3

Vehicle Subsystems

INTRODUCTION

The long-range goals of the FreedomCAR and Fuel Partnership—to transition to a transportation system “that uses sustainable energy resources and produces minimal criteria or net carbon emissions on a life cycle or well-to-wheels basis”—are extremely ambitious (DOE, 2004a). The difficulties are compounded when the additional constraints associated with the FreedomCAR and Fuel Partnership are imposed: energy freedom, environmental freedom, and vehicle freedom. These goals and associated constraints effectively eliminate the continued evolution of the gasoline-fueled internal combustion engine (ICE) vehicle as a possible answer. “Sustainable energy resources” and “energy freedom” both suggest non-petroleum-based alternative fuels. The emphasis on “net carbon emissions” and “environmental freedom” suggests that CO2 and other emissions from the production and consumption of alternative fuels should be reduced, through highly efficient processes, to minimize adverse environmental effects. Finally, “vehicle freedom” implies that the fuel and onboard energy conversion systems should not limit the options and choice that buyers expect to have available in their personal vehicles. These goals, if attained, are likely to mean new transportation fuel(s) utilized in more efficient power plants in lighter vehicles having reduced power requirements while maintaining equivalent utility and safety.

DOE envisions that the path to achieving the long-term goals of the FreedomCAR and Fuel Partnership involves a transition from improved gasoline- and diesel-fueled ICE vehicles, to a greater utilization of gasoline- and diesel-fueled hybrid electric vehicles (HEVs), to hydrogen-fueled ICEs and HEVs, and ultimately to hydrogen-fueled fuel cell vehicles (DOE, 2004a). For

this transition to take place, the industry will require enhanced understanding in many areas so that it can develop new vehicle subsystems and vastly improved vehicles. The DOE-sponsored activities described in this section are intended to provide such understanding.

Near-term reductions in fuel consumption and emissions can be accomplished by improving ICEs. Specifically, better understanding of the combustion process and how emissions are produced could both increase efficiency and decrease engine-out emissions. Higher thermal efficiency means reduced fuel consumption and lower engine-out emissions means less extensive, and probably less expensive, exhaust aftertreatment systems. Improved ICEs, which could come in the near term, would benefit both conventional vehicles and HEVs.

The fuel cell subsystem is an energy converter that has the potential to be more efficient than an ICE. However, fuel cell systems of the type deemed appropriate for transportation systems use only hydrogen as fuel. The hydrogen can be stored onboard the vehicle in pure form or it can be extracted from hydrogen-bearing hydrocarbon fuels and water using onboard fuel processors. However, DOE effectively eliminated the latter alternative from its R&D portfolio after years of R&D offered little prospect of meeting essential cost and performance targets within the program time frames. Without this option, sufficient pure hydrogen must be carried onboard the vehicle to meet range requirements. Further, since it is extremely difficult with typical light-duty vehicles to carry hydrogen quantities with an energy content equivalent to that of a typical fuel tank filled with gasoline, it is imperative to minimize fuel consumption. This implies reducing the mass of the vehicle and maximizing the efficiency of the energy converter.

Current experimental hydrogen-fueled fuel cell systems demonstrate efficiencies approaching 50 percent over a fairly wide range of operation. Further, such systems produce zero criteria emissions (occasional discharges of small quantities of hydrogen may occur). However, there are performance, durability, and cost issues to be resolved if fuel cells are to become viable options for personal transportation vehicles.

Hybrid electric vehicles require compact, efficient, and low-cost power electronics and energy storage systems as well as other advanced electrical components to make vehicle costs and weights competitive with conventional vehicles. Many of the same technologies also are applicable to fuel cell vehicles since fuel cell vehicles will be basically electric vehicles with various degrees of hybridization. Consequently, advances in the power electronics and electrical subsystems are critical for improved viability of both mid-term HEVs as well as longer-term fuel cell vehicles.

One important means of minimizing fuel consumption for mid-term HEVs and longer-range fuel cell vehicles is the partial recovery of vehicle kinetic energy during deceleration and stopping. Thus, these vehicles will need some form

of energy storage capable of accepting some of this energy (regenerative braking) and providing it back to the drive train for propulsive power. The mostly likely form of such energy storage is electrochemical (batteries), but ultracapacitors are also being investigated. For such relatively small-scale energy storage, the most important parameters are cost per kilowatt, specific power (kW/kg), and cycle and calendar life.

Even though hybrid electric vehicles are currently on the market, the projected cost savings due to higher fuel mileage will probably not offset the higher initial cost of the vehicle at foreseeable fuel prices. This implies that further cost reductions may be necessary for the hybrid vehicles to gain widespread acceptance and have a significant impact on fleet fuel mileage. Such cost reductions require additional understanding in the areas discussed.

Beyond the need for small-scale energy storage required to handle energy from regenerative braking is the need for sufficient on-board energy storage to propel the vehicle for a reasonable range without use of the power plant (e.g., fuel cell or engine). Moving in this direction could add design flexibility to HEVs and reduce some of the performance requirements for the fuel cells (e.g., start-up time and power ramp-up rate) in a fuel cell vehicle. Further increases in on-board energy storage capacity could enable plug-in hybrid vehicles (a vehicle whose battery could be recharged by plugging into a source of electricity while it is parked) or even all-electric vehicles. Both plug-in hybrids and all-electric vehicles could provide the immediate benefit of shifting some transportation energy demand from onboard petroleum-based fuels to the electric grid, which is mostly non-petroleum-based but, of course, not emission-free. The most important parameters for these energy storage systems will be cost per kilowatt-hour, specific energy (kWh/kg), cycle life, and calendar life. These storage systems would also have to maintain adequate specific power (kW/kg), even at low states of charge and low ambient temperatures.

Irrespective of the propulsion technology, reducing the mass of a vehicle for a given mission will have the effect of reducing fuel consumption. However, to conform to FreedomCAR goals, any such mass reduction would have to be accomplished without compromising safety or overall vehicle utility. To accomplish significant weight reductions, several materials, including aluminum, high-strength steel (HSS), and carbon-fiber-reinforced polymer composites could replace a large part of the (mostly) mild steel currently used. Other material substitutions, such as cast magnesium, in other vehicle components could further decrease vehicle weight. Unfortunately, thus far all of these potential material substitutions would result in large cost penalties. Therefore, research in materials production and manufacturing techniques is essential if the mass-reduction benefits of these materials are to be realized.

The following sections discuss in more detail the issues associated with the alternative technologies for vehicle components.

ADVANCED COMBUSTION ENGINES, EMISSION CONTROLS, AND HYDROCARBON FUELS

Introduction

The ICE plays a critical transitional role in achieving the FreedomCAR and Fuel Partnership’s long-term goal. If the Partnership meets its objective—namely, of enabling the private sector to make a commercialization decision on fuel cell vehicles by 2015—it would still be decades after that before these vehicles penetrate the market sufficiently to have a measurable impact on total fleet fuel consumption. If commercialization is delayed beyond 2015, the impact will be pushed even further into the future. In contrast, improvements in engine and aftertreatment technologies could be incorporated into a large spectrum of new vehicles quite rapidly. With approximately 16 million new vehicles sold in the United States every year, improving the energy efficiency of vehicles sold now will have near-term and growing impact on the petroleum consumption of the entire vehicle fleet.

FreedomCAR’s transition strategy to hydrogen-fueled vehicles envisions a sequence of improved ICEs, increasing use of advanced ICE hybrid vehicles and hydrogen-fueled ICE hybrid vehicles, and—ultimately—a transition to hydrogen-fueled fuel cell vehicles (DOE, 2004a). The focus of the advanced combustion engines and emission controls (ACEC) activity of the FreedomCAR and Fuel Partnership is to improve the efficiency of the engines of these transitional vehicles and reduce their emissions.

