/3. b poly(p-phenylene-2,6-benzobisoxazole) c denier SOURCE: P.M. Cunniff, M.A. Auerbach, E. Vetter, and D.J Sikkema. 2004. High performance “M5” fiber for ballistics/structural composites. Paper AO-04 at the 23rd Army Science Conference. Available at http://www.asc2004.com/23rdASC/manuscripts/A/AO-04.PDF. Accessed September 2004. |

||||

Liquid Crystalline Polyesters

Development of LCPs followed commercialization of p-aramids. Like the p-aramids, LCPs are based on aromatic structures. Finding a balance between processibility and properties has been a constant challenge for this technology. To achieve melt processibility into fibers, various copolymer compositions have been used and materials have to be spun at low molecular weight. To obtain adequate physical properties, a slow heat treatment process has to be applied. While the strength and stiffness of fibers in this class are of the same order of magnitude as aramids, their thermal properties are somewhat lower. LCP fibers are used in applications such as tow ropes, cargo tie-downs, tethers, and cables.

High-Strength Polyethylene

Ultrahigh-molecular-weight polyethylene (UHMWPE) offers the first demonstration that the fully extended chain configuration and resultant high-performance properties can be achieved in flexible polymers. The shaping process is relatively complex. Gel spinning at low polymer concentration is followed by extraction of the solvent and the critical drawing step. The very high draw ratio achievable in this system is responsible for the development of high strength and stiffness of the fiber.14 However, the low melting point of this material limits its applicability at elevated temperatures, and its nonpolar nature decreases its adhesion to resins.

TABLE 1.2 Physical Properties of Some Organic Commercial Fibers

|

|

p-Aramid |

UHMWPEa |

PBOb |

|

Yarn tenacity, gpdc |

18-27 |

30-38 |

40-42 |

|

Density, g/cm3 |

1.44 |

0.97 |

1.56 |

|

Moisture regain, percent |

1-7 |

0 |

0.6-2 |

|

Heat resistance, °C |

550 |

150 |

650 |

|

LOId, percent |

29 |

20 |

68 |

|

a ultrahigh-molecular-weight polyethylene b poly(p-phenylene-2,6-benzobisoxazole) c grams per denier d limiting oxygen index SOURCE: Chemical Economics Handbook. 1999. Menlo Park, Calif.: SRI Consulting. |

|||

Spectra fibers are used in numerous applications, including ballistic vests, helmets, armored vehicles, sailcloth, fishing lines, marine cordage and lifting slings, and cut-resistant gloves and safety apparel. Ballistic applications have become important for this material since the development of unidirectional composite laminated structures, which allow for diminishing blunt trauma.

PBO

The invention and development of high-performance fibers based on aramids led to an understanding of principles underlying this area of science and technology. The natural extension was to move to even more rigid polymers. The development of PBO and PBZT (polyphenylene benzobisthiazole) compositions by Wolf and others, with the continuing work of Dow Chemical Company and finally Toyobo, culminated in commercialization of Zylon fiber in the second half of the 1990s. Toyobo expects to increase the capacity of this fiber to 500 megatonnes by 2007.

As for other rigid polymers, the shaping of this fiber is through processing of anisotropic solutions, but this time from polyphosphoric acid. Higher rigidity than aramids and lack of amide bond translate to improved thermal properties and improved mechanical properties (Table 1.2). Expensive ingredients and highly aggressive solvent combined with the extremely high viscosities of these solutions result in significantly higher prices versus aramid fibers.

While the advantages previously cited are generically associated with very rigid polymers, some disadvantages are due to specific chemistries. Poorer ultraviolet (UV) stability and adhesion to resins limit its use in some applications. More recently, there have been reports of some possible problems with hydrolytic stability. This issue is important enough to warrant careful following of future developments.

M5® Fiber

Although the fibers previously discussed are produced at very different volumes, the entire set is considered commercial. The committee has given significant consideration to one fiber, which is in the precommercial stage of development, M5 (poly{2,6-diimidazo[4,5-b:4’,5’-e]pyridinylene-1,4-(2,5-dihydroxy)phenylene}), or PIPD.15 The fiber is being developed by Magellan Systems International, which expects to start up a pilot plant in 2005, with a commercial facility likely in 2007. M5 is a rigid polymer spun from an anisotropic solution; its properties are given in Table 1.3. While the tensile properties realized are similar to those of PBO, the fiber offers potential for significant improvement of compressive properties above those of any of the commercial organic fibers. The compressive strength of the fiber ranges from two to four times that of other organic fibers. This is attributed to the higher level of hydrogen bonding, which improves its structural integrity. Such properties offer potential for combining both structural and ballistic requirements of systems. This is further strengthened by a very good adhesion to resins (imidazole group) and, thus, improved performance in composite applications. The differences

|

15 |

Advanced Lightweight Engineering. 1998. M5 materials research. Available at http://www.lightweight.nl/akzo.htm. Accessed March 2005. |

