4

Roadmapping

Technology roadmaps accomplish a variety of things, but most importantly they may help to communicate among stakeholders from a wide range of communities. They can be used to direct basic science, to identify critical technology paths, or to help estimate when a technology could be available to be implemented into a system.

For example, adhesion between the matrix and the fiber clearly affects the durability of a PMC, and a number of current and potential research efforts can help to modify or improve this adhesion. The management of PMC degradation due to interfacial reactions would be greatly aided by expanding such knowledge, developing new techniques, or applying such knowledge and techniques more widely. The overall endeavor to improve the durability and life prediction of PMCs can be greatly informed by cataloging the existence and progress of such efforts.

Additional participants—also called stakeholders or team members—in the overall process include designers of the systems where the PMCs will be used. Codifying their expectations can also be very useful. In this way, roadmaps can provide a guide to where technology efforts should be focused and where technology gaps exist.

USING ROADMAPS

Roadmaps have been used extensively by a number of industries. For example, the first electronics industry roadmap, initiated by the Defense Advanced Research Projects Agency (DARPA), was published in 1994. This effort resulted in the organization of the National Electronics Manufacturing Framework Committee—a group of 200 individuals from industry, government, and academia—to study the challenges facing the nation in electronics manufacturing and to develop technology roadmaps and policy options with which to address these challenges. The National Electronics Manufacturing Initiative was incorporated the following year, and the consortium has published a roadmap every other year since 1994. Today, several roadmaps anticipate what lies ahead for the electronics industry. These additional roadmaps provide detailed information about segments of the electronics industry, such as semiconductors (International Technology Roadmap for Semiconductors) or interconnection substrates (IPC roadmap).

In the chemical industry, the first vision for future technology needs was based on then-current and anticipated market and consumer requirements. At a workshop, industry experts identify the goals, technical challenges, and priority R&D needs for a specific area, culminating in a roadmap and an extensive industry review process to build consensus among stakeholders. Progress towards achieving the goals is monitored over time. To date, 12 roadmaps have been published. However, developing roadmaps is only the beginning. To make an impact on the industry, collaborative teams need to pursue the priority R&D. The chemical industry's Vision2020 initiative encourages the development of

partnerships to address the high-priority areas identified in roadmaps.1 Collaborative R&D will ultimately lead to new commercial technology. Similar roadmaps have been developed and implemented for the steel, glass, aluminum, metal casting, forest products, and mining industries.

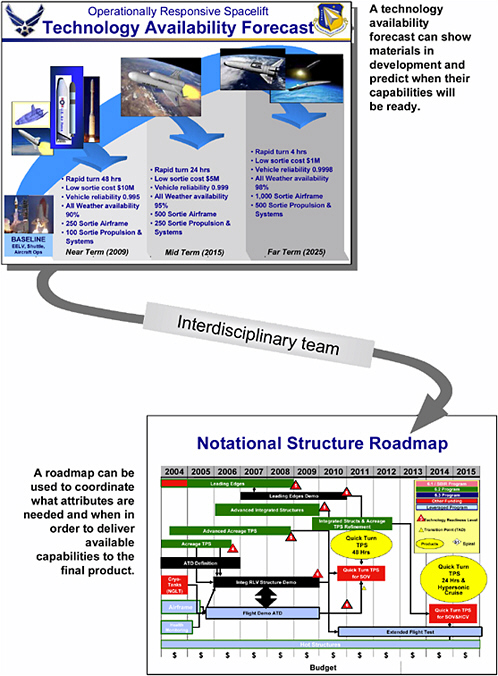

Roadmaps come in a variety of formats, and each is created to meet a specific need. Accordingly, separate roadmaps would need to be developed for PMCs in space applications, aerospace applications, land-based battlefront applications, and undersea applications. An example of a hierarchical roadmap for space lift vehicles is shown at the top of Figure 4-1. In this figure, the flight vehicles are grouped into near term, mid term, and far term, and under each vehicle are listed its key operational requirements. These requirements are the key capabilities needed for that vehicle implementation. While the vehicle attributes are essentially capabilities, the needs can be thought of as attributes, and how technologies satisfy those attributes is the product that the technology develops. These needs can then be broken down into distinct needs. Another way to think about it is, What does the technologist have to do to deliver the product?

At the bottom of Figure 4-1 is a notational structure product roadmap. This type of roadmap translates needs into a series of actions to develop a technology or product to meet the various space lift needs—for example, leading edges, cryogenic fuel tanks, and airframes. The technology readiness level (TRL) is noted at the end of the development cycle. The various TRLs have been defined by the Air Force and NASA; while the definitions are not exactly the same, the idea behind them is the same.2 For example, a TRL of 6 means that the concept has been demonstrated in a relevant environment and is ready for demonstration in an operational environment.

This discussion has focused so far on high-level roadmaps, but they can be used to provide guidance on development schedules and data gaps for subtasks. For example, on the structure development chart there is a requirement to develop an integrated structure to a TRL of 6 by 2009. An integrated structure would have a thermal protection system (TPS) over it, so depending upon the efficiency of the TPS, the underlying structure could be a PMC.

Assuming a PMC could be used, the technology availability forecast shows that an airframe able to last 250 flights will be available by 2009. Assuming the PMC can operate at 350°F to 400°F, a development schedule can be drawn up that shows what is needed (for example, data feeds and funding levels) and when, to achieve a TRL of 6. Input to the chart would come from universities, researchers, industry, and fabricators. The chart would make clear when a certain technology is expected to be ready and whether it will be on time to help the vehicle.

ROADMAPPING GOALS

A roadmap for PMCs could accomplish a number of things. It could facilitate communication between database and modeling teams. A good roadmap could impact technology development and implementation by providing information for the database and justifying the allocation of funds. To accomplish this, a roadmap needs to include existing and near-term public and private programs and their intended deliverables and outcomes.

Certain organizational issues must be resolved. Like other successful roadmaps it could include an oversight committee of persons from industry, government, and academia who meet annually to develop and update the roadmap. A good roadmap should be impartial and flexible and should outline several alternative paths and timelines for achieving the stated goals.

A roadmap to guide the use of PMCs in extreme environments would need to be coordinated with PMC roadmaps for the Air Force, NASA, and their contractors. It would need to show when a material’s insertion is planned, including the lead time, what testing is needed and when, and the relationships to existing and still-to-be developed models. Most importantly, a roadmap must make clear what work cannot be done in parallel.

|

1 |

A list of roadmaps developed under the Chemical Industry Vision2020 Technology Partnership are available at <http://www.chemicalvision2020.org/techroadmaps.html>. Accessed April 2005. |

|

2 |

J.C. Mankins. 1995. Technology readiness levels. Available at <http://advtech.jsc.nasa.gov/downloads/TRLs.pdf>. Accessed April 2005. |