3

Dispersant-Oil Interactions and Effectiveness Testing

Dispersants are mixtures of solvents, surfactants, and other additives that are applied to oil slicks to reduce the oil-water interfacial tension (NRC, 1989; Clayton et al., 1993). Interfacial tension is the free energy change that is associated with a change in the contact area at the interface between two immiscible phases (e.g., solid-liquid, liquid-liquid, liquid-gas). The term surface tension is also used to describe this phenomenon. Although these two terms are often used interchangeably, interfacial tension is considered to be the more general term, which can be applied to describe the free energy at the interface between any two phases, whereas surface tension applies specifically to those cases in which one of the phases is a gas (Lyklema, 2000). Reduction of the interfacial tension between oil and water by addition of a dispersant promotes the formation of a larger number of small oil droplets when surface waves entrain oil into the water column. These small submerged oil droplets are then subject to transport by subsurface currents and other natural removal processes, such as dissolution, volatilization from the water surface, biodegradation, and sedimentation resulting from interactions with suspended particulate material (SPM).

For the purpose of this and subsequent discussions, it is important to define two terms that are used interchangeably in the dispersant literature: entrainment and dispersion. In this report, entrainment is specifically the transport of oil from a surface slick into the water column by wind and waves, while dispersion includes both entrainment and subsurface transport (mixing and advection) by turbulent forces. It should also be mentioned that in the hydrodynamics literature the term dispersion

(sometimes shear dispersion) refers to a specific mixing process resulting from the combination of shear in the mean velocity coupled with turbulent mixing (or other transport mechanism) in the direction of the shear. This process will be discussed in Chapter 4 and will be denoted as hydrodynamic dispersion to avoid confusion.

The following sections address dispersant chemistry, the physical and chemical interactions of dispersants with oil slicks and droplets, oil chemistry and weathering behavior and how they affect the window of opportunity for effective dispersant applications, and the importance of turbulence for introducing the energy necessary to entrain oil droplets into the water column as well as their subsequent transport by dispersive and advective processes. Next is a discussion of effectiveness testing and related issues, including laboratory systems, wave-tank tests, field studies, and studies involving spills of opportunity. Several of these topics are only considered briefly because there are a number of excellent reviews that consider the mechanisms of dispersant action and laboratory and field testing of dispersant performance (e.g., Meeks, 1981; Rewick et al., 1981; Mackay et al., 1984; Nichols and Parker, 1985; NRC, 1989; Clayton et al., 1993; Trudel, 1998; Etkin, 1999). Topics for which there are still major uncertainties or where data gaps exist are considered in greater detail, along with explicit findings and recommendations for areas requiring additional research.

COMMERCIAL DISPERSANT PRODUCTS AVAILABLE FOR USE IN U.S. WATERS

A typical commercial dispersant is a mixture of three types of chemicals: solvents, additives, and most importantly, surface-active agents (i.e., surfactants). Solvents are added primarily to promote the dissolution of surfactants and additives into a homogeneous dispersant mixture. In addition to keeping the surfactants in solution, these solvents reduce the product’s viscosity and affect the dispersant’s solubility in oil. Also, solvents determine to what extent the dispersant may be premixed with water for some spraying applications. Because aqueous-based solvent systems freeze in spray nozzles at ambient temperatures below 0° C (roughly 32° F) their usefulness is often limited in arctic or subarctic environments. Additives may be present for a number of purposes, such as improving the dissolution of the surfactants into an oil slick and increasing the long-term stability of the dispersant formulation.

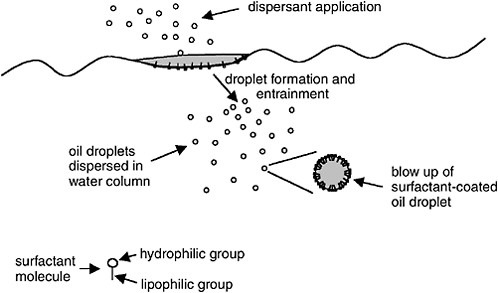

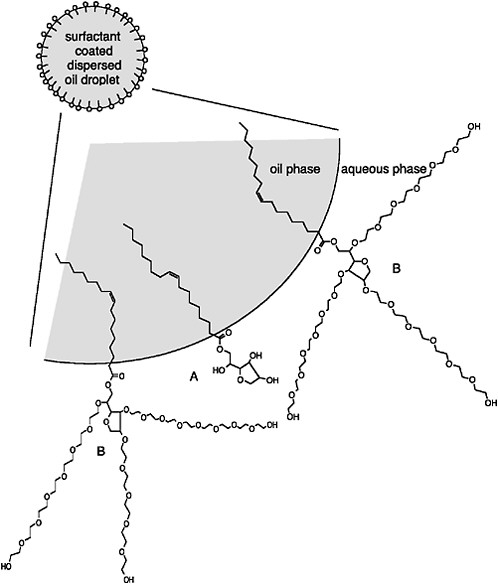

Surfactants are compounds containing both oil-compatible (i.e., lipophilic or hydrophobic) and water-compatible (i.e., hydrophilic) groups. Because of this amphiphatic nature (i.e., opposing solubility tendencies), the surfactant molecules will reside at the oil-water interface as shown in

Figure 3-1. The surfactant reduces the oil-water interfacial tension by orienting with the hydrophilic groups interacting with the water phase and the hydrophobic groups interacting with the oil. Reduction of the oil-water interfacial tension facilitates the formation of a large number of small oil droplets that can be entrained into the water column.

Commercial formulations of modern chemical dispersants are usually comprised of two or more surfactant molecules that have differing solubilities in both water and oil. One parameter that has been used to characterize these different solubilities is the hydrophile-lipophile balance (HLB). The HLB ranges from 0 (no hydrophilic group) to 20 (no hydrophobic group), and the specific value characterizes the tendency of the surfactant to preferentially dissolve in either the oil phase (low HLB) or the aqueous phase (high HLB). The dominant group of the surfactant molecule will tend to orient in the outer phase to form a droplet of either oil or water (Porter, 1991). Therefore, a predominantly lipophilic surfactant (with a HLB below 7) will favor water-in-oil emulsions (mousse) where oil forms the continuous phase with discrete water droplets entrained within it (Porter, 1991). Natural components that promote the for-

FIGURE 3-1 Mechanism of chemical dispersion: surfactant accumulates at oil-water interface, facilitating formation of small oil droplets that become entrained in the water column. Blow-up of oil droplet shows orientation of surfactant at the droplet surface with the hydrophilic group projecting into the water phase and the lipophilic group projecting into the oil phase.

mation of mousse (e.g., the resin and asphaltene fractions of crude oil) are generally lipophilic. In contrast, a predominantly hydrophilic surfactant (with an HLB greater than 7) will favor oil-in-water dispersions (i.e., entrained oil droplets in a water body) (Porter, 1991). The blend of surfactants in commercial dispersant formulations tend to be hydrophilic and the current formulations usually consist of surfactant mixtures with an overall HLB in the range of 9 to 11 (Clayton et al., 1993).

An example of the orientation of surfactant molecules at the oil-water interface is presented in Figure 3-2. Compound A is sorbitan monooleate (HLB = 4.3; predominantly lipophilic). Compound B is similar to A but has been ethoxylated with molecules of ethylene oxide to make it more hydrophilic (HLB = 15). The dispersant formulation shown in Figure 3-2 contains more compound B than A. Such a balance will promote formation of stable oil-in-water dispersions (entrained oil droplets in the water column) because the dominant hydrophilic group of the surfactant mixture favors the formation of oil droplets in water. The use of two or more surfactants with differing HLB values, but an overall average HLB in the range of 9-11, allows for closer physical interactions (i.e., packing) of the surfactant molecules at the oil-water interface compared to a single surfactant with an HLB value in this range (Porter, 1991). This produces a stronger interfacial surfactant film. Although ionic surfactants can inhibit coalescence of small droplets into larger droplets that would resurface more quickly by providing an electrostatic repulsion barrier (Porter, 1991), recent measurements suggest that this barrier is too small to significantly affect the collision efficiency (i.e., the fraction of collisions that result in coalescence), at least for dispersants (e.g., Corexit 9500) that consist mainly of nonionic surfactants, even when the dispersant-to-oil ratio (1:10) is relatively high (Sterling et al., 2004c).

Exact compositions for commercial dispersant formulations are proprietary, but their generic chemical characteristics are broadly known (e.g., Wells et al., 1985; Brochu, et al., 1986; NRC, 1989; Fingas et al., 1990; Singer et al., 1991, 1996; George-Ares and Clark, 2000). In general, a limited number of surfactant agents are currently used. Current dispersant formulations consist of mixtures of one or more surfactants, which may be either nonionic or anionic. Cationic (positively charged) surfactants are not used in current formulations (Clayton et al., 1993) because they are usually quaternary ammonium salts that are inherently toxic to many organisms.

