6

Cross-cutting Technologies

INTRODUCTION

This chapter discusses two technology areas that have the potential to yield dramatic improvements in aerospace propulsion—namely, fuels and materials. While the ensuing discussion and recommendations are related primarily to air-breathing propulsion, advances in fuels and materials research are applicable also to access-to-space and in-space propulsion; those applications are discussed in Chapter 4 and Chapter 5.

FUELS

Gas Turbines

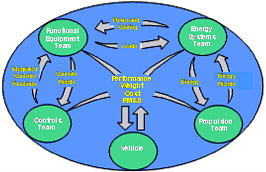

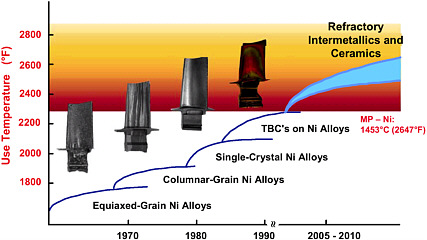

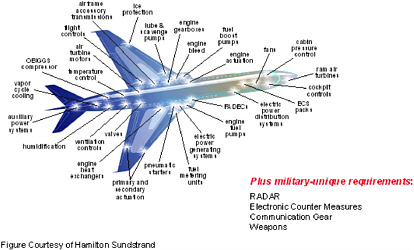

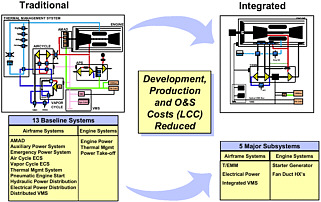

One key to improved warfighter design and performance will be the total integration of a vehicle and its propulsion system. Figure 6-1 demonstrates a systems-level approach to total vehicle design, including thermal loads, energy transfer, and control systems.

FIGURE 6-1 A systems-level approach to warfighter design. SOURCE: Burkhard (2003).

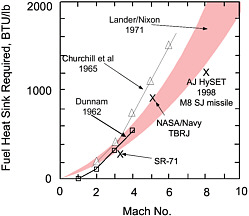

Another important issue is fuel efficiency, because a reduction in specific fuel consumption (SFC) enhances range and payload and decreases fuel costs. Gas turbines operate on constant pressure Brayton cycles, and to improve the Brayton cycle thermal efficiency requires higher turbine inlet temperatures. Not only do higher engine operating temperatures demand high-heat-sink fuels capable of cooling hot section components to preserve life and durability, but significant material barriers also prevent achieving higher turbine inlet temperatures. One way to circumvent this problem is to use a fuel to cool the cooling

air, thereby enhancing its heat sink, decreasing its mass flow, and improving engine SFC. At the same time, employing cooled cooling air (CCA) might enhance the turbine blade thermal gradient and accelerate thermal fatigue, which means the turbine materials would need better low-cycle fatigue capability. Future development of low-fuel-consumption engines with CCA or engine power generation for directed-energy weapons will dramatically increase the heat load rejected to the fuel. The fuel heat sink requirement is shown in Figure 6-2.

FIGURE 6-2 Fuel heat sink requirements vs. Mach. SOURCE: Edwards (2003).

The thermal management challenge is exacerbated at higher Mach numbers, where fuel temperatures can exceed 900°F at Mach 4 and 1300°F at Mach 7 (hypersonic). The problem is not the high fuel temperatures per se—it is preventing any resulting fuel system deposit (coking) from crippling the operation of the engine and limiting its life. The quality of a fuel is measured by a rule-of-thumb bulk and wall temperature limit corresponding to 2,000+ hours of fuel system life. Thus, the development and use of high-heat-sink fuel for thermal management is a paramount challenge. Research into fuel additives and deoxygenation systems is required to increase fuel system life, which is typically a few hundred hours, by an order of magnitude at temperatures above 500°F.

