7

Other Case Studies

Light-duty vehicles (LDVs) have had the longest emissions-regulation history of any mobile sources and have raised many of the key policy and technical issues related to mobile-source emissions control. Regulation of non-LDV vehicles and engines, however, has raised several new issues that are important to state emissions standards. This chapter presents four case studies of emissions standards for non-LDV vehicles and engines:

-

Spark-ignition marine outboard and personal watercraft engines. This case study of a newly regulated source is also one of the few instances where a state (New York) has exercised its opt-in authority to adopt a California emissions standard for a nonroad engine. (Texas has also adopted California's standards for large spark-ignition engine.)

-

On-road heavy-duty engines. EPA’s 2007 standards, which include fuel sulfur limits, are technology forcing and projected to result in widespread use of exhaust after-treatment.1 California has adopted nearly identical standards after 2007, although there are differences for 2005 and 2006. Some other states have chosen to adopt California’s program over federal regulations.

-

Small nonroad spark-ignition (SI) engines. Small SI engines, primarily in lawn and garden equipment, are important sources of non-

-

road emissions nationwide. The most recent California emissions standards regulate evaporative emissions on such engines for the first time and are expected to require catalyst after-treatment on more types of engines than in previous regulations. These California standards drew increased attention because of economic and safety issues related to controlling emissions from small SI engine equipment.

-

Voluntary programs. A number of incentive-based nonregulatory programs have provided for significant cost-effective emissions reductions in nonattainment areas.

SPARK-IGNITION MARINE OUTBOARD AND PERSONAL WATERCRAFT ENGINES

The 1990 Clean Air Act (CAA) amendments focused regulatory attention on reducing emissions from nonroad vehicles and engines. In the 1991 “Nonroad Vehicle study” to Congress, EPA found that recreational marine engines contributed approximately 30% of the total hydrocarbon (HC) emissions from nonroad sources, second only to small SI lawn and garden engines (EPA 1991). Data presented in the figures in Chapter 2 confirm that percentage in 2002. Most recreational marine emissions come from SI engines, which can be divided into two groups: outboard and inboard engines. Outboard engines typically hang on the hull of a boat and are traditionally light two-stroke engines. Personal watercraft (PWC) commonly have two-stroke jet drives and have been regulated with marine outboard engines as discussed below. Inboard engines are within the hull of the boat and are mostly derivations of four-stroke automobile engines.

Separate standards apply to SI outboard and PWC engines, and this case study focuses on those sources. Early rule-makings note that EPA was most concerned about outboard and PWC engines since they use two-stroke engine technology with much higher rates of HC emissions then inboard or stern-drive engines (61 Fed. Reg. 52087 [1996]).

EPA Standards for Outboard and Personal Watercraft Engines

Stringency

The U.S. Environmental Protection Agency (EPA) finalized first-time HC and nitrogen-oxide (NOx) emissions standards in 1996 for out-

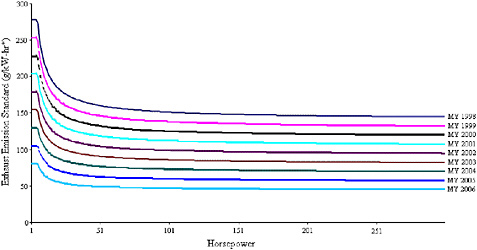

FIGURE 7-1 EPA model-year 1998-2006 exhaust (HC + NOx) emissions standards curves for recreational marine outboard and personal watercraft engines. Note that the emissions standards at the smallest levels, approximately less than 5 horsepower, reach an upper maximum and do not correspond to the equation given in the text. *Grams per kilowatt-hour. Source: CARB 1998b.

boards and PWC. Because it is typically more difficult to reduce emissions on a given type of engine as its rated power decreases, the EPA emissions standards are a function of the rated power of the engine. Furthermore, the standards become progressively more stringent from the beginning of the regulations in model-year 1998 to 2006. The formula (EPA 1996a) for calculating the emissions standards as a function of rated power of the engine is

where HC + NOx is the level of the emissions standards in grams per kilowatt hour, P is the rated power of the engine, and A* and B are coefficients that decrease each year between 1998 and 2006.

Manufacturers are allowed to meet the standard as a corporate average. A graphic depiction of the formula is presented in Figure 7-1.

Scientific and Technical Analysis

As noted above, EPA identified a need for emissions standards for the SI sources based on their contribution to emissions. A regulatory im-

pact analysis (RIA) accompanying the regulations included technical feasibility, economic impacts, and environmental impact analyses (EPA 1996a). These analyses are summarized below.

HCs are the pollutant of concern from outboards and PWC because large quantities are emitted from standard two-stroke engines. Candidate technologies listed in the RIA to meet EPA standards were four-stroke engines, direct-injection two-stroke technology, and catalyst additions. Switching to four-stroke engines or direct-injection technology would result in both significant reductions in HC emissions and improvements in fuel economy. Four-stroke engines were especially promising because of the growing availability of these products. Manufacturer and in-house test data demonstrated a 75-95% reduction in HC emissions by switching from traditional two-stroke to four-stroke engines, a 75-90% reduction by switching from traditional two-stroke to two-stroke engines with direct injection, and a 65-75% reduction by adding a catalytic converter (EPA 1996a). EPA also found that switching to four-stroke or direct-injection increased NOx emissions, although the increases were small compared with the HC benefits. EPA states that manufacturers could use such technologies as exhaust gas recirculation (EGR) and better air and fuel control to counter the NOx increases.

Projected engine changes to meet the EPA standards were expected to have several other impacts. For example, switching from traditional two-stroke engines would mean using approximately 30% less fuel, which previously was exhausted unburned (EPA 1996a). EPA stated that engines would be easier to start and have improved performance, faster accelerations, and less smoke, fumes, and noise (61 Fed. Reg. 52087 [1996]). EPA stated that, in its view, the regulations did not violate or conflict with safety mandates. Although EPA acknowledged that the Coast Guard was concerned about fuel-injection systems on marine vessels, EPA believed that manufacturers would work with the Coast Guard to ensure the safety of fuel-injection systems, which were already in use on some outboard engines (EPA 1996a).

EPA’s estimates of technology costs were based on confidential data provided by manufacturers. Cost and cost effectiveness estimates were not presented for specific technologies because of the possibility of associating specific technologies with specific manufacturers based on those data. Rather, EPA presented its cost method for a fictitious engine family and presented the range of marginal manufacturing costs and cost-effectiveness across potential combinations of technologies and engines

without identifying which technologies were used for which engine family (EPA 1996a). In assessing economic impacts, EPA noted that a small number of engine manufacturers dominated the SI marine industry. As part of the RIA, EPA contracted with two independent companies to gather information on engine and vessel markets. EPA estimated that total annualized costs due to the rule-making would reach a near-term peak of $370 million in 2006, roughly 8% of projected retail expenditures in that year. The estimated average per-engine-cost increase to the consumer would be $700 in 2006, which takes into account $480 in fuel savings.

EPA estimated a 75% reduction in HC emissions, approximately 550,000 tons nationwide, from the sources under consideration by 2025 as a result of its rule. A qualitative discussion of air quality and of health and welfare benefits was also included for ozone; no modeling was completed to estimate the effects of the rule on ambient concentrations. Estimated emission-reduction benefits for benzene, 1,3-butadiene, formaldehyde, acetaldehyde, and carbon monoxide were presented along with an assessment of the expected health and welfare impacts of lower concentrations of each pollutant. However, these health and welfare impacts were not quantified or monetized (EPA 1996a).

The California Air Resources Board Standards for Outboard and Personal Watercraft Engines

Stringency

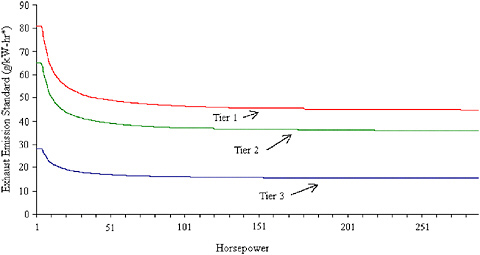

In 1998, the California Air Resources Board (CARB) adopted new exhaust emissions standards for outboard and PWC marine engines to take effect in model-year 2001. In adopting the rule, CARB stated that the regulations were designed to harmonize as closely as possible with federal rules. The regulations included corporate averaging and used EPA test procedures and test cycles for certification and testing. CARB’s standards took EPA’s model-year 2006 exhaust standard for HC and NOx and applied it to model-year 2001. CARB also set two lower tiers of standards at 80% and 35% of the 2006 value to begin in 2004 and 2008, respectively. The emissions standards calculated as a function of power rating are shown graphically in Figure 7-2. Water quality was also ex-

FIGURE 7-2 HC and NOx Tier 1 will begin in 2001 (EPA’s 2006 model year standard); Tier 2, which is 80% of Tier 1, will begin in 2004; and Tier 3, which is 35% of Tier 1, will begin in 2008 Note that the emissions standards at the smallest levels, approximately less than 5 horsepower, reach an upper maximum and do not correspond to the equation given in the text. *Grams per kilowatt-hour. Source: CARB 1998b.

pected to benefit from reduced unburned-fuel emissions, and CARB ac counted that as an important benefit of the rule.