The Corexit products are by far the most prevalent of all dispersants held in industry stockpiles within the United States, making up as much as 95 percent is some instances (J. Clark, ExxonMobil Research and Engineering Company, Fairfax, Virginia, written communication, 2005). Corexit 9527 was developed in the 1980s; it was supplemented in the 1990s

FIGURE 3-2 Orientation of surfactants at oil-water interface in dispersed oil droplets. Surfactant A is sorbitan monooleate (a.k.a., Span 80; HLB ≈ 4.3); surfactant B is ethoxylated (E20) sorbitan monooleate (a.k.a., Tween 80; HLB ≈ 15).

by the introduction of Corexit 9500, which includes the same surfactants incorporated into a different solvent (George-Ares and Clark, 2000). Both products contain a mixture of nonionic (48 percent) and anionic (35 percent) surfactants. The major nonionic surfactants include ethoxylated sorbitan mono- and trioleates and sorbitan monooleate; the major ionic sur-

factant is sodium dioctyl sulfosuccinate (Singer et al., 1991). Neither Corexit product contains polyethoxylated alkyl phenols (J. Clark, ExxonMobil Research and Engineering Company, Fairfax, Virginia, written communication, 2004). A different solvent was used in Corexit 9500 for two reasons. First, prolonged exposure to Corexit 9527 caused adverse health effects in some responders. These effects were attributed to its glycol ether solvent (2-butoxyethanol). Therefore, the solvent was replaced by a mixture of food-grade aliphatic hydrocarbons (Norpar 13; n-alkanes ranging from nonane to hexadecane) in Corexit 9500 (Varadaraj et al., 1995). The second reason for changing the solvent in the reformulated dispersant was to extend the window of opportunity for dispersant use. This window of opportunity is limited by the effects of weathering on the chemical and physical properties of the spilled oil, especially the increase in oil viscosity. Corexit 9500 has been shown to be slightly more effective with high-viscosity oils than Corexit 9527.

THE PHYSICAL CHEMISTRY OF DISPERSANT-OIL INTERACTIONS AND THE ENERGY REQUIREMENTS FOR EFFECTIVE OIL-DROPLET ENTRAINMENT AND DISPERSION

The objective of an oil-spill dispersant application is to lower the oil/water interfacial tension to enhance entrainment of small oil droplets into the water column at lower energy inputs. Entrainment of small oil droplets into the water column (by either physical or chemical means) increases the oil-water interfacial area, which as shown in Eq. (3-1), requires energy:

(3-1)

where WK is the mixing energy (ergs or g-cm2-s−2; 1 erg equals 10−7 joule (kg-m2-s−2)), γo/w is the oil-water interfacial tension (dynes-cm−1, where 1 dyne equals 1 g-cm-s−2; equivalent to ergs-cm−2), and Ao/w is the oil-water interfacial area (cm2). Therefore, reduction of the oil-water interfacial tension allows creation of a larger amount of interfacial area for the same level of energy input. Note that Eq. (3-1) provides an estimate of the minimum energy input that is required to disperse oil as droplets in the water column. Additional energy, which is proportional to viscosity, will be required to form droplets by stretching a continuous oil layer to the point at which it breaks.

The seven requirements for a chemical dispersant to enhance the formation of oil droplets (NRC, 1989) are:

-

The dispersant must hit the target oil at the desired dosage.

-

The surfactant molecules in the dispersant must have time to penetrate and mix into the oil.

-

The surfactant molecules must orient at the oil-water interface with the hydrophilic groups in the water phase and the lipophilic groups in the oil phase.

-

The oil-water interfacial tension must decrease due to the presence of the surfactant molecules at the oil-water interface, thereby weakening the cohesive strength of the oil film.

-

Sufficient mixing energy must be applied at the oil-water interface (by wind and/or wave action) to allow generation of smaller oil droplets (with a concomitant increase in interfacial surface area).

-

The droplets must be dispersed throughout the water column by a combination of diffusive and advective processes to minimize droplet-droplet collisions and coalescence to form larger droplets (which can resurface in the absence of continued turbulence).

-

After entrainment, the droplets must be diluted to nontoxic concentrations and remain suspended in the water column long enough for the majority of the oil to be biodegraded.

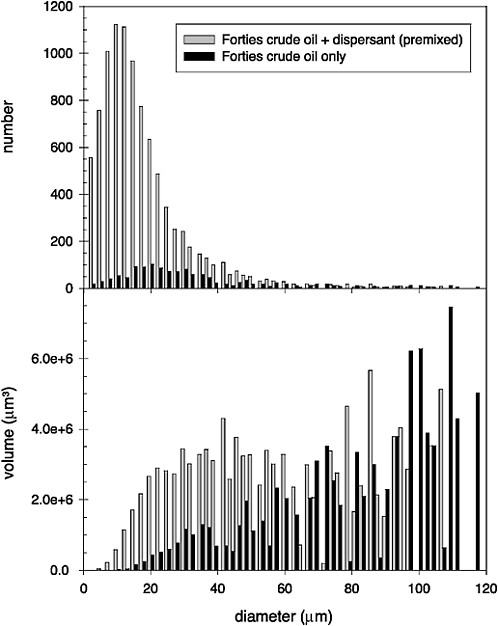

Turbulent energy is the environmental parameter most responsible for generating and transporting dispersed oil droplets in the ocean. Delvigne and Sweeney (1988) studied natural dispersion and argue that the smallest scales of turbulence, with the greatest shear, are responsible for initial droplet formation, while the larger eddy scales are responsible for the subsequent vertical transport (described in more detail in Chapter 4—Transport and Fate). Conversely, Li and Garrett (1998) argue that natural dispersion is generated mainly by dynamic pressures associated with larger eddy scales, resulting in the creation of relatively large droplets (i.e., order of 100 µm diameter) that resurface relatively quickly. They suggest that reduction of the oil-water interfacial tension by chemical dispersants allows the mechanism of turbulent shear to govern droplet formation, which leads to smaller droplets (i.e., order of 10 µm diameter), which is more consistent with the diameters observed for “permanently dispersed” droplets. Unfortunately, the droplet-size distributions of chemically dispersed oil have only rarely been compared directly to those produced when untreated oil was dispersed under identical conditions (see Box 3-1). In the few cases where direct comparisons were made, however, the volume mean diameter was reduced by 30–40 percent by dispersants (Jasper et al., 1978; Lunel, 1995b). Figure 3-3, which was reconstructed from data presented by Lunel (1995b), shows the effect of a chemical dispersant (premixed Dasic Slickgone NS) on the droplet-size distribution produced when Forties crude oil was dispersed at sea: the number of small droplets (<50 mm) increased by about 5- to 30-fold,

|

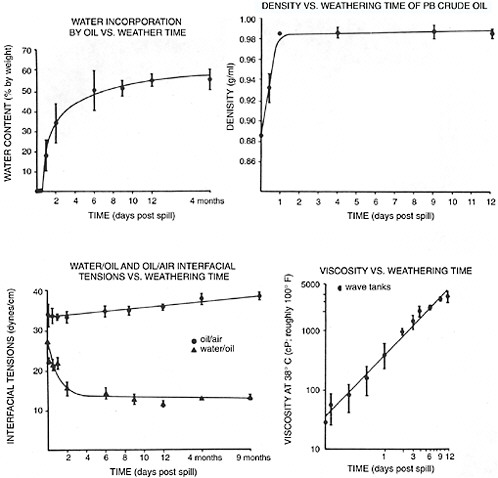

BOX 3-1 When oil is entrained in the water column due to input of turbulent energy, droplets of various sizes are produced, regardless of whether the process is enhanced by addition of dispersants. Droplet-size distributions describe the relative abundance of droplets of various sizes, which may range from <1 µm to >100 µm in diameter. These distributions can be based on either droplet number or volume, although the volume distribution may be most informative, because the relationship between droplet volume and oil mass is constant regardless of droplet size (i.e., the proportionality constant is the density), whereas the relationship between droplet number and oil mass is not. The most common metrics for characterizing the central tendency of droplet-size distributions are the mean and median diameter, which will be approximately the same if the droplet sizes are normally distributed. The number mean diameter (NMD) is a simple average of droplet diameters, whereas the volume mean diameter (VMD) is the diameter of a droplet with the average volume (i.e., the mean of the volume distribution):

(3-2) where ni is the number of droplets with diameter Di. The VMD is larger than the NMD. Number and volume median diameters (also commonly referred to as NMD and VMD) are those droplet diameters that divide the number and volume distributions in half (i.e., 50 percent of the oil volume is present as droplets smaller than the volume median diameter). |

whereas the number of large droplets (>50 mm) produced from dispersant-treated and untreated oil were similar. Note that although there were relatively few very large droplets produced from either treatment, these represented a significant fraction of the oil mass in both treatments, because the volume of oil in each droplet is proportional to the diameter cubed. Therefore, the volume distribution is extremely sensitive to uncertainty in the number of large droplets. This uncertainty can be seen in the reconstructed volume distribution shown in Figure 3-3. It is not clear whether the differences in characteristic droplet size are statistically significant, but if real, they would result in a 50–65 percent decrease in droplet rise velocity. Therefore, this phenomenon is potentially important and should be investigated further.

