2

Regulations, Non-regulatory Approaches, and their Limitations

This chapter provides an overview of the existing regulatory framework as well as non-regulatory approaches that are intended to protect drinking water quality within water distribution systems. Included is a discussion of federal and state statutes and regulations and local codes, along with their limitations. In addition, several non-regulatory programs are described that are intended to complement existing regulations.

REGULATORY ENVIRONMENT

Federal and state statutes and regulations along with local codes are used to establish requirements intended to protect the drinking water quality within distribution systems. The federal Safe Drinking Water Act (SDWA) is the vehicle used nationally to address drinking water quality issues. Prior to the passage of the SDWA, federal involvement in water supply had been limited to development of large multi-purpose water projects and regulation of water quality with respect to interstate carriers. After passage of the SDWA, the federal government became involved in developing national drinking water regulations pursuant to the new law and in conducting research to support these regulations. States implement the federal mandates but also utilize their own statutory and regulatory requirements to protect drinking water quality. For example, the states play a significant role in oversight functions ranging from licensing of water treatment plant operators to the approval of new sources of supply and the approval of new treatment facility design. Local agencies such as health departments, environmental health programs, and building departments implement codes and ordinances that address water distribution systems, most often that portion of the infrastructure not controlled by public water systems. This section provides an overview of the various statutory and regulatory approaches that apply to distribution systems.

Safe Drinking Water Act

The SDWA (Public Law 93-523), enacted in 1974 and amended in 1986 (Public Law 99-339), 1988 (Public Law 100-572), and 1996 (Public Law 104-182), provides the statutory bases by which public water systems are regulated.

Pursuant to the SDWA, the U.S. Environmental Protection Agency (EPA) is mandated to establish regulations for drinking water in the form of either maximum contaminant levels (MCL) or maximum contaminant level goals (MCLGs). MCLs are water quality standards that must be met by utilities and are enforced by state or federal agencies. Unlike MCLs, MCLGs are non-enforceable and are set at a level at which no known or anticipated adverse human health effects occur. Where it is not economically or technologically feasible to ascertain the level of a contaminant, a treatment technique is prescribed by EPA in lieu of establishing an MCL. For example, because the viable concentration of Giardia lamblia is difficult to measure, it has been established that if water is treated at a given pH, temperature, and chlorine concentration for a specified length of time (all of which are verified by the water utility), a fixed level of Giardia inactivation will take place.

The SDWA also provides EPA with the authority to delegate the implementation of the SDWA requirements to the states through the process of primacy. Forty-nine (49) of the 50 states have accepted primacy, with Wyoming being the exception. The SDWA applies to public water systems, which can be publicly or privately owned. Public water systems are defined as providing drinking water to at least 25 people or 15 service connections for at least 60 days per year. As mentioned in Chapter 1, there are approximately 160,000 public water systems in the United States, providing water to more than 290 million people.

Currently, 51 organic chemicals, 16 inorganic chemicals, seven disinfectants and disinfection byproducts (DBPs), four radionuclides, and coliform bacteria are monitored for compliance with the SDWA (EPA, 2005a). Standards for most contaminants are required to be met at the point of entry to the distribution system, such that the SDWA does not directly address distribution system contamination for most compounds. Despite these spatial restrictions, the SDWA does provide EPA with the authority to regulate contaminants within distribution systems—an authority that EPA has used to promulgate several regulations that address distribution system water quality including the Total Coliform Rule (TCR), the Lead and Copper Rule (LCR), the Surface Water Treatment Rule (SWTR), and the Disinfectants/Disinfection Byproducts Rule (D/DBPR).

The 1996 amendments to the SDWA mandated that EPA conduct research to strengthen the scientific foundation for standards that limit public exposure to drinking water contaminants. Specific requirements were given for research on waterborne pathogens such as Cryptosporidium and Norovirus, DBPs, arsenic, and other harmful substances in drinking water. EPA was also directed to conduct studies to identify and characterize population groups, such as children, that may be at greater risk from exposure to contaminants in drinking water than is the general population. In response to that mandate EPA has developed a Multi-Year Plan that describes drinking water research program activities and plans for fiscal years 2003–2010 (see Box 2-1).

|

BOX 2-1 EPA Multi-Year Plan for Drinking Water The Multi-Year Plan establishes three long-term goals:

Some of the tasks in the Multi-Year Plan related to distribution systems include:

SOURCE: EPA (2003a). |

Associated Federal Regulations

There are several federal regulations that are designed to address specific distribution system water quality issues, although none of these regulations deal wholly with the integrity of distribution systems as defined in Chapter 1. The following provides a brief description of each of these regulations.

National Interim Primary Drinking Water Regulations

Following the passage of the SDWA, EPA adopted the National Interim Primary Drinking Water Regulations (NIPDWR) on December 24, 1975 and on July 9, 1976. The NIPDWR established the first national standards for drinking water quality. These standards included limits for ten inorganic chemicals, six organic pesticides, turbidity, and five radionuclides. In addition, the NIPDWR established standards for microbiological contamination based on total coliform organisms.

Total Coliform Rule

The primary purpose of the TCR is to ensure public health protection from microbial contamination of drinking water, and it applies to all public water systems. It is the only regulation that is intended to measure the microbiological quality of water within that part of the distribution system controlled by the public water supply. In 1989 EPA promulgated the TCR as a revision to the existing regulation that required public water systems to monitor for coliform organisms in the distribution system. The TCR changed the concept of monitoring for coliform organisms from one based on measuring the concentration of coliforms to determining the presence or absence of coliforms. In addition, the TCR established an MCL based on the presence or absence of total coliforms, modified monitoring requirements including testing for fecal coliforms or E. coli, required the use of a sample siting plan, and also required sanitary surveys for water systems collecting fewer than five samples per month. The MCL for total coliforms is as follows:

-

For a system serving more than 33,000 people and collecting more than 40 samples per month, a non-acute violation occurs when more than 5.0 percent of the samples collected during the month are total coliform positive.

-

For systems serving 33,000 people or less and collecting less than 40 samples per month, a non-acute violation occurs when more than one sample is total coliform positive in a given month.

-

Any fecal coliform positive repeat sample, E. coli positive repeat sample, or any total coliform positive repeat sample following a fecal coliform or E. coli positive routine sample constitutes an acute violation of the MCL for total coliforms.

The sampling frequency ranges from one sample per month for water systems serving 25 people to 480 samples per month for the largest of water systems serving greater than 3,960,000 people (40 CFR 141.21 & 141.63). Sampling locations, identified in the sample siting plan, are required to be representative of water throughout the distribution system, including all pressure zones and areas supplied by each water source and distribution reservoir.

Trihalomethane Rule

In 1979 EPA promulgated a rule that established a drinking water standard for trihalomethanes (THMs), a group of chemicals produced as a consequence of chlorine disinfection. These chemicals are regulated because of the concern over their potential carcinogenic risk. The drinking water standard set at 0.10 mg/L addressed the total concentration of four specific THMs: chloroform, dichlorobromomethane, dibromochloromethane, and bromoform. This rule was the first to regulate the chemical quality of drinking water in the distribution system. The rule affected public water systems serving greater than 10,000 people because EPA was concerned that smaller systems would not have sufficient expertise available to deal with elevated levels of THMs without compromising microbiological safety. Water systems were required to sample quarterly at a minimum of four points in the distribution system and determine the average concentration of the four sample points. Compliance with the standard was based on the running average of any four consecutive quarterly results (EPA, 1979).

