4

Addressing Energy Intensity of the Chemical and Allied Process Industry

The high standard of living accorded by the availability of food, water, clothing, shelter, transportation, and recreation, are the result of great advances in chemical and biological sciences and technology. However, the chemical products resulting from these advances require considerable energy input or intensity.1 The U.S. energy use constitutes about 24 percent of the global consumption of energy, 88 percent of which is derived from fossil fuels (petroleum, coal, and natural gas combined).2 Industrial activity accounts for 33 percent of all the energy (fossil fuels, electricity, etc.) used in the U.S. The U.S. chemical process industry (CPI) consumes nearly 25 percent of this,3,4 or about 7.7 percent of all the energy resources used in the United States. In short, energy use in the CPI is significant. The readily available and relatively inexpensive sources of fossil fuels that the chemical industry has enjoyed for the last century are in part responsible for the present situation.

The implications for sustainability of the high energy use in the CPI are well documented. Similar to the discussion in Chapter 3, these include business risks associated with the:

-

Increasingly higher cost of energy which is reflected in the increasing production cost of chemical products;

-

Uncertainties in the reliability of supply;

-

Impacts on global climate change from emissions of greenhouse gases (CO2, etc.) as well as ones causing acid rain and ground-level ozone pollution (NOx, etc.)

-

Competition with other industries (transportation, domestic, etc) for fossil fuel resources.

Global events in the last three decades, however, have brought the realization that fundamental changes in energy use are necessary for continued sustainability of the chemical and allied industries. Recently, the price of a barrel of oil reached more than $60, and is likely to continue to fluctuate, with the mean value staying substantially above the price over the last 20 years. The price of natural gas is at an all time high in the United States, which is the highest price in the world. This places the U.S. chemical industry at an economic competitive disadvantage. The fourfold increase in oil prices since the mid-1990s has driven the CPI to discover energy efficient technologies that have contributed to more useful products, reduced emissions, and improved productivity. Indeed, there are numerous examples of real gains made by the chemical industry in addressing the high energy intensity. One company has publicly reported5 achievements of more than 20 percent improvement in energy efficiency in a ten year period from 1994 to 2004. However the exploration, discovery and implementation of innovative and more energy efficient technology are, and must remain, ongoing pursuits.6

The goal of these pursuits is for the chemical industry to continue to deliver products essential to improved living conditions of the current generation and still be able to meet the needs of future generations. As pointed out by Jeff Siirola during the workshop, it is expected that in the near term the chemical industries will continue to rely on fossils fuels, eventually converting from oil and natural gas to coal, as dictated by price. However, it is anticipated that carbon (i.e., CO2) management—closing the carbon cycle—will become vital prior to the depletion of fossil fuel reserves (Table 4.1).7 Eventually, the use of renewable energy sources will be required. The following innovative strategies and technologies are necessary for success:

|

5 |

http://www.dow.com/commitments/stewardship/increase.htm |

|

6 |

Hoffert, M. I., et al. 2002. Advanced Technology Paths to Global Climate Stability: Energy for a Greenhouse Planet. Science 298:981–987. |

|

7 |

See comments by Jeff Siirola and Klaus Lackner, Workshop Summary, Appendix D, p. 139 and p. 151, respectively. |

TABLE 4.1 Fossil Fuel Reserves

|

|

Recoverable Reserves (Gigaton Carbon)a |

Reserve life at current consumption rate (years)b |

Reserve life at projected GDP growth (years)c |

|

Oil |

120 |

35 |

25 |

|

Natural Gas |

75 |

60 |

45 |

|

Coal |

925 |

400 |

100 |

|

aSOURCE: Energy Information Administration website (www.eia.doe.gov). bEstimated reserves divided by current consumption cSOURCE: Population trends for each geographic sector of the world were taken from the Population Reference Bureau website (www.prb.org) and GDP per Capita for every country were taken from a table at www.photius.com/wfb1999/rankings/gdp_per_capita_0.html. Estimates were made for how fast GDP/Capita (in constant dollars) might grow in each country, and were then multiplied by the expected population growth in each country and summed for the whole world to get a ratio for how energy demand will grow (energy demand grows historically at half the rate of GDP growth). Provided courtesy of Jeffrey Siirola. |

|||

-

Continually reduce the energy intensity of the CPI towards practical minimum levels, with the obvious benefit of reducing the cost to manufacture

