4

Tier 1 International Munitions Processing Technologies

INTRODUCTION

In the course of its information gathering, the committee recognized that one particular type of international technology has risen to prominence in addressing the cleanup of old and abandoned chemical weapons at sites in other countries. Detonation-type destruction technologies rely on the ability of the energy from explosive charges within a containment vessel to efficiently destroy recovered chemical munitions and the agent and energetics contained therein.

There are several versions of detonation-type technologies. An earlier version of the controlled detonation chamber (CDC) was reviewed by a previous National Research Council committee.1 Since then, this technology has undergone further development and implementation in several European venues. Meanwhile, two more recent examples of detonation-type technologies that are in use or being developed for destroying recovered chemical warfare munitions have come to the committee’s attention, namely, the Japanese detonation of ammunition in vacuum integrated chamber (DAVINCH) technology and the Swedish Dynasafe technology. The committee considers these two technologies and the latest CDC technology as sufficiently capable and mature to warrant Tier 1 status for further consideration by the Non-Stockpile Chemical Materiel Project (NSCMP) as an alternative to the explosive destruction system (EDS) currently used by NSCMP, or as a complementary means of processing recovered non-stockpile munitions.

MEASUREMENT OF PERFORMANCE FOR DETONATION TECHNOLOGIES

A discussion of the Tier 1 detonation-type technologies will be informed by first considering appropriate means for gauging their performance. A measure of performance for detonation processes would be useful to the U.S. Army because it would allow comparing the relative effectiveness of different technologies. Also, although the level of performance and the precise test used to measure such performance is ultimately a decision for federal and state regulators, any information the U.S. Army might obtain or generate on the performance of these technologies would certainly be helpful in obtaining regulatory approvals to deploy such technologies. Moreover, the process of developing a detailed test procedure could form the basis for reaching a consensus with regulators. Furthermore, many members of the public interested in the destruction of CWM distinguish between destruction efficiency (DE) and destruction and removal efficiency (DRE).2 Thus, an accepted measure of performance for detonation technologies will assist the Army in addressing questions from the public (see also discussion of public involvement in Chapter 2 and DREs in Chapter 3).

However, determining such a measure of performance for detonation processes appears to offer unusual challenges, and, based on the information available to the committee, the committee believes the Army should specify requisite documentation from vendors and employ engineering contractors to review it to determine if the data provide a consistent and reliable measure of performance. For other processes,

|

1 |

See the National Research Council report Systems and Technologies for the Treatment of Non-Stockpile Chemical Warfare Materiel (2002). |

|

2 |

For a definition of destruction efficiency, see <http://www.basel.int/techmatters/popguid_may2004_uk_pros%20and%20cons.pdf>. |

procedures have been established or are obvious and straightforward. Thus, the trial burn approach is well established for incinerators. A selected organic compound (which is more difficult to destroy than the typical waste burned in the incinerator during normal permitted operation) is fed at a known rate to the process. The mass of each effluent stream is measured, along with the concentration of the selected organic compound. The degree of destruction is then calculated. For incinerators, this is the DRE, which refers to “the percent of waste material that is either destroyed or otherwise removed from the waste feed” (ATSDR, 2005, p. 18).

In the equation DRE = 100 [(feed rate emission rate)/(feed rate)], the feed rate is the measured amount of chemical in the wastes fed to the incinerator and the emission rate is the measured amount of a chemical in the stack exhaust (ATSDR, 2005). The DRE measures the effectiveness of the treatment process as a whole.

For neutralization, hydrolysis, and many other processes that treat agent, the procedure is straightforward. Agent is fed at a known rate or in a known amount to the process. The mass of each effluent stream is measured, along with the concentration of the agent. Generally, there is no formal DRE that applies to neutralization and hydrolysis processes, although one can perform such a calculation.

Detonation processes destroy whole munitions, in discrete events. A procedure for determining the degree of destruction for a detonation process should ideally involve feeding complete munitions into the process; the feeding of neat agent in place of complete munitions would not give meaningful information.3

One possible approach involves determining the mass of the liquid in the munitions and the concentration of agent in the liquid, then measuring the mass and agent concentration in all the streams leaving the process. This approach could also involve measuring agent retained within the system, i.e., within the detonation chamber, but this could be difficult. Information thus obtained could then be used to calculate the DRE. The committee anticipates that the DRE will be a more important number than the DE. It would also be helpful to gather and report additional information gained from analysis of effluent streams, such as quantity of dioxins and furans produced, quantities of Schedule 2 compounds, and the proportions of the three valence states of arsenic. Comparison of these measurements with similar EDS performance measurements would also be important.

The DRE reflects how well the offgas management system is designed as well as how effectively the detonation destroys agent. Both are important. In evaluating detonation-type technologies, the degree of agent destruction in the actual detonation event should be measured. Of course, permits and regulatory approvals of such systems will typically entail process monitoring to ensure that they are operating as designed. Hence, in addition to being able to demonstrate an acceptable DRE, technologies must be able to demonstrate that agent is effectively destroyed and that secondary waste streams, including gases vented into the atmosphere, do not contain agent above agreed-on levels.

CONTROLLED DETONATION CHAMBER TECHNOLOGY

Description

The CDC, previously known as the Donovan blast chamber or the contained detonation chamber, was developed and is manufactured by DeMil International, Inc., of Huntsville, Alabama. The CDC was applied earlier to replace open detonation operations for destruction of conventional high-explosive munitions. It provides a contained environment that prevents the release of blast fragments, heavy metals, and energetic by-products. It was later proposed that a CDC could be used to destroy chemical warfare materiel (CWM) by detonation in its enclosed environment. The working assumption was that the heat and pressure of a contained explosion would destroy the chemical agent, especially in the wet environment produced by inclusion of water bags in the detonation chamber. Initial tests on World War I munitions recovered in Belgium indicated that a high level of agent destruction could be achieved. The preliminary results were reviewed in an NRC report (NRC, 2002).

Following the encouraging results of the Belgian tests, the U.S. Army has supported further testing in cooperation with the British Defence Science and Technology Laboratory at Porton Down, England. This further testing involved extensive modification of the basic Donovan blast chamber system to make it suitable for destruction of chemical munitions in an U.S. regulatory context. The Belgian tests were performed with a relatively small T-10 unit that had undergone only modest modifications to make it suitable for destroying toxic chemicals. The systems that have evolved from the Porton Down tests are much larger (requiring two 40-foot trailers for transport of the TC-25 or eight for the TC-60 vs. one for the T-10). The larger systems can process larger weapons, and most of the manual handling of munitions has been eliminated (Bixler, 2005).

Description of Original Test Unit

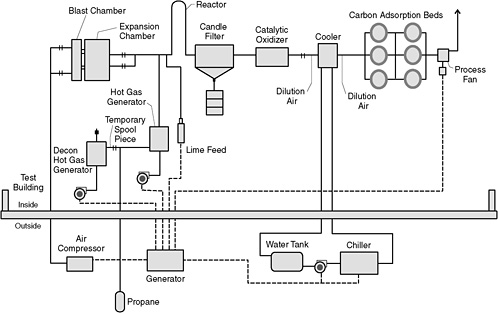

As tested in Belgium, the CDC consisted of three main components: the detonation chamber, an expansion chamber, and an emissions control unit, the latter comprising a particle filter and a bank of activated carbon adsorption beds (NRC, 2002). The maximum explosive rating of the T-10 mobile unit is 12 pounds of TNT-equivalent, including the donor charge used to access the burster and the agent.

The detonation chamber is connected to a larger expansion chamber. A projectile wrapped in explosive is mounted in the

detonation chamber. The floor of the chamber is covered with pea gravel, which absorbs some of the blast energy. The gravel is renewed periodically because it fractures during the explosions. Bags containing water are suspended near the projectile to help absorb blast energy and to produce steam, which reacts with agent vapors. After the detonation chamber is loaded, its entry port is sealed and the exit from the expansion chamber is closed. After the explosive is detonated, the chambers are kept sealed for about 2 minutes to maintain heat and pressure. The gases are then vented through the main duct to the baghouse and the carbon adsorption beds. Gases are monitored at several points in the CDC system for agent, carbon monoxide, and volatile organics as well as for agent at the exit duct outlet. The concentrations of particulates suspended in the vapors, such as soot, gravel dust, and metal oxides, were also monitored during the Phase 1 tests (De Bisschop and Blades, 2002). Water vapor from the explosives and from the explosion-quenching water bags collects on the charcoal filters.4

After the detonation, the atmosphere in the detonation chamber clears fairly rapidly as air is drawn through the system to remove residual organic vapors, thereby permitting reentry for placement of the next round. During the tests in Belgium, 15 chemical munitions were treated in the CDC in 3 hours, including 20-minute breaks after every five munitions (U.S. Army, 2001). This amounted to an average treatment time of 12 minutes per munition, including the time for breaks. Analysis of the pea gravel and of wipe samples from the chamber walls showed low agent concentrations (1.2 to 64.4 mg/kg in pea gravel; 0.39 to 78.65 mg/m2 in wipe samples from detonation chamber) during the Belgian test series (De Bisschop and Blades, 2002).

