2

Key Features and Capabilities of Midsize Facilities

GENERAL OBSERVATIONS

Based on the site visits of committee members to nearly 50 facilities and on information gleaned from the 75 responses to the questionnaires developed for this study, the committee’s general overall finding regarding the characteristics of midsize facilities is that they have great diversity—in funding, business strategies, operations, staffing, and users.

By definition, midsize facilities provide instrumentation, support, and services to a user community. Within this grouping, however, the committee found substantial variation in facility missions, business plans, and expectations for the future, as exemplified below:

-

Origins. The longest-lived facilities are typically connected to centers of the highest-caliber expertise: that is, facilities able to draw on the collective wisdom of an established group of world-class researchers have the longest histories. More modern facilities are typically initiated by collections of individual researchers at a university, often with the support of the department or dean of the school. According to the questionnaire responses, more than 70 percent of midsize facilities are located at universities.

-

Operating modes. To remain viable, all midsize facilities make an effort to systematically recoup their operating expenses. Importantly, none includes amortized or depreciated capital expenditures as one of the expenses recovered annually, because the recovery of the cost of depreciation for government-

-

funded capital investments at universities is not allowed. A variety of techniques are employed to cover operations. Some facilities attempt to subsist primarily on user fees, operating as so-called recharge facilities. Another model, principally in the Department of Energy (DOE) laboratories, relies heavily on institutional and/or federal support and has no user fees. Most facilities rely on a mix of funding sources. Among those that depend on user fees as a primary source of support, several make special allowances for graduate student and postdoctoral users. For example, the Microfabrication Laboratory at the University of California at Berkeley caps the maximum hourly charges that can be incurred by a single user in any one month so that a principal investigator’s grant would not be drained by a burst of concentrated effort by a student. This type of policy cap on charges incurred by student users is common. Another interesting model for covering professional staff costs involves “backstopping,” so that if a facility loses its primary source of funding, its technical staff will have alternative support over a short period of time (perhaps 1 to 3 years), allowing them to identify other opportunities. Harvard University supports such a policy for its Center for Imaging and Mesoscale Structures, for instance. Some facilities are designed primarily for service work, while others are focused more on carrying out cutting-edge research that is commonly done as a collaboration between users and facility staff.

-

Ease of access. Larger facilities tend to have well-defined access rules and formal booking systems, while others, especially the smallest ones, have a less formal access structure.

Research Activities Supported

Materials research spans a broad program of exploration into the properties of materials—the substances of which everything is made. Generally speaking, experimental materials research can be grouped into different categories, although any one research project typically cuts across many activities. Borrowing nomenclature developed by the community, the committee believes that most small to midsize multiuser facilities support one or more of the following types of research:

-

Synthesis—a chemical or physical process used to prepare a material of specific chemical composition and/or spatial arrangement of the component atoms. A very large number of synthetic processes and techniques have been or are being continuously developed to prepare known and novel materials. The first generation of ceramic high-temperature superconductors was discovered by materials synthesis.

-

Fabrication—the process of creating a structure through direct assembly of the component materials, using layering or deposition techniques and selective removal techniques such as etching or trimming. Many common semiconductor devices are built through a process of microfabrication; the first single-electron transistor was fabricated in 1987 at Bell Laboratories.

-

Characterization—the process of determining a material’s nature, such as elemental composition, characteristic length scales, or electronic and crystalline structure. The discovery of carbon nanotubes and the determination of their structure were first achieved by the high-resolution electron microscopy work of S. Iijima in 1991.

-

Measurement—the process of determining a material’s physical or electronic attributes, often by a stimulus-response experiment under certain conditions. As high-performance circuits are fabricated, measurement processes are often used to ensure the highest quality, greatest yield, and ultimate value.

-

Computation—the use of computing resources to extract or predict material property information from models or sets of measurements. For instance, in 2004, DOE formed the Computational Science Center at Brookhaven National Laboratory to focus on computational biology; open to users, the center will help determine the structure and functions of proteins.

According to responses to the committee’s survey, the predominant activities at midsize facilities are characterization and measurement, together representing more than 60 percent of the responses, followed by fabrication or processing. The least popular activity is materials synthesis (about 10 percent), a deficit in the materials research portfolio that has been noted elsewhere with some alarm.1 While considerations of the detailed balance of the portfolio were judged to be outside the committee’s purview, this observation merits further attention by the community.

Funding

Experience from the commercial analytical laboratory sector (in which a business must provide for “running in the black” to accord with the most realistic form of accounting) suggests that annual budgets should ideally be split evenly among labor charges, capital depreciation and amortization, and “operations” that include

utilities, space rental, maintenance, and supplies. Other costs include general and administrative expenses (including accounting and higher-level management).