To this end ACEC has established a sequence of technical targets during the transition (Table 3-1). The benefits of improved ICEs could begin in the very near term. However, the total impact would be limited by the slow rate of market penetration and the large number—roughly 225 million—of light-duty vehicles in the current fleet. As part of the Government Performance and Results Act, EERE estimated the potential fleet fuel savings from introducing these new technologies to the market. In performing this analysis, it was assumed that the technical targets of Table 3-1 were met, and because these new technologies would add to the cost of the vehicle, the analysis was performed on a cost-competitive basis, assuming that the incremental cost of the technology is paid back by fuel savings in 3 years. Vehicle price and fuel economy were the two most important attributes characterized (DOE, 2004b). The results of the analysis indicated that for light-duty vehicles, oil savings, in millions of barrels per day (mbpd), from diesels and diesel hybrid vehicles would be approximately 0.05 mbpd in 2015, 0.22 mbpd in 2020, and 0.57 mbpd in 2025. These are small reductions considering the light-duty vehicle petroleum consumption in 2004 was approximately 8 mbpd. However, a different rate of market penetration would change these projections. These new technologies would be incorporated into the market more quickly, as enabling technologies, if the market drivers were

TABLE 3-1 Goals and Status of the Advanced Combustion Engines and Emission Controls Activity

|

Goals |

Unit |

2004 Status |

Goals by Fiscal Year |

||||

|

PFI |

DI |

FY07 |

FY10 |

FY13 |

FY15 |

||

|

For hydrocarbon fuel |

|||||||

|

ICE peak brake thermal efficiency |

% |

30 |

41 |

43 |

45 |

46 |

|

|

ICE powertrain costa |

$/kW |

20 |

30 |

35 |

30 |

30 |

|

|

Projected vehicle emissions |

Tier 2 |

<Bin 10 |

Bin 10 |

Bin 5 |

Bin 5 |

Bin 5 |

|

|

Emission control fuel economy penaltyb |

% |

|

|

<5 |

<4 |

<3 |

|

|

Emissions durability |

1,000 miles |

120 |

120 |

120 |

120 |

120 |

120 |

|

For hydrogen fuel |

|||||||

|

H2 ICE peak brake thermal efficiency |

% |

38 |

|

|

45 |

|

45 |

|

H2 ICE powertrain costa |

$/kW |

|

|

|

45 |

|

30 |

|

Projected vehicle emissions |

Tier 2 |

<Bin 5 |

|

|

Bin 5 |

|

Bin 5 |

|

NOTE: PFI, port fuel injection; DI, direct injection. The emission standards are based on EPA Tier 2 emission regulations. The description of the test procedures and the regulated levels for each Bin may be found at <http://www.dieselnet.com/standards/us/light.html>. aHigh-volume production of 500,000 per year. bFuel economy penalty over combined federal test procedures due to emission control relative to diesel vehicle with 2003 emissions. SOURCE: K. Howden and R. Peterson, “Advanced combustion and emission controls (ACEC) activities,” Presentation to the committee on November 17, 2004. |

|||||||

to change—for example, if the price of fuel were to increase or by any of the policy alternatives discussed in Chapter 2.

Program Technologies

Because a primary goal of the program is to reduce fuel consumption, the most fuel-efficient power plant available is being considered as the basis for the research effort. For light-duty vehicle applications, the compression ignition direct injection (CIDI, diesel) engine is the most fuel-efficient engine currently in production. It is well known, however, that current diesel engines will not meet future emission standards. Therefore, to reduce fuel consumption through the more widespread introduction of diesel engines into the market, advances must be made in emission reduction technologies. Here, the most significant barriers are cost and insufficient fundamental understanding of engine combustion phe-

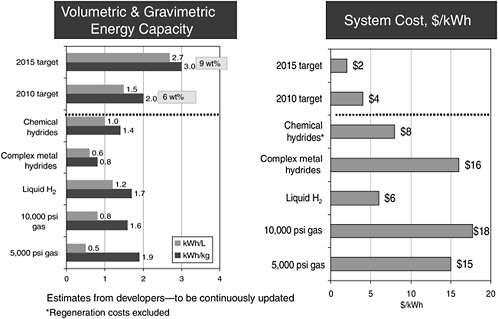

FIGURE 3-1 Technical areas and relative funding for the ACEC activity, FY04. DPF, diesel particulate filter; HCCI, homogeneous charge compression ignition; LTC, low-temperature combustion; PM, particulate matter; SCR, selective catalytic reduction.

SOURCE: Response to questions from the committee to DOE, received January 19, 2005.

nomena, exhaust emission control technologies, and engine controls. It is important to realize that the phenomenon of diesel combustion and its emission reduction is fundamentally different from that of the conventional spark ignition engine. The technologies are not transferable. New technologies are required. The research directly addresses all of the barriers except cost. The operating paradigm of the program is to expand the fundamental understanding of combustion, aftertreatment, and controls phenomena in a precompetitive research environment and then let industry address cost as it works to incorporate the new technologies into vehicle power plants.

The individual project topic areas within each research focus are shown in Figure 3-1. Details on the specific research projects within those topics are available in the DOE annual report (DOE, 2003). The vehicle manufacturers all have in-house programs that could be grouped under the topic headings given in Figure 3-1. Government-supported research efforts in these areas differ from industry efforts in the nature of the understanding being sought. Industry is focused on trying to find workable engineering embodiments of the various technologies—for example, establishing the operating parameters of an engine that facilitate low-temperature combustion (LTC); a classification of combustion processes that includes homogeneous charge compression ignition (HCCI) combustion;

and devising strategies to switch from low-temperature combustion to conventional diesel combustion when loads outside the LTC regime are required. The activities supported by federal money at the national laboratories and universities are pursuing a fundamental understanding of the processes that will enable LTC technology to be extended or optimized. For example, federal programs are working to understand the thermochemical interactions that constrain LTC to its current regime. If these are better understood, a wider range of LTC will be possible, with a corresponding improvement in efficiency and reduction in emissions.

As seen from the budget distribution (Figure 3-1), the research effort tilts strongly toward the fundamentals of combustion and aftertreatment, with smaller efforts addressing component subsystems and sensors. The subsystem and sensor research programs are aimed at the question of controls. Control algorithms for the power train system will need inputs from sensors that are monitoring component performance; commands would then be issued, adjusting the engine and aftertreatment system operation.

During this last year the ACEC technical team has shifted the emphasis of its research programs. If the current diesel engine combustion process were left unaltered, the conversion efficiency for the nitrogen oxides (NOx) and particulate matter (PM) aftertreatment systems would need to be maintained at levels in excess of 90 percent for the lifetime of the vehicle—a huge challenge. The emphasis has therefore shifted from controlling emissions with aftertreatment technologies to reducing the in-cylinder formation of emissions, thereby reducing the burden on exhaust gas aftertreatment. Research has demonstrated that LTC, of which HCCI combustion can be viewed as a subset, has the potential to generate very low levels of NOx and PM (Akihama et al., 2001; Siebers and Pickett, 2004). The challenge is that to date, LTC has been limited to low-load operation, and the parameter space for controlling it is not well understood.

The research effort on NOx and particulate matter aftertreatment is very closely aligned with the effort of industrial partners. The formulation and development of new or improved catalysts is conducted primarily in industry, where catalyst suppliers team with vehicle or engine manufacturers. Catalyst mechanisms such as sulfur poisoning, desulfation of lean NOx traps, thermal aging, and soot filter regeneration are being investigated at the national laboratories using diagnostic microscopy and spectroscopy techniques not readily found in industry. These investigations use both model catalysts and real formulations. The data are being made available for the development of computer simulations of emission control devices, being done at the national laboratories and universities involved in the Crosscut Lean Exhaust Emission Reduction Simulation (CLEERS) activity.

The direct fueling of ICEs with hydrogen is also under investigation. This is an area where partner companies have in-house programs, so the DOE-supported effort is minimal. Using hydrogen in an ICE would of course provide some of the emission benefits at much lower capital cost than changing to fuel cells and

electric propulsion. The focus of DOE-funded research in this area is direct injection (DI) hydrogen engines. DI hydrogen engines offer higher power density than engines in which the hydrogen is introduced in the intake manifold.