Surface Water Treatment Rule

On June 29, 1989, the EPA published the SWTR in response to Congress’ mandate to require systems that draw their water from surface water sources (rivers, lakes, and reservoirs) and groundwater under the influence of surface water to filter, where appropriate, and to disinfect their water before distribution. The SWTR seeks to reduce the occurrence of unsafe levels of disease-causing microbes, including viruses, Legionella bacteria, and the protozoan Giardia lamblia. The SWTR requires water systems that filter to meet specific turbidity limits, and it assumes that this will achieve reductions in Giardia lamblia cysts (99.9 per cent) and viruses (99.99 per cent). Also, water systems are required to continuously monitor the residual disinfection concentration entering the distribution system, except those serving less than 3,300 people, which are allowed to

collect grab samples. Furthermore, water systems (both filtered and unfiltered) are required to ensure a residual disinfectant concentration of not less than 0.2 mg/L entering the distribution system and to maintain a detectable residual disinfectant concentration in the distribution system measured as total chlorine, combined chlorine, or chlorine dioxide. The use of the heterotrophic bacteria plate count (HPC) is allowed as a surrogate for a detectable disinfectant in the distribution system provided that the concentration of heterotrophic bacteria is less than or equal to 500 colony forming units/milliliter (EPA, 1989). Samples for measuring residual disinfectant concentrations or heterotrophic bacteria must be taken at the same locations in the distribution system and at the same time as samples collected for total coliforms.

Lead and Copper Rule

The LCR was published in June 1991 and is intended to address the concern over chronic exposure of young children to lead in drinking water, the lead being principally from the leaching of the chemical from premise plumbing, fixtures, solder, and flux, and acute effects from copper. Indeed, since June 19, 1986, the use of solder and flux with more than 0.2 percent lead and the use of pipes and pipe fittings with more than 8.0 percent lead in the installation or repair of any public water system or plumbing in residential or non-residential facilities has been prohibited. States are required to enforce these requirements through state or local codes.

Unlike the TCR, which is intended to assess water quality that is representative of the entire distribution system in a dynamic or flowing state, the LCR is predicated on assessing water quality that represents worst case conditions. The LCR established monitoring requirements for tap water at “primary” locations—homes that contain lead pipes or copper pipes with lead solder installed after 1982. These homes were generally identified through a review of permits and records in the files of the building department(s) that indicate the plumbing materials installed within publicly and privately owned structures connected to the distribution system and the material composition of the service connections. The number of required samples depends on the size of the water system. Samples are collected from interior taps where water is typically drawn for consumption and after the tap has been left unused in a static state for a minimum of six hours. Table 2-1 describes the standard and reduced monitoring requirements of the LCR.

The LCR also established requirements for corrosion control treatment, source water treatment, lead service line replacement, and public education. The LCR establishes “action levels” in lieu of MCLs. The action level for lead was established at 0.015 mg/L while the action level for copper was set at 1.3 mg/L. An action level is exceeded when greater than 10 percent of samples collected from the sample pool contain lead levels above 0.015 mg/L or copper levels above 1.3 mg/L. Water systems exceeding the respective action level are

TABLE 2-1 Standard and Reduced Monitoring Requirements of the Lead and Copper Rule

|

System size (number of people served) |

Standard monitoring requirements (number of sites) |

Reduced monitoring requirements* (number of sites) |

|

100,000 |

100 |

50 |

|

10,001 to 100,000 |

60 |

30 |

|

3,301 to 10,000 |

40 |

20 |

|

501 to 3,300 |

20 |

10 |

|

101 to 500 |

10 |

5 |

|

< 100 |

5 |

5 |

|

*Utilities can reduce the number of sampling sites and the frequency of monitoring from the required semi-annual frequency to a lesser frequency if their water system meets the following conditions: Reduce to Annual monitoring if:

Reduce to Triennial Monitoring if:

Reduce to Monitoring once every nine years if:

|

||

required to install corrosion control treatment and conduct lead service line replacement and mandatory lead education.

Information Collection Rule

In May 1996, EPA promulgated the Information Collection Rule (ICR), which established monitoring and data reporting requirements for large public water systems including surface water systems serving at least 100,000 people and groundwater systems serving at least 50,000. The rule was intended to provide EPA with information on the occurrence in drinking water of (1) DBPs and (2) disease-causing microbes including Cryptosporidium (EPA, 1996). EPA used the information generated by the rule to develop new regulations for disinfectants and DBPs (EPA, 2006a).

Operator Certification

Pursuant to the SDWA amendments of 1996, EPA in cooperation with the states was directed to issue guidelines specifying minimum standards for certification and recertification of the water treatment and distribution system operators of all public water systems. The guidelines were required to take into account the size and complexity of the system, existing state programs, and other factors aimed at providing an effective program at reasonable cost to states and public water systems (EPA, 1999). EPA, through grants to the states allocated on the basis of “reasonable costs,” was required to reimburse training and certification costs for operators of systems serving 3,300 persons or fewer, including an appropriate per diem for unsalaried operators who had to undergo training as a result of the federal requirement. States are required to adopt and implement a program for the certification of operators of public water systems that meet or are equivalent to the requirements of the EPA guidelines.

Stage 1 Disinfection and Disinfection Byproducts Rule

On December 16, 1998, EPA published the Stage 1 D/DBPR, making more stringent the existing standard for trihalomethanes as well as establishing new standards for disinfectants and other DBPs (EPA, 1998a). The rule, which applies to all public water systems, lowers the existing TTHM standard from 0.10 mg/L to 0.080 mg/L and establishes new standards for five haloacetic acids (HAAs) at 0.060 mg/L, bromate at 0.010 mg/L, and chlorite at 1.0 mg/L. In addition, the Rule establishes limits for disinfectants including chlorine, chloramine, and chlorine dioxide within the distribution system (via Maximum Residual Disinfectant Levels or MRDLs). For chlorine and chloramines, samples for measuring residual disinfectant must be taken at the same locations in the distribution system and at the same time as samples collected for total coliforms. For chlorine dioxide, samples must be taken daily at the entrance to the distribution system. Compliance with the MRDLs for chlorine and chloramines is based on the annual running average of all monthly samples collected, while compliance with the MRDL for chlorine dioxide is based on each daily sample. Finally, the Rule requires enhanced coagulation for certain systems in order to achieve specific reductions of DBP precursor material (as measured by total organic carbon concentrations).

Interim Enhanced Surface Water Treatment Rule

In December 1998, EPA promulgated the Interim Enhanced Surface Water Treatment Rule (IESWTR) that applied to public water systems serving greater than 10,000 people that were subject to the original SWTR. The IESWTR established a requirement for the reduction of Cryptosporidium and a more strin-

gent turbidity requirement for filtered water supplies, among other provisions. The IESWTR also requires certain water systems to evaluate their disinfection practices to ensure that there will be no significant reduction in microbial protection as the result of modifying disinfection practices to meet MCLs specified by the Stage 1 D/DBPR. In addition, the IESWTR requires that all finished water storage facilities, for which construction began after February 16, 1999, be covered. EPA further indicated that it would consider whether or not to require the covering of existing reservoirs during the development of subsequent microbial regulations (EPA, 1998b).

