4

Transport and Fate

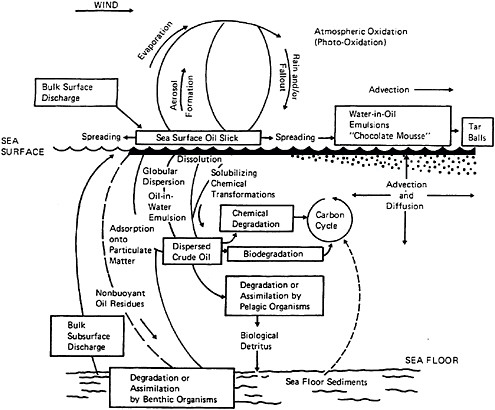

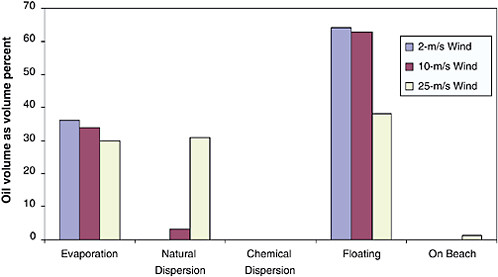

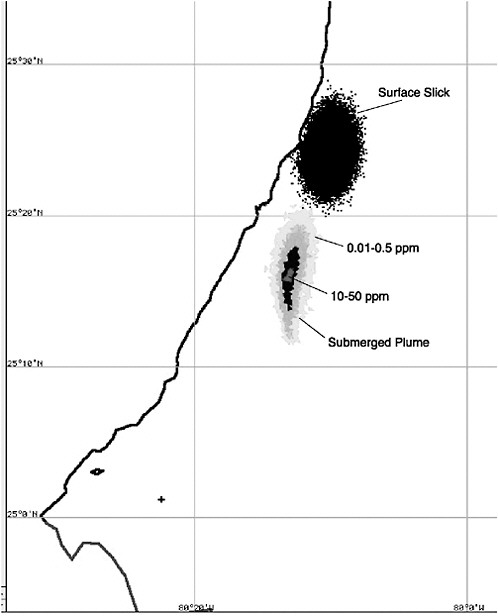

Spilled oil is transported, and its composition and character altered, by a variety of physical, chemical, and biological processes (Figure 4-1). Use of chemical dispersants changes the relative importance of these processes, affecting the fate of the oil, and altering subsequent ecological effects. Thus, it is important to understand the transport and fate of oil with and without dispersant use. A number of comprehensive studies have reviewed these mechanisms including Stolzenbach et al. (1977), Kerr and Barrientos (1979), Huang and Monastero (1982), Payne and McNabb (1984), Payne et al. (1984), Delvigne et al. (1986), Spaulding (1988), Lee et al. (1990), Payne et al. (1991a,b,c,d), Yapa and Shen (1994), ASCE (1996), Reed et al. (1999), Payne and French-McCay (2001), Payne and Driskell (2003), and NRC (1985, 1989, 2003). These mechanisms are reviewed briefly in the first two sections of this chapter, with a focus on how transport and fate influence the subsurface concentration of oil, and how the composition and concentration of surface and entrained oil droplets can be expected to vary with and without application of chemical dispersants. The latter portion of the chapter and Appendix E discuss how the mechanisms are integrated into computer oil spill models that simulate the fate of spilled oil, and how such models are used (or might be used) for purposes of pre-planning, emergency response, and natural resource damage assessment.

TRANSPORT PROCESSES

There are three major modes of transport for spilled oil or petroleum products discussed in the following subsections. The first deals with the

FIGURE 4-1 Major open-ocean oil fate and transport processes.

SOURCE: NRC, 1985.

surface transport of slicks, which is important because the shape, thickness, and location of a slick affect the ability to effectively apply dispersants. The second subsection deals with vertical transport, which is responsible for the initial dilution of dispersed oil. Finally, the last subsection deals with horizontal subsurface transport, which is responsible for the ultimate dilution of dispersed oil.

Surface Transport

Oil spilled directly on a calm water surface spreads radially by gravity and is resisted by inertia, viscosity, and surface tension until the slick reaches a thickness of ~0.1 mm. Fay (1969), Hoult (1972), and others have modeled this spreading under idealized conditions (e.g., instantaneous spill, no wind, no waves). Application of chemical dispersants can temporarily affect this spreading through the phenomenon of herding.

Additional spreading takes place because (1) oil is usually spilled over a period of time and into a moving current, (2) wind, waves, and non-uniform currents diffuse and break up the slick, and (3) droplets periodi-cally disperse and resurface, tending to stretch the plume. This last mechanism has been described by Johansen (1984) and Elliott et al. (1986) and may increase in significance when considering the fate of chemically dispersed oil.

Slick thicknesses were estimated during several well-documented oil spills, usually indirectly by dividing volume/area (Mackay and Chau, 1986; Lunel and Lewis, 1993a,b; Lewis et al., 1995a,b; Walker et al., 1995; Brandvik et al., 1996; Brown et al., 2000). These studies indicate that oil does not spread uniformly, but is irregular in shape and thickness—generally elongated in the direction of the wind and often composed of thick patches (>1 mm) and thinner sheens (<0.01 mm). S.L. Ross (1997) gives a general rule of thumb that 90 percent of an oil spill’s volume is contained in 10 percent of its area. Figure 2-5 (in Chapter 2) presents representative descriptions of the wide range of slick thicknesses typical of an oil slick along with an approximation of the estimated volume/unit area for the different thicknesses. The non-uniform characteristics of a slick can be included in models (e.g., Mackay et al., 1980a,b; Lehr et al., 1984), but such models are basically empirical.

Surface spreading has important implications for the operational effectiveness of dispersant application because dispersant delivery systems have finite encounter rates (area coated per unit time) and capacities (total volume of dispersant used; Gregory et al., 1999). As such, dispersants are most effective when they are applied as soon as possible (before the slick has had time to spread and break up), and with the benefit of airborne sensing to identify locations of maximum slick thickness. In particularly thick regions, it is not practical to treat the slicks with a single pass and lacking visual confirmation of dispersion, a multi-pass approach is often used (S.L. Ross, 1997; Lunel et al., 1997b).

Of additional concern is oil that is accidentally released from subsurface blowouts during offshore exploration or production. Here the oil will likely be mixed with substantial quantities of natural gas, which provides the major source of buoyancy. Masutani and Adams (2004) and Tang (2004) describe the spectrum of oil droplet sizes that can be expected as a function of dimensionless exit conditions. The combination of gas and oil forms a buoyant droplet/bubble plume that entrains seawater as it ascends toward the surface. A similar situation, but without the gas, would occur with the rupture of an underwater oil pipeline. Models to describe such plumes have been developed by Yapa and Zheng (1997; 1999) and Johansen (2000) among others. If the oil is released in shallow water (less than roughly 100 m), it will rise as a coherent plume, containing a mixture

of gas, oil, and water. Once the plume surfaces, the oil and water will spread radially in a surface layer (Fannelop and Sjoen, 1980). Because of the presence of water, the resulting oil slick will be significantly thinner than those produced by oil spilled directly on the surface. In deeper waters, ambient currents, and potentially density stratification, will cause the gas bubbles and larger oil droplets to separate from the remainder of the plume and ascend as individual (or small groups of) droplets and bubbles (Socolofsky and Adams, 2002). Because droplet rise velocity depends on diameter, the larger oil droplets will reach the surface sooner and closer to their source than the smaller droplets. This fractionation leads to a substantially longer (and thinner) plume than would be produced by a surface spill.

Work is being conducted both in the United States and abroad, to assess if and how to chemically disperse oil from a subsurface blowout. In many cases, it is impractical to apply dispersants at the surface because the slick is too thin. However, if the surface slick is subsequently concentrated by Langmuir circulation cells or other convergence mechanisms, dispersants can be applied to the thicker portions. In the absence of such surface convergence, the most effective method would be to apply dispersant within the well (down hole) before the oil can mix with seawater, but this may be difficult, so attention is being paid to schemes that dispense the dispersants directly into the plume. This should be done as close to the seafloor as possible to minimize dilution, and hence achieve the desired dispersant-to-oil ratio (DOR) without bearing the cost and potential environmental consequences of using excessive quantities of dispersant. Some initial concepts for dispersant application to blowouts can be found in Johansen and Carlsen (2002).

Slicks are advected downwind by a combination of wind and waves. Pure advection (without spreading) does not affect the concentration of oil or the effectiveness of dispersants, but it is important for understanding where an oil slick will end up. Many researchers have studied these processes from theoretical and empirical perspectives, and a rule of thumb is that slicks move at approximately 3 percent of the wind speed measured 10 m above the water surface (i.e., the “wind factor” is about 3 percent). For moderate to high sea states, approximately two-thirds of this transport can be attributed to Stokes drift (the fact that near-surface wave orbits in deep water waves do not follow exact circles, as linear theory would suggest, but exhibit a net transport in the direction of wave propagation). The remaining one-third represents the slick moving relative to the water directly underneath it (Lehr et al., 2002). Coriolis acceleration causes the slick to drift ~10–20 percent to the right of the wind in the northern hemisphere, but this effect is often omitted in transport models. Experimental observations support these conclusions, with some sugges-

tion that the wind factor and deflection angle decline with wind speed (Youssef and Spaulding, 1993).

