7

Integrating Approaches to Reducing Risk from Distribution Systems

The few regulations that govern water quality in distribution systems are the result of years of research leading to the demonstration of a risk to the water-consuming public from specific contaminants. The development of regulations is a complex process that includes cost analysis (EPA, 2003) and, more recently, stakeholder input as described in the Federal Advisory Committee Act. Many state regulatory agencies are either reluctant to or prohibited by statute to require measures to protect drinking water beyond those mandated by federal statute. However, drinking water utilities may independently choose to conform to industry standards to design and operate their systems beyond regulatory requirements.

Standards are useful to water suppliers that have adopted such a precautionary stance. Recommended Standards for Water Works: Ten State Standards (The Great Lakes-Upper Mississippi River Board of State Public Health and Environmental Managers, 2003), NSF International, and the American National Standards Institute (ANSI) are third party producers of standards that are widely used in the drinking water industry. Voluntary adoption of standards by a utility requires reallocation of resources. Nevertheless adoption of certain standards is almost universal for community water systems, such as ANSI/NSF 60 governing components that come in contact with drinking water, ANSI/NSF 61 governing additives to water, and many American Water Works Association (AWWA) standards related to design of infrastructure such as D100-96—Welded Steel Tanks for Water Storage. Other widely used AWWA standards related to distribution system integrity include the C651—Disinfecting Water Mains, C652—Disinfection of Water-Storage Facilities, and D101-53 (R86)—Inspecting and Repairing Water Tanks, Standpipes, Reservoirs, and Elevated Tanks for Water Storage. In addition to industry standards, AWWA “Manuals of Water Supply Practices,” such as M6 Water Audits and Leak Detection, are commonly used by drinking water utilities to enhance their operations and service to the public.

In 1999 a technical workgroup was organized to develop a Drinking Water Distribution System Assessment Workbook, which began the process that culminated in the G200 Standard. The purpose of the G200 standard is to “define the critical requirements for the operation and management of water distribution systems, including maintenance of facilities” (AWWA/ANSI, 2004). Several components of the G200 standard relate directly to issues highlighted in the U.S. Environmental Protection Agency (EPA) Distribution System White Papers (see Chapter 1) and characterized as high priority by this committee (see Appendix A).

These include Section 4.1.1: Compliance with regulations, 4.1.3: Disinfectant residual maintenance, 4.2.1 System pressure monitoring and requirements, 4.2.2 Backflow prevention, and 4.3.1 Storage facilities. As listed in Table 7-1, G200 includes requirements related to water quality, distribution system management, and facility operation and maintenance. The standard references several existing standards such as those cited above.

TABLE 7-1 G200 Requirements

|

Section |

Title |

Requirement |

|

4.1 |

Water Quality |

|

|

4.1.1 |

Compliance with regulatory requirements |

Meet or exceed regulatory requirements. |

|

4.1.2 |

Monitoring and control |

|

|

4.1.2.1 |

Sampling plan |

Establish plan, review annually, analyze/trend data, have action plan to respond to changes. |

|

4.1.2.2 |

Sample sites |

Include all types of locations including dead ends and storage. Past problem areas require more sampling. |

|

4.1.2.3 |

Sample collection |

Use Standard Methods, standardized labels and chain of custody forms. |

|

4.1.2.4 |

Sample taps |

Protect from contamination. Inspect annually. |

|

4.1.3 |

Disinfectant residual maintenance |

|

|

4.1.3.1 |

Disinfectant residual |

Maintain detectable or HPC ≤ 500 CFU/mL. |

|

4.1.3.2 |

Nitrification control |

Monitor free ammonia, control chlorine-to-ammonia ratio. |

|

4.1.3.2.2 |

Nitrification monitoring |

Monitor nitrification indicator parameters. |

|

4.1.3.3 |

Booster disinfection |

|

|

4.1.3.3.1 |

|

Document residual goals. Monitor compliance with goals. |

|

4.1.3.3.2 |

|

Maintain operating procedures that take into account seasonal variation, quality, flow, and system operations. |

|

4.1.3.3.3 |

|

Written Plan showing response to variation between goals and observed values. |

|

4.1.3.4 |

Disinfection byproduct monitoring and control |

|

|

4.1.3.4.1 |

|

Monitor and control DBPs. Set goals for DBPs at critical points. |

|

4.1.3.4.2 |

|

Have action plan to respond to levels that exceed goals. |

|

4.1.4 |

Requirements for utilities not utilizing a disinfectant residual |

Monitor and record HPC. |

|

4.1.4.1 |

Response program |

Have action plan to respond when HPC levels are above goals. |

|

Section |

Title |

Requirement |

|

4.1.5 |

Internal corrosion monitoring and control |

|

|

4.1.5.1 |

Prevention and response program |

Have action plan to respond to internal corrosion and deposition. |

|

4.1.6 |

Aesthetic water quality parameters |

|

|

4.1.6.1 |

Color and staining |

Have action plan to address color and staining. |

|

4.1.6.2 |

Taste and odor |

Have action plan to address taste and odor. |

|

4.1.7 |

Customer relations |

|

|

4.1.7.1 |

Customer inquiries |

Have system to document customer inquires. |

|

4.1.7.2 |

Service interruptions |

Have system to document planned and unplanned service interruptions. |

|

4.1.8 |

System flushing |

Develop and implement a systematic flushing program. |

|

4.2 |

Distribution System Management Programs |

|

|

4.2.1 |

System pressure |

|

|

4.2.1.1 |

Minimum residual pressure |

Minimum pressure > 20 psi. |

|

4.2.1.2 |

Pressure monitoring |

Monitor pressure. Pressure alarms may be used. |

|

4.2.2 |

Backflow prevention |

Have program at least as stringent as AWWA M14. |

|

4.2.3 |

Permeation prevention |

Address in utility operation plan. |

|

4.2.4 |

Water losses |

|

|

4.2.4.1 |

Water loss |

Have goal for the amount of water loss. Document calculation. |

|

4.2.4.2 |

Response program |

Have action plan to respond if goal is not met. |

|

4.2.4.3 |

Leakage |

Quantify leakage on annual basis. |

|

4.2.5 |

Valve exercising and replacement |

|

|

4.2.5.1 |

Valve exercising program |

Have valve exercising program. |

|

4.2.6 |

Fire hydrant maintenance and testing |

|

|

4.2.6.1 |

Maintenance and testing |

Comply with AWWA M17. |

|

4.2.7 |

Materials in contact with potable water |

|

|

4.2.7.1 |

Approved coatings or linings |

Specify in accordance to AWWA standards, NSF 61, or other. |

|

4.2.8 |

Metering |

|

|

4.2.8.1 |

Metering requirements |

Determine daily peak flows and maximum day peak flows. |

|

4.1.8.2 |

Metering devices |

Meters shall meet AWWA requirements or other applicable standard. |

|

4.2.8.3 |

Testing |

Test as recommended in AWWA M6. |

|

4.2.8.4 |

Repair and replacement programs |

Have program that includes records to verify conformance with AWWA M6. |

|

Section |

Title |

Requirement |

|

4.2.9 |

Flow |

|

|

4.2.9.1 |

Flow requirements |

Be capable of delivering maximum day demand and fire flow. |

|

4.2.10 |

External corrosion |

|

|

4.2.10.1 |

Leaks/breaks |

Have a standardized system for recording and reporting leaks and breaks. |

|

4.2.10.2 |

Monitoring program |

Have external corrosion monitoring plan. |

|

4.2.11 |

Design review for water quality |

|

|

4.2.11.1 |

Policies and procedures |

Have standardized design procedures that review construction projects to reduce potential for water quality degradation. |