The main waste materials from destroying chemical munitions were solids: soot, charcoal (from the filters), pea gravel, inorganic dust, and metal fragments from the weapons. The major liquid waste from the CDC was spent hypochlorite solution from decontamination of the system prior to maintenance operations.5 The solids, which may have been contaminated with traces of chemical agent and explosives residues, were packaged in plastic bags and placed in shipping containers that were sent to a commercial hazardous waste incinerator for disposal.

Current TC-25 and TC-60 Chemical Munitions Destruction Units

The CDC T-10 model tested in Belgium can treat complete chemical munitions up to 105-mm in diameter. A larger mobile unit (TC-25) was tested extensively at Porton Down, England (Blades et al., 2004) (see Figure 4-1). A still larger unit (TC-60) with an explosive capacity of 60 pounds of TNT-equivalent is now available (Bixler, 2005). It can handle munitions over 200 mm in diameter, according to the manufacturer. Table 4-1 provides the dimensions of the pressure chambers for the three CDC models.

The latest versions incorporate a mechanical system to move explosive-encased munitions from the preparation area through a reduced pressure vestibule into the detonation chamber. Double doors on the detonation chamber minimize any chance that agent vapors or detonation debris might escape. For standard varieties of munitions, the explosive charge is precast in a plastic form that can be slipped over the projectile. This packaging mode minimizes worker contact with the munitions and facilitates the mechanical transport of the projectile into the detonation chamber. Nonstandard items may require wrapping the munitions in sheet explosive, as was done in Belgium.

In the detonation chamber itself, armor plate can be affixed to the walls to reduce the likelihood of damage by flying metal fragments. The experience to date suggests that the chamber will retain full integrity for thousands of shots. Predicted lifetime is greater than 200,000 shots (Bixler, 2005). Injection of hot air or gaseous oxygen into the detonation and expansion chambers facilitates decomposition of any chemical agent adhering to the walls or adsorbed on the pea gravel or other solids.

A significant change in operating procedure from that used in the Belgian tests is applied in decontaminating the chambers in preparation for maintenance. In the early tests, the walls of the chambers and the pea gravel were washed with sodium hypochlorite (bleach) solution to oxidize any residual chemical agent. This procedure was effective but required much manual effort and resulted in a liquid waste that required separate disposal. In the revised procedure, the chambers are flushed with hot (450F) air for up to 24 hours to destroy residual agent. An alternative procedure is to detonate a small explosive charge that destroys the residual agent thermally. Both procedures reduce worker exposure and eliminate the generation of a liquid waste stream (Bixler, 2005).

The back end of the system, into which the offgases from the expansion chamber vent, has also been modified extensively (Blades et al., 2004). The vapors and particulates arising from the detonation of the munition pass through a reactive-bed filter (hydrated lime or sodium bicarbonate) to remove acidic gases and a porous ceramic filter to collect particulates, including soot and dust from the pea gravel. A lime precoating on the ceramic scavenges acidic vapors

FIGURE 4-1 TC-25 CDC system layout. SOURCE: Blades et al., 2004.

TABLE 4-1 Dimensions of the Pressure Chambers in Three CDC Models Designed for Destroying Chemical Warfare Agents

|

CDC Model |

Detonation Chamber |

Expansion Tank |

Total Volume (m3) |

||

|

Interior (m) |

Volume (m3) |

Interior (m) |

Volume (m3) |

||

|

T-10 |

1.524 × 1.524 × 1.524 |

3.5 |

2 × 2 × 2.3 |

9.2 |

12.7 |

|

TC-25 |

1.981 × 2.286 × 2.845 |

12.9 |

2.438 × 2.438 × 10.515 |

62.5 |

75.4 |

|

TC-60 PD |

2.438 × 2.438 × 3.657 |

21.5 |

2.286 dia × 10.516a |

43.1 |

64.6 |

|

aThe expansion tank for Model TC-60 PD is cylindrical. SOURCE: Briefing by CH2MHILL to Thales and the Délegation Générale pour l’Armament, October 2005. |

|||||

that escape the reactive filter. A catalytic oxidation unit (CATOX)6 oxidizes carbon monoxide and organic vapors from the gas stream prior to venting through a two-stage carbon adsorption bed system. MINICAMS7 monitoring of the gas stream indicates that no detectable agent reaches the adsorption bed.8

|

6 |

A CATOX unit facilitates the oxidation of carbon monoxide, hydrogen, and volatile organic compounds contained in an air stream such as that emerging from the particle filter in the pollution control system of the CDC. Generally, the air stream is passed through a bed of a catalytic solid that acts very much like that in an automotive catalytic converter. |

|

7 |

A MINICAMS is an automatic, near-real-time continuous air monitoring system using gas chromatography and sample collection with a solid-adsorbent preconcentrator or fixed-volume sample loop. The MINICAMS collects an air sample, performs an analysis, and reports the result. Reported agent concentrations above a user-set threshold generate an alarm status, which can be reported in various ways (see <http://www.oico.com/default.aspx?id=product&productID=75>). |

|

8 |

Controlled detonation chamber (CDC) update. Briefing by DeMil International to the Non-Stockpile Program Core Users Group, November 2004. |

Country-by-Country Experience

Belgium is the only nation in which the CDC has been used in a production mode for destroying chemical weapons. Although tests were carried out with a variety of World War I chemical agents and munitions, the CDC has been used primarily to destroy German 77-mm artillery projectiles containing Clark II (diphenylcyanoarsine) agent, an arsenical irritant. The system has been generally satisfactory, and over 2,000 such projectiles have been destroyed in 5 years.

The United States and the United Kingdom have collaborated on a series of tests that demonstrated the ability of a transportable CDC to safely destroy other chemical munitions that may be found at sites in the United States and the United Kingdom (Blades et al., 2004). Many improvements have been made to the CDC system to reduce manual operations, to simplify waste disposal, and to ensure that chemical agent vapors do not escape into the environment. Pending successful completion of a test series under way in early 2006, the system should be ready for implementation if it proves cost effective and publicly acceptable.

Evaluation Factors Analysis for CDC

Process Maturity

The use of the CDC to destroy chemical munitions has been demonstrated in a series of campaigns over a 5-year period. As mentioned above, the first tests were carried out in Belgium in May and June 2001. During those tests, live munitions containing sulfur mustard agent, Clark arsenical agent, and phosgene were destroyed. The original Donovan CDC system and the operating procedure were modified to enhance worker safety and reduce potential emissions of residual chemical agent or agent decomposition products. Extensive monitoring was conducted to determine agent DE and establish the quantity and nature of the decomposition products (De Bisschop and Blades, 2002).

Subsequently, the Belgian military used the TC-60 CDC in a production mode to destroy part of its large stockpile of recovered chemical warfare materiel (RCWM) at Poelkapelle. Over 2,000 German 77-mm projectiles containing Clark arsenical agents were destroyed in the T-60 unit (Bixler, 2005).

Following the success of the Belgian testing, the U.S. Army supported a series of tests at Porton Down in the United Kingdom to demonstrate the usefulness of the CDC for operations in the United States. These tests included modifications of the system to enhance DE, to improve worker safety, to improve productivity, and to minimize any possibility for escape of agent vapors.

Phase I testing was carried out from April to September 2003 (Blades et al., 2004). A variety of munition types containing sulfur mustard agent, phosgene, a phosgene-chloropicrin mixture, and a smoke composition were destroyed.

Phase II demonstration/validation testing was conducted at Porton Down in 2004 (Bixler, 2005). The tests included detonation of two munitions per shot, a key point in establishing the potential throughput of the CDC. Extensive computer control and safety interlocks were added to regulate contact of any agent vapors with the treatment system and to remove any opportunity for a detonation to occur before the complete system is ready for operations.