Vertical Transport

Dispersion of a surface slick, whether caused naturally or through application of chemical dispersants, results in the formation of droplets that are entrained into the water column and transported with the subsurface currents. The importance of vertical transport is clearly seen by a simple calculation for illustrative purposes: a surface slick that is 0.1 mm thick and dispersed with an efficiency of 50 percent to an average depth of 5 m, will receive a dilution of 105, resulting in an immediate drop in concentration to ~10 ppm.

Dispersion results in a distribution of droplet sizes with the smaller droplets being transported deeper and longer. If Q is the mass of oil entrained per unit area of the slick, and d is a characteristic droplet diameter, it is clear that the goal of chemical dispersants is to increase Q and decrease d. And while it is obvious that use of chemical dispersants increases the mass of oil within the water column, it may or may not increase the concentration of oil, because the greater dilution achieved by smaller droplets may offset the increase in mass. This question will be revisited at the end of this subsection.

The initial depth of droplet penetration, hi, is proportional to the wave height, hw, with many studies showing that ![]() (Nilsen et al., 1985; Delvigne and Sweeney, 1988). [Variables used in this chapter are summarized in Table 4-1.] Subsequent vertical transport depends on a balance between vertical diffusion (characterized by a vertical diffusivity Ez, with dimensions of L2/T) and buoyant rise (characterized by a terminal velocity ws). Vertical diffusivity transports droplets deeper into the water column, while buoyancy makes them return to the surface.

(Nilsen et al., 1985; Delvigne and Sweeney, 1988). [Variables used in this chapter are summarized in Table 4-1.] Subsequent vertical transport depends on a balance between vertical diffusion (characterized by a vertical diffusivity Ez, with dimensions of L2/T) and buoyant rise (characterized by a terminal velocity ws). Vertical diffusivity transports droplets deeper into the water column, while buoyancy makes them return to the surface.

Vertical diffusivity generally ranges between 1 and 200 cm2/s depending on a number of environmental factors. Near the surface, diffusivity is a strong function of wave height, and a number of investigators report Ez ~ hw2 (Koh and Fan, 1970). Because wave energy decreases with depth, Ez decreases below the surface. For example, Ichiye (1967) suggests that, in the absence of density stratification,

(4-1)

where L is wave length, T is wave period, and hw is taken as the significant wave height. Other formulations suggest a stronger cut-off with depth, attributed to the depth of Langmuir circulation (windrows), which is caused by the interaction of wind and waves (Leibovich and Lumley, 1982;

TABLE 4-1 Variables Used in Scaling Arguments in Chapter 4

|

Variable |

Definition |

Dimension |

|

Cdiss |

Oil concentration in dissolved phase |

ML−3 |

|

Cdrop |

Oil concentration in droplet phase |

ML−3 |

|

d |

Droplet diameter |

L |

|

Ez |

Vertical diffusion coefficient |

L2T−1 |

|

Er |

Horizontal (radial) diffusion coefficient |

L2T−1 |

|

hchar |

Characteristic depth of oil droplets |

L |

|

hi |

Initial depth of oil droplets |

L |

|

hw |

Wave height |

L |

|

L |

Wave length |

L |

|

Q |

Mass of oil entrained per unit area of slick |

ML−2 |

|

T |

Wave period |

T |

|

ws |

Droplet slip (rise) velocity |

LT−1 |

|

λz |

Vertical velocity gradient |

T−1 |

|

σr |

Radial standard deviation of spreading patch |

L |

|

ν |

Kinematic viscosity |

L2T−1 |

|

P1 |

Water density |

ML−3 |

and references in Champ, 2000). Diffusivity also decreases under the influence of vertical density stratification, and a host of formulations suggest that Ez is inversely proportional to the vertical density gradient (Koh and Fan, 1970; Broecker and Peng, 1982). A thermocline is a region of maximum density gradient suggesting small Ez, and if stratification is strong enough, a “diffusion floor” may be assumed. Some models assume that the depth of this floor is simply proportional to wave height.

Unless there is significant interaction with suspended particulates, most oil droplets will be positively buoyant and will rise toward the surface. Those with a diameter less than about 300 mm will obey Stokes Law and rise with a velocity of:

(4-2)

where ν is the kinematic viscosity of water, Δρ/ρ is the normalized density difference between seawater and oil, g is gravitational acceleration, and d is droplet diameter. The quadratic dependence of rise velocity on droplet diameter suggests that the smallest droplets will rise very slowly, accentuating dispersion. For example, with Δρ/ρ = 0.13 (for an oil with a density of 0.89 mg/mL and seawater at 1.025 mg/mL), ν = 10−2 cm2/s and g = 981 cm/s2, droplets with a diameter of 300µm will rise with a velocity of 0.6 cm/s while droplets with a diameter of 30 µm will rise with a velocity of 0.006 cm/s. The former will take less than 8 minutes to rise a height

of 3 m, while the latter will take over 12 hours. And, because of vertical diffusion, the smaller droplets will most likely reside deeper in the water column, further prolonging their ascent.

The above discussion can be used to estimate how the concentration of droplet and dissolved phase oil might depend on dispersion efficiency and vertical transport mechanisms. The concentration of oil in the droplet phase is proportional to the mass of oil entrained per unit area, Q, divided by a characteristic depth of droplet penetration, hchar, or

(4-3a)

The rate of dissolution of dispersed oil per volume of seawater is proportional to the number of droplets per volume (~Q/hchard3) times the surface area of a drop (~d2). Hence the concentration of dissolved oil

(4-3b)

A simple model for the characteristic depth is hchar ~ Ez/ws, where Ez ~ hw2 (independent of depth), and ws ~ d2 (from Eq. 4-2). The wave flume experiments by Delvigne and Sweeney (1988) suggest that Q ~ hw1.14, while d is independent of hw. Thus, from Eq. (4-3a), cdrop ~ d2/hw0.86, and from Eq. (4-3b), cdiss ~ d/hw0.86. With this “model” both droplet and dissolved phase concentrations decrease with wave height and increase with droplet diameter. In reality, diffusivity is not likely to be constant with depth so an alternative model assumes a characteristic depth that is proportional to wave height, or hchar ~ hw. In this case, equations (4-3a) and (4-3b) give cdrop ~ hw1.14 and cdiss ~ hw1.14/d. Here both droplet and dissolved phase concentrations increase with wave height and either decrease with, or are independent of, droplet diameter, i.e., quite different from the conclusions of the first model.

These arguments are qualitative, and more precise information should come from computer models that integrate multiple mechanisms in a quantitative manner as later discussed. But computer models are no better than our understanding of the individual mechanisms upon which they are based, and the uncertainty in even the direction of change noted above suggests we need better understanding of dispersant effectiveness (i.e., the dependence of Q and d on oil properties and environmental parameters), as well as better models of the vertical distribution of Ez, in order to accurately predict the concentrations of dispersed oil.

Horizontal Subsurface Transport

Subsurface advection of dispersed and dissolved phase oil by a uniform current affects the location of the oil, but does not, in itself, cause

additional mixing. However, mixing is produced when the currents are non-uniform, and this mixing is responsible for the ultimate dilution of the oil. Without horizontal mixing, and under sufficiently calm weather conditions, vertically dispersed oil droplets could all ultimately resurface given enough time.

Horizontal mixing consists of two fundamental processes. The first process is called scale-dependent diffusion and represents the fact that large eddies will advect a patch of marked fluid if the patch is smaller than the scale of the eddies, but mix and dilute the patch if it is larger than the eddies (Csanady, 1973). The second process is termed shear dispersion and results from the combination of velocity gradient(s) in combination with mixing (or other transport mechanism) in the direction of the gradient(s) (Fischer et al., 1979). The latter effect is enhanced with the use of chemical dispersants, because the smaller droplets that are produced are transported deeper, where they experience greater differences in horizontal velocity. Unfortunately, field measurements cannot always distinguish the two processes, and frequently their effects are combined.

Horizontal mixing is determined best using site-specific measurements, but as these are often not available, literature values should be used. Okubo (1971) summarizes a number of coastal tracer studies and shows that

(4-4)

where σr is a characteristic radius (standard deviation) of an equivalent circular tracer patch (cm) and t is time (sec). Other investigators report similar trends. Okubo’s data apply to patch sizes ranging from ~30 m to ~100 km, and more recent data suggest the approximate relationship applies to even larger scales (Ledwell et al., 1998). Simple relationships such as this are useful because dilution resulting from horizontal mixing is proportional to patch variance, σr2, and hence Eq. (4-4) can be used to directly compute changes in concentration due to horizontal mixing. Also, predictive models make use of horizontal diffusion coefficients (Er, with dimensions of L2/T) defined by the time rate of change of patch variance. For example, using Eq. (4-4)

(4-5)

For σr = 100 m, Er = 0.3 m2/s, while for σr = 1,000 m, Er = 5 m2/s. Note that these values of horizontal diffusivity are orders of magnitude larger than the corresponding vertical values (Ez) suggesting that horizontal mixing is much stronger than vertical mixing. However, horizontal mixing is also much less effective, because horizontal plume dimensions are much larger

(and hence horizontal concentration gradients are much smaller) than in the vertical.