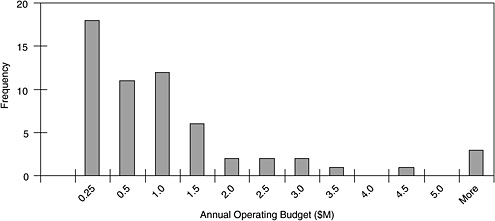

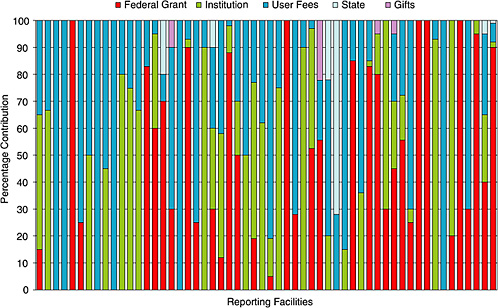

Of the 56 midsize facilities that responded to the committee’s survey, total operating budgets quoted range from $0 to $35 million (see Figure 2.1). Different methods of accounting for facility costs are clearly being used by the different facilities. Sources of funding include state, institutional, and federal monies, and user fees. In some cases, funding comes almost entirely from federal agencies, while support in a few special cases was reported to be derived entirely from user fees (in most of the latter cases, the user facility is housed within a larger center that provides infrastructure support). The 56 reporting facilities alone represent an operating budget of close to $70 million, of which university centers represent about 70 percent (in dollars). The distribution of funding sources for the 56 different midsize facilities is illustrated in Figure 2.2. The dominant sources of support overall are from federal research programs (35 percent) and from user fees (35 percent), closely followed by contributions from host institutions (27 percent). All facilities reported that identifying sources of annual operating funds was one of their most significant concerns.

Staff

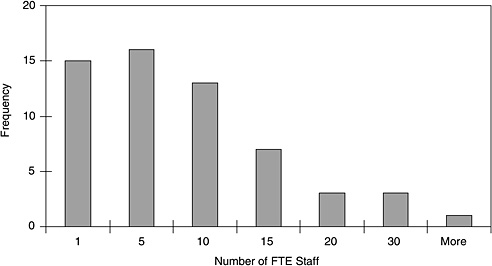

The number of full-time-equivalent (FTE) staff supporting the operation of midsize facilities ranges from 0 to more than 25, peaking in the range 1 to 10, as

FIGURE 2.1 Distribution of midsize facility annual operating budgets. Data based on responses to the committee’s survey (see Appendix C).

FIGURE 2.2 Comparison of sources of support for individual facilities’ annual operating budgets; facilities not meeting the committee’s definition are not included. The dominant sources of support overall are from federal research programs (35 percent) and user fees (35 percent), followed by contributions from the host institutions (27 percent). Data based on responses to the committee’s survey (see Appendix C).

reported in survey responses (see Figure 2.3). There appears to be no strong correlation between the number of FTEs and the annual operating budgets of the facilities, probably because different methods are being used by different facilities to account for their operating, staff, and student costs. Different facilities take different approaches to staffing. In some cases, one or more experienced technicians are available to operate and maintain equipment. Some midsize facilities necessarily manage by employing graduate students for this function. Finally, some facilities explained that in order to attract the most competent and qualified staff, the facility must offer competitive research opportunities for them.

Industrial Partnerships

In common with larger facilities, many midsize facilities have developed partnerships with industry. Nearly every facility that the committee visited in 2003 (the sites are listed in Appendix D) had industrial collaborators. That is, the facility infrastructure clearly benefited more than just the academic user community. Product development and prototyping exercises now have such an initial investment overhead that many companies cannot initiate a facility on their own. For

FIGURE 2.3 Distribution of the number of full-time-equivalent (FTE) staff supporting midsize facilities. Each bar represents the number of facilities that have the indicated number of FTE staff or fewer; for instance, the leftmost bar indicates that about 15 facilities have one staff member or fewer. Data based on responses to the committee’s survey (see Appendix C).

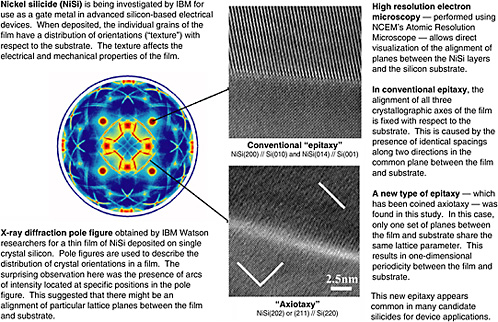

instance, the committee learned that having commercial property zoned for clean-room space was increasingly difficult for investors; by contrast, many universities have developed permitting and regulatory relationships with local authorities that make this process much easier. See Figure 2.4 for one example of a collaborative endeavor between industry and a midsize facility.

The types of partnerships between midsize facilities and industry typically fall into three general classes:

-

Fee for service. Small companies, usually in the particular facility’s locale, bring or send samples or requests for service to the facility. Under this arrangement, the company pays access fees approximating what the host institution defines as full cost recovery to the facility for the transaction. This type of arrangement is generally used to provide one-time services such as fabrication or characterization.

-

Membership. For a certain annual fee, member companies are granted special privileges, including access to both equipment and staff at the facility. However, to meet the requirements of federal accounting standards, the industrial partners still must often also pay hourly access rates to use the equipment. Facilities using this model of partnership with industry tend to rely on high industrial membership fees to help offset other costs of running the facility, such as supporting staff salaries. Several facilities reported that under their particular membership arrangements, company staff might spend significant time at a bench in the facility, sometimes developing a product or optimizing a process.

