5

Nuclear Power

Nuclear power could make a substantial contribution to the base-load electrical system of the United States in the intermediate term. Advanced converters or fission breeders could enlarge this contribution, and extend it many decades or thousands of years. Nevertheless, the expansion and further development of nuclear power face uncertainties and controversies.

-

The demand for electricity is difficult to predict.

-

The amount of uranium that will be available to fuel the present generation of reactors at economical prices is uncertain.

-

The safety of nuclear reactors is a controversial topic.

-

Policies for disposal of radioactive waste have not been developed, and delay in their development has heightened concern about the efficacy of proposed methods.

-

The possibility that terrorists or other groups might divert nuclear materials is a matter of concern. The degree of protection that can be achieved against diversion has been discussed and argued without resolution.

-

The contribution nuclear power might make to increasing or decreasing the risks of nuclear weapons proliferation and nuclear war is controversial, and the obvious importance of this issue makes it a matter of urgent concern.*

|

* |

See statement 5–1, by E.J.Gornowski, Appendix A. |

These and related issues are addressed in this chapter. We first present a summary statement and principal conclusions. The balance of the chapter takes up these items in detail.†

SUMMARY

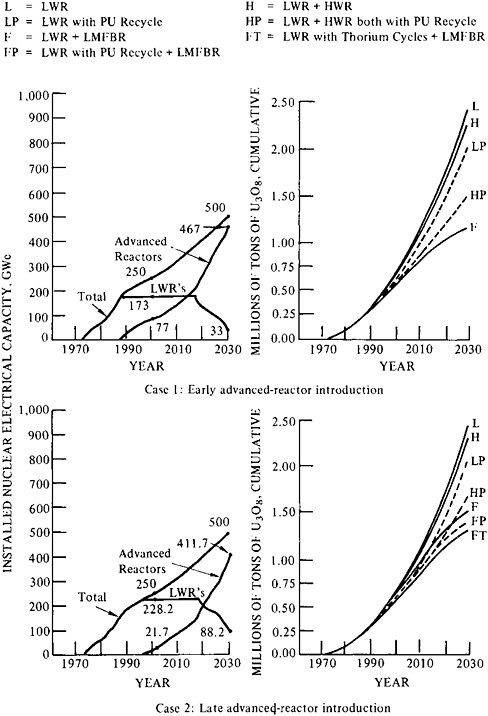

Nuclear power contributes to diversity in the sources of energy on which the United States can draw. In 1978, 66 light water reactors (LWR’s) supplied close to 13 percent of the electricity generated in the United States. In some regions of the country, the share of electricity generated by nuclear power exceeded 40 percent. The distribution of nuclear plants is illustrated in Figure 5–1. The generating capacity of nuclear power plants totals 52 gigawatts (electric) (GWe).1

Of the energy sources that can be used to generate large amounts of electricity, only coal and nuclear power offer reasonably assured ability to support significant expansion in electrical generating capacity over the next few decades. The costs of electricity produced from coal and nuclear power are roughly comparable and depend on plant location and financing conditions. Nevertheless, new orders for nuclear power plants were offset by cancellations of previous orders the past 3 years, and this will create a pause in the expansion of nuclear capacity after 1985 unless the licensing of nuclear plants is accelerated and their construction time reduced. The nuclear industry in the United States can produce at least 500 GWe of nuclear generating capacity for installation by the year 2000, and more than 750 GWe by 2010. The actual rate at which this capability will be called upon depends on several factors.

First, there is the question what the demand for electricity will be. The Supply and Delivery Panel evaluated a number of projections and concluded that an annual average growth rate of 4 percent to the year 2010 represents a reasonable figure for planning the growth of electrical capacity.2 This would lead to a total demand for just under 2000 GWe of capacity in 2010, if the total system’s capacity factor is unchanged. In the scenario of highest energy consumption considered by CONAES (assuming constant real prices and 3 percent annual average rate of growth in gross national product (GNP)), the required electrical capacity falls below 1500 GWe in 2010. Assuming a higher rate of electrification, the required capacity might be about 1750 GWe in 2010. (See chapter 11.) Although these projected rates fall below the historical rate of growth, they may still

|

† |

See statement 5–2, by E.J.Gornowski, Appendix A. |

FIGURE 5–1 Nuclear power plants in the United States as of January 1, 1979. Source: Atomic Industrial Forum, Electricity from Nuclear Power (Washington, D.C.: Atomic Industrial Forum, 1979).

be unrealistically high. Models constructed for the CONAES study project lower and declining rates of growth in GNP than the rates experienced in the past.3 The CONAES models have also explored the effects of higher and increasing prices for energy, or equivalent policies. These assumptions lead to scenarios in which the demand for electricity ranges from below present values to just under 3 times present values (2.8 times) by 2010.4

Correspondingly, utility capacity would be between about 400 and 1450 GWe of installed central station power (1978 capacity was 560 GWe). These estimates assume that the fraction of total energy demand satisfied

by electrical end-use remains constant.* In the past, electricity has tended to displace the direct use of fuels at the point of consumption, and the fraction of total energy demand met by electricity has increased.

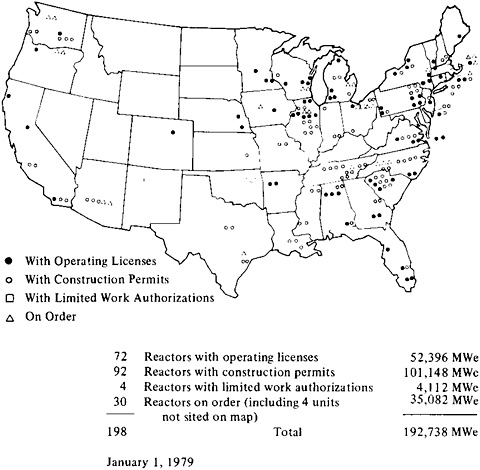

How much of this demand for electricity will be met by nuclear power is also uncertain. Nuclear power has a slight economic advantage over coal. This advantage has good prospects for enhancement, but also has some chance of reversal. Prudent utility planners are likely to plan mixed systems of nuclear power and coal, given these contingencies, but the proportion of each can only be guessed. In addition to cost, planners must also consider the reliability of supply, the stability of regulatory requirements, and prospective public policy. Some considerations will favor nuclear power, others, coal.

A major reservation against too great a reliance on nuclear power may arise from uncertain availability of natural uranium, the primary resource for nuclear fuel. The Uranium Resource Group of this study5 concluded in 1977 that not more than 1.8 million tons of minable domestic uranium oxide (U3O8) reserves and probable resources should be considered as a basis for prudent planning. CONAES has revised its own figure to 2.4 million tons, reflecting higher estimates recently published by the U.S. Department of Energy. (Table 5–1, under the section “Availability of Uranium,” sets out the pertinent estimates.) Translating these figures into nuclear power capacity, 2.4 million tons of U3O8 would meet the lifetime fueling requirements of about 400 GWe of installed capacity, assuming the continued use of light water reactors on once-through fuel cycles. The total nuclear capacity in operation, under construction, or planned in the United States in 1979 amounts to 193 GWe.6 According to the Supply and Delivery Panel, the uranium production rates required to reach installed nuclear capacities much above 200 GWe by 2010 would demand a national commitment to uranium resource exploration and extraction.7

Further expansion and continuation of nuclear power could be accommodated if fuel reprocessing were permitted. The industrial position is that expansion much beyond current commitments would not be undertaken unless the durability of nuclear power were confirmed by commitment to a breeder reactor (or to equivalent fuel production systems, such as accelerator breeders, or fusion-fission devices).† Without firm plans for reactor designs to follow light water reactors, or for fuel reprocessing and recycle, nuclear capacity would have to be gradually phased out as reactors were retired, beginning early in the twenty-first century. However, if (as some resource economists believe) considerably more uranium is found as the price rises, then nuclear capacity could be

|

* |

See statement 5–3, by L.F.Lischer, Appendix A. |

|

† |

Statement 5–4, by E.J.Gornowski: It is unlikely that there is unanimous opinion that no new LWR’s would be built if the breeder were forever excluded. |

expanded even if the introduction of new reactors and fuel cycles were to be postponed.

Some expansion of light water reactor capacity (with a once-through fuel cycle) could also be achieved by reconfiguring the light water reactor to minimize U3O8 consumption, and also by lowering enrichment tails to 0.1 percent or less (see “Uranium Enrichment”). This might raise the allowable capacity in the year 2000 for the same resource base by nearly 25 percent, to 500 GWe.