Fueling of ICEs with hydrogen through an intake manifold is also under investigation. Using hydrogen as an ICE fuel is not new. Because hydrogen has such wide flammability limits and high flame speeds, it may be possible to extend the lean operating limits of the engine, which would reduce fuel consumption and emissions. The issues associated with implementing this are pragmatic and not fundamental. Consequently much of the research on direct fueling on ICEs with hydrogen is being done by industry, with little or no DOE involvement.

One challenge with direct fueling an engine with hydrogen is the loss of volumetric efficiency because the fuel is gaseous. In addition, lean burn mixtures—combined with loss of volumetric efficiency—causes a large power reduction (for the same displacement engine), necessitating a supercharger or turbocharger to bring power levels back up. If a stoichiometric mixture of hydrogen and air is introduced into the engine in the intake manifold, hydrogen will comprise approximately 30 percent of the mixture by volume. This disadvantage can be overcome if hydrogen is directly injected into the cylinder. In this connection some fundamental issues need investigation. The penetration and mixing phenomenon surrounding low-density, high-velocity gas inside a cylinder during direct injection is the subject of DOE-supported investigations at the Sandia Combustion Research Facility. These activities are aimed at increasing the power density of a hydrogen-fueled engine.

Budget and Organization

The FreedomCAR and Fuel Partnership is focused on light-duty passenger vehicles. However, the fundamental knowledge being pursued to enable fuel-efficient technologies is not exclusive to light-duty passenger vehicles. It also applies to engines used in the commercial sector—for example, heavy-duty trucks. To capitalize on these synergies in the combustion engines and emissions technical area, the FreedomCAR and Fuel Partnership is collaborating with the 21st Century Truck Partnership, a partnership of DOE, DOD, EPA, and DOT and 15 industrial partners. The combined budget for advanced combustion for both the FreedomCAR and Fuel Partnership and the 21st Century Truck Partnership for FY04 was $54.4 million. Of this total, $19.5 million was under the direct control of the FreedomCAR and Fuel Partnership. The distribution of these directly controlled funds to the research topics is shown in Figure 3-1.

The vision of the Partnership is that hybrid vehicles will be an important part of the transition. However, because hybrid vehicles are already on the market and are being further developed by the individual automotive companies that are part of the partnership, government-funded efforts for the ACEC activity aim to get a better fundamental understanding of ICEs and aftertreatment systems. This should

lead to better engines, which would become part of better hybrid power trains. The technical goals in Table 3-1 are related to engine and aftertreatment performance; hybrid vehicles as such do not appear.

The technical teams, made up of researchers at government laboratories, including the DOE national laboratories, and industry and university laboratories, have established a good process for interaction, feedback, and review. There is interaction between the technical teams of FreedomCAR and 21st Century Truck in the form of crosscut teams, workshops, biannual program reviews, and discussions facilitated by memoranda of understanding. The industrial partners provide input for the setting of research priorities through the workshops and technical reviews, whose outcomes are reflected in DOE solicitations for proposals. As technologies are considered for commercialization the developmental research is performed by vertically integrated teams of industry partners.

Achievements

Quantifying the achievements of the ACEC activity is challenging in that the primary outcome of the government-supported research is new knowledge. In this sense, progress is good. The advanced combustion and emissions control technical team has demonstrated new understanding of the LTC process, including HCCI, and has achieved low-temperature operation in running engines. New understanding of phenomena occurring at the spray nozzle tip, where fuel atomization and air entrainment begin, has been obtained through x-ray imaging, and the boundaries of clean, injection-driven combustion are being expanded. Operational windows of lean catalyst and mechanisms of catalyst poisoning are being studied, and a real-time exhaust stream particulate sensor is being tested. These are important accomplishments; however, it is not known at this time to what extent these advancements in knowledge will be integrated into light-duty vehicle power plants in the near term.

Comments and Recommendations

The various types of ICEs will play a critical transitional role in achieving the FreedomCAR and Fuel Partnership’s long-term goal. Even assuming the eventual success of hydrogen as a primary transportation fuel, for several decades ICE will be the automotive power plant that consumes most of the fuel in the fleet. Reducing its fuel consumption and emissions is therefore critically important. Novel emission technologies are needed, and the cooperation of energy companies in such research will increase the likelihood of finding solutions.

The energy companies joined the Partnership in September 2003, adding a new dimension to the program: Now, the impact of fuel modification or substitution on the combustion, emission, and aftertreatment performance can be examined. The variety of fuels that could be investigated is huge, as is the number of

pragmatic constraints relative to refining and distribution that need to be considered. The role of fuel characteristics in ongoing research and how best they should be integrated into the program is not well known at this time. Many of the research activities within the ACEC use pure fuels or controlled mixtures. Fuel composition could be systematically varied to enhance our understanding of different chemical processes during combustion and the reduction of emissions by catalyts or to evaluate the impact of fuel composition on the fundamental processes being studied. The issue of real-world fuels found in the marketplace and whether their properties can be used as enablers to achieve desirable results is not part of the program at this time. It is difficult to know whether this will be a fruitful area of research, but it should be considered. It seems that the energy company partners are still not completely integrated into this research program.

Much of the fundamental work is being done with pure fuels or simple blends. Knowing the extent to which these pure fuels or simple blends will be representative of real-world fuels expected to be available in the marketplace (for example, low-sulfur fuels or reformulated gasoline contain small amounts of sulfur or oxygenates) or knowing their deficiencies relative to real-world fuels will be important in interpreting the fundamental results achieved in the laboratory for expected behavior in real-world application.

Recommendation. DOE should encourage the energy industry to become involved in establishing research parameters for the work on pure fuels that will be most relevant to real-world fuels expected in the marketplace.

If specific fuel blends are identified as having a positive impact on meeting the technical targets for an advanced ICE, it will be important to understand the ability of the energy companies to make those blends and what the costs and capital requirements would be.

Recommendation. DOE and the energy industry should develop refinery models for making tailored fuel blends.

At present, there is still no commercially attractive aftertreatment system for CIDI engines that meets the EPA Tier 2, Bin 5, emission standard. Industry is intensely pursuing the development of various technologies for PM and NOx removal. In general, aftertreatment systems are unsatisfactory in terms of their cost, fuel penalty, durability, or effect on engine performance. This is particularly so for NOx removal devices. Engine manufacturers and catalyst companies devote significant in-house effort to satisfying the Tier 2 standard. In accordance with the mission of the FreedomCar and Fuel Partnership to “examine precompetitive, high-risk research,” the ACEC technical team is encouraged to identify breakthrough and innovative technologies that could provide long-term solutions to the CIDI emissions problems and to begin to anticipate, analyze, and

look for solutions to potential emissions problems and solutions for emerging fuels, the fuel infrastructure, and propulsion systems. For example, the emissions problem associated with a distributed hydrogen production system could be quite different and costly, and treatment of emissions from low-temperature combustion could pose new challenges.

Recommendation. Increased emphasis should be placed on novel emission control technologies, and the advanced combustion and emission controls technical team should plan for, analyze, and seek solutions for emission problems associated with emerging fuels, fuel infrastructure, and propulsion systems.

FUEL CELLS

If hydrogen is to account for a significant share of the fuels used for transportation, the transition will be greatly facilitated by fuel cell power systems whose performance and cost are compatible with automotive requirements. This is especially true if costs and onboard storage continue to be problem areas for hydrogen. Fuel cells promise higher conversion efficiencies for hydrogen than ICEs, thus reducing fuel consumption and onboard storage requirements by increasing equivalent fuel economy.