-

Reduce dependence on the increasingly costly and unreliable supply of fossil fuels

-

Allow the greater use of renewable energy resources, including solar energy and biomass-derived energy

-

Reduce the environmental impact by decreasing carbon emissions

OPPORTUNITIES FOR R&D

One area of opportunity for research and development in sustainability for the chemical industry has to do with improving energy efficiency and reducing the energy intensity of the CPI. Well known endeavors towards reduction of energy intensity involve continuous improvements and optimization of existing processes and operating practices, heat recovery and heat integration methods (including co-generation of electric power and steam), selection and use of equipment with enhanced mechanical and electrical efficiencies. Greater investments are being made to capture and use currently wasted natural gas in the form of liquefied natural gas (LNG). At the workshop, several other ideas for reducing the energy intensity of the chemical and allied process industry were suggested. Several of these ideas are already in use at some level but require further research and development to achieve breakthrough inno-

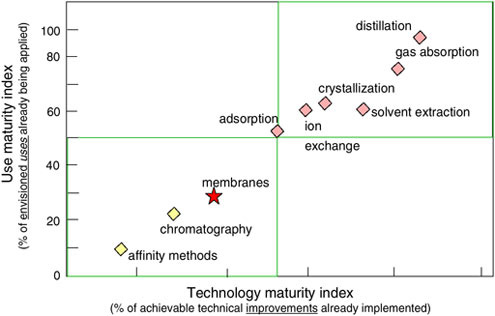

FIGURE 4.1 Maturity of separation technologies.

SOURCE: William Koros, adapted from Humphrey, J. L. and Keller, G. E., II, 1997, Separation Process Technology, McGraw-Hill.

vations. A few of these ideas are presented below, and note the research challenges to be addressed.

Energy Efficient Separations

Chemical processes typically include one or more energy intensive separation steps. Distillation is by far the most common separation method, and this one unit operation consumes 35-40 percent of the all the fuel used for energy by the CPI (dominated by petroleum refining), amounting to roughly 3 percent of all the energy needs of the entire United States.8 At the same time, as shown in Figure 4-1, distillation is quite a mature technology that is becoming increasingly difficult to improve upon.9 A large percentage of achievable technical improvements have been made and a large percentage of envisioned uses have already been

|

8 |

U.S. Department of Energy (Energy Information Administration). 2004. Country Analysis Brief, USA. www.eia.doe.gov/emeu/cabs/usa.html |

|

9 |

Humphrey, J. L., and G. E. Keller, II. 1997. Separation Process Technology. McGraw-Hill, and comments by William Koros during workshop, p. 147. |

applied to distillation. In contrast, less mature technologies such as membrane separations, adsorption, and extractions usually occur at lower temperatures and consequently tend to be lower energy intensive processes. However, there are significant technical challenges that currently limit the use of these alternative separation processes and that must be overcome to realize significant reductions in the energy intensity of the CPI.

Membrane Separations

Membranes are increasingly being used in separation processes and novel synthetic processes.10 As pointed out by William Koros during the workshop,11 membranes have the greatest potential for low energy intensity processing, but they are the least technologically mature of large scale separations. Further growth in membrane applications will require research and development effort that includes the following:

-

Development of advanced membrane materials with well-characterized physical and performance (selectivity and permeability) properties as well as appropriate selection and applications guidelines

-

Development of quantitative predictive models that relate membrane structure to the performance characteristics for separating complex mixtures

-

Development of catalytic membrane reactors

-

Manufacturing technology for cost effective assembly of reliable membrane separation modules for both liquid and gas phase separations

-

Fouling: understanding the mechanisms for fouling and ways to reduce or prevent it.

|

[Membrane separation] technology is about where I would say aqueous reverse osmosis was in the late 1960’s. It was clear that it worked, but it didn’t work very well, and there still has to be a significant investment made. We are making a decision. We are either going to invest in something that has this ability to cause an order of magnitude reduction [in cost], or we won’t. William Koros, Georgia Institute of Technology |

|

10 |

Koros, W. J. 2004. Evolving Beyond the Thermal Age of Separation Processes: Membranes Can Lead the Way. AIChE J. 50(10):2326–2334. |

|

11 |

See comments by William Koros in the Workshop Summary, Appendix D, p. 147. |

Adsorption

The design of novel materials provides the opportunity for highly selective adsorption separations. Research challenges associated with adsorption include the following:

-

Finding adsorbents with appropriate selectivity for specific separations and that retain their integrity through many adsorption-desorption cycles

-

Energy efficient and cost effective desorption strategies

-

Improving the science and technology of simulating moving beds technology to make adsorption technology effective for essentially continuous operations.