Another possibility for a more durable industry is to switch from the present generation of light water reactors on the once-through cycle (no reprocessing or other reuse of spent fuel) to reactors and nuclear fuel cycles that make more efficient use of uranium. Under present conditions, only about 0.6 percent of the fission energy potentially available is used. The fission of uranium-235 (235U) contributes 0.4 percent, and the fission of plutonium-239 (239Pu) created in the reactor contributes 0.2 percent. If the spent fuel removed from the reactor were reprocessed, and the 235U and 239Pu recycled in fuel, the use of uranium could be raised to 0.9 or 1 percent. Such reactor types as the Canadian CANDU or advanced high-temperature gas-cooled reactors (HTGR’s) could be designed and operated to use up to 2.0 percent of the energy embodied in uranium on a once-through cycle. Combining lower enrichment tails and the possible stripping of existing accumulated tails with the use of the enriched CANDU once-through cycle might further increase the capacity that could be safely committed by 2000, perhaps to more than 525 GWe.

By loading uranium and plutonium into breeder reactors, and recycling the load many times through similar reactors after reprocessing, it is possible to recover perhaps 70 percent of the energy in the original uranium ore—an improvement in energy recovery by about a factor of 100 over light water reactors. This possibility not only multiplies the energy from existing resources (including existing enrichment plant tails), but permits economic recovery of energy from much less concentrated and more widely distributed uranium ores, essentially making uranium a potential source of energy for hundreds of thousands of years.

In addition to recovering a large fraction of the energy in 238U, it is possible to recover the energy in another element, thorium, that is probably 4 times more abundant in the earth’s crust than uranium. The single isotope of thorium, thorium-232 (232Th), can be converted to another fissile isotope of uranium, 233U, in nuclear reactors. Various combinations of thorium-uranium and uranium-plutonium fuel cycles can greatly multiply energy resources.

Making more efficient use of nuclear fuel resources depends on using new designs for reactors and operating these reactors in combination with fuel reprocessing.8 These reactor designs may be divided into two classes:

advanced converters designed for the use of thermal neutrons and generally operating on the thorium cycle, and fast breeders designed for the use of fast neutrons that can generate more plutonium from 238U than they consume in generating power. Breeders can also generate 233U from thorium. Advanced converters using thorium and 233U can be designed to function as thermal breeders. With sufficiently careful design and frequent fuel reprocessing, they can operate without additional fissile isotopes from nature. However, these conditions are not likely to yield economical power generation.9

The breeder design closest to commercial status in the United States and elsewhere is the liquid-metal fast breeder reactor (LMFBR). In the most resource-efficient version, this reactor would be fueled with plutonium separated from the spent fuel of light water reactors and with depleted uranium left behind in the enrichment process for today’s light water reactor fuel. The energy available from uranium already mined and stored as depleted tails from domestic enrichment plants, if used in LMFBR’s, could provide one third to one half of the energy recoverable from domestic coal reserves and resources.

Advanced converters can also extend resources, but unless they are fueled with plutonium from the spent fuel of light water reactors, their operation will require some additional uranium feed. The amount of this required feed can be minimized by frequent reprocessing and by features in the converter designed to hold down the loss of neutrons to fission products, control rods, and structural materials. The advanced converter most widely used in the world is the natural-uranium, heavy water CANDU, developed in Canada. The advanced converters closest to commercial status in the United States are the high-temperature gas-cooled reactor and the light water breeder reactor (LWBR). They both use the thorium-uranium cycle with enriched 235U feed. Both require more uranium for their initial inventories of fuel than light water reactors.10 This uranium requirement can be reduced somewhat by mixing in plutonium from reprocessed light water reactor fuel. Advanced converters require far less uranium ore over their operating lives than light water reactors.

The thorium-233U fuel cycle can be used to greatest advantage in thermal advanced converters, and the uranium-plutonium fuel cycle can be used to greatest advantage in fast breeders. This suggests the possibility of using various integrated fuel cycles: combinations of fast breeders, advanced converters, and light water reactors.

These technical possibilities are unlikely to be realized unless nuclear power is publicly acceptable. Public opinion may show swings and trends in the future, as it has in the past. Public concern about nuclear power has centered on four issues: the safety of routine operation of the nuclear fuel

cycle and of reactors; the possibility and effects of major nuclear accidents; the handling of radioactive wastes; and the production of nuclear bombs by nations or subnational groups using fissile materials obtained from nuclear-powered facilities.

At all stages of the nuclear fuel cycle, some radioactivity is released to the environment. The largest burden from these releases has come from the underground mining of uranium and from the milling process by which uranium is concentrated from its ores. The hazards of uranium mining have been estimated as resulting in about 15 deaths per year per 10,000 miners. The radioactivity in the mine increases the hazard of cancer, although the risk of accidental fatality in mining accidents is higher than the increased cancer risk.11 Per miner-year, the hazards of uranium mining are comparable to those of coal mining, but because the same energy is recoverable from only about 1 percent as much material, the mortality of uranium mining is, per unit of power, far less serious than that of coal mining. (See chapter 9.)

Additional radioactive emissions come from the mill tailings—the residues from the uranium concentration process—which contain over 80 percent of the ore’s original radioactivity. Past practices have been careless, resulting in exposure of the tailings to weathering, which releases some of the radioactivity to the environment, and in their incorporation into concrete and landfill for homes and schools, in extreme cases. Although the total morbidity from such handling has been quite small, these consequences have cast doubt on the seriousness with which the industry and the responsible federal agencies approach the job of protecting the public.*

Other routine sources of emission are the releases permitted from nuclear power plants (within set limits) of materials that have become radioactive, and potential releases of radioactive gases (such as krypton-85 (85Kr), tritium, and carbon-14 dioxide) from reprocessing plants.

All these “normal” or routine releases of radioactivity are estimated to increase environmental radiation by a small fraction of the existing background, and on this basis, their effects per unit of power generated are small compared to the mining risks, or to the risks of other energy sources.†

More controversial is the possibility of reactor accidents. Much of the controversy has focused on the validity of risk assessments made in the Reactor Safety Study for the Nuclear Regulatory Commission (also known as the Rasmussen Report or WASH-1400). This report attempted to

|

* |

See statement 5–5, by E.J.Gornowski, Appendix A. |

|

† |

Statement 5–6, by J.P.Holdren: The statement is too sweeping. NAS estimates prepared for CONAES imply 0.5–2.0 excess cancer deaths per GWe-year from routine exposures and emissions, excluding tailings. |

estimate the probability (per reactor-year of operation) that accidents of varying severity would occur.12 Its stated findings are that the actuarial risks (sums of the probabilities of consequences multiplied by the severity of consequences) are very small, and that the chances of severe accidents that would cause large numbers of casualties are extremely small—so small as to be within the range of risks we hardly deign to consider. Nevertheless, these findings have been challenged on several grounds: that the statistical treatment is in some respects incorrect and in others misleadingly presented; that casualty figures for the most severe types of accidents are underestimated; and that accident frequencies may have been overestimated (industry analysts typically arguing the latter, and nuclear critics, the former).13

The Risk and Impact Panel of this study examined the controversy, but could not reach more than qualitative conclusions. These conclusions are, briefly, that the statistical inferences of the report should be corrected upward, owing to the report’s use of medians rather than means of certain probability distributions where the correct procedure would have been to use the mean values, and that in addition to this upward correction in the “best estimate” of the accident risk, the counterclaims of optimism and pessimism for accident frequencies and consequences ought at least to be interpreted as indicating that the uncertainties accompanying both probabilities and consequences are greater than the uncertainty factors stated in WASH-1400.

We would estimate higher average risks than WASH-1400—not so high as to be alarming, but with sufficient uncertainty that there remain legitimate grounds for controversy whether the risk of reactor accidents ought to be an important consideration in decisions about nuclear power. Thus on safety grounds alone, the expansion of nuclear power would be acceptable,* provided the rate of expansion were consistent with the rate of improvement of knowledge about accident risks, especially reductions in uncertainty.

The reactor accident at Three Mile Island occurred after most of CONAES’s deliberations had been completed. That fact and the fact that several investigations of the accident are still in progress make it inappropriate for CONAES to discuss its implications at length, and impossible to do so with authority. The information so far released about the accident (and interpreted by nuclear specialists on the committee) seems consistent with CONAES’s cautious, positive findings on reactor safety.

Another element of public concern is apprehension about the ability of

institutions and industry to manage or dispose of radioactive wastes. The most acute concern is the fate of high-level wastes generated in reprocessing plants or contained in spent fuel, but the management or disposal of the much larger bulk of intermediate- and low-level waste generated throughout the nuclear industry also raises public apprehension. Most experts are of the opinion that no technological obstacles stand in the way of safe management of any of these wastes,14 but governmental inaction, changes of program and emphasis, and the lack of approved facilities are not reassuring.