It should also be recognized that different investigators define horizontal diffusion coefficients differently. For example, as implied above, some data used to determine mixing coefficients include the effects of vertical shear, while others do not. Also some analyses separate Er into separate components in the longitudinal and lateral direction (i.e., an Ex and Ey), and some analyses define an apparent diffusivity based on a cumulative, rather than instantaneous, change in σr2 (i.e., Era = σr2/4Δt). In order for a predictive model not to over or under account for mixing, care should be taken to define Er in the same way in the model that it was defined in the analysis of field measurements used to determine its value.

Horizontal mixing can be considered important to the dilution process when it has caused the patch concentration to be diluted by a significant amount. Again using Eq. (4-4), the time required for patch size to increase from σr to ![]() σr (a two-fold increase in dilution) is

σr (a two-fold increase in dilution) is

(4-6)

where Δtdouble is in sec, and σr is in cm. For example, Δt = 12 hours for σr = 1,000 m, and only about 1.7 hours for σr = 100 m. The fact that this time increases with σr suggests that horizontal mixing is more important for small spills, and that dispersants can be used more effectively when applied before substantial spreading has occurred (i.e., small σr). Of course, other factors affecting dispersant effectiveness are also time dependent. Tank studies, or small-scale field experiments, cannot be used to directly simulate horizontal mixing because the spills in such tests are too small, and there are additional artifacts due to the presence of walls.

While horizontal mixing data such as those compiled by Okubo (1971) usually include the effects of shear dispersion, it is interesting to consider this component separately and evaluate how it varies with sea state and dispersant effectiveness. One type of shear dispersion that was discussed previously involves larger droplets that become vertically entrained into the water column and later rise to the surface. Because the slick generally travels faster than the underlying water, the droplets will re-enter the slick at the “back-of-the-pack,” leading to a long tail. This effect can be especially important nearshore, where vertical circulation is more pronounced. Indeed, this effect has been proposed as the reason oil from the Braer spill off the Shetland Islands was observed to travel in the opposite direction of the surface current (Proctor et al., 1994; Ritchie and O’Sullivan, 1994; Spaulding et al., 1994).

Smaller droplets that are (nearly) permanently dispersed, and hence behave like water, are also affected by conventional shear dispersion. Con-

sider a parcel of marked seawater occupying a depth hchar. If there is a vertical gradient in the near-surface velocity of magnitude λz (dimensions of velocity per depth, or T−1), the patch will experience a top-to-bottom velocity difference of Δu = λzhchar. Following Taylor’s analysis of longitudinal dispersion (see Fischer et al., 1979), a shear dispersion coefficient Esd (part of Er) ~ (Δu)2hchar2/Ez ~ λz 2hchar4/Ez. Based on the previous discussion of hchar, Esd is expected to increase strongly with increasing wave height and decreasing droplet diameter, suggesting an increase in shear-induced mixing, and hence dilution of dispersed oil, as sea state and dispersant effectiveness increase.

The above discussion clearly implies that the vertical dimension needs to be included in modeling the transport of dispersed oil—not just to represent the concentration field, but also to properly represent the velocity field (i.e., a model needs to realistically represent the vertical gradients in velocity). Normally this requires a 3-D model. In shallow water, dispersed oil may become distributed over the entire water depth. However, even in this case, vertical gradients in velocity are important for dispersing the oil and these gradients should be accounted for, either by explicitly simulating the vertical shear in a 3-D model, or by computing horizontal shear dispersion coefficients for use in a 2-D (depth-integrated) model. In deeper locations where the dispersed oil is not uniformly distributed over depth, the oil will tend to be concentrated in a relatively thin horizontal layer near the surface. As with models of thermal or salinity stratification, this horizontal layering can present numerical challenges associated with resolving strong near-surface gradients. Resolution can be enhanced by employing models with stretched coordinates, such as σ-coordinates (that use a constant number of vertical grid cells regardless of water depth) or γ-coordinates (that, in addition, provide unequal grid spacing, allowing greater resolution near the surface). However, care should be taken to minimize or counteract the spurious vertical mixing that may result with such models due to the fact that the “horizontal” grid lines are not parallel with the stratification (Huang and Spaulding, 1995).

FATE AND WEATHERING

In addition to spreading and drift as discussed earlier, there are numerous processes that affect the ultimate fate of spilled oil or petroleum products (Figure 4-1). These include evaporation, dissolution, dispersion of whole oil droplets into the water column (entrainment), interaction of dissolved and dispersed components with suspended particulate material (SPM), photooxidation, biodegradation, uptake by organisms, water-in-oil emulsification (mousse formation), and stranding on shorelines (NRC, 1985, 1989, 2003).

Chapter 3 summarized the changes in rheological properties (viscosity, interfacial tension, density, etc.) that begin to occur immediately after oil is spilled. The changes in physical properties caused by water-in-oil emulsification are particularly important because they affect how spilled oil is physically dispersed (entrained) into the water column (with and without dispersants), the ability of oil spill skimmers to recover oil from the sea surface, the ability of pumps to transfer the collected oil, and the volume of collected material that requires storage and disposal.

In the following sections, the chemical and physical changes to oil on the water surface (generally thought of as weathering) caused by evaporation, photooxidation, and water-in-oil emulsification are discussed, with particular emphasis given to the latter (including identification of the chemical constituents within oil that largely control emulsion behavior) because of its importance in controlling dispersant effectiveness. After that, the fate of physically and chemically entrained oil droplets in the water column is considered. In evaluating the fate of entrained oil droplets, the primary focus is on biodegradation of dispersant-treated oil and the interaction of both physically entrained and dispersant-treated oil droplets with suspended particulate material.

Surface Oil Evaporation Weathering

Evaporation of lower-molecular-weight volatile components from a surface slick is important for dispersant applications because it can indirectly affect the formation of stable water-in-oil emulsions through the precipitation of asphaltenes and resins that help to stabilize the emulsion (Fingas and Fieldhouse, 2003). As the solvent components are evaporated from the slick, these higher-molecular-weight components can precipitate to coat entrained water droplets in the emulsion and inhibit water-water droplet coalescence and phase separation (Sjoblom et al., 2003). In addition, the evaporative loss of mono-aromatic components (benzene, toluene, xylenes, etc.) and two- and three-ring polynuclear aromatic hydrocarbons (PAH) and their alkyl-substituted homologues can significantly reduce the toxicity of the oil and the concomitant water-soluble fractions generated after physical or chemically enhanced entrainment of oil droplets into the water column.

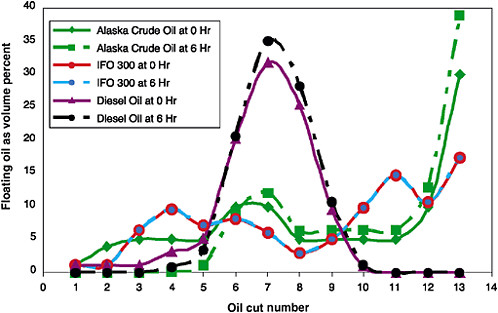

Evaporation is the single most important and rapid of all weathering processes (McAuliffe, 1989), and it can account for the loss of 20–50 percent of many crude oils, 75 percent or more of refined petroleum products, and 10 percent or less of residual fuel oils (Butler, 1975; Butler et al., 1976; NRC, 1985; 2003). Most of the early studies on evaporation focused on the loss of individual hydrocarbon components as a function of their vapor pressures and other factors such as temperature, wind speed, and

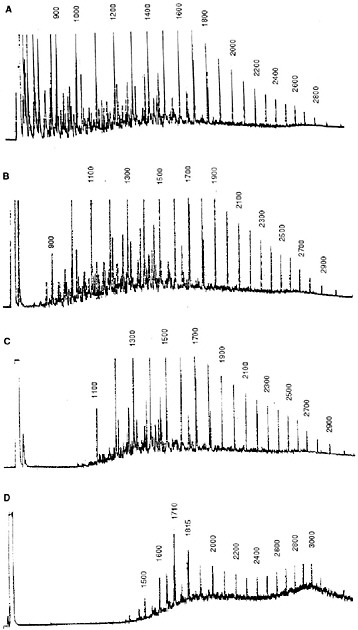

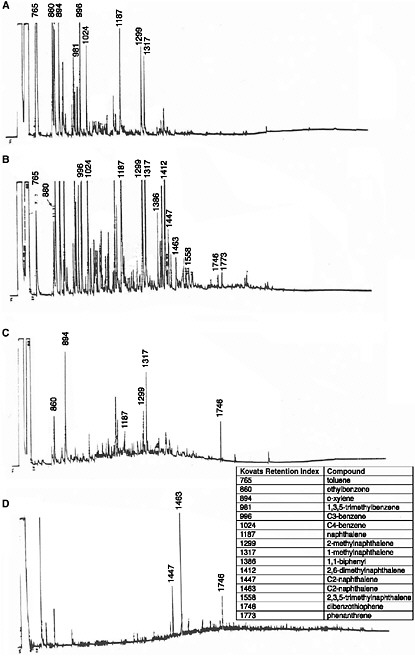

sea state. Traditionally, loss of lower-molecular-weight hydrocarbons as a function of time and weathering conditions was tracked by gas chromatographic (GC) analyses of the residual components in the oil. For example, Figure 4-2 shows time-series chromatograms from Prudhoe Bay crude oil weathered in subarctic summer conditions in the flow-through wave-tank systems described in Chapter 3. Note that all compounds with volatilities (vapor pressures) greater than n-C11 (b.p. < 400° F, roughly 204° C) were lost within the first twelve days. (In these and subsequent chromatographic profiles, individual peaks are identified by relative GC retention time indices (i.e., n-C11 = 1100, n-C12 = 1200, etc., with a peak eluting midway between n-C11 and n-C12 = 1150) as defined by Kovats (1958). Between the late spring and the following summer and fall period, there was little additional evaporative loss. There was, however, a significant change in the straight-chain/branched-chain hydrocarbon ratios due to selective bacterial degradation of the n-alkanes in preference to the isoprenoid components (Figure 4-2D).