Scientific and Technical Analysis

CARB’s technical feasibility assessment for their proposed standards included an evaluation of commercially available two-stroke carbureted and direct-injection engines and four-stroke engines (CARB 1998b). Data from federally certified direct- injection two-stroke engines showed emissions to be about 85% lower than emissions from carbureted two-stroke outboard engines. Compared with the emissions from conventional carbureted two-stroke engines, the emissions from four-stroke engines were typically 75-90% lower. Direct-injection two-stroke engines could meet the first and second tiers of the proposed standards, but compliance with the third tier would probably require addition of a catalyst (CARB 1998b). Emissions data collected by EPA demonstrated that existing four-stroke engines could easily comply with the proposed California Tier 1 and Tier 2 standards, and many already complied with the

proposed Tier 3 standards. Engine manufacturers had expressed concern about 4-stroke engines, including their larger size, heavier weight, and increased cost. However, four-stroke engines were found to offer similar power-to-weight ratios and consume less fuel and oil, thereby offsetting increases in purchase costs. For exhaust after-treatment, engine modification and use of catalytic converters were considered technically feasible (CARB 1998b).

Cost analysis for compliance with Tier 1 and Tier 2 standards for outboard engines took into account horsepower rating, annual engine sales, emissions-control requirements under the national and California standards, carbureted two-stroke and controlled engine emissions levels, incremental engine prices, and fuel-economy improvements and associated savings. For different horsepower engines, CARB estimated the number of additional emissions-controlled engines that would have to be sold, the associated retail prices, and the lifetime emissions benefits (CARB 1998b). Estimating cost of compliance with Tier 3 standards required a different approach because outboard engines and PWC were not manufactured with catalysts at the time of the assessment. Therefore, CARB conducted a cost assessment similar to that for adding a catalyst to four-stoke engines.

CARB estimated additional statewide emissions reductions for outboard engines and PWC by 2010 and 2020 that would be achieved through the accelerated implementation of the EPA emissions standards (CARB 1998b). Estimates of reductions were obtained using the OFFROAD inventory computer model (CARB 2004e), which showed substantial additional reductions for reactive organic gas (ROG) and smaller additional reductions for NOx. One benefit of accelerated implementation of the EPA standards was the faster elimination of carbureted two-stroke engines. These engines, as noted above, eject as much as 30% of their fuel into the air and water uncombusted and are a significant source of HCs (some of which are ozone precursors) and hazardous air pollutants (HAPs) (CARB 1998b).

Section 11346.3 of the California Government Code requires state agencies to assess the potential for adverse economic impacts on California business enterprises and individuals when proposing to adopt or amend any administrative regulation. The assessment must include a consideration of the impact of the proposed regulation on California jobs; business expansion, elimination, or creation; and the ability of California business to compete. CARB expected that the proposed regulations would not impose a significant cost burden on marine engine manufac-

turers within the state because most manufacturers are large and located outside California. Annual costs of the proposed regulations were estimated to be around $33 million in 2001, $20 million in 2004, and $21 million in 2008. Those costs were expected to be passed on by manufacturers to marine engine buyers, resulting in an increase of about 14% in average retail prices of a marine engine. The impact on retail sales of these additional costs was anticipated to be minimal, as the most important factors in the purchase of a marine vehicle include the cost of maintenance, which should be reduced in the newer engines, and fuel efficiency, which should improve substantially with the availability of direct-injection two-stroke engines and improved four-stroke engines (CARB 1998b).

New York Adoption of CARB Standards

During the summer of 1999, New York was out of attainment of the National Ambient Air Quality Standards (NAAQS) for the 8-hr ozone standard for 38 days, and the New York City metropolitan area was out of attainment for the 8-hr standard for 26 days. To help bring nonattainment areas into compliance with the NAAQS, the state sought additional ways to reduce emissions of compounds that result in ozone formation. Emissions from PWC were identified as one such source; PWC were responsible for 8,850 tons of volatile organic compounds (VOCs) and 39 tons of NOx emissions in 1999 (NYDEC 2003).

In 2000, the New York state legislature amended its Environmental Conservation Law by adding language that would allow for the adoption of regulations consistent with the California emissions reductions and labeling regulations for new SI marine engines used in PWC. The legislative objective of these changes was to “reduce emission of hydrocarbon and oxides of nitrogen into the air as well as exhausted into the water, from SI engines, specifically personal watercraft engines.” The state cited reductions in particulate matter (PM) emissions as an additional benefit of the proposed regulations. The adoption of the PWC regulations would be incorporated into the state implementation plan (SIP).

The proposed PWC regulations were identical to California PWC regulations. The New York program included the implementation of increasingly more stringent PWC emissions standards between 2001 and 2008, and the application of new test procedures for new and in-use engines. New York found that the CARB standards resulted in PWC emis-

sions 59% lower than the federal program for the average horsepower engine for 2001 and 49% lower for 2004. The total estimated cost of implementation for New York was determined from the incremental cost estimates generated by CARB and the PWC fleet estimated for the year 2004. The New York Department of Environmental Conservation (DEC) agreed with CARB that cost increases would be passed on to the consumer but found that the impact on sales would be reduced by the resulting increase in fuel efficiency, lower maintenance costs, and a demand for new technologies offering performance advantages. No substantial impact on employment was expected, as the marine engine manufacturing industry accounted for only 0.9% of manufacturing jobs in the state (NYDEC 2003).

HEAVY-DUTY-VEHICLE ENGINE STANDARDS

Current Standards

Emissions standards for highway heavy-duty trucks and buses have traditionally been less stringent than those for light-duty passenger cars and trucks. Emissions standards apply to the engines and not the vehicles, and early regulations have been met primarily by engine modifications rather than exhaust after-treatment. More details on early standards for these engines are given in Chapter 4.

In 1995, EPA, CARB, and engine manufacturers signed a statement of principles (SOP) that recognized the need for significant controls on highway HDV engines, particularly for NOx and PM, and ensured regulatory certainty for the industry (EPA 1995). The SOP included agreements to achieve the following:

-

Reduce NOx emissions standards to roughly 50% of 1998 standards beginning in model-year 2004.

-

Harmonize certain California and federal standards for HDV engines.

-

Evaluate the role of fuel in achieving even lower future emissions.

-

Research achieving NOx and PM emissions as low as 1.0 grams per brake-horsepower-hour (g/bhp-hr) and 0.05 g/bhp-hr, respectively. The latter PM emissions limit already applied to urban buses.

Model-Year 2004 Rule

EPA adopted rules in 1997 (62 Fed. Reg. 54694 [1996]) that included a 2.4 g/bhp-hr (NOx plus nonmethane hydrocarbon [NMHC])2 emission standard to take affect in model year 2004. Emission standards for carbon monoxide (CO) and PM continued at their 1998 levels of 15.5 and 0.10 g/bhp-hr, respectively. In 1999, California adopted those same emissions standards for model-year 2004 HDVs. Since most HDV engines are in trucks that conduct interstate transport, many of these sources in California are not registered there; thus, California has an interest in a stringent national standard. In 1999, EPA also reaffirmed their standards after determining that the technology would be available to achieve those levels of emissions by 2004.

Consent Decree

In 1998, the U.S. Department of Justice, EPA, CARB, and seven major engine manufacturers reached a settlement over the manufacturers’ use of software programs that allowed better fuel economy at cruise speeds but resulted in excess NOx emissions. The software had been used on most model-year engines in the 1990s, and the NOx emission increases were not detected with standard federal test procedure (FTP) certification. Although manufacturers declared that existing regulations allowed this fuel-saving strategy, EPA declared this practice illegal. The result of the settlement included civil penalties and a consent decree in which manufacturers agreed to perform the following:

-

Reprogram the software controlling the engine if the engine was rebuilt, also referred to as chip reflash.

-

Meet the model-year 2004 emissions standard for NOx and NHMC in 2002 nationwide.

-

Certify engines using a supplemental steady-state test procedure based on European certification tests (the EURO III European stationary cycle [ESC test]) and require that engine emissions not exceed 1.25 times the FTP emissions limits under certain operating conditions (the not-to-exceed [NTE] rule). The ESC and NTE test procedures would

-

be required in addition to the FTP and applied up to model-year 2004 engines when the consent decree expired. CARB later adopted a rule requiring the additional ESC and NTE test procedures to apply to model-years 2005 and 2006 engines as well.