In the reprocessing and refabrication of fuel essential to making effective use of resources in advanced converters or breeders on either the thorium or the uranium fuel cycle, fissile material (either 233U or 239Pu) is separated from the spent fuel elements and is thus more readily subject to theft or illicit diversion than if it remained in the spent fuel elements. The appearance of pure plutonium or 233U in some stages of the fuel cycle presents the troubling possibility that weapons-usable material could be stolen by terrorists. Proposals have been advanced for reprocessing methods that avoid separation of plutonium in pure form. These schemes are given the generic name “coprocessing” when the plutonium is chemically mixed with its parent uranium throughout the cycle, and “Civex” when it is given the additional protection of retaining some highly radioactive fission products. Such processes are not now available and would require development.

A graver possibility than illicit diversion is that countries installing reprocessing plants would thereby have the means to build up arsenals of nuclear weapons in short order. This concern is particularly acute for breeder reactors, which have little or no value without reprocessing, and it was this consideration that persuaded the Carter administration to defer both commercial reprocessing and commitment to the fast breeder.

A possible advantage of the thorium-233U fuel cycle for fast breeders or advanced converters (it can be used in either) is that the 233U or 235U used to feed these reactors can be diluted with 238U in a 4:1 ratio (for 235U) or a 7:1 ratio (for 233U), making either undesirable as weapons material without physical isotope separation as well as chemical reprocessing. This is the “denatured” thorium cycle. The efficacy of denaturing is now the subject of extensive debate. It is being studied in the United States and will be studied further in the ongoing program of the International Nuclear Fuel Cycle Evaluation (INFCE).

In spite of the unsettled state of the reactor-safety issue following the Three Mile Island incident (which occurred late in the committee’s deliberations), the committee continued to regard proliferation and diversion as the most important—perhaps the overriding—issue in nuclear power. The degree to which the risks of national proliferation of nuclear

armaments or subnational diversion of material for nuclear weapons could be controlled was discussed at length. The problem was acute: Subjective estimates of the magnitude of these risks were balanced against equally subjective estimates of the benefits that nuclear power might provide in easing the world’s problems of energy supply.

There was general agreement that the greatest threat of nuclear technology lies in existing stockpiles of nuclear weapons and weapons material throughout the world. There was further agreement that to the extent that high enrichment of 235U and isolation of 233U and plutonium are needed for a civilian nuclear power industry, these steps of the fuel cycle should be conducted in secured plants, preferably under international control. However, some members of the committee believe that the economic importance of nuclear energy is not great enough to warrant accepting significantly increased risk of international proliferation or subnational use of nuclear weapons, and that such increased risk will attend the spread and growth of nuclear power if these should occur more rapidly than improvements can be made in existing safeguards and deterrents. Other members of the committee believe that the world’s energy problems already pose a greater long-term threat than does proliferation, and that the benefits of the rapid spread of nuclear power in alleviating these problems outweigh any plausible increase in the risks of proliferation and diversion.* Divergent opinions on what steps to take follow from these beliefs.

Some argue that international solutions such as the Non-Proliferation Treaty, safeguards (monitoring by the International Atomic Energy Agency), and strengthened controls on fuel cycles can only be effected if the United States is an active participant, a reliable supplier of nuclear materials and know-how. These are arguments for carrying forward, and very probably exploiting, the development of reprocessing and breeder reactors, since both increase our ability to provide nuclear fuel.

Others argue that the current policy of the United States—staying the commercialization of reprocessing for the time being and limiting the development of breeders to technology-level studies—is essential as an example to others.† They maintain that this forbearance is necessary to avoid a situation in which countries that have legitimate domestic needs for major nuclear power enterprises are tempted to manufacture nuclear weapons. The argument is that the moral position of the United States is strengthened in international negotiations by what may be some self-sacrifice.

|

* |

See statement 5–8, by E.J.Gornowski, Appendix A. |

|

† |

Statement 5–9, by E.J.Gornowski: The United States has lost this argument. Reprocessing is going ahead in other countries regardless of the U.S. position. |

The issues of diversion and proliferation make the future of reprocessing and the breeder reactor uncertain. As a consequence, the future of nuclear power beyond the point of resource scarcity is also uncertain. The undecided future of reprocessing adds to uncertainty about the form of waste that must ultimately be banished from the environment. The committee cannot resolve these uncertainties, but in the recommendations that follow, suggests ways they might be reduced by improving the reliability of information, by narrowing and clarifying areas of dispute, and by instituting interim programs that preserve flexibility of response in anticipation of better information.

CONCLUSIONS

The committee draws the following conclusions about technical factors that should be considered in formulating nuclear policy.

-

The rate of growth in the use of electricity is a primary factor affecting the strategy of nuclear power development. Low rates of growth allow the electric utilities sufficient flexibility to regard coal and nuclear capacity as interchangeable to a considerable degree. This becomes increasingly difficult for higher electricity growth rates; rapid expansion of both coal and nuclear capacity would be required. The highest growth rates in electricity use examined by the committee call for technically achievable rates of expansion of both new coal and nuclear capacity that many members of the committee regard as incompatible with environmental and political restrictions.

-

The growth of conventional nuclear power (today’s light water reactors) will be limited by the producibility of domestic uranium resources, probably before the year 2000. With today’s once-through fuel cycle and no change in the prevailing policy against reprocessing, a maximum nuclear capacity of about 400 GWe could be reached by 2000, diminishing thereafter. This contribution could be extended to about 600 GWe with reprocessing and recycle of fuel in light water reactors. A more complete assessment is needed of domestic and world uranium resources, and of the rate at which they can be produced at various costs.

-

A greater, or more sustained, contribution of nuclear power beyond 400 GWe and past the year 2000 could only be supported by the installation of advanced reactor systems, particularly those using recycle of nuclear fuel. Even if very extensive new uranium resources are identified before 1990, advanced converters would still be attractive because they could extend the uranium energy base appreciably. Nevertheless, only the

-

breeder can provide insurance of satisfying very high demand, or of abating a shortage of uranium.

-

Several different breeder reactors could serve in principle as candidates for an indefinitely sustainable source of energy. Only the liquid-metal fast breeder reactor could be built and operated by the year 2000.

With regard to the major domestic issues that surround nuclear power, the committee draws the following conclusions.

-

The short-term health risks from routine operation of the LWR nuclear fuel cycle appear to be far below the risks from the coal fuel cycle. This remains the case if reactor accidents are included, using the risk estimates of the Reactor Safety Study (WASH-1400). The accuracy of the WASH-1400 results and the validity of this type of comparison are disputed both inside and outside CONAES. Long-term risks are even more difficult to compare. The maximum estimates of nuclear power risks are within the range of risks for the coal cycle. An analysis of reactor safety such as WASH-1400 cannot be carried out for advanced reactors until specific commercial designs are available.

-

No insurmountable technical obstacles are foreseen to preclude safe disposal of nuclear wastes in geological formations. All necessary process steps for immobilizing high- and low-level wastes have been developed, and there are no technical barriers to their implementation. Geological emplacement can be carried out with standard mining techniques. There is still some controversy about the assured integrity of the backfill.

-

The main problems with geological waste disposal are site-specific: characterizing sites that exhibit a high degree of stability, transmit water only by pore flow, and offer no ready access to groundwater. Storage of waste at such sites would engender much smaller risk to the public than that of routine emissions from the rest of the fuel cycle, Routine emissions from the nuclear fuel cycle are generally recognized to present very small risks to health.

-

Radiation has been released from stored nuclear waste, notably from the wastes of military production operations, but also from some wastes of civilian operations. These incidents have not so far resulted in public hazards. They do, however, illustrate the inadequacies of existing surveillance and regulatory practices, and they emphasize the need for permanent disposal facilities.

-

Nuclear waste disposal has suffered in the past from decision making by the federal government that has been both dilatory and capricious. The time for decisions is upon us, but we have not yet arrived at a decision-making process that is both legitimate and authoritative.

Finally, with regard to international issues, we note the following conclusions.

-

The United States, with relatively large reserves of both coal and uranium, is in a very favorable position compared to many countries of the world that have little or no indigenous fuels. In the absence of practical alternatives, these countries may well find nuclear power, especially breeder reactors, attractive as an energy source that greatly reduces reliance on fuel imports.

-

The problem of diversion of nuclear materials by terrorist or criminal groups, and the related question of the vulnerability of nuclear facilities to sabotage, are serious matters. Domestic security measures, such as those practiced in laboratories and facilities handling enriched materials, can be effective. However, if our society moves in the direction of turbulence and polarization, questions might be raised about our ability to carry out domestic security measures properly.

-

The proliferation threat must be viewed from the perspective that the overriding security problem is to avoid war; failing this, it is to avoid war between or among superpowers, and failing that, to avoid devastating nuclear exchanges among them. Nuclear power can reduce this threat by reducing the competition for scarce resources, one of the causes of war. Nuclear power can also increase this threat by facilitating the acquisition of nuclear weapons, particularly by countries whose possession or use of them might catalyze superpower war.