|

Droplet-size distributions result from the interaction of two processes: (1) droplet formation due to turbulent shear and (2) size fractionation due to differential rise velocities (Lunel, 1995b). Although the mechanism of droplet formation has not been proven, the initial size distribution of chemically dispersed oil droplets is thought to be related to the scale of the smallest eddies (i.e., microscale turbulence; Delvigne and Sweeney, 1988; Lunel, 1995b; Li and Garrett, 1998), but the distribution will be shifted toward smaller droplets following a period of quiescence due to resurfacing of larger droplets (Daling et al., 1990; Lunel, 1995b). Lunel (1995b) has suggested that dispersant effectiveness tests should be conducted in laboratory-scale systems and wave tanks that generate microscale turbulence similar to that which prevails in surface seawater, because such similarity suggests that the droplet-formation mechanisms will also be similar. Therefore, effectiveness testing should include measurement of droplet-size distributions, preferably in the presence of turbulent mixing energy, so that the observed size distribution will not be affected by size fractionation. Although droplet-size distributions have been measured in some lab-scale effectiveness-testing systems (Byford et al., 1984; Daling et al., 1990a; Lunel, 1995b; Fingas et al., 1995d), the effects of energy dissipation rate, oil and dispersant characteristics, and dispersant treatment should be more thoroughly investigated, because the existing database is not sufficient to support general conclusions regarding how (or whether) these factors affect the droplet-formation mechanisms and kinetics. Even fewer data are available regarding droplet-size distributions formed during dispersant effectiveness tests in wave tanks (Lunel, 1995b). Since one argument for increased use of these systems is their presumed ability to simulate sea surface conditions, it would be prudent to test this hypothesis by measuring droplet-size distributions and comparing them to those measured at sea. |

More effort has been focused on studying the relationship between droplet size and dispersant effectiveness, but conflicting results have been obtained. For example, one study demonstrated an inverse relationship between dispersant effectiveness and the volume median droplet diameter (Byford et al., 1984), whereas others observed no correlation between effectiveness and characteristic droplet size (Daling et al., 1990a; Fingas et al., 1995d; Lunel, 1995b). Although the relationship between effectiveness and droplet-size distribution is uncertain, the droplet-size distributions clearly vary among different experimental systems: volume mean diameters of about 3 mm were observed in a system that was mixed by a six-blade vaned-disk turbine (Jasper et al., 1978), whereas significantly larger diameters (volume median diameters of 20 to 45 µm) were observed in

experimental apparatuses that are more commonly used in dispersant testing (e.g., the Warren Springs Laboratory, Mackay-Nadeau-Steelman, and swirling flask tests) (Daling et al., 1990a; Fingas et al., 1995d). The strong dependence of droplet-size distributions on the characteristics of the experimental system are consistent with the hypothesis that they reflect microscale turbulence (Delvigne and Sweeney, 1988; Lunel, 1995b; Li and Garrett, 1998), and Lunel (1995b) suggested that laboratory-scale or wave-tank effectiveness tests should be evaluated based on their ability to produce size distributions similar to those observed at sea.

In the ocean, turbulent energy is provided mainly by the wind, either by its direct action in shearing the water surface, or through the generation of surface waves. Above a critical wind speed, waves break, creating local areas of intense mixing. Internal waves, bottom shear stress caused by tidal or wind-driven currents interacting with a fixed bottom, and river inflows may also provide turbulent energy. Because of the variety of energy sources and mechanisms for oil droplet generation, it is unlikely that any single parameter can completely characterize the mixing energy responsible for oil dispersion. This is particularly true when including consideration of bench-scale lab tests (see below) in which mixing is produced by other mechanical means such as stirring, swirling, or tumbling. Nonetheless, the parameter that is most likely to be correlated with effective entrainment and dispersion is energy dissipation rate.

Turbulent energy enters a water body at large length scales and is transferred to smaller scales by the process of vortex stretching until it is dissipated by viscosity into thermal energy at the smallest scales. At equilibrium, the rate of energy input equals the rate of energy transferred at each scale, and hence the rate of energy dissipation (Tennekes and Lumley, 1972). Energy dissipation rates can be expressed in units of energy loss per volume per time, e (J-m−3-s−1) where J is joules (kg-m2-s−2). So, the volumetric energy dissipation rate, e, can also be expressed as kg-m−1-s−3. The energy dissipation rate can also be expressed as energy loss per unit mass per time, denoted by ε (J-kg−1-s−1 or m2-s−3). The latter is numerically smaller than e by a factor of the water density (about 103 kg-m−3). Table 3-1, adapted from Delvigne and Sweeney (1988), gives approximate ranges of e and ε for a variety of water bodies.

In-situ values of the dissipation rate can be determined from highly resolved velocity measurements. Doron et al. (2001) describe several methods involving either evaluation of fine-scale velocity gradients or finding a fit to the spectrum of turbulent kinetic energy

(2)

where E(k) is the turbulent kinetic energy density as a function of wave

TABLE 3-1 Energy Dissipation Rates for Different Water Bodies

|

Water Body |

e (J-m−3-s−1) |

e (m2-s−3) |

|

Deep sea |

10−4 to 10−2 |

10−7 to 10−5 |

|

Estuary |

10−1 to 1 |

10−4 to 10−3 |

|

Surface layer |

1 to 10 |

10−3 to 10−2 |

|

Breaking waves |

103 to 104 |

1 to 10 |

|

SOURCE: Modified from Delvigne and Sweeney, 1988. |

||

number, k. The turbulent kinetic energy (i.e., the integral of E(k) over k), expressed per unit mass (units of J-kg−1 or m2-s−2), equals

where ui are the turbulent velocity fluctuations in up to i = 3 coordinate directions (Tennekes and Lumley, 1972).

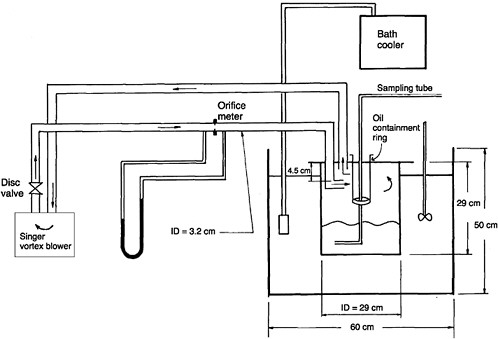

Turbulent velocities themselves have been measured using a variety of techniques, some more appropriate to the lab and others more appropriate to the field. Point measurements can be made using airfoils, acoustic time-of-travel current meters, drag-sphere devices based on the instantaneous acceleration of a small sphere, hot-wire anemometers, and acoustic and laser Doppler velocimeters (Osborn, 1974; Agrawal et al., 1992; Terray et al., 1996; Doron et al., 2001). A one-dimensional velocity field can be determined using an acoustic Doppler current profiler (Veron and Melville, 2001), or by attaching probes to a vertical profiler, glider, or moving vessel. A two-dimensional velocity field can be obtained simultaneously using particle image velocimetry where a laser is used to illuminate a plane, and velocities are determined by correlating the displacement of natural particles observed in successive images captured with a charge-coupled device camera (Doron et al., 2001; Bertuccioli et al., 1999). In a laboratory flask, column, or tank, the rate of energy dissipation can also be determined indirectly by the rate of energy input by assuming that all input energy turns into turbulence. For example, in their “grid column,” Delvigne and Sweeney (1988) determined ε by measuring the hydraulic resistance of their oscillating grid, while in their wave flumes, they determined ε by measuring the decline in wave energy as a function of distance along their tank. To the extent that ε uniquely determines oil dispersion, designing a laboratory experiment with values of ε equal to

those expected in the field allows one to directly apply observations of dispersion effectiveness in the laboratory to predict dispersion effectiveness in the field. Unfortunately, this approach has not been typically utilized in laboratory and flume studies to date.