-

Collaboration. Under this arrangement, research scientists from the collaborating industrial partner spend significant time at the facility, paying for equipment time and use and performing development research in association with the facility staff. Papers with coauthorship might even result. For instance, at the Frederick Seitz Materials Research Laboratory at the University of Illinois at Urbana-Champaign, committee members spoke with a scientist from Gillette Razor, Inc., who had just completed a long-term development effort in collaboration with facility staff. The representative commented that, in his case, the most important resource offered by the host institution was consultation with and advice from the resident staff.

Instruments

Midsize facilities provide materials research instruments that include characterization, measurement, fabrication, synthesis, and computing equipment, as indicated to the committee during its site visits and in survey responses. Typically

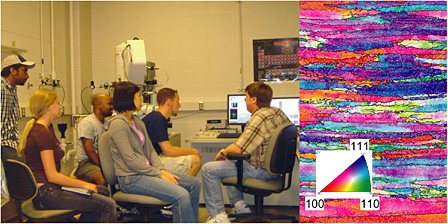

FIGURE 2.4 A collaborative project between researchers at the IBM T.J. Watson Research Center and Eric Stach at the National Center for Electron Microscopy (NCEM) resulted in the discovery of a new type of thin-film texture. Coined “axiotaxy,” this texture is characterized by the sharing of only one set of lattice spacings between the film and its growth substrate. Conventionally, texture is determined through the use of large-area x-ray diffraction “pole figures” that depict the relative orientation of crystalline grains in a material. In this work, researchers at the IBM Watson Research Center utilized pole figures obtained at the National Synchrotron Light Source. Surprisingly, in addition to evidence of conventional epitaxial texture, complex arcs of intensity in specific locations were seen, indicative of an unusual fiber texture. High-resolution electron microscopy was required to confirm the existence of this new type of texture. These samples presented several particular microscopy challenges that required the use of a unique microscope at NCEM: the 800 kV Atomic Resolution Microscope. This microscope has sufficient point-to-point resolution (1.6 Å)), sample tilting capabilities (±45 along two orthogonal axes), and high voltage (for increased sample penetration of the strongly scattering nickel silicide layers) to produce atomic resolution images of these samples. Extensive microscopy confirmed the presence of both conventional epitaxial grains and grains with the new axiotaxy texture. Courtesy of the National Center for Electron Microscopy and the IBM T.J. Watson Research Center.

in response to the needs of users, facilities choose either to specialize narrowly or to offer a broad suite of tools. A discussion of the means of acquisition of instrumentation and the type of instrumentation sought at midsize facilities follows:

-

Acquisition. Most facilities tend to rely heavily on their major users to help acquire new instrumentation through grants from federal agencies. For example, a facility would agree to provide floor space and staff from its operating budget in exchange for management of the tool. The capital investments would be obtained from individuals or small groups of individual investigators who would submit grant proposals to federal agencies for acquisition of the new instrument. Successful grantees would transfer responsibility for the instruments to the facility, effectively “outsourcing” the operations, maintenance, and support of the instrument to the facility. In turn, the facility’s operating budget would only have to cover the cost of maintaining and operating the equipment. This type of model was indicated to be common for facilities that specialize in suites of instruments such as clean rooms. Some investigators reported that this type of operating model made their proposals more competitive.

It should be noted that promises of the purchase of costly instrumentation are also being used by universities as a means of attracting new faculty with start-up packages; the funds for these efforts are usually levied from various sources such as endowments or donor gifts or from federal reimbursement of indirect research costs. Whether this practice can be a viable long-term strategy for university facilities when overall federal funding in materials research is relatively flat remains to be seen, but it illustrates the extent to which universities are struggling to assist in the purchase of advanced instrumentation.

-

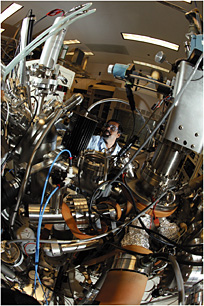

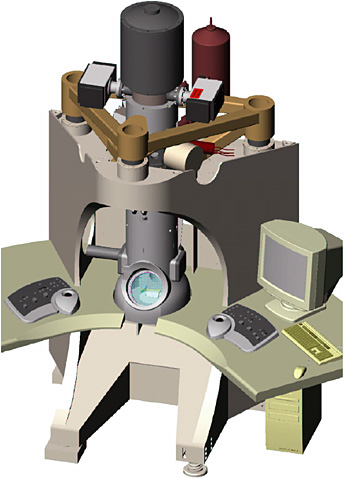

Character of instruments. Some facilities focus on novel (“racehorse”) instrumentation (see Figures 2.5 and 2.6), whereas others offer more basic equipment and services (“workhorse” instrumentation). Although racehorse instruments are often required for the most discriminating analyses, workhorse instruments serve broader communities and can act as feed-and-filter stages for the sophisticated racehorse instruments. For instance, a workhorse instrument may be invaluable for preparing samples or techniques for a more specialized instrument in a so-called hub-and-spoke arrangement.