-

Nuclear power is not the most likely route countries with the will to acquire nuclear armaments might follow, but it is not an impossible one. The most likely scenario by which nuclear power could contribute to nuclear armament is the appropriation of plutonium or 233U from nuclear fuel cycles by a country that might not, in the absence of this opportunity, have made the decision to acquire nuclear weapons.

RECOMMENDATIONS

The committee’s principal recommendations are listed below. More detailed recommendations appear in subsequent sections of this chapter.

-

National policy should support the continued use of nuclear power for the next few decades.15 The rationale for such support rests on the availability of nuclear power as a domestic energy resource whose risks are

-

at worst comparable* to those of other energy sources, its competitive economics, and the undesirability of relying too heavily on coal or nuclear power, to the exclusion of the other, until the risks of each are better understood.

-

Advanced reactor types should be developed to the point that they can be evaluated for possible introduction, if needed. Three advanced reactor types can be considered: the liquid-metal fast breeder reactor, the high-temperature gas-cooled reactor, and advanced versions of heavy water reactors. Of these, the LMFBR would be recommended if industrial economic factors were the only consideration. The LMFBR has the best chance of providing insurance that a nuclear industry could in the long term meet any electrical demands that might eventuate.† A major consideration is, of course, the question whether the fuel reprocessing necessary to operate LMFBR’s (and eventually, other advanced converters) is compatible with national antiproliferation objectives. We recommend that development of proliferation-resistant reprocessing for LMFBR’s proceed, pending a decision whether such methods as coprocessing, Civex, or radioactive spiking are sufficient or necessary to counter this policy objection to the LMFBR.

-

High-temperature gas-cooled reactors or heavy water reactors (HWR’s) (or both) are appropriate advanced reactors if (as in most CONAES scenarios) electrical demand grows at a moderate rate, or if appreciable uranium supplies can be produced at a price in the range of $100–$200/lb of U3O8. Uranium supplies in this price range are not believed to be abundant in the United States. These reactors could probably be installed with fewer siting restrictions than LMFBR’s, and they would be compatible with LMFBR’s in a mixed system, with the breeders operating as fuel factories. They might, for a considerable period, produce power more economically than breeders. Their development at some level of effort is therefore recommended, regardless of the decision on the LMFBR.

-

Exploration for uranium resources and their specification must continue at a vigorous pace. This information is basic to the timing of expanding the existing light water reactor industry, and to the pace of commercializing advanced reactors.

-

Technological designs and licensing requirements should be available “off the shelf” for the reprocessing plants that would handle fuel from the various reactor types to reduce the lead time needed if reprocessing is approved. This means that both research and development activities

|

* |

Statement 5–10, by J.P.Holdren: I disagree. Implied here is a kind of apples-plus-oranges comparison that cannot be done. The public might well decide some nuclear risks are intolerable. |

|

† |

See statement 5–11, by L.F.Lischer, Appendix A. |

-

through the pilot-plant stage must be undertaken, as well as licensing of these pilot plants. In view of the uncertain future for commercial reprocessing as a consequence of national policy, there is no alternative to government funding of this activity.

-

Within the national nuclear energy program specifically, and as an integral part of the national technological research program, a much higher level of support is needed for fundamental engineering and materials sciences. These include basic studies in heat transfer, fluid flow, the mechanics of materials under dynamic stresses, corrosion, solid-state diffusion in technical materials, and many other similar fields. Such studies are necessary to resolve questions of reactor safety by means other than complicated and expensive overdesign, and should be the core of any nuclear safety research program.

-

Ore tailings and low-level radioactive wastes from the nuclear industry need a sound program of environmental protection to ensure that they do not present significant health risks to the public. Since even the worst-case risks from these sources are quite low, the steps required should be based on the most probable values of costs and risks, rather than on the most conservative possible assumptions.*

-

High-level and transuranic wastes from the nuclear industry should be disposed of by emplacement in a geological repository. The responsibility for site selection must ultimately rest with the federal government, as the benefits from a well-chosen repository accrue to the nation as a whole, and the risks to local populations are not high.† The target for placing a first repository in operation should be the mid-1990s. In the interim, spent-fuel storage should be practiced without assuming or precluding reprocessing.

-

Radioactive wastes from weapons-material production facilities, military propulsion reactors, weapons fabrication facilities, and other military activities must be dealt with independently. These wastes exist in quantity and in less-than-ideal form for geological disposal. They should, at minimum, be immobilized and collected at a few isolated sites. After these steps, they can be prepared for geological disposal (probably at the same sites). Within the category of defense wastes, the transuranic waste and (possibly) the high-level waste from propulsion-reactor reprocessing are the only types that can be considered for disposal at the Waste Isolation Pilot Plant near Carlsbad, New Mexico.

|

* |

Statement 5–12, by J.P.Holdren: I disagree. Conservatism is particularly appropriate when the potential victims are in future generations, as is the case with tailings and low-level wastes. |

|

† |

See statement 5–13, by J.P.Holdren, Appendix A. |

Finally, what can we say about the problem of nuclear weapons proliferation that is not a homily or a statement of alternatives? It should be continued national policy to search for ways to avoid nuclear war, but it is by no means clear that this country is prepared to give up the option of nuclear weapons for use in extreme circumstances. In this quandary, any technical or industrial policy steps are, at best, supportive of larger national policy. All the antiproliferation measures we can conceive have an experimental character, including such relatively recent measures as the deferral of domestic plans for reprocessing and breeder reactors. If they promote a more peaceful and prosperous world (and thus, necessarily, a more peaceful and prosperous United States), such policies warrant continuation and can be used as the foundations for far-reaching policies. If they do not promote these ends, they should be firmly and quietly scrapped. In the committee’s view, therefore, the country should recognize that any antiproliferation measures (Civex, no reprocessing, or whatever) are not ends in themselves, but only practical measures in the service of policy decisions.

NUCLEAR GROWTH RATES AND THE EFFECT OF REACTOR TYPES ON DEMAND FOR URANIUM

Nuclear power, as visualized now or for the intermediate period of this study, can contribute to our energy supply as a source of electricity. Thus, the contribution we can expect from nuclear power is tied to projections of the demand for electricity. A number of sources compete to satisfy this demand—coal, nuclear, hydroelectric, geothermal, and advanced systems. Nuclear power will only be a part of a mix. If a large part is desirable for nuclear power, it could be constrained by the availability of uranium, or by the availability of reactor types and fuel cycles that would make more efficient use of the available uranium.

This section takes up these questions within the context of a neutral policy. Policy decisions are rarely neutral. Even domestic decisions to select one reactor or fuel cycle over another cannot be simplified and isolated from their context, a context determined by the mutual interaction of technology, the environment, human values, and world affairs. The relative importance of various measures to achieve resistance to diversion and proliferation, the measure of risk and benefit the public assigns to nuclear power, the desirability of competing technologies, and the interaction between the United States and the rest of the world will figure as prominently in domestic decisions about nuclear power as considerations of demand and supply.

NUCLEAR GROWTH SCENARIOS, URANIUM REQUIREMENTS, AND REACTOR TYPES

The question examined here is, “What are the implications for uranium requirements of filling nuclear demands by various reactor and fuel cycle strategies?” The number of variables that affect the answer is large. Several studies have been conducted on the subject, using slightly different assumptions, The results, however, exhibit similar characteristics. The results presented here have their own set of detailed assumptions, but we consider them to be typical. The conclusions to be drawn are qualitative rather than quantitative. (The examples are taken from Zebroski and Sehgal.)16

