2

Fibers in Composites

Although fibers have many of the desired properties that are needed for military, aerospace, and commercial applications, they generally act as part of a composite system. The matrix protects the fibers from the environment, and both the matrix and the interface transmit external stresses to the fibers. Therefore, the overall properties of composite structures depend on the properties of the individual components (fibers, matrix, and the interfacial region connecting them) as well as the processes and methods used to fabricate the finished structures. We are only beginning to understand how fiber properties can be translated into superior properties of the overall composite.

MATRIX RESINS

Although the fibers play a dominant role in determining the stiffness and strength of a composite, the choice of the matrix will determine maximum service temperature, viable processing approaches, and long-term durability. Matrix materials can be divided into two broad categories: thermosetting and thermoplastic. Thermosetting materials are characterized by having a low-viscosity, reactive, starting oligomer that cures (reacts) to form an insoluble, infusible network.1 The cure temperature and time influence many matrix properties. An incomplete cure affects mechanical properties, swelling behavior in solvents, and moisture susceptibility. On the other hand, an incomplete cure (increased distance between cross-links) may improve flexibility and toughness.

Thermoplastics are linear or slightly branched polymers of relatively high molecular weight. They are of significant interest because they can be remelted, thus easing repair in the field, and because they are melt-processable. The use of thermoplastics also allows other composite processing techniques such as injection molding of short fiber composites and extrusion of long fiber composites. Thermoplastic polymer morphology may be either amorphous (disordered) or semicrystalline (partially ordered). The semicrystalline and even liquid crystalline morphologies can impart superior solvent resistance to the overall matrix resin. Semicrystalline polymers display a melting temperature for the crystalline regions as well as a glass transition, and processing must be performed in excess of the melting temperature. Amorphous thermoplastics, on the other hand, are processed above the glass transition temperature. A possible limitation for some applications of semicrystalline polymers concerns the morphological changes that may occur during processing or in the service environment, particularly due to the application of heat or exposure to solvent while under stress. These changes in the crystalline structure and/or content may cause changes in the overall composite properties and are highly undesirable. Likewise, control of morphology during processing is critical to achieving the desired matrix properties such as toughness and chemical resistance.

Various resins exist today that provide a wide range of service temperatures. For example, epoxies, vinyl esters, and polyesters will meet the relatively low-service-temperature requirements (160 to

180°F) of the Army’s Future Combat System ground and tactical vehicles as well as Navy ship systems. Vacuum-assisted resin transfer molding (VARTM) has been identified as an affordable process and is used to fabricate structural armor for ground vehicle hull structures containing integral ceramic composites, as well as large-scale topside ship and hull structures. Desirable resin attributes for these applications include relatively low viscosity at room temperature to enable room-temperature infusion as well as the lowest cure temperature possible to meet hot-wet glass transition temperature requirements. Resins meeting these needs enable low-temperature tooling materials to be used, providing significant cost savings. However, the performance demands on these composites remain high. For example, structural armor requires resins that have high elongation to failure to survive ballistic impact, but current VARTM resins fall short of the service temperature requirement. Higher-cure-temperature resins meet service temperature requirements, but ballistic performance is degraded. Additional research in resins is needed to balance processing ease and performance for these important Department of Defense (DoD) applications.

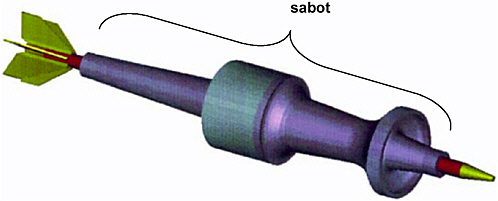

FIGURE 2.1 The M829A2 sabot, which stabilizes the trajectory of the munition early in flight, was designed with graphite fiber-reinforced epoxy material that resulted in a 30 percent weight reduction in the sabot component. This weight reduction enabled an increased muzzle velocity of approximately 60 meters per second, significantly increasing the range and armor penetration capability of the projectile. The M829A2 accounts for one of the largest uses of composite materials in DoD. DATA SOURCE: Army Research Laboratory. Description available at http://www.arl.army.mil/wmrd/Tech/AntiArmor-both.pdf. Accessed March 2005.