|

4.2.11.2 |

Records |

Prepare as-built drawings. |

|

4.2.12 |

Energy management |

|

|

4.2.12.1 |

Energy management program |

Review and optimize electrical energy usage. |

|

4.3 |

Facility Operation and Maintenance |

|

|

4.3.1 |

Treated water storage facilities |

|

|

4.3.1.1 |

Storage capacity |

Establish minimum operating levels in storage facilities. |

|

4.3.1.2 |

Operating procedures |

Write Standard Operating Procedures for turning over facilities and minimizing water age. |

|

4.3.1.3 |

Inspections |

Write Standard Operating Procedures for facility inspection. |

|

4.3.1.4 |

Maintenance |

Have a maintenance program for facilities. |

|

4.3.1.5 |

Disinfection |

Facilities shall be disinfected according to ANSI/AWWA C652. |

|

4.3.1.6 |

Additional requirements |

All facilities shall be covered. |

|

4.3.2 |

Pump station operation and maintenance |

|

|

4.3.2.1 |

Operating procedures |

Write Standard Operating Procedures describing the operation of each pump station. |

|

4.3.2.2 |

Maintenance program |

Write Standard Operating Procedures describing the maintenance of the equipment in each pump station. |

|

4.3.3 |

Pipeline rehabilitation and replacement |

|

|

4.3.3.1 |

Rehabilitation and replacement program |

Have a program for evaluating and upgrading the distribution system. |

|

4.3.4 |

Disinfection of new or repaired pipes |

|

|

4.3.4.1 |

Disinfection of new or repaired pipes |

Disinfect according to ANSI/AWWA C651 requirements. |

|

4.3.4.2 |

Bacteriological testing |

Testing shall be performed according to ANSI/AWWA C651. |

|

4.3.4.3 |

Disposal of chlorinated water |

Disposal shall follow local, state, and federal regulations. |

|

Section |

Title |

Requirement |

|

5.1 |

Documentation Required |

|

|

5.1.1 |

General |

Include statements of policy and quality objectives, standard operating procedures etc. |

|

5.1.2 |

Examples of documentation |

Document to include requirements of Section 4. |

|

5.1.3 |

Control of documents |

Establish procedures to review and approve and maintain documents. |

|

5.1.4 |

Control of records |

Maintain evidence of conformity to requirements of this standard. |

|

5.2 |

Human Resources |

|

|

5.2.1 |

General |

Personnel performing work on the DS will be competent on the basis of appropriate education, training, skills, test requirements, and experience. |

|

5.2.2 |

Competence, awareness, and training |

The utility shall provide training and determine competence. |

|

SOURCE: Excerpted, with permission, from AWWA/ANSI G200 (2004). © 2004 by American Water Works Association. |

||

As discussed in Chapter 2, the use of the standards such as ANSI/NSF 60, ANSI/NSF 61, and AWWA G200 and Manuals of Practice have advantages over programs such as Hazard Analysis and Critical Control Points (HACCP) in that they are more easily adapted to the dynamic nature of drinking water distribution systems. Use of a standard such as G200 that is intended to assess whether the system can be managed under all conditions is appropriate for utilities that desire to operate beyond regulatory requirements. To minimize the public health risks of distribution systems, it is recommended that drinking water utilities adopt G200 or an equivalent program in order to develop distribution system management plans that combine their regulatory requirements and available voluntary standards.

The purpose of this chapter is to discuss certain elements of G200 that deserve more thoughtful consideration because emerging science and technology are altering whether and how these elements are implemented by a typical water utility. Much of the current scientific thrust is in the development of new monitoring methods, models, and methods to integrate data, all to better inform decision making.

MONITORING

Drinking water of “acceptable quality” is defined by the Safe Drinking Water Act (SDWA) and its amendments and is framed in terms of the Maximum Contaminant Levels (MCLs), treatment techniques, rules, and regulations promulgated under the Act. The regulations contain significant monitoring require-

ments that prescribe the sampling frequency (minimum monitoring frequencies), sampling locations, testing procedures, record keeping, and the water quality parameters to be monitored, and are classified according to system size and vulnerability. The regulations also cover specific reporting procedures to be followed if a contaminant exceeds an MCL. Failure to have the proper water quality analyses performed or to report the results to the state primacy agency can result in the water system having to provide public notification.

Under the SDWA, monitoring or treatment techniques are required for all contaminants regulated under the Act, both at the entry point to a water distribution system and, in some cases, at various locations within the system. Rules and regulations that explicitly require monitoring in the distribution system include the Total Coliform Rule (TCR), the Surface Water Treatment Rule (SWTR) and Long-Term Enhanced Surface Water Treatment Rule (LTESWTR), Lead and Copper Rule (LCR), and the Stage 2 Disinfectants/Disinfection By-Products Rule (Stage 2 D/DBPR). These requirements are summarized in Table 7-2. Routine compliance monitoring is a useful tool for detecting and assessing some common water quality problems throughout a system if the event is large enough and long enough in duration to be detected (Byer and Carlson, 2005). Note that pressure monitoring is not required by any of the existing rules, which is unfortunate.

The compliance monitoring required by the SDWA is limited in its ability to protect public health because the end-point or customer tap monitoring required under the regulations is typically (1) not sufficient to provide early warning of contamination, (2) not indicative of what could have gone wrong between the treatment plant and the consumer’s tap so as to effectively guide remediation, and (3) too limited across space (too few sampling locations) and time (discrete small volume samples are collected too infrequently) to provide information that applies to every potential user. The realities of financial and personnel resources in most cases preclude expanding monitoring programs to cover vastly larger areas and periods of time.

Rather, it is more useful for utilities to consider how to control the processes taking place within the distribution system, as well as activities to maintain the processes, such that the risk of the customer being exposed to contaminated drinking water is minimized. This concept hinges on viewing a water distribution system as a linkage of processes working together to maintain flow, pressure, and water quality. These processes include pumping, valving, metering, transmission, distribution, service, storage, and corrosion control, to name a few. Though each individual distribution system is a unique linkage of processes, the processes have common characteristics that allow generalizations to be made about their control. For example, the number of storage tanks from one system to another may be different, but there are common problems with hydraulic retention time and chlorine loss in all storage tanks. The variety of pipes used (materials and sizes) will differ from one system to another, but cast iron displays a common corrosion problem in all systems.

TABLE 7-2 Federal Distribution System Water Quality Monitoring Requirements

|

Regulation |

Monitoring Requirement |

|

Total Coliform Rule |

|

|

Surface Water Treatment Rule (SWTR) and multiple Long-Term Enhanced Surface Water Treatment Rules (LTESWTRs) |

|

|

Lead and Copper Rule (LCR) |

|

|

Stage 2 Disinfectants/ Disinfection By-Products Rule (DBPR) |

|

|

SOURCE: Owens (2001) and Lansey and Boulos (2005). |

|

In addition to being a linkage of processes, the distribution system is also a reactor, in that treated drinking water begins to change physically (e.g., iron and manganese particles settle out), chemically (e.g., chlorine begins to decompose) and biologically (e.g., bacterial cells begin to adhere to pipe surfaces and form biofilms) as soon as water leaves the treatment plant. Each of the processes display common tendencies to promote these changes irrespective of how they are linked within a distribution system.

Real-time feedback on whether a utility’s distribution system processes are in or out of control goes beyond the regulatory requirements for water quality monitoring mentioned above. The following sections discuss monitoring for process control; they are intended to build upon discussions of detection methods and tools, such as such Geographic Information System (GIS) and hydraulic modeling, found earlier in the report. A systematic strategy for distribution system monitoring to detect water quality alterations is comprised of the following actions: (1) develop a list of parameters to be monitored, (2) assess appropriate temporal and spatial scales for monitoring, (3) develop a response plan for monitored parameters, and (4) implement. Each of these activities is discussed

below, focusing on recent scientific developments that should lead to improvement in how the activities are conducted.