Model-Year 2007 Rule

In 2001, EPA finalized the most stringent emissions standards to date for HDV engine emissions standards for model year 2007, referred to hereafter as 2007 HDV engine standards. A PM emission standard of 0.01 g/bhp-hr is to begin with model-year 2007. NOx and NMHC standards of 0.20 g/bhp-hr and 0.14 g/bhp-hr, respectively, will be phased in for model-years 2007-2010 diesel engines; the standards will apply to 50% of sales in model-years 2007-2009 and 100% of sales in model year 2010.3 A major part of this control effort is the coincidental low-sulfur fuel regulations, which limit diesel-fuel sulfur content to 15 parts per million (ppm) beginning phase-in in 2006. Present day diesel-fuel sulfur limits are 500 ppm; however EPA estimated in 2000 that diesel fuel in the United States on average contained sulfur at 340 ppm (EPA 2000c). Manufacturers are required to certify engines by using the supplemental steady-state test procedure and NTE rule beginning with model-year 2007 as part of these standards. California will adopt the same emissions standards and test procedures for HDV diesel engines beginning with model-year 2007. The emissions standards require a reduction of more than 90% in NOx and PM from new engines by 2010.

The 2007 HDV engine standards are technology-forcing and are expected to require widespread use of new types of exhaust after-treatment devices. EPA conducted two biennial assessments of the feasibility of meeting these standards. The last assessment in March 2004 concluded that manufacturers were on track to achieve the required emissions reductions.

Despite EPA, CARB, and manufacturers having worked cooperatively to achieve a uniform standard for HDV engines, a number of legal disputes arose over the standard. Engine manufacturers and their trade association (EMA) challenged the NTE rule in courts, arguing that NTE

limits are illegal and technically infeasible. Manufacturers argued that imposing NTE limits is effectively imposing an emissions standard rather than a certification test. Further, they argued that laboratory tests cannot ensure compliance with a NTE cap under all real-world driving conditions. These suits led to a settlement among manufacturers, CARB, and EPA in which manufacturers agreed to a manufacturer-run, in-use compliance testing program to coincide with the 2007 emissions standards (EPA 2003d). Manufacturers have also opposed a CARB rule to require installation of modified engine-control software (chip reflash) when in-use engines are rebuilt. CARB found that engines were not being rebuilt as quickly as anticipated and started a voluntary reflash program in 2004. CARB subsequently found that the voluntary program was not meeting its goals, and adopted a rule in 2004 to make the reflash mandatory. Finally, the South Coast Air Quality Management District (SCAQMD) attempted to achieve further emissions reduction in its airshed by mandating that HDV fleets include advanced technology engines. As discussed in Chapter 3, the Supreme Court ruled that this regulation was an emissions standard and that the SCAQMD had no authority to establish it.

Scientific and Technical Practices in Setting 2007 HDV Engine Standards

The HDV engine standards for 2007 have much in common with the LDV standards of the 1970s: The 2007 standards are highly technology-forcing, providing substantial emissions reductions and requiring exhaust after-treatment. The amount of analysis that supported the 2007 HDV standards, however, is much greater than the amount that supported the standard setting for LDVs in the 1970s. EPA took the lead in setting the HDV standards, and this section focuses mostly on EPA’s practices as described in the RIA (EPA 2000c). As in the LDV case study, standard-setting practices were divided into health and environmental impacts, technical feasibility, and economic impact analyses. As mentioned above, a major part of this rule-making was the simultaneous regulation to reduce sulfur content in fuel. Because the engine and fuel are viewed as an integrated system and the 2007 standards can be met only by using low-sulfur fuel, the RIA includes a similar analysis for the technology and costs required to produce low-sulfur diesel fuel, including the costs for production and distribution. The fuel production costs and the engine

technology costs were used to compute the cost-effectiveness and cost-benefit analysis that is presented in the RIA.

Health and Welfare Effects

The RIA for the 2007 HDV engine standards described the health and welfare effects of reducing ozone concentrations and emissions of its precursors. EPA performed photochemical grid modeling analysis for the eastern United States to project the effects of the proposed rule on ozone in 2020 and 2030 relative to a baseline of no proposed rule. EPA also considered the effect of the rule based on analysis of a number of local SIPs. The HDV engine standard was projected to reduce ozone concentrations in nonattainment areas and reduce the number of nonattainment areas for ozone. The RIA also discussed the health and welfare effects of the proposed rule on PM concentrations (and PM nonattainment areas), diesel exhaust emissions, HAP concentrations, visibility and regional haze, acid deposition, eutrophication and nitrification, polycyclic organic matter deposition, and CO concentrations.

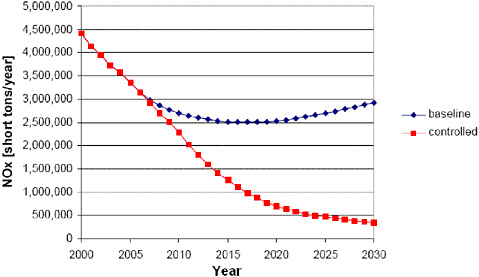

Emissions benefits were estimated by EPA using MOBILE5b (NOx, VOC, and CO) and PART5 (PM and sulfur dioxide [SO2]). Some adjustments were made to these models to account for updated data in MOBILE6 (which had not been released at the time of the analysis). HAP emissions were estimated by an EPA contractor using MOBTOX5b, a model based on MOBILE5b that includes HC toxic fractions by vehicle type and driving conditions. The RIA presented estimated emissions reductions of benzene, formaldehyde, acetaldehyde, and 1,3 butadiene. Emissions were estimated from diesel engines, including crankcase emissions, and from HDV gasoline engines, including evaporative HC emissions. EPA also included estimates of the emissions benefits of the low-sulfur requirement for non-HDVs. Figure 7-3 shows projected NOx emissions resulting from the 2007 HDV engine standards (controlled) relative to the 2004 HDV engine standards (baseline). The 2007 standards were estimated to reduce HDV engine on-road NOx emissions by 90% in 2030. The RIA also estimated a 90% reduction in PM10 emissions in 2030 and a 30% reduction in NMHC emissions in 2030 (EPA 2000c).

Health benefits from the 2007 HDV rule were estimated for many of the same respiratory health end points considered in the Tier 2 rule (see Table 6-12 in Chapter 6). The rule was expected to result in 8,300

FIGURE 7-3 Projected nationwide NOx emissions with and without the 2007 HDV engines and fuel sulfur standards. Source: EPA 2000c.

avoided cases of premature mortality, 5,500 avoided cases of chronic bronchitis, and 361,400 avoided asthma attacks annually in 2030. The reader is referred to a 2002 NRC report on estimating public health benefits of proposed air pollution regulation, which includes the 2007 HDV rule as a case study and lists the estimated types, numbers and monetized value of the health benefits (NRC 2002b).

Technical Feasibility

The 2007 rule includes standards for HDV diesel engines and for HDV gasoline engines. Because the standards are most important for diesel engines, only these technologies are summarized here. Candidate technologies target PM and NOx—the pollutants controlled to the greatest degree by the standards. Earlier standards, including the 2004 HDV engine standards, were met largely by reducing the formation of pollutants in the engine during combustion (engine-out emissions), for example, by introducing electronic fuel systems. EPA stated in its RIA that cooled EGR would be used widely to meet the 2004 and 2007 standards. Although improvements to EGR technology were expected and it would

be more effective with low-sulfur fuel, this strategy alone was not thought to be sufficient to meet the 2007 HDV engine standards.

Catalyzed diesel particulate filters (CDPFs), in conjunction with low-sulfur fuel, were identified as the only control devices capable of meeting the 2007 standards of 0.01 g/bhp for PM. Particulate filters work by filtering PM on a ceramic or metal filter, which is later burned off (filter regeneration). Catalyzed filters contain precious metals and base metal catalyst components that allow regeneration to occur at the temperatures of normal engine operation (passive regeneration). Because CDPFs constantly regenerate, they maintain low back pressure and thus minimize fuel economy penalties. CDPFs are able to achieve 90% reduction in exhaust PM emissions by using 15-ppm sulfur fuel. EPA states that some manufacturers had already developed and field-tested these filters and determined their feasibility and durability. Other research and field evidence, such as CDPF use on European trucks, also supports the feasibility of this technology for control of PM mass and ultrafine PM number concentrations (EPA 2000c).