Another series of tests at Porton Down was scheduled for early 2006. A major goal of these demonstrations was to demonstrate the potential throughput of the TC-60 CDC. Modeling indicates that 22 shots (up to 40 munitions)9 can be conducted in a 10-hour shift (DeMil International, 2005a).

Process Efficacy/Throughput

The CDC appears to be well suited for destroying a range of either chemical or conventional munitions (NRC, 2002). While it has yet to be tested for the destruction of nerve agents (cf. Table B-2), the hot, wet, oxidizing atmosphere in its detonation chamber can reasonably be expected to decompose these compounds rapidly. The CDC has also not been demonstrated for munitions encased in overpacks for storage.

The DE achieved by the detonation alone appeared to be above 99 percent, as measured by the postdetonation environment in the Belgian tests (De Bisschop and Blades, 2002). A similar analysis done in the U.S. Army/U.K. Defence Science and Technology Laboratory tests gave a DE from detonation of 99.408 to 99.998 percent in a series of five tests with HD-loaded 4.2-inch mortars. In five tests in which agent destruction was enhanced by the addition of gaseous oxygen to the detonation chamber prior to the blast, the DEs from detonation ranged from 99.965 to 99.996 percent.10 These calculated efficiencies were based on measurement of residual agent in the pea gravel and the walls of the detonation chamber. No residual agent was found downstream in the expansion chamber or the pollution control system.

The more important measure from the viewpoint of preventing releases that might endanger workers, the public, or the environment is the DRE. No published DRE figure has been found, but it is likely to be as least 99.9999 percent (“six nines”) because the posttreatments reduce agent concentrations to below detectable levels as measured by a MINICAMS before the offgases reach the carbon adsorption beds (Bixler, 2005).11 It does not, however, qualify as a hold-and-test system like the EDS.

TABLE 4-2 Estimated Throughput Rates for CDC TC-60

|

Munition |

Munitions per Cycle |

Cycles per 10-hr Day |

Munitions per 10-hr Day |

|

4.2-in. mortar, M1 |

2 |

20 |

40 |

|

75-mm projectile, M64 |

2 |

20 |

40 |

|

5-in. projectile, MK VI |

1 |

22 |

22 |

|

5-in. projectile, MK 54 |

1 |

22 |

22 |

|

155-mm projectile, MK II |

1 |

22 |

22 |

|

8-in. projectile, T174 |

1 |

22 |

22 |

|

Bomblet, M139 |

3 |

20 |

60 |

|

105-mm projectile, M60 |

1 |

22 |

22 |

|

100-lb bomb, M47 |

— |

30 |

6a |

|

115-lb bomb, M70 |

— |

30 |

5b |

|

aAgent drained into five 20-lb lots; each lot detonated in CDC. Five 20-lb lots/bomb × 6 bombs/day = 30 cycles/day. bAgent drained into six 20-lb lots; each lot detonated in CDC. Six 20-lb lots/bomb × 5 bombs/day = 30 cycles/day. SOURCE: CH2MHILL, responses to committee questions of February 6, 2006. |

|||

Models of the CDC up to the TC-60 are designed to be transportable although there may be some restrictions on road transport because of the physical size of the detonation chamber. These models are designed to be set up within 5 days. The typical operating crew comprises 18 staff, including laboratory, safety and supervisory personnel (DeMil International, 2005b).

Because there is no time-consuming neutralization step, the CDC’s throughput could be much higher than that of the EDS, which conducts only one detonation every other day. However, the comparison is complicated by the fact that the EDS can destroy more than one munition per shot, depending on the size of the munitions. The EDS-1 can handle three mortar rounds, and the EDS-2 has destroyed as many as six per shot. As noted above, the CDC has demonstrated destruction of two munitions per shot and could potentially destroy 40 projectiles per 10-hour shift. Estimated throughput rates per 10-hour day for representative U.S. munitions are shown in Table 4-2. The current CDC also has the advantage in operation of generating little or no liquid waste that requires subsequent processing, in contrast with the substantial neutralent and rinsate effluents produced with the EDS.

Process Safety

The continuing development of the CDC has significantly reduced the manual operations in the treatment of CWM. The original T-10 system tested in Belgium involved personal protective equipment (PPE)-clad workers in operations such as wrapping projectiles in sheet explosive, moving the projectile into the detonation chamber, and connecting fuzes and detonators. After detonation and cooling of the chamber, the workers had to prepare the chamber for reloading despite the presence of traces of agent on the chamber walls and the pea gravel. Preparation for weekly maintenance operations included washing the walls and floor of the chamber with decontamination solution. Workers also packed agent-contaminated filter material for shipment to a TSDF (De Bisschop and Blades, 2002).

The modifications applied during the Porton Down tests reduced manual operations by slipping precast donor explosives over the projectile and mechanically moving the round into the detonation chamber. Even in the advanced TC-60 system, however, there remains a manual step. Between shots, an operator must reach inside the door to the detonation chamber to unplug the electrical connector for the detonator from the last detonation, then plug in the connector for the next detonation. This approach might slightly increase the potential for worker exposure, but it eliminates the chance of mechanical failure of an automated plug connection system.

Routine munition preparation operations are conducted by workers in Level C PPE. Level B PPE, offering a higher level of protection than Level C, is used for maintenance work in and around the chambers (Blades et al., 2004). A process hazards analysis for the current TC-60 model was conducted in mid-2005 (DeMil International, 2004). According to the technology proponent, it was a “qualitative analysis prepared in accordance with U.S. Army’s AR 385-64 and AR 385-61 directives, and Guidelines for Hazard Evaluation Procedures….”12 The analysis covered an extensive range of operations, failure modes, and corrective actions and provided qualitative severity assessments of failure modes. Supporting systems such as that which supplies oxygen to the detonation chamber were included in the evaluations and process modifications. It was reported by the technology vendor that this process hazards analysis had been reviewed

and agreed with by the U.S. Army’s Edgewood Chemical Biological Center.13

The substitution of hot air purging for washing the chamber and detonation debris with decontamination solution removed a set of operations that probably constituted a significant risk of agent exposure. The improvements to the pollution control system seem to have minimized agent-contaminated waste materials (Bixler, 2005).

Public and Regulatory Acceptability in a U.S. Context

The CDC has not been permitted for use in destroying CWM in the United States, although it has been used successfully in Europe. Additional testing of the CDC may be required if the system is to be permitted in the United States for treatment of CWM. The system’s DE from detonation of 99 to 99.99 percent is modest; the DRE of the entire system, including thermal decontamination and offgas treatment, would be much higher. In extensive testing at Porton Down, agent vapors were never detected at the entrance to the carbon adsorption bed, let alone the exit (DiBerardo, 2004). Evidently, the offgas cleanup prior to the adsorption beds was effective, and a DRE of at least 99.9999 percent may be assumed.

Unlike the EDS and the DAVINCH, the CDC does not have provisions for holding, testing, and retreating detonation debris before opening the detonation chamber, a feature that many public stakeholders desire.

Public concerns in the United States about using the CDC to treat chemical munitions are not known at this time. However, the extensive U.S. use of the CDC for destruction of conventional munitions, including at the Naval Surface Warfare Center (Bixler, 2005), the Massachusetts Military Reservation, and the Blue Grass Chemical Depot, may contribute to public acceptance. The operations at Blue Grass were conducted under a RCRA permit.14 The experience with conventional munitions seems to demonstrate that the CDC can be operated without noise or vibration problems for its neighbors.

Secondary Waste Issues

Since the introduction of hot air purging for the CDC system, the secondary waste concerns regarding CDC operations have been substantially reduced. The primary wastes are solids:

-

Munition fragments,

-

Pea gravel and dust,

-

Lime from the reactive bed filter, and

-

Carbon from adsorption units.

It was reported that the hot air purging (450F for 24 hours) yields solids in a condition suitable for transport under government control (Blades et al., 2004). Some post-treatment, such as smelting for metal scrap or incineration for carbon, may be required if the solids are not to be disposed in a hazardous waste landfill.

Process Cost Issues

No quantitative cost information was available to the committee, but some qualitative factors indicate that the CDC technology may be cost effective for some non-stockpile applications. Chief among these factors is the use of the CDC for RCWM destruction operations in Belgium over a period of almost 5 years, including an upgrade in technology from a prototype version of the T-10 model to the more sophisticated TC-60 model.

Similarly, extensive U.S. experience with destruction of conventional and agent-like munitions (smokes, white phosphorus, CS agent) indicates that the basic CDC technology is cost effective for destroying projectiles and other types of explosive-containing munitions in a U.S. context.