Parameters to be Monitored

The parameters that are useful for monitoring distribution system processes may include those that are required from a regulatory point of view (e.g., turbidity, chlorine residual), but likely would include others. The key requirements are that the monitoring parameters can be measured relatively quickly, inexpensively, and (ideally) continuously at multiple locations in the system. The parameters should be selected with consideration for the potential mechanisms that may induce adverse changes in water quality. For example, in corrosive waters passing through ductile iron pipe, conductivity, pH, and oxidation reduction potential (ORP) may be useful. In waters passing through polymeric pipe or vulnerable to intrusion in contaminated overlying soils, UV254 or TOC may be useful.

Table 7-3 lists sentinel parameters that could be used to indicate changes in distribution system integrity. These parameters include indicators of physical deterioration (pressure changes, main breaks, water loss, or corrosion), hydraulic failure (turbidity, complaints of low flow or pressure) or a water quality failure

TABLE 7-3 Sentinel Parameters for Distribution System Integrity

(particulates, tastes, odors, or color). For some of the parameters (listed in bold), on-line monitoring equipment is available to provide real-time control of distribution system operations. Most methods for monitoring physical characteristics of water (e.g., flow, velocity, water level in a storage tank) tend to be relatively inexpensive, quite durable, and able to generate continuous, real-time, on-line data (Grayman et al., 2004; Panguluri et al., 2005a). Less available in on-line, real-time versions are methods for detecting inorganic chemicals, synthetic organic chemicals, volatile organic chemicals, and radionuclides. The direct real time detection of biological changes within distribution systems remains beyond current technology (Bernosky, 2005).

Pressure. One of the most important parameters for utilities to consider monitoring for is transient pressure change using high-speed, electronic pressure data loggers. Recent research has documented the frequency and magnitude of pressure transient events (Friedman et al., 2004; Gullick et al., 2005). High-speed data loggers are required for monitoring distribution system pressure transients because such transients may last for only seconds and may not be observed by conventional pressure monitoring. High-speed pressure data loggers can measure pressures at a rate of up to 20 samples per second, allowing measurement of sudden changes in pressure. The units can be programmed with preset alarm levels to notify operators when specific thresholds have been exceeded. Additionally, some units can be programmed to capture and store specific data surrounding a pressure transient event, permitting the episode to be analyzed and corrective actions to be determined.

Turbidity. Turbidity in distribution systems, which can be can be caused by suspended sediments, oxidized iron or manganese, or other corrosion products, is another critical parameter for which on-line, real-time methods are available. Various models exist but in the finished water distribution system, turbidity probes need to be sensitive at low ranges (i.e., < 1 NTU). Measurement accuracy may be improved further by employing wiper or shutter mechanisms that are activated immediately prior to measurements to avoid interferences from particulates or air bubbles. In general, turbidity units from different manufacturers behave similarly, and calibration frequencies vary from weekly up to three monthly intervals, but require a good level of operator skill. On-line turbidimeters are being used successfully under the Partnership for Safe Water Program to monitor low level (< 0.3 NTU) turbidity, and therefore should prove valuable for low level turbidity in distribution system monitoring.

Disinfectant Residual. Disinfectant residual monitors can measure free chlorine, chloramines, or ORP. The principle of detection for residual on-line sensors relies on either polarographic, voltametric, or colorimetric methods which can influence their sensitivity, calibration, and interferences from other water quality parameters. Operation of an ORP sensor is similar to that of the pH sensor where a two-electrode system is used to make potentiometric meas-

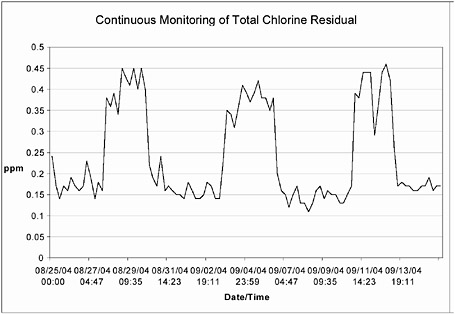

urements. The calibration frequency for these monitors is usually on a monthly basis. Typical data from continuous monitoring of total chlorine residual is shown in Figure 7-1.

Flow. In-line meters are available to measure flow in the distribution system but are typically used only to monitor flows into distribution system sub-districts. Monitoring flows by sub-district can be compared to customer meter data to indicate the amount of leakage in specific areas of the distribution system. Flows can be influenced by pumping regimes, storage tank operations, and manipulations of hydrants or blow-off valves. Use of a well-calibrated distribution system hydraulic model along with pump, tank, and flow data is required to generate detailed descriptions of distribution system water velocities and flow reversals.

pH. Measurements of pH are made with a pH meter using a glass indicator electrode. These measurements are reliable, but the meter requires regular calibration to avoid drift.

Temperature. Temperature thermistors typically work over a relatively small temperature range and can be very accurate within that range. The measurements are very reliable and typically do not require routine calibrations.

FIGURE 7-1 Data from a continuous, on-line chlorine analyzer, showing how a total chlorine residual can vary through a day and the need to relate this to system operations. SOURCE: Data from Philadelphia Water Department, Bureau of Laboratory Services.

Chemical Parameters. For chemical parameters, EPA has been examining the reliability of on-line sensors under the Environmental Technology Verification (ETV) Program (EPA, 2004a,b). Currently this program has examined 40 monitoring and treatment technologies and plans to conduct additional testing under the newly formed Technology Testing and Evaluation Program (TTEP)—an off shoot of the ETV program, which is not dependant upon voluntary vendor involvement. This independent testing is providing a valuable database on the reliability of on-line monitors (http://www.epa.gov/etv/). The sensors being developed are not specific for the chemical contaminants themselves. Rather, the premise of the research is that a chemical contaminant in a distribution system would elicit a pattern of changes in other, primary parameters that can be easily measured in real time, such that changes in their detection would indicate the presence of the contaminant. Table 7-4 shows the responsiveness of various water quality parameters to a range of contaminants in controlled experimental tests.

It should be noted that the actual ability of the on-line sensors shown in Table 7-4 to detect a target contaminant in field situations has not been ascertained. Hence, whether a particular pattern of shifts in a battery of on-line analysis results can be reliably associated with a particular type of contaminant (e.g., malathion) is uncertain. Another National Research Council committee is in the process of examining research needs in the area of drinking water homeland security, and further discussion of this issue may be found in its report.

TABLE 7-4 Responsiveness of parameters that can be easily measured on-line to various contaminants

|

Contaminant Compound |

Water Quality Parameter |

||||||||

|

Free/total chlorine |

ORP |

TOC |

SC |

Turbidity |

NH3 |

N2 |

NO3- |

Cl- |

|

|

Ferricyanide |

NC (F+ w/DPD test) |

+ |

++a |

+ |

+ |

F- |

|

F- |

F- |

|

Malathion (pesticide) |

+ |

+ |

+ |

NC |

+ |

|

|

|

+ |

|

Glyophosphate (herbicide) |

+ |

+ |

+ |

NC |

NC |

|

|

|

+ |

|

Nicotine (organic) |

++ |

|

++ |

NC |

|

|

|

|

|

|

Arsenic trioxide |

++ |

++ |

NC |

|

+ |

++ |

++ |

|

|

|

Aldicarb |

++ |

|

++ |

|

|

|

|

|

|

|

Groundwater |

+ |

+ |

NC |

+ |

NC |

|

|

|

+ |

|

Wastewater |

+ |

+ |

+ |

+ |

+ |

|

|

|

+ |

|

Key: ++ = very responsive, + = responsive, F+ = false positive, F- = false negative, NC = no change Abbreviations: ORP, oxidation/reduction potential; TOC, total organic carbon; SC, specific conductance. aMay be due to bound carbon in the cyanide complex, from Hall et al. (2005). Note: For the pesticides and herbicides, commercial products were used that had different concentrations of organic compounds. SOURCE: Adapted from Hall et al. (2005). |

|||||||||

Secondary Parameters. In addition to the primary on-line monitoring tools, a range of other monitoring approaches can be used to enhance the measurement of distribution system integrity. Both ultraviolet absorbance and transmittance monitors operate on the optical principle where light of known wavelength (typically 254 nm) and intensity is passed through a sample cell of a known path length. A photo-detector on the opposite side to the light source measures the degree of light attenuation by the sample. The percent of UV light passing through the water determines the UV transmittance (UVT) or alternatively can be translated into absorbance. Double bonds and ring structures strongly absorb light at 254 nm and therefore absorbance (or transmittance) provides useful relative measures of the amount of organic matter, which can contribute to color in water. Because the detection procedure utilizes optics, small particles or other materials (such as dissolved iron) that can deposit on the cell windows can lead to interference.