Outside materials science, a good example of this hub-and-spoke model was observed during the committee’s site visit to the Lick Observatory near San Jose, California. The light-gathering power of the telescope at the Keck Observatory on Mauna Kea in Hawaii is far greater than are the capabilities

FIGURE 2.5 Nuclear microprobe at the Center for Accelerator Mass Spectrometry at the Lawrence Livermore National Laboratory. Courtesy of the Center for Accelerator Mass Spectrometry.

FIGURE 2.6 A generic “super scanning transmission electron microscope” from LEO Electron Microscope. Courtesy of Carl Zeiss SMT AG.

-

of the telescope at Lick. To remain competitive, Lick management redirected the observatory’s research to focus on two important activities: first, on providing sufficient observing time and support so that observers can test and tune their experiments at Lick before traveling to Keck for their final data gathering and, second, on providing longer observing time for measurements or discoveries first made at Keck. Lick Observatory has therefore become an important staging ground for observers taking advantage both of the Keck Observatory and of the Palomar Observatory. It has become an instrument development laboratory, as scientists can access the telescope more frequently and have greater freedom to develop new tools and techniques. Finally, Lick maintains a niche as a telescope that can provide extended access for measurements that integrate over many nights (for instance, monitoring the long-term evolution of a phenomenon discovered at Keck or Palomar).

Specialized Laboratory Environments and Services

In addition to investments in costly instruments, midsize facilities have also made significant investments in specialized laboratory environments and other enabling capabilities. Vibration-sensitive equipment such as lithography and imaging tools can require expensive remediation during laboratory construction in order to avoid problems such as mechanical vibration, stray magnetic fields, and electrical ground loops. Crystal growth chambers, thin-film deposition processes, and ion implantation systems often make use of materials that require chemical scrubbers, negative-pressure rooms, monitoring equipment, and industrial hygiene reviews and inspections and unique safety procedures. Many electronic device and materials studies require high-efficiency particulate air (HEPA)-filtered clean rooms and employ purified and deionized water in their preparation. Biological assay experiments can require ultrafiltration to reduce the total organic carbon and avoid interferences.

A laboratory renovation project for a single instrument with special environmental requirements such as those described above can cost several million dollars and involve significant zoning issues for universities. Clean-room construction, for example, exceeds $1,000 per square foot, and high-hazard clean space can approach $2,000 per square foot. This investment is often underappreciated, yet it is critical to achieving a required specialty environment or top performance from an instrument. Today’s research tools cannot be treated as isolated, independent units.

Maintenance and Upkeep

According to responses to the committee’s questionnaire, some facilities, typically those having cutting-edge equipment and providing services to a broad user base, rely heavily on service contracts provided by equipment manufacturers. Other facilities reported that expert support staff are expected to perform routine service and maintenance. Some facilities reported that when their operating budgets become tight, maintenance or service contract arrangements with manufacturers are often identified as the first place to go to trim costs, which is clearly detrimental to the continued performance of the instruments. A few facilities identified the recruitment of expert technical staff from industry as a pivotal moment in their evolution—obtaining the ability to support their instruments independently was necessary for sustainable (and affordable) operation.

Users

Since it is by definition a multiuser operation, a midsize facility relies on its users as its core constituency. According to the facilities questionnaire responses, there is no specific correlation between the number of users of a facility and the operating budget beyond the generally positive one. Several different methods are employed to account for numbers of users and annual budgets, which could explain the lack of correlation.

Utilization of midsize facilities is generally dominated by local researchers (nearly 75 percent): that is, users come primarily from within the host organization (university, national laboratory, and so on) or from relatively nearby. The committee thus observed that midsize facilities appear to serve relatively small “regions.”

One factor contributing to a lack of long-distance users is associated travel and accommodation costs; most facilities, even those that do not charge specific user fees for instrument usage, cannot provide support for travel. As a result, access to a facility by long-distance users is often limited by their ability to cover the travel expenses from their own research grants. Another factor, of course, is the time required to travel.

Details such as access, training, and operating hours that affect users and user numbers follow:

-

Access. Most facilities open their doors to all qualified users. However, as competition for access has increased, facilities have developed more sophisticated screening procedures. The general screening criterion is “the highest-quality science.” In extreme cases, users are required to submit proposals

-

for peer review by a panel of experts; such procedures engendered delays of up to 6 months for access. Generally, however, users are required to employ online or on-site mechanisms to reserve tools in advance.

-

Training. The degree of training necessary to use the equipment of a facility varies widely, depending on the level of sophistication and automation of the instruments. In simple cases, self-teaching is perceived as adequate. Most widespread is the model in which users are trained by resident staff and are then given access privileges. For the most complicated systems, complete operation by staff members is common, and often considered most desirable because of concerns about possible unintentional damage by an inexperienced operator.

-

Operating hours. Some facilities emphasize 24-hour-a-day, 7-day-a-week operation and access. Other facilities have restricted access hours, often as determined by the host institution’s assessment of safety and security. For facilities with 24-hour access, the users are usually required to complete a training sequence alongside facility staff in order to gain open access and operation privileges for the particular equipment of interest.