Fuel cell systems are operating successfully on hydrogen in dozens of experimental vehicles in the United States and several other countries. These systems are not compatible, however, with the requirements for mass-manufactured automobiles. They are too expensive, too large, and too heavy, and they have performance problems such as slow start-up and slow power transients, and poor durability, such as degraded performance and limited component life. The status in 2004 of these and other characteristics as well as the targets for 2005 and 2015 are shown in Table 3-2. As can be noted, the 2005 targets (established in 2003) were essentially being met in 2004 in some areas but still had a long way to go in others, such as durability, survivability, and start-up time. Indeed, a review of these parameters not only through the early stages of the FreedomCAR program but also through the entire PNGV program preceding FreedomCAR would show impressive and continuing progress in every area. However, comparing the 2005 targets with the 2015 targets shows clearly that much additional progress is needed.

As delineated in Table 3-3, the fuel cell program is focused on R&D to improve fuel cell technologies for both transportation and stationary applications. The fuel cell program is being implemented by DOE’s Office of Hydrogen, Fuel Cells, and Infrastructure Technology Program (HFCIT), which is identifying and developing the critical technology and knowledge needed. The fuel cell part of the FreedomCAR and Fuel Partnership is organized to facilitate the engagement of automobile developers, component suppliers, and related participants so as to meet the 2015 objectives. It is a multidimensional, complex effort spanning many

TABLE 3-2 Technical Targets for an 80-kWe (net) Integrated Transportation Fuel Cell Power System Operating on Direct Hydrogena

|

|

Goals |

||||

|

Characteristic |

Unit |

2004 Status |

2005 |

2010 |

2015 |

|

Energy efficiencyb at 25% rated power |

% |

59 |

60 |

60 |

60 |

|

Energy efficiency at rated power |

% |

50 |

50 |

50 |

50 |

|

Power density |

W/L |

450 |

500 |

650 |

650 |

|

Specific power |

W/kg |

420 |

500 |

650 |

650 |

|

Costc |

$/kWe |

125 |

125 |

45 |

30 |

|

Transient response time |

s |

<3 |

2 |

1 |

1 |

|

Cold start-up time to max power |

|

||||

|

at −20°C ambient |

s |

120 |

60 |

30 |

30 |

|

at +20°C ambient |

s |

60 |

30 |

15 |

15 |

|

Emissions |

|

zero |

zero |

zero |

zero |

|

Durabilityd |

hr |

1,000 |

2,000e |

5,000f |

5,000 |

|

Survivabilityg |

°C |

−20 |

−30 |

−40 |

−40 |

|

aTargets exclude hydrogen storage and are based on an aerodynamic 2500-lb vehicle. bRatio of DC output energy to the lower heating value of the input fuel (hydrogen). Peak efficiency occurs at about 25% rated power. cIncludes projected cost advantage of high-volume production (500,000 units per year). dPerformance targets must be achieved at the end of the durability time period. eIncludes thermal cycling. fIncludes thermal cycling and realistic drive cycles. gAchieves performance targets after 8-hour cold-soak at temperature. SOURCE: DOE, 2005. |

|||||

TABLE 3-3 Funding for Fuel Cell Technology Programs (thousands of dollars)

|

Technology Component (Interior Appropriations) |

FY04 |

FY05 |

FY06 Request |

|

Transportation systems |

7,317 |

7,495 |

7,600 |

|

Distributed energy systems |

7,249 |

6,902 |

7,500 |

|

Fuel processor R&D |

14,442 |

9,721 |

9,900 |

|

Stack component R&D |

24,551 |

32,541 |

34,000 |

|

Technology validation |

9,828 |

17,750 |

24,000 |

|

Technical program mgmt support |

395 |

535 |

600 |

|

Total |

63,782 |

74,944 |

83,600 |

|

SOURCE: Provided by DOE in response to a request by the committee. Interior Appropriations refer to the Congressional Subcommittee on the Interior and Related Agencies, which funded these activities. |

|||

technologies across a number of organizations, including government agencies, national laboratories, automotive fuel cell developers, original equipment manufacturers (OEMs), and potential suppliers. Owing to the interdependency of the fuel cell and hydrogen, there is also a growing and evolving relationship with the fuel component of the Partnership. To maximize the chances for a successful outcome, plans and schedules must be adhered to, yet the fuel cell program must be flexible enough to allow evolutionary changes to it.

A successful fuel cell development effort will, by itself, not guarantee that the key objectives of the FreedomCAR and Fuel Partnership are met. Success also depends on achieving on-board hydrogen storage, related systems integration, and the broader requirement of a hydrogen fueling infrastructure. The efforts must be fully interactive. For example, fuel quality standards are partly driven by fuel cell developers.

The fuel cell program is focused on the high-risk, precompetitive, industry-wide issues that are hindering the technological and commercial success of the power generation module (stack) and related ancillary processes. The program is broken down into critical and enabling components, with the funding allocated to diverse teams in industry and academia. Selection of the critical components was based on the outcome of workshops organized and facilitated by DOE. Specific technology and cost targets were set by the industry participants and then formulated into a technology milestone plan (DOE, 2005). The primary themes are stack subcomponent (e.g., catalyst, plate hardware, membranes) development, operation, durability, efficiency, and cost; hydrogen fuel as it relates to stack performance; and transportation power systems (cost and performance analyses). The funding for each technology component is presented in Table 3-3. The results of the development efforts are communicated among the technical teams and may ultimately be integrated into the program of an individual developer of automotive fuel cells.

Technology Issues

The PEM fuel cell is based on compartmentalized hardware (cells), in which the reactant gases (H2 and air) are separated by a membrane. The catalyst, which is in intimate contact with the membrane, initiates the chemical reactions that generate power. Coolants, cell separators, and sensors are other parts of the package. The properties of the membrane and catalyst layers, which impact performance and reliability, are highly dependent on water content. If water is not properly managed in the cell, failure modes are enabled, reducing lifetime, reliability, and durability (the focus of many FreedomCAR projects). The key goals are for a fuel cell vehicle to achieve characteristics, including power and drivability, manufacturability, and cost, that do not compromise consumer expectations. The technical targets necessary to meet these key goals (see Table 3-2) do not take into account the benefits of overall fuel efficiency and protection of the

environment. Some of the more important 2015 technical targets are these: 60 percent peak efficiency; 300-mile driving range (vehicle target); 5,000-hr lifetime; $30/kW cost for the fuel cell system; low Pt catalyst loading (<0.2 g/kW); and 30 s at 20ºC cold start-up capability.

Although the near-term FreedomCAR objectives for the development and eventual commercialization of membrane fuel cell technology are currently on target, deployment in the automotive sector in the long term is still at considerable risk. Performance, reliability, durability (current stack lifetimes of 1,000 hr vs. the project goal of 5,000 hr), and cost (estimated at ~$125/kW in 2004 vs. the goal of $30/kW, not including the hydrogen storage system) remain major obstacles (DOE, 2005). (The estimated cost of a fuel cell with a hydrogen storage system is about $175/kW [TIAX, 2004]. However, the validity of these cost estimates is questionable and is discussed further in the section “Cost Issues.”)

Some of the critical technical barriers will need breakthrough invention, not just incremental improvements to existing technology. For example, to meet the 2015 targets, it is expected that new materials for membranes, catalysts, catalyst supports, and plate compositions will have to emerge. This adds a high degree of risk to the overall development effort, and the large improvements that are needed make it likely that additional unforeseen roadblocks will arise as the program proceeds.

Because many elements of the program are carryovers from earlier DOE-funded initiatives—for example, the PNGV program (NRC, 2001)—selected activities and development plans are already in place to address the known critical issues. For example, the technical roadmap (DOE, 2005) contains detailed plans and schedules for new membrane development, lower catalyst loadings and increased electrode durability. However, in order to meet the overall targets for fuel cells, it is likely that the various technical scenarios will probably have to be revised as new technologies and issues emerge. The roadmap calls for several specific development activities to take place in parallel. However, the most critical issues may have to be resolved before secondary, less important issues can be addressed. DOE leadership, along with the technical teams, must be alert and make needed changes to the roadmap as they are required.