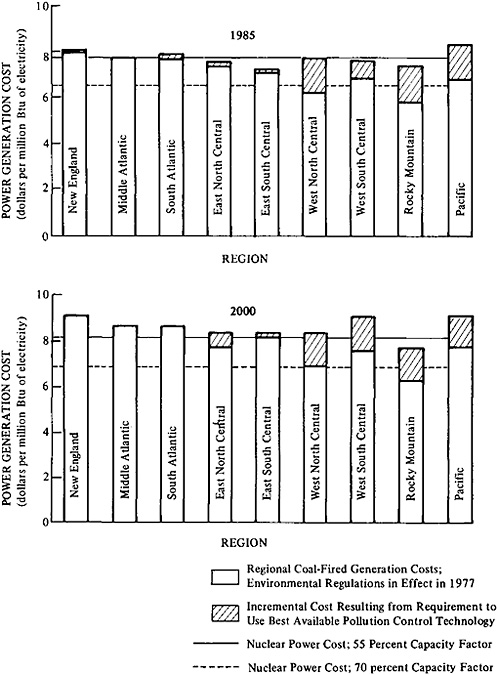

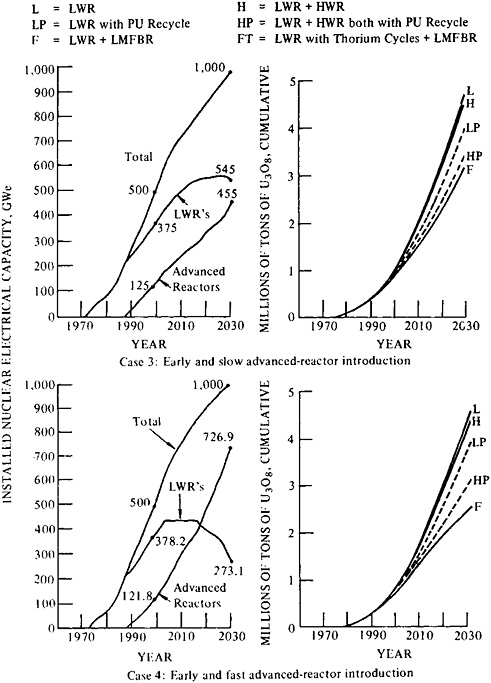

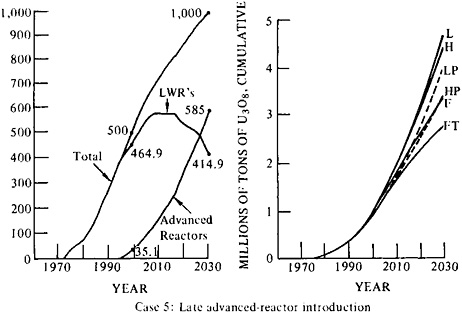

Figure 5–2 shows introduction and installation schedules with corresponding requirements for uranium of two cases, both of which correspond to fairly low growth of demand for nuclear electricity. Although 200 GWe of installed electrical generating capacity from nuclear power plants in 1990 is slightly higher than the installed capacity now scheduled or expected by that date, the approximately 50 GWe assumed in the figure to be installed from 1990 to 2000, and the approximately 60 GWe to be installed between, 2000 and 2010, are well below the expected figures. Case 1 assumes early introduction of advanced reactors (1987) and a rate of installation that results in about 80 GWe by 2000, or a third of total nuclear generating capacity. Case 2 assumes that advanced reactors are introduced in 1995* and installed at a rate resulting in 20 GWe by 2000 (about 8 percent of total nuclear generating capacity), and in 310 GWe by 2030 (62 percent of total nuclear generating capacity). In both cases, the total of the uranium consumption and forward commitments for fueling any of the combinations of reactor types that might be selected to achieve the postulated demand for nuclear generating capacity falls below 2 million tons, even by 2030. Indeed, with only light water reactors on a once-through cycle (the most resource-intensive system), cumulative ore requirements by 2010 would amount to just 1.2 million tons of U3O8. The use of more separative work in the enrichment process, leaving tails at an assay of 0.1 or 0.15 percent, would hold the resource requirement below 2 million tons until 2030, but not beyond.

Figure 5–3 illustrates three schedules of nuclear installation to meet moderately high growth of demand for nuclear-generated electricity. The starting point in 1990 is about 250 GWe rather than 200, but this difference does not affect the conclusions that can be drawn. The cases are (1) early introduction of advanced reactors and gradual installation, (2)

|

* |

See statement 5–14, by L.F.Lischer, Appendix A. |

early introduction and rapid installation, and (3) late introduction and rapid installation. A resource base of 2 million tons of U3O8 is sufficient to meet any of these three schedules to 2010, but only those cases that assume the introduction of fast breeders or high utilization of 235U from natural uranium (low tails assay) and fissile-isotope recycle in advanced converters (or both) manage to avoid outstripping 4 million tons of U3O8 in consumption and forward commitments by 2030.

Figure 5–4 depicts a very high rate of growth in nuclear generating capacity. In fact, Figure 5–4 is based on an unrealistic initial rate of installation—400 GWe by 1990—but as with Figure 5–3, the qualitative conclusions are not affected. In all cases, 2 million tons of uranium resources are exhausted soon after the year 2000, and 4 million tons are exhausted soon after 2010. Only those schedules that show early introduction and rapid installation of fast breeder reactors keep consumption and forward commitments of uranium oxide under 6 million tons by 2030. The simultaneous introduction and installation of advanced converters helps relieve some of the pressure on resources, but in all the cases illustrated, the demands on uranium, and possibly on thorium, exceed the rate of production the committee considers possible with present methods, as detailed in the section on uranium production. This scenario is therefore unrealistic unless a “heroic” program of breeder deployment is begun immediately.

The projections illustrated in Figures 5–2, 5–3, and 5–4 correspond roughly to the CONAES study scenarios, assuming that half or more of the electrical generating capacity required is supplied by nuclear power plants. Figure 5–2 represents projections compatible with the low- to medium-consumption scenarios I3, II2, and III2; Figure 5–3, with the medium-high to high scenarios III3, IV2, and IV3; and Figure 5–4, with the specific high-electrification variants of these latter scenarios. (See chapter 11 for details of the study scenarios.) One difference between the examples presented here and the CONAES study scenarios is that the former show demand for electricity continuing to rise at a signficant rate, while the latter show demand for electricity tending to saturate by 2010.

AVAILABILITY OF URANIUM17

In the previous section, the demands of various schedules for installation of nuclear electrical capacity, and of various strategies for developing and installing reactor systems, were expressed in terms of the amounts of uranium they might require. The availability of uranium could limit some of these strategies or schedules.

The federal government, for many years the only customer for uranium,

FIGURE 5–2 Low growth of installed nuclear capacity (350 GWe by 2010): comparison of reactor types and cumulative ore requirements from 1972 forward In case 1, LWR’s without recycle would approach an estimated 2.4 million tons of uranium supplies by 2030. Advanced converters (introduced in 1987 and reaching 80 GWe installed capacity by 2000) with reprocessing, along with reprocessing in LWR’s, could significantly extend the life of nuclear power within the uranium supply estimate of the Uranium Resource Group (1.8 million tons) through 2030. In case 2, late introduction of advanced converters offers less extension time than case 1, but still more than 10 years. Advanced converters, introduced in 1995, reach an installed capacity of 20 GWe by 2000. Source: Adapted from E.L.Zebroski and B.Sehgal, “Advanced Reactor Development Goals and Near-Term and Mid-Term Opportunities for Development” (Paper presented to the American Nuclear Society, Washington, D.C., November 18, 1976).

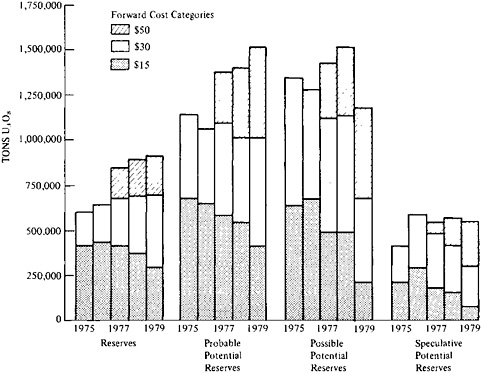

publishes a systematic annual estimate of potential resources and reserves. The figures for reserves represent ore deposits that have been measured by drilling, and assayed within a 20 percent degree of accuracy, and material available under existing practices as by-products from mining or treating other materials. Reserves can be characterized as the supply of ore the mining industry is confident it can produce. Potential resources represent ore deposits inferred to exist from tacit knowledge and field judgments: the amount of ore that can reasonably be expected to occur in producing strata, or in nonproducing areas that display the characteristics of producing areas.

Figure 5–5 shows the annual estimates made in recent years. The estimates are set out by incremental or forward costs: the additional cost to recover uranium oxide over expenditures already incurred in exploring, filing claims, buying or leasing mineral rights, and determining the extent of deposits. “Forward costs” make no allowance for profit; they represent neither total costs to recover ores nor market prices. The reserves of uranium set out in various categories of forward cost should not be interpreted as representing the ores that can be economically recovered today. They do represent relative cost; for example, reserves in the $30/lb category will be about twice as expensive to recover as those in the $15/lb category. The estimates of potential resources are set out in three categories: probable, possible, and speculative.

The Uranium Resource Group of this study reviewed the 1976 estimate and compared it to information from geologists, experts advising the uranium industry, and others. The group concluded that the possible and speculative categories were not well enough established for resource planning. It judged that the estimate for probable resources, 1.06 million tons, was the closest approximation to a quantitative estimate for all potential resources18 and estimated the domestic uranium producible by

conventional mining at 1.7 million tons. The federal government has reported higher estimates since, partly as the result of better information on uranium in the $30–$50/lb forward-cost category. This uranium is not producible under prevailing market conditions, but its production will become economic as higher-grade deposits are depleted.