Extraction

While not new technology, liquid-liquid extraction needs to be more fully exploited in the CPI. The primary limitations have been selectivity, cross-contamination, and the toxicity of the solvents. Thus, the primary research challenges that exist are:

-

Developing and identifying solvents that give the appropriate selectivity and partition coefficients, without significant loss of the solvent to the raffinate12

-

Developing and identifying solvents with lower toxicity

Separation and Recovery of Components from Dilute Aqueous Solutions

Separation of valuable components and waste products from dilute solutions is a particularly challenging separations problem that warrants special attention. Removing contaminants from wastewaters is vitally important, as is the recovery of products from fermentation broths. Evaporation of large amounts of water is usually a poor choice from an energy standpoint due to the large heat of vaporization of water. Thus, strategies for removal of components from dilute aqueous solutions constitute a particularly urgent research challenge.

Novel and Effective Catalysts

As pointed out in a recent special issue of Science magazine on catalysts,13 “Industrial catalysis will continue to require chemical engineers to take the work of chemists, and increasingly biologists, and run it efficiently on a grand scale.” Improvements in chemical and biological catalytic selectivity and activity under varying conditions has the potential to substantially reduce the energy intensity of the CPI, in addition to other aspects of achieving sustainability discussed elsewhere in the report (e.g., managing carbon dioxide, producing feedstocks from biomass, developing green chemistry and engineering, etc.). Recent advances in nanoscience14,15 are now contributing to a greater understanding of how particle size, structure, and composition affect catalyst performance, which should lead to greater opportunities for reducing the energy intensity of the CPI.

Biocatalysis16 through use of enzymes was highlighted in the workshop as a promising approach to reducing the energy intensity of the CPI, and as a way of creating innovative solutions to fuel growth for future generations without the environmental insult (also see discussion in Chapter 3 on “Technologies for Converting Biomass into Chemical Feedstocks”). Glen Nedwin pointed out how the use of enzymes exploits their key properties, which include: specificity of catalytic activity; effectiveness at low temperature and concentrations; ability to biodegrade; and availability from renewable resources.

Nedwin suggested several areas of research and development that need to be explored to reduce the manufacturing cost of enzymes, and increase the enzyme specific activity per gram. Many of these advances will involved improvements in overall genetic engineering capabilities to support enzyme production, and include:

-

Finding less costly feedstocks for the manufacture of enzymes

-

Enhancing enzyme recovery and separation methods to make them less costly

-

Ways to increase fermentation yields for enzyme production

-

Developing process technologies for on-site or in-situ production

-

Finding more stable enzymes or develop methods to enhance their stability

-

Discovering enzymes with greater specificity

-

Optimization of cellulase enzyme mix

Alternative Fuels

Reducing the energy intensity of biofuel17 and biofeedstock production (see Chapter 3 of this report) is another important research area. A major challenge associated with biomass utilization for both fuels and feedstocks is developing technologies for carrying out separations, especially separation of relatively dilute chemicals from aqueous solutions (e.g., fermentation broths), as mentioned in Chapter 3. According to Stanley Bull, only recently has even ethanol production from corn sugars (which has been invested in heavily) become efficient enough that it is a net energy producer.18

There is also a continued need for technologies for cogeneration of high value chemical building blocks and power starting with fossil fuel feedstocks, such as coal and lignite as oil supplies dwindle in the short term and renewables become more viable sources of fuel in the long term. The chemical industry has steadily increased its cogeneration capacity over the years, more than doubling between 1985 and 1998—providing about 20 percent of the net demand for electricity in for the CPI in 1998.19 Optimization of production of chemical feedstocks, power production and efficient heat recovery will continue to be needed regardless of the sources of energy.