While compound-specific and gravimetric pan-evaporation studies were useful in characterizing rates of evaporation processes and served as input for early model development (Mackay and Matsugu, 1973; Mackay and Leinonen, 1977; Mackay et al., 1980a,b; 1982; Payne et al., 1983), in the mid 1980s the concept of using True Boiling Point (TBP) distillation data (available for all crude oils and refined products) to generate “pseudocomponents” for modeling evaporation behavior was introduced by Payne et al. (1984). The pseudo-component approach allowed a mass balance to be calculated for the oil remaining after evaporation (something that couldn’t be done on a compound-specific basis), and it was validated for Alaska North Slope crude oil by National Oceanic and Atmospheric Administration (NOAA) and Minerals Management Service (MMS) sponsored laboratory and outdoor wave-tank studies and ultimately comparison of model predictions with measured oil weathering behavior after the T/V Exxon Valdez oil spill (Payne et al., 1991a).

Many oil weathering observations have been reported at accidental spills (Mackay, 1993; Thomas and Lunel, 1993; Harris, 1997; Law et al., 1997; Lunel et al., 1996, 1997b) and various controlled dispersant field trials in Canada and Europe (Green et al., 1982; Bocard et al., 1987; Humphrey et al., 1987; McDonagh and Colcomb-Heiliger, 1992; Lunel and Lewis, 1993a,b; Lunel, 1993, 1994a,b; Lunel et al., 1995b,c; Walker and Lunel, 1995; Lewis et al., 1995a,b; Strom-Kristiansen et al., 1995; Brandvik et al., 1995, 1996; Lunel and Davies, 1996), plus numerous shorter-term laboratory and wave-basin studies on a variety of different oils with and without dispersants (Mackay and Chau, 1986; Brown and Goodman, 1987; Cormack et al., 1987; Daling and Lichtenthaler, 1987; Bobra, 1990; Brandvik and Daling, 1990; Daling et al., 1990b; Brandvik et al., 1991, 1992; Ross and Belore,

FIGURE 4-2 FID gas chromatograms of oil samples obtained from 2,800 L flow-through open-air summer wave-tank experiments using 16 liters of Prudhoe Bay crude oil. A) fresh oil; B) the oil slick after 48 hours of weathering, showing loss of the most volatile compounds; C) the oil slick after 12 days of weathering, showing the loss of all compounds with molecular weights less than n-C11 (Kovats Index 1100); and D) the slick after 12 months of weathering, showing significant biodegradation (Kovats Indices 1710 and 1815 represent the isoprenoids pristane and phytane, respectively).

SOURCE: Modified from Payne et al., 1984.

1993; Knudsen et al., 1994; Major et al., 1994; Strom-Kristiansen et al., 1994; Lunel et al., 1995a; Mackay, 1995; Hokstad et al., 1996; Venosa et al., 1999).

Many of these studies have been reviewed and recently summarized by S.L. Ross (1997) and in the proceedings of a two-day symposium held in Anchorage, Alaska, in March 1998 on oil spill dispersant applications in Alaskan waters (Trudel, 1998). The data from these studies have led to refinements in the overall ability to mathematically model oil spill behavior, and significantly more oil-specific data are now available on the magnitude and rates of change of density, viscosity, and water content for numerous oils and water-in-oil emulsions (Fingas and Fieldhouse, 2003; 2004a,b). No attempt will be made to duplicate or even briefly cover the findings presented in each of these most recent papers. Instead, several of the most significant observations specifically related to predicting evaporation and spilled oil behavior will be highlighted below.

A recent oil-weathering development has been the evaporation modeling approach proposed by Fingas (1996; 1997; 1999a) who has taken issue with the boundary layer regulation model based on earlier work by Mackay (Mackay and Matsugu, 1973; Mackay et al., 1980a,b; Stiver and Mackay, 1984; Berger and Mackay, 1994) that has been the basis for most evaporation algorithms used for predicting oil-weathering behavior. Fingas now proposes that evaporation rates are independent of oil film thickness and surface area and, instead, he has developed a set of empirical equations for estimating oil-specific evaporation rates as a function of exposure time (natural log or square root time-dependence) and the percentage of oil distilled at 180° C (roughly 356° F). Most of these experiments were conducted with a calculated film thickness (based on the cross-sectional area of the experimental evaporation dish and the volume of oil added) ranging from 0.8 to 10 mm. Tasaki and Ogawa (1999) have also reported that evaporation processes are not affected by oil film thicknesses in the range of 1 to 4 mm. A similar representation for evaporation from film thicknesses around 15 mm was also reported earlier by Bobra (1992). Additional discussions of the significance of Fingas’ approach and counter arguments based on modifications of more traditional pseudocomponent approaches are considered by Jones (1996,1997), who has proposed a simplified pseudo-component (SPC) model relating molar volume, vapor pressure, and molecular weight to the boiling point of the component. Thus, only the boiling points and initial volume fractions of the components need to be specified to implement the model.

Overprediction of evaporation rates can be a problem with oil-weathering models that assume a well-mixed oil phase (which is probably valid for very thin slicks) and also assume that resistance to mass transfer is entirely in the air phase (Berger and Mackay, 1994). Results from several studies suggest that evaporation rates may be controlled in the oil phase,

especially at low temperatures and for higher viscosity water-in-oil emulsions (Payne et al., 1984, 1987c; Ross and Buist, 1995) and for waxy oils where a skin may form on the oil surface inhibiting component loss from within the oil phase (Berger and Mackay, 1994). As a result, it may be inappropriate to always model oil as a well-mixed phase, and algorithms for both well-mixed and diffusion-controlled fluids may need to be sequentially utilized as a function of oil weathering-dependent viscosity changes to better approximate spilled oil evaporative behavior. The possibility of oil-phase diffusion-controlled evaporative weathering was discussed at length by Payne et al. (1984). Experimental evidence for the importance of liquid-phase resistance for lower molecular weight compounds (e.g., hexane, cyclohexane, toluene, p-xylene) was presented by Berger and Mackay (1994), and experimental confirmation of the phenomenon for intermediate molecular weight components (decane through tetradecane) was obtained by Payne et al. (1987c; 1991b) during cold-room experiments examining the evaporation behavior of oil spilled onto ice.

In a related study, Ross and Buist (1995) reported that hydrocarbon evaporation was reduced when oil is mixed with water to form a stable water-in-oil emulsion. The degree of evaporation inhibition appears to increase with increasing water content and increasing slick thickness, which again suggests internal resistance to mass transfer within an emulsified slick, in line with the observations of Payne et al. (1987c; 1991b).

Most research indicates that differences in evaporation rates due to different slick thicknesses should be considered in evaporation weathering algorithms. These observations are in direct contrast with the findings by Fingas (1996; 1997; 1999a), who concluded that evaporation was not a function of wind speed, turbulence level, slick area, or thickness. In the modeling approach used by S.L. Ross (1997), smaller slicks are emulsified faster, yielding higher viscosities because of faster evaporation caused by thinner films. This is a subtle effect, but it is worth noting in developing models to predict oil weathering and slick behavior. The S.L. Ross model also predicts that smaller slicks will dissipate faster, which is at variance with the viscosity prediction, because Payne et al. (1984), Lunel et al. (1997b), and others have observed that as viscosity increases, natural dispersion of oil droplets decreases and eventually becomes self-limiting.

Photooxidation

Numerous laboratory studies have been completed on photochemical oxidation of oil, and in general, increases in the water-soluble fraction of most crude oils are readily apparent. As discussed in greater detail below, the photochemical generation of additional polar products (resins, carboxylic acids, ketones, aldehydes, alcohols, and phenols) with low hydro-

philic-lipophilic balance (HLB) values that remain in the oil phase can also lead to the formation and stabilization of water-in-oil emulsions with greater water content (Payne and Phillips, 1985b; NRC, 1985; Daling and Brandvik, 1989; Daling et al., 1990b; Lewis et al., 1994). In addition, photooxidation of oil on the water surface can result in higher-molecular-weight products through the condensation of peroxide and other free-radical intermediates to yield intractable tar and gum residues (NRC, 1985; 2003). To the extent that chemical dispersion of surface oil can remove it from exposure to direct sunlight (or prevent it from stranding on shorelines where additional direct photo-transformations and tar/gum formation can occur), the effects of photooxidation as described below may be reduced.