Measurement of specific conductance, color, TOC, chemical ions, and metals can be used to measure changes in water quality baseline values. Conductivity is directly affected by the number of dissolved ions, and when adjusted for a given temperature (usually 25°C), it is referred to as specific conductance (Siemens per cm) and can be used for approximating the total dissolved solids content. Ion selective electrodes for Cl-, NO3-, NH4+ and others analytes are available but are not entirely ion-specific and can lead to problems of ionic interference. Several on-line TOC monitors are commercially available but the routine maintenance and calibration are cumbersome and require oxidants, carrier gas, and UV lamp replacements. Some units have simplified this process by using pre-packaged chemical packs that are easily replaced. Some units use high temperature catalysis for the oxidation step, and thus eliminate the need for oxidant chemicals.

***

Various manufacturers have either single or multi-parameter sensors that can monitor distribution system water quality and directly communicate the data to the Supervisory Control and Data Acquisition (SCADA) system, as shown in Table 7-5. There are a multitude of options currently available that have been recently reviewed (Hasan, 2005). Multi-parameter sensors are available in a panel format that uses a side-stream to draw a sub-sample of water from the distribution system or alternatively exist as sondes that can be installed directly or indirectly within distribution system pipes. The former are large conspicuous units, and, to avoid being tampered with, their use in the distribution system would have to be limited to secure locations. Also, the side-stream of water drawn from the distribution system into the multi-parameter sensors requires

appropriate disposal (i.e., into a sanitary sewer) under normal operation. In contrast, the in-line sondes have the potential to be installed discretely within the distribution system, which reduces their vulnerability to tampering but may complicate routine calibration.

It should be noted that the on-line monitoring technologies discussed above are currently cost-prohibitive and too complex for premise plumbing and service lines. However, this may change with technological advances.

Consumer Complaints

A final type of monitoring that utilities may want to consider is consumer complaints monitoring. Consumers can detect off odors, changes in taste or flavor, color, turbidity, and particulates resulting from system failures (e.g., water main breaks, cross connections) as well as from system operations (e.g., hydrant flushing, valve operations). While these untrained assessors are subjective and unreliable from a laboratory testing point of view, they are everywhere at all times in a distribution system and thereby serve as valuable sources of information on potential water quality problems (Burlingame, 1999a,b; Laurer, 2005).

Collection and mapping of customer complaints should be done in the context of a GIS-linked database to monitor conditions in the distribution system, track operational issues, and determine the boundary of water quality events. Critical to the functionality of using customer data as a monitoring tool is the seamless integration and transfer of complaint data into operational databases so that all functional departments (production, network, water quality, management, communications, etc.) are instantly aware of any disturbances. Use of mobile computers can effectively communicate and coordinate workforce resources in the field to respond to and mitigate any events. Unfortunately, a survey in North America showed that while 84 percent of the responding utilities have formal procedures in place for investigating customer complaints, only 61 percent had a customer complaint database (Deb et al., 2000). This was the case even though these utilities often relied on customer notification for early detection of problems.

A three-year study demonstrated the benefits of certain practices at reducing customer complaints related to water quality from a distribution system in Southern California (Wen et al., 2005). Problems with manganese, old cast iron pipes, and rusty water were addressed by keeping good records of customer complaints and developing a database to sort and track the complaints. These data were then used to show the improvements made by the chosen controls.

One drawback to customer complaints is that they are end-user in origin and so cannot distinguish between contamination originating within the customer’s premise, the service line and local water main, a regional storage facility, or all the way back to the treatment plant and the source water (Burlingame, 1999b). Nonetheless, customer complaints may be the first line of detection of water quality problem short of having an exhaustive and expensive monitoring plan.

TABLE 7-5 Performance Specifications of Commercially Available Sensors

|

Manufacturer |

Dascore |

YSI |

Hydrolab-Hach |

Analytical Technology, Inc |

|

|

Model |

Sixcense |

6-series |

(DS5X, DS5, MS5) |

Series Q45 |

Model A 15/B-2-1 |

|

Brief description |

Multi-parameter, on-line, free chlorine or chloramines |

Multi-parameter, on-line |

Multi-parameter, on-line |

Multi-parameter, customizable on-line |

Free chlorine or chloramines |

|

Cost (US $) |

9,700 |

15,000 |

15,000 |

< 10,000 |

3,000 |

|

Free chlorine (mg per L) |

0–5 |

|

|

0–2, 0–20 or 0–200 |

0–2, 0–20 or 0–200 |

|

Chloramines (mg per L) |

0–20 |

|

|

0–2, 0–20 or 0–200 |

0–2, 0–20 or 0–200 |

|

TOC (mg per L) |

|

|

|

|

|

|

ORP (Volts) |

-1.4–1.4 |

-0.999–0.999 |

-0.999–0.999 |

-0.999–2.0 |

|

|

SC (mS per cm) |

0.1–10 |

0–100 |

0–100 |

0–0.2 and 0–40 |

|

|

DO (%) |

0–200 |

0–500 |

0–200* |

0–40 ppm |

|

|

Turbidity (NTU) |

|

|

0–3000 |

0.001–4 plus other wider ranges |

|

|

PH |

2–12 |

0–14 |

0–14 |

0–14 |

|

|

Temp (°C) |

0–50 |

-5–45 |

-5–50 |

|

|

|

*LDO: luminescent DO measurements. For the bottom nine rows, the values given are the detection ranges of the sensors. SOURCE: Reprinted, with permission, from Bukhari and LeChevallier (2006). © 2006 by American Water. |