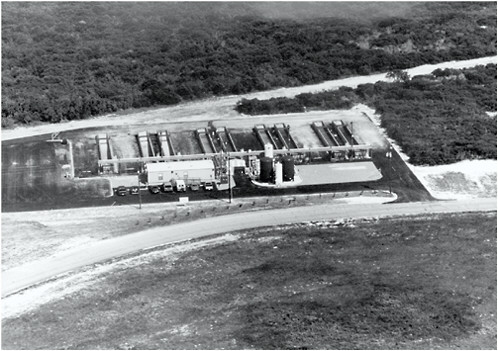

FACTORS THAT AFFECT THE OIL/DISPERSANT INTERACTION—THE WINDOW OF OPPORTUNITY AS CONTROLLED BY OIL CHEMISTRY AND WEATHERING STATE

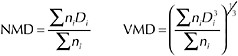

When crude oil or refined petroleum products are released at sea, they are immediately subject to a wide variety of weathering processes that affect the resulting oil’s chemical composition and physical (rheological) properties. These properties, including the chemical components responsible for stabilizing water-in-oil emulsions, are described more fully in Chapter 4. With regard to interactions with dispersants, the two most important weathering factors include evaporation and the formation of stable water-in-oil emulsions, because they both affect the spilled oil’s in-situ viscosity on the water surface. Not surprisingly both of these processes are influenced by temperature (evaporation occurs more rapidly at higher temperatures, while emulsification can occur more rapidly at lower temperatures). Figure 3-4 summarizes the changes in bulk physical properties and water content in weathered Prudhoe Bay crude oil measured in experiments conducted in three 2,800-liter outdoor flow-through wave tanks over a 13 month period at Kasitsna Bay (lower Cook Inlet), Alaska (Payne et al., 1984, 1991a). The residence time of water flowing through the tanks was 4 hours, and the water temperature ranged from about 2° C (roughly 35° F) in the winter to 14° C (roughly 57° F) in the summer. Note the rapid change in properties after as little as 1–2 days of weathering under subarctic conditions. Although the initial oil-water ratio in these experiments was relatively high (1:175) and surface spreading of the oil was limited by the walls of the tank, the changes in oil chemistry and rheological properties that occurred in this oil over time were remarkably similar to those that were observed in the Alaska North Slope crude oil released from the T/V Exxon Valdez oil spill in Prince William Sound, Alaska (Payne et al., 1991a).

Viscosity is typically reported in dynamic units of centipoise (cP; 0.01 dyne-s-cm−2 or 0.01 g-cm−1-s−1). It may also be reported in kinematic units of centistokes (cSt; 0.01 cm2 s−1) by dividing the dynamic viscosity by the fluid density. Because the density of oil is usually between 0.8 and 1.0 g-cm−3, viscosities reported as cP and cSt are numerically similar, but the kinematic viscosity may be up to 25 percent larger than the dynamic viscosity. To provide perspective on the viscosity of weathered oil, Table 3-2 presents data for the water-in-oil emulsions from the wave-tank

FIGURE 3-4 Changes in various physical properties of Prudhoe Bay crude oil as a function of weathering time. The values given are means from the three replicate summer wave tank experiments ± one standard deviation.

SOURCE: Payne et al., 1991a.

studies along with examples of the viscosities for several common food and household items.

During most of the 1980s, oils or emulsions with viscosities greater than 2,000 cP were considered to be difficult or impossible to chemically disperse (NRC, 1989). More recent studies (Fiocco et al., 1999; Guyomarch et al., 1999a) have shown that a number of intermediate fuel oils and weathered water-in-oil emulsions with viscosities approaching 20,000 cP can at least be partially dispersed in laboratory and field trials with multiple applications of newer hydrocarbon-solvent-based dispersants and demulsifiers (e.g., Corexit 9500, Inipol IP 90, Slickgone NS, Alcopol,

TABLE 3-2 Example Viscosities of Foods and Other Liquids.

|

Product |

Temperature (°C) |

Viscosity (cP) |

|

Water |

20 |

1.0 |

|

Ethyl alcohol |

20 |

1.2 |

|

Olive oil |

40 |

36 |

|

Fresh Prudhoe Bay crude oil (PBCO) |

14 |

68 |

|

Olive oil |

20 |

84 |

|

Olive oil |

10 |

138 |

|

Castor oil |

20 |

986 |

|

48-hr weathered PBCO water-in-oil emulsion |

14 |

1,080 |

|

72-hr weathered PBCO water-in-oil emulsion |

14 |

2,350 |

|

Pancake syrup |

20 |

2,500 |

|

144-hr weathered PBCO water-in-oil emulsion |

14 |

5,400 |

|

Honey |

20 |

10,000 |

|

Chocolate syrup |

20 |

25,000 |

|

Ketchup |

20 |

50,000 |

|

Peanut butter |

20 |

250,000 |

|

SOURCE: Data from CRC (1967), Transtronics (2000), and outdoor subarctic wave-tank experiments described by Payne et al. (1984, 1991a). |

||

Demoussifier, Gamabreak, and Demulsip). As a result, these researchers have concluded that there is no hard and fast rule for the upper viscosity limit for dispersibility of water-in-oil emulsions.

If the pour point of the oil or refined product is above the ambient temperature encountered during a spill, the oil will not flow (it behaves as a semi-solid plastic-like material) and cannot be chemically dispersed. It has also been noted that certain highly paraffinic (waxy) crude oils can form a surface film due to evaporation of light ends (Berger and Mackay, 1994) and that photooxidation can lead to the formation of tar and gum residues (Payne and Phillips, 1985a,b; NRC, 1985, 2003), and it has been suggested that such surface layers may inhibit dispersant penetration into those oils.

Extensive research has been undertaken on the numerous factors responsible for the formation of stable water-in-oil emulsions with different oils (Bridie et al., 1980a,b; Zagorski and Mackay, 1982; Payne and Phillips, 1985b; Mackay, 1987; Bobra, 1990, 1991; Fingas and Fieldhouse, 1994, 2003, 2004a,b; Fingas et al., 1995a,b, 1996b, 1998, 1999, 2000a,b; Walker et al., 1993a,b, 1995), and the major findings from much of this research are briefly summarized in Chapter 4. The current consensus among researchers is that the type and stability of the emulsions is controlled by the properties of the starting oil, especially the asphaltene and resin content and

initial oil viscosity (Fingas and Fieldhouse, 2003). Notwithstanding these advances, most of the existing knowledge on whether or not a particular oil will emulsify under given environmental conditions is empirical, and Fingas and Fieldhouse (2003) compiled a comprehensive data set that was used to develop a model of emulsification rate and stability (Fingas and Fieldhouse, 2004a, b). Although the predictions of this model are reasonably accurate, it is not always possible to predict whether a particular oil will emulsify under specified environmental conditions in the field and what the final water content will be. Often at the time of a spill, the critical compositional data (percent saturates, asphaltenes, resins, etc.) for the oil are not immediately available, and as a rough approximation the >343° C (roughly >650° F) boiling point fraction has been used as a surrogate in predicting whether mousse formation is likely (NRC, 1989). If that fraction is greater than 40 percent, the oil may emulsify and be difficult to disperse.

Empirical models of oil dispersibility with Corexit 9500—as measured in the swirling-flask laboratory test—were also recently developed (Fingas et al., 2003b). These models, which range in complexity from two (viscosity and density) to fourteen parameters, were developed by determining the effects of twenty-nine physical and chemical properties on oil dispersibility. Viscosity was found to be the most important physical property in determining dispersibility, but various aspects of chemical composition (e.g., the concentrations of n-dodecane, n-hexacosane, and naphthalenes) were more highly correlated. The most effective models were used to predict the dispersibility of 295 oils in the Environment Canada oil properties catalog (Environment Canada, 2005). Although these correlations may be useful for predicting and ranking the dispersibility of a large number of oils, the authors caution that the laboratory tests (upon which the correlations are based) may not provide a direct representation of what can be obtained in the field where different salinity and energy regimes are likely to be encountered.

Based on the above considerations and from practical experience, it is evident that response actions using dispersants should be initiated as soon as possible, and every effort should be made to apply the dispersants before significant oil weathering has occurred (usually within 24–72 hours in temperate conditions and possibly within 12–24 hours during the winter and under arctic conditions) to improve the probability of success. It should be noted that increased viscosity and water content in an emulsion also affect the ability to treat spilled oil by other response methods. For example, increased viscosity makes oil harder to pump, and increased water content increases the volume of material that must be handled and stored. For heavier oils, water contents above 20–30 percent make in-situ combustion essentially impossible (Twardus, 1980; Fingas and Punt, 2000).

Weather Considerations and the Window of Opportunity

Another important factor to be considered in evaluating the window of opportunity for effective dispersant applications is the energy regime at the time of dispersant application. As discussed in the previous section, a certain minimum energy (i.e., wind speed of 5 m/s; Allen, 1988; Fingas and Ka’aihue, 2004a), is required to break up the oil slick into small droplets, but applications under higher energy conditions can be plagued by other factors, such as:

-

dispersant drift in the wind (missing the target as discussed in Chapter 2),

-

possibly washing the dispersant off the slick before it penetrates into the oil phase, and

-

the fact that the benefits of dispersant application begin to diminish compared to natural dispersion at wind speeds of 12–14 m/s (Allen, 1988; Fingas and Ka’aihue, 2004a).