NOx emission control for light-duty vehicles is provided in part by EGR, when used, and by efficient three-way catalyst technology that achieves more than 95% NOx reduction under stoichiometric combustion conditions where oxygen content is less than 1% before the catalyst. Diesel exhaust under typical driving conditions has excess oxygen (6% to 18%), which reduces PM formation but makes it more difficult to remove NOx. EPA (2000c) discussed three main technologies, described in Table 7-1, that reduce NOx in lean-burn conditions and that have the potential to be used to meet the 2007 standards.

Field testing and research evidence for NOx control are presented in the RIA only for NOx adsorbers, which EPA considered, at the time, the leading candidate technology to meet the most stringent 2010 NOx emissions limits. EPA found later that technologies such as selective catalytic reduction (SCR) will probably be used by some manufacturers to meet the standards (EPA 2004g). EPA noted in the RIA that HDV engine companies had already introduced NOx adsorber technology on products in Japan, Europe, and the United States, and all were achieving significant NOx reductions. EPA noted that research was conducted on NOx adsorber technology by the U.S. Department of Energy and the Oak Ridge National Laboratory. Finally, EPA staff conducted bench-scale testing of four NOx adsorber systems provided by the Manufacturers of Emissions Control Association (MECA) at the National Vehicle and Fuel Emissions Laboratory (NVFEL) and showed that the systems could

TABLE 7-1 NOx After-Treatment Devices for HDV Diesel Engines

|

1. Lean NOx catalysts. A zeolite coating on a catalyst adsorbs hydrocarbons that oxidize and create an oxygen poor environment conducive to NOx reduction. Even when HCs are actively introduced into the exhaust stream, these systems are expected to achieve only a 30% NOx reduction. 2. NOx adsorber. An adsorber is an advancement of the three-way catalyst in that it contains a mechanism that stores NOx under lean-burn conditions and then releases it for conversion by the three-way catalyst under periodic, short, fuel-rich, and stoichiometric exhaust conditions. Fuel sulfur content is critical to the performance and durability of the adsorber. NOx adsorbers have been shown to achieve greater than 90% NOx control efficiency. The majority of the technology description in this RIA covers NOx adsorbers. 3. Selective catalytic reduction. Reduces NOx over a vanadium-titanium catalyst by introducing ammonia upstream of the catalyst in the form of a urea ([NH2]2CO) solution. A diesel oxidation catalyst (DOC) may be introduced up- and downstream of the vanadium-titanium catalysts to convert nitrogen oxide to the desirable nitrogen dioxide form and to oxidize any unreacted ammonia. EPA cites evidence that 70-80% of NOx reduction could be achieved in the temperature conditions typical of diesel exhaust. EPA identified two difficulties with this technology: the necessity for a urea infrastructure and the lack of incentives for users to replenish their urea supply. |

|

Source: EPA 2000c. |

achieve greater than 90% control over a broad range of operating conditions. A detailed description of performance and durability testing and results is presented in the RIA (EPA 2000c). EPA (2004g) identified four improvements necessary for commercial application of NOx adsorbers: (1) broaden the temperature range over which the adsorbers were effective, (2) improve thermal durability, (3) improve methods for desulfation (desulfation is the process by which sulfur is cleansed from the NOx absorbers), and (4) improve the integration of NOx adsorbers with engines to achieve regeneration and maximize fuel economy (EPA 2004g).

The RIA included cost estimates for meeting the 2007 HDV engine standards, which included variable costs (incremental hardware costs, assembly costs, and associated markups) and fixed costs (tooling, research and development, and certification) (EPA 2000c). EPA also accounted for a “learning curve,” which reduces manufacturer costs over time as they innovate and lower the operating costs needed to meet the standards. Costs were estimated for four classes: light HDVs (8,500-19,500 lb gross vehicle weight [GVW]), medium HDVs (19,501-33,000

lb GVW), heavy HDVs (33,001+ lb GVW), and urban buses. EPA used contractor estimates of some of the variable costs of projected control equipment as well as maintenance savings associated with the use of low-sulfur diesel fuel. Cost estimates for the heavy HDVs are presented in Table 7-2. EPA also presented a cost-effectiveness analysis comparing these regulations with others, and a cost-benefit analysis as required under Executive Order 12866 (discussed in Chapter 3). EPA estimated the total monetized benefits in 2030 of the 2007 HDV rule to be $70.4 billion (in 1999 dollars), 90% of which is due to the avoided cases of premature mortality due to reduced PM concentrations. Annual costs of the rule were estimated to be $4.2 billion (in 1999 dollars). To characterize uncertainty, EPA provided alternative calculations of the benefits using different assumptions and values for the key parameters used in the calculations. The reader is referred to the RIA (EPA 2000c) and the NRC’s report on health benefits (NRC 2002b) for details on these analyses.

Scientific and Technical Practices in CARB’s Adoption of HDV 2007 Standards

CARB (2002) adopted slightly modified versions of the EPA 2007 standards and test procedures for HDV diesel engines. Despite the differences, the two sets of standards are widely considered to be identical. CARB’s proposed rule was accompanied by a staff paper (“Initial Statement of Reasons”) that assessed emissions benefits, technical feasibility, and economic impacts (CARB 2001b). CARB noted that the emissions reductions proposed in this rule were in addition to those in the 1994 SIP but that additional reductions from HDV engines would be necessary for some areas in California to attain the NAAQS. CARB briefly reviewed technologies with a reference to information presented in EPA’s RIA and reviewed ongoing research and demonstration projects. Cost estimates were also taken from EPA’s RIA. CARB calculated emissions benefits statewide and for various basins by calculating a ratio of the 2007and 2004 emissions standards and applying it to the projected emissions resulting from the 2004 standards. No separate emissions modeling or air quality modeling was done for this rule. CARB presented cost-effectiveness estimates of the rule and compared them with other California mobile-source regulations.

TABLE 7-2 Per-Vehicle Incremental Cost Estimates of 2007 Heavy (33,001+ lb gross vehicle weight) HDV Diesel- Engine Standards Compliance

|

Item |

Fixed Cost, $ |

Variable Cost, $ |

Operating Cost, $ (net present value in year of sale of lifetime operating costs) |

|

Near-Term (2007) (1999 dollars per engine) |

|||

|

NOX adsorber catalyst |

191 |

1,456 |

0 |

|

Catalyzed diesel particulate filter |

89 |

1,103 |

208 |

|

HC and H2S cleanup catalyst |

0 |

338 |

0 |

|

Closed crankcase system |

0 |

49 |

218 |

|

Low-sulfur diesel fuel |

0 |

0 |

3,969 |

|

Maintenance savings |

0 |

0 |

(610) |

|

Total |

280 |

2,946 |

3,785 |

|

Long-Term (2012–) (1999 dollars per engine) |

|||

|

NOX adsorber catalyst |

0 |

932 |

0 |

|

Catalyzed diesel particulate filter |

0 |

686 |

208 |

|

HC and H2S cleanup catalyst |

0 |

216 |

0 |

|

Closed crankcase system |

0 |

32 |

172 |

|

Low-sulfur diesel fuel |

0 |

0 |

4,209 |

|

Maintenance savings |

0 |

0 |

(610) |

|

Total |

0 |

1,866 |

3,979 |

|

Abbreviation: H2S, hydrogen sulfide. Source: EPA 2000c. |

|||

Biennial Reviews and Status of 2007 Rule Implementation

In the preamble to the 2007 HDV engine rule, EPA committed itself to biennial assessments of heavy-duty NOx adsorber technology (66 Fed. Reg. 5002 [2001]); two of them have been released (EPA 2002b, 2004g). Although the initial intent of the assessments was public periodic review of the status of the NOx adsorber technologies, the assessments have reported more broadly on industry progress toward all aspects of the 2007 standards. Some main points from the 2004 review are the following:

-

CDPFs will be used by all manufacturers to meet the 0.01-g/bhp-hr standard in 2007 and are already being successfully used where fuel meets the 15-ppm sulfur.

-

Because of flexibility in the phase-in requirements in 2007-2009, most manufacturers appear to have chosen to meet a fleet-average standard of 1.2 g/bhp-hr for NOx in those years (as opposed to 50% of the fleet meeting the 0.20-g/bhp-hr standard and 50% meeting the existing 2.5-g/bhp-hr standard), followed by a jump to 100% compliance to meet the 0.20-g/bhp-hr standard in 2010. Improvements to EGR systems could also allow manufacturers to meet the interim 1.2-g/bhp-hr standard without NOx adsorbers. Some manufacturers may also use selective catalytic reduction.

-

Despite the lack of widespread use of NOx adsorbers, they continue to improve and are used in light heavy-duty trucks in Japan.

-

Prototype vehicles with NOx adsorbers will be introduced in 2005 in the United States for early customer fleet testing.