TABLE 1.3 Properties of M5® Fiber

|

Fiber |

PBO Zylona |

M5 1999-2000 |

M5 April 2002 |

M5 Targets |

|

Tenacity, GPa |

5.5 |

4 |

5.3 |

9.5 |

|

Elongation, % |

2.5 |

1.2 |

1.5 |

>2 |

|

Elastic modulus, GPa |

280 |

330 |

350 |

>400 |

|

Compressive stressb, GPa |

0.42 |

1.6 |

1.7 |

2 |

|

Compressive strainb, % |

0.15 |

0.4 |

0.5 |

0.5 |

|

σmax compressive, GPac |

0.8 |

3 |

3 |

4 |

|

Density, g/mL |

1.56 |

1.7 |

1.7 |

1.7 |

|

Water regain, % |

0.6 |

2.0 |

2.0 |

2 |

|

Onset of thermal degradation in air, °C |

550 |

530 |

530 |

530 |

|

LOId, %O2 |

68 |

>50 |

|

>50 |

|

Electrical conduction |

− − |

− − |

|

− − |

|

Impact resistance, composites |

++ |

++ |

|

+++ |

|

Damage tolerance |

N/A |

++ |

|

+++ |

|

Weaving properties |

+/− |

+ |

|

+ |

|

Stability in UV radiation |

− − |

++ |

|

++ |

|

a Toyobo data, available at http://www.toyobo.co.jp/ b Measured in unidirectional composite test bars, three-point bending test, onset of deflection for the organic fiber reinforced composites; catastrophic failure for the carbon composites. M5 composites proved to be able to carry much higher loads than the load at onset of deflection and to absorb much energy at high strains in a mode analogous to the flow behavior in steel being damaged. c In a bending test on unidirectional composites, the maximum apparent stress on the outermost fibers (neglecting change of shape, at the compression side, by ductile response at high deformation). d limiting oxygen index SOURCE: Magellan Systems International. |

||||

between oxazole and imidazole rings results in better UV stability and potential for improved hydrolytic stability.

The high-performance fibers that are currently available have been in production for decades, and the technology is now mature. Their properties depend sensitively on microstructure and in some cases are approaching theoretical limits. Thus, for commercial fibers only incremental improvements in fiber properties are expected in the near future. The new fiber M5, which is in precommercial development, offers a potential for a unique combination of properties that promises a unique set of applications.

Raw Materials for Organic Fiber Development

The development of advanced organic fibers is a complex and expensive endeavor. It usually requires the establishment of a raw materials base in addition to processes for polymerization and shaping. Of the fibers discussed in this report, only UHMWPE did not require the introduction of a new raw material. Raw materials and their development represent a significant portion of the cost associated with the development of advanced fibers. For example, PBO fibers are extremely expensive because of the expensive ingredients required to produce them, despite the fact that the development of these fibers began approximately 20 years ago. The need to develop an ingredients base is also essential to successful commercialization of M5 fiber.

Properties and Design Needs

It is well established that the thermal properties of organic fibers are controlled by the chemistry and morphology of the fibers and that little can be done to improve these properties within a given chemical composition. Therefore, it is important to choose a material that can maintain its properties over the expected operating temperature range. On the other hand, the mechanical properties of all materials in Table 1.1 can be tailored to meet the needs of specific applications. A good example of such tailoring

can be found in the aramid family, where production technology has been developed to alter the balance between the elongation and modulus of fibers to meet the demands of applications that are driven by fatigue (e.g., reinforcement of rubber) as well as polymer matrix composite applications, where stiffness is a controlling factor. These two extremes cover the range of elongation and modulus described in Table 1.2.

Current estimates of theoretical strength and stiffness for p-aramids and polyethylene are shown in Figure 1.4. The elastic modulus realized in commercially available fibers approaches 80 percent of the theoretical values for these fibers. Thus, a dramatic increase in the stiffness of these organic fibers is not expected. For higher stiffness, one would have to look at the fibers described in Table 1.3. Estimating the theoretical strength of a material is more difficult and less reliable than estimating the theoretical modulus. However, there is general agreement that the strength values attained for organic fibers are further from theoretical values than are the modulus values. For example, demonstrated values of strength are estimated at 30 to 50 percent of theoretical expectations. Thus, it is reasonable to expect incremental improvements in strengths of existing commercial fibers over the next several years.