Likewise, when dispersants are applied under low-energy conditions (little or no wind and/or reduced sea states), there may be a time lag between dispersant application and a subsequent increase in sea state (energy regime) to enhance dispersion. This delay also can lead to the potential for leaching of the dispersant from the oil phase before there is sufficient energy to promote droplet dispersion. It is believed that this problem might be avoided with some of the newer hydrocarbon-solvent-based dispersant formulations (or by additional adjustments to the HLB), but no studies on leaching of surfactants from the oil phase have been conducted at realistic oil-to-water ratios and under different energy regimes to test this hypothesis. In particular, the effects of surfactant leaching on the effectiveness of initial oil dispersion and the potential for dispersed oil droplet coalescence should be understood better. Recent laboratory studies have shown that surfactants do not appear to inhibit droplet coalescence, but the behavior of dispersed droplets and the concomitant leaching of surfactant under conditions of high dilution have not been studied. This is important because it will eventually affect dispersed oil behavior and the potential for re-surfacing in the field.

HISTORY OF DISPERSANT USE IN THE UNITED STATES

At the time of this writing, dispersant use in the United States had been limited to spills in Alaska (i.e., the T/V Exxon Valdez spill in 1989) and a series of smaller spills in the Gulf of Mexico (spanning 1999 to 2004). Understanding the circumstances and results of these actions provides

some insight into the consequences of dispersant use, and thus is summarized below.

T/V Exxon Valdez Oil Spill (EVOS), Prince William Sound, Alaska (1989)

Spilled Oil Type/Volume/Conditions

An estimated 38,000 tonnes (roughly 250,000 bbls) of Alaska North Slope crude oil were released from T/V Exxon Valdez when it grounded on Bligh Reef in northeast Prince William Sound, Alaska, on March 23, 1989. Alaska North Slope crude has an API gravity of 29.8, a relatively high asphaltene content, and tends to form stable emulsions. Weather conditions were calm and clear.

Physical and Biological Setting

Prince William Sound includes many narrow fiords with deep, cold (<5° C [roughly 41° F]) seawater of low salinity and modest circulation. Rocky outcroppings and gravel beaches are common. There are an extensive local fisheries for both finfish and shellfish, as well as robust sport-fishing and tourist industries throughout the Sound.

Dispersant Application

Two weeks prior to the spill, the Alaska Regional Response Team had adopted the first pre-approval zones for dispersant use in the United States. The spill occurred in Zone 1, where the state and federal coordinators could approve dispersant use on their own authority. Stockpiles of Corexit 9527 were available locally in Valdez, Anchorage, and Kenai. Both helicopters and large military C-130s were available within the state. However, there were no large capacity application packages (e.g., ADDS pack) in Alaska, and only a single helicopter bucket spray system was stored in Kenai (Alaska Oil Spill Commission, 1990)

Twelve hours into the spill, the helicopter bucket system arrived in Valdez and was immediately loaded with Corexit 9527 and used on the evening of March 24, and again on the morning of March 25. A third attempt on the morning of March 26 failed due to applicator malfunction. A fourth and final helicopter application occurred late in the afternoon of March 26. The first large-scale dispersant application occurred on the morning of March 27, 80 hours into the spill. In total, 5,500 gallons (roughly 20,800 liters) of Corexit 9527 were applied by C-130 (Alaska Department of Environmental Conservation [ADEC], 1993).

Monitoring Results

The U.S. Coast Guard and State of Alaska agreed that, on the first two days of helicopter applications, calm conditions did not supply sufficient mixing energy to achieve any noticeable effects. On the evening of the third day, visibility was poor and visual monitoring of the final helicopter application was inconclusive. Nevertheless, with the weather picking up, the decision was made to allow full-scale application in Zone 1 with a one-mile exclusion zone around the grounded tanker. Unfortunately, both T/V Exxon Valdez and the lightering tanker Baton Rouge were heavily sprayed during the next application, forcing a suspension of this extremely vital and difficult operation in order to decontaminate both personnel and equipment. No other effects of this dispersant application were observed. The State of Alaska, citing Exxon’s inability to “accurately and effectively target the dispersant,” declined to allow further dispersant application outside of Zone 1 (Alaska Department of Environmental Conservation, 1989). In any event, a large storm arrived with 40–70 knot (roughly 74–129 kilometers per hour) winds. The window for dispersant use was closed.

In its final report on the T/V Exxon Valdez oil spill, ADEC felt it necessary to state, “There was never a case in which loaded dispersant planes were held on the ground because the government couldn’t or wouldn’t make a decision” (Alaska Department of Environmental Conservation, 1993, p. 58).

Gulf of Mexico (1999 to 2004)

Between 1999 and 2004, dispersants were used seven times to combat oil spills in the Gulf of Mexico. In six of these cases, dispersants were used under the existing pre-approval plan for oil spills greater than 3 nautical miles offshore and in waters of greater than 10 m depth. Four of these dispersant cases are summarized below.

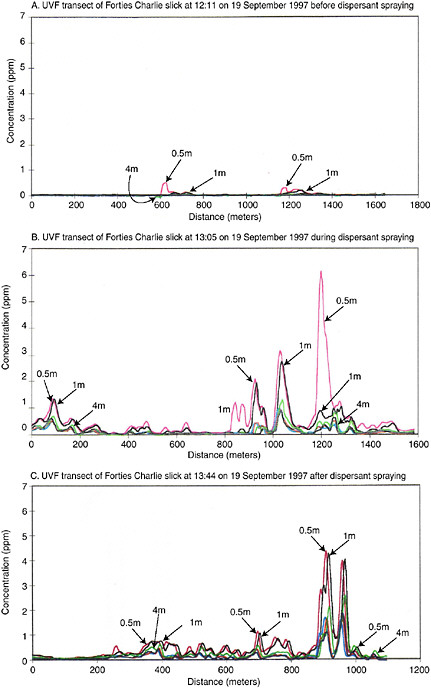

High Island Pipeline Spill (January 1998)

Approximately 360 tonnes (roughly 2,500 bbls) of South Louisiana crude (API gravity 38.2) were treated with Corexit 9527 using DC3 and DC4 aircraft. The application was very successful, based on aerial observations, SLAR measurements that showed decreased slick size, and SMART monitoring using field fluorometers that showed increased dispersed oil concentrations under the treated slick (Gugg et al., 1999).

BP-Chevron Pipeline Spill (October 1998)

Between 530 and 1,070 tonnes (roughly 3,700–7,500 bbls) of South Louisiana crude (API gravity 28.6) were released during a routine pipeline transfer operation at an offshore oil platform. Approximately 12,000 L of Corexit 9500 and 6,650 L of Corexit 9527 were applied to two of the three oil slicks over a period of two days using DC3 and DC4 aircraft. Visual observations suggested that the dispersant application was successful, but no confirmatory water-column data were obtained due to malfunction of the in-situ fluorometer that was deployed with the on-water monitoring team. Chemical analysis of water samples collected from the area of one of the treated slicks on the second day of dispersant operations showed only low concentrations of dispersed oil in the water column. British Petroleum estimated that approximately 160 tonnes (15 to 31 percent) of oil were chemically dispersed based on an assumed 80 percent effectiveness on the first day and 60 percent effectiveness on the second day, but these values were not independently confirmed by NOAA or the U.S. Coast Guard. ADIOS modeling predicted that about 33 percent of the oil was removed by evaporation. Only about 3 bbls of oil were recovered by mechanical response. This dispersant operation was considered to be successful due in part to the quick and aggressive chemical-treatment response and the good dispersibility of the oil (C. Henry, National Oceanic and Atmospheric Administration, New Orleans, Louisiana, written communication, 2004).

M/V Blue Master Spill (August 1999)

Approximately 17 tonnes (roughly 100 bbls) of IFO 180 (specific gravity of 0.988) were released from the M/V Blue Master following a collision with a fishing vessel 55 km south of Galveston, Texas. With light winds and calm seas, the oil was concentrated in a current-generated convergence zone. Within 12 hours after the spill and just before dark, 2,660 L of Corexit 9500 were applied (ratio of 1:6). Next-day observers reported a marked reduction in heavy concentrations of oil. It was considered a “cautious success” because only 0.25 tonne (roughly 1.8 bbls) of tarballs stranded onshore two weeks later (Kaser et al., 2001). Water-column oil concentrations were not measured to confirm that dispersion occurred.

Poseidon Pipeline Spill (January 2000)

Approximately 290 tonnes (roughly 2,000 bbls) of S. Louisiana crude (API gravity 31.5) were released from a 24 inch (roughly 60 cm) pipeline 65 miles (roughly 110 km) south of Houma, Louisiana that was caught

and dragged by a large anchor. Due to 1–2 m seas, mechanical recovery was determined to be ineffective. Within 7 hours after the release, 11,400 L of Corexit 9527 were applied by DC3 and DC4 aircraft, resulting in an estimated 75 percent effectiveness, based on visual observations and fluorometry measurements. The next day, another 3,800 L were applied to the remaining patches of dispersible oil. There was no visual observation of a dispersed oil plume, but fluorometry did detect increased oil concentrations in the water under the treated oil. By the end of the second day of the release, it was determined that the remaining oil slicks were not dispersible. The applications were considered to be highly successful (Stoermer et al., 2001).