|||||

|

Wallace & Tiernon |

Emerson |

Hach |

ProMinent |

In-Situ |

|

|

Depolox 3 plus |

Model 1055 Comp II Analyzer |

WDM Panel or Pipe Sonde™ |

TOC Process Analyzer |

D1C &D2C |

Troll 9000 |

|

Free or total chlorine (or chlorine dioxide or ozone) |

Multi-parameter, customizable, on-line |

Multi-parameter, on-line |

Used with WDM |

Multi-parameter, on-line |

Multi-parameter, on-line |

|

3,500 |

15,885 |

12,000 |

18,000 |

7,000 |

11,200 |

|

0–20 |

0–10 |

0–4 (DPD) |

|

0–0.5, 0–2, 0–10 |

|

|

|

0–15 |

0–5 (total) |

|

0–0.5, 0–2, 0–10 |

|

|

|

|

|

< 5–20,000 |

|

|

|

|

-1.4–1.4 |

-1.5–1.5 |

|

-1.0–1.0 |

-1.4–1.4 |

|

|

0–200 |

0–100 |

|

0–200 |

0–200 |

|

|

0–20 ppm |

0–20 ppm |

|

0.1–10 or 0.1–20 ppm |

0–20 ppm |

|

|

0.001–200 |

1–100 |

|

|

1–2000 |

|

|

0–14 |

0–14 |

|

0–12 |

0–12 |

|

|

|

-5–50 |

|

0–100 |

-5–50 |

Temporal and Spatial Scales for Monitoring

Two important aspects of distribution system monitoring need to be reconsidered by many utilities. The first involves the timing of sampling, which is dictated largely by the method by which samples are taken. Currently most routine water quality monitoring in a distribution system is carried out through manual grab samples followed by analysis in the field or in the laboratory. A grab sample is a single water sample collected at a specific point in time. Essentially all distribution system regulatory monitoring uses this method. For example, samples required under the SWTR are manually collected at sites within the distribution system and manually tested for disinfectant levels in the field. Samples taken to satisfy the requirements of the TCR are also manually collected in the field and subsequently analyzed in the laboratory. Manual sampling is labor intensive, and the number of samples that can be collected is limited by personnel and analysis costs. In addition, grab sampling can only show the water characteristics at the time the samples were taken. Important events (e.g., night-time events) that occur between samples are lost or unusual results may be dismissed (Premazzi and Hargesheimer, 2002). Thus, grab sampling is of limited use as an alert system to warn against potential contaminants that might pose a threat to public health.

Moving from grab-sampling to real-time, on-line monitoring is essential for more expeditious and accurate water quality assessment. This trend is being reinforced because of increased emphasis among water utilities in consolidating and automating data processing and control functions (Premazzi and Hargesheimer, 2002). On-line monitoring has the benefit of providing—in real time— early warning of intentional or accidental contamination, and when fully develop and deployed it could help water utilities take the appropriate actions to safeguard public health. On-line monitoring requires a mechanism for moving the sample water from the distribution system to an instrument, instrumentation for analyzing the water, a mechanism for communicating the results, and a means of assessing the results of the monitoring. As discussed above, relatively inexpensive on-line water quality monitoring instruments are becoming more prevalent (Byer and Carlson, 2005). Additionally, the instrumentation must be periodically calibrated and maintained for quality control/quality assurance to guarantee the reliability of generated data (i.e., minimize false positives and negatives). The issue of minimizing false positives cannot be too strongly emphasized. Unless the individual analyzer false positive rate is kept extremely low (e.g., < 1/1000 analyses), when a large number of analyzers are deployed in a single system there is a high likelihood that most of the “hits” will be the result of false positives (if the occurrence of actual true “hits” is rare). Furthermore, for any given analyzer there is likely to be a trade-off between its specificity (ability to detect specific contaminants) and its sensitivity (ability to detect lower levels of contaminants). The statistics of deploying systems of analyzers with specific false positive and negative rates must be considered during the design of the monitoring program.

A second critical consideration is the location of sampling points. The TCR requires the development of an approved distribution system sampling plan. Unfortunately, there is a requirement for routine access for sample collection to both the primary monitoring site and locations within five service connections up-stream and down-stream of the primary site. This results in decreased monitoring in residential areas of the system where access can be limited. Although use of dedicated sampling stations can be used to overcome accessibility problems in these areas, installation of sampling stations require extra cost and can be prone to vandalism, freezing, and contamination.

Current practices for on-line monitors typically locate these devices on utility-owned property where power, sewer, and telemetry to the SCADA system are available so that the results can be instantly communicated to a central operations office for improved system management. These requirements typically restrict monitoring locations to pump stations, storage tanks, well stations, and perhaps government-owned buildings (all of which, coincidentally, may be high priority areas for monitoring for security purposes because they represent points of easy access). Rather than relying on such “convenience monitoring,” utilities should consider employing more “risk-based monitoring” where sensors are strategically located based on hydraulic flow, the population at risk, and sensitive locations (e.g., hospitals, government installations, etc.). In particular, water utilities should strive to sample areas where water quality may be more prone to intensive deterioration. These areas may include (depending on the system), areas of low flow, areas subject to frequent flow reversal, areas achieving variable blends of waters from different plants, and areas of old and/or deteriorating pipe. Utilities need the technology, regulatory support, and public understanding to customize their routine water quality monitoring programs to accomplish these more risk-based goals.

Recent research has examined algorithms for placing sensors based on population exposed and time and flow for contaminant detection (Berry et al., 2004). Often, there are trade-offs for one approach versus another, such that optimization programs are needed to choose a best overall strategy. EPA’s Threat Ensemble Vulnerability Assessment (TEVA) program is developing an add-on tool in EPANET to allow water utilities to select the optimal number of sensors and identify strategic locations for installation of on-line sensors to maximize public health protection (http://www.epa.gov/NHSRC/news/news111505b.htm). Conceptually, given a spectrum of potential threats or vulnerabilities to a distribution system (from either unintentional or intentional events) it is possible to determine the optimal locations to site a given number of detectors such that the likelihood of detecting such events is maximized. The computational framework uses Monte Carlo simulations to vary parameters, such as the quantity or concentration of contaminant, location of injection, duration (or rate) of injection and the probability of ingesting an infectious or toxic dose of these selected contaminants, to generate threat ensembles (collections of many threat scenarios). These threat ensembles are collectively analyzed to estimate health impact statistics, including mean infections or mean fatalities. The

public health benefits of no sensors in the distribution system have been compared with both utility convenience monitoring and TEVA designs (Table 7-6).

These computer simulations support the use of on-line sensors in providing an early indication of drinking water contamination events. However, achieving the maximum benefits from on-line installation of sensors requires optimization of the number of sensors in the distribution system. Clearly this number is likely to be system specific and will vary depending upon the distribution system network, the number of service connections, the type of service connections (i.e., primarily residential or commercial), the size of the population being served, and the length of the distribution system pipes. Modeling tools like those being developed by the TEVA program and others (Lee et al., 1991; Murray et al., 2004; Ostfeld, 2004; Ostfeld and Salomons, 2004; Uber et al., 2004a,b) are still under evaluation and will likely undergo significant refinement and validation before finalization. However, until these have been adequately tested, sensor deployment at locations serving the highest population densities may be an appropriate initial strategy. Of course, practical considerations, such as access to power, communication lines, waste disposal (from samplers), and equipment security may limit where sampling can be located. Nonetheless, TEVA analyses could be used to delineate which locations, amongst those identified as feasible, would offer the highest protection.

Data Analysis and Reporting

Although on-line monitors can provide a continuous stream of information, the data needs to be analyzed, reported, and stored at some prescribed frequency. For example, a single on-line multi-parameter sensor measuring six water quality parameters every 15 minutes on a 24-hour basis will lead to the

TABLE 7-6 Public health benefits provided by various sensor location strategies

generation of 4,032 data points per week. Thus, timely management and interpretation of large quantities of data are imperative to the efficient utilization of an on-line monitoring system. It can quickly become an onerous task without the aid of interpretative software. It would be desirable for an automated data analysis package to be capable of not only capturing data from on-line monitoring devices, but also able to (1) perform automated trend analysis that would compare real-time data with baseline historic data to define and characterize anomalies and (2) allow user-defined and programmable triggers with automated notification by means of alarms (on cell phones, pagers, or via e-mail). Presently there are only a limited number of options for predicative data management tools, making this an area ripe for research and innovation.