-

Discussions with manufacturers led EPA to conclude that manufacturers have solutions to meet the standards. Manufacturers provided evidence that compliance with the standards was integrated into their business plans, and resources toward compliance were allocated.

California Standards for HDVs and State Adoption of California Standards

Differences between California and Federal Standards

California’s standards are widely considered to harmonize with EPA’s standards for HDV diesel engines for model-year 2007 and be-

yond. Nevertheless, several states, using their authority under CAA section 177, adopted California’s standards for those engines. As discussed above, manufacturers were required to use the ESC and NTE tests in addition to the FTP test for engine certification for model-years 2002-2004 and will be required to certify engines using all three tests for model-year 2007. EMA challenged these requirements in the courts. California adopted a regulation requiring that NTE and ESC tests be used for California-certified engines for model-years 2005 and 2006 to ensure that engines would continue to achieve low emissions for those interim model years (the “NTE rule”).

State Adoption of NTE Testing

The State and Territorial Air Pollution Program Administrators and Association of Local Air Pollution Control Officials (STAPPA/ALAPCO 2001) published a model rule for states to adopt NTE test procedures for model-years 2005 and 2006 engines (STAPPA/ALAPCO 2001). As of March 2003, California’s NTE rule had been adopted by 12 states: North Carolina, New Jersey, Maryland, Delaware, Georgia, Massachusetts, Maine, Texas, Rhode Island, New York, Pennsylvania, and Connecticut as well as the District of Columbia. STAPPA/ALAPCO states that these adoptions would affect one-third of national truck sales and produce emissions benefits equivalent to removing 30 million cars from the road (Becker 2004).

State Adoption of California 2007 Standards

STAPPA/ALAPCO (2004) published a model rule for states to adopt California’s HDV diesel-engine standards, although the standards and test procedures for model year 2007 and beyond are the same as EPA’s. The rationale behind this model rule is to ensure that states keep the level of emissions control achieved by the 2007 standards even if EPA changes the rule or otherwise relaxes the standards (Becker 2004). The perception that EPA could change the rule stems from strong opposition to the 2007 standards from the trucking industry, engine manufacturers, and the fuel industry concerning technical feasibility, the ability to distribute low-sulfur fuel, and the cost to industry of new engines and fuel. The American Trucking Association (ATA), the American Petro-

leum Industry (API), and Mack Trucks/Volvo Powertrain all filed petitions asking EPA to reconsider the 2007 standards; all petitions were rejected by EPA (2001a,b,c). In 2004, the trucking industry brought their concerns to Congress, who in turn requested a Government Accountability Office (GAO) study on the issue. The study found that refiners and engine makers were on track to meet the 2007 standards but urged that an independent review panel be appointed to assess the technical feasibility issues and to consider financial incentives to ensure industry compliance (GAO 2004). Executives from the trucking industry also publicly called for delay of the rules (Clean Air Trust 2003). ATA has since endorsed the 2007 standards (Heilprin 2004); however, it has expressed doubts that the expected emissions benefits will be realized, especially if truck buyers stock up on less-expensive higher-emitting trucks before the first model year of regulations (Barber and Sween 2005). The majority of engine manufacturers are confident they will meet the 2007 standards (EPA 2004g).

As a result of concerns that pressure on EPA could cause a delay or change in the 2007 standards, nine states adopted California’s program for HDV engines: North Carolina, New Jersey, Maryland, Delaware, Georgia, Maine, New York, Pennsylvania, and Connecticut (STAPPA/ALAPCO 2005). States view California’s program as having a higher certainty of delivering the HDV diesel emissions reductions that many states have included in their SIP and air quality plans. Similar to the adoption of the NTE testing, industry strongly opposes state adoption of California’s 2007 standards (Clean Air Report 2004).

OFF-ROAD EQUIPMENT WITH SMALL SPARK-IGNITION ENGINES

Off-road equipment with small spark-ignition (SI) engines includes lawn mowers, lawn tractors, generator sets, pumps, augers, leaf blowers, brush cutters, and string trimmers. The majority of small SI engines are in lawn and garden equipment; others are in commercial-turf equipment, golf-course related equipment, and handheld equipment such as chain saws. For regulation purposes, small engines are defined by CARB and EPA as engines rated below 19 kilowatts (kw), or 25 hp. Nonroad emissions are an appreciable part of the anthropogenic emissions inventory in the United States and, as discussed in Chapter 2, represent important controllable emissions for states to meet the NAAQS.

Federal Standards

The CAA amendments of 1990 designated for the first time that EPA set emissions standards for nonroad mobile sources. As discussed in Chapter 3, CAA section 209(e), also added in 1990, extended California’s authority to set their own standards to most nonroad sources, including small SI engines. EPA first approved a waiver for California for small-engine emissions standards in 1994. In legislation passed by Congress in 2003, states other than California were explicitly preempted from setting or adopting standards separate from EPA’s for small SI engines (P.L. 108-199 Division G Section 428). (This law is sometimes referred to as the Bond Amendment of 2003.) The Bond Amendment effectively creates a new category of regulated mobile sources. Previously, mobile sources, such as locomotives, aircraft, and some agricultural equipment, could have either one standard in all states or a second standard in California and in any state that chose to adopt that standard (CAA section 177). Small SI engines are now separate in how they may be regulated: they may be subject to a second (California) standard but, unlike other sources with California standards, the second standard may not be adopted by other states under section 177 of the CAA.

EPA finalized their Phase I rule-making for most new small SI engines on handheld and nonhandheld equipment in 1995 for model-year 1997. Phase I emissions standards were expected to reduce HC emissions by 32% and CO emissions by 7% in 2020 when complete fleet turnover was expected (60 Fed. Reg. 34582 [1995]). Phase I standards promoted the conversion from two-stroke to four-stroke engine design.

In 1996, EPA signed two statement of principles (SOPs) with manufactures to reduce emissions from handheld and nonhandheld small SI engines (EPA 1996b,c). The SOPs, among other things, outlined technologies and laid the framework for achieving Phase II emissions standards that would further reduce HC and NOx emissions. EPA finalized their Phase II rule-making for nonhandheld engines in 1999 and for handheld engines in 2000 for exhaust emissions of HC and NOx. Phase II standards for nonhandheld engines were predicted to reduce emissions of HC and NOx by 59% by 2027 (EPA 1999c) and for handheld engines were predicted to reduce emissions of HC and NOx by 70% by 2027 (EPA 2000d) nationwide. Phase II standards also included some efforts to harmonize EPA and CARB’s certification procedures. The Phase II standards is expected to result primarily in engine redesign to reduce

engine-out emissions and to increase durability, although after-treatment (catalysts) was expected for some handheld equipment. Nonhandheld engines were expected to switch from side-valve to cleaner over-head-valve technology to comply. EPA is expected to introduce new national standards for small engines in 2006 per the Bond Amendment. Table 7-3 summarizes EPA’s existing small-engine exhaust emissions standards. The table shows emissions standards for various engine displacement classes defined in the RIA for nonhandheld (EPA 1999c) and handheld engines (EPA 2000d).

California Standards

CARB first adopted rules for small engines in 1990 that consisted of exhaust emissions standards, test procedures, warranty provisions, and compliance programs. The first Tier 1—standards became effective with model-year 1995 engines. Later Tier 2 standards became effective with model-year 2000 engines and included exhaust emissions standards for HC and NOx, CO, and PM (two-stroke engines only). Although CARB stopped separating engines into handheld and nonhandheld equipment, engines less than 65 cubic centimeters (cc) were assumed to be used primarily in handheld equipment and were allowed higher emissions than engines greater than 65 cc. In 2004, CARB amended its small-engine standards (known as Tier 3) by setting stricter emissions limits for HC and NOx exhaust and by introducing evaporative emissions standards for the first time for these engines. CARB harmonized with EPA’s HC and NOx exhaust standard for engines less than 50 cc and expanded its “small” handheld range to include engines less than 80 cc. CARB’s Tier 3 exhaust emissions limits for larger engines (more than 80 cc) are the same as EPA’s for model-year 2005, but they become more stringent than EPA’s in future model years and are then expected to require widespread use of exhaust after-treatment in the form of low- to medium-efficiency catalysts. Table 7-4 summarizes CARB’s existing small-engine exhaust emissions standards.