A number of critical technical issues that are shared by the entire fuel cell industry must eventually be resolved if the overall program goals are to be achieved. Because many of these issues relate to the subcomponents of the fuel cell stack, they involve vendors, suppliers, and OEMs. DOE understands such issues and dynamics and has provided substantial project funding for these areas. The primary technical issues that are being addressed are short-lived membranes, degraded catalysts, suboptimal stack design, and complicated operating strategies. In addition, the high costs of the membrane materials (>$200/m2 vs. the target of $50/m2 at volume) are problematic. Since most membrane properties are affected by the water concentration, new materials with a lower hydration dependency are required. Current and planned efforts focus on these challenges.

The quantities of platinum catalyst required to meet performance and reliability targets are currently excessive (~1 mg/cm2 vs. a target of 0.2 mg/cm2) yet, even with this high loading, cells still exhibit gradual degradation in performance. Existing and new projects will have to come up with novel advances in both catalysts and catalyst layer architecture to resolve this problem. Since catalyst performance is related to operating conditions, gas distribution, and membrane interactions, the technical teams must continue to coordinate and enhance their activities. The 2004 Annual DOE Merit Review, held in Philadelphia in May 2004, reports initial progress in these key areas of more durable membranes and lower catalyst loadings.1

The inadequate lifetime and performance characteristics of today’s vehicular fuel cell systems can be contrasted with those of stationary applications that use nearly the same technology. Stationary fuel cell systems have demonstrated lifetimes of 8,000 hr compared to the FreedomCAR goal of 5,000 hr (DOD, 2003).2 DOE is taking a proactive role in learning the causes of such differences by funding selected stationary projects to obtain additional understanding. These projects could be extremely valuable to the project teams by providing an understanding of the importance of differences in operating modes, water management, and impact of environmental conditions. It is difficult to assess the results of such programs at this time but it is expected that recent and future workshops facilitating direct interactions between vehicle and stationary developers will accelerate successful solutions.

There are significant schedule risks attached to current development efforts since there is no clear path to achieving acceptable reliability, performance, and cost solutions. Therefore, the fuel cell program should be carefully monitored and frequently assessed. The present limitations of membranes and electrodes and the status of related stack development should be given the highest priority within HFCIT and in efforts funded in other DOE programs (such as Basic Energy Sciences [BES], in the Office of Science). Longer term, next-generation, outside-the-box concepts of the kind that are typically funded by BES are highly encouraged by the committee. It is not apparent that there are any significant radical technical R&D initiatives in the current fuel cell program, and even if a decision to commercialize membranes and electrodes can be made in 2015, DOE should continue to support the development of next-generation materials.

While it is possible that viable solutions may emerge during the remaining decade, there is no guarantee that any of the solutions will meet the stringent requirements of the fuel cell program. Understanding the failure mechanisms of current materials is often the way to develop new concepts and solutions. Such

|

1 |

Annual DOE Program Review Proceedings available on the Web at <http://www.eere.energy.gov/hydrogenandfuelcells/2004_annual_review.html>. |

|

2 |

Personal communication between committee member Glenn Eisman and Alan Feitelberg, Plug Power. Also see Roger Saillant, “Stationary fuel cells,” Plenary address at the 2004 Fuel Cell Seminar, San Antonio, Texas. |

mechanisms must be painstakingly studied and delineated and, therefore, it is important that some of our strongest and most talented scientists and engineers, particularly at the national laboratories, focus on them in a precompetitive, open environment.

There are also significant government activities outside the Department of Energy—for example, in the Defense Advanced Research Projects Agency (DARPA), DOD, the Department of Commerce’s National Institute of Science and Technology (NIST), and the National Science Foundation—that are contributing to related fuel cell technical issues. FreedomCAR can learn from the knowledge and technical direction of such activities and incorporate them into its own effort. In some cases DOE is already funding such activities. A case in point is the development of a new process to assist in the understanding of fuel cell performance related to water dynamics. The technique, based on the imaging of fuel cells, is under development at the Neutron Research Center at NIST. The NIST effort is important in that it has been able to develop a CAT-scan-like technique to “see” the water within a working cell, enabling the development of concepts that might improve performance. This is a considerable achievement and one of the most significant analytical advances in the membrane fuel cell realm in decades. The NIST facility offers the entire fuel cell community unique research opportunities that previously eluded them.

Cost Issues

The program is in the process of developing a comprehensive cost model for fuel cell systems (TIAX, 2004). Because the program is so complex, the model is a work in progress, and the technology is evolving, it is too early for the committee to assess the viability and accuracy of specific findings at this time. In its present form, the model should be useful for tracking cost changes with design modifications, for establishing goals for component cost, and for prioritizing cost reduction targets. However, the committee found that TIAX predictions had not yet been validated against the cost of existing entire fuel cell systems, making such predictions speculative. Furthermore, details of the economies expected with manufacturing improvements and the large-volume production of components must be carefully documented and validated for reasonableness before a realistic systems cost estimate can be established. The program is currently reporting a large-volume cost for the fuel cell system of $125/kW and $175/kW with hydrogen storage (TIAX, 2004). These estimates are well below the published costs for many experimental systems (as they should be), but it was not possible for the committee to verify their validity.

For viable fuel cell systems costs to reach the FreedomCAR goal of ~$30/kW, low-cost materials, new, high-volume manufacturing technologies, and better performance and reliability must converge. Currently, membranes and catalysts are both costly. Volume manufacturing may alleviate some of the cost burden, but the

catalyst pricing is dictated by market dynamics (the price of platinum in 2004 was $900 per ounce, nearly twice the average price during the 1990s). The unpredictable cost of platinum provides further incentive to reduce catalyst loadings and/or develop a nonprecious metal system. While the balance-of-plant costs are not insignificant, they are based on more conventional engineering processes.

The analysis of costs associated with the fuel cell (TIAX, 2004) points to and supports the conclusion that significant advancements must be made in order for the FreedomCAR cost targets to be met. Such analyses are extremely valuable, but because they are based on numerous assumptions, it is too early to attach any great significance to them. This is especially true for elements related to the power generation module, because such technology is still evolving.

Findings and Recommendations

Overall, the committee finds that the DOE fuel cell program is well organized, has a well developed and comprehensive technology roadmap, has focused on the appropriate priorities and initiatives, and has effectively budgeted and applied program and project management processes. The facilitation of the relationships between the various groups and the ability to set targets that are appropriate yet not without risk are examples of successful program implementation by EERE, with execution by the supporting teams.

The results of this review are indicative of a program that is in its early stages. The review finds that a foundation has been laid that will address the critical issues. The reallocation of project funds to more basic and applied research addressing more fundamental issues is an example of recent proactive changes in the program. It should be pointed out that although the program is sound on numerous fronts, its success is highly dependent on communication and cooperation among the members of the fuel cell technical teams. Fortunately, communication between different parts of EERE, as well as among EERE managers at the various technical teams, is well established, though in some cases not formalized.

Procedures are in place for effective communication and project coordination, leading to the aforementioned conclusion that the fuel cell program is being efficiently managed. The annual merit program review is one such procedure. Because the program is so complex and the detailed objectives are spread over so many technical teams and academic and industrial projects, an additional level of scrutiny for specific efforts would be beneficial. It is also expected that the go/no-go decision making process will continue and that additional evaluation mechanisms will be incorporated into the effort.

Recommendation. DOE should broaden its collaboration with industry, academia, and other government agencies on precompetitive, industry-wide technical issues and solutions. Stationary fuel cell developers should be included as well. For example, DOE could sponsor one or more conferences, workshops, debates, or fo-

rums to facilitate in-depth interactions or it could set aside some discretionary funds that would allow program managers to accelerate progress on promising new ideas.

Recommendation. To promote new fuel cell water and hardware imaging techniques that could address technical barriers, DOE should enhance its existing collaboration with the NIST Neutron Research Center. DOE should also determine whether similar capabilities exist at the national laboratories and related academic centers so it could capitalize on this significant analytical advancement.