Education and Outreach

The midsize facilities that responded to the committee’s questionnaire are estimated to impact a student population of greater than 7,000, with about 90 percent of this number using university-based facilities. These numbers clearly indicate that the overall impact of all midsize facilities on student education and training must be regarded as highly significant. Some facilities offer the formal instruction that is needed for the operation of their equipment and interpretation of results, while others offer individual, hands-on training at the instrument. Several sites offer opportunities for students and teachers participating in the Research Experience for Undergraduates and Research Experience for Teachers programs.

USER COMMENTS

Although the facility users’ response rate to the committee’s survey was modest, certain features bear mention. Users spent on average about 25 percent of their research time at midsize facilities, and over half used facilities sited primarily within their host institution. Respondents unanimously agreed that midsize facilities are critical enablers for their research. They cited reasons such as “better equipment than I have in my own laboratory,” “allowed me to do measurements not otherwise possible,” and “without this shared infrastructure and its maintenance and relevant training personnel, my research program simply couldn’t function.”

All respondents were generally satisfied with their experiences at midsize facilities, although the leading concern was the age and upkeep of the instrumentation. Another point of widespread agreement was the belief that the capabilities of midsize facilities are not well known or advertised; the primary technique for finding out about midsize facilities was reportedly word-of-mouth at conferences from colleagues. Many respondents asked for a Web-based directory of services so that they could become more easily acquainted with resources in their own area.

Users’ comments were varied with respect to the most important criterion determining their choice of which midsize facility to use. The comments ranged from “has the capabilities needed but without the operational costs, which are restrictive” to “proximity, provided the tools work” to “helpful staff willing to collaborate and train graduate students on state-of-the-art equipment.” Most respondents cited technical capabilities and proximity to their home institution as important criteria determining their choice. Most users reported that while visiting facilities, they obtained assistance and research advice from the facility director or staff.

In response to the committee survey’s question about “what level of cost would be prohibitive,” respondents expressed the constraints that they felt in terms of costs to their research grants; a typical level of cost considered prohibitive is $100 per hour of use, so the desirable range is significantly less. Depending on the nature of the services required, the maximum lead time that researchers indicated they were willing to tolerate varies considerably, ranging from 6 months for nationally unique materials analysis studies to 1 to 3 days for access to certain microscopy facilities. In general, researchers preferred to travel to facilities that were close enough to keep the entire trip confined to 1 day. In fact, when seeking participants for its Materials Centers of Excellence program, the Army Research Laboratory used a geographical limitation of an approximately 400 mile radius to constrain the range of the institutions that could apply for funding as a team to form the center.2

In terms of budgeting for facility use, almost all users who responded to the survey reported that they had budgeted for user fees when developing funding requests, and all made specific mention of facility use as part of their research proposal. Most respondents indicated that they would ideally prefer about $10,000 per year to cover their facility usage. A simple calculation, assuming the $100 per hour usage cost (as an upper limit), suggests that the annual usage of facilities numbers in the hundreds of hours per year.

The most common suggestions from users are typified in comments such as, “It’s hard to lump together midsize facilities … some exist to help users complete projects … others are more of a large group of scientists who collaborate together” and “[the provision of] ongoing support for small centers … [is needed] in order to provide staff to train users and keep instruments repaired” and “reinstate support for travel.” One user enthusiastically suggested, “Strongly encourage universities to provide hard-money support for technical staff!”

SELECTED EXAMPLES

The committee presents the following examples mainly to illustrate the diversity in funding, funding sources, and level of operation of different midsize facilities.3

-

The Center for Microanalysis of Materials at the Frederick Seitz Materials Research Laboratory at the University of Illinois at Urbana-Champaign is a large midsize facility, operating entirely without user fees, that is supported primarily by the host institution (70 percent)4 and DOE (30 percent). With an annual operating budget of $1.5 million, it has 16 FTE staff members who provide support for materials fabrication, characterization, and measurement to roughly 600 users. The user demographics are graduate students (65 percent), government (20 percent), industry (10 percent), and undergraduate (5 percent). Users predominantly come from on campus (70 percent), but many of the remaining users travel significant distances. Clearly a relatively modest, consistent investment by DOE in a university-based facility has had significant positive impact. (See Box 2.1 for further discussion.)

-

The Shared Experimental Facilities of the Center for Materials Research at Cornell University support research investigations of the NSF-funded Materials Research Science and Engineering Center (about 45 percent) and other, separately funded researchers on campus (about 45 percent) and off campus (about 10 percent). The facility has an annual budget of $1.2 million that comes primarily from user fees (70 percent) and federal sources (30 percent), a staff of 15 FTE, and roughly 450 users. The reported user demographics are graduate students (65 percent) and undergraduates (15 percent), with these users originating primarily on-site (90 percent).