Perhaps the most appropriate technology against which to compare cost effectiveness in non-stockpile applications is the EDS-2, which, like the CDC, performs the complete sequence of accessing the chemical agent, destroying the agent, and yielding solid debris that may be disposed of by a TSDF. For small caches of RCWM (one or two munitions), a comparison between the EDS and the T-10 model of the CDC may be appropriate because they appear to be comparable in complexity and mobility. A detailed analysis of costs, including those of waste disposal, would be necessary to see if the CDC offers any advantages over the EDS for sites involving “small finds,” i.e., limited numbers of items.

For large caches of RCWM such as may be found at old burial sites, the presumed greater productivity (munitions per week) of the larger CDC systems would seem to offer a cost advantage over the EDS-2. Again, a detailed analysis based on productivity demonstrated in the 2006 Porton Down tests would be required to establish the presumed cost advantage. In this type of operation, the CDC should also be compared to transportable versions of the DAVINCH and Dynasafe systems.

Summary

The CDC system is relatively mature, having been used in a production mode for destroying RCWM in Belgium for more than 4 years in addition to also having been used extensively in the United States for destroying conventional munitions. Modifications made during testing at Porton Down have minimized manual operations and have almost

entirely eliminated the production of liquid wastes. Agent emissions during normal operations appear to have been completely eliminated.

The basic design and operating principles of the CDC are simple. Munitions are encased in explosive and loaded into a large, almost cubical, double-walled steel chamber along with bags of water for thermal control and steam generation. The system is sealed and the explosive is detonated. This explosion breaks open the munition, detonates any energetics contained therein, and releases the chemical agent. The heat, oxygen, and steam in the detonation and expansion chambers destroy over 99.99 percent of the chemical agent. Starting immediately after detonation and proceeding over a 10-15 minute period, the offgases are released to the pollution control system, where they are filtered, the acidity is neutralized, and organic matter is oxidized catalytically. These steps reduce the agent concentration below detection limits before the gases are vented through a bank of carbon adsorption beds. The internals of the destruction systems are decontaminated with hot air, which also decontaminates the residual solids such as munition fragments.

The CDC is safe, reliable, and effective. It is made in three transportable versions that are appropriate for destroying small, medium, and large numbers of munitions. In addition, there is a large fixed model that could be used at a large burial site or firing range.

The smallest mobile CDC model (T-10) seems generally comparable to the EDS-2 in size and complexity. The T-10 has an advantage relative to the EDS in that it produces little or no liquid waste, but it lacks the hold-test-release capability of the EDS for assuring that offgases are devoid of agent emissions. A detailed cost calculation would be required to determine the cost effectiveness of the CDC T-10 vs. the EDS-2 for disposing of small RCWM caches (ones or twos). The presumed greater productivity of the larger CDC models (TC-25 and TC-60) might make them more cost effective for destroying large quantities of RCWM.

The CDC might gain public and regulatory acceptance in the United States without excessive difficulty on the basis of extensive prior operating experience and testing, but some community members may view the lack of a hold-test-release capability as a disadvantage. The committee does not believe that this lack is a significant technical issue, given the batch nature of the process and the proven effectiveness of the offgas treatment system. Still, it believes that this is one of the many factors that must be considered when comparing the CDC with other detonation technologies.

DETONATION OF AMMUNITION IN VACUUM INTEGRATED CHAMBER

Description

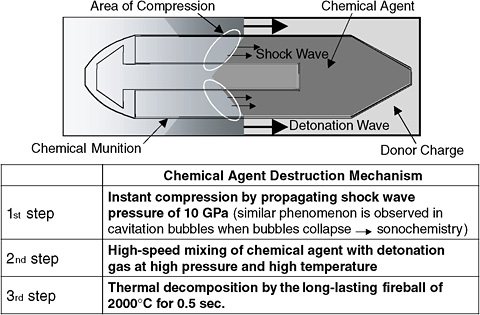

DAVINCH is a trademarked acronym for the detonation of ammunition in a vacuum integrated chamber and is a controlled detonation system for the disposal of chemical munitions.15 DAVINCH technology was developed by the Japanese company Kobe Steel, a manufacturer of large steel pressure vessels. Munitions placed in the DAVINCH vessel are detonated in a near vacuum using a slurry explosive to open the munitions and access the chemical agent. The agent is destroyed as a result of the high temperature (3000K) and pressure (10 gigapascals) generated by the shock wave, followed by high-speed cavitation and then a fireball. DAVINCH is a dry process in that no post-detonation reagent is used because the agent is destroyed in the vessel (see Figure 4-2).

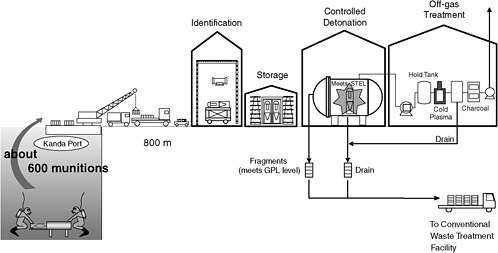

DAVINCH technology is a successor to an explosion containment vessel (DV10) that was used in 2000 at Lake Kussharo on Hokkaido Island in Japan to explosively access 26 World War II bombs containing a mixture of mustard agent and lewisite (Yellow bombs). Holes were drilled in the bombs and the agent was drained and neutralized. The drained bombs, containing explosives, were placed in the DV10 and destroyed using slurry explosives. A successor vessel was developed that was able to both access the agent and destroy it, as noted above. This vessel, the DV45, has been used at Kanda Port in Kyushu Island, Japan, to destroy recovered Yellow bombs and recovered Red bombs containing Clark I and Clark II vomiting agents (DC/DA) (see Figure 4-3). Between October 2004 and May 2005, 100 Yellow bombs weighing 50 kg each and 500 Red bombs weighing 15 kg each were destroyed in the DV45. The experience in using DAVINCH at Kanda Port is described in Lefebvre et al. (2005a), Asahina et al. (2005), and Asahina (2005). A detailed description of the DAVINCH, its design basis, its structural and operational characteristics, and the testing conducted to date are found in Lefebvre et al. (2005b).16

The DAVINCH is a double-walled steel chamber. The replaceable inner vessel is made of armor steel and the outer vessel is made of multilayered carbon steel plates with a corrosion- and stress-crack-resistant inner plate made of, for example, stainless steel, Hastalloy, or a similar material. The chambers are separated by air. Owing to its double-wall design and the materials of construction, the DAVINCH has the ability to confine high-pressure detonation gases, eliminating the need for an expansion tank to contain them following a detonation.

The DV45 weighs about 75 tons and has an explosive containment capacity of 45 kg TNT-equivalent. Its inner vessel has an inside diameter of 2.6 meters and an inner length of 3.5 meters. In contrast, the U.S. EDS-2 has a diameter of 0.74 meters and a length of 1.42 meters. A larger version

|

15 |

Except where otherwise noted, the majority of the technical information in this section came from various meetings with representatives of Kobe Steel (Japan) (see Appendix D). |

|

16 |

Joseph Asahina, Kobe Steel, “DAVINCH: Detonation of ammunition in vacuum integrated chamber,” presentation to representatives of the committee on November 11, 2005. |

of DAVINCH, the DV65, has been fabricated and is available. It has the same diameter as the DV45 but is longer and has an explosion containment capacity of 65 kg TNT-equivalent.

Munitions to be destroyed in a DAVINCH vessel are placed in a boxone munition per box with spacers at each corner to provide room for injecting an emulsive explosive around the munition. The explosive is extruded into the gap between the munition and the inner wall of the box either manually or automatically. The emulsion explosive can also be injected into the overpacks of leaking munitions or, if there is a filler between the overpack and the munition, the explosive can be placed outside the overpack. In this case, additional donor explosive is added to ensure that the explosive in the munition burster is sympathetically detonated by the blast.

A detonator is inserted into the slurry explosive that surrounds the munition and the top of the box and a lifting sling is attached. The munition in its box, with the detonator and detonation wire attached, is lifted by the sling and carried into the vessel by a robotic arm mounted on an operation deck that does not touch the inner walls of the vessel. The robotic arm hangs the sling from a hook on a linear rack at the top of the vessel and then connects the firing wire to a plug-in fixture mounted inside the vessel door. The prongs at the end of the detonation wire are inserted by the robotic arm into a sealed, gas-tight port in the side of the vessel.