Advanced Monitoring for Contaminant Identification

As discussed above, real-time monitoring is currently not useful for identifying specific contaminants in distribution systems; rather, they determine baseline water quality conditions and look for deviations from historical trends (Hrudey and Rizak, 2004; Watson et al., 2004). On-line sensors that could detect a range of chemical or biological parameters are a number of years away from commercial development or utility utilization. Additionally, there is a need to advance the technology for parameters that cannot be measured in real-time and on-line. Advances in microfluidics, robotics, and miniaturized components are lowering costs and may have the potential to perform analyses for chemical and microbiological contaminants that just a few years ago required sophisticated and expensive laboratory equipment. Ultimately, a multi-tiered monitoring system is envisioned where on-line water quality monitoring sensors would detect a deviation in baseline water quality and draw a side-stream sample that would be automatically analyzed using an advanced “lab-on-a-chip” that can detect multiple contaminants. On-site microprocessors would analyze the results and send an alarm to the centralized SCADA system. While a mobile analyst is dispatched to verify the on-line monitoring results, the centralized event management software is checking other on-line monitors, customer service, and operational databases for any other anomalies to determine potential causes and a range of corrective actions.

Although the above description of distribution system monitoring is years away from implementation, some water utilities have begun developing elements of what will likely evolve into the envisioned comprehensive monitoring program. For example, the Arizona Department of Environmental Quality has partnered with the Tucson Water Department, the University of Arizona, and several Pima County agencies, businesses, and organizations to provide citizens with on-line information about drinking water quality. The effort was made possible by an Environmental Monitoring for Public Access and Community Tracking (EMPACT) grant from EPA. System monitoring focuses on three components: water quality parameters that are common to all water systems;

specific water quality parameters that focus on public health in water and wastewater treatment; and the volume of water flowing through the cycle. The monitored parameters include pH, conductivity, temperature, hardness, sodium, and total dissolved solids. Additional parameters important for public health include coliform bacteria, disinfectant residuals, total trihalomethanes, fluoride, and nitrate. The overall objectives of the project are (http://www.ci.tucson.az.us/water/water_quality.htm):

-

Increase the amount of water quality testing by continuous on-line sampling

-

Improve the access to water quality data in the potable distribution system

-

Provide information for customers by identifying specific constituencies and methods to individualize data by location

-

Create a context for understanding water resources data, thus removing misperceptions

-

Serve as a source of reliable, authoritative information on fast-breaking water quality issues

The automatic monitoring stations are currently running and continuously updating water quality data on a map-based website; this program is a model for other utilities.

How to Interpret Data and Respond to Monitoring Data

Given a stream of data from a monitoring program, a critical task is to determine whether the results indicate an “event” or “problem” and if so, how utilities should respond. The occurrence of alterations may be ascertained by formal statistical tests (Ortiz-Estarelles et al., 2001), of which there are several types. The presence of outliers (from historical past behavior) can be ascertained using statistical quality control methods (Egan and Morgan, 1998; Lalor and Zhang, 2001). There can be tests of trends to determine if a systematic drift in water quality has occurred. The underlying concept is to assess water quality using a statistical process control concept. To do this, a utility needs to assess what the “normal” water quality, and its fluctuations, might be. Furthermore, water quality data streams require site-specific “tuning” of software in order to detect unusual deviations, and there has been reluctance on the part of some vendors to disclose their tuning and detection algorithms.

There are other fields in which similar problems to the one outlined above have been experienced; it is possible that the methods used in their solution could be adapted. These include the following:

-

Identification of financial enterprises that are on the verge of difficulty (Booth et al., 1989)

-

Assessment of machine malfunctioning (Javadpoour and Knapp, 2003)

-

Detection of outliers in chemical (Egan and Morgan, 1998) and geochemical (Lalor and Zhang, 2001) data

-

Structural health monitoring (Omenzetter et al., 2004)

-

Detection of computer intrusion or other unwarranted use of computer resources (Lazarevic et al., 2003)

There are several broad approaches to the problem of identifying unusual observations in time series of multivariate data that have been outlined in the literature. These include (1) distance and generalized distance approaches, (2) regression approaches, and (3) neural network approaches. In distance and generalized distance approaches, an observation is regarded as unusual if it is away from the typical population of observations. There are a number of design alternatives for this strategy including the following:

-

Euclidean versus other distance scales

-

Transformation of variables prior to evaluation (including rank transformations and extraction of principal components)

-

Use of direct versus cross-validation distance

-

Choice of criteria to call an observation unusual (false positive and negative rates that are deemed acceptable)

-

Use of “de-trending” or other preprocessing steps to eliminate non-stationary components of the data.

These methods have been reviewed and discussed by Egan and Morgan (1998) in the context of interpreting analytical chemistry data. These authors discuss use of trimming, distance measurements, use of sub-sampling and test various approaches against sample data from the literature, and specifically recommend against the use of ordinary distance measurements and Mahalanobis distance measurements (i.e., distance scaled by the sample variance/covariance matrix) in detecting outliers. Future research is needed to assess the applicability, sensitivity, and selectivity of the various numerical approaches applied to various combinations of measurements which might be taken in a distribution system.

Utilities deploying advanced monitoring in their distribution systems should do so with a specific response plan developed in advance. There are limited options for responses at the disposal of utilities, including boil-water, do-not-consume, or do-not-use notices, that can be applied for particular sections of a system or system-wide. The response to a detection event from a monitoring network carries risks associated with both false positives and false negatives. If an alarm signal is triggered when an actual system deterioration has not occurred (a false positive) and results in an action such as a “do-not-use” or a “boil-water” notice, there may be consequences associated with unavailability of supply for fire fighting and economic impacts on individuals and businesses. If an alarm signal fails to result when an actual deterioration has occurred (a false negative), then there is a failure to detect and respond to an event and thereby

reduce its impact. The adverse consequences from such false negatives and false positives need to be considered when determining the action levels at which management will respond to monitoring data.

Implementation of an Enhanced, Process-Oriented Monitoring Program

The monitoring program discussed above, which includes pressure and chlorine residual monitoring as well as other parameters as needed, all continuously monitored and with deviations followed up on in a timely manner, represents a considerable step up from what many water utilities may already be doing. This will require an increase in training, supervision, maintenance, documentation, and management. Training will be needed for using new on-line technology and for its data management and interpretation; for using GIS, hydraulic modeling, and other data integration tools; and for identifying deviations in monitoring data and in responding to the deviations to determine if the associated processes are being adequately controlled. New tools, such as on-line water quality analyzers, will need quality assurance and quality control (calibration, maintenance, data approval) in order to provide reliable data. Software will be needed for the data management and integration. Documentation is critical to providing feedback for the whole program; not only must data be recorded but associated information is needed (on maintenance, accuracy, and quality control) to provide an appropriate level of certainty. The monitoring program outlined above will require comprehensive management, with lines of responsibility clearly outlined and funding and staffing adequately provided for. Furthermore, the monitoring program will have to evolve as the distribution system is adjusted and expanded to meet changing demands over time.

At present, a program of real-time monitoring and the use of the advanced technologies discussed in this section is likely to be feasible only for the largest and most sophisticated utilities and not to smaller (and even non-community) systems, which unfortunately are where a large fraction of disease outbreaks are reported. This mismatch highlights the need for further technical development of sensors alongside alternative strategies for protecting water quality (discussed extensively in Chapter 4, 5, and 6) among smaller utilities.

DISTRIBUTION SYSTEM MODELING

Water distribution network (mathematical) models have become increasingly accepted within the water industry as a viable mechanism for simulating the behavior of water distribution systems. They are intended to replicate the behavior of an actual or proposed system under various demand loading and operating conditions. Their purpose is to support the decision-making processes in various utility management applications including planning, design, operation, and water quality improvement of water distribution systems:

-

Planning applications include capital investment decisions to identify and prioritize capital improvements to meet projected growth or to replace aging infrastructure; development of water system master plans to schedule, stage, locate, and size new facilities to support projected growth as well as to analyze the interconnection of separate systems for emergencies; infrastructure rehabilitation and replacement to identify and prioritize water mains that need to cleaned, lined, paralleled (duplicated), or replaced; and water conservation studies to maximize the use of existing supply sources and evaluate sound conservation measures to reduce overall water consumption and capital improvement costs.