Recommendation. DOE should expand activity and place a higher priority on membrane R&D, new catalyst systems, and electrode design (with the BES program). In particular, the national laboratories and other appropriate scientific centers should be focused on the fundamental failure mechanisms, including a better understanding of the chemistry, physics, and materials involved.

HYDROGEN STORAGE

Hydrogen storage activities are organized within the DOE Hydrogen Fuel Initiative (HFI), with oversight by the hydrogen storage technical team of the FreedomCAR and Fuel Partnership. As the technical team noted in its presentation to the committee’s November 2004 meeting, “Hydrogen storage is critical to the success of the hydrogen economy! No current technology meets the needs for hydrogen storage.” The goal of the hydrogen storage technical team is to drive the development and demonstration of commercially viable hydrogen storage that meets FreedomCAR goals.

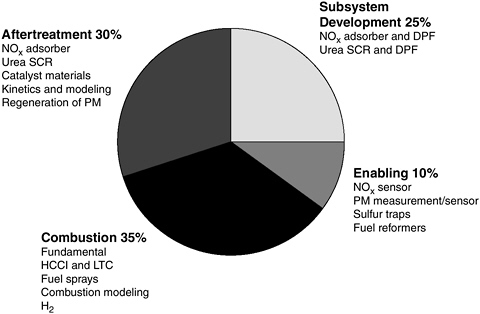

Hydrogen storage is a key enabling technology for the advancement of fuel-cell-powered technologies for all applications—transportation, stationary, and portable. The goals for hydrogen storage on board the vehicle are shown in Table 3-4. These goals are chosen to drive the development of technologies that will compete with current vehicles in terms of cost, performance, and durability. The mass goal is based on providing a vehicle with a driving range of more than 300 miles. The volume required must leave enough space to satisfy other functional needs. Gravimetric, volumetric, and cost targets have been developed for 2010 and 2015. These goals represent a consensus within the DOE hydrogen technology program. They are used by the technical teams to select and evaluate prospective hydrogen storage materials and related technologies. The 2015 energy density goal of 2.7 kWh/L and specific energy goal of 3.0 kWh/kg are half of what is provided by gasoline (6 kWh/L). A bulky hydrogen storage technology that does not meet these goals would increase fuel consumption and decrease the useable space available on-board the vehicle. Other targets include system fill time, temperature, pressure, flow rates, cycle life, and transient response time.

No current hydrogen storage technology meets the 2015 target. Figure 3-2 shows estimates provided by DOE to the committee for current storage technolo-

TABLE 3-4 Hydrogen Storage Goals

|

Parameter |

2010 |

2015 |

|

Specific energy (net), kWh/kg |

2.0 |

3.0 |

|

(7.2 MJ/kg) |

(10.8 MJ/kg) |

|

|

(6% by weight) |

(9% by weight) |

|

|

Energy density (net), kWh/L |

1.5 |

2.7 |

|

(5.4 MJ/L) |

(9.7 MJ/L) |

|

|

(0.045 kg/L) |

(0.081 kg/L) |

|

|

Storage system cost, $/kWh |

4 |

2 |

|

SOURCE: S. Satyapal, S. Jorgensen, and F. Bavarian, “Hydrogen storage joint technical team,” Presentation to the committee on November 18, 2004. |

||

gies. Compressed hydrogen and liquid hydrogen, followed by chemical hydrides, come closer to meeting the goal than do the complex metal hydrides or carbon. The hydrogen storage technical team has developed a roadmap of tasks, milestones, and go/no-go decision points to guide the R&D and evaluation of these alternatives.

The committee believes that hydrogen storage technology is one of the greater risks for reaching the program goals in 2015. Hydrogen storage needs a breakthough discovery as the forerunner of development and innovation. Some vehicle manufacturers have in-house programs for hydrogen storage, but they are not able to pursue all of the options. They tend to focus more on the implementation challenges than on broad-based, high-risk exploratory research.

It is too early for the committee to assess technical progress, because the hydrogen storage projects were funded for the most part starting in FY05. The program technical goals are judged by the committee to be appropriate for a commercially viable vehicle, but target dates cannot be set with any certainty. Discovery is needed and cannot be scheduled.

While on-board hydrogen storage is a critical issue for vehicle use, it is also very important for the development of infrastructure (see Chapter 4). Hydrogen will also have to be stored at the dispensing site and at intermediate points in the transport network. Both the infrastructure and on-board storage needs would benefit from a research breakthrough that would significantly increase energy density and reduce the cost of the storage system. One possibility is an integrated solution to the dual difficulties of infrastructure/on-board storage—for example, chemical hydrides, which might be transferred (in cartridge form) to the vehicle. However, recharging a vehicle storage system with gaseous hydrogen appears to be preferable from the standpoints of speed and simplicity.

In all, 71 hydrogen storage projects were funded in FY05, for a total of $23,654,000. Three centers of excellence were established under the leadership of the national laboratories. Other areas receiving funding are the new, independent, so-called Grand Challenge projects being carried out at universities, industry, and national laboratories. New materials and concepts, physical storage off-board, and analysis are also being studied. Physical storage off-board is important because off-board storage will be required at all hydrogen fueling stations.

Tanks for the on-board storage of compressed and liquid hydrogen are being developed by the private sector and are now only a small effort within the program. The focus of the work on tanks within the program is on cost reduction and advanced concepts such as cryocompressed hydrogen and conformable tanks in various shapes. The primary cost driver is tank materials, with carbon fiber representing 40-80 percent of the material cost. Future efforts in compressed and liquid hydrogen storage tanks will involve off-board storage. Metal hydride hydrogen storage materials are not expected to meet the targets, but work in this area is providing an understanding of storage capacity and reversibility. Carbon-based materials for hydrogen storage will focus on reproducibility of results, onsite peer review of projects, and verification of results using standard materials. A go/no-go decision point on carbon nanotubes is scheduled for the fourth quarter of FY06. In chemical hydrogen storage, the storage material is recharged with hydrogen off-board the vehicle and, following use, is recovered and recycled. A chemical composition with a hydrogen capacity of 5.5 percent by weight has been demonstrated. The main technical issue that needs to be addressed for this approach to be viable is off-board regeneration efficiency. Reversible chemical hydrogen is the focus of many exploratory projects. Reversible storage would permit charging the system with hydrogen on-board the vehicle and eliminate recovery and reprocessing of the spent fuel material.

Findings and Recommendations

The hydrogen storage technical team is newly formed and received significant funding only in FY05. Further, DOE’s Office of Science basic research on hydrogen storage was first funded in FY05 as well. Although many approaches are worthy of consideration, most will not be able to demonstrate adequate capacity and/or suitable storage release characteristics.

Recommendation. In view of the exploratory nature of the work and the need to take technical risk and thereby foster discovery, DOE should check progress at appropriate times with go/no-go decisions. In this way, new ideas are able to emerge and the most promising approaches are adequately supported.

A center-of-excellence approach involving collaboration among the national laboratories, universities, and industry is being taken by the hydrogen storage

program. Three centers of excellence have been selected based on a program solicitation: one on metal hydrides, one on chemical hydrides, and one on solid state, carbon-based materials. The center of excellence approach should enable focused interdisciplinary research by teams of researchers that provide for sharing of facilities and rapid dissemination of findings. The FY04 and FY05 hydrogen storage project participants at the time of the committee review are shown in Appendix E.

Recommendation. The center-of-excellence research model should be carefully evaluated in parallel with peer review of the research. The committee believes centers of excellence are a good concept, but DOE should wait for an evaluation of the three centers’ performance before expanding the concept to other areas of research.

Recommendation. In view of the risk posed to the entire hydrogen program by the need for a viable hydrogen storage system, the hydrogen storage technical team and the FreedomCAR and Fuel Partnership leadership team should report annually to all program participants, DOE, and Congress on the state of hydrogen storage technology worldwide relative to the goals and targets of the program.