Long Term 1 Enhanced Surface Water Treatment Rule

In 2002 EPA promulgated the Long Term 1 Enhanced Surface Water Treatment Rule (LT1ESWTR). The LT1ESWTR applies to public water systems that use surface water or groundwater under the direct influence of surface water and serve fewer than 10,000 persons. The purposes of the LT1ESWTR are to improve control of microbial pathogens, specifically Cryptosporidium, in drinking water and to address risk trade-offs with DBPs. The LT1ESWTR requires systems to meet strengthened filtration requirements as well as to calculate benchmark levels of microbial inactivation to ensure that microbial protection is not jeopardized if systems make changes to comply with requirements of the Stage 1 D/DBPR (EPA, 2002a). The only difference between this rule and the IESWTR is the size of the affected community.

Stage 2 Disinfectants and Disinfection Byproducts Rule

On January 4, 2006, EPA adopted the Stage 2 D/DBPR that makes more stringent the previous rule regulating certain DBPs. Under the Stage 1 D/DBPR water systems are allowed to average the DBP sample results from across the distribution system. As a result some customers could be exposed to levels of DBPs that consistently exceeded the MCLs and that might escape detection. The new rule requires that water systems meet the MCLs for THMs and HAAs at each sampling location based on the running annual average of any four consecutive quarterly sample results at that location. The intent of this change is to reduce DBP exposure and provide more equitable health protection and to lower potential cancer, reproductive, and developmental risks (EPA, 2006a).

To determine the locations within the distribution system where the highest levels of THMs and HAAs are expected to occur, the Rule requires water systems to conduct an Initial Distribution System Evaluation. Initial Distribution System Evaluations are studies that evaluate THM and HAA levels at various points within the distribution system. The results from these studies along with existing compliance monitoring information will be used to determine future compliance monitoring locations.

Long Term 2 Enhanced Surface Water Treatment Rule

On January 5, 2006, EPA adopted the Long Term 2 Enhanced Surface Water Treatment Rule (LT2ESWTR). The LT2ESWTR applies to public water systems that use surface water or groundwater under the direct influence of surface water. The purpose of the LT2ESWTR is to reduce disease incidence associated with Cryptosporidium and other pathogenic microorganisms in drinking water. The LT2ESWTR supplements existing regulations by targeting additional Cryptosporidium treatment requirements to higher risk systems based on actual monitoring data of source water quality.

The LT2ESWTR also contains provisions to mitigate risks from uncovered finished water storage facilities. Water systems with uncovered finished water storage reservoirs are required to cover the reservoir or treat the reservoir discharge to the distribution system to achieve inactivation and/or removal of at least 2-log Cryptosporidium, 3-log Giardia, and 4-log virus (EPA, 2006b).

Finally, to ensure that systems maintain microbial protection as they take steps to reduce the formation of DBPs the LT2ESWTR requires water systems that proposed to modify their disinfection process to reduce THMs and HAAs to assess the existing levels of disinfection that the system provides. Systems are required to establish a benchmark, which is the system’s lowest monthly average microbial inactivation. If the benchmark is more than the required inactivation of 3-log removal for Giardia and 4-log removal for viruses, the system may consider decreasing the amount of disinfectant added or the contact time, or altering other disinfection practices to lower THM and HAA levels (EPA, 2006b).

Unregulated Contaminant Monitoring Rule 2

On August 22, 2005, EPA proposed the second of two Unregulated Contaminant Monitoring Rules (UCMR2), which will require monitoring for a list of 26 chemical contaminants suspected to be present in drinking water. The purpose of the UCMR2 is to develop data on the occurrence of these contaminants in drinking water, the size of the population exposed to these contaminants, and the levels of the exposure. This information will be used along with health effects information to determine whether or not drinking water standards should be established for these contaminants. All community water systems and non-transient, non-community water systems serving more than 10,000 people will be required to monitor, while a representative sample of 800 community water systems and non-transient, non-community water systems serving less than 10,000 people will have to carry out monitoring. The monitoring is proposed to begin in 2007.

Unlike the first UCMR (which is not discussed above), the UCMR2 will include contaminants that are considered potential DBPs and for which monitoring will be conducted in the distribution system. These contaminants include the nitrosamines N-nitroso-diethylamine (NDEA), N-nitroso-dimethylamine

(NDMA), N-nitroso-di-n-butylamine (NDBA), N-nitroso-di-n-propylamine (NDPA), N-nitroso-methylethylamine (NMEA) and N-nitroso-pyrrolidine (NPYR). Nitrosamines are considered potential human carcinogens, and NDMA has been shown to form in chlorinated or chloraminated water as a result of disinfection (EPA, 2005b).

Water Security-related Directives and Laws

Although not a new issue, security has become paramount to the water utility industry since the events of September 11, 2001. The potential for natural, accidental, and purposeful contamination of water supply has been present for decades whether in the form of earthquakes, floods, spills of toxic chemicals, or acts of vandalism. For example, in May 1998, President Clinton issued Presidential Directive (PDD) 63 that outlined a policy on critical infrastructure protection, including our nation’s water supplies. However, it was not until after September 11, 2001, that the water industry truly focused on the vulnerability of the nation’s water supplies to security threats. In recognition of these issues, President Bush signed Public Health Security and Bioterrorism Preparedness and Response Act of 2002 (the “Bioterrorism Act”) into law in June 2002 (PL107-188). Under the requirements of the Bioterrorism Act, drinking water utilities are required to prepare vulnerability assessments and emergency response plans for water systems serving at least 3,300 people.

***

Table 2-2 summarizes the key requirement(s) of federal rules and regulations from a distribution system perspective.

State Regulatory Programs

State regulatory programs that address water distribution systems can vary significantly. In general most states have statutory and regulatory requirements that cover (1) design, construction, operation, and maintenance of distribution systems, (2) cross-connection control, and (3) plumbing products certified for use pursuant to American National Standards Institute/ NSF International (ANSI/NSF) standards 60 and 61. Furthermore, most states have adopted a plumbing code that dictates the types of materials that can be used for premise plumbing, although these codes are not generally enforced from a state statutory or regulatory standpoint but rather are implemented at the local county and/or municipal level.

TABLE 2-2 Summary of Regulated Distribution System Requirements

|

Law/Rule/Regulation |

Key Distribution System Requirements |

|

SDWA |

|

|

NIPDWR |

|

|

THM Rule |

|

|

TCR |

|

|

SWTR |

|

|

LCR |

|

|

ICR |

|

|

1996 SDWAA |

|

|

IESWTR |

|

|

Stage 1 D/DBPR |

|

|

Law/ Rule/Regulation |

Key Distribution System Requirements |

|

LT1ESWTR |

|

|

Stage 2 D/DBPR |

|

|

LT2ESWTR |

|

|

UCMR2 (Proposed) |

|

Requirements for Design, Construction, Operation, and Maintenance

Using their existing statutory authority, many states have established requirements for the design, construction, operation, and maintenance of distribution systems. This was revealed in a survey of state drinking water programs conducted by the Association of State Drinking Water Administrators (ASDWA) in March 2003. Of the 34 states responding, the majority reported having some requirements for water-main design and construction, storage facilities and pump station design and construction, and distribution system operation and maintenance (ASDWA, 2003). A summary of the responses is provided in Tables 2-3, 2-4, and 2-5, respectively.

There appears to be less consistency between states, however, regarding the individual elements that each state requires be met. For example, most states have requirements for minimum operational pressures and the types of pipes that can be used, while less than half the states have requirements for storage and handling of pipes and distribution system maintenance plans. Only a small number of states have requirements for nitrification control and storage tank water quality monitoring. States also use different approaches for establishing these requirements. In some cases states have established their own requirements, while in others requirements are based on third party standards such as

TABLE 2-3 Summary of Results from the ASDWA Distribution System and Total Coliform Rule Survey: Water Main Design and Construction

TABLE 2-4 Summary of Results from the ASDWA Distribution System and Total Coliform Rule Survey: Storage Facilities and Pump Station Design and Construction

those developed by the American Water Works Association (AWWA) or the Ten State Standards (ASDWA, 2003).