Lubrication

A vast amount of the energy used by modern societies is wasted as a result of unproductive friction in internal combustion and aircraft engines, gears, cams, seals and bearings. According to some estimates,20one third of the world’s energy resources in present use disappear as friction in one form or another. Typical automobile engines convert only 20-35 percent of the chemical energy of combustion to useful mechanical work. The rest is lost due to frictional losses and heat via engine cooling and exhaust. Jost has estimated21 that the United States could save in excess of $16 billion

|

17 |

This includes fuel such as methane produced from renewable resources, especially plant biomass and treated municipal and industrial wastes. |

|

18 |

See comments by Bull in the Workshop Summary, Appendix D, p. 128. |

|

19 |

Energy Information Administration. 2001. Manufacturing Energy Consumption Survey. |

|

20 |

Bhushan, B., ed. 1996. Handbook of Micro/Nano Tribology. Boca Raton, Florida: CRC Press. |

|

21 |

Jost, P. 1976. Economic Impact of Tribology. Proc. Mechanical Failures Prevention Group. NBS Spec. Pub. 423. Gaithersburg, MD. |

per year from better tribological practices. Advances in nanoscience have led to new understanding of adhesion, friction, wear, and thin-flm lubrication at sliding surfaces taking place from the atomic and molecular scales to microscales.22 Further developments in micro/nanotribology have the potential to provide breakthrough technology for reducing the energy intensity of the CPI. Major research challenges include:

-

Development of a fundamental understanding of how lubrication works to allow design and selection of compounds and mixtures with the appropriate properties

-

Development of more stable, higher temperature lubricants

Solar and Other Non-Fossil Fuel Sources of Energy

While reduction in energy intensity and improvements in energy efficiency of using fossil fuels in the short term are absolutely vital for the sustainability of the CPI, eventually the CPI must look to alternative and renewable feedstocks and energy sources. These may include landfill gas, wind, and solar energy. Renewable sources are a vital component of any effort to be less dependent on conventional feedstocks and fuels, to reduce manufacturing costs, and to decrease the impact of the CPI on the environment.

Among the options that exist, solar energy is the only truly sustainable energy solution. Obviously the sun is the primary source of energy on earth. Solar energy is abundant, clean, and renewable, but unfortunately it is intermittent and diffuse. To realize its potential, it must be captured, concentrated and stored or converted to other useful forms. The research challenges include:

-

Advances in technologies that will reduce the cost and the environmental impact of producing photovoltaic systems.

-

Advances in technologies that allow the direct use of solar energy for cost-effective splitting of water to produce hydrogen

-

Improvements in heat transfer fluids that enable direct use of solar energy for meeting some of the heating requirements of the CPI

-

Advances in storage systems for electric power generated from solar energy.

It should be noted that nuclear energy is often mentioned as a potential long-term source of energy as an alternative to fossil fuels. As pointed out in the workshop and elsewhere,6,23 current (fission based) nuclear reactor technology does provide electricity without carbon dioxide emissions. However, it also generates highly toxic wastes, presents safety and security concerns for centuries [half life of plutonium is 24,100 years], and utilizes limited uranium resources; thus it is not a sustainable energy option. At the same time, nuclear technology based on the energy released by the fusion of deuterium and tritium is a promising long-term energy source [greater than 30 years] without the negative attributes of nuclear fission, but it still requires significant research advances to make it a viable option.6

Carbon Management

Since fossil fuels are significantly less expensive than alternative energy sources (due to the many research challenges; see section on “Solar and Other Non-Fossil Fuel Sources of Energy” above), it is anticipated that the CPI will continue to use fossil fuels for energy for many decades into the foreseeable future. In addition, there is significant capital investment that would be required to convert from fossil fuels to renewable sources. When the price of oil and natural gas becomes prohibitively high due to dwindling supplies or other factors, the CPI will convert to relatively abundant coal. Even with steady growth in GDP, it is anticipated that coal reserves will last for at least another century (Table 4.1).24 There is general agreement among the scientific community that there is a link between atmospheric CO2 concentrations and global temperature increases.25 Moreover, as atmospheric CO2 concentration increases, it is projected that the associated global climate change will reach a critical stage by mid century, well before the depletion of all fossil fuel reserves. Thus, developing technology and strategies for effective carbon management is a key to sustainability of not just the CPI, but life on earth in general.

Current estimates for the energy required for CO2 recovery from flue gas by amine scrubbing, pressurization, and re-injection into geological formations varies from about 13-25 percent of the energy value of the

original fuel that produced the CO2 (natural gas vs. pulverized coal).26 This is a very significant burden that needs to be reduced if effective CO2 management is to be employed on a widespread basis. In addition, there are issues with regard to leakage from geological formations that have not been fully resolved.