In summary, dispersants have been used successfully on oil spills in the Gulf of Mexico on several occasions in the past seven years. Because of the close proximity of dispersant application resources, responders were able to mobilize dispersant operations relatively quickly, which may have contributed to the overall success. Effectiveness, however, was evaluated primarily by visual observation, and not all operations included confirmation by measurement of dispersed oil in the water column. Therefore, the reliability of effectiveness estimates is unknown.

EFFECTIVENESS TESTING AND EFFECTIVENESS ISSUES

The overall effectiveness of oil dispersion has three components: (1) operational effectiveness, which describes the encounter probability of the dispersant application and the ability of the dispersant to become incorporated into the floating oil, (2) chemical effectiveness, which is measured by the fraction of treated surface oil that becomes stably entrained as small droplets in the water column, and (3) hydrodynamic effectiveness, which describes the transport of the chemically dispersed oil plume and its dilution by turbulent diffusion through horizontal and vertical mixing processes. The main focus of this section is a review of the experimental methods that have been used to investigate the chemical effectiveness of oil dispersants, but because the effectiveness that would be realized during spill-response operations at sea is determined by the interaction of all three components, those aspects of operational and hydrodynamic effectiveness that can be studied in effectiveness tests are identified and discussed where appropriate.

Operational effectiveness is determined by site-specific parameters, such as the patchy distribution of oil on the water surface, the ability to accurately target and hit the thicker parts of oil slicks with the dispersant spray, and the size distribution and impact velocity of dispersant droplets that hit the floating oil (as discussed in Chapter 2). It is difficult to simulate important characteristics of dispersant application in laboratory-scale

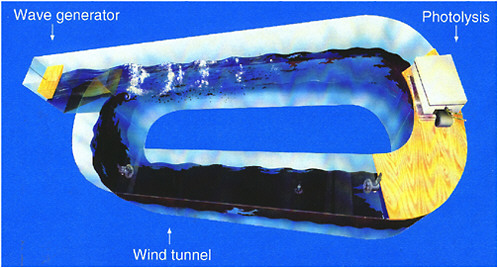

experimental systems due to their relatively small size. Some large wave tanks can investigate many, but not all aspects of operational effectiveness. Operational effectiveness can be tested best in studies conducted at sea, provided the scale of the experiment is sufficient. Monitoring of operational effectiveness is the primary objective during real spill applications.

Hydrodynamic effectiveness is discussed primarily in Chapter 4 because it is governed by the transport of the dispersed oil plume. Hydrodynamic effectiveness cannot be tested in laboratory-scale systems or wave tanks, because significant dilution can only occur due to externally imposed flow through the system, not due to eddies of varying scales (e.g., turbulent diffusion and hydrodynamic dispersion). In principle, full-scale field studies can test hydrodynamic effectiveness, but appropriate measurements can be difficult and this is not always done.

Chemical effectiveness has been investigated in the laboratory, in wave tanks, and at sea. In many of these studies, effectiveness was defined based on chemical effectiveness, which was quantified as the mass fraction of oil that was measured in samples collected from the water column or the mass fraction that was not recovered from the water surface as floating oil. This definition has resulted in some confusion when attempting to compare studies conducted using different experimental systems, because these effectiveness metrics are operationally defined and measure different things in different systems. For example, some experimental designs include oil droplets that are large enough to resurface relatively quickly in the dispersed-oil concentration (e.g., those that measure water-column oil concentrations during periods of intense mixing), whereas others do not (e.g., those that include a settling period before measurement of dispersed-oil concentrations). Similarly, oil that is not recovered on the water surface may have been transferred to any of several compartments, of which the water column is only one. The droplet-size distribution of dispersed oil is a particularly important factor for chemical and hydrodynamic effectiveness, because it will determine whether the entrained oil will remain in the water column or float back to the surface under low energy conditions, which are unlikely to be the same during spill-response operations and effectiveness tests, regardless of the scale of the test. Future studies should include measurement of droplet-size distribution or some related metric to facilitate comparison among treatments. Lunel (1995b) has suggested that effectiveness tests should produce droplet-size distributions similar to those observed at sea, because this indicates similarity in the droplet-formation mechanisms.

Objectives of Effectiveness Testing

Dispersant effectiveness testing is performed using experimental systems that encompass a wide range of physical scales, from small (hundreds of milliliters) bench-scale systems to large (thousands of cubic meters) wave tanks, to open-ocean testing. All experimental systems used to evaluate dispersant effectiveness suffer from significant limitations; thus, it is important to clearly identify the objectives of the investigation before selecting an experimental system and designing an effectiveness study. Investigations of dispersant effectiveness are conducted for several common reasons: product screening; comparison of commercially available products for specific applications; fundamental investigations into the mechanisms that control dispersion of floating oil; and prediction of dispersant effectiveness under spill-response conditions. These objectives are quite different, and the experimental designs should reflect the differing requirements for data quality and application.

Effectiveness tests can be grouped into four broad categories: bench-scale tests; wave-tank tests; planned field studies; and spills of opportunity. Bench-scale tests often involve relatively common equipment, such as flasks and separatory funnels that are adapted or modified for the specific purpose of testing dispersants. They are also called laboratory-scale tests. Most wave tanks or hydraulic flumes are relatively small, but at least one, the Oil and Hazardous Materials Simulated Environmental Test Tank (OHMSETT), is very large. Although both are considered in the same category, the advantages and disadvantages of large vs. small wave tanks for dispersant effectiveness tests can be significant. Planned field studies and spills of opportunity also have many similarities, but the advantages and disadvantages are sufficiently different that they are considered separately. In general, as the physical scale of an effectiveness test increases, the cost and realism (i.e., the degree to which the test includes all three components of effectiveness) increase, but the degree to which the factors that affect dispersion effectiveness can be controlled and the ability to quantitatively measure effectiveness decrease. As a result of these competing trends, especially between realism and control, effectiveness tests at different scales are appropriate for achieving different objectives, and experimenters should be careful to match the objectives with the appropriate experimental scale.

Screening of dispersant products is often conducted for regulatory purposes. In the United States, dispersant products must be on the National Contingency Plan (NCP) Product Schedule to be considered for use as a response alternative for oil spills in U.S. marine and coastal waters (EPA, 2003). Inclusion on the NCP Product Schedule is contingent on demonstration that the candidate dispersant is capable of dispersing at least

45 percent of South Louisiana crude oil and Prudhoe Bay crude oil in the laboratory-scale swirling flask test. Although the specific method used in this procedure is likely to change in the near future, the objective of this test remains the simple demonstration of a prescribed degree of chemical effectiveness as measured by the concentration of oil in water samples collected from the bottom of the flask after a specified settling period to allow larger droplets to return to the water surface. The outcome is a pass-fail decision: if the product achieves the prescribed degree of dispersion, it may be included on the NCP Product Schedule (assuming it meets all other required criteria, such as successful toxicity testing); if it does not, the dispersant will not be included on the NCP Product Schedule, and it cannot be used in the United States as an oil spill countermeasure.

A related objective of effectiveness testing is comparison of available dispersants for specific applications, such as their ability to disperse specific crude oils or refined products under the environmental conditions that are known to prevail in certain regions (Blondina et al., 1997; Moles et al., 2002; White et al., 2002; Stevens and Roberts, 2003). These tests often attempt to compare the performance of specific oil-dispersant combinations under defined or standardized testing conditions. The results of these studies are intended to provide guidance for spill responders and regulators regarding selection of appropriate response actions or products. Due to the very large number of potential oil-dispersant combinations, the wide range of environmental conditions that may need to be considered, and the difficulty of extrapolating performance data beyond specifically tested conditions, these tests should be relatively simple. As a result, these comparisons are often conducted in bench-scale systems, but more limited testing has also been conducted in wave tanks and at sea.

Effectiveness tests may also be used in fundamental investigations of the mechanisms that control natural or chemically enhanced dispersion of oil into water (Belk et al., 1989; Fingas et al., 1991; Blondina et al., 1999; Canevari et al., 2001; Chandrasekar et al., 2003). Factors that have been investigated include dispersant-to-oil ratio (DOR), salinity, dispersant characteristics (e.g., hydrophilic-lipophilic balance, surfactant chemical structure, solvent characteristics), mixing energy, and the physical-chemical characteristics of the oil. Again, due to the wide range of conditions that may be of interest, the requirement for appropriate control treatments, and the need to rigorously control experimental conditions to facilitate testing of specific mechanisms, bench-scale systems are often used for these studies.