Cross-Connection Control Requirements

One of most common means of contaminating distribution systems is through a cross connection. Cross connections occur when a nonpotable water source is connected to a potable water source. Under this condition contaminated water has the potential to flow back into the potable source. Backflow can occur when the pressure in the distribution system is less than the pressure in the nonpotable source, described as backsiphonage. Conditions under which backsiphonage can occur include water main breaks, firefighting demands, and pump failures. Backflow can also occur when there is increased pressure from the nonpotable source that exceeds the pressure in the distribution system, described as backpressure. Backpressure can occur when industrial operations connected to the potable source are exerting higher internal pressure than the pressure in

TABLE 2-5 Summary of Results from the ASDWA Distribution System and Total Coliform Rule Survey: Distribution System Operation and Maintenance

the distribution system or when irrigation systems connected to the potable system are pumping from a separate water source and the pump pressure exceeds the distribution system pressure.

Of 30 states surveyed by ASDWA, the vast majority required some sort of cross-connection control program, either through regulations (23 states) or guidelines, that is administered by the Drinking Water Program or as part of the State’s Plumbing Code (ASDWA, 1999). However, these requirements and the authority to implement them vary considerably in terms of how detailed a water system’s program must be, the types of systems (community and/or non-community) required to have a program, and the role the states play in implementing and maintaining a program. Some states rely solely on plumbing codes to address cross connections and backflow, which is problematic because plumbing codes, in most cases, do not require testing and follow-up inspections of backflow prevention devices.

A similar assessment of state cross-connection control requirements by EPA (EPA, 2002b), which is summarized in Table 2-6, demonstrates the variability in state requirements. Based on the EPA review, there are 48 states which have some minimum requirement relating to cross connections in their state administrative code or state law (EPA, 2002b). A number of states do not go beyond these minimum requirements or require public water systems to administer any type of cross-connection control program at the local level. These states tend to rely on community water systems to implement cross-connection control programs. In a few cases, states specify that systems which serve a population of a certain size category must implement a cross-connection control program.

There are five primary elements of an effective cross-connection control program. The first is authority; effective cross-connection control programs must have the legal authority to implement program requirements. Legislation must provide the authority to: (1) enter premises and inspect facilities to determine hazards; (2) install, repair, and test backflow devices; (3) license inspectors to test assemblies; and (4) terminate water service in case of non-compliance. According to the American Backflow Prevention Association State Program Survey (ABPA, 1999), 16 of 26 states require utilities to have the authority to implement program requirements. However, on average only 55 percent of systems required to have an enforceable program actually have one in place.

The second requirement is to inspect facilities and test devices. It is important to conduct site inspections, and the right of entry enables the inspector to identify where a high hazard might exist. The frequency of inspections and testing is typically based on the degree of hazard. A testing program must identify the appropriate standards that a backflow prevention device must meet, and assemblies must be tested by a certified backflow assembly tester. Many states require in regulation some of the critical components that make up a testing program. For example, 35 of 50 states specified a list of design standards that backflow assemblies must meet, and 34 of 50 states stipulated a testing frequency interval for various backflow assemblies in their regulations (EPA, 2002b). A

TABLE 2-6 State Cross-Connection Control Requirements

|

Requirement |

Number of States with Requirement |

|

Does the state have a requirement for the control of cross-connections and/or backflow prevention? |

50 |

|

Is it specified in the requirement that the system must implement or develop a cross-connection control and/or backflow prevention program? |

32 |

|

Does the state require authority to implement a local ordinance or rule for cross-connection control and/or backflow prevention? |

33 |

|

Must the authority cover testing of backflow prevention assemblies? |

27 |

|

Must the authority cover the use of only licensed or certified backflow assembly testers? |

16 |

|

Must the authority cover the entry of the premises for the sake of inspecting the premises? |

14 |

|

Must the authority cover the entry of the premises for the sake of inspecting and/or installing backflow prevention assemblies? |

15 |

|

Does the state require training, licensing, or certification of backflow prevention assembly testers? |

26 |

|

Does the state require training, licensing, or certification of backflow prevention assembly and/or device installers? |

6 |

|

Does the state require training, licensing, or certification of backflow prevention assembly and/or device repairers? |

10 |

|

Does the state require training, licensing, or certification of cross-connection control inspectors? |

19 |

|

Does the state require inspection of backflow prevention devices and/or testing of backflow prevention assemblies? |

37 |

|

Does the state require the system to include recordkeeping as part of cross-connection control? |

34 |

|

Does the requirement include keeping records of hazard assessment surveys? |

11 |

|

Does the state require the system to notify the public following the occurrence of a backflow event? |

3 |

|

Does the state require the local rule or ordinance to allow the system to take enforcement action against customers who do not comply with the cross-connection control and backflow prevention requirements? |

23 |

|

Does the state conduct periodic reviews of cross-connection control programs? |

3 |

|

Does the state regulation or plumbing code require public education regarding cross-connection control and/or backflow prevention? |

7 |

|

SOURCE: EPA (2002b). |

|

fewer number of states included certification specifications for testers in regulation.

A third issue is training and certification. The testing of backflow prevention assemblies by a certified tester is necessary to ensure that the assembly is functioning properly and will prevent backflow. The EPA survey revealed that 26 of 50 states require certification of backflow assembly testers (EPA, 2002b). The states often require the tester to pass a proficiency test and written exam to qualify for certification. A smaller number of states expand their training requirements to program managers, installers, and/or repairers. States rely on plumbers for cross-connection control testers/repairers, survey inspectors, and program managers. Twenty-seven (27) percent of the training was conducted by plumber-affiliated organizations, 15 percent by AWWA-affiliated organizations, 12 percent by state agencies, 6 percent by others, and 40 percent did not specify the source of training.

A fourth important element is record keeping following inspections and testing. According to the ABPA survey, 17 of 26 states require record keeping, and 10 of 26 states indicated a requirement for water systems to report backflow incidents to the state. Additional details are found in Table 2-7.

Public education is a final critical element. According to the ABPA survey, five of 26 states required public awareness of backflow potential as an element of their cross-connection control program. Public education is usually a function of the local water purveyor which may educate the public through bill inserts and special mailings. States also maintain internet sites that educate consumers about cross-connection control programs and the role they play in protecting the public’s drinking water.

TABLE 2-7 ABPA State Survey Results on Record Keeping Requirements

|

Record Keeping Requirement |

Percent of States |

|

|

Number of States that require record keeping |

(17 of 26) |

65% |

|

Records of inventory of backflow assemblies in service |

(14 of 26) |

53% |

|

Records of reports of routine testing of assemblies |

(16 of 26) |

61% |

|

Records of hazard assessment surveys |

(9 of 26) |

34% |

|

Records of enforcement activities |

(8 of 26) |

30% |

|

Number of States which require annual reporting to the States |

(6 of 26) |

23% |

|

Number of States which require reporting of backflow incidents |

(10 of 26) |

38% |

|

SOURCE: Reprinted, with permission, from The American Backflow Prevention Association (ABPA) State Program Survey (1999). © 1999 by ABPA. |

||

At the current time, there is no unified basis from which cross-connection control programs are designed, adopted, and implemented, which is reflected in the immense variability in programs discussed above. EPA has not adopted national cross-connection control program requirements, although the agency has provided guidance on cross-connection control issues for approximately two decades through its Cross-Connection Control Manual. In 2003 EPA published the third edition (EPA, 2003b), which is designed as a tool for health officials, waterworks personnel, plumbers, and any others involved directly or indirectly in water supply distribution systems. It is intended to be used for educational, administrative, and technical reference in conducting cross-connection control programs. Interestingly, the states that have strong cross-connection control programs are generally not in favor of greater EPA involvement because their programs might be compromised. Those states with programs that are lacking, however, could benefit greatly from EPA directives.