ELECTRICAL ENERGY STORAGE

The FreedomCAR and Vehicle Technologies (FCVT) program is responsible for advancing the development of energy storage systems. The primary focus of the effort is the development of advanced batteries and includes work on ultracapacitors. Advanced battery work in support of all light- and heavy-duty vehicles is conducted through this program. Energy storage technologies are critical enablers for the development of fuel-efficient ICE hybrid electric vehicles (HEVs) as well as fuel cell hybrid electric vehicles (FCHEVs). Advanced batteries can also be the primary source of power for plug-in hybrids and electric vehicles that provide alternatives to reduced petroleum consumption.

DOE has supported battery research for a long time. With the formation of the United States Advanced Battery Consortium (USABC) in 1991, followed by the establishment of the PNGV program in 1993, the battery effort was directed more toward large battery modules. The PNGV program advanced technologies for nickel metal hydride (NiMH), lithium ion (Li-ion), and other rechargeable batteries for hybrid automotive applications. At that time it was realized that most battery systems under consideration had one or more problems—such as abuse tolerance, cost, and calendar life—limiting their potential use. Thus in 1997 the DOE initiated applied battery research, mainly based at five DOE national laboratories. In 2000, a long-term exploratory research activity program was organized to understand fundamental impediments to the development of advanced batteries.

Today the technology effort for storing electrical energy is organized into three subactivities:

-

Battery development, the primary activity, consists of full battery system module development, technology assessment, and benchmark testing.

-

Applied battery research focuses primarily on gaining an understanding of failure modes and limiting parameters of the Li-ion system that currently is closest to meeting the technical goals of HEVs.

-

Long-term exploratory research focuses on specific electrochemical systems to solve fundamental problems limiting the performance of advanced battery systems.

DOE undertakes these efforts in collaboration with USABC, and the work is conducted at battery developers, DOE national laboratories, and universities and through Small Business Innovation Research (SBIR) grants. The total budget for all energy storage technologies in FY04 and FY05 was $22.3 and $23 million, respectively. Of this total, most of the funds, over 75 percent, are used to fund the battery development effort. In FY05, $17.4 million is allocated to battery development, $1.4 million to applied battery research, and $4.2 million to long-term exploratory research.

The plan of FCVT is to develop affordable advanced batteries covering the full range of applications, including start/stop 42-V systems, power assist for HEVs, FCHEVs, and battery electric vehicles (EVs). The technical targets for the various applications are listed in Table 3-5. As noted in FCVT’s multiyear plan, a primary goal of the energy storage program is to develop by 2010 an electric drive train that includes a battery with a 15-year life at 300 Wh of available energy, discharge power of 25 kW for 18 s, and a $20/kW cost (DOE, 2004a).

Program Status and Assessment

The main achievement of the battery effort is the demonstration of high-power Li-ion batteries that will be able to meet or exceed most of the performance targets for an HEV, including specific power, power density, specific energy density, and cycle life. Battery calendar life is now estimated to be greater than 10 years vs. the target of 15 years. These batteries have two major deficiencies: abuse tolerance and cost. Li-ion high-power batteries are not intrinsically tolerant of abuse such as short circuits, overcharge or overdischarge, vibration, and fire. Some of these issues can be addressed by external electronic control; however, it is imperative to continue to look for battery chemistries that are resistant to voltage or thermal abuse.

Partly to address abuse tolerance, the battery effort has programs to develop Li-ion/gel polymer and lithium sulfur (Li/S) batteries. The gel electrolyte in a Li-ion battery is expected on the one hand to reduce the rate at which the electrolyte reacts with the electrodes during abuse conditions. On the other hand, it may reduce the power capability of the battery, particularly at low temperatures. The Li/S battery is expected to be more abuse tolerant due to a sulfur shuttle reaction. In addition, it has the theoretical potential to meet all the EV performance targets.

However, several technical barriers have to be overcome to make the Li/S chemistry work efficiently, particularly dendritic growth of metallic lithium during cycling. The Li-ion/gel polymer battery and the Li/S battery are being tested to determine how they will meet the various performance targets in Table 3-5. A go/ no-go decision based on the performance data will be made in FY06.

Further understanding and control of thermal abuse is being done through battery thermal management studies at the National Renewable Energy Laboratory (NREL) using thermal modeling, characterization, and control. This work is critical, not only for managing thermal abuse conditions but also for achieving more uniform temperature control over the battery module, which should increase battery life.

Battery development teams are working on several fronts to reduce the cost of the Li-ion battery. They are assessing new cathode materials, such as a spinel-based lithium manganese oxide and lithium iron phosphate as an alternative cathode material for Li-ion batteries. These materials are a lower cost alternative to the lithium cobalt oxides used today and may have greater stability under abuse conditions. Other cost reduction efforts are based on earlier studies showing that the cost of nonactive material in a high-power battery, particularly the separator material, can exceed the cost of the active material. Thus, support is being provided to develop low-cost polypropylene-based materials with a cost goal for the separator of $1/m2. The goal is to have a direct replacement for the current separator material that is cheaper and more stable at high temperature.

The main barriers for high-power batteries—abuse tolerance, cost, and calendar life—are also being pursued by the applied battery research and the long-term exploratory research groups. Both groups are looking at newer materials and electrochemical couples to obtain a basic understanding of the failure mechanisms and factors that limit performance of the systems. The applied battery research activity is conducted primarily at five national laboratories—Argonne National Laboratory, Brookhaven National Laboratory, Idaho National Engineering and Environmental Laboratory (INEEL), Lawrence Berkeley National Laboratory (LBNL), and Sandia National Laboratories (SNL). The focus here is to work on a second-generation Li-ion system, determine performance and failure mechanisms, and relate them to the individual components of the system. The long-term battery research is carried out primarily at LBNL and looks at the performance of a large number of promising electrode materials and electrolytes and determines their limitations by advanced material diagnostics and sophisticated modeling studies.

The committee commends the FCVT program for expanding its primary focus on battery development to include both the basic and applied research necessary to enhance the performance of the battery. The committee believes strongly that this expanded process should continue and that funding and effort on long-term exploratory research and applied battery research should be accelerated. It is clear that solutions to the main barriers of abuse tolerance, cost, and calendar life for high-power batteries will come only with the introduction of new materials and electrochemical couples and from a better understanding of the factors that limit battery performance. Thus the efforts being conducted in the

TABLE 3-5 Technical Targets for Electrochemical Storage

|

Target |

Unit |

42-volt |

HEV (Power-Assist) |

Fuel Cell Vehicle |

Battery EV |

||||

|

Stop Start |

M-HEV |

P-HEV |

Low Power |

High Power |

Low Power |

Commercialization |

Long Term |

||

|

Discharge power |

kW |

6 for 2 s |

13 for 2 s |

18 for 10 s |

25 for 10 s |

40 for 10 s |

25 for 18 s |

|

|

|

Specific power-discharge, 80% DOD/30 s |

W/kg |

|

|

|

|

|

|

300 |

400 |

|

Regenerative pulse |

kW |

N/A |

8 for 2 s |

18 for 2 s |

20 for 10 s |

35 for 10 s |

25 for 5 s |

|

|

|

Specific power-regeneration, 20% DOD/10 s |

W/kg |

|

|

|

|

|

|

150 |

200 |

|

Engine-off accessory load |

kW |

|

3 for 5 min |

|

|

|

|

|

|

|

Recharge rate |

kW |

2.4 |

2.6 |

4.5 |

|

|

|

|

|

|

Power density |

W/L |

|

|

|

|

|

|

460 |

600 |

|

Available energy at 3 kW |

Wh |

250 |

300 |

700 |

300 |

500 |

250 |

|

|

|

Specific energy—C/3 discharge rate |

Wh/kg |

|

|

|

|

|

|

150 |

200 |

|

Energy density—C/3 discharge rate |

Wh/L |

|

|

|

|

|

|

230 |

300 |

|

Specific power/specific energy ratio |

h−1 |

|

|

|

|

|

|

2:1 |

2:1 |

|

Total energy |

kWh |

|

|

|

|

|

|

40 |

40 |

applied and long-term research groups are crucial to meeting all the target goals of a high-power battery. At present less than 25 percent of the total energy storage budget is allocated to the applied and long-term research. This share should be increased significantly.