Table 5–1 shows the increase in estimates of reserves and probable potential resources since 1976. CONAES has adjusted its resource estimate, reflecting this increase, to 2.4 million tons of U3O8 (excluding by-product recovery).

FIGURE 5–3 Moderately high growth of installed nuclear capacity (700 GWe by 2010): comparison of reactor types and cumulative ore requirements from 1972 forward, In all three cases, 2.4 million tons of uranium can sustain moderate rates of growth in installed nuclear capacity to 2010, with recycle of fissile isotopes in the selected mix of reactors. In case 5, however, the late introducton of advanced converters would realize significant savings in resource consumption only if the uranium resource base is more than 3 million tons. At the lower estimate, the late-arriving breeder would be necessary to sustain growth in installed nuclear capacity beyond 2020, In all three cases, the introduction of advanced converters or breeders, or both, is necessary to hold the consumption of uranium and forward commitments below 3 million tons to 2030. Source: Adapted from E.L. Zebroski and B. Sehgal, “Advanced Reactor Development Goals and Near-Term and Mid-Term Opportunities for Development” (Paper presented to the American Nuclear Society, Washington, D.C., November 18, 1976).

Experience with other minerals indicates that projections of potential resources usually fall far below the resources subsequently discovered and produced.19 This is because increasing quantities of lower-grade ores are exploitable as the price rises. But uranium deposits that have been identified in the United States are either rather high grade (>700 ppm uranium by weight) or quite low grade (<100 ppm, or 0.01 percent) with no large intermediate range. Many geologists believe that this is an intrinsic and unique feature of uranium mineralization. Moreover, uranium deposits tend to be discrete and sharply bounded; the edges of the deposits, contrary to experience with other minerals, are barren. Finally, low-grade deposits (less than 0.01 percent uranium oxide), such as those in black shale, may not be producible in quantity because of the massive rock volumes to be moved, uncertain milling requirements, and vast quantities of mill tailings to be managed.

Uranium exploration is a chancy venture. Discovery of the Grants mineral belt in New Mexico (1956–1957), and of the Wyoming Basins deposit (1969–1970) added 60,000 tons/yr to uranium reserves, but

FIGURE 5–4 High growth of installed nuclear capacity (1300 GWe by 2010): comparison of reactor types and cumulative ore requirements from 1972 forward, Conditions can be met only by introducing fast breeder reactors and assuming abundant supplies of uranium—5 million tons for early introduction and rapid rates of installation. Source: Adapted from E.L. Zebroski and B.Sehgal, “Advanced Reactor Development Goals and Near-Term and Mid-Term Opportunities for Development” (Paper presented to the American Nuclear Society, Washington, D.C., November 18, 1976).

FIGURE 5–5 Changes in domestic uranium estimates, as of January 1 in each of the years 1975–1979. Source: Leon T.Silver, “Discussion of U.S. Uranium Supplies,” testimony before the Subcommittee on Energy Research and Production, Committee on Science and Technology, U.S. House of Representatives, May 31, 1979.

between these two discovery periods, annual additions totaled only 10,000–30,000 tons/yr. Exploration for new uranium deposits concentrates on areas similar to those with known deposits, Only one new district has been discovered in more than 15 years. The odds that uranium exploration will lead to discovery can be improved by better understanding of the factors that govern deposition.

The Uranium Resource Group has estimated that under prevailing

TABLE 5–1 Estimates of Reserves and Probable Potential Resources of Uranium in the United States (tons of U3O8)

|

Year |

Reserves |

Probable Potential |

Total |

|

1976 |

640,000 |

1,060,000 |

1,700,000 |

|

1977 |

840,000 |

1,370,000 |

2,210,000 |

|

1978 |

890,000 |

1,395,000 |

2,285,000 |

|

1979 |

920,000 |

1,505,000 |

2,425,000 |

|

Source: U.S. Department of Energy, Statistical Data of the Uranium Industry (Grand Junction, Colo.: Department of Energy (GJO-100 [79]), 1979), pp. 21, 30–31. |

|||

conditions, uranium discovery will increase to a rate of 50,000 tons/yr in 1985 and decline thereafter. Under conditions favoring discovery, the rate would improve (for a resource base of 1.8 million tons) to 62,000 tons/yr by 1991, and under conditions favoring all-out discovery efforts, rates of 80,000 tons/yr might be reached by 1989.

To maintain adequate reserves—8–12 years’ worth of production at prevailing rates—new ore deposits must be discovered and measured continuously. Production of these reserves normally lags behind discovery about 5 years. Under conditions of uncertainty in future demand similar to those prevailing today, this lag would lengthen to about 10 years. The 5-yr lag could be maintained if there were reasonable assurance of demand.20

Expansion of exploration and mining must be accompanied by expansion of milling21 capacity. Discovery of new ore deposits takes 1–5 years after exploratory effort begins; evaluation by drilling and assay takes an additional 1.5–2 years; mine development, 1–3 years, and construction of a mill, 2–3 years. Some of these steps must be completed before others can be undertaken. The deposit must prove sufficient to justify a new mill, for example. Others may be undertaken simultaneously. Nevertheless, 10 years usually elapses between the decision to expand uranium exploration and the production of uranium oxide.

The nuclear power industry must plan for relatively distant futures, A light water reactor requires at least 10 years to license and build, and the utility must be assured fuel at reasonably predictable prices for at least 10 full-power years of its 30-yr life. In planning for future advanced converters or breeders, the nuclear power industry will be particularly concerned that fuel is both available and producible at rates that correspond to the planned rate of buildup of the industry. Here the

uncertainties that plague uranium resource availability interact with other uncertainties to complicate the planning of both suppliers and consumers,

Under conditions that constitute business as usual for uranium producers, and under prevailing reactor fueling practices, the rate of uranium production in 2000 could fuel only 228 GWe from light water reactors. Accelerating the rates of discovery and increasing production could provide fuel for 310 GWe22 around the year 2000. If the producible uranium oxide is 2.25 million tons, a 310 GWe capacity might then be sustained for 5–10 years before being restricted by a declining production rate as reserves decline.

URANIUM ENRICHMENT

Several enrichment methods were tested in pilot plants during World War II, including gaseous diffusion, thermal diffusion, and modified mass spectrography. Gaseous diffusion proved most effective and economical, In this process, the lighter isotope 235U, in the form of gaseous uranium hexafluoride (UF6), passes more readily than 238U through porous barriers. By repeating the process in successive stages of a cascade, any degree of enrichment can be achieved. In the United States, three facilities (in Oak Ridge, Tennessee, Paducah, Kentucky, and Portsmouth, Ohio) are operated as a single enrichment complex. Enrichment plants using gaseous diffusion also exist in Great Britain, France, the U.S.S.R., and China.

Gaseous diffusion is itself energy intensive. On the average, a little over 5 percent of the electrical energy generated by a light water reactor is needed for the enrichment process.

The increasing cost of energy has made the alternative method of separation by gas centrifuge economically competitive. In this process, the heavier 238U (again, as uranium hexafluoride) is spun to the outside of a centrifuge and the lighter 235U withdrawn from the center. The process requires one twentieth or less of the electricity needed in gaseous diffusion. The savings in electricity justify a large capital cost, and the Department of Energy is now planning to add at least one gas centrifuge to its enrichment facilities, at a cost of $4.2–$4.5 billion.23 Abroad, a tripartite consortium (URENCO), sponsored by Great Britain, the Federal Republic of Germany, and the Netherlands, is building one plant in England and planning others on the European continent.

Among other processes in the United States, laser separation of isotopes has been demonstrated in the laboratory. A chemical exchange method is being investigated in France, and separation by jet nozzles, a process developed in Germany, is being tried on a commercial scale in Brazil and (by a different process) in South Africa. Developers of the chemical exchange method claim it is practical for slightly enriched uranium, but

not for the higher enrichments that would be needed for weapons. If this is confirmed, it would be preferred as a proliferation-resistant technology. The laser process has some promise as a method for almost entirely removing 235U from the rejected material (tails) of existing enrichment plants, in which case it could increase effective uranium reserves by perhaps 20–30 percent (this is the fraction of 235U in natural uranium that is now discarded). The nozzle separation method does not appear practical for the United States, as it is too energy intensive.

Both the laser separation method (which is not yet proved) and the gas-centrifuge method have the potential to produce weapons-grade 235U in significant quantity at relatively small-scale installations.* Both processes employ sophisticated technology that few countries can use. However, technology always spreads. Over time, these processes might provide the easiest access to nuclear weapons: Because of the low level of radioactivity involved, enrichment plants could be built secretly with greater ease than reactors or reprocessing plants.