An indirect benefit of a cross-connection control program that has an effective inspection aspect is its ability to identify improper customer account information, missing water meters, unauthorized use of water, and illegal connections. This can result in a reduction in lost water and in the generation of more revenue.

Requirements for Drinking Water Products, Components, and Materials

Because of the potential for drinking water products, components, and materials to add contaminants to drinking water, EPA initiated the development of a Drinking Water Additives third party certification program in 1985. The purpose was to establish standards by which products, components, and materials would be tested to ensure that contaminants of health concern would not introduced into drinking water at levels that imposed a risk to the public. The resulting standards—ANSI/NSF Standard 60 and ANSI/NSF Standard 61—were initially adopted by NSF through a consensus standards development process in October 1988. These standards are designed to test products that are added to drinking water (Standard 60) and products, components, and materials that come into contact with drinking water (Standard 61).

ANSI/NSF Standard 61 is the more relevant standard with regards to water distribution systems. Thirty-six (36) states have adopted ANSI/NSF Standard 61 by either statute or regulation and thus require water systems to use only water distribution system products, components, and materials that are certified pursuant to the standard. Eight additional states have policies (but not requirements) that water systems use products, components, and materials that meet the standard (ASDWA, 2004). Standard 61 applies to all distribution system materials (including pipes, valves, coatings, storage tank materials, etc.) as well as to premise plumbing including home water faucets. These standards can be used by water utilities (along with AWWA industry standards) in the specification of materials they purchase or allow to be installed in their systems.

Plumbing Codes

Plumbing codes are used by states, territories, counties, local governments, and any other form of governance which has a responsibility to protect their constituents’ health and safety. Plumbing code requirements do not generally apply to the utility-owned portion of public water systems but rather to residential and non-residential property. Accountability in enforcing the codes primarily resides with the inspection entity, though in many states the licensed plumber and design professionals are also held accountable. Once adopted the codes are used by all sectors of the plumbing industry and public, including inspectors/plan reviewers; contractors/masters; journeymen/apprentices; engineers/architects; material, pipe, and product manufacturers; and certification organizations and test labs. Plumbing codes are usually implemented by the “Authority Having Jurisdiction”, which can be a state agency, county commission, or local building department. In some cases plumbing codes are implemented by agencies of the federal government such as the Army Corps of Engineers, Air Force, or the Department of Housing and Urban Development (Chaney, 2005).

The major plumbing codes include the Uniform Plumbing Code (UPC), the International Plumbing Code (IPC), and the Southern Building Code Congress International. As indicated in Table 2-8, by 1999 47 states had adopted plumbing codes, with the UPC, developed and maintained by the International Association of Plumbing and Mechanical Officials (IAPMO), being the most commonly used code (14 states) (EPA, 2002b). More recent information indicates that the various codes were amalgamated by the year 2000 into the three codes that are in use today: the UPC, the IPC, developed and maintained by the International Code Council (ICC), and the National Standard Plumbing Code

TABLE 2-8 Plumbing Codes Adopted by the States by 1999

|

Plumbing Code |

Number of States Adopting |

|

Statewide Code |

47 |

|

No Statewide Code |

3 |

|

Statewide Codes Adopted |

|

|

Uniform Plumbing Code |

14 |

|

State Code |

7 |

|

International Plumbing Code |

5 |

|

National Standard Plumbing Code |

4 |

|

Southern Building Code Congress International |

4 |

|

Other |

13 |

|

SOURCE: EPA (2002b). |

|

(NSPC). NSPC, published by the Plumbing, Heating, and Cooling Contractors National Association, is adopted in New Jersey and some counties of Maryland but is otherwise not used widely. The UPC has now been adopted in approximately 28 states (Chaney, 2005).

The UPC and IPC have different contents and permit different materials and devices. The UPC, for instance, allows for some piping material that is not permitted under the IPC. The IPC permits air admittance valves not permitted in the UPC. Some venting configurations are permitted in one code and not the other. Both the UPC and the IPC include important cross-connection control requirements intended to prevent contamination of the domestic water supply that is internal to the property as well as to the drinking water delivered by the public water system. Both codes also establish minimum requirements for the separation of water and sewer lines as well as requirements for the disinfection of new or repaired potable water systems. Both codes, however, have certain shortcomings. For examples, the UPC does not prohibit the installation of water service or water distribution pipe in soil contaminated with solvents, fuels, organic compounds, or other detrimental material which could cause permeation, corrosion, degradation, or structural failure of the piping material. The UPC does not require that water service and distribution pipe and fittings conform to ANSI/NSF Standard 61, which is intended to prevent the use of materials that will leach contaminants into drinking water at levels that may constitute a health risk. The IPC requires that all cross-connection control devices be inspected annually including devices that cannot be tested and air gaps, while the UPC only requires inspection of testable devices. Inspection of all devices is preferable to ensure that tampering has not occurred. Both the IPC and UPC have established minimum distances between water supply wells and sewage disposal systems. The distances established by the IPC are less conservative and may not provide adequate protection from potential contamination. A comparison of the two codes with regard to the principal requirements within the codes that address water distribution system integrity is contained in Table 2-9.

The major difference between the UPC and IPC is the procedural process by which the codes are maintained. IAPMO uses an American National Standards Institute (ANSI) consensus development process for the UPC, while the ICC uses a government or inspector only process for the IPC. The ICC predominantly consists of building inspectors from three organizations (Building Officials and Code Administrators, Southern Building Code Congress International, and International Conference of Building Officials) that have been widely involved in developing structural and fire codes for years. The ANSI consensus code development and maintenance process used by IAPMO is open to all interested parties, it is balanced to prevent any one sector of the industry from dominating, and it provides for due process (participants have appeal rights to ANSI) (Chaney, 2005). Given the disparities between the codes, and the possible resulting confusion, efforts are underway to combine the UPC and the IPC into a single model code (IAPMO, 2005).

TABLE 2-9 Comparison of UPC and IPC: Requirements for the Protection of Water System Distribution Systems

In the United States, plumbing codes are adopted in one of two ways: (1) through statutory adoption which usually occurs through the enactment of legislation or (2) through regulatory adoption which occurs upon the implementation of regulations or procedures. At the state level, codes are usually adopted through a public hearing process that allows interested parties to present testimony (Chaney, 2005).

Although states will adopt the UPC or IPC as their base plumbing code, they may amend the code to address specific issues. In addition, plumbing codes may also be adopted at the local county and municipal level that are at least as stringent as the state plumbing code. For example, in Iowa, the state adopted the UPC as the plumbing code but then amended the UPC to add additional backflow prevention provisions including a requirement that cities with populations of 15,000 or greater enact a backflow prevention program with containment by January 1, 1996. Although local jurisdictions in Iowa must adhere to the provisions of the state plumbing code, these jurisdictions may adopt local ordinances or rules and regulations that provide for higher but not lower standards than those found in the state plumbing code (State of Iowa, 2005). As examples, the City of Des Moines, and Linn County, Iowa have adopted the UPC with some modifications. In the case of Linn County the modifications require the examination, qualification, and licensing of plumbing contractors, plumbers, and the registration of apprentice plumbers (Linn County, 2004). In addition, homeowners are prohibited from carrying out plumbing work on their residence unless they pass the County’s homeowners examination.