|

BOX 2.1 The Center for Microanalysis of Materials (CMM) is a user-oriented and user-friendly facility that provides the modern analytical capabilities essential to today’s materials research efforts. Many researchers at the town hall meetings conducted by the Committee on Smaller Facilities in the spring of 2004 commented that the CMM is the leading analytical user facility in the country, also recognizing that the facility would be difficult to duplicate elsewhere. The CMM is one of four Department of Energy (DOE) Electron-Beam Microcharacterization Centers, and as a DOE Basic Energy Sciences user facility and collaborative research center, it is open to researchers from universities, government laboratories, and industry, nationwide as well as internationally. The CMM is located in the Frederick Seitz Materials Research Laboratory (MRL) on the campus of the University of Illinois at Urbana-Champaign. The facility dates back to about 1965, when it was an Advanced Research Projects Agency (ARPA)-supported materials research laboratory. The facility was funded jointly by DOE and the National Science Foundation (NSF) for many years, but lost NSF core support altogether in about 1994. Overall NSF participation in the laboratory has since actually risen through the involvement of individual investigators. The CMM emphasizes the microstructural and microchemical composition of materials, the chemistry and electronics of surfaces, crystal structures, phase transitions and defect structures of materials, and the relationship between the structure and the properties of solids. By using the center’s services, materials researchers from academe and from industry can access 25 major instruments in the areas of electron microscopy, surface microanalysis, x-ray diffraction, and backscattering spectroscopies (see Figures 2.1.1 and 2.1.2). The breadth of instrumentation available through the center enables researchers to find the best instrumentation techniques for their specific needs. The CMM’s annual operating budget (in 2004) is about $1.5 million, about 33 percent of which is provided directly by DOE’s Office of Basic Energy Sciences; the remainder is provided through the university by the state (the facility’s director estimates that the operating budget is closer to $2.2 million when including fringe and other personnel benefits covered by the university). The university waives overheard charges on the federally contributed funds. The 2004 operating costs break down as follows: 70 percent for staff salaries, 5 percent for service contracts, and about 25 percent for maintenance and supplies. A separate capital equipment budget provides about $1.2 million each year, shared between DOE and the university. The CMM provides an extensive suite of equipment, including secondary ion mass spectrometers (2); an Auger electron spectrometer (1); x-ray photoelectron spectrometers (3); transmission electron microscopes (TEMs) (6); scanning electron microscopes (3); x-ray diffractometers (5); a focused-ion beam (1); scanning probe microscopes (5); a low-energy electron microscope (1); and ion accelerator instruments (2). The total replacement cost is estimated to be more than $50 million. The CMM staff consists of about 12 Ph.D.- and M.S.-level members and 4 highly trained technicians. In the words of the director, the “system would collapse without technical staff.” The technicians do the majority of the maintenance work,b and so maintenance contracts with the manufacturers are generally not required. The center is staffed with experts in each technique who teach researchers so that they can operate the instruments to conduct their own measurements. Licensed users have 24-hour access to the instruments. CMM staff members also provide guidance, consultation, and collaboration in the microanalysis of materials. |

-

The Shared Equipment Authority at Rice University is a larger midsize facility supported primarily by the host institution (62 percent) and user fees (38 percent). With an annual operating budget of $650,000, it has 6 FTE staff providing support to about 140 users. The user demographics are graduate students (90 percent) and industry (10 percent), and they originate on-site (89 percent), locally (10 percent), and regionally (1 percent). This campus-wide effort serves as an interesting model for connecting existing resources into a larger enterprise that is coordinated and centrally planned, not unlike a small-scale regional network of facilities. (See Box 2.2 for an extended discussion.)

-

The W.R. Wiley Environmental Molecular Sciences Laboratory (EMSL) at the Pacific Northwest National Laboratory is a multipurpose laboratory that provides national computing, nuclear magnetic resonance (NMR), spectroscopic, and nanoscale characterization services. Users engaged in open research generally are not charged for using EMSL facilities or equipment. The facility serves more than 1,600 users per year, with an annual operating budget of about $40 million. EMSL serves both the adjacent DOE laboratory and users from around the country. As many of its facilities, such as those for high-field NMR, are unique, it attracts users from the entire country—serving as more than just a “regional” facility. Furthermore, because of its role within DOE, it aspires to having an international reputation for its research rather than simply serving the Northwest. (See Box 2.3 for more information.)

-

The Keck Microfabrication Laboratory at Michigan State University is a small midsize facility supported by the host institution (80 percent) and user fees (20 percent). Its operating budget is about $100,000, and it has 1 FTE staff member who provides support for 20 users, of whom 90 percent are graduate students and 10 percent are undergraduates.

ESSENTIAL QUALITIES OF SUCCESSFUL MIDSIZE FACILITIES

Based on the site visits made for this study and on the committee members’ own experiences, it has become clear that midsize facilities generally recognized as being successful share a number of the following key characteristics:

-

Contain well-maintained equipment that facilitates both routine and state-of-the-art research;

-

Incorporate a mix of permanent scientific and well-trained technical staff;