CARB also adopted HC evaporative emissions standards for small engines in 2004. The standards are aimed at reducing leaks in the fuel storage and delivery systems, and the rules combine performance and design standards. Performance standards apply to emissions from an entire piece of equipment or vehicle. Certification for performance standards involves measuring evaporative emissions from equipment in an

TABLE 7-3 Existing EPA Phase II Exhaust Emissions Standards for Small SI Engines in Handheld and Nonhandheld Equipment

|

EPA Category |

Engine Displacement |

Year, HC + NOx, g/kW-hr |

|||||

|

2002 |

2003 |

2004 |

2005 |

2006 |

2007+ |

||

|

Handheld |

<20 cc (Class III)a |

238 |

175 |

113 |

50 |

50 |

50 |

|

|

20-50 cc (Class IV)a |

196 |

148 |

99 |

50 |

50 |

50 |

|

|

>50 cc (Class V)a |

Ph 1 |

Ph 1 |

143 |

119 |

96 |

72 |

|

Nonhandheld |

<66 cc (Class IA) |

Ph 1 |

16.1b |

16.1b |

16.1b |

16.1b |

16.1 |

|

|

66-100 cc (Class IB) |

Ph 1 |

16.1b |

16.1b |

16.1b |

16.1b |

All |

|

|

100-225 cc (Class I) |

Ph 1 |

16.1b |

16.1b |

16.1b |

16.1b |

engines |

|

|

>225 cc (Class II) |

16.6 |

15.0 |

13.6 |

12.1 |

12.1 |

12.1 |

|

aThe finalized standards are based on a 25%, 50%, 75%, and 100 % phase-in of 50 g/kW-h for Classes III and IV and 72 g/kW-h for Class V. bFor any new engine family produced after Aug 1, 2003. Source: EPA 1999c, 2000d. |

|||||||

TABLE 7-4 Existing CARB Small-Engine Exhaust Emissions Standards, Adopted in 2004 (also referred to as Tier 3)

|

Engine Displacement |

HC + NOx, g/kW-h |

CO, g/kW-h |

|||

|

2005 |

2006 |

2007 |

2008+ |

2005+ |

|

|

<50 cc |

50 |

50 |

50 |

50 |

536 |

|

50-80 cc |

72 |

72 |

72 |

72 |

536a |

|

80-225 cc |

16.1 |

16.1 |

10.0 |

10.0 |

549 |

|

>225 cc |

12.1 |

12.1 |

12.1 |

8.0 |

549 |

|

aSlightly lower CO standard for vertical shaft engines in this category for model-year 2005. Bold numbers show where the standards deviate significantly from EPA Phase II. Source: CARB 2004f. |

|||||

enclosure. Design standards, in contrast, are defined as specifications (for example, for permeability) of equipment components. Certification of each component does not involve measuring emissions. Design standards were adopted at manufacturers’ request so that the numerous small-engine equipment makers could avoid the expense of measuring emissions for certification. Manufacturers have the option to certify small engines according to either design or performance standards for some larger engines. The reader is referred to CARB’s rule-making web page for the exact limits, which vary by engine displacement and model year (CARB 2005g).

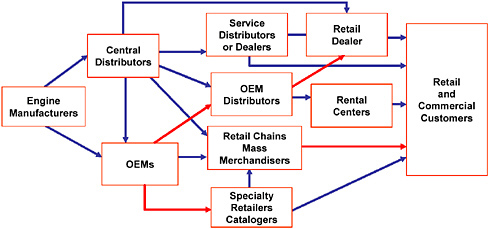

CARB’s Tier 3 exhaust and evaporative emissions standards were met with opposition from some engine manufacturers, their trade organizations, and other stakeholders. Three general concerns were raised. The first was that compliance with two emissions standards in different areas of the country would be particularly difficult in a nonintegrated industry where engine manufacturers have little control over product distribution. The second was that the costs of complying with regulations that require catalyst after-treatment would be particularly burdensome for the small-engine manufacturing industry because the costs of after-treatment devices are high compared with the prices of some engines. The third was that the use of heat-generating catalysts on equipment close to the operator and in close contact with grass and other flammable matter is an important fire hazard. The remainder of this case study focuses on the three concerns listed above.

FIGURE 7-4 Flow chart of small SI engine distribution process. Source: Guerry 2004.

Distribution of Engines Certified to Different Emissions Standards

A major concern in meeting California’s emissions standards was that distributing two separate products, a federal- and a California-certified engine, is problematic because of the nature of the small-engine equipment market. This market is largely nonintegrated and dominated by hundreds of small manufacturers and component suppliers. Many engine manufacturers sell engines to original equipment manufacturers (OEM), who then produce and distribute equipment though multistep national supply chains, as shown in Figure 7-4 (Guerry 2004). A more detailed 1992 description of the industry can be found in the Appendix of EPA’s Phase II RIA (EPA 2000d). Some companies are more integrated than others because some manufacture both engines and original equipment, such as riding lawn-tractors. Another difference is that some engine and equipment makers sell products directly to retailers, and some sell them to wholesalers and distributors who then sell to retailers (“two-tier” distribution). The committee heard arguments that distributing a new product to small geographic areas through a multistep national supply chain is difficult and expensive (Guerry 2004). A multistep distribution chain also increases the chances of federal-certified engines being sold in California, raising compliance issues for industry. California’s economic impact assessment when adopting a rule is focused on in-state

businesses4 and does not include an assessment of distribution and inventory costs associated with compliance with a separate standard, either in California or elsewhere. The committee did not come across any quantitative analysis, regulatory or otherwise, of the impacts of a second California standard on distribution of small-engine equipment. A qualitative discussion of distribution costs under uniform versus multiple emissions-standard scenarios is presented in Chapter 5; however, a detailed assessment of product distribution for the small-engine and equipment industry is beyond the scope of this study and the publicly available information.

Increased Manufacturing Costs for Small Spark-Ignition Engines

A second concern raised by manufacturers was the economic burden imposed on the small-engine equipment industry by the additional costs of emissions controls. Although catalysts were used in the past on some small-engine handheld equipment, CARB’s Tier 3 regulations seemed to necessitate use of after-treatment devices on many more engines of varying size, horsepower, and price. Catalyst use had not been widespread on nonhandheld equipment, because standards had been met by reducing engine-out emissions alone. Furthermore, CARB’s evaporative emissions standards would require more expensive, less permeable parts. CARB estimated that the retail cost increase of adding a catalyst and complying with Tier 3 evaporative standards on a Tier-2 nonhandheld engine would be $37-$52 for engines 80 to 225 cc and $71-$179 for engines more than 225 cc (CARB 2003d).5 Some manufacturers and their trade associations argued that these costs are large fractions of the retail prices of small-engine equipment, and imposing those cost increases on consumers would reduce demand for equipment (Guerry 2004). For example, some equipment such as walk-behind lawnmowers may retail for prices on the order of $100, only a fraction of which is the cost to manufacture the engine. The committee heard testimony from the Outdoor Power Equipment Institute (OPEI) that CARB’s Tier 3 proposal was expected to increase the costs of certain lower-priced products by one-third (Guerry 2004). Briggs and Stratton also testified that the average walk-

behind mower could increase in price by 20% as a result of the standards (Hanz and Hotz 2005).

Briggs and Stratton, whose manufacturing operations are located outside California, stated that economic consequences of complying with CARB’s Tier 3 regulations could force them to shift manufacturing offshore (Briggs and Stratton 2003). A contractor to Briggs and Stratton reported that this relocation could result in the loss of up to 22,000 jobs at parts suppliers and manufacturers in multiple states (NERA 2004). These economic impacts were used in support of the Bond Amendment, which restricted states’ ability to adopt California’s emissions standards for small engines (Congressional Record S14469, Nov. 12, 2003). The committee did not have any economic information or analysis in support of Briggs and Stratton’s statements that widespread adoption of California standards would shift manufacturing offshore. As discussed in previous chapters, economic data for such an analysis is often considered confidential and is guarded by companies. Because neither EPA nor CARB assesses the national economic impacts of a second standard, the committee did not have sufficient information available to assess practices or develop findings on the economic impacts of a second small-engine emission standard on specific companies, the small-engine industry, or the national economy.

Safety of Emissions-Control Equipment on Small Spark-Ignition Engine Equipment

A third concern that received attention during CARB’s Tier 3 rulemaking was safety. Some manufacturers, trade associations, fire-safety officials, and the Consumer Product Safety Commission (CPSC) raised concerns about the use of heat-generating catalysts that could burn equipment operators or ignite fires in dried vegetation or other flammable material. Forest and vegetation fire hazards were of particular concern because of the potential use of catalysts on lawn and garden equipment. Debris build up from grass clippings, leaves, and other vegetative materials can become dry and combustible during equipment storage, posing a danger when the equipment is next used. Some equipment might include shielding devices or insulation to protect against high surface temperatures; however, insulation can prolong cool-down time, resulting in the equipment being at higher temperatures when placed in storage. Refueling of heated equipment might also pose a fire risk, for

example, fumes igniting from a small spark from carbon or from smoldering debris. CARB’s initially proposed evaporative regulations requiring pressurized fuel tanks also raised concerns as a potential explosive hazard.