Thus, the research and development challenges for carbon management include:

-

Development of energy efficient technologies for CO2 separation, not just from flue gas, but also from the atmosphere

-

Development of technologies for CO2 sequestration. Questions that need to be addressed include:

-

Is it technically feasible to make carbonates from CO2 without excessive energy use and with a viable carbonate disposal plan?

-

Is it possible to effectively utilize CO2 in the production of cement?

-

Can CO2 hydrates be made a practical solution?

-

What are the issues (e.g., leakage) associated with storage of compressed CO2 in geological formations?

-

Development of technologies for CO2 utilization is needed. CO2 is considered to be a cheap, nontoxic, and renewable feedstock that is currently being used to produce entirely new materials and for new routes to existing chemicals such as urea, salicylic acid, cyclic carbonates, and polycarbonates.27 With further progress, utilizing CO2 for synthesis of chemicals could play a more significant role in managing global carbon emissions.

CONCLUSIONS AND RECOMMENDATIONS

Reducing the energy intensity of the CPI is an absolutely vital component in ensuring the sustainability of the chemical and allied industries. Continued reliance on fossil fuels can be anticipated, with eventual conversion from less abundant oil and natural gas to more abundant coal. This makes the issue of carbon management extremely important. The CPI will eventually need to look to renewable energy resources. Finally, it is clear that development of more energy efficient technologies will be

necessary whatever the source of energy being used by the CPI, with priority given to research and development in the following areas:

More energy efficient separation processes. Chemical processes typically include one or more energy intensive separation steps. Distillation is by far the most energy intensive. In contrast, membrane separations, adsorption, and extractions tend to be lower energy intensive processes. However, there are significant technical challenges that currently limit the use of these alternative separation processes and that must be overcome to realize significant reductions in the energy intensity of the CPI.

Utilization of improved catalysts for energy reduction and selectivity increases. Biotechnological and other emerging technological solutions need to be explored to reduce the energy intensity of the CPI. In contrast to the typical catalysts in chemical reactions that require high temperatures and pressures while offering low selectivity, biocatalytic approaches and new developments in nanoscience have the ability to provide greater specific catalytic activity under mild reaction conditions. In the case of enzymes, such activity can be very specific under mild reaction conditions, while at the same time being biodegradable and produced from renewable resources. Such approaches present possible solutions for reducing the energy intensity of the CPI, and as a way of creating innovative solutions for future generations without harming the environment.

Improvements in energy efficiency for the production of biofuels and biofeedstocks. A major challenge for sustainability in the chemical industry is how to reduce the energy intensity of biofuel and biofeedstock production (see Chapter 3 of this report for more discussion). There is a need for an effective biomass feedstock process to recover not only hemi-cellulose and sugars for oxygenated molecular building blocks but also lignin as a source of aromatic molecules.

Development of more effective lubricants. A vast amount of the energy used by modern societies is wasted as a result of unproductive friction in internal combustion and aircraft engines, gears, cams, seals, and bearings. Fundamental understanding of how lubrication works is needed to allow design and selection of compounds and mixtures with the appropriate properties. There also needs to be development of more stable, higher temperature lubricants

Step change improvements in the use of solar energy and other renewable energy sources. While reduction in energy intensity and improvements in energy efficiency are absolutely vital for the sustainability of the

CPI, eventually, the CPI must look to alternative and renewable feedstocks and energy sources. These may include landfill gas, wind, and solar energy. Renewable sources are a vital component of any effort to be less dependent on conventional feedstocks and fuels, to reduce manufacturing costs, and to decrease the impact of the CPI on the environment.

Technological breakthroughs in CO2 separation, sequestration, and use. It is anticipated that the CPI will continue to use fossil fuels for energy for many decades into the foreseeable future. This is mainly due to abundant supplies of coal and the significant capital investment that would be required to convert from fossil fuels to renewable sources. At the same time, there is general agreement among the scientific community that there is a link between atmospheric CO2 concentrations and global temperature increases. As atmospheric CO2 concentration increases, it is projected that the associated global climate change will reach a critical stage well before fossil fuel reserves run out. Thus, developing technology and strategies for effective carbon management is a key to sustainability of not just the CPI, but life on earth in general.