Payne and Phillips (1985a) reviewed the earlier literature on the photooxidation of petroleum, and details on component-specific transformations, photooxidation products, viscosity changes, reaction mechanisms, the role of various sensitizers, reaction rates, etc., are summarized in that paper. An even more comprehensive treatise on organic photochemistry is available in Schwarzenbach et al. (1993) who review the basic principles of photochemistry, the roles of direct and indirect (sensitized) photolysis of numerous organic compounds in aqueous solutions, and the effects of particulates on photolytic transformations. While several PAH components are discussed, their treatment doesn’t focus specifically on petroleum, and additional details on oil-related compounds can be found in Kochany and Maguire (1994) who completed a critical review of the chemical and photooxidation of PAH and polynuclear aromatic nitrogen heterocycles (PANHs) in water. More recently, Garrett et al. (1998) studied photooxidation of PAH in a variety of crude oils, and a general overview is presented in NRC (2003).

In general, aliphatic hydrocarbons in oils are more resistant to photochemical oxidation whereas aromatic compounds are particularly sensitive, and alkyl substitution increases the sensitivity of the aromatic compounds. Aliphatic sulfur compounds were more easily oxidized compared to aromatic thiophene compounds, with the sulfur in the aliphatic components being oxidized to sulfoxides, sulfones, sulfonates, and sulfates in approximately equal amounts. PAH degrades to relatively stable quinones via reactions initiated by electron transfer from singlet state PAH to molecular oxygen (Sigman et al., 1998), and natural organic mater (humic and fulvic acids) in seawater may enhance indirect photolysis of PAH through the generation of triplet excited states (NRC, 2003).

The extent of photooxidation of dissolved petroleum constituents is controlled by the spectrum and intensity of incident light, and photooxidation occurs faster with shorter-wavelength light (<300 nm), which is rapidly absorbed by seawater and natural dissolved organic matter (which can both enhance and inhibit photochemical processes).

Another more recent finding with regard to photochemical processes is the apparent increase in toxicity to transparent oil-exposed organisms when they are subsequently exposed to sunlight. Phototoxicity may occur by two processes: photomodification and photosensitization. Photomodification (or photooxidation) is the structural modification of a chemical in the oil or water column to more toxic or reactive oxidation products as described in NRC (1985, 2003), Garrett, et al. (1998), Kochany and Maguire (1994), and Payne and Phillips (1985a). In photosensitization, the bioaccumulated chemical transfers light energy to other molecules within the organism causing tissue damage. Phototoxic components in oil are primarily three- to five-ring PAH and heterocycles. The importance of this phenomenon as it relates to the toxicological effects of dispersed oil is discussed in Chapter 5.

Water-in-Oil Emulsification

Significant progress has been made in the identification of factors affecting water-in-oil emulsification (Bridie et al., 1980a,b; Zagorski and Mackay, 1982; Payne and Phillips, 1985b; Mackay, 1987; Bobra,1990; 1991; Fingas and Fieldhouse, 1994; 2003; 2004a,b; Fingas et al., 1995a,b; 1996b; 2002a,b; 2003a; Walker et al., 1993a,b, 1995; McLean and Kilpatrick, 1997a,b; McLean et al., 1998; Sjoblom et al., 2003). It has long been recognized that the indigenous petroleum emulsifying agents are contained in the higher boiling fractions (boiling points >350–400° C [roughly >662–752° F]), and particularly in the non-distillable residuum (Lawrence and Killner, 1948). These higher boiling fractions contain the higher-molecular-weight asphaltenes and resins that are now recognized as the necessary emulsifying agents for stable water-in-oil emulsion formation. These higher-molecular-weight components are believed to orient within the continuous oil phase at the water-droplet/oil interface where they retard recoalescence of the water droplets to form separate water and oil phases.

It is now known that, to be effective, these emulsifying agents should be in the form of precipitated, finely divided, submicron particles (Bobra, 1990, 1991; McLean and Kilpatrick 1997a,b; McLean et al., 1998; Sjoblom et al., 2003). Secondly, it has been shown that the lower-molecular-weight alkane and aromatic components in fresh crude oils serve as solvents to control the in-situ solubility and precipitation behavior of these higher-molecular-weight constituents within the oil phase. The chemical composition of the oil also determines the amount and size of the precipitated asphaltene and resin particles, as well as the “wetting” properties of those particles.

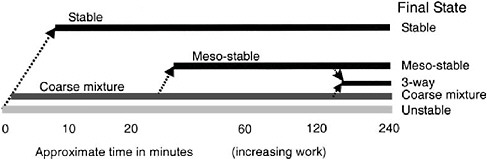

Fingas et al. (2002a, 2003a) and Fingas and Fieldhouse (2003, 2004a,b) classified four “states” that describe how water can exist in combination

with oil. These include: stable emulsions, unstable water-in-oil mixtures, meso-stable emulsions, and (simply) entrained water. These states are differentiated by rheological properties as well as by differences in visual appearance, and very few emulsions were reported by these authors to have questionable stability. The viscosity of a stable emulsion can be as much as three orders of magnitude greater that the starting oil, and the product has significant elasticity. Stable emulsions are also usually reddish or red-brown in color. An unstable emulsion usually has a viscosity no more that about 20 times greater than the starting oil, and no elasticity is observed. Unstable or entrained-water mixtures are always the color of the starting oil (brown or black). Meso-stable emulsions are emulsions that have properties between stable and unstable emulsions, and can be either reddish or brown/black in color. Fingas et al. (1999) hypothesized that meso-stable emulsions lack sufficient asphaltenes to render them completely stable or that they still contained too many de-stabilizing materials such as the smaller aromatic solvent components that solubilize the asphaltenes. If the viscosity of the initial oil is high enough, it can stabilize some water droplets for a period of time in a meso-stable state. However, meso-stable emulsions may evolve to form either separate layers of oil and water or stable emulsions. Unstable emulsions are those that rapidly decompose to separate water and oil phases after mixing energy is removed, generally within a few hours. Some water (usually <10 percent) may be retained by the oil, especially if the oil is viscous.

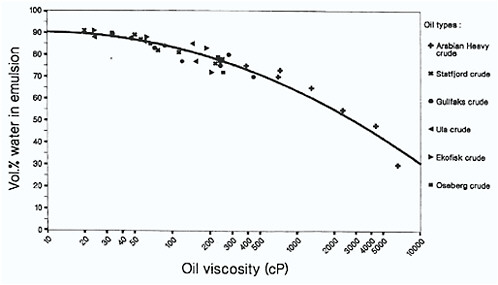

The type of emulsion produced is determined primarily by the properties of the starting oil, and the most important of these are the asphaltene and resin content as noted above, and the initial viscosity of the oil (Fingas and Fieldhouse, 2003). At one time, waxes were thought to be important in the formation of water-in-oil emulsions, but Fingas et al. (2000a) have shown that they are not a factor in the formation of either stable or mesostable emulsions. They may, however, play a role in certain circumstances by temporarily stabilizing entrained water with highly viscous oils. Stable emulsions have more asphaltenes and fewer resins, and interestingly, a narrow initial viscosity window. Instability results when the parent oil has too high or too low an initial viscosity, and as a result, the formation of stable emulsions may not occur with highly viscous oils. While this may initially appear to be contrary to intuitive reasoning, it has been explained by diffusion-controlled migration of asphaltenes and resins being too slow in the highly viscous oils to permit water-water droplet stabilization. In line with these observations, Daling and Brandvik (1989) previously reported that the maximum water uptake versus initial parent oil viscosity actually decreases as higher initial oil viscosities increase (Figure 4-3).

Turbulent kinetic energy is the most important form of energy related to emulsion formation. Although they were unable to measure turbulent

FIGURE 4-3 Maximum water uptake in water-in-oil emulsions versus initial parent oil viscosity. The mixing time is 24 hours at 6 and 13° C. Note that water uptake decreases as initial oil viscosity increases.

SOURCE: Daling and Brandvik, 1989.

energy directly in their laboratory experiments, Fingas et al. (1999) and Fingas and Fieldhouse (2003) correlated emulsion stability with total kinetic energy (proportional to the rotational speed of their rotary agitator and measured in ergs) and work (a measure of the power input to the agitator integrated over time, recorded in joules—same dimensions as energy—and proportional to time for a given energy). Neither of these metrics was normalized by the mass of oil, so results can only be interpreted in a relative sense. Oil that forms an entrained water state required relatively little threshold energy (200–300 ergs), and showed no increase in stability with increasing energy. Oil that forms a mesoscale emulsion required a relatively high level of energy (about 25,000 ergs) but also displayed no increase in stability with additional energy. Meanwhile oils that form stable emulsions showed increasing stability with increasing energy. Figure 4-4 displays the trend in emulsion state as a function of time (work) for oils displaying various final emulsion states. An implication is that formation of a given emulsion type at sea may require both a threshold energy level (corresponding to a given sea state) and a finite period of time. Because of the lack of higher-molecular-weight asphaltenes and resins, most light refined products (such as gasoline, kerosene, heating oil, and diesel fuels) do not easily form a stable water-in-oil emulsion.