-

Provide open and reasonable access with clear guidelines for the particular user community;

|

BOX 2.2 In 2001, the science and engineering faculty of Rice University collaborated on developing a proposal to the university administration for coherent, systematic, and unified support of their facility and instrumentation needs. The university accepted the proposal, and the Rice Shared Equipment Authority (SEA) was formed. The SEA is not a centralized facility per se; rather, it is a mechanism for the centralized management of distributed resources across the campus. It is managed through a faculty committee that sets user rates and policies through consensus-based governance. The SEA Board consists of 19 faculty members, 5 technicians, and 2 administrative staff. The SEA has an annual operating budget of $650,000, of which 62 percent is derived from the host institution and 38 percent from user fees, and represents a replacement capital investment of more than $13 million. The host institution covers the salaries of the 6 FTE technical and administrative support staff. At present, more than 140 different users access the SEA per year, 90 percent of whom are affiliated with Rice directly. There are many useful insights to be gained by a careful review of the proposal prepared by the SEA. The SEA provides service in sophisticated research equipment and facilities at an affordable cost to all members of the Rice University community. It also provides support and open instrumentation usage to outside companies, nanotechnology start-ups, and other universities based on availability. The creation of this service center infrastructure and management has enabled Rice and its faculty to become innovative leaders in the fields of photonics, bioinformatics, nanotechnology, and environmental systems. Currently the Rice SEA supports more than 50 instruments—in x-ray diffraction, optical microscopy, electron microscopy, optical spectroscopy, nuclear magnetic resonance, mass spectrometry, thermal analysis, scanning probe microscopy, clean rooms of class 100/1000, and micro-/nanofabrication (see Figure 2.2.1). Under the SEA these instruments are maintained by full-time, professional technical staff, supported directly by the university. The professional staff scientists provide a variety of assistance in operating, training, maintenance, sample preparation, and safety procedures to all users. A key component of the successful initiation of this university-wide transformation was a careful analysis by the SEA board of the issues at its institution and the preparation of a 5-year strategic plan, excerpts of which are reprinted below.b In a policy statement that accompanies

FIGURE 2.2.1 Several instruments included in the Rice SEA are (left to right) a thermogravimetric analyzer with infrared spectroscopy, a Fourier transform infrared microscope, and a Raman microscope. Courtesy of Rice University Shared Equipment Authority. |

|

the strategic plan, the SEA describes procedures for acquiring new instruments, setting user fees, managing equipment usage, and replacing underused or underperforming instrumentation. Rice aims to be an international leader in the emerging interdisciplinary areas of nanotechnology, biotechnology, information technology, and environmental research and identified its infrastructure as a key component to success: To take full advantage of [its] investment in interdisciplinary research, Rice must develop its research infrastructure. Facilities that support electron microscopes, magnetic resonance spectrometers, and clean rooms, for example, are the necessary framework that supports any nano-bio-info-enviro research program. They are the bricks and mortar tools that will make it possible for Rice’s faculty to become leaders in the new areas of photonics, bioinformatics, nanotechnology and environmental systems. The expenses of shared equipment fall into three categories: maintenance, staff support, and equipment acquisition. The Rice SEA board broke its budget into these categories (see Table 2.2.1). An important observation, however, is that maintenance and staff alone represent nearly a quarter of the anticipated needs. TABLE 2.2.1 Rice Shared Equipment Authority Budget, 2001-2006, by Category

As presented below, the Rice SEA board factored its strategic plan into three areas—management, policy, and fund-raising: Objective #1. Management: Create and nurture campus-wide faculty oversight of shared equipment planning and administration. Current climate: Faculty that critically depend on shared equipment are very reluctant to share control over these instruments. Many feel that their research programs will suffer unless they have nearly complete authority over user policies, fees and administration. As a result, small faculty groups and departments will set up “fiefdoms” to operate instrumentation for their own particular interests; this results in an enormous duplication of space, staff and maintenance resources. For example, this university has invested over the past 5 years in the acquisition and maintenance of 8 x-ray diffractometers, two in the last three months alone; these machines are spread among four departments with varying levels of public access and faculty oversight. Similar duplications exist for scanning electron microscopes, nuclear magnetic resonance instruments and GC-MS systems. It is true that for many of these techniques, the specific user base (i.e. biologists as opposed to chemists for example) requires separate instruments with different capabilities. However, these distinctions are becoming less pronounced in the new interdisciplinary paradigm while the duplication of efforts continues to waste valuable resources. Future Goals

|

Recommended Policy Changes

Objective #2. Policy: Revise institutional policy on cost centers to allow for more efficient management of shared research equipment. Objective #3. Fundraising: Raise funds, through both federal and private sources of funding, for shared equipment acquisition and maintenance. Here at Rice, user fee revenue has traditionally not offset the instrument costs in most cases. The reasons for this are twofold: first, Rice is a small campus with relatively few faculty compared to other private research institutions. Thus, the on-campus user base is small and most instruments while essential for conducting research are used at only 40-60% capacity. Second, for much of the shared equipment there has been no staff support for upkeep and training. Given the university culture, staff are awarded to departments to maintain internal instruments. Shared equipment has had no lobby for institutional support, and thus no staff. As a result, there is no mechanism for training users or keeping instruments well maintained. This has resulted in significant downtime on instruments (the TEM was down over 20% of the time one year) which inhibits the development of a stable user group. Limited staff support has also curtailed our ability to attract external users. Thus, we estimate slightly more than half of the instrument maintenance costs can be realistically gathered through user fees. The SEA board convinced the university that it should fund hard-money staff positions to supervise the maintenance of shared equipment and user training. In return, the SEA ensured that the equipment would pay its own way and that the facilities would be of as broad use to the university community as is reasonably possible. The hard-money staff positions were important in enabling the SEA to hire some superb staff. On the university research scale of use, there was simply no way to recover professional staff salaries from user fees. The implementation of the SEA plan overcame the traditional territorial concerns of individual investigators once it was realized that the SEA would serve the common good. It has dramatically improved the operations of several instruments by providing for standardized training and maintenance; no one department or principal investigator is in charge; and the people who pay are the people who use the facilities, meaning that there is no arbitrary tax on nonusers to support the instruments, except in the most indirect sense through the university.