Higher-temperature performance can be achieved (250 to 400°F) with epoxies, bismaleimides, and polyimide resins using traditional prepreg or towpreg2 and autoclave, filament winding, and fiber placement process technologies. Formulations of these materials have been developed to enable the use of resin transfer molding (RTM) processes for smaller-scale components.

The need for more damage-tolerant aerospace structures has led to the development of toughened thermosets and thermoplastic matrices that are resistant to impact damage and delamination growth. High matrix toughness has also been proven to be a key property in ballistic performance of tank munitions such as the M829A2 (toughened thermoset) and the M829A3 (polyetherimide thermoplastic) carbon fiber sabots (see Figure 2.1). The capability of electron-beam (e-beam) processing for non-autoclave cure of large-scale structures such as rocket motors and fuel tanks has been demonstrated. Improvements in resin toughness and interface optimization for e-beam resins are needed to improve properties and resistance to microcracking.

The role of the matrix in the long-term durability of a composite is a critical issue. Durability is affected by the state of the resin, which may undergo physical aging or environmental degradation, as well as changes in the interaction with the fiber at the interface. In addition, the stress state within the matrix due to processing, thermal and fatigue cycling, and other mechanical loads is critical to the long-term performance. Microcracking is one of the first damage modes observed in the matrix phase. Microcracking can initiate fiber fracture, interface debonding, and delamination that can limit the lifetime of the component. An even more severe case occurs when microcracks provide pathways for accelerated

degradation by the environment, for example, moisture ingress into honeycomb structures followed by freeze-thaw or elevated temperature thermal oxidation that can dramatically reduce mechanical properties. Advances in modeling the failure mechanisms and the development of new microcracking-resistant composites are needed.

FIBER-MATRIX INTERFACE

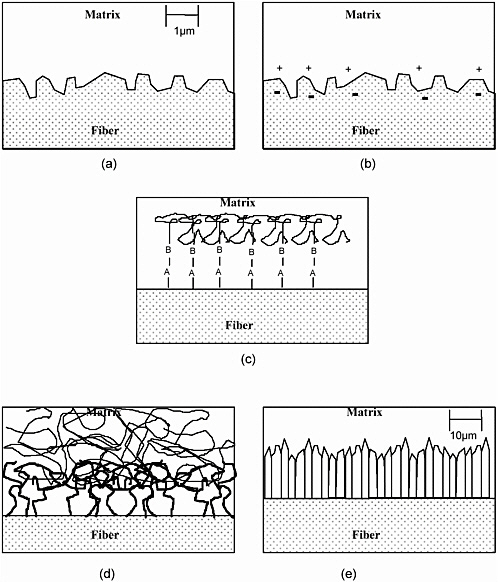

The interface can be defined as the three-dimensional boundary between the fiber and matrix. It is critical to controlling composite properties because fiber-matrix interaction occurs through the interface. This interaction can occur through three mechanisms: mechanical coupling or micromechanical interlocking of the two materials, physical coupling such as van der Waals or electrostatic interaction, and covalent bonding (by way of a coupling agent) between the fiber and the matrix (see Figure 2.2 for some examples). These interactions create an interphase region—which is a three-dimensional region near the fiber with properties different from either the fiber or the matrix. For example, in thermosets, the interphase can form due to preferential absorption of either the curing agent or the resin at the fiber surface, leading to a region of higher or lower cross-linking and in thermoplastics, the interphase can be a region of transcrystallinity. For ease of discussion, the term "interface" is used to describe both the two-dimensional interface and the three-dimensional interphase.

FIGURE 2.2 Schematic depictions of various interactions at the fiber-matrix interface: (a) micromechanical interlocking, (b) permanent or induced dipole interactions, (c) chemical bonding, (d) chain entanglement, and (e) transcrystallinity.

To control the properties of the interface, surface treatments are often used on the fiber. Surface treatment generally involves surface oxidation of the fiber, either electrolytically or using gas or liquid chemicals. This provides some functionality on the fiber surface by increasing the surface area and the number of reactive groups on the surface and can improve adhesion in terms of mechanical interlocking and physiochemical interactions. The surface can then be coated with different organic and/or inorganic compounds to promote further interaction. A sizing may also be used to protect the fiber from process damage. Some sizings, such as organosilanes, may also be referred to as coupling agents, as these couple the active fiber surface to a nonpolar resin, predominantly through increased oxygen functionality. Other types of materials, including oligomer polyimides and polyamides, can be grafted to the surface in order to promote adhesion through other mechanisms, such as transcrystallization.