In addition to the influence of indigenous asphaltenes and resins in

FIGURE 4-4 The overall concept of state and approximate kinetics in emulsion and water-in-oil state formation.

SOURCE: Fingas and Fieldhouse, 2003; courtesy of Elsevier.

the oils themselves, oxidation products from oil photolysis-weathering have also been suspected to play a significant role in water-in-oil emulsification behavior (Payne and Phillips, 1985a,b; NRC 1985). Daling and Brandvik (1989) correlated the increase in resin components in photolyzed oils with increased water contents and smaller-sized water droplets in the resultant water-in-oil emulsions. Specifically they found that photolysis results in:

-

the formation of polar compounds (resins)

-

significant reductions in oil-water interfacial tension

-

slightly increased rates of water-in-oil emulsion formation (not for waxy crudes)

-

slightly higher maximum water content in the water-in-oil emulsion

-

significantly higher stability in viscosity of the water-in-oil emulsion

-

a higher concentration of chemicals needed to break or inhibit water-in-oil emulsion formation, and

-

oil-specific changes in chemical dispersibility

In subsequent dispersant tests, Daling and Brandvik (1989) reported that naphthenic crudes were more highly dispersible after photolysis. Waxy crudes showed drastic reduction in dispersibility. Photolyzed components were believed to facilitate the accumulation of waxes at the oil-water interface, which were believed to “block” the access and penetration of the dispersant’s surfactant into the oil phase. Without such stabilizing agents the water droplets in a water-in-oil emulsion will tend to coalesce and separate from the oil phase.

In an attempt to generate a database of oil properties that might be useful in predicting water-in-oil emulsification and dispersibility behavior as a function of the degree to which oil weathering has occurred, Daling et al. (1990b) undertook the systematic study of emulsification behavior on three standard test oils that had been artificially weathered in the laboratory. The results demonstrated that the rate of weathering processes (water uptake, viscosity increases, etc.) was critically dependent on the type of oil studied and the different environmental conditions. Even when the variations in the physical-chemical parameters of the starting oils were relatively small, the weathering behavior of the oil and effectiveness of the different dispersants varied significantly. The authors suggested that this approach be considered by other laboratories and used in a similar way to generate a larger database of valuable information, which could be used in oil weathering modeling. Using experimental weathering data available for a wide range of oils, they hoped that correlations could be developed for model predictions of oil-weathering behavior based on only generally available crude oil assay data (e.g., true boiling point curves, density, pour point, wax, resin, and asphaltene content).

Lewis et al. (1994) expanded Daling et al.’s weathering approach and incorporated a mesoscale flume to investigate the chemical dispersion of oil and water-in-oil emulsions after different stages of weathering. In addition to the more common laboratory bench-scale methods used for assessing chemical dispersibility, the flume approach allowed testing of higher viscosity water-in-oil mixtures and more closely approximated conditions that might be encountered at sea.

This approach, or modifications of it, has now been successfully used to investigate the oil weathering properties and dispersibility of a wide variety of heavier and more viscous crude oils and emulsions (Guyomarch et al., 1999a,b,c; Fiocco et al., 1999), and the more recent data have significantly expanded the viscosity-limited range of dispersant effectiveness (and the concomitant time window available for responding to an oil spill at sea). In addition, the flume approach has allowed the rapid and cost-effective evaluation and testing of various emulsion breaking chemicals and the effectiveness of multiple dispersant applications and sequential emulsion breaker/dispersant combinations to disperse particularly recalcitrant slicks.

Without question, water-in-oil emulsification is a critically important process that affects oil droplet entrainment and dispersant effectiveness, and for many years it was believed to be the most difficult process to model or predict on a oil-specific basis (S.L. Ross, 1997). Except for the few oils that had been extensively tested, it was virtually impossible to predict when a particular oil would start to emulsify or how long it would take for the spilled oil to form a “stable” highly viscous emulsion. Like-

wise, it was not possible to predict the final water content that a water-in-oil emulsion might contain.

Nevertheless, oil spill models have to deal with the problem of emulsification because it is such an important process. Traditionally, many oil spill models used data from an older laboratory test, called the Mackay-Zagorski Test (Zagorski and Mackay, 1982) that was developed to measure: (1) an oil’s tendency to form an emulsion, and (2) the stability of the emulsion once formed. The test did not, however, predict the rate of emulsification under field conditions. Likewise, the conventional emulsification equation (Mackay and Matsugu, 1973) that had been generally used in oil-weathering modeling includes some inconsistencies. For example, it does not include the influence of initial oil thickness and the progress of evaporation on emulsification. Emulsified oil takes up water as evaporation progresses, thus maintaining a constant oil-to-water (OWR). Therefore, Tasaki and Ogawa (1999) developed a new equation and governing parameters for emulsification of crude oil. Through the differentiation of a formula defining the water content ratio, a water-in-oil emulsification equation for crude oil was derived to include the effects of evaporation loss and entrained water with time. The equation reveals that the emulsification is governed by two fixed parameters (related to the evaporation process) and four free constant parameters selected to fit the numerical solutions to the measured values obtained in flume tests on six types of Middle East crude oils.

Noting the requirement for the loss of lower-molecular-weight alkane and aromatic solvents to precipitate asphaltenes for the formation of stable mousse with Alaska North Slope (ANS) crude oil, S.L. Ross (1997) and NOAA (in their Automated Data Inquiry for Oil Spills [ADIOS] 2 oil weathering model) do not initiate the formation of a water-in-oil emulsion in their computer models until after a specified percent evaporation for the crude oil has occurred.

To further this research effort and develop an empirical database that can be used in a predictive sense, Fingas and Fieldhouse (2003) have examined the emulsion forming tendencies of over 200 oils. The resulting emulsified products were characterized as a function of time (day of formation and after one week) by viscosity, complex modulus, elasticity modulus, viscosity modulus, water content, and several other parameters, including visual appearance. These empirical data were then used to develop a numerical model that uses the density, viscosity, and the saturate, asphaltene, and resin contents to compute a class index, which in turn yields either an unstable or entrained water-in-oil state or a meso-stable or stable emulsion (Fingas and Fieldhouse, 2004a,b). This approach has been used to develop a prediction scheme to estimate the water content and viscosity of the resulting water-in-oil state and the time to formation

with input of wave-height. When compared to the laboratory data upon which the empirical approach was based, this model was reported to provide accurate predictions of stability class about 50 percent of the time, and 90 percent of the predictions were no more that one category off. Predictions could not be compared to field data because there are very few data available for the comparison; however, this empirical approach clearly advances the ability to make a priori predictions about how a particular oil might behave in a spill situation.

Fate of Physically and Chemically Entrained Oil Droplets in the Water Column

Physical Entrainment of Untreated Oil

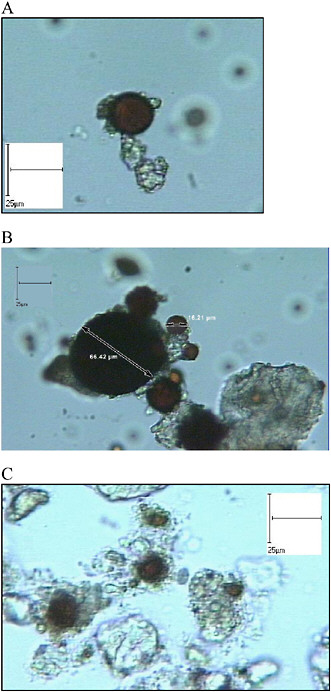

Notwithstanding the fact that most oils will not readily sink (NRC, 1999), fresh oil can be temporarily entrained/driven into the water column by wind and wave turbulence as described previously. In such instances, however, droplets above a certain size range (generally greater than 60–80 µm or 0.06–0.08 mm) would be expected to quickly resurface after the turbulence regime subsides. Then, as the viscosity of the surface slick increases due to evaporation and water-in-oil emulsification (mousse formation), it becomes increasingly difficult for wind-driven waves to plunge discrete oil droplets into the water column.

In the wave-tank systems used by Payne et al. (1983; 1984; 1991a) for subarctic oil weathering studies with Prudhoe Bay crude oil, the total entrained oil droplet concentrations in the water column were over 9,000 µg/L immediately after the oil release, 2–3 µg/L after 4 hours, 0.5 µg/L after 2 days, and less than 0.1 µg/L after 12 days. Initial chromatograms of the entrained oil droplets appeared essentially identical to those from the simultaneously collected surface oil samples (Figure 4-2), but between 8 and 48 hours, there was evidence for slightly enhanced evaporation and/or dissolution loss of lighter molecular weight components in the physically entrained oil droplets compared to the surface oil slick. Presumably, this loss resulted from the increased surface-area-to-volume ratio of the smaller physically entrained oil droplets compared to the more continuous surface oil slick. After 12 days with continued constant turbulent mixing in the wave tank there was little evidence of physically dispersed oil droplets in the water column.