Ultimately, the objective of most effectiveness tests is to provide insight into the potential effectiveness of dispersants under actual spill-response conditions. Although most spill responders agree that quantitative prediction of dispersant performance is extremely difficult—if not

impossible—based on current understanding of the factors that control it, the decision-making process during oil spill response involves implicit assumptions regarding expected effectiveness. For example, most oil transport and fate models that include an option for simulating dispersant application (e.g., French-McCay and Payne, 2001; Lehr et al., 2002; Simecek-Beatty et al., 2002; French-McCay, 2004) use effectiveness estimates as model inputs. These estimates are often based on experience and professional judgment rather than extrapolation from effectiveness tests and, as such, are not predictive. A major goal of chemical dispersant research should be development of quantitative tools for predicting dispersant performance (i.e., mathematical models) that can systematically incorporate many different types of information and the best current scientific understanding regarding droplet-formation and transport mechanisms. Ideally, dispersant effectiveness would be an output of a mathematical model, and the inputs would be factors such as oil characteristics, weather conditions, and other operational factors (e.g., dispersant type, effective DOR). Although multiple-regression models that relate oil dispersibility in a lab-scale effectiveness test to chemical composition have been proposed (Fingas et al., 2003b), these are completely empirical and cannot predict performance in the field—due at least in part to the inability to scale performance predictions from laboratory conditions to the field—and are not, therefore, useful for this purpose. Regardless of whether the predictions are quantitative (i.e., based on a mathematical model) or qualitative (i.e., based on the judgment of experienced professionals), effectiveness tests may provide the needed input parameters. In order to be useful, however, the effectiveness tests should be properly designed and the results should be interpreted with appreciation of their strengths and limitations.

Design of Effectiveness Tests

Effectiveness tests, regardless of the specific objectives or configuration of the experimental system, should explicitly consider how the experimental design will affect the results. Factors that are known to affect the extent of oil dispersion should be carefully controlled or characterized to the extent that is possible given the configuration of the experimental system. Examples of such factors include but may not be limited to the following: physical and chemical characteristics of the oil; physical characteristics of the surface slick; oil-water and dispersant-oil ratios; salinity and temperature; physical and chemical characteristics of the dispersant; method used to apply the dispersant to the oil; energy provided to disperse the oil; and the method used to measure effectiveness. In addition, the experimental design should include a clear description of the data

analysis procedures that will be used, especially those used to estimate the random error term in the response variables, which is required in order to compare treatments. When possible, experimental designs should include independent replication of treatments and appropriate controls. Positive as well as negative controls (as discussed below) should be included whenever possible. Although these principles can be applied at all scales at which dispersant effectiveness can be tested, time and financial constraints will limit the degree to which they can be implemented as the scale of the test system increases. Such practical limitations, however, make clear definition of objectives and careful experimental design more—not less—important with increasing scale.

Among the factors that affect dispersion efficiency, the physical characteristics (e.g., pour point, viscosity, density) and chemical composition (especially aliphatic, aromatic, and asphaltic hydrocarbon concentrations) of the oil have received considerable attention. These characteristics are important because they can vary greatly among oils from different sources and change relatively quickly as oil weathers following a spill. Viscosity, which is roughly correlated with API gravity and density (Speight, 1991), has long been recognized to be an important parameter controlling the efficiency of oil dispersion (Daling, 1988), but viscosity alone is an insufficient predictor of dispersion efficiency (Fingas et al., 1991; Canevari et al., 2001). As a result, the chemical composition of the oil has also been considered, with various investigators identifying either positive or negative correlations between chemical effectiveness and the aliphatic, aromatic, polar, and asphaltene fractions of oil (Fingas et al., 1991, 2003b; Blondina et al., 1999; Canevari et al., 2001). Unfortunately, the nature of the relationships between composition and dispersion effectiveness is not well understood, and many of the results are contradictory. So, additional well-planned investigations are needed. It seems likely that some of the confusion may be due to unrecognized or unquantified differences among the experimental systems, such as the energy input or the characteristics of the oil droplets that are measured as dispersed. Therefore, future experiments should measure energy dissipation rates and the droplet-size distributions of dispersed oil. The dynamic changes that can occur in physical properties and chemical composition of oil during weathering make empirical investigation of these relationships particularly complex.

An important interaction likely exists between the physical characteristics of the oil and the method of dispersant addition. The dispersant must penetrate into the oil phase to effect dispersion, and certain physical characteristics (e.g., high viscosity) of the oil can prevent this from occurring efficiently (Canevari, 1984). Some investigators have suggested that evaporative weathering of waxy crude oils can lead to the formation of a viscous “skin” (Berger and Mackay, 1994) that may provide additional

resistance to dispersant penetration. Few dispersant effectiveness tests use realistic weathering or dispersant application methodologies, and pre-mixing the dispersant with oil is not uncommon. Many bench-scale tests add dispersant to floating oil, but the drop size is typically much larger (>1,600 µm diameter) than would be expected from a typical spray system (350–500 µm; NRC, 1989). For example, several studies involved addition of dispersant to floating oil in volumes ranging from 2 to 10 µL (Blondina et al., 1997, 1999; Venosa et al., 2001; Sorial et al., 2004a), which correspond to droplet diameters ranging from about 1,600 to 2,700 µm. Droplet velocity at impact with the oil is another important aspect of dispersant application that is not adequately simulated in existing bench-scale effectiveness tests. In general, this aspect of dispersant effectiveness, which would be considered operational, is not adequately characterized or controlled in most existing effectiveness tests at any scale. Wave tanks provide the most appropriate system for investigating the relationship between dispersant penetration and oil characteristics, because these systems are large enough to use realistic dispersant application systems (e.g., spray booms with typical nozzles) and can be controlled well enough to characterize the fraction of dispersant droplets that come into contact with floating oil. Therefore, the effects of oil characteristics (e.g., chemical composition, rheological properties, extent and mechanism of weathering) on the ability of dispersants to interact effectively with the oil should be investigated in future wave-tank studies and should be considered when interpreting the results of field-scale effectiveness tests.

The DOR and oil-to-water ratio (OWR), both typically measured on a volume-to-volume basis, are critical factors affecting dispersion effectiveness. Several investigators have shown a direct relationship between DOR and dispersion efficiency (Fingas et al., 1991; White et al., 2002); a DOR of 1:25 is commonly used, but this value can vary by a factor of two or more in either direction in some studies. The OWR of experimental systems for testing the chemical effectiveness of different dispersants can vary over a much larger range, with the values of lab-scale systems reportedly ranging from 1:1 to 1:120,000 (Fingas et al., 1989). The OWR affects the efficiency of oil dispersion in a variety of ways, some of which can have opposing effects. For example, anionic and nonionic surfactants with a high HLB will tend to partition into the aqueous phase where they cannot effectively promote formation of small oil droplets. The extent of partitioning will be determined in part by the OWR: when the OWR is high, more of the surfactant will be associated with the oil phase where it can facilitate droplet formation. Alternatively, high OWR could reduce the observed dispersion efficiency by increasing the rate of droplet coalescence, which is proportional to the number concentration of oil droplets (NRC, 1989). Droplet coalescence will produce larger oil droplets that can resur-

face more quickly and reduce the mass of oil entrained in the aqueous phase.

One of the most important factors in dispersant effectiveness testing is energy dissipation rate (e.g., mixing energy). Energy is required to create new oil-water interfacial area, which occurs when an oil slick breaks up into dispersed oil droplets. Successful oil dispersion will increase the oil-water interfacial area by a factor of ten or more, and sufficient energy should be provided to form the new oil-water interfacial area. Increased mixing energy, therefore, should result in the formation of smaller droplets (i.e., larger oil-water interfacial area). Because smaller droplets will have less tendency to resurface, higher mixing energy should result in more efficient and more stable dispersion. Energy dissipation rate is a parameter that varies widely among experimental systems, and differences among the results obtained with various systems are often attributed to differences in this parameter. Despite its importance, the energy dissipation rate is not measured in most dispersant effectiveness tests, and the relationship between mixing energy and effectiveness is only rarely investigated (Kaku et al., 2002; Fingas, 2004b). When it is, however, dispersion effectiveness is found to be directly proportional to mixing energy, but the proportionality varies among oil-dispersant combinations (Fingas et al., 1996a; Sorial et al., 2001; Chandrasekar et al., 2003). Predicting dispersant effectiveness for spill response based on bench-scale or wave-tank studies is hampered by our lack of understanding of the effect of mixing energy on oil dispersion for specific oil-dispersant combinations and the relationship between energy dissipation rates that prevail in common experimental systems and typical values at sea (1 to 10 J-m−3-s−1 in open-ocean surface) (Delvigne and Sweeney, 1988).