The issue of burn and fire hazards from emissions-control equipment was not a new concern. LDV and motorcycle manufacturers voiced similar concerns when the widespread use of catalytic converters was first promoted by emissions standards in the 1970s. In addition, catalytic converters had been used on handheld equipment preceding EPA’s Phase II standard for this equipment (EPA 2000d). EPA and CARB have given consideration to safety in their rule-makings. EPA is required by the CAA to “take into account safety factors associated with application of emission control technologies to non-road engines and vehicles” (CAA section 213(a)(4)). CARB is required to “determine the technological feasibility of the adoption or amendment of the standard or regulation. That determination shall include, but is not limited to, the availability; effectiveness, reliability, and safety expected of the proposed technology in an application that is representative of the proposed use” (California Health and Safety Code section 43013(e)(2)).

Safety concerns associated with catalyst use were discussed qualitatively in the Phase II RIAs for handheld and nonhandheld small-engine standards. EPA stated that low-efficiency catalysts had been in use on some handheld products and met existing standards. To comply with new emissions standards and meet Forest Service equipment temperature requirements, EPA acknowledged the limitations of using high-efficiency (high-temperature) catalysts and discussed how catalyst use would need to be balanced with reductions in engine-out emissions. EPA (2000d) concluded that “the engine and equipment manufacturer must carefully consider the cooling and safety implications of catalyst installation and reflect this in its design strategy for the engine and equipment.”

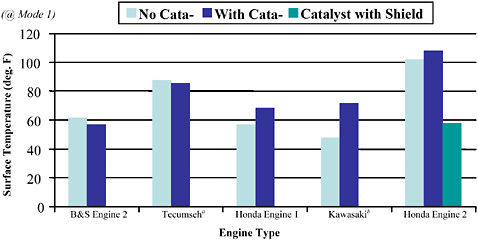

CARB addressed safety to some extent in its Tier 3 emissions standards. In a proof-of-concept study for CARB performed by Southwest Research Institute (SwRI), catalysts were attached to stock engines and equipment to demonstrate the ability to meet proposed emissions limits. As part of this study, SwRI also measured temperatures of the mufflers with and without catalysts for an estimate of how surface temperatures change with the addition of a catalyst (see Figure 7-5). CARB (2003d) suggested that a catalyst combined with a heat shield resulted in equipment surface temperatures in the range of those measured near mufflers from existing noncatalyzed engines (see Figure 7-5). CARB’s staff paper

FIGURE 7-5 Results of research at Southwest Research Institute under contract to CARB to test surface-temperature effects of adding catalysts to small SI engines. a, at 250 hr; b, at 125 hr. Abbreviation: B&S, Briggs and Stratton. Source: CARB 2004g.

includes a discussion of manufacturers concerns and points out that heat shields and other insulating material were being used by many manufacturers to reduce temperature around mufflers. Manufacturers, however, critiqued SwRI methods in comments submitted to CARB, raising concerns that they did not measure the areas of highest temperatures, which were observed by manufacturers to reach up to 1100F in some muffler locations without the use of a heat shield (CARB 2004g). In response to some early manufacturer safety concerns, CARB relaxed its proposed standards, thus reducing the required catalyst efficiency and resulting in lower exhaust and equipment temperatures (CARB 2004g). With respect to practical catalyst use, CARB states that “much of the effort needed to make the catalyst system operate on equipment is the responsibility of product engineers working for either the engine or equipment manufacturers” (CARB 2004g).

Manufacturers remained concerned about safety after CARB’s regulations were adopted, and voiced concerns to this committee on the issue (Guerry 2004). Furthermore, the National Association of State Fire Marshals (NASFM), the California Fire Chiefs Association (CFCA), and the CPSC also expressed concerns to CARB of the potential burn and fire hazard associated with their proposed and final regulations (inferred from comments in CARB 2004g). The CFCA and NASFM later sent

letters to members of Congress and EPA voicing their concern that CARB had moved forward with catalyst-forcing standards while ignoring safety concerns (Congressional Record S14469, Nov. 12, 2003). CARB agreed to participate in a pre-implementation cooperative safety study with manufacturers and fire officials, although its regulations remained unchanged. Congress later passed the Bond Amendment, which specifically charged EPA to “give appropriate consideration to safety factors (including the potential increased risk of burn and fire) associated with compliance with the California standards” when considering a waiver request from California for small SI engine standards (P.L. 108-199 Division G Section 428). Furthermore, Congress passed legislation in 2005 requiring EPA to perform a technical study on safety issues before EPA proposes new small-engine emissions standards (P.L. 109-54 Title II Section 205). The results of the CARB/manufacturer study and the EPA study were not available to the committee before finalizing this report. Although the focus of the safety discussion for small SI engines was on fire and burn hazards, the committee notes that stricter emissions standards reduce inhalation exposure of hazardous fumes for operators of small SI engine equipment. (Inhalation exposure is discussed, for example, in CARB [2000e] and Dost [2003].) It might be appropriate to consider reduced inhalation exposure in combination with the increased burn and fire hazard when considering safety of small-engine equipment.

VOLUNTARY PROGRAMS

Incentive Programs

A number of NAAQS nonattainment areas faced with the need to reduce emissions dramatically have used voluntary programs or programs that provide financial incentives for reducing emissions from federally preempted sources. These programs are important in that they provide an alternative to the development of state emissions standards. Because the programs typically track what types of sources are being reduced and the cost-effectiveness of emissions reductions, they provide an opportunity to compare the costs of emissions controls for preempted sources with the costs of controls on non-preempted sources. Many of the voluntary or incentive-based programs that have been or are being implemented at the federal, state, and local levels in the United States focus on either on-road HDV diesel-engine fleets or nonroad equipment.

These programs include the following:

-

Federal Programs

-

U.S. Department of Transportation (DOT) Transportation Equity Act for the Twenty-First Century (TEA-21)

-

Congestion Mitigation and Air Quality Improvement Program (CMAQ)

-

-

U.S. Department of Energy (DOE) Energy Policy Act of 1992 (EPAct)

-

State and Alternative Fuel Provider Program

-

Federal Fleet Program

-

Private and Local Government Fleet Program

-

Alternative Fuel Petition Program

-

Clean Cities Program

-

-

EPA Office of Air and Radiation Programs

-

Voluntary Diesel Retrofit Program

-

Clean School Bus USA

-

-

-

California Programs

-

California Air Resources Board

-

Diesel Risk Reduction Plan

-

Carl Moyer Program

-

-

California Department of Transportation (Caltrans) Greening the Fleet Program

-

South Coast Air Quality Management District’s Mobile Source Air Pollution Reduction Review Committee Funding Program

-

Sacramento Emergency Clean Air and Transportation Program

-

San Joaquin Valley Emergency Clean Air Attainment Program

-

Gateway Cities Clean Air Program

-

Port of Los Angeles and Port of Oakland Clean Air Programs

-

Bay Area Air Quality Management District’s Transportation Fund for Clean Air Program

-

-

Programs in Other States

-

Texas Commission on Environmental Quality’s Texas Emissions Reduction Plan

-

Houston-Galveston Area Council Clean Cities/Clean Vehicles Program

-

New York State Department of Environment Conservation’s Clean Water/Clean Air Bond Act Program

-

Puget Sound Clean Air Agency’s Diesel Solutions Program

-

Two of the largest incentive-based programs are the California Carl Moyer Program and the Texas Emission Reduction Program.

Carl Moyer Program

The State of California implements a voluntary incentive-based program called the Carl Moyer Program, which provides grant funds for the incremental cost of reducing emissions of NOx from federally preempted sources. The incentives are available for on-road and off-road sources, including heavy-duty trucks, marine engines, locomotive engines, stationary agricultural pump engines, forklifts, airport ground-support equipment, and auxiliary power units. The Carl Moyer Program is administrated by CARB, and approximately $150 million in grants were made between 1998 and 2002. Funds are provided by the state and by local air quality management districts. Recent legislation has expanded funding for the program to an anticipated $140 million per year. Both private companies and public agencies operating HDV engines in California are eligible to apply for the grants. CARB is currently revising the guidelines to address PM as well as HC emissions reductions.

Participation in the Carl Moyer Program is summarized in Table 7-5, and the types of projects funded are shown in Table 7-6. The data in Tables 7-5 and 7-6 reveal a number of key features of the Carl Moyer Program. First, the estimated cost-effectiveness of the emission reductions is generally well below the cost of many of the control measures implemented in California. CARB cost-effectiveness estimates of proposed SIP measures average approximately $8,300 per ton of NOx reduced, the range being $1,000-$22,000 per ton of NOx reduced (CARB 2004h). Second, the emission reductions achieved through the program (4-16 tons per day of NOx statewide) are a small fraction of the emission inventory and the required emission reductions. Total NOx emission in the South Coast Air Quality Management District in 1997, for example, was estimated to be 1,024 tons per day (annual average day) (SCAQMD 2003). Finally, the program has grown because of its ability to continue to provide relatively low-cost emission reductions.