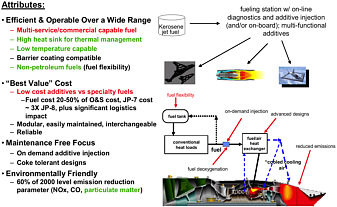

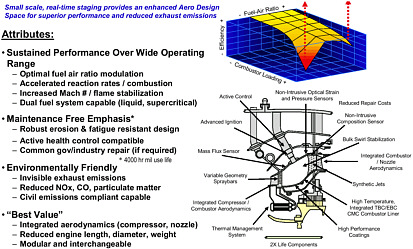

The Air Force Research Lab (AFRL) high-heat-sink fuel program seeks to increase the thermal stability of JP-8 from its current operating temperature of 325°F to 550°F (120 percent higher heat sink) and eventually to prefect the fuel designated as JP-900 for the hypersonic flight regime. Ideal gas turbine fuel attributes are envisioned in Figure 6-3.

Jet fuels are complex, and technology transition often involves multiple partners such as engine companies, airframers, fuel system suppliers, additive manufacturers, university researchers, the Air Force Petroleum Office, the Defense Energy Support Center, and the Air Force system program offices. Also, coordination with commercial aviation and industry through the International Air Transport Association, the American Society for Testing and Materials, the Federal Aviation Administration, and the North Atlantic Treaty Organization is required. Interchangeability of military and commercial fuels is a key logistical benefit.

AFRL has been conducting research in the following areas to enhance fuel thermal stability using fuel deoxygenation, advanced additives, and surface coatings:

-

Evolving technologies such as nanoparticles could allow developing the JP-900 type fuel. Nano fuel technology shows promise in enabling advanced smart additives. Advanced fuel system

-

sensors (such as might be used for onboard monitoring of fuel system health) might also benefit from advances in nano fuel technology.

-

Modeling of fuel oxidation and deposition would enhance the development and optimization of thermal management systems. Such modeling might allow predicting time-dependent location and quantity of deposition.

-

Investigation of the effect of deposit formation on spalling and heat transfer coefficients, which in turn affect the CCA and the thermal management system, is critical to reducing turbine blade cooling air mass flow and improving engine SFC.

FIGURE 6-3 Gas turbine fuel vision. SOURCE: Edwards (2005).

Fuel freezing is of concern for extended-duration, high-altitude flight missions such as loitering by unmanned aircraft systems (UASs) and transpolar commercial flights. Additive formulations need to be developed to extend the lower limit of operability of JP-8, from -52°C to -60°C and lower at modest additive concentrations (ppm).

High-Altitude, Long-Endurance Unmanned Aircraft Systems

These types of aircraft missions challenge the fuel at both ends of the temperature spectrum. Long-endurance aircraft imply low SFC, which in turn implies high cycle temperature. In contrast, the fuel in the wing tanks will be cold-soaked at temperatures of -53.6°C (-65°F) or so. At that temperature, conventional jet fuel is solidly frozen. Although additives are being developed, current practice requires undesirably high concentrations (~4,000 mg/L) to be effective. A much better solution would be an additive at a concentration of 250 mg/L, similar to the existing JP-8+100 additive. In addition, there is a gap in our understanding of the chemistry and physics of long-chain paraffins “freezing out” of the fuel, which controls the lower temperature limit of the fuel during use. Current aircraft such as the Global Hawk are pushing the low-temperature limits of JP-8. Aircraft using fuels that are not logistically supportable (such as the Predator, which uses avgas) present technical challenges. Additives that have different functionalities at different operating conditions (smart additives) would improve both the low-and high-temperature properties of jet fuels.

Small UASs powered by spark ignition engines or more efficient diesel engines will require alternative or diesel fuels with good flowability for a high-altitude, extended-loiter mission. Such fuels need to be developed to meet future warfighter needs.