The boxed munitions are positioned along the long axis of the vessel a specific distance apart depending on their configuration and contents. The DAVINCH contains an airtight, circular, double-flanged door that is remotely opened and closed. The door is not hinged but moves laterally until it is aligned with the vessel. It is then moved toward the vessel until contact is established and then secured in place. Following a detonation, the door’s flanges and gasket can be cleaned using the same robotic arm that moves munitions into the inner vessel.

After the door is sealed, air is evacuated from the inner vessel using a vacuum pump. This process takes about 10 minutes. The resulting vacuum reduces noise, vibration, and blast pressure, thus increasing the vessel life. The munitions are then detonated under near-vacuum conditions (about 0.2 psi). Using an electric delay detonator, the munitions are sequentially detonated such that the second munition is detonated before the shock wave from detonation of the first munition reaches it. The detonations are sequential to reduce the maximum pressure on the inner vessel walls. If more than two munitions are to be sequentially detonated (three have been sequentially detonated in the DV65), the length of the inner vessel can be increased, holding the vessel diameter constant. The munitions are imploded, reducing noise, vibration, fragment velocity, and gouging/scoring of the walls of the inner vessel. By detonating in a near vacuum, the volume of offgas to be treated is also reduced, since following a detonation, the vessel is repressurized to 1 atmosphere and the volume of offgas that is pumped out is the volume of the DAVINCH inner vessel. As a result, an expansion tank is not needed.

The initial shock wave from the detonation of explosives increases the pressure in the inner vessel to up to thousands of atmospheres (10 gigapascals) in 0.3 milliseconds. As illustrated in Figure 4-2, agent is destroyed as a result of a three-sequential-step process:

-

Destruction by a propagating detonation shock wave that compresses the agent.

-

Destruction due to high-temperature and high-pressure detonation gases.

-

Thermal destruction resulting from a 2000C fireball in the vessel. A proprietary additive increases the time duration of the fireball to 0.5 seconds to ensure agent destruction.

Following the detonation, air is introduced into the inner vessel, with atmospheric pressure reached after about 1 minute. Using the vacuum pump, the internal pressure in the vessel is again reduced to a near vacuum in order to remove the offgases resulting from the detonation of munitions and destruction of agent and energetics. If agent is detected in the offgas, the capability exists to recycle the gas back into the vessel.

Several methods are available to cleanse the DAVINCH vessels. An electrostatically charged decontamination aerosol can be sprayed in the inner vessel and in the gap between the inner and outer vessel in the event that any residual agent is detected. This is done prior to removing the replaceable inner vessel. A water jet spray is available to rinse out this decontamination solution. Finally, following the evacuation of the offgas from the inner vessel, the DAVINCH door can be opened and an explosive cleansing shot can be placed inside. The door is closed and the explosive charge detonated in the empty inner vessel to destroy any residual agent by means of the shock wave and heat from the detonation of the explosive.

Munition fragments are left in the inner vessel and are removed by the robotic arm after a period of time, about once per week. As a result of the heat generated by the fireball, the metal fragments are decontaminated to a point such that they are releasable to the publicthat is, they do not exceed the Centers for Disease Control’s recommended general population limit (GPL) value for the agents destroyed (for mustard agent, this value is 10–6 mg/m3).

Following the detonation, offgases are cleaned, filtered, and stored in a buffer tank. They are then pumped into a combustion chamber and heated. The combustion gases are quenched and passed through an activated carbon adsorption bed before being released to the atmosphere. An alternative to combustion that is under consideration involves sending the filtered offgas to a small, cold plasma arc unit to treat the gas prior to its release.

TABLE 4-3 DAVINCH Experience in Destroying Japanese WW II-Era Bombs Containing Lewisite, Mustard Agent, and Agents Clark I and Clark II (Vomiting Agents)

|

Type of Bomb |

Lengtha (cm) |

Width (cm) |

Weight (kg) |

Quantity of Explosives (kg) |

Quantity of Agent (kg) |

|

Yellow |

70 |

20 |

50 |

2.3b |

18.9 |

|

Red |

50 |

10 |

15 |

1.3c |

0.37 |

|

aWithout tail fins. bPicric acid. cTNT-15% naphthalene. SOURCE: Asahina et al., 2005. |

|||||

Since the agent in the Yellow bombs destroyed by DAVINCH is a 50:50 mix of lewisite and mustard agent, arsenic removal is part of the process. Eighty percent of the arsenic is metallic and can be recovered without further treatment. The remaining 20 percent consists of arsenic oxides and requires further treatment. The arsenic and arsenic oxides recovered from the DAVINCH process are sent to a contractor for such treatment.

When destroying two Yellow bombs per shot, DAVINCH DV45 has had a throughput rate of three shots per 8-hour day or about 2.5 hours per cycle, including preparation of the munitions, loading the inner vessel, sealing the door, drawing a vacuum, the detonation itself, evacuating the offgases, vessel decontamination if needed, and opening the vessel door to prepare for the next cycle. The DV65 has processed up to three Yellow bombs per shot, or nine bombs per 8-hour day. Under automatic operation, the throughput is estimated to be five shots per 8-hour day according to the manufacturer, but this has yet to be demonstrated.

Country-by-Country Experience

The DAVINCH DV45 unit has been used in Japan, at Kanda Port, to dispose of 600 World War II chemical bombs, some containing a lewisite/mustard agent mix and others containing vomiting agents (Lefebvre et al., 2005a; Asahina et al., 2005; Asahina, 2005). This is the only use of DAVINCH technology to date. It is expected that this DAVINCH unit will be used again at Kanda Port to dispose of bombs that remain underwater and that will be brought to the surface in sealed containers. It is also possible that DAVINCH technology will be used for applications in China, France, and Belgium in the future.

Evaluation Factors Analysis

Process Maturity

DAVINCH is a developed technology with experience in destroying Japanese World War II-era bombs containing lewisite, mustard agent, and agents Clark I and Clark II (vomiting agents). The characteristics of these bombs are given in Table 4-3.

Although DAVINCH technology has not been tested or used with U.S. non-stockpile munitions, the stated capabilities indicate it could process such munitions. For example, a representative large non-stockpile item, the 8-inch, T-174 projectile, has a length of 35.17 inches (89 cm), a width of 8 inches (20.3 cm), and weighs 200 pounds (91 kg)somewhat longer and heavier than the Japanese Yellow bomb but still within the physical capability of a DAVINCH DV45. This projectile contains 6.95 pounds (3.15 kg) of Composition B explosive in its burster, a somewhat greater quantity than found in the Japanese Yellow bomb but still well within the 45 kg explosive containment capability of the DV45.

Although DAVINCH technology is used in Japan, it has not been permitted for use in the United States, but the manufacturer, through a U.S. corporate partner, is looking into permitting requirements and procedures. As of the close of information gathering for this report, Kobe Steel has not yet applied for a permit to test DAVINCH technology in the United States.

Process Efficacy/Throughput

DAVINCH technology appears to be well suited for destroying a variety of non-stockpile munitions and containers in the United States as well as for destroying both stockpile chemical munitions and conventional high-explosive rounds (although it has not been used to destroy munitions filled with nerve agents). It has the potential to destroy chemical weapons with different fills in a single shot as well as to destroy a combination of chemical and conventional munitions in a single shot, although this has yet to be demonstrated.

DAVINCH units exist that are considerably larger than the largest detonation vessel used by the U.S. Army’s NSCMP, the EDS-2. The DAVINCH vessel used in Japan at Kanda Port, the DV45, has an inner diameter of 2.6 meters and an inner length of 3.5 meters. Comparable dimensions for the EDS-2 are 0.37 meters and 1.42 meters; consequently,

the internal volumes differ by a factor of about 30. Explosion containment capabilities are also substantially different: 45 kg (99 pounds) for the DV45 vs. 5 pounds for the EDS-2, a factor of about 20. The DAVINCH footprint, including the detonation vessel, gas treatment, lab space, and personnel support, is a rectangle having dimensions of about 80 meters by 60 meters, based on the Kanda Port experience.

DAVINCH units can be mounted on a flatbed trailer and made transportable; this is planned for use at various locations in China, where relatively small quantities of munitions have been found. At these locations, a transportable unit is more cost effective than construction of a fixed facility. Supporting infrastructure would also be transportable.