LIMITATIONS OF REGULATORY PROGRAMS

Existing federal regulations such as the TCR, SWTR, LCR, LT1ESWTR, and the Stage 1 and Stage 2 D/DBP Rules are intended to address only certain aspects of distribution system water quality and are not designed to address the integrity of the distribution system in its totality. Of these regulations, only the TCR may provide some indication of potential problems with distribution system integrity related to microbial contamination. However, the TCR has significant limitations that affect its use as an indicator of distribution system integrity.

TCR sampling requirements are based on water system size and as a result vary widely, from as many as hundreds of samples per month to one sample per month. Each water system is required to develop a sample siting plan that is approved by the state regulatory agency. For larger water systems even a sample siting plan that results in hundreds of samples per month may not adequately cover the myriad of potential points where contamination could occur, such as storage tanks, premise plumbing, and service connections. For smaller systems the sampling is so infrequent that contamination would be easily missed. Although most reported outbreaks associated with distribution systems have occurred in community water systems because of their greater size and complexity, there have been a number of outbreaks associated with noncommunity water

systems that have been attributed to deficiencies in the distribution system. In addition to the problems associated with sample locations and the frequency of sampling, TCR monitoring does not provide real-time information. There are inherent delays between sampling and reporting of coliform results that do not allow for sufficient time to recognize a contamination event and to prevent public exposure and disease transmission. (It generally takes about 24 hours to obtain results from the time of sample collection to the completion of coliform analysis using presently available analytical methods.)

The TCR encompasses only microbiological indicators. With the exception of monitoring for disinfectant residuals and DBPs within the distribution system and lead and copper at the customer’s tap, existing federal regulations do not address other chemical contaminants within the distribution system. Yet there have been a number of examples of waterborne outbreaks associated with chemical contamination (chlordane, ethylene glycol) of the distribution system as a result of cross connections, contamination of water mains during construction, and contamination of storage facilities (Craun and Calderon., 2001; Blackburn et al., 2004).

Some federal regulations are inherently contradictory to one another, as they relate to distribution integrity and maintenance of water quality, such that water suppliers have found it difficult to be in compliance with both simultaneously. For example, the SWTR and TCR recommend the use of chlorine to minimize risk from microbiological contamination. However, chlorine or other disinfectants interact with naturally occurring organic matter in treated water to form DBPs. As a result many water systems have changed disinfectants (generally from chlorine to chloramine) in order to be in compliance with the MCLs for DBPs in the distribution system. The increased reliance on chloramine can be problematic if close attention is not paid to controlling nitrifying bacteria in the distribution system. Biological nitrification can result in the loss of chloramine residual, which may then present a health threat to the consumer (as discussed in Appendix A). Simultaneous compliance with the D/DBPR and the LCR can also create problems for the maintenance of distribution integrity and water quality. Raising the pH of treated water will assist in controlling corrosion (and hence reduce lead concentrations) but may increase the formation of THMs.

In areas where federal regulations are weak, state regulations and local ordinance contribute to public safety from drinking water contamination. States have adopted requirements that address certain aspects of distribution system integrity. All states appear to have provisions for the control of cross connections and/or backflow prevention, although there is considerable variation in how they are implemented and by whom. The majority of states have established regulations within their drinking water programs requiring cross-connection control programs to be implemented by water systems or local authorities, while some have adopted plumbing codes that included the requirements and others have established only guidelines for cross-connection control programs (ASDWA, 2003; EPA, 2002b). In general, very few states provide

dedicated resources for implementing a cross-connection control program but rather incorporate the program activities into the overall public water system supervision program. At best, most states attempt to assess that a water system has an effective cross-connection control program when carrying out a sanitary survey of the water system. However, because sanitary surveys may occur only once every several years, it is difficult to ascertain the level of compliance. A few states track the number of cross-connection control devices that are annually installed and tested while others determine programs effectiveness by the number of backflow incidents reported (ASDWA, 1999).

Although most states have also established requirements for the design, construction, operation, and maintenance of distribution systems, as discussed previously these requirements vary significantly and some states only encourage certain contamination prevention activities while others do not address them at all. For example, some states only encourage the separation of water mains and sanitary sewers to protect the water main from contamination or the disinfection, flushing, testing, and other follow-up actions before returning a water main to service after repairs. Even where states have established extensive requirements, the onus for ensuring implementation is placed on the water system. States do not dedicate resources to routinely oversee that implementation occurs.

Local regulatory programs are implemented through the plumbing code. Because local plumbing codes must be consistent with the provisions of the state plumbing codes, local regulatory programs should have the authorities to address certain distribution system integrity issues including cross-connection control, use of appropriate pipe and other plumbing materials, and separation of water and sewer lines. However, program implementation can vary from one local jurisdiction to another. For example, licensing of plumbing contractors and plumbers is normally part of the local jurisdictions regulatory program. Neither of the two prominent plumbing codes—the UPC and the IPC—address licensing requirements, and there is no national system for licensing of plumbers or plumbing inspectors. There also appears to be no uniformity regarding the training and licensing of personnel who install, maintain, and inspect backflow prevention devices. Yet there are numerous organizations such as AWWA, New England Water Works Association, American Society of Safety Engineers, American Backflow Prevention Association, Backflow Prevention Institute, University of Southern California Foundation for Cross-Connection Control and Hydraulic Research, and IAPMO that offer personnel certifications that address competency.

There also is a significant difference between the approach taken by state drinking water regulatory programs and water systems to ensure high water quality within premises, particularly residential dwellings, versus utility-owned portions of the distribution system. Plumbing codes (UPC and IPC) address requirements for the installation of plumbing fixtures, appurtenances, and backflow prevention devices within premise plumbing where necessary such as to prevent contamination of the public water system (UPC, 2003; IPC, 2003). However, there are no provisions for ongoing inspections or surveillance to en-

sure that modifications to the premise plumbing by the homeowner will not adversely affect the quality of the drinking water, either within the premise or within the water distribution system. Plumbing codes (UPC and IPC) have also never addressed ongoing water quality within the premise. Provisions for periodic premise inspections to check for cross contamination, to ensure that the integrity of the system is being maintained, and to assess premise water quality could be required by local ordinances, but funding mechanisms would have to be created (Chaney, 2005).

Finally, there is no incentive for homeowners to keep their premise plumbing in compliance with codes. Houses are built to code but many fall out of compliance due to age and as the code changes. In addition there are no organizations that advise homeowners on how to maintain their plumbing systems such as when flushing is necessary, water temperature recommendations, home treatment devices, etc. (Chaney, 2005). A further discussion of issues associated with premise plumbing and possible solutions can be found in Chapter 8.