The chemistry of such treatments is proprietary, but they may perform a variety of functions, as follows:3

-

Protect the fiber surface during shipment and handling and subsequent processing,

-

Bind the fibers together (which makes processing of prepreg and weaves easier),

-

Reduce static electricity, and

-

Improve the chemical bonding to the matrix.

While it is often assumed that the sizing improves the coupling between the fiber and the matrix, several studies have shown that sizing can create a brittle interface region.4,5 Thus, sizings can be detrimental to bulk mechanical properties. In addition, sizings and other fiber treatments can lead to variability in the interface properties. This variability in interface properties can originate from several sources, including how evenly the sizing or coating covers the fiber; variability in wetting of the matrix that can create poorly bonded regions; variation in surface roughness of the fiber; and matrix variability.

The interface is crucial in controlling composite properties because load is transferred from the matrix to the fiber through the interface and deformation of the interface region (debonding or yielding) is critical in absorbing energy during failure.6,7 In high-performance fiber-reinforced polymer matrix composites, the fiber has a much higher modulus than the matrix. Therefore, when the composite is loaded to a given strain, the fiber will carry more load than the matrix. This load must be transferred from the matrix to the fiber through the interface region.

The interface is particularly relevant in applications requiring damage tolerance and durability in aggressive environments,8 because the interface controls damage development. When a fiber breaks, the neighboring fibers are subjected to a stress concentration.9-11 The location of the next break due to the stress overload is dictated by the interface properties. Figure 2.2 shows some different types of interface bonding. Changing interface properties can have a dramatic effect on overload behavior. For the perfectly elastic case (from a strong interface), the stress concentration factor is large and narrow. This will lead to in-plane fiber failure and prevent energy absorbing mechanisms such as debonding and fiber pullout. Thus, brittle failure will occur. If the interface is compliant or debonding occurs, the stress concentration factor will decrease significantly and the region of overload in the neighboring fibers will be larger. This type of interface will lead to a brush-like fracture surface and higher ductility and toughness because of the debonding and fiber pullout that occur. In organic fibers, the fiber breaks are more diffuse and even the initial stress concentration is lower and more diffuse.12 However, similar failure mechanisms apply. Thus a relatively weak interface contributes to high toughness for both organic and carbon fiber

composites, but it can result in a significant reduction in strength. This combination has proven to be successful in composite armor.13

What is clear from prior work is that control over the interface is important not only for protecting fibers, but for controlling properties. In light of this, some areas of interface development are important for improving composite performance.

There are some specialized needs for better sizings for carbon fiber. This includes sizings for vinyl ester resins and, in particular, sizings for carbon-vinyl ester composites of interest to the Navy for topside ship structures. Vinyl ester resins offer significant processing advantage and affordability over bisphenol-based resins. Recent work has shown that thermoplastic sizings of polyhydroxyethers lead to improved processing, improved fiber durability during handling, and improved composite properties in a vinyl ester-based resin.14 Therefore, it is clear that there are sizing materials that will lead to improved composite properties. Further work in this area is warranted.

Higher-temperature sizings are required that do not degrade in use. As the use temperatures for composites continue to increase, the stability of the interface at high temperature is required to maintain composite performance. Although some work has been done in this area—namely the use of LaRC PETI-5, a phenylethynyl-terminated imide oligomer, as well as some proprietary resins—this is an area in need of some focus.15,16

The role of the interface in controlling properties is still not fully understood, particularly as it applies to lifetime prediction, and a better understanding is needed. The interface has a significant effect on fatigue behavior, creep, and environmental stability, yet direct inclusion of interface properties into lifetime models is still under development.17 To complicate matters further, the interface variability is also a relevant parameter and can lead, for example, to enhanced toughness.18 One opportunity for improving the cost-effectiveness of composites is tighter design criteria, and this requires—in addition to an understanding of matrix and fiber effects—a thorough understanding of the role of interface variability on composite properties.