Most of the work sponsored by the energy storage technology team is directed to the development of high-power batteries. Specifically, in FY04, 80 percent of the funds were spent on high-power batteries for HEVs. Some funds were used to develop high-energy batteries to meet the target for an EV. The applied and long-term exploratory research on new materials and electrochemical couples is also primarily for high-energy batteries. The committee recognizes that the distinction between a high-power and high-energy battery is somewhat arbitrary, particularly when attempting to gain a basic understanding of the factors limiting the performance of the battery. The fundamental property of a battery is its specific energy, and generally the specific power is determined by design optimization for a given application. Thus, the Li-ion battery is a high-energy battery that has been optimized to meet the power and cycle life requirements of a high-power battery for HEV applications, and increased effort on high-energy batteries will increase the likelihood of meeting the high-power battery goals for hybrid application.

The target requirements for the HEV listed in Table 3-5 show that as one moves from a 42-V application to a more demanding power-assist HEV and then to a FCHEV, the power requirement increases from 13 kW to 25 kW. Not only is the power increased for the more demanding hybrid applications, but it is also required for a longer time, increasing from 2 s in the 42-V application to 18 s for a FCHEV (DOE, 2004a). Thus one would require a battery with not only a higher power rating but also significantly higher specific energy. It is clear that various hybrid designs will have different power requirements and there is continuum of energy requirements. Higher energy can be utilized to gain a better mix of power and energy density in battery design for a given application or it can also be used to optimize the size of the ICE engine.

The target requirements for an EV are listed in Table 3-5. The main requirement is a high-energy battery with specific energy of 200 Wh/kg and 2:1 power to energy ratio. An EV represents an alternative route to achieving the primary goal of the FreedomCar and Fuel Partnership: energy independence and an environmentally friendly transportation system. The development of high-energy batteries is consistent with DOE’s goal of investing in high-risk technologies. The challenge of such an effort is probably no greater than the challenges of hydrogen storage and the hydrogen infrastructure requirements for a hydrogen fuel cell vehicle. The committee feels that the effort for high-energy batteries should be significantly increased.

Ultracapacitors

The double-layer capacitor (DLC), commonly referred to as an ultracapacitor, is an energy storage device having a state-of-the-art energy density about 1/10

that of a Li-ion battery but a power density about 10 times that of a Li-ion battery. DLCs in large sizes (>5,000 farads) are receiving considerable international research attention and could prove to be an important element in a FCHEV. Current research is focused on innovative electrode structures and new electrolytes, the goal being to achieve both a higher cell voltage and a larger specific capacitance. The DLC has no mass transport and compared with a battery, has a considerably longer cycle life and better tolerance of temperature extremes. As noted in the section “Electric Propulsion, Electrical Systems, and Power Electronics,” the FreedomCAR program has benchmarked commercially available DLCs. In view of the potential benefits of a high-energy-density DLC, the funding of research in advanced DLC technologies may be warranted.

Comments and Recommendations

Efforts directed toward the development of new materials and electrochemical couples in these programs present the best chance to remove the major barriers of abuse tolerance, cost, and calendar life for high-power batteries.

Recommendation. DOE should direct more of its effort and funding for high-power batteries for HEVs to applied and long-term exploratory research rather than battery development.

High-energy batteries for electric vehicles and plug-in hybrid applications would also serve to meet the FreedomCar and Fuel Partnership goals. Further, more support for high-energy battery research would increase the likelihood of meeting the requirements of various HEVs for high-power batteries.

Recommendation. A significantly larger effort and higher priority should be placed on searching for breakthrough technology in the area of high-energy batteries for electric vehicles.

Recommendation. In view of the potential benefits of a high-energy-density DLC in hybrid vehicles, the energy storage technical team, in conjunction with the electrical and electronics system technical team, should maintain an activity that explicitly monitors progress of international DLC research programs and should consider funding research in advanced DLC technologies.

ELECTRIC PROPULSION, ELECTRICAL SYSTEMS, AND POWER ELECTRONICS

The multiple systems in both hybrid electric vehicles (HEVs) and fuel cell hybrid electric vehicles (FCHEVs) require both control and coordination. These functions will be provided by electronics, both power- and signal-level. Although

a fuel cell (FC) alone may be compatible with the dynamic requirements of electrical traction, regenerative braking requires that the FC be augmented by an energy storage device—e.g., a battery or an ultracapacitor. This electrical energy storage may also be used to enhance the dynamic performance of the propulsion system by, for instance, providing fast transient power for acceleration. The battery may also be used for drive-away when fuel cell start-up time is excessive. The charge/discharge cycles of this device will require power electronics. Control of the FC itself will also require electrical system controls. The integrating role of the vehicle electrical system makes it an important technology, both functionally and economically. However, the FreedomCAR goal for the electrical and electronics (EE) technical team, as stated, is limited to the propulsion system—that is, the electric machine and the power electronics to drive it.3 Although the multiyear plan of the FCVT program also states this goal, the surrounding discussion does refer to many of the other EE functions necessary for the complete system (DOE, 2004a; FCVT, 2004).

Program Status and Progress

Within the restricted goals established for the EE systems, the EE technical team has built on the results of the motor and electronics development in the PNGV program. The power electronics technology for FreedomCAR is evolving from the PNGV-funded automotive integrated power module (AIPM) developments. While several companies (one is Rockwell Automation) continue to develop AIPMs that may be applicable to FreedomCAR, the FCVT program is currently funding work at Semikron.

Table 3-6 shows the power electronics and traction motor status in 2003, the 2010 targets, and the gap between status and target. The reported status of the power electronics in November 2004 had not changed from that in 2003. The principal challenges are thermal performance, lifetime, and cost. Although the 2003 status for power electronics shows a lifetime of 15 years, this is with a coolant temperature of 70°C. The lifetime would be considerably less at the 2010 target temperature of 105°C. Although the specific power and volumetric power density of the motor are still shy of their 2010 targets, it is the motor cost and thermal performance that remain the most significant challenges. The committee is not convinced that the motor cost goal of $7/kW is achievable, since the cost is principally a matter of commodity prices (e.g., copper and iron prices), and it seems unlikely that cost can be reduced much through research.

Thermal performance of the power electronics has been a challenge using conventional component technology, and the EE technical team is exploring

TABLE 3-6 Technical Targets for Power Electronics and Electric Motors

|

|

2003 Status |

2010 |

Gap |

|

Power electronics (inverter/controller)a |

|

||

|

Specific power at peak load (kW/kg) |

11 |

>12 |

1 |

|

Volumetric power density (kW/L) |

11.5 |

>12 |

0.5 |

|

Costa ($/kW peak) |

6 |

<5 |

1 |

|

Efficiency (%) |

97 |

97 |

0 |

|

Coolant inlet temperature (°C) |

70 |

105 |

35 |

|

Lifetime (yr) |

15 |

15 |

0 |

|

|

|||

|

Specific power at peak load (kW/kg) |

1.0 |

>1.3 |

0.3 |

|

Volumetric power density (kW/L) |

3.5 |

>5 |

1.5 |

|

Cost ($/kW peak) |

15 |

<7 |

8 |

|

Efficiency (%) |

>90 at 35% to 100% maximum speed |

>93 at 10% to 100% maximum speed |

|

|

aThe targets are based on a series power train with 30-kW continuous power and 55-kW peak power. Entries for 2003 are taken from AIPM and automotive electric motor drive (AEMD) specifications. bTechnical targets include the gearbox and connectors. SOURCE: FCVT, 2004. |

|||

alternatives through an advanced R&D program whose salient elements are the development of silicon carbide (SiC)-based converters and high-temperature capacitors. The Semikron inverter is being retrofitted with SiC diodes, and a number of research programs at different organizations are directed toward higher temperature capacitors. New thermal management techniques applicable to both the electronics and the motor are being explored.