The capacity of enrichment plants is measured in separative work units (SWU’s) per year, which have the dimensions of mass flow rate (e.g., kilograms of uranium per year). The amount of uranium and separative work required to deliver a given amount of reactor fuel at a given enrichment can be varied within the limits of enriching plants to operate at different tails assays. For the Department of Energy’s existing enriching complex, the tails assay can be varied from 0.2 percent to 0.3 percent 235U without loss of separative capacity. Table 5–2 illustrates the variation possible in feed and separative work per kilogram of light water reactor fuel within this range.

To a limited extent, separative work substitutes for natural-uranium feed. As illustrated in Table 5–2, light water reactor fuel enriched to 3 percent 235U can be produced at 0.2 percent tails assay with about 20 percent less natural-uranium feed, but with 26 percent more separative work, than at 0.3 percent tails assay.

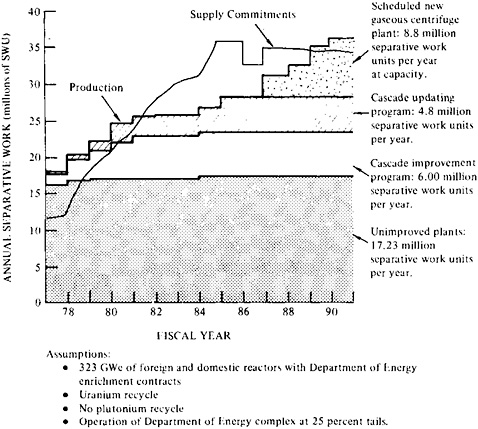

The three-plant complex operating in the United States has a capacity of 18 million SWU/yr, and as of 1977 was intended to reach 28 million SWU/yr in 1981.24 (Requirements have since decreased, and expansion has been delayed accordingly.) The expanded plants are expected to reach full-capacity production by 1985.25 This expanded capacity has been committed to domestic and foreign obligations (323 GWe of light water reactors—two thirds in the United States and one third in foreign countries). The new centrifuge plant is expected to operate at its full capacity of 8.8 million SWU/yr in 1988.26

TABLE 5–2 Ratios of Uranium Feed and Separative Work Units to a Kilogram of Enriched Reactor Fuel, 3 Percent 235U, for Selected Tails Assays

|

|

Tails Assay (percent 235U) |

||

|

0.20 |

0.25 |

0.30 |

|

|

Natural uranium, kg |

5.479 |

5.965 |

6.569 |

|

Separative work units |

4.306 |

3.811 |

3.425 |

|

Source: A.de la Garza, “An Overview of U.S. Enriching Resources,” report to the Supply and Delivery Panel, Committee on Nuclear and Alternative Energy Systems, National Research Council, Washington, D.C., 1976. |

|||

Figure 5–6 illustrates production expected from enrichment plants over the next decade and contract commitments for separative work. The apparent gap between commitments and production from 1981 to 1988 could be closed if operation at high tails assay—about 0.36 percent—were possible. But this inordinately high tails assay would require more feed at a time when uranium supplies may become scarce. Conversely, since enrichment plants are being added in Europe, and since the Soviet Union apparently has spare enrichment capacity, some relief might be available from these sources.

A recent report points out that utilities holding long-term fixed-commitment contracts are required to provide uranium feed to the enrichment complex in amounts that may not agree with their fuel requirements, and it suggests that most of the apparent gap between production capacity and commitments could be eliminated through case-by-case adjustments.27 The substitution of fuel “enriched” by the addition of plutonium from reprocessed old fuel could also help prevent an “enrichment gap.”28

Whether additional enrichment capacity will be needed beyond 1990, and if so when, depends on the number and type of reactors built and their particular fuel needs. Existing and planned enrichment capacity, for example, can supply the fuel for 215 GWe generated by today’s light water reactors using a once-through cycle. Domestic capacity might approach this figure in the early 1990s, and in addition, it would be proper for the United States to supply its share of the enrichment needs of countries that must buy this service. The introduction of new reactors in the form of advanced converters would also affect projected demands for enrichment. Heavy water reactors using natural uranium, or uranium enriched to 1.2 percent 235U, have no enrichment requirements in the first case, and

FIGURE 5–6 Separative capacity schedule for the Department of Energy complex of uranium enrichment plants (in Oak Ridge, Tennessee, Portsmouth, Ohio, and Paducah, Kentucky) and contract supply commitments to domestic and foreign utilities.

modest requirements in the second. Advanced converters on the thorium-uranium cycle (such as the HTGR or LWBR) with fuel recycle have heavy requirements for highly enriched uranium for their initial critical loadings, but after the first loading, they use less separative work than LWR’s.29 Breeder reactors started on plutonium have no separative work requirements and could indeed provide some fissile fuel (above and beyond what is needed to fuel new breeders) to converters.

However, in spite of the uncertainties in future demand for separative work, enrichment is not a bottleneck in nuclear expansion. An enrichment plant takes only as much lead time as a reactor to plan and build, so enrichment capacity can be scheduled to match reactor commitments.*

|

* |

See statement 5–16, by E.J.Gornowski, Appendix A. |

NUCLEAR REACTORS AND FUEL CYCLES

Nuclear power is generated from the fission of heavy elements. The heat of fission is liberated in nuclear reactors. This heat is then transported by the reactor coolant to external equipment, where it is converted into electricity. The different types of reactors that have been developed for this purpose employ the major approaches that have been considered attractive. Table 5–3 lists these reactors and the status of their development.

Nuclear fuel is made of isotopes that are easily fissioned by slow neutrons. These are known as fissile isotopes. The only fissile isotope that exists in nature in usable abundance is 235U. This makes up about 0.7 percent of natural uranium, and natural uranium is therefore the basic resource for nuclear power. There are two other isotopes from which fissile isotopes can be made in a reactor. These are 238U, the more common isotope and the major constituent of natural uranium, and 232Th, naturally occurring thorium. Fissile 239Pu, the commonest form of plutonium, is made from 238U, and fissile 233U is made from thorium (238U and 232Th are called fertile isotopes).

As the fissile isotopes originally loaded in a reactor are destroyed, new fissile isotopes are formed from fertile isotopes. The relative rate of replacement is the conversion ratio. When the conversion ratio is greater than 1, new fissile isotopes are formed faster than the original fissile isotopes undergo fission, and the reactor is called a breeder. A reactor that operates at conversion ratios below 1 is known as a converter.

The fuel cycle for a reactor describes the way the fissile and fertile isotopes are used. If natural or slightly enriched uranium is the fuel, plutonium is formed and partly fissioned during reactor operation. Spent fuel still contains some 235U and 239Pu. It could be recycled, or the spent fuel could be considered waste material. Recycle reduces the amount of fresh 235U that has to be supplied, and thus reduces the commitment of natural uranium needed to fuel the reactor.

More highly enriched uranium can also be mixed with thorium in reactor fuel, creating a Th-U fuel cycle. This is not generally economic unless the 235U and 233U left in spent fuel are recycled; however, some once-through cycles in some reactors are only slightly more expensive than their uranium counterparts. A version of the Th-U cycle, in which some 238U is added to keep concentrations of fissile isotopes in uranium below weapons-usable amounts, is the denatured U-Th cycle. This cycle is discussed later in this chapter (under “Reprocessing Alternatives”). Similarly, plutonium could be extracted from spent reactor fuel and combined with 238U to form new fuel. This would be done in recycling natural or slightly enriched uranium fuel, using plutonium at low concentrations. This is the fuel cycle for fast breeder reactors—at higher

TABLE 5–3 Nuclear Reactors and Fuel Cycles: Development Status

|

Reactor Type |

Fuel Cycles |

Development Status |

Possible Commercial Introduction in the United Statesa |

|

Light water reactor (LWR) |

Slightly enriched U (~3 percent 235U) |

Commercial in United States |

1960 |

|

Spectral-shift-control reactor (SSCR) |

Th-Ub |

Conceptual designs, small experiment run; borrows LWR technology |

1990; fuel cycle, 1995 or laterc |

|

Light water breeder reactor (LWBR) |

Th-Ub |

Experiment running; borrows LWR technology; fuel cycle not developed |

1990; fuel cycle, 1995 or laterc |

|

Heavy water reactor (CANDU or HWR) |

Natural uranium |

Commercial in Canada, some U.S. experience |

1990 |

|

|

Slightly enriched U (~1.2 percent 235U) |

Modification of existing designs |

1995 |

|

|

Th-Ub |

Modification of designs; fuel cycle not developed |

1995 |

|

High-temperature gas-cooled reactor (HTGR) |

Th-Ub |

Demonstration running; related development in Germany; fuel cycle partly developed |

1985; fuel cycle, 1995 or laterc |

|

Molten-salt (breeder) reactor (MSR or MSBR) |

Th-Ub |

Small experiment run; much more development needed |

2005 |

|

Liquid-metal fast breeder reactor (LMFBR) |

U-Pub |

Many demonstrations in the United States and abroad |

1995 |

|

|

Th-Ub |

Fuel cycle not developed |

1995 |

|

Gas-cooled fast breeder reactor (GCFBR) |

U-Pub Th-Ub |

Concepts only; borrows LMFBR and HTGR technology |

2000 |

|

aBased on the assumption of firm decisions in 1978 to proceed with commercialization. No institutional delays have been considered except those associated with adapting foreign technology. On the basis of light water reactor experience, it can be estimated that it would take about an additional 15 years after introduction to have significant capacity in place. bIndicated fuel cycles demand reprocessing. cThorium-uranium fuel reprocessing is less developed than uranium-plutonium reprocessing. Indicated reactors could operate for several years before accumulating enough recyclable material for reprocessing. |

|||

concentrations of plutonium—although a Th-U cycle could also be used. The cycle with plutonium and uranium is designated the U-Pu cycle; as with the Th-U cycle, recycle is always assumed.