The vision for the future should be one in which the fiber properties, matrix properties, and interface properties as well as the stochastic aspects are included in lifetime prediction models that have the confidence of composite designers. In a very ideal future, their performance is monitored in service conditions and data are added back into computer-aided design and computer-aided engineering (CAD/CAE) models to validate and improve their predictive properties.19-21

|

13 |

M. Tanoglu, S.H. McKnight, G.R. Palmese, and J.W. Gillespie, Jr. 2001. Effects of glass fiber sizings on the strength and energy absorption of the fiber/matrix interphase under high loading rates. Composites Science and Technology 61(2):205-220. |

|

14 |

J.J. Lesko, J.S.Riffle, N.S. Broyles, N. Verghese, and S.V. Davis. 2000. Composites of thermosetting resins and carbon fibers having polyhydroxyether sizings. U.S. Patent No. 6,020,063. |

|

15 |

D. Cho and L.T. Drzal. 2000. Characterization, properties, and processing of LaRC PETI-5 as a high-temperature sizing material. II. Thermal characterization. J. Appl. Poly. Sci. 75(10)1278-1287. |

|

16 |

D. Cho and L.T. Drzal. 2000. Characterization, properties, and processing of LaRC PETI-5 as a high-temperature sizing material. I. FTIR studies on imidization and phenylethynyl end-group reaction behavior. J. Appl. Poly. Sci. 76(2)190-200. |

|

17 |

N.S. Broyles, K.N.E. Verghese, S.V. Davis, H. Li, R.M. Davis, J.J. Lesko, and J.S. Riffle, 1998. Fatigue performance of carbon fiber-vinyl ester composites: The effect of two dissimilar polymeric sizings agents. Polymer (39):3417-3424. |

|

18 |

T.U. Marston, A.G. Atkins, and D.K Felbeck. 1974. Interfacial fracture energy and the toughness of composites. J. Materials Science 9:447-455. |

|

19 |

Advanced Insertion of Materials (AIM) Program. 2004. Available at http://www.darpa.mil/dso/thrust/matdev/aim/index.html. Accessed March 2005. |

|

20 |

G.L. Hahn, K.M. Nelson, and C.R. Saff. 2002. Accelerated Insertion of Materials–Composites. Presented at the 34th International Society for the Advancement of Material and Process Engineering (SAMPE) Technical Conference. |

|

21 |

Materials Engineering for Affordable New Systems (MEANS) Program. Available at http://www.afosr.af.mil/pdfs/Hartley/MEANSInfo.pdf. Accessed March 2005. |

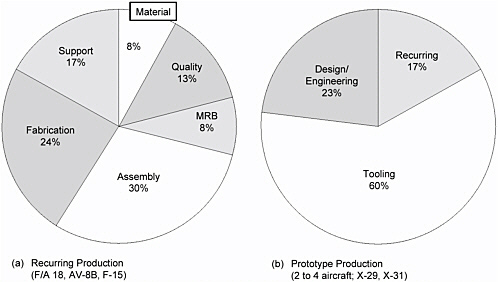

FIGURE 2.3 Manufacturing costs are substantially higher than materials costs for aerospace composite structures.

COMPOSITE SYSTEMS

Future DoD systems must become more affordable. The service life of several key tactical aircraft can be measured in decades. For example, the Navy's F/A-18A/B became operational in 1983. The F/A-18C/D was first delivered in September 1987. The F-15 entered the Air Force inventory in 1975; all of these are still in service today The EA-6B, a 1970s-era electronic warfare platform, is slated to remain operational through 2015. Consequently, acquisition and life-cycle costs will have to decrease for future systems. Composite structures offer the potential to last longer and require minimal maintenance.

Future DoD applications will also require a new class of multifunctional materials. The Future Combat System, next-generation ship structures, and unmanned aircraft are some examples of programs where lightweight structure, ballistics, shock attenuation, radar signature reduction, power generation, and embedded sensors and actuators will be needed. Composites provide the opportunity to integrate these functions into a single material system. Affordable processes and robust design methods will be needed to develop and optimize these multifunctional composite materials.