Kobe Steel has estimated the DRE for the detonation chamber at >99.9999 percent. However, the procedures were not consistent with U.S. regulatory requirementsthat is, the methodology cannot be used to calculate the regulatory DRE. The committee believes, however, that the DAVINCH technology should be able to achieve a high DRE, considering that no agent has been detected downstream of the detonation chamber.

The gases resulting from detonation in the DAVINCH vessel are primarily H2 and CO. These gases are pumped from the vessel and passed through a cyclone to remove particulates. They are then held in a storage tank for testing of the offgas content. In the event that 99.9999 percent DRE is not achieved, the offgas can be returned to the DAVINCH vessel for further treatment via a cleansing shot in which another detonation takes place. Rather than being returned to the vessel, the offgas can also be sent to an adjacent combustor and passed through a two-bed charcoal filter before being released to the atmosphere.

As an alternative to offgas combustion, the DAVINCH manufacturer is considering use of a small cold plasma unit to treat the detonation offgas. The cold plasma unit is about 1.5 meters high and has the appearance of a home hot water heaterbasically a vertical cylinder. The unit operates at a temperature of 900°C and processes about 1 m3 of offgas per minute, based on the 20 m3 offgas volume resulting from a shot in the DV45 and a 20-minute processing time to pass the gas through the cold plasma unit. It operates under a slightly negative pressure, and an oxygen supply is provided to aid in the destruction of the offgas constituents. Although intended to be a gas treatment unit, the cold plasma also is claimed to remove 99.9 percent of any agent that may remain in the offgas. This unit can be plugged into a standard 220-volt wall outlet.

With the cold plasma unit as an alternative for offgas processing, a proposed modification to the process flow would place the plasma unit before the offgas storage tank. The treated offgas can still be held in the tank and tested for its constituents. If any agent is detected, the treated offgas can be returned to the DAVINCH vessel for further treatment via the cleansing shot or can be recirculated through the vessel and returned to the cold plasma unit for further treatment in that unit.

At Kanda Port, the DAVINCH DV45 processed two Yellow bombs per shot with an average cycle time of 150 minutes, or 3.2 shots per 8-hour day. Over a 3.5-month period, 600 bombs were destroyed in 250 shots; an average of 2.4 bombs per shot. Assuming a 22-working-day month, the average number of shots per day was 250/(3.5 22) = 3.25, consistent with the 150-minute cycle time per shot.

Each Yellow bomb contained 18.9 kg of lewisite/mustard agent fill; thus, 83.3 pounds of agent were destroyed per shot. If manual operations, e.g., inserting the emulsion explosive into the box containing the munition, are replaced with a more automated operation, the DAVINCH throughput may increase to five shots per day, although this has not been demonstrated. Also, a larger version of DAVINCH (DV65) has the capability of destroying three Yellow bombs in a single shot; thus with automated operation, a throughput of up to 15 munitions per day is possible.

For U.S. non-stockpile munitions, the expected throughput will depend on several factors, including the size of the DAVINCH vessel to be used, the munition size, the quantity of agent to be destroyed, the explosive content of the munition and the donor charge, and whether or not automated handling procedures are used. Estimated throughput rates per 10-hour day for representative U.S. munitions have been provided by Kobe Steel and are shown in Table 4-4. These rates are for a DAVINCH DV65 having an explosive containment capability of 65 kg TNT-equivalent and assume that manual handling procedures are used. If automated procedures were to be used, the estimated number of cycles per 10-hour day would increase from 6 to 8.

The cycle time that was provided by the technology proponent for the DV65 operating under manual handling procedures was 1.5 hours. This is equivalent to the 6 cycles per day given in Table 4-4 plus a presumed 1-hour allowance for start-up and shutdown and/or minor delays. This cycle time is substantially shorter than the demonstrated 2.5-hour cycle time for the smaller DV45 that operated in Japan.

The quantity of agent that can be destroyed in a single DAVINCH cycle will also vary. Table 4-5 gives these quantities for the same munitions as those in Table 4-4.

Because there is no neutralization step, the throughput rate for DAVINCH is higher than it is for the EDS-2, which conducts only one detonation every other day, albeit with up to six munitions destroyed per detonation, depending on the munition size. The DAVINCH generates some liquid wastes. These result from use of the decontamination spray, when used; from residual liquid in munitions recovered from underwater; and from the cooling of the offgas. The volumes are small relative to those generated from neutralization and are sent to an offsite waste treatment facility for further processing and disposal.

TABLE 4-4 Estimated DAVINCH DV65 Throughput Rates

|

Munition |

Munitions per Cycle |

Cycles per 10-hr Day |

Munitions per 10-hr Day |

|

4.2-in. mortar, M1 |

6 |

6 |

36 |

|

75-mm projectile, M64 |

5 |

6 |

30 |

|

5-in. projectile, MK VI |

3 |

6 |

18 |

|

5-in. projectile, MK 54 |

2 |

6 |

12 |

|

155-mm projectile, MK II |

2 |

6 |

12 |

|

8-in. projectile, T174 |

1 |

6 |

6 |

|

Bomblet, M139 |

12 |

6 |

72 |

|

105-mm projectile, M60 |

5 |

6 |

30 |

|

100-lb bomb, M47 |

1 |

6 |

6 |

|

115-lb bomb, M70 |

1 |

6 |

6 |

|

SOURCE: Information provided by Ryusuke Kitamura, Kobe Steel, Ltd., to the committee, March 25, 2006. |

|||

TABLE 4-5 Agent Quantities Destroyed per DAVINCH DV65 Cycle

|

Munition |

Agent and Weight |

Items per Cycle |

Agent Weight per Cycle (lb) |

|

4.2-in. mortar, M1 |

Mustard agent, 6.5 lb |

6 |

39 |

|

75-mm projectile, M64 |

Mustard agent, 1 lb |

5 |

5 |

|

5-in. projectile, MK VI |

Mustard agent, 5.4 lb |

3 |

16.2 |

|

5-in. projectile, MK 54 |

GB, 4.2 lb |

2 |

8.4 |

|

155-mm projectile, MK II |

Phosgene, 11 lb |

2 |

22 |

|

8-in. projectile, T174 |

VX, 15.7 lb |

1 |

15.7 |

|

Bomblet, M139 |

GB, 1.3 lb |

12 |

15.6 |

|

105-mm projectile, M60 |

Mustard agent, 3.2 lb |

5 |

16 |

|

100-lb bomb, M47 |

Mustard agent, 70 lb |

1 |

70 |

|

115-lb bomb, M70 |

Lewisite, 83 lb |

1 |

83 |

|

SOURCE: Information provided by Ryusuke Kitamura, Kobe Steel, Ltd., to the committee, March 25, 2006. |

|||

The inner DAVINCH vessel is replaceable and, as stated by the manufacturer, can be used for at least 1,000 shots. Because the munition fragments tend to strike the vessel walls in the same general area following each shot, the liner is periodically rotated in order to distribute the impact areas around the circumference of the vessel.

Process Safety

DAVINCH requires between 20 and 25 workers plus laboratory personnel. All operations involving munition handling and the manual insertion of slurry explosive around the munitions are carried out by workers wearing low-level PPE (Level D). Higher levels of PPE are used if leaking munitions are to be handled. Since insertion of the munitions into the inner vessel is done using a robotic arm, presumably there is no worker exposure during that operation. Following detonation and evacuation of offgases, a spray decontamination solution is used if residual quantities of agent are detected. The heat-treated munition fragments are periodically removed remotely. Consequently, there should be no worker exposure to agent after the munitions are destroyed.

Public and Regulatory Acceptability in a U.S. Context

DAVINCH technology has not been permitted for use in destroying chemical weapons in the United States, although it has been used successfully in Japan for this purpose. No significant regulatory issues were identified to indicate that the DAVINCH technology could not meet U.S. environmental regulatory requirements if appropriate information (such as verified DRE, residual levels of dioxin, furans, arsenic, and any other chemicals of regulatory concern) is developed and provided to the regulators in a timely manner.

Additional testing of DAVINCH technology will be required prior to its being permitted in the United States for treatment of chemical weapons and materiel. Following a detonation, the inner vessel can be monitored for the presence of agent and, if necessary, an additional explosive cleansing shot can be carried out to remove trace quantities of agent, and/or a spray decontamination solution can be injected into the inner vessel for the same purpose. Offgases from the detonation are held in a storage tank and tested for agent. Depending on the agent level detected in the offgas, it can be either returned to the inner vessel for further agent destruction in a cleansing shot or sent to a gas treatment

unit either a combustor (incinerator) or a cold plasma unit before being passed through carbon adsorption beds.