Expendable Missiles with Turbine Engines

The key drivers for missile fuels are their low-temperature properties (due to long cold soak on-wing) and their high density (due to volume limitations on fuel storage). JP-10 (a single-component hydrocarbon, exo-tetrahydrodicyclopentadiene, with an impressively low freezing point of -110°F) is the current state-of-the-art missile fuel. Boron slurry fuels offer improved theoretical performance over JP-10 in terms of energy density but have poorer combustion efficiency and less efficient handling and stability. Therefore, a key technology challenge is the development of high-energy fuel that has an ultralow freezing point.

Hypersonic and Scramjets Vehicles

In many ways, liquid hydrogen is the ideal fuel; however, it has two major drawbacks from a military perspective—low density (1/12 that of jet fuel) and extreme cryogenic storage requirements. The use of liquid hydrocarbon fuels like JP-7 solves the logistics issues but raises two other important issues: (1) relatively slow combustion and long ignition delays in contrast with air speed through a hypersonic combustor and (2) limited regenerative cooling capability. The technical problem of flame stabilization needs to be solved. Fuel regenerative cooling capability above 1000°F is (again) limited by coking that occurs within 1 hour. A promising approach has been the use of wall-coated catalysts to enhance fuel cracking reactions while minimizing carbon formation. Until now catalyst selection has been largely empirical, as there is a poor understanding of the impact of fuel system conditions on catalyst performance. Thus, there is an urgent need to develop high-heat-sink hydrocarbon fuels, alternative fuels, suitable catalysts, and fuel systems.

Pulsed Detonation Engines

It is anticipated that pulse detonation engines (PDEs) will be regeneratively cooled. The fuel issues will therefore be similar to those for gas turbine engines (GTEs)—namely, minimizing coking and fuel system deposition in JP-8 fuel and maximizing system life.

Combined Cycle Engines

There are apparent payoffs for using the same fuel for both cycles in combined-cycle engines (one set of tanks, one fuel system/pump, etc.). Accordingly, the use of a highly thermally stable kerosene (jet) fuel for rocket- and turbine-based combined cycle engines would seem to be a good idea, and the technical challenge will be to optimize the combined-cycle performance using a single fuel.

Liquid Hydrocarbon Propellants for Rockets

For many rocket applications where propellant density is important—such as small rockets and the first stages of multistage vehicles—liquid hydrocarbon propellants are preferred to higher performance liquid hydrogen. The key issues for hydrocarbon propellants are performance (specific impulse) and stability during regenerative cooling. Hydrocarbons are relatively poor performers compared to hydrogen, with the key challenge being effective ways to add energy to the hydrocarbon without compromising the stability of the propellant during use. The current approach pursued by NASA and the Air Force is to add strain energy to the propellant by forming three-carbon rings and triple bonds. The key gap is in understanding how to add this energy without destabilizing the molecule to the point that it falls apart inside the fuel system rather than inside the combustion chamber. This is mainly a concern for rocket engines that are fuel-cooled (i.e., regeneratively cooled) since the heat is not lost to the cycle.

Current NASA and DoD research in hydrocarbon regenerative cooling has identified improvements to the current hydrocarbon propellant RP-1 to improve its regenerative cooling performance, but the

search for a usable high-energy hydrocarbon propellant is still in its infancy. Because of uncertainties in funding, NASA’s role in this effort is unclear.

Modeling and Simulation of Complex Hydrocarbon Fuels

Military and commercial jet fuels contain thousands of hydrocarbons, with the mixture loosely bounded by specification requirements for boiling range, low temperature and combustion properties, and some composition limits. The complexity of these fuels has created significant gaps in the knowledge we need for modeling their physical, chemical, and combustion properties. Chemical kinetic modeling of jet fuel combustion represents a significant technical barrier to the development of better fuels and additives.