VOLUNTARY AND NON-REGULATORY PROGRAMS THAT INFLUENCE DISTRIBUTION SYSTEM INTEGRITY

Voluntary and non-regulatory programs exist that are designed to provide public water systems with approaches for maintaining and improving distribution system integrity. There are several objectives of these non-regulatory water quality improvement programs for water supplies, foremost among them being to further protect public health and to engage in risk management efforts beyond what is provided by federal, state, and local regulations and the enforcement system developed for primacy agencies. A related motivation for a utility to implement such programs is to help organize their many activities—i.e., to have a unifying umbrella that encompasses all of the piecemeal requirements of the federal, state, and local regulations. A second important objective of these programs is to increase customer satisfaction, which is based largely on a perception of the quality of service and the cost and quality of the delivered product. One common theme among these programs is their intent to assist utilities in identifying best practices and then affirm that the utility is employing these practices. Examples of best practices include continuing or expanding monitoring of water quality and setting up water quality goals, engagement in plant optimization projects, studies on applicability of emerging technologies, and proactive preparation for upcoming regulations—activities that, along with routine operation, compliance monitoring, and maintenance, are often collectively described in a utility’s distribution system management plan (if one exists). Voluntary and non-regulatory programs can also help utilities to improve efficiency, as manifested in responsiveness and cost. Performing services at a low cost is desirable but customers and others require a high level of service. A balance must be achieved to satisfy the expectations of regulators, customers, and owners at a reasonable cost.

Voluntary programs are attractive because although public water systems recognize the need for health and environmental regulations to protect the public, utilities (particularly larger ones) seek the flexibility to undertake activities that will achieve these goals within the broader existing regulatory framework while reducing the need for intensive regulatory oversight. Programs such as voluntary accreditation are being designed that will allow water systems to implement industry best practices that go beyond regulatory requirements to produce a drinking water quality that exceeds the minimum established by law.

Given the need to improve public confidence in drinking water quality, water systems can use the recognition that they receive from implementing these voluntary programs to promote these efforts to their customers. In particular, water systems can communicate how they are achieving their water quality goals along with an increased level of service without the need for a significant increase in cost to their customers. Water systems are also able to demonstrate that the product that they are providing not only exceeds regulatory requirements but competes equally with other sources such as bottled water, vended water, and home treatment devices, at far less cost.

A few select voluntary, non-regulatory programs are described below, including accreditation, Hazard Analysis and Critical Control Points (HACCP) Plans, and Water Safety Plans, that can serve as guides to water utilities that want to improve their distribution system management. Note that the Partnership for Safe Water and QualServe, two voluntary AWWA programs that target drinking water quality, are not discussed because distribution systems are not their primary focus. QualServe uses self-assessment and peer-review methods to identify opportunities for improvement in water and wastewater utility services, while the Partnership for Safe Water focuses on water treatment plant optimization.

Accreditation Standards

Currently, there is no nationwide system that accredits water utilities. However, a voluntary, nationwide accreditation program for all water utilities, including small utilities, is currently under development by AWWA. The basis of the program is to verify the application of standards and best practices that will ensure the delivery of high quality services, exceeding regulatory compliance. The program will be carried out by independent auditors who will verify conformation with the accreditation standards on-site. The goals of the program are not only to improve customer satisfaction, but also to provide a tool for regulatory agencies to use in evaluation of water utilities and to encourage utilities to evolve beyond seeking compliance with existing regulations to seeking the best strategies to protect public health.

The accreditation standards developed so far are water treatment plant operation and management (G100), distribution system operation and management (G200), and source water management and protection (G300). (After piloting

the implementation of these standards at both large and small systems in August 2005, other areas of accreditation standards will be developed.) The Distribution System Operation and Management Standards (G200) (AWWA/ANSI, 2004), published in May 2004, are intended to improve distribution systems’ water quality and utility’s management efficiency by voluntarily adhering to standards that exceed current regulatory requirements and by performing independent audits to verify performance. The standards call for development of water quality sampling plans at prescribed sites in distribution systems. Nitrification control; booster chlorination; internal corrosion monitoring and control; reduction of the formation of DBPs; and color, taste, and odor monitoring and control are defined as programs that should have individual goals and action plans established specifically for each utility. Distribution system management activities listed in the standard include system pressure monitoring, backflow prevention, permeation prevention, water loss minimization, valve exercising and replacement, fire hydrant maintenance and testing, maintenance of coatings and linings, water use metering, external corrosion control, water quality monitoring, and energy management. The verification step of the standard includes providing certain required documents and records. For those utilities that decide to develop a distribution system management plan that meets the AWWA G200 standard, conformance would be verified on a periodic basis. Because G200 provides a comprehensive framework in which a water utility can manage distribution system integrity and it targets those activities felt by the committee to be of highest priority in reducing public health risks, it is further discussed in Chapter 7.

Hazard Analysis and Critical Control Points

Voluntary programs that deal with water quality and management issues from the perspective of risk evaluation and reduction are being adapted to drinking water treatment, operations, and distribution from other branches of the industry. An example is the Hazard Analysis and Critical Control Points (HACCP) program, which was developed by NASA in the 1960s for the U.S. space program, later transferred to food safety, and recently formatted for drinking water quality. The program relies on three steps, which are addressed continuously in a cycle: hazard identification, remediation, and verification. HACCP for the drinking water industry is based around the same seven principles as were developed for NASA and other industries (NASA, 1991; Codex Alimentarius Commission, 1993, 1997; Mucklow, 1997). The HACCP principles are to:

-

Identify hazards and control measures

-

Identify critical control points

-

Establish critical limits

-

Identify monitoring procedures

-

Establish corrective action procedures

-

Verify and validate the HACCP Plan

-

Establish record keeping and responsibility

HACCP is a risk management program because utilities use it to first identify and evaluate hazards/risks, and then to establish control systems to minimize the occurrence and effects of incidents that may impact the safety and quality of the water. A water utility can choose to apply HACCP to any one “process”—i.e., watershedprotection, treatment, or the distribution system. Some utilities may already have good watershed protection programs and good control over treatment facilities, and so may view the distribution system as a priority. However, because HACCP is a proactive approach to system management that helps the utility to identify “hazards” further upstream, it works quite well as a comprehensive system plan, from source to tap. For maximum benefits, it is important to leave the decision to individual utilities and not be too prescriptive about how to apply HACCP (Friedman et al., 2005).

A recently completed project sponsored by the AWWA Research Foundation (Friedman et al., 2005) describes HACCP pilot studies conducted with three utilities’ distribution systems—Greater Cincinnati Water Works, Cincinnati, Ohio; Calgary Water Works, Calgary, Alberta; and the City of Everett, Everett, Washington. Training workshops were held at each utility location to explain HACCP terminology and to initiate development of the utility’s HACCP plan. Each participating utility formed a HACCP team to further develop the HACCP plan and to guide its implementation. The goal was for each utility to implement their HACCP plan over a 12-month period during which certain operational and water quality parameters would be monitored. The participating utilities found that the implementation of HACCP to water supply distribution was feasible and practical, but that the time and resource requirements were greater than originally anticipated. The development of the HACCP plan was useful in honing in on the most important risks and process controls for water quality management. Within the 12-month pilot study period, none of the three participating utilities developed a fully implemented HACCP program for certification. A longer period of time and/or a greater resource commitment was likely to be required before the HACCP systems would be considered fully implemented, complete, and certifiable. Box 2-2 describes two other HACCP case studies in detail, for Austin, Texas, and Burwick, Maine.