Table 5–4 presents fuel cycle characteristics of the reactors in Table 5–3. Some caution is needed in interpreting Table 5–4. There are continuous possibilities for varying enrichments, fuel concentrations, lattice spacings, and other reactor fueling parameters. How designers choose to operate a fuel cycle depends on finding a minimum fueling cost within broad technical limits, and only those parameters that seem interesting now are presented. Table 5–4 is schematic and highly simplified. In some cases, particularly those involving future developments, relatively crude estimates have been used.

Virtually all the nuclear power in the United States today, and all planned expansion of nuclear power, is in the form of light water reactors. As can be seen in Table 5–4, these reactors make large demands on supplies of natural uranium at economical prices. Such supplies (as pointed out under “Availability of Uranium”) are limited; therefore, this type of reactor has a limited term of service. How long this term might be depends, of course, on the demand for nuclear power as well as on the supply of uranium. A very long-lasting nuclear industry could only persist by the use of some form of breeder reactor, whose ultimate source of fuel, the fertile isotopes, could probably be supplied at economical prices for hundreds of millennia.

All U-Pu recycle schemes and all Th-U schemes that do not use denatured uranium present the problem that pure fissile material could be chemically isolated during the recycle steps. In particular, breeder reactors are intrinsically fuel-recycle systems. As such, they present the possibility that nuclear materials usable in weapons could be diverted, or that the fuel cycle could be used in national proliferation of nuclear arsenals. On these grounds, the United States has deferred civilian nuclear fuel reprocessing and is attempting to persuade other countries to do the same. On the same grounds, the Administration has opposed proceeding with the latest demonstration breeder reactor project in the United States, the Clinch River breeder reactor (CRBR), a subject discussed later in this chapter.

Nevertheless, a vigorous and durable nuclear power industry could be a very important part of our future energy supply system. Therefore, in what follows, we explore the various reactor systems that might be used, even though many interesting systems rely on recycle of nuclear fuel.

ADVANCED REACTORS30

It has already been noted (Table 5–4) that the current generation of power reactors in the United States, consisting of light water reactors, is not very

TABLE 5–4 Fueling Characteristics of Various Reactors (each 1 GWe capacity)

|

Reactor Type |

Fuel Cycle |

Conversion Ratio |

Natural U3O8 Committed to System Inventory (tons)a |

Natural U3O8 Consumed over System Life (tons)b |

Thorium Requirements (initial inventory plus tons per year) |

Referencec |

|

Light water reactor |

~3 percent 235U, once-through ~3 percent 235U, U recycle ~3 percent 235U, U and Pu recycle Th-235U, once-through Th-235U, U recycle |

0.5–0.65 0.5–0.65 0.45–0.55 0.6 0.65 |

700 ~1000 ~1000 900 ~1200 |

5300 4200 3200 6200 2800 |

— — . 120+30 120+30 |

|

|

Spectral-shift-control reactor |

Th-235U, U recycle |

0.75 |

~1300 |

2300 |

120+10 |

|

|

Light water breeder reactor |

Th-235U, seed recycle Th-233U, recycle |

~0.75 ~1 |

700 ~1000d |

5000 0 |

120+40 4e |

|

|

Heavy water reactor (CANDU) |

Natural U, once-through Natural U, Pu recycle 1.2 percent 235U, once-through Th-235U, once-through Th-235U, U recycle |

0.7 0.6 0.7 0.75 0.9 |

160 ~350 310 700 ~1200 |

4300 1800 3300 2800 1200 |

— — — 160+140 160+140 |

|

|

High-temperature gas-cooled reactor (pebble bed) |

~8 percent 235U, once-through Th-235U, once-through |

0.58 0.58 |

280 300 |

4400 4100 |

— not available |

|

High-temperature gas-cooled reactor (prismatic) |

Th-235U, once-through Th-235U, U recycle |

0.6 0.7–0.9 |

280 ~600 |

4200 2300 |

150+10 150+10 |

|

|

Molten-salt breeder reactor |

Th-233U |

0.9–1.07 |

~400d |

0 |

Inventory not available; 3 |

|

|

Liquid-metal fast breeder reactor |

U-Pu Th-233U |

>1.15 > 1.1 |

1000–2000d 1000–2000d |

Breeder Breeder |

— Not available |

|

|

Gas-cooled fast breeder reactor |

U-Pu Th-233U |

>1.2 >1.15 |

1000–2000d 1000–2000d |

Breeder Breeder |

— Not available |

|

|

a Estimate of reactor inventory plus out-of-reactor inventory for recycle systems. bDoes not include inventory, which is assumed to be recoverable at end of reactor life. cSources: As indicated on the table, the following sources were consulted for descriptions of reactor fueling characteristics. The conversion ratios and tonnages listed in the table (intended for comparative purposes) are the responsibility of CONAES. 1. P.R.Kasten et al., Assessment of the Thorium Fuel Cycle in Power Reactors (Oak Ridge, Tenn.: Oak Ridge National Laboratory (ORNL/TM-5565), 1977), Appendix B. 2. Resources Planning Associates, The Economics of Utilization of Thorium in Nuclear Reactors—Textual Annexes 1 and 2 (Oak Ridge, Tenn.: Oak Ridge National Laboratory (ORNL/TM-6332), n.d.). Table 2.13, p. 158. 3. Battelle Columbus Laboratories, Study of Advanced Fission Power Reactor Development for the United States, vol. 3 (Columbus, Ohio: Battelle Columbus Laboratories (BCL-NSF-C946–2), 1976), pp. C-80–C-120. 4. J.S.Foster and E.Critoph, “The Status of the Canadian Nuclear Power Program and Possible Future Strategies,” Annals of Nuclear Energy 2 (1975):689–703. 5. E.Teuchert et al., “Once-Through Cycles in the Pebble Bed HTR,” ANS Transactions 27 (1977):460. 6. Battelle Columbus Laboratories, Study of Advanced Fission Power Reactor Development for the United States, vols. 2 and 3 (Columbus, Ohio: Battelle Columbus Laboratories (BCL-NSF-C946–2), 1976), vol. 2, pp, IV-II and vol. 3, pp. C-80–C-120. 7. National Research Council, U.S. Energy Supply Prospects to 2010. Committee on Nuclear and Alternative Energy Systems, Supply and Delivery Panel (Washington, D.C.: National Academy of Sciences, 1979). dEstimates based on requirements for equivalent highly enriched 235U to initiate fuel cycles. ePublished estimates of LWBR thorium requirements apparently assume refabrication. |

||||||

efficient in its use of uranium. This is particularly significant if fuel is not recycled, as the fissile isotopes in spent fuel could replace some of the 235U in freshly mined uranium. It is possible to use uranium more efficiently. The key is to use reactors with higher conversion ratios and long fuel lifetimes. Higher conversion ratios can substitute for recycling to the extent that the fissile atoms formed undergo fission in place. With recycle, the higher conversion ratio permits more fissile atoms to be substituted for natural 235U.

Although light water reactors do not now have high conversion ratios, a great deal of the plutonium created in their operation undergoes fission in place. About one third of all the energy in LWR’s is obtained from plutonium fission, and at the end of fuel life, more than 60 percent of the fissions occur in 239Pu. LWR’s could, in principle, be designed for higher conversion ratios and better use of natural uranium, a fact that should be remembered in comparing them to other reactors. Such designs would have lower enrichments and burnups than existing LWR cycles and could only achieve better use of natural uranium through plutonium recycle.31 The required rate of reprocessing might be twice as high, per unit of electrical energy generated, as that for the standard LWR recycle mode estimated in Table 5–4, but lifetime uranium consumption would be less than 3000 tons. For all reactors, the conversion ratio varies with the composition of the fuel loaded and with fuel management. Differences among reactors often correspond to differences in the conversion ratio that can be readily achieved for fuel loading and management practices permitting economical power generation.