The public reaction to DAVINCH is not yet known and may be complex since no DAVINCH units are operating in the United States upon which to base a perception. Moreover, there is no U.S. regulatory experience with this technology, and the use of thermal treatment to destroy any remaining agent in the detonation offgases might receive a mixed reaction from both the concerned public and regulators. However, public acceptance is likely to be favorable in light of the high DRE that is achieved and because all process residuals can be held and tested prior to release. Moreover, because the munitions are detonated in a vacuum, DAVINCH technology can be used in an urban area (and was so used in Japan) with greatly reduced noise and vibration, possibly to a point where these would not be of concern to the general public. At a distance of 0.2 km (640 feet), the noise resulting from a DAVINCH detonation was reduced from 72 dB at atmospheric pressure to 65 dB under vacuum conditions, and this 7 dB reduction in noise held for greater distances as well. An extensive public outreach process was undertaken prior to and during use of DAVINCH at Kanda Port in Japan, with frequent meetings held with public interest groups (Asahina, 2004). It is anticipated that a similar outreach effort would take place in the United States were DAVINCH technology to be used here.

Secondary Waste Issues

The waste streams produced by the DAVINCH technology are (1) gases resulting from the detonation and (2) heat-treated munition fragments that have been decontaminated to a point where they can be released or recycled. The gases can be stored in a buffer, tested for agent and other constituents, and sent to a post-processing facility for cleaning. Although the gases are currently combusted/incinerated and scrubbed, it may be possible to treat them in a plasma arc process that would clean them and destroy any residual agent. The public acceptability of doing this is not known, since treatment in a plasma unit could also be perceived as incinerating the offgases.

Arsenic recovery also presents a problem since nearly all of the arsenic resulting from DAVINCH operations is in dust, on munition fragments, or on the walls of the inner vessel. Although most of the arsenic on the vessel walls can be scraped off, some may remain in microcracks in the vessel wall that result from the detonations. Because removal of this arsenic is difficult, it is not routinely removed.

Process Cost Issues

Quantitative cost information for the acquisition and operation of a DAVINCH system was not available to the committee. Based on operating experience in Japan, the DAVINCH could be a cost-effective technology, especially if moderately large quantities of items (several hundred or more) are to be destroyed and if the physical sizes and/or the net explosive weights of the items to be destroyed exceed the capacities of other detonation-based technologies.

Operating costs may be greater than they are for the EDS since more staff may be needed (about 20 to 25 for the DAVINCH vs. 6 to 12 for the EDS). This may be offset, however, by the fact that DAVINCH technology has a greater capacity for accepting munitions and a higher throughput rate than the EDS, thus shortening the time that may be required for a specific application.

The life-cycle costs of acquiring, installing, operating, and removing a DAVINCH unit at a particular location will depend on numerous factors, including (1) the costs of acquiring the DAVINCH unit and transporting it and related equipment to the site; (2) site preparation costs; (3) the number of items to be destroyed, their explosive configuration, and the quantities of agent fill (these factors will influence the throughput rate and time duration of a campaign); (4) site-specific regulatory compliance costs; (5) the costs of secondary waste treatment; and (6) the requirements for disposal of treated residuals.

Summary

The DAVINCH technology uses a large detonation chamber in which chemical munitions and their contents are destroyed when donor charges surrounding the munitions are detonated under a near vacuum. Although the process does not require use of a reagent to destroy the agentthe destruction is accomplished by a shock wave, expansion and thermal heating from the detonation gases, and a fireball in the chamberoffgases are produced that require some secondary treatment by, for example, combustion and scrubbing.

DAVINCH technology has been used in Japan to destroy 600 Japanese chemical bombs, some containing a lewisite/ mustard agent mixture and others containing vomiting agents. The technology has not been used to destroy any U.S. non-stockpile chemical munitions.

The size and the explosion containment capability of versions of the DAVINCH technology are substantially greater than those of the largest treatment technology used in the United States for RCWM (the EDS-2), and its throughput also exceeds that of the EDS-2 by a factor of at least 3. It has demonstrated the ability to destroy over 80 pounds of agent (a lewisite/mustard agent mix in two Japanese Yellow bombs) in a single application and to have destroyed 10.14 pounds of explosive (picric acid) in these bombs.

The DAVINCH technology appears to be safe and effective. The external donor charges allow DAVINCH to be used to open agent-filled containers, inert munitions, and munitions containing energetics in order to access and destroy the agent. Because it is larger, DAVINCH is less mobile than the EDS-2, although a transportable version is under development.

TABLE 4-6 Size Specifications for Two Dynasafe Static Kiln Models

|

|

SK1200 |

SK2000 |

|

Explosive containment TNT-equivalent, lb (kg) |

2.64 (1.2) |

5.06 (2.3) |

|

Length, m |

4.5 |

6.0 |

|

Width, m |

4.35 |

5.5 |

|

Height, m |

6.0 |

8.0 |

|

Weight, kg |

24,000 |

40,000 |

|

Approx. detonation chamber volume, m3 |

0.91 |

4.19 |

|

SOURCE: Information provided to the committee by UXB International, Inc., August 19, 2005; <http://www.dynasafe.com/destruction-of-munitions-static-kiln.html>. |

||

Although application of DAVINCH technology to future U.S. non-stockpile disposal needs will depend on the nature of the items to be disposed of, DAVINCH technology has potential applicability at those U.S. sites where a temporary facility can be placed and could be used to dispose of medium to large quantities (hundreds to thousands) of items containing chemical agent or that are agent contaminated. It is probably not cost effective to dispose of items unlikely to contain agent, e.g., containers that have been previously burnt out, or for small numbers of small chemical-containing items, e.g., bomblets or small caliber projectiles, where the EDS technology would have greater applicability.

DYNASAFE TECHNOLOGY

Description

Dynasafe is the tradename for a static kiln manufactured by Dynasafe AB, a Swedish company that designs and manufactures products for the containment of explosions, including mobile explosion containment vessels used by police departments and the Burster Detonation Vessel, used by the NSCMP at its Munitions Assessment and Processing System facility in Edgewood, Maryland.17

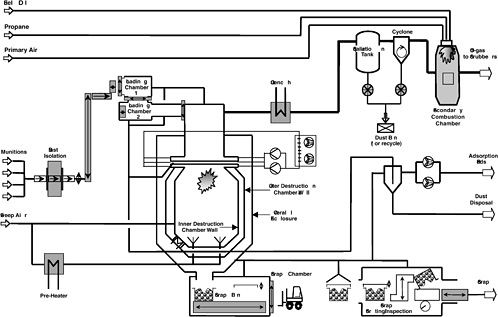

The Dynasafe static kiln is a near-spherical, armored, dual-walled high-alloy stainless steel detonation chamber (heated retort) inside a containment structure (Ohlson et al., 2004).18 The total thickness, including a safety layer, is 15 cm. The detonation chamber can operate in a pyrolytic or oxidizing environment. Intact munitions are indirectly heated by electrical resistance elements between the inner and outer walls of the detonation chamber. The munitions are heated to a temperature of 400C-600C, resulting in deflagration, detonation, or burning of the munition’s explosive fill. The chemical agent in the munition is destroyed as a result of the shock wave from the detonation when this occurs, the resulting gas pressure (measured at 10 bars, or 9.87 atmospheres), and decomposition due to the heat in the chamber. No explosive donor charge is used, and no reagent is needed to neutralize the agent. The kiln operates in a semibatch mode. Two sizes of the static kiln are available. Specifications are provided in Table 4-6.

Chemical munitions are placed in a cardboard box or carrier, preferably by robot but if need be, manually. The box is placed on an elevator for the SK2000 version or on a trolley conveyor for the smaller units and is transported to the top of the kiln. Leaking munitions are placed in an airtight plastic bag and then in the box before being loaded. Munitions that are already in a single round container can be loaded onto the conveyor or elevator while in the container.

The boxed munitions are fed into the kiln through two loading chambers (see Figure 4-4), each having its own hydraulically operated door and inflatable seal. The upper loading chamber has airlock doors and the lower loading chamber has a hot blast door between it and the kiln’s detonation chamber. The doors, loading chambers, and detonation chamber are all designed to resist and contain the overpressure from a detonation of up to 2.3 kg TNT-equivalent. An additional 2.3 kg TNT-equivalent of overpressure containment is included in the design as a safety margin. To provide total containment, the doors are gas-tight as well as explosion-resistant. The interior of the detonation chamber is not open to the atmosphere while munitions are loaded, and the loading chambers are offset for safety purposes.