An important aspect of any experimental design is identification and measurement of the endpoint. For dispersant effectiveness testing, the endpoint is often defined to be the percent of added oil that is dispersed into the water column. For larger-scale systems, such as wave tanks and field studies, the water-column sample collection protocols can affect the observed effectiveness because the distribution of dispersed oil droplets is likely to be heterogeneous (Brown et al., 1987; Brown and Goodman, 1988; Lewis and Aurand, 1997). The concentration that is measured will depend on the location at which the sample is collected, and multiple samples will be required to characterize the distribution and estimate the total mass of dispersed oil. The mass of floating (non-dispersed) oil remaining on the surface is sometimes measured in wave tanks (Brown et al., 1987; Brown and Goodman, 1988; Louchouarn et al., 2000; Belore, 2003; Bonner et al., 2003) and field studies (Lewis et al., 1995a,b, 1998a), but many errors can be reflected in these measurements, including incomplete recovery of floating oil, unquantified losses due to evaporation, dis-

solution, or sorption to surfaces in the experimental system, and uncertainty in the distribution of floating oil (e.g., the size of the slick and variations in slick thickness with position; Fingas and Ka’aihue, 2004c).

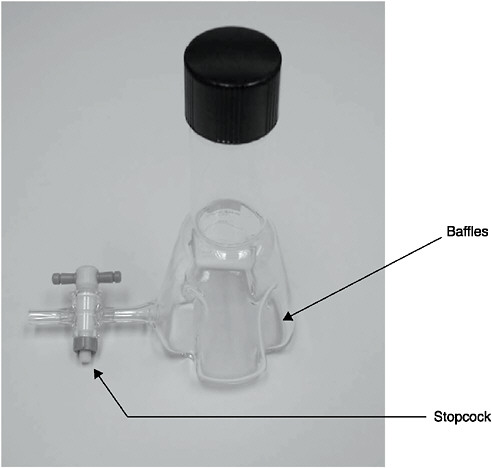

In laboratory-scale tests, chemical effectiveness measured as percentage of oil dispersed into the water column is very sensitive to the settling time that precedes collection of samples, regardless of which method is used to measure the dispersed oil concentration (Fingas et al., 1989; Daling et al., 1990b; Venosa et al., 1999). This sensitivity is largely due to resurfacing of large oil droplets. Experimental methods that measure the dispersed oil concentration while mixing is occurring (e.g., the Institute Francais du Petrole and Mackay-Nadeau-Steelman tests) tend to result in greater “effectiveness” than those that involve a discrete settling period (e.g., the Labofina, swirling flask, and baffled flask tests). Coalescence of oil droplets, which is promoted by high oil-to-water ratios, can further decrease the measured effectiveness for tests that involve a settling period. Like mixing energy, settling periods vary among effectiveness tests, ranging from zero to about ten minutes. Because mixing energy affects the droplet-size distribution, which will affect the fraction of dispersed oil that resurfaces during the settling period, interpretation of dispersion effectiveness is difficult when the only endpoint is percentage of oil dispersed into the water column. As a result, more generally useful information would be obtained if effectiveness tests measured droplet-size distribution in addition to the mass fraction of oil dispersed into the water column or remaining on the water surface.

An objective of dispersant effectiveness testing at all levels is to determine whether addition of a chemical dispersant to a floating oil slick will increase the amount of oil that is transferred into the water column as small droplets relative to the amount that would be transferred from an untreated oil slick or from a slick treated with a different dispersant. This implies that a comparison should be performed to achieve the objectives of the experiment. For example, if one wishes to determine whether a particular dispersant is effective on a particular oil, the extent of dispersion that occurs for the oil-dispersant combination under specified conditions of temperature, salinity, and mixing energy should be compared to the extent of dispersion that occurs when the oil is exposed to the same conditions in the absence of dispersant. Such a comparison should involve estimation of the uncertainty in the amounts of dispersed oil measured in the presence and absence of the dispersant. The statistical significance of the effect of the dispersant is determined by estimating the probability that the difference in the amount of dispersed oil observed in the presence and absence of dispersant could be due to chance (i.e., the probability that a similar difference would be observed if the experiment were conducted without application of dispersant to either treatment).

The most reliable method for estimating the uncertainty in a measurement is to repeat it several times under identical but independent conditions. Independence of replicate measurements requires, at a minimum, that they be performed in separate experimental units (Hurlbert, 1984; Ruxton and Colegrave, 2003). In addition, some experimental designs, especially those involving large physical scales (e.g., field studies, large wave tanks), may require replication over time (see Box 3-2). Because the experimental conditions (e.g., weather) may vary from day to day, the replicates for different treatments should be interspersed in time to preclude the possibility that factors other than the treatment(s) under investigation will result in endpoint differences that are correlated with the treatment.

When an experimental design requires tests to be conducted over a prolonged period of time or by different analysts, precautions should be taken to ensure that results are comparable. That is, a mechanism should

|

BOX 3-2 Dispersant effectiveness is often quantified by measuring the amount of oil that is transferred to the water column or remains on the surface (or both) following application of a dispersant and mixing energy. All measurements are subject to some error, thus, the measured effectiveness is an estimate of the true effectiveness. The quality of this estimate is determined by its accuracy and precision. Accuracy is a measure of the agreement between the estimate and the true value, whereas precision provides an estimate of the reproducibility of replicate measurements. Since the true effectiveness is unknown, the accuracy cannot be independently evaluated, but the precision is used to identify a range that is likely to contain the true value. This range of values, sometimes called a confidence interval, is often used to compare one estimate of dispersant effectiveness to another (e.g., the extent of dispersion observed for dispersant-treated oil might be compared to the extent observed for an untreated control or to a threshold value specified by a regulatory agency). Statistical analysis is used to determine the probability that the two values that are being compared both estimate the same true effectiveness and appear to be different only due to the effects of random errors. Two types of errors can cause measured estimates of dispersant effectiveness to be different from the true values: systematic errors and random errors. Systematic errors affect all measurements in the same direction, and therefore, bias the estimate. Evaporation of volatile compounds and incom- |

exist to identify errors caused by differences in procedures or reagents that are not related to the treatment that is under investigation. One such mechanism is the use of controls. Controls are treatments (i.e., tests) that are performed periodically throughout a study for the purpose of quality control. Positive controls usually involve treatment with a reagent or procedure that produces a well-known and predictable result. A negative control usually involves measurement of the background response variable in experimental systems that are either untreated or treated with a mixture containing the inert ingredients (e.g., solvent) but lacking the active ingredients (e.g., surfactants). For oil dispersant effectiveness tests, a positive control might involve treatment of a standard easily dispersible oil with a standard dispersant under standard conditions. A negative control might involve subjection of the same standard oil to the physical conditions that would be applied in the dispersant test but without application of a chemical dispersant. Positive and negative controls are often

|

plete recovery of floating oil are two examples of systematic errors that can introduce a positive bias in estimates of dispersant effectiveness when the mass of oil remaining on the surface after treatment is used as the measure of effectiveness (i.e., the measured effectiveness will be greater than the true effectiveness because processes other than dispersion can reduce the mass of recovered oil). Random errors, which can be introduced by uncontrolled (or uncontrollable) variations in experimental conditions or measurement technique, will reduce the likelihood that two independent measurements of dispersant effectiveness will produce the same result even when they are made under nominally identical conditions. For example, small variations in the energy input or dispersant-to-oil ratio may cause the measured extent of dispersion to be different in replicate effectiveness tests. If a sufficiently large number of independent replicate measurements are made, however, positive errors will be offset by negative errors, and the mean (or another appropriate measure of the central tendency of the distribution) will be approximately equal to the true effectiveness. The more replicate measurements that are made, the closer the mean of those replicates is likely to be to the true effectiveness. Statistics can be used to quantify and correct for the effects of random errors, but systematic errors can only be mitigated by proper experimental design (including using appropriate experimental systems, sample collection procedures, and measurement techniques) and careful experimental technique. Proper experimental design should include provisions that eliminate systematic errors, minimize the size of random errors by controlling known sources of variation, and quantify the magnitude of unknown or uncontrollable random errors. |

compared to expected values, which may be determined from experience with the experimental system, and if the results are outside of a predetermined range, the tests should be repeated. Use of a standard oil in controls during dispersant effectiveness testing requires that the characteristics of the oil remain constant over time. As such, the oil should be stored under conditions that prevent evaporation, photooxidation, and other changes in the physical and chemical properties that can affect its dispersibility.

In the following sections, all of the four categories of tests for dispersant effectiveness are discussed, in terms of their roles and objectives, the types of systems and methods used, and advantages and disadvantages.

Bench-Scale Tests

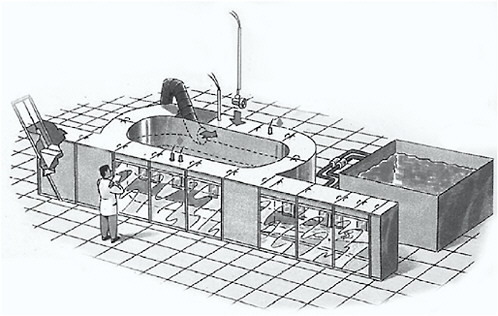

Role of Bench-Scale Testing in Evaluating Dispersant Performance