Processing

The acquisition costs for a composite part are comprised of numerous factors including design aspects as well as the costs of raw materials, processing, tooling, assembly, and inspection. Manufacturing and assembly costs have traditionally been significant cost drivers and are typically greater than material costs in aircraft structures (see Figure 2.3). The selection of the process dictates the capital equipment required. The influence of capital equipment costs on final part cost is strongly dependent on the number of parts produced. There are many opportunities for DoD to reduce the cost per part based on the processing methods selected.

Autoclave and automated tow placement (ATP) of prepreg materials and resin transfer molding are commonly used for aerospace applications where performance is the key driver. The robotic ATP process has been shown to dramatically lower costs and improve quality and performance over hand-layup techniques. Manufacturing and assembly costs remain the most significant cost drivers for these applications. Pultrusion, VARTM, and e-beam curing are being evaluated against requirements as alternative lower-cost processes.

One opportunity for reducing composite processing costs is through e-beam curing of resins at room temperature. E-beam curing is a nonthermal process that uses high-energy electrons and/or X-rays to initiate polymerization and cross-linking reactions at controlled rates. The advantages are numerous

and include the following:

-

Curing at ambient temperatures, which reduces dimensional changes and internal stresses in the finished product,

-

Lower-cost tooling,

-

Reduced curing times and continuous operation, and

-

Improved resin stability (resins do not have to be stored at low temperature and have extended shelf-life).

The primary challenges facing the current state-of-the-art e-beam resins are the lack of toughness, hot-wet operating temperature limits, consolidation rheology, cost of e-beam equipment, and the general perception of safety concerns. Long-term durability of composites may require optimization of the fiber-matrix interface that forms during e-beam processing.

The needs of the Navy ship, Army ground vehicle, and infrastructure applications are quite different from the needs of aerospace applications. For many of these applications, material costs can become a cost driver. Non-autoclave processes and low-temperature-cure resins are required for large-scale composite structures such as vehicle hulls, ship masts and other topside structures, as well as for bridges, docks, and piers. Affordability is more critical for these applications, with desired costs in the range of $10 to $30 per pound of fabricated structure. The emergence of lower-cost commercial carbon fiber in the range of $6 to $10/lb is now allowing DoD to consider carbon fiber as a cost-competitive alternative to S2-glass. The higher specific properties offered by carbon fiber may even be cost competitive with certain E-glass applications.

Fiber-reinforced polymer matrix composites are becoming increasingly important in many applications such as bridges and highways, off-shore oil platforms, and piers for both new construction and rehabilitation of existing infrastructure.22,23 In many applications, such as steel girder and concrete rehabilitation, commercially available carbon fiber is the material of choice. In these applications, the service temperatures are relatively low and the matrix must be low cost (polyester, vinyl ester, or phenolic), cure at room temperature, and be available in large volume. In rehabilitation applications, low-cost prepreg and hand-layup, pultrusion of reinforcing strips and secondary bonding, filament winding, and VARTM are examples of typical fabrication processes. For bridge decks, pultrusion and VARTM of polyester and vinyl ester have been demonstrated successfully using glass fiber preforms.24 Substitution of commercially available carbon fiber for glass in these stiffness-critical applications is a possibility, but the durability of the bond between the carbon fiber and the vinyl ester matrix must be improved. The issue of long-term durability is especially important in these applications, which have lifetime requirements of 30 to 75 years. DoD has a huge infrastructure of piers and docks in need of rehabilitation and should leverage materials and process technologies being developed for civilian infrastructure applications.

A current trend across the industry is the assessment of VARTM to replace more costly processes. As mentioned earlier, ship, ground vehicle, and infrastructure applications currently use this processing technology. However, advancements in resin formulations to improve fire, smoke, and toxicity properties, while retaining the desirable attributes of low viscosity and room temperature cure, are needed. To meet the needs of aerospace, VARTM resins must not only be processible under vacuum pressure (RTM uses much higher positive pressure), but also deliver acceptable structural performance, including mechanical properties and geometric tolerances. Advancement in toughened VARTM resins is needed, and the new

class of low-viscosity cyclic thermoplastics that polymerize after infusion offers the potential for improved toughness.25

Cost studies conducted for the Composites Armored Vehicle Advanced Technology Demonstrator concluded that VARTM offers significant cost savings over the ATP process for multifunctional materials such as integral armor hull structure (hybrid construction consisting of signature layer, alumina ceramics, and polymer matrix composites) at a cost of $30 to $40 per pound.26 In addition, VARTM has been the process of choice for fabrication of large-scale ship prototype structures. VARTM processing of low-permeability carbon preforms for topside structures is in the early stages of development.