NSF International provides HACCP certification to water utilities in the United States through its HACCP-9000 registration program. The program consists of third-party verification of utility HACCP plans, combined with a registration with ISO 9000 standards. However, adoption of the HACCP approach need not be tied formally to such administrative programs. HACCP could be an integral part of a utility’s distribution system management plan, either in addition to or in lieu of G200 (given the substantial similarities between the two programs). In particular, HACCP is useful for improving a utility’s awareness of its existing databases and how it can better manage the information

contained within, and for promoting record keeping and reporting. Critics contend that HACCP is little more than properly operating a distribution system. Indeed, there may be little value added in the United States where utilities are relatively heavily regulated compared to other countries where HACCP has been successfully adopted (such as Australia, which has no national water quality standards). However, advocates contend that the part of HACCP that most utilities do not already engage in is checking to verify that actions are working (Martel, 2005). Furthermore, HACCP puts an increased focus on operator training, which can be ignored in the face of so many other competing activities, like compliance monitoring. The program is more likely to be adopted by larger-size utilities because of the need for a larger staff and budget to carry out HACCP.

Nonetheless, there is another practical consideration that makes G200 a more attractive organizing program for distribution systems than HACCP. Programs like HACCP are ideally suited to industries that experience little variation on a day-to-day basis (such as food and beverage processing plants) and are not as easily adapted to the dynamic nature of drinking water distribution systems that may experience changes in water quality depending on season, source of supply, and changing daily demands. Furthermore, unplanned disruptions such as water main breaks require immediate responses in areas that may not be considered critical control points, making it very difficult to proactively control contamination events. Finally, the vast number of locations within a distribution system that could be potential critical control points (presumably every residence where a cross connection exists) argues against the formal adoption of HACCP.

The cost of creating a HACCP plan for a community of 10,000 may be in the range of $10,000, including a day- or two-day-long workshop.

Water Safety Plans

In 1994, the World Health Organization (WHO) adapted the HACCP program through Water Safety Plans, which can be prepared for individual water systems. The WHO’s Guidelines for Drinking Water Quality (2004) describe an approach to follow in preparing Water Safety Plans. The approach is to identify, prioritize, and prevent risks arising from hazards associated with distribution of drinking water. The three critical components of a water safety plan are:

-

System assessment regarding both the quantity and quality of supplied water

-

Identification of control measures

-

Management plans describing actions during both normal and extreme conditions and documenting, monitoring, communication, and improvement efforts.

|

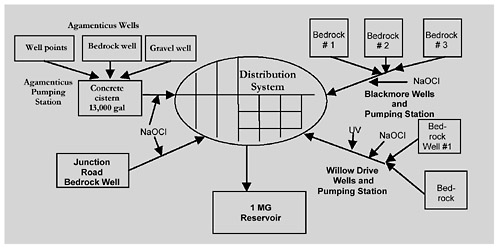

BOX 2-2 HACCP Case Studies There are few case studies of where HACCP has been applied to distribution system management. One involves a relatively small utility, the South Berwick Water District, in South Berwick, Maine, which serves about 4,000 people. At this utility, a HACCP training workshop was held on June 2003 to assemble the HACCP team, which included the superintendent, foreman, and a service person, as well as outside experts such as an engineer familiar with the South Berwick system, a microbiologist from EPA, a state regulator who was an expert on cross-connection control, and a risk manager from the bottled water industry. As in other cases where HACCP has been applied, assembling a team that has as many people from different cross sections of the water utility as possible is one of the benefits of doing HACCP, but because of the small size of the utility this required outside assistance. The process flow diagram for the entire water system is shown in Figure 2-1.  FIGURE 2-1 Process Flow Diagram for the South Berwick Water District. SOURCE: Reprinted, with permission, by Martel (2005).© 2006 by AwwaRF. Three priority hazards were identified by the HACCP team, two of which involve the distribution system: (1) backflow through unprotected cross connections, (2) long dead-end mains with zero or poor disinfectant residual, and (3) unintentional contamination of shallow well points at the Agamenticus Wellfield. It should be noted that it was very difficult to gather enough information to determine the frequency of occurrence or the severity of these hazards, given the utility’s lack of data. For this reason, South Berwick’s initial HACCP plan focused on monitoring activities to further characterize these hazards and improve existing control measures. Unfortunately, the HACCP plan was not fully implemented because of a lack of manpower and because of other priorities. With only three full-time employees at the utility, daily system operation and maintenance took priority over HACCP plan implementation. Furthermore, the utility personnel were involved with building a new treatment facility, developing a new rate structure, and addressing local and state political issues. This case study illustrates the need for sufficient manpower to successfully implement a HACCP Plan. A second case study is from Austin, Texas, a much larger water supply that serves approximately 770,000 people. The interdisciplinary HACCP team consisted primarily of inhouse staff: the water quality manager, the water laboratory supervisor, an engineer |

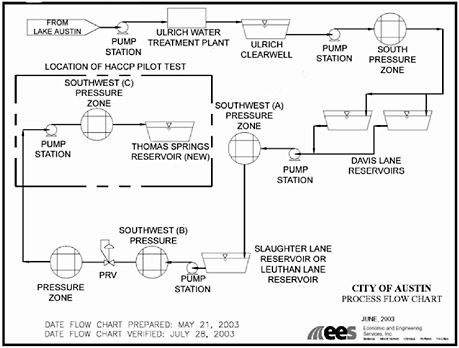

|

/planner, a construction inspector, the cross-connection control supervisor, the Assistant Director of Treatment, the Infrastructure Superintendent, and a state regulator. A HACCP pilot study was conducted from May 2003 to September 2004. The team focused on one pressure zone within the distribution system for the HACCP pilot study (see the flow process diagram below in Figure 2-2):  FIGURE 2-2 Flow Process Diagram for the Austin Water Supply. SOURCE: Reprinted, with permission, from Martel (2005).© 2006 by AwwaRF. Austin’s HACCP team identified two high priority hazards: backflow through unprotected cross connections (focusing specifically on irrigation and hydrant vandalism) and contamination from new construction sites (primarily via improper valve turning). Austin found that HACCP is more complex than initially envisioned. Originally, the utility thought that HACCP would involve identifying critical flow paths within the distribution system and monitoring these flow paths more intensively to assure water quality to downstream sites. Instead, by nature of the selected hazards, the measures used to control these hazards focused on operations and maintenance activities rather than water quality monitoring. This approach added layers of complexity to the existing monitoring program. On a positive note, the HACCP approach helped the utility (1) improve understanding of their distribution system hazards; (2) heighten employee awareness of pressure zone boundaries, pressure transients, the need to maintain pressure and to respond quickly to main breaks in small pressure zones; (3) improve awareness of existing databases and monitoring programs; (4) improve data management skills; (5) identify needed improvements to existing databases; and (6) improve reporting procedures for acceptance of new mains. SOURCE: Martel et al. (2006). |

Water safety plans present an affordable risk management tool for all drinking water suppliers, regardless of size. While some critical elements of the plan should be assured by all systems, more costly or time-consuming elements, characterized as not critical, may be added to the plans based on budgetary and staff availability. The most critical elements of the water safety plan documents include system description, water flow diagrams, hazard identification, identification of a team, and contingency plan. Additional items include specification of chemicals and materials, job descriptions for staff responsible for individual operations, corrective actions for deviations, record-keeping procedures, validation data, and incident documentation procedures. Finally, optional elements may include manuals for hygiene, preventive maintenance, and equipment calibration; job descriptions for all staff; training programs and records; documentation of corrective actions, audits, and verification procedures; and consumer complaint policy and procedures.

Clearly, the elements of a Water Safety Plan closely resemble the elements of a HACCP Plan: (1) source-to-tap system assessment; (2) control measures for identified hazards and operational monitoring of control measures; and (3) a management plan that documents the system assessment, control measures, monitoring plan, corrective action procedures to address water quality incidents, communication plan, and supporting programs such as standard operating procedures, employee training, and risk communication. Both HACCP and Water Safety Plans should be used continuously.