-

Design applications include estimation of fire protection capacity (e.g., available flow at 20 psi) to verify compliance with fire protection standards; pressure zone management to keep supply pressures within acceptable ranges in regions with significant differences in elevation; determination of the location and size (or capacity) of new water mains, storage facilities, and pump stations to keep pace with projected growth; and hydraulic transient analysis to identify weak spots and select the optimal combination of surge protection or suppression devices to ensure safe system operation.

-

Systems operations include energy management applications to optimize storage-pumping trade-off and minimize energy costs; emergency planning to develop an effective emergency response program to reduce or eliminate the damage or impact of unplanned outages at wells, pump stations, pipes, storage tanks, and treatment plants; and daily operational and management decisions to optimize use of existing facilities and train system operators.

-

Water quality improvement applications include calculation of water retention time for tanks, travel time in pipes, and the spatial and temporal distribution of water quality throughout the system to predict locations of poor water quality and evaluate improvement measures such as installation of rechlorination facilities and improving reservoir turnover; locating permanent water quality monitoring stations for compliance with federal regulations; and design and implementation of unidirectional flushing programs. Other applications include area isolation during repairs, water loss calculation, leakage minimization, statistical and probabilistic analyses, and, more recently, water security assessment.

Early models simulated hydraulic behavior only and were steady state (static) in nature. But with the advent of more powerful computers and numerical algorithms, extended period simulation (dynamic) models were developed (e.g., Wood, 1980) to simulate behavior under time varying demand and operational conditions, which is necessary because system demands and consequently the flows in the network vary over the course of a day. These models have become ubiquitous within the water industry and are an integral part of most water system design, master planning, and fire flow analyses. In the early 1980s investigators began introducing the concept of water quality modeling (Clark and Males, 1986; Grayman, et al., 1988; Clark and Coyle, 1990), and now most water distribution system models routinely incorporate sophisticated water quality

simulation capability. In addition to hydraulic and water quality simulation, many distribution network models are capable of analyzing water hammer (surge/transient) and tank and reservoir mixing characteristics. Currently available water distribution network models have become very sophisticated and many incorporate Computer Aided Drafting and Design (CADD) and GIS capability as well as interfacing with SCADA and Asset Management Systems (AMS).

This section discusses the basic principles underlying routine hydraulic and water quality modeling in drinking water distribution systems and presents new developments. In addition, integration of network modeling and optimization with a range of information management systems into an effective decision support and utility management and protection system is presented.

Hydraulic Modeling

Hydraulic models simulate flows and pressures throughout the water distribution system and can be divided into four broad categories (Wood et al., 2005a):

-

Steady State Theory: The basic network hydraulic approach, applicable to time-invariant conditions, solves the conservation of mass (at each node) and energy (around each loop) equilibrium expressions using an iterative scheme (e.g., Newton-Raphson) based on known (static) demand loading and operating conditions.

-

Extended Period Simulation (EPS): The second approach, applicable to very slow transients, is called extended period simulation (EPS) or quasi-steady theory, and involves solving a sequence of steady-state solutions linked by an integration scheme for the differential equation describing the storage tank dynamics. Both inertial and elastic effects are neglected. These models have become ubiquitous within the water industry and are an integral part of most water system design, master planning, and fire-flow assessment studies. They also provide flow information used in distribution system water quality models.

-

Rigid Water Column Theory: Another category of unsteady flow is suitable for faster (but still relatively slow) transients and is called rigid water column theory (lumped parameter approach). It considers gradually varied flow and slow moving transients under the assumption that water acts as a rigid-column and elastic properties of the pipe walls are of no consequence. In this approach, the inertia of the fluid in a particular pipe is treated as lumped instead of continuously distributed.

-

Waterhammer (Surge) Theory: The last category of unsteady flow applicable to rapid transients is called elastic or waterhammer theory (distrib-

-

uted parameter approach) and takes into account the elasticity of both the fluid and the pipe walls in the calculations. It represents situations with more rapid and sudden changes in flow velocity (e.g., rapid valve closure, pump trip) that require consideration of liquid compressibility and pipe wall elasticity.

The last three hydraulic modeling categories are known as unsteady (or dynamic) flow analysis. These models can be effectively used to estimate intrusion potential, identify susceptible regions in the distribution system that are of greatest concern for vulnerability to objectionable (low or negative) pressure surges, and evaluate how they may be avoided and/or controlled (Boulos et al., 2005).

Rigorous optimization approaches have been developed and applied to a full range of problems associated with water distribution systems (Boulos et al., 2006). Applications include optimizing network model calibration, satellite treatment (booster disinfection station location and operation), data collection and sampling/monitoring, as well as pump and storage tank operations to minimize energy cost, and valve operation for pressure management and leakage reduction. The optimization methods applied are common between problems and include linear, nonlinear and dynamic programming, and stochastic search procedures.

Water Quality Modeling

Water quality models utilize the flow and velocity information generated by the hydraulic models to predict the temporal and spatial variability of water quality within the distribution system. They can be used to simulate water quality concentrations and water age, and they can perform source tracing through the distribution system. As with hydraulic models, water quality modeling has evolved from the initial development of steady-state models (Wood, 1980; Males et al., 1985; Clark and Males, 1986; Males et al., 1988) to more dynamic models (Liou and Kroon, 1986; Hart et al., 1986; Clark et al., 1988; Grayman et al., 1988). Dynamic water quality models are predicated on extended period simulation quasi-steady network hydraulics, and they solve the equations for nodal mixing and advective transport in pipes to compute the spatial and temporal variation in water quality parameters. Solution methods for dynamic models can be classified as either Eulerian or Lagrangian (Rossman and Boulos, 1996; Clark and Grayman, 1998; Panguluri et al., 2005b). Eulerian methods consider fixed grids or cells and move water to the grid locations or through the cells to represent the movement of a constituent in a pipe. Chemical reactions are included during transport. Lagrangian methods track locations of discrete changes in water quality known as fronts. Front locations are updated at a fixed time step or when a front reaches a junction node. Longitudinal dispersion is neglected and complete mixing at the junction nodes is assumed.

In a distribution system water quality analysis, the constituents of concern may be conservative (e.g., inert) or non-conservative (e.g., reactive). Conservative substances are useful as tracers that are purposely injected, monitored, and modeled to improve model calibration with measured travel times and dilution effects. Non-conservative constituents, such as bacteria, disinfection byproducts, or chlorine, undergo reactions that are dealt with in most water quality models via simple reaction kinetics (Panguluri et al., 2005b).

During the 1990s, advancements focused more on making existing models user friendly and less on improving predictive capabilities. For example, the EPA public domain EPANET model (Rossman et al., 1994; Rossman, 2000) greatly facilitated the easy application of existing water quality models to municipal drinking water distribution systems. In early 2000s, research initiated by Zierolf et al. (1998) and Shang et al. (2002) focused on development and application of control theory-based methods. While distribution system water quality models are forward methods (i.e., they begin at a source and track forward in time and space to determine where a constituent is going), control theory begins at a location of interest and tracks backward in time and space to identify the constituent source. This approach has at least two important uses. The first is developing injection policies; if the disinfection level is unacceptable at a certain location, control theory will determine the relative contributions from alternative booster stations in one analysis rather than performing a series of forward tracer runs. Another application is identifying the potential sources of contamination detected at a downstream monitor. A contaminant that is detected at a given location may be supplied by a number of inlet points and times, and control theory can identify the range of locations and the pipes and nodes that contribute to flow at the monitor. Because of uncertainty due to changing demands and pump and tank operations, these analyses generate a significant amount of data. Fortunately, control theory model analysis can be done on-line, which facilitates data collection and information storage. After the potential sources have been identified, a forward model can be applied to determine the extent of contamination for containment purposes and the need for flushing.