The VARTM process is also being evaluated critically for aerospace applications as an alternative to RTM. VARTM is a low-pressure process that offers reduced tooling costs. Fiber volume fractions and associated properties are lower than those of higher-pressure processes such as RTM and autoclave. Parts may have to be redesigned and may add weight. The process uses one-sided tooling, and strict control of geometry is not yet possible and may add to assembly costs. Advances in preform technologies may allow for improved properties and dimensional tolerances. Future studies should consider these cost-performance trade-offs.

Virtual manufacturing and simulation should play an increasingly important role for accelerated insertion of materials and processes into DoD systems. In the case of VARTM, advancements in intelligent processing will allow for risk and cost reduction but require advancements in three-dimensional flow simulation in porous media as well as models to predict input properties such as the permeability tensor as a function of fiber architecture, compaction, and distortion.

In summary, VARTM is being considered by all services as an affordable process. However, it is largely a manual process. Research in automation using simulation, sensing, and control systems should be pursued to advance this process from prototype to a production-ready process.

Translation of Fiber Properties to Composite Properties

Precisely how the distribution of individual fiber strengths affects the reliability of a composite structure containing billions of continuous fibers is an extremely important question. This issue was noted in the earlier discussion of large-tow strength distributions versus those from small tows. The effect of fiber property variability on design allowables for composite structures must be understood in order to take advantage of incremental improvements in small-tow SAF fibers to achieve weight reduction in legacy systems and to effectively use textile fiber processing that may offer significant cost savings. Although stiffness is important, certification of a detailed design will depend on an accurate strength analysis of the problem. Simply stated, if the individual fiber strength distribution is known, can one predict how this will be translated into a composite tow, then into a fabric consisting of many tows, then into a multilayer laminate, and finally into a composite structure?27 Verification of this approach remains to be done, but the ramifications, if it is successful, are very far reaching for aerospace, commercial, and DoD structural applications.

Precise control of fiber orientation is needed during processing to achieve full translation of the fiber properties into the composite. In high-modulus fibers such as carbon and organic fibers, a misorientation of only 5 degrees in a unidirectional material can cause a modulus drop of 15 to 25 percent (depending on the fiber volume loading) for a carbon-epoxy composite.28 Preimpregnated fabrics are also commonly used in many applications. These systems are typically two-dimensional weaves of fibers ranging from 1k to 24k in a variety of patterns that offer different ranges of properties in orthogonal directions (e.g., plain weave, 5-harness satin, 8-harness satin, etc.). In other applications, such as RTM and VARTM, the fiber tows are woven dry, placed in a tool, and impregnated with resin.

Preform technologies are advancing with an almost unlimited degree of freedom to orient fiber tows in three dimensions and weave them to near net shape. Advanced three-dimensional preforms offer increased stiffness and strength in the through-thickness direction (at the expense of in-plane properties), improved damage tolerance, and potential for improved ballistic performance for composite armor.

Mechanical property models exist for the prediction of thermoelastic properties of these various fiber architectures. However, the ability to predict damage evolution and long-term durability is not sufficiently robust and is currently dependent on expensive testing programs. Future research should be directed toward establishing reliable models to relate fiber, matrix, and interface properties, processing effects, and fiber architecture to damage mechanisms and life prediction.

FIBER QUALIFICATION COST ISSUES

Historically, the development of structural fibers has been driven by two competing factors: performance and cost. In general, fibers with higher strength and modulus are more expensive than fibers with more moderate properties. Early in the development of structural fibers, the selection of a fiber for a particular application—especially a military application—was driven primarily by performance requirements. With the emergence of non-aerospace, non-military applications, cost—given an acceptable level of performance—has become the driver for fiber selection. Cost has also become a major concern of DoD when making material selections for future military applications. Despite this concern about cost, however, DoD continues to require a high degree of fiber consistency. Demonstration of this consistency (by the fiber producer) drives up material costs.