|

|

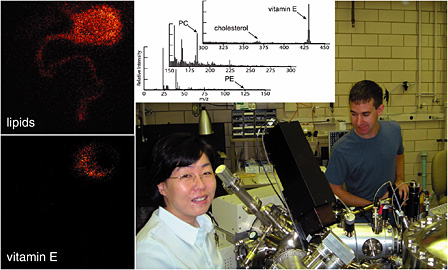

BOX 2.3 The W.R. Wiley Environmental Molecular Sciences Laboratory (EMSL), operated by the Pacific Northwest National Laboratory for the U.S. Department of Energy and located in Richland, Washington, helps educate students and scientists to meet the demanding multidisciplinary challenges of the future. Challenges to explore alternative energy products are leading to studies of new and innovative materials. Solid oxide fuel cells are just one possible “clean” energy source, and the specialized instruments at EMSL are being used to explore these types of designer materials. With six topical facilities and more than 130 staff, EMSL capabilities include more than 12 nuclear magnetic resonance spectrometers, arrays of surface deposition and analysis tools, and mass spectrometers, as well as computational resources (Figure 2.3.1). The EMSL super-computer is among the top 20 in the world, and the 900 MHz nuclear magnetic resonance spectrometer is one of the highest-field wide-bore instruments in operation worldwide (see Figure 2.3.2). A multidisciplinary user facility, EMSL makes its instruments and staff expertise accessible worldwide through a peer-reviewed proposal process. Since operations began in 1997, EMSL has benefited more than 5,500 researchers on topics ranging from chemistry and nanocatalysis to proteomics and materials science. Many EMSL instruments are one-of-a-kind, developed

FIGURE 2.3.1 Shown (left to right) are Environmental Molecular Sciences Laboratory (EMSL) students T. Kaspar and A. Tuan and EMSL staff member S. Chambers, with the photoelectron spectrometer connected to EMSL’s Molecular Beam Epitaxy (MBE) I system, which was based on the MBEII prototype and recognized by the 2002 Federal Laboratory Consortium Excellence in Technology Transfer Award with Motorola. Courtesy of the Environmental Molecular Sciences Laboratory. |

FIGURE 2.3.2 Many unique instruments developed at the Environmental Molecular Sciences Laboratory (EMSL) make technology more accessible to the scientific community. The flexible control system for ion trap mass spectrometers can be built at a fraction of the cost of commercial products. Here, EMSL researcher K. Swanson is shown with the Asymmetric Ion Trap Mass Spectrometer (patent pending), which was developed by EMSL and Pacific Northwest National Laboratory staff members S. Barlow and M. Alexander. Courtesy of the Environmental Molecular Sciences Laboratory. through teamwork between researchers and the scientific and technical staff of EMSL to address ambitious scientific questions. Researchers participate in activities individually or as members of large, multiuser teams. The synergy of these teams—composed of experts from diverse focus areas—enables solutions for scientific challenges previously considered insurmountable. EMSL provides a problem-solving environment of advanced instrumentation and computational tools to scientists engaged in research on physical, chemical, and biological processes in pursuit of the nation’s most difficult and critical scientific challenges. Individuals and teams of researchers around the world draw upon the unique capabilities at EMSL to advance scientific breakthrough and discovery (see Figure 2.3.3). In March 2004, the National Science Foundation (NSF) and EMSL created a formal affiliation and instituted a grant program. University students, faculty, and postdoctoral users of |

-

Focus their attention on sending users back to their home institutions with high-quality, useful data;

-

Engage in critical self-assessment, and consider it important to have mechanisms for taking account of feedback from users;

-

Enjoy stable, long-term funding source(s), with local institutional support;

-

Are often enhanced by having an enthusiastic and broad user base;

-

Are directed by effective and energetic management; and

-

Advance the technology (instrumentation and/or techniques and/or applications) through the operation of the facility.

The committee found several instances of successful facilities that are characterized by high-level recognition and backing (with funding) from the host institution. For example, at the Lawrence Livermore National Laboratory, the Center for Accelerator Mass Spectrometry is supported in part by laboratory director funds; at Northwestern University, NUANCE (Northwestern University Atomic and Nanoscale Characterization Experimental Center) is supported in part financially from the university president’s office. The committee cannot overemphasize the importance of a clear and well-defined role for the host institution in the success of a midsize facility. The level and type of commitment from host institutions vary widely, but its presence was a constant in all of the facilities that the committee visited.