Energy dissipation rates and oil droplet-size distributions were not measured in the wave-tank studies by Payne et al., but these parameters have been measured in other studies (Delvigne and Sweeney, 1988; Sterling et al., 2004a). Delvigne and Sweeney (1988) measured droplet sizes in their turbulent grid and breaking-wave experiments with both Ekofisk

and Prudhoe Bay crude oils. These studies showed that droplet sizes between 60 and 200 µm were obtained with the non-dispersant-treated oils in their turbulent-grid column experiments at the highest turbulence regimes tested, and that droplet size diameters increased significantly as the oil viscosity increased and the turbulence regime decreased. In their breaking wave experiments, Delvigne and Sweeney (1988) measured droplet sizes from 6 to >800 µm with the highest number concentrations in the 6–50 µm size range with greater numbers of the smaller droplets driven deeper into the water column and greater numbers of larger droplets near the surface. Clearly, as oil viscosity increased, droplet dispersion was inhibited with a concomitant increase in the proportions of larger droplets with faster rising velocities being generated. Similar findings of inhibited oil droplet dispersion/entrainment from higher-viscosity water-in-oil emulsions have also been reported by Lewis et al. (1994).

Enhanced Entrainment of Smaller Droplets with Dispersants

Franklin and Lloyd (1986) presented various size distributions for oil:dispersant mixtures studied in the laboratory using a toxicity test developed by the United Kingdom’s Ministry of Agriculture, Fisheries and Food. All droplet sizes were reported as volume median diameter, which is the droplet diameter that divides the sample distribution into two equal parts by volume. The hydrocarbon solvent based dispersants yielded droplet histogram plots that peaked at 20 µm (the mode diameter). Water-dilutable concentrates yielded drops in the 25–65 µm range. Dispersants that were concentrates applied to the oil undiluted generated a flat bimodal distribution with a large proportion of droplets <5 µm.

More recently, Lunel (1993a,b; 1995b) reported the first successful field measurements of oil droplet-size distribution below experimental dispersant-treated oil slicks at sea from a premixed oil-dispersant combination (medium fuel oil and Slickgone NS) measured at sea using a Phase Doppler Particle Analyzer (see Figure 3-3 in Chapter 3). For a variety of test oils and dispersants, the range of mean diameters was between 15 and 25 µm (volume distribution 35 to 50 µm). Smaller droplet sizes (or increased number densities of smaller droplets) were observed in both instances.

Compound-Specific Dissolution Behavior

True dissolution of individual components from an oil slick is not generally significant in terms of the overall mass balance of an oil spill (NRC, 1985; 2003). As a result, many oil-weathering models generally do not include dissolution in their mass-balance calculations. Dissolution of

individual components is important, however, when considering the potential for biological impacts.

The dissolved concentrations of individual components from an oil slick are controlled by partition coefficients, rather than the solubilities of individual oil components. Payne et al. (1984) and Payne and McNabb (1984) presented data for Prudhoe Bay crude oil:seawater partitioning reporting that the truly dissolved components were almost exclusively alkyl-substituted lower-molecular-weight mono-aromatic hydrocarbons (MAH) and two-ring PAH. The water-soluble fraction contained no appreciable n-alkanes. Published octanol:water partition coefficients, Kow, for many parent (and fewer alkyl-substituted) PAH can be used to predict dissolution behavior (Nirmalakhandan and Speece, 1988; Hodson et al., 1988; Blum and Speece,1990; McCarty, 1986; McCarty et al., 1992; Mackay et al., 1992; McCarty and Mackay, 1993; Varhaar et al., 1992; Swartz et al., 1995; French-McCay et al., 1996; French-McCay, 1998; 2001; 2004). For modeling dissolution behavior, partition coefficients, not pure component solubility data, should be used.

In the case of an oil spill, true dissolution of individual components is controlled by the mole fraction of each component in the slick, the oil/water partition coefficient, the oil-water interfacial surface area (which significantly increases with successful dispersant application), and the interphase mass transfer coefficient. During a spill, however, a static equilibrium can never be established because the dissolved components are removed (diffused and advected) away from the surface oil source (and dispersed oil droplets), mixed with fresh uncontaminated water, and subjected to evaporation loss from the water column itself.

As a result of these processes, dissolution should not be modeled as an equilibrium process, but instead as a kinetics-controlled process where the driving force is determined by the distance of the system from equilibrium. The oil-water interfacial area should be a term in the rate equation, and the aqueous-phase concentration could be modeled as being arbitrarily low (e.g., zero) or through a mass balance on the water-soluble components. In a study related to this conceptual approach, Page et al. (2000b) reported on the importance of kinetics, thermodynamics, and colloidal phenomena in controlling the partitioning of naphthalenes from West Texas and Arabian medium crude oils into seawater. Under conditions of light turbulence, the alkyl-substituted naphthalenes showed an inverse correlation between both the dissolution rate coefficients and saturation concentrations and the degree of alkyl-substitution. At higher turbulence levels and variable oil loadings, there was a direct correlation between the measured total petroleum hydrocarbon concentrations in the water and the nominal oil loading; however, there was no such correla-

tion between the naphthalenes and oil loading. It was concluded that the first experiment was controlled by dissolution kinetics across the oil/water boundary and solubility phenomenon, while the second experiment also included a colloidal oil-phase contribution to the measured constituent concentrations.

Sterling et al. (2003) examined the partitioning of PAH components from oil droplets into the water column and the influence of the shear stresses used to generate those droplets. Their approach was based on Raoult’s Law using pure component solubilities and individual-component mole fractions in the oil phase. At low shear stresses generating relatively low dispersed oil droplet concentrations, the influence of PAH solubility dominated the observed PAH concentrations. At higher shear stresses and dispersed oil droplet loadings, the PAH concentrations in the water column were influenced primarily by the mole fraction of the individual PAH in the entrained oil droplets.

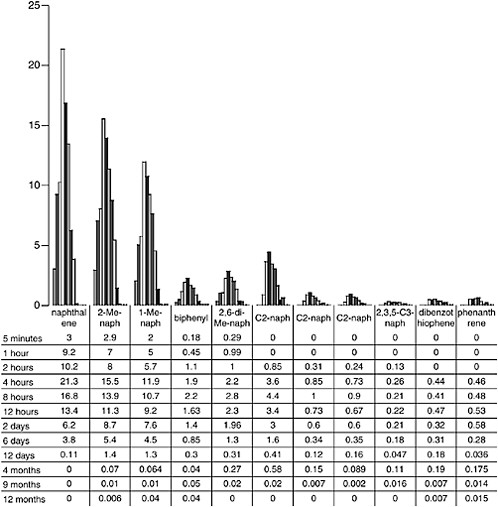

To assess the time-series water-column concentrations in the subarctic flow-through wave-tank studies discussed above, Payne et al. (1984) filtered 20-liter subsurface seawater samples through 0.7 µm pore-size 293 mm diameter glass-fiber filters for separate analyses of the dissolved components and dispersed- and/or particulate-bound oil droplets (Gordon et al., 1973). Chromatograms of dissolved components measured in time-series filtered seawater samples from the wave-tank systems are shown in Figure 4-5. These chromatograms are characterized only by the individual aromatic components, not the evenly repeating series of n-alkanes that predominate in the dispersed oil droplets and surface oil samples (Figure 4-2). As shown in Figure 4-5A, dissolution of lower-molecular-weight aromatic components began immediately, as little as five minutes after the spill. The major dissolved components measured over time include benzene, toluene, xylene(s), ethylbenzenes, C3-substituted benzenes, naphthalene, methylnaphthalenes, C2- and C3-substituted naphthalenes, phenanthrene, and C1- and C2-substituted phenanthrenes.

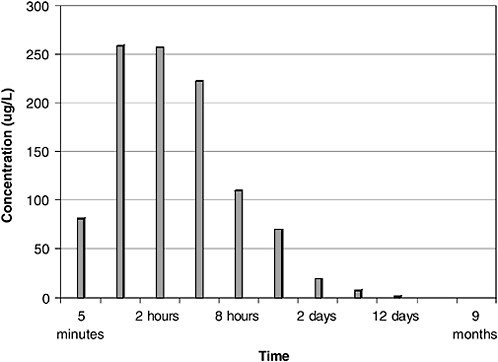

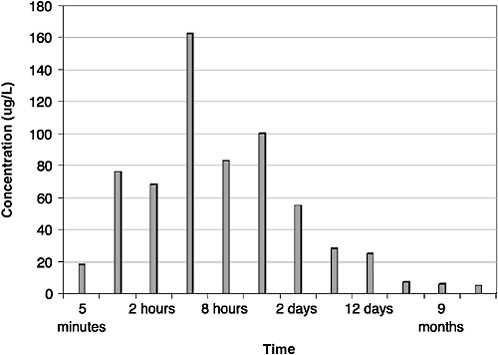

As shown in Figures 4-6 and 4-7, maximum dissolved-component concentrations were observed very early in the spill. Dissolved-phase total benzene, toluene, ethylbenzene, and xylenes (BTEX) concentrations reached a maximum of 250 µg/L during the first 2 hours of the spill and were less than 25 µg/L after 2 days. The maximum total PAH concentration was somewhat delayed, occurring between 4 and 12 hours (Figure 4-7). Subsequent water-column concentrations decreased from a combination of evaporative losses from the water surface and advective/diffusion processes (simulated by one tank-volume water exchange every 4 hours). Concomitant (and orders of magnitude greater) evaporative losses of these same components also occurred from the surface slick over the same time frame. However, the higher-molecular-weight PAH were persistent in the

FIGURE 4-5 FID gas chromatograms of filtered water samples showing dissolved-phase components obtained from 2,800-liter flow-through open-air summer wave-tank experiments using 16 liters of Prudhoe Bay crude oil after: A) 5 minutes; B) 48 hours; C) 12 days and D) 12 months of weathering. Selected components are identified by Kovats Retention Index (see text and inset).