There are several important factors controlling fiber cost: the cost of the raw material; processing costs; and—for military applications—the cost of qualifying a material for a given application, including the quality control and reporting that are required for fibers to meet military specifications. Commercially available fibers do not have this third cost and, as a result, are significantly cheaper.

It is important to recognize that material costs, and specifically fiber costs, are just one factor affecting the cost of a composite part. The recurring costs associated with composite processing, component assembly, and product inspection can be significant. In some applications, material costs are a small fraction of the total cost of the system. In addition, nonrecurring costs may be related to material qualification of the fiber, of the resin, and of the fiber and resin combination in the composite, at both the coupon and the structural levels.

The magnitudes of composite material and component qualification or certification efforts and costs vary widely and depend on many factors, including specific product requirements, the criticality of the application, and the degree to which human safety is involved. In military aircraft, for example, the process of design development, material qualification, process development, structural analysis, and testing can be extremely complex and costly due to mission criticality, the need for high reliability under extreme conditions, and survivability requirements. With increasingly stringent requirements and more sophisticated composite products, qualification and certification programs have become more and more complex over the years, and with this complexity has come increased cost. Therefore, if new materials have only marginal (though desirable) benefits compared to existing systems, end users may be unwilling to expend the resources necessary to qualify them if qualification costs remain at present levels. Conversely, for DoD to take advantage of incremental improvements in current fibers or lower-cost commercial fibers, more efficient approaches to material qualification will be needed.

COMPOSITES AS SYSTEMS

In the past, research on composites has been viewed as a collection of issues, such as fiber development, matrix studies, interfacial bonding, processing, and finally structural mechanics. Traditionally, matrices have been thought to protect the fibers. However, it is now understood that the matrix will influence the entirety of process-structure-property relationships for the composite system while leaving the fibers unchanged. Further, the properties and structure of the resin matrix are different when reinforced, and this presents a major challenge. Only recently has the industry matured to the point where the fiber, resin matrix, interface, and surface are routinely seen as a system.

With the development of computers capable of modeling structures at the molecular scale, the time is approaching when it will be possible to design the optimum composite for a given system performance and cost. This systems perspective will involve modeling the structure and the manufacturing processes

at various length scales to relate microstructural behavior to system performance. This modeling will include the placement of the reinforcing phase, the structure of the matrix phase, and even the degree of bonding at the interface. The methodology could be used to predict (and even control) the final structure of the composite. In other words, future engineers will not merely analyze the mechanics of the final product, but will apply a systems perspective and employ advanced modeling techniques to create reinforced structures that best meet given system requirements. This approach is the key to reduced cost and accelerated insertion of new materials into DoD systems.29-32

A systems approach is also crucial to understanding the stochastic aspects of composite failure, which is essential for improving the design criteria of these systems. Lack of knowledge in this regard can lead to excessive design safety margins that result in increased weight and cost and lower system performance. A better understanding of the effect of constituent variability on composite properties is crucial to taking advantage of fibers on the market today as well as future fibers, as is the development of micromechanical and continuum-based models that include the stochastic process for the prediction of composite behavior.

The transition to a systems approach is likely to occur gradually, with full implementation 10 or more years in the future. While this approach is evolving, researchers and material suppliers will continue to make incremental improvements in reinforcing fibers, matrix resins, and composite forms and processes.

|

29 |

G.L. Hahn, K.M. Nelson, and C.R. Saff. 2002. Accelerated Insertion of Materials—Composites. 34th International Society for the Advancement of Material and Process Engineering (SAMPE) Technical Conference. |

|

30 |

G. Havskjold, Materials and Manufacturing Directorate, Air Force Research Laboratory. 2000. Robust Design Computational System. AFRL-ML-WP-TR-2000-4093. April. |

|

31 |

National Research Council. 2004. Accelerating Technology Transition. Washington, D.C.: National Academies Press. |

|

32 |

Advanced Insertion of Materials (AIM) Program: Available at http://www.darpa.mil/dso/thrust/matdev/aim/index.html. Accessed March 2005. |