Texas Emissions Reduction Plan

The Texas Emissions Reduction Plan (TERP) was established in fiscal year (FY) 2002 by the Texas state legislature. The goal of TERP is

TABLE 7-5 Program Summary by Fiscal Year of the Carl Moyer Program (through mid- 2003)

|

Fiscal Year |

Number of Participating Districts |

Carl Moyer Funding ($ millions) |

Matching Funds from Districts ($ millions) |

NOx Reduction (tons per day) |

Average Cost-Effectiveness of All Projects Statewide ($ per ton) |

|

1998-1999 |

16 |

24.5 |

12.25 |

4 |

3,000 |

|

1999-2000 |

20 |

19 |

9.31 |

7 |

<5,000 |

|

2000-2001 |

21 |

45 |

12.00 |

14 |

4,000 |

|

2001-2002 |

NA |

16 |

~8 |

16 |

NA |

|

2002-2003 |

NA |

19.68 |

~9.8 |

NA |

NA |

|

Source: Chan et al. 2005. Reprinted with permission; copyright 2005, ENVIRON. |

|||||

TABLE 7-6 Project Summary for the First Three Fiscal Years of the Carl Moyer Program (through mid- 2003)

|

Source Category and Equipment Type |

NOx (tons per year) |

Cost-Effectiveness ($ per ton) |

|

Heavy-duty line haul |

41 |

2,570 |

|

Refuse haulers |

432 |

6,563 |

|

Urban transit buses |

413 |

4,715 |

|

School buses |

4 |

10,039 |

|

Other on-road sources |

116 |

5,756 |

|

Farm equipment |

36 |

4,179 |

|

Construction |

54 |

3,627 |

|

Other nonroad sources |

52 |

3,587 |

|

Locomotives |

22 |

1,160 |

|

Marine vessels |

698 |

3,044 |

to reduce emissions of NOx from federally preempted sources in the non-attainment and near-nonattainment areas of Texas through voluntary incentive programs. TERP was initially funded at a level of approximately $20 million per year, and that funding has been increased to a level of approximately $130 million per fiscal year in 2004 and 2005. The current level of funding is projected to continue through 2008. The Texas Commission on Environmental Quality (TCEQ) administers TERP grants and other TERP financial incentives.

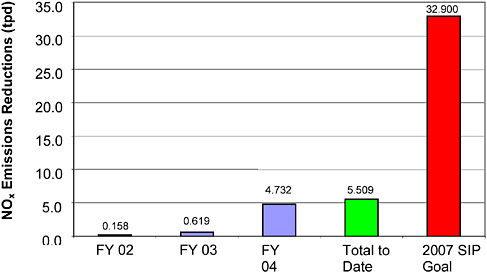

TERP provides funding for cleaner on- and off-road engines, energy efficiency programs, cleaner fuel and other infrastructure programs, and research and development of new technologies. Emission reductions to be achieved through TERP have been incorporated into the ozone SIPs for the Houston-Galveston-Brazoria area (HGB) and the Dallas-Fort Worth area (DFW). Tables 7-7 and 7-8 summarize data on TERP-funded projects for FYs 2002, 2003, and part of 2004 in the HGB and DFW areas. To put the numbers in Table 7-8 in context, the 2007 NOx SIP budget for HGB is approximately 525 tons per day, 33 tons per day of which are TERP projects. Total NOx emissions in the HGB area in 1996 were projected to be approximately 1250 tons per day.

Comparison of Tables 7-4 through 7-8 reveals many similarities between the TERP and Carl Moyer programs. In both states, the estimated cost-effectiveness of the emissions reductions is generally below the cost of many of the control measures that are implemented in the states. Second, the emissions reductions achieved through the program are a small fraction of the emissions inventory and the required emissions reductions. In TERP, specific goals were set for emissions reductions in the DFW and HGB areas. Although substantial resources have been expended on the program, and the program provides cost-effective emissions reductions, the HGB and DFW areas still have a shortfall of needed emission reductions, as shown in Figure 7-6 for HGB. (A similar shortfall is found in Dallas-Fort Worth.)

CONCLUSIONS

As discussed in Chapter 2, mobile sources other than LDVs are important contributors to emissions inventories. EPA’s and CARB’s regulations for these other mobile sources raised a variety of issues, as discussed in Chapter 7. The chapter also described incentive-based mobile-source emissions reductions programs an alternative to emissions stan-

TABLE 7-7 Summary of TERP-Funded and -Recommended Projects to Date in the HGB and DFW Areas (as of November 2, 2004)

|

|

HGB |

DFW |

HGB and DFW |

|

NOx Emission Reduction (tons per day) |

|||

|

FY 02 |

0.16 |

1.17 |

1.33 |

|

FY 03 |

0.62 |

0.33 |

0.95 |

|

FY 04 |

4.73 |

2.97 |

7.71 |

|

Total to Date |

5.51 |

4.47 |

9.98 |

|

2007 SIP Goal |

32.9 |

16.3 |

49.2 |

|

TERP Funding ($ in millions) |

|||

|

FY 02 |

3.0 |

8.8 |

11.9 |

|

FY 03 |

12.8 |

1.7 |

14.5 |

|

FY 04 |

44.6 |

23.2 |

67.8 |

|

Total to Date |

60.4 |

33.7 |

94.2 |

|

TERP Projects |

|||

|

FY 02 |

24 |

11 |

35 |

|

FY 03 |

21 |

11 |

32 |

|

FY 04 |

76 |

97 |

173 |

|

Total to Date |

121 |

119 |

240 |

|

TERP Average Cost-Effectiveness ($ per ton) |

|||

|

FY 02 |

10,005 |

4,367 |

5,101 |

|

FY 03 |

8,104 |

3,009 |

6,792 |

|

FY 04 |

6,218 |

5,210 |

5,832 |

|

Average to Date |

6,675 |

4,795 |

5,853 |

|

Source: Chan et al. 2005. Reprinted with permission; copyright 2005, ENVIRON. |

|||

dards. The following conclusions are drawn from the case studies presented in this chapter:

-

The biennial reviews of the 2007 HDV rule are similar to the biennial reviews of the zero-emission-vehicle mandate discussed in Chapter 6. These reviews of technological progress are beneficial to stakeholders and the public.

-

Some states have indicated that they consider the adoption of California’s 2007 HDV standards, which are nearly identical to EPA’s, to be a safety net in case EPA delays federal standards.

-

Small-engine emissions control poses special challenges to the design, production, and distribution of small-engine equipment. CARB has shown some flexibility in setting emissions standards for small engines to deal with some of the difficulties inherent in the nonintegrate

TABLE 7-8 Summary of TERP- Funded and -Recommended Projects to Date in the HGB and DFW Areas by Emission Sources (as of November 2, 2004)

|

Project Types |

Approved Amount ($) |

Total Project NOx Reduction (tons) |

Total NOx Emission Reduction (tons per day) |

Cost-Effectiveness ($ per ton) |

|

FYs 2002, 2003 and 2004 Projects by Type: HGB/DFW Combined |

||||

|

Railroad projects |

27,800,000 |

5,400 |

3.57 |

5,100 |

|

On-road vehicles |

28,900,000 |

4,600 |

2.27 |

6,300 |

|

Nonroad vehicles and equipment |

32,000,000 |

5,100 |

3.61 |

6,200 |

|

Commercial marine vessels |

5,400,000 |

940 |

0.53 |

5,700 |

|

Total |

94,200,000 |

16,000 |

9.98 |

5,900 |

|

Source: Adapted from Chan et al. 2005. Reprinted with permission; copyright 2005, ENVIRON. |

||||

FIGURE 7-6 TERP NOx emission reductions to date versus the 2007 SIP TERP goal in the HGB area. Source: Chan et al. 2005. Reprinted with permission; copyright 2005, ENVIRON.

-

industry. Manufacturers and fire safety officials have raised safety concerns about widespread use of heat-generating catalysts on lawn and garden equipment. Safety studies beyond normal EPA and CARB practices are ongoing; the committee did not have enough information to assess safety concerns fully.

-

As a result of a 2003 law passed by Congress, small SI engines form a new regulatory category different from other mobile sources. California may set a second standard for those sources; however, the California standard for small SI engines is the only California standard that other states may not adopt under CAA section 177.

-

Some states have devised nonregulatory, incentive-based emissions-control programs for mobile sources. These programs to date have provided emissions control from mobile sources that would not otherwise have been provided by regulation.