With the recent concern over water distribution systems as part of the nation’s critical infrastructure, research into water quality modeling has become more active, with the intent of developing greater predictive capabilities. For example, EPA has extended EPANET to allow general multi-species reactions. However, the code lacks a user interface at present, it is intended for research purposes, and it is in the beta-testing phase (http://www.epa.gov/nhsrc/pubs/tbEPANet051106.pdf). Other recent developments include the application of transient analysis software (Boulos et al., 2005) and optimization tools for calibration, design, and operational purposes (Berry et al., 2004; Uber et al., 2004a; Murray et al., 2004; Ostfeld, 2004; Ostfeld and Salomons, 2004). An emerging area of research is the incorporation of stochastic analysis to water quality modeling (Buchberger et al., 2003). More complex kinetics can be used to describe multi-component interactions (relating transformation rates to the concentration of other constituents) and are known as multi-component or multi-species mod-

els. Clark (1998), Clark et al. (2001), and Clark and Sivaganesan (1998, 2002) have furthered the development of multi-species and competitive reaction models that could be included in general purpose algorithms such as EPANET. Examples of two promising areas for future research are illustrated by Uber et al. (2004a), which has extended EPANET to allow for modeling the fate and transport of multiple interacting chemical and biological components, and Uber et al. (2004b), which has developed algorithms for optimizing the location of water quality sensors in drinking water distribution systems.

Flushing Models

The last two years have seen the introduction of computerized unidirectional flushing models of water distribution systems (Boulos et al., 2006). Unidirectional flushing models utilize the flow and velocity information generated by the hydraulic models and make use of graph-theoretical algorithms to determine the sequences of fire hydrants and water main valves that should be manipulated to create a one way flow in the water mains while avoiding excessive pressure drops (e.g., below 20 psi) and maintaining the desired level of hydraulic performance in the distribution system. These models also compute the minimum flushing time, total flushing volume and pipe length, and the flushing velocity of every pipe in the sequence.

Modeling of Storage Facilities

The hydraulics and mixing of waters within storage facilities must be properly understood to accurately represent the constituent reactions and the effect of tanks on system water quality. In addition, understanding the mixing characteristics in storage facilities is useful in assessing the likely impacts of an injected contaminant. Tank models simulate both aging and mixing phenomena within distribution system tanks and reservoirs. The most complex is computational fluid dynamic or hydrodynamic modeling that includes a detailed physical tank description and divides a tank into a mesh of small discrete volumes known as finite elements (Grayman and Arnold, 2003). The basic governing laws of conservation of mass, energy, and momentum are written in partial differential form for each element to describe the flow patterns and the distribution of substances through the tank. The remaining approaches are known as systems models. Systems models are classified by the spatial representation in the tank. The simplest model, a continuous stirred tank reactor, considers the tank as a single unit and assumes complete mixing of water within the tank. The next level of detail represents the water in the tank in layers assuming plug flow. The tank is partitioned into several compartments to represent the flow patterns and mixing zones. These are known as multi-compartment tank models (Mau et al., 1995; Clark et al., 1996).

***

All network models are approximate representations of distribution systems, and many sources of error exist that can hinder their ability to accurately simulate actual system behavior. Sources of error can range from measurement and typographical errors to errors derived from system maps or introduced by the skeletal representation of the network as well as uncertainties in some system parameters and boundary (e.g., loading and operating) conditions. Network models should be properly calibrated and validated so that a level of confidence in their predictive capabilities can be established. Box 7-1 discusses these activities in greater detail.

|

BOX 7-1 Calibrating and Validating Network Models A water distribution network model must be properly calibrated before it can be used to support planning, design, operation, or water quality improvement decisions. Calibration establishes the accuracy and credibility of the network model so that its predictions can be interpreted with confidence. It is the process of fine-tuning (adjusting) network model parameters so that the simulated hydraulic and water quality results sufficiently mirror field observations. If the field data and model results are reasonably close, the model is considered calibrated. The objective is to reduce the uncertainty in the model parameters to accurately reproduce actual “real-world” system behavior. To be calibrated, the network model must accurately simulate pressure, flow, tank level, and chlorine residual values within an acceptable tolerance for a range of specified time horizons. Hydraulic parameters that are typically adjusted include pipe roughness factors, minor (local) loss coefficients, isolation valve status, control valve settings, pump curves, base demands, and demand patterns. For water quality models, the parameters include reaction rate coefficients, source quality, and initial conditions. The calibration tolerance refers to the difference between model simulated and actual field values. The smaller the tolerance the greater the accuracy of model predictions. Calibration can be performed to a single time frame such as maximum hour or dynamically such as maximum day for an extended period simulation (EPS). The more calibration time frames, the more accurate the model predictions will be. Common practice is to calibrate the network model first for maximum-hour and minimum-hour static conditions and then in an EPS mode for maximum day. The network model is first calibrated for hydraulic parameters and the water quality parameters are subsequently adjusted. Thus, if the hydraulic model is not properly calibrated, resulting in inaccurate flow and velocity estimates, the water quality model will not perform correctly. Water quality simulations require a dynamically calibrated (EPS) model. Network model parameters can be adjusted manually using an iterative trial-and-evaluation approach or automatically using optimization techniques until the desired degree of accuracy is attained (Panguluri et al., 2005b; Boulos et al., 2006). Although automated calibration methods are becoming more readily available, manual calibration still remains the predominant methodology. However, since there is a vast number of combinations of parameter values that can be considered for adjustment, manual evaluation of all options through trial-and-error is unlikely to be practically feasible or manageable, and even knowledgeable modelers often fail to obtain good results. As a result, model calibration has generally been neglected or done haphazardly. |

|

There are currently no universally accepted standards for calibrating water distribution network models. The extent of calibration will normally depend on the intended use of the model. A greater degree of calibration will be required for models that are used for detailed analyses, such as design, operations, and water quality modeling, than for models used for more general planning purposes (e.g., master panning). The AWWA Engineering Computer Applications Committee (AWWA ECAC, 1999) has proposed a draft set of calibration guidelines for modeling based on intended use. These performance criteria were not intended as true calibration standards, but can serve as a good starting point for illustrating the extent of calibration needed for various modeling applications. These calibration criteria are summarized in Table 7-7. Network model validation follows the calibration process and makes use of an independent field data set for use in verifying that the model is well calibrated. The model must first be calibrated using one or more sets of field data and then validated with an independent set of field data. The degree of confidence in the model increases with the number of independent data sets with which it is validated. Tracer studies can also be used to validate network models. These studies consist basically of measuring the concentration of a tracer over time (e.g., using on-line monitors and grab samples) at various locations throughout the distribution system and comparing observed values with model predictions. The most commonly used tracers are fluoride, calcium chloride, and sodium chloride. The use of tracer studies greatly enhances the ability of network models to accurately estimate water age and travel times in the system. TABLE 7-7 Draft Calibration Criteria for Modeling

The efficacy of calibration and calibration techniques is highly dependent on the quality of the calibration data available and the quality of the constructed network model (e.g., skeletal representation of the network, node elevation, geometric anomalies). Poorly collected field data (e.g., from poorly calibrated measuring equipment) and poorly defined network models will result in inadequate calibrations and unreliable model predictions, and would defeat the whole purpose of the calibration process. |

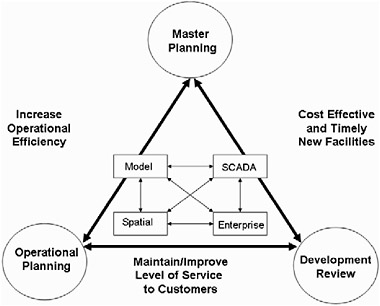

DATA INTEGRATION