Using a hydraulic arm, the boxed munitions are pushed into the loading chambers, moving from one chamber to another, and are then dropped onto a heated (500C-550C) shrapnel (scrap) bed at the bottom of the detonation chamber. The maximum drop is about 2 meters. The purpose of this bed is to protect the chamber walls from munition fragments when detonation occurs. If sufficient energy from energetics in the munition is released, no additional external heating from the electrical resistance elements is required. If the munition does not contain energetics, then additional heat can be provided by the electrical resistance elements.

|

17 |

Except where otherwise note, technical information for this section came mostly from meetings with representatives of Dynasafe AB (Sweden) and UXB International, Inc. (United States) (see Appendix D). |

|

18 |

See also <http://www.dynasafe.com/destruction-of-munitions-static-kiln.html>. |

During operations, conditions in the detonation chamber are monitored using an air-cooled camera located in a tube that protrudes into the chamber. A slight negative pressure is maintained in the chamber to enable detection of the pressure pulse that takes place when a munition detonates. A microphone is used to detect the sound of a detonation, and vibration of the chamber is also recorded.

When the detonation chamber has a full scrap load, i.e., when it is about 50 percent full, a clean burning period takes place during which the scrap metal is heated to 550C-650C for several hours to meet GPL requirements. After completion of the clean burning period, the detonation chamber disengages from the lower loading chamber and is rotated almost 180 degrees clockwise in order that most of the munition fragments can be dropped into a scrap bed in a bin. A low baffle plate in the detonation chamber, near the place where the scrap exits, retains some of the scrap/shrapnel for the next load. The metal scrap bins are enclosed within the outer housing of the kiln to prevent dust from escaping and to allow confirmation that the metal can be released. When scrap removal has been completed, the kiln rotates back to its upright position and the retained scrap in the detonation chamber falls to the bottom.

During operations, offgases from pyrolysis and detonation are continuously evacuated from the kiln, and compressed air is used to sweep all offgases from the combustion chamber. If the process is operated as a closed systemthat is, as a batch reactorthe offgases can be held inside the detonation chamber for as long as necessary to ensure that agent destruction takes place. The offgases can also be analyzed prior to their release to the offgas treatment system. If necessary, nitrogen can be used as the sweep gas. When the process is operated as an open system, the offgases are transferred to a heated buffer that serves as an expansion tank and as a cyclone to remove coarse dust. European Union environmental regulations require that to ensure agent destruction, a secondary combustion chamber with a 2-second residence time and operating at 1100C must be used. Other offgas treatment steps may include use of a quench tower to cool the gases to prevent dioxins and furans from forming, as well as various scrubbers and equipment to capture fine particulates and to remove heavy metals and metallic oxides. The use of such equipment will depend on whether the Dynasafe unit is operated as an open or a closed system, the constituents of the offgas, and environmental requirements.

The elapsed time for a munition destruction cycle will vary with the explosive and agent content of the munition. For conventional munitions, throughput of 25-35 detonation cycles per hour has been demonstrated for explosive loads of 2 kg TNT-equivalent and can be greater for smaller explosive loads. Daily throughput includes the clean burning time. The throughput for chemical munitions will depend on whether the Dynasafe is operated as an open or a closed system, the number of munitions that are fed into the detonation chamber per cycle, and the number of cycles per hour.

Country-by-Country Experience

Dynasafe static kilns have been used to destroy a substantial variety of conventional munitions in several countries. The applications include these:

-

Sweden, destruction of detonators and small arms ammunition in SK400 (1997) (no longer available).

-

Spain, destruction of conventional munitions in SK1200 (1997).

-

Sweden, destruction of conventional munitions in SK800 (1999) (no longer available).

-

Japan, destruction of antipersonnel mines and conventional munitions in SK1200 (2000).

-

Portugal, destruction of antipersonnel mines and conventional munitions in SK1200 (2001).

-

Asia, destruction of conventional munitions in SK2000 (2003-2004).

A prototype development unit has destroyed over 100 kg of mustard, lewisite, and Clark I and II agents, although these agents were not contained in chemical munitions. In February 2006, 100-mm German grenades containing energetics and 1.5 kg of mustard agent fill were successfully destroyed in the Dynasafe SK2000 at the GEKA facility in Munster, Germany.19 Three grenades were destroyed per feed cycle. The ability of Dynasafe to access and destroy agent in thick-walled steel munitions will also be demonstrated at GEKA. A detailed description of the use of the Dynasafe SK2000 at the facility is provided in Weigel et al. (2004).

Evaluation Factors Analysis

Process Maturity

The Dynasafe family of static kilns is a mature technology that has been used for several years to destroy a substantial variety of conventional munitions, as noted above. The kilns have been both safe and effective for this application. Using this experience as a basis, the Dynasafe static kiln has been modified to destroy chemical munitions and was doing so at the above-mentioned German government facility in Munster, Germany, when this report was being prepared. As of April 21, 2006, at least 1,000 munitions containing mustard agent, phosgene, or diphenylchloroarsine (Clark I) agent had been destroyed.

Modifications include making the kiln gas-tight to contain any agent remaining in offgases, heating the scrap metal to remove all traces of agent on metal surfaces, and using an elaborate offgas treatment system to scrub the detonation gases and remove any remaining traces of agent.

Although the Dynasafe static kiln has not yet been tested or used to process U.S. non-stockpile chemical munitions, it appears to have the capability to do so since many of these munitions are within the size and explosive containment capabilities of the largest Dynasafe unit, the SK2000, and contain the same mustard agent fill found in the munitions being destroyed in Munster. As this report was being prepared, none of the Dynasafe kilns had been permitted for operation in the United States for the destruction of chemical munitions.

Process Efficacy/Throughput

The Dynasafe static kiln heats munitions until the energetics within them detonate, causing the agent to be exposed to the resulting shock wave, blast pressure, and heat. It is possible, however, that for some items, the energetics and/or agent will undergo deflagration (rapid combustion driven by heat transfer). In fact, deflagration rather than detonation is stated to be the usual destruction process in the detonation chamber.20 Some items only contain agent, the energetics having been removed or never having been placed in the munition (as would be true, for example, with a test round). In these cases, although the agent may vaporize within the munition body and may rupture the munition body as a result, this is not guaranteed to happen. In such cases, the manufacturer states that the agent will escape as it vaporizes, either through the threads in the munition nose closure or through a weak point in the munition body.

In testing at GEKA in early 2006,21 empty inert grenades were filled with water, welded shut, and placed in the SK2000 detonation chamber. The water fill vaporized and, as a result of the increased internal pressure, destroyed the grenades, as observed by the control room operators. In additional testing, partially sealed, water-filled grenades were placed in the detonation chamber and heated. As internal pressure slowly increased, the water vapor escaped through screw threads. Absent the sudden destruction of the grenades, it was not possible to detect the escaping vapor, and the grenades emerged intact. The grenades were then x-rayed and cut open to verify that they were empty.

Results to date indicate that the agent in all sealed or partially sealed inert munitions is destroyed, although operating results for grenades and other munitions that may contain mustard agent heels were not available. However, the absence of a positive indication that agent destruction has taken place for those munitions where agent slowly escapes may be a concern, and it may increase process costs and complexity if post-processing actions are required to confirm that no agent remains in the munition.

Finally, testing of explosively configured munitions containing agent simulants has been conducted to demonstrate accessing and destruction of the agent simulant in the munitions.

The technical director at GEKA has stated that the worst case would be one in which a munition containing neither agent nor energetics is fed into the chamber: in that case, the munition would experience nothing other than being heated and would emerge as it entered and have to be opened under controlled conditions to ascertain its original condition.22 Opening the munition would increase costs as well as the potential for human exposure. If processing needed to stop while the munition was examined to confirm that it is empty and inert, throughput might also be reduced.

The Dynasafe static kilns and related material handling equipment are large: For example, the largest unit, the SK2000, is 6 meters long, 5.5 meters deep, and 8 meters high. The weight of this unit is 44.1 tons. A smaller version, the SK1200, is 4.5 meters long, 4.35 meters deep, and 6 meters high. This unit weighs 26.4 tons, but a mobile version is under development (Dynasafe, 2006). The mobile version consists of eight containers: three for the static kiln, three for the offgas treatment system, and two for spare materials and a workshop. These containers can be carried on three flatbed trailers, and the mobile version can be operated in either an open or closed mode.