SOURCE: Modified from Payne et al., 1984.

FIGURE 4-6 Total dissolved benzene, toluene, ethylbenzene, and xylenes (BTEX) concentrations in ppb over time from flow-through open wave-tank experiments using Prudhoe Bay crude oil. BTEX concentrations peaked at 1–2 hours.

SOURCE: Data from Payne et al., 1984.

oil, and continued dissolution of C2-substituted naphthalenes and alkyl-substituted phenanthrenes from the surface oil occurred for periods of up to 4 to 7 months (Figure 4-8) even though there was little or no physical dispersion of oil droplets occurring at that time. There was no evidence of significant aromatic hydrocarbon dissolution into the water column after 13 months in the wave-tank systems.

Clearly, the absolute concentrations of oil droplet- and dissolved-phase components presented in Figures 4-5 through 4-8 were influenced by the size of the wave tank systems (2,800 L), the water-column turnover rate or residence time (one tank volume every 4 hrs), and the volume of oil (16 L) used for the experiments. Slick spreading was also inhibited by the walls of the tanks, so extrapolating these data to actual open-ocean conditions must be done with caution. Nevertheless, it is worthy of note that excellent agreement was obtained between the wave-tank data and observed changes in oil rheology and oil chemistry after the T/V Exxon Valdez oil spill (Payne et al., 1991a). Both the wave-tank studies and the

EVOS observations are representative of ice-free Alaskan subarctic conditions, and the rates of evaporation, emulsification, (and possibly to a lesser extent, dissolution) would be different in warmer environments, but the processes themselves would still occur. Computer models can help define the anticipated changes in these rates for other environmental conditions and oil types. The data are included here to provide insight on the dynamic nature of the dissolved- and oil-phase component concentrations in the water column that ultimately drive toxicity considerations.

Although the use of chemical dispersants will clearly increase the upper water column concentration of entrained oil droplets, and theoretically should lead to enhanced dissolution of water-soluble PAH components (French-McCay and Payne, 2001), no field measurements of this phenomenon have been successfully completed to date. It is known that enhanced dissolved-phase concentrations occur with subsurface blowouts (Brooks et al., 1980; Payne et al., 1980a,b; Boehm and Fiest, 1980, 1982; Fiest and Boehm, 1980) and after extensive surface entrainment of fresh

FIGURE 4-7 Total dissolved polynuclear aromatic hydrocarbons (PAH) concentrations in ppb over time from flow-through open wave-tank experiments using Prudhoe Bay crude oil. PAH concentrations peaked at 4 hours but continued to dissolve from the surface slicks for one year.

SOURCE: Data from Payne et al., 1984.

FIGURE 4-8 Dissolved individual PAH concentrations in ppb over time from flow-through open wave-tank experiments using Prudhoe Bay crude oil.

SOURCE: Data from Payne et al., 1984.

petroleum products, such as occurred with the North Cape (French-McCay, 2003). However, attempts to measure this during dispersant applications to accidental spills have not documented similar behavior.

Dispersants were used during the response to the Mega Borg spill of 3.9 million gallons (roughly 13,000 tonnes) of Angola Planca crude oil off Galveston, Texas, in 1990, and Payne et al. (1993) examined target and control areas of the treated slick to see if evidence of enhanced PAH dissolution could be observed. The measured concentrations of dispersed oil droplets were very heterogeneous and reflected the patchy distribution of oil on the water surface before dispersant application. Nevertheless, the

ratio data for aliphatic:aromatic concentrations showed no evidence of significantly enhanced dissolution of lower- and intermediate-molecular-weight aromatics as a result of the dispersant treatment.

Payne et al. (1991d) demonstrated that dissolved aromatic compounds from oil introduced into refreezing leads can be advected as conservative components in the brine generated during frazil ice formation to the benthic bottom boundary layer in field experiments completed in the Chukchi Sea. If dispersants were applied to oil released in open water during freezing conditions or to oil contained in open leads/broken sea ice during a refreezing event, it is conceivable that the enhanced dissolution process predicted by French-McCay and Payne (2001) could lead to transport of dissolved aromatic components to the benthos before significant evaporative weathering could otherwise occur. Clearly, any such enhanced transport would be spill or location specific, as it assumes only minor horizontal transfer.

Biodegradation

The effects of surfactants and commercial oil dispersant mixtures on the rate and extent of biodegradation of crude oil, petroleum products, and individual hydrocarbons have been intensively investigated for over thirty years with mixed results. In some studies, biodegradation is stimulated, others find evidence of inhibition, and others observe no effects attributable to the presence of surfactants or commercial dispersants. Experimental systems have used a wide variety of substrates (e.g., crude oil, individual hydrocarbons), surfactants (e.g., commercial dispersant mixtures, pure surfactants), and microbial communities (e.g., natural seawater microbiota, microbial communities enriched by growth on crude oil, pure cultures). None of these factors appear to systematically affect the outcome. Instead, the effects of surfactants or commercial dispersant mixtures on the biodegradation rates of crude oil and defined hydrocarbons appear to depend on the chemical characteristics of the surfactants, the hydrocarbons, and the composition of the microbial community. Other factors, such as nutrient concentrations, oil-water ratios, and mixing energy, can also be expected to affect the observed biodegradation rate of dispersed oil.

One source of confusion in the literature on dispersant effects on oil biodegradation is that conclusions are often based on indirect evidence. For example, Corexit 9527 (DOR = 1:10) was shown to increase the rate of oxygen uptake in suspensions of South Louisiana and Kuwait crude oils relative to suspensions of physically dispersed oil (Traxler and Bhattacharya, 1978), and several dispersants increased the rate or extent of microbial growth on Arabian (Mulkins-Phillips and Stewart, 1974) or For-

ties (Swannell and Daniel, 1999) crude oil. Unfortunately, this stimulation cannot be unambiguously attributed to growth on dispersed oil as opposed to growth on the dispersants themselves, which are usually readily biodegradable and support microbial growth (Mulkins-Phillips and Stewart, 1974; Bhosle and Row, 1983; Bhosle and Mavinkurve, 1984; Lindstrom and Braddock, 2002). Corexit 9500 (DOR = 1:10), however, had no effect on the growth rate of hydrocarbon degraders on Alaska North Slope crude oil, and it slightly decreased the gross rate of oil mineralization (Davies et al., 2001; Lindstrom and Braddock, 2002). Total extractable material (TEM), which is a gravimetric measurement of the concentration of hydrophobic (e.g., oil and grease) compounds, is a somewhat more direct measure of oil biodegradation than is oxygen consumption or microbial growth rate, but it is still subject to interference from surfactants or other dispersant components. Based on this metric, Dispolene 34 S (DOR = 1:5) decreased the rate of biodegradation of Kuwait crude oil by about two-thirds relative to physically dispersed oil when both were present at realistically low concentrations in natural seawater (Literathy et al., 1989).

More direct evidence for the effects of dispersants on oil biodegradation rates involve measurement of oil composition, usually by gas chromatographic-flame ionization detector (GC-FID) or gas chromatographic-mass spectroscopy (GC-MS), or measurement of the rate of biotransformation of specific hydrocarbons to carbon dioxide (e.g., mineralization). Based on changes in oil composition, Corexit 9527 was found to inhibit the biodegradation of normal and branched alkanes and sulfur heterocycles in Prudhoe Bay crude oil, but biodegradation of PAH was not affected (Foght and Westlake, 1982; Foght et al., 1983). Corexit 9500 had no effect on the rate of n-alkane biodegradation in Alaskan North Slope crude oil when compared to physically dispersed oil (Davies et al., 2001). The rate of biodegradation of naphthalene and phenanthrene in the water-accommodated fraction (WAF) of a heavy residual fuel oil was not affected by the presence of a dispersant (Taiho Self-Mixing S-7), but the biodegradation rates of the 4-ring PAH pyrene and chrysene were faster (Yamada et al., 2003). It should be noted, however, that the initial concentrations of pyrene and chrysene in the WAF that was prepared with chemically dispersed oil were sufficiently high that their final aqueous-phase concentrations were higher after biodegradation than the initial concentrations in the water-only WAF.

Although disappearance of target compounds from samples provides a very detailed and sensitive view of changes in oil composition that occur during incubation under specified experimental conditions, the mechanism that causes the observed compositional changes and the fate of the compounds that disappear often must be inferred. It is, for example, often difficult to determine whether specific compounds were lost from the