Fuel Cost and Logistics Barriers and Alternative Fuels

As described at the beginning of this chapter, fuel cost is one of the largest single contributors to aircraft operating cost and is therefore a key factor in the selection of a fuel. To reduce its dependence on foreign oil, DoD has initiated a Clean Fuels Initiative.1 DoD intends to encourage industry to produce clean fuels from secure, diverse domestic resources for use in all military tactical vehicles, aircraft, and ships to reduce its dependence on foreign oil, its supply chain vulnerabilities, and pollutant emissions.

DoD has been working toward a more universal (single) battlefield fuel that will be usable in current and legacy systems and also in the next generations of hybrid propulsion, fuel cells, and hypersonic vehicles. For example, nine fuels are provided to U.S. forces operating in the Middle East and Afghanistan, creating supply chain inefficiencies. Therefore, DoD and the Department of Energy (DOE) are jointly working to develop, test, certify, and use jet fuels derived from coal, natural gas, and oil shale (e.g., via the Fischer-Tropsch process and coal liquefaction) and to assess their national security benefits and weigh them against cost and availability concerns. Production of jet fuels from these sources is feasible, but a number of technical hurdles remain. These include improving the lubricity, seal swell, and storage stability of these fuels and evaluating their combustion performance.

Recommendation 6-1. The Air Force should initiate a 5- to 7-year comprehensive program of fundamental fuels research. The goal of this program should be to study properties of smart fuel additives, surrogate fuels, synthetic fuel process technologies, synthetic fuels produced from feedstocks such as coal, oil shale, and biomass, and synthetic-conventional fuel blends. Systematic molecular and chemical kinetics modeling studies should be performed to establish a fundamental database of fuel and combustion properties.

MATERIALS

Advances in new materials have been an important factor in aerospace propulsion systems ever since the Wright brothers used a lightweight, age-hardening aluminum alloy in their Wright Flyer engine in 1903.

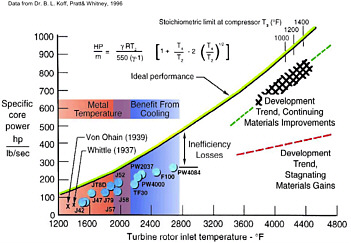

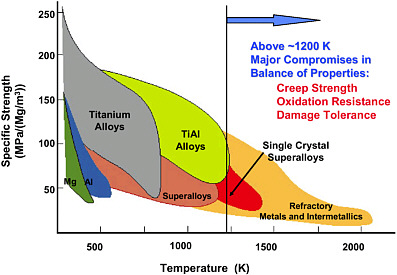

High-temperature cobalt base and nickel base alloys have allowed improving the performance and efficiency of the turbine section of GTEs for the last 50 years, through progressive increases in turbine inlet temperature. These increases have also been aided by improved cooling schemes, single crystal technology, and thermal barrier coatings. Significant improvements have also been made in materials for other sections of the engine, including compressor and disk materials, combustor materials, and bearing materials. As shown in Figure 6-4, further increases in turbine inlet temperature will have to await either significantly improved cooling of the first- and second-stage metallic blades or the incorporation of a

|

1 |

More information on the Clean Fuels Initiative may be found at http://www.westgov.org/wieb/meetings/boardsprg2005/briefing/ppt/congressionalbrief.pdf#search=%22harrison%20clean%20fuels%20initiative%22. Last accessed on August 30, 2006. |

totally new class of materials, such as ceramic matrix composites (CMCs) or nanoscale carbon-tube-based materials.

FIGURE 6-4 Materials and core engine performance. SOURCE: Hardwick (2005).

With respect to current Air Force requirements, materials in today’s commercial engines are primarily stressed during takeoff and spend most of their life at much cooler cruise conditions. Military engines have temperature spikes corresponding to throttle excursions, but still most of the time the engine materials would not be highly stressed unless the air vehicle was in constant maneuver. The picture for extended supersonic operation is far different. In conceptual long-range-strike aircraft, the hot section materials spend most of their life at high temperatures and high stresses. This is a completely new regime for materials, and old solutions will not suffice under these new conditions. Degradation modes related to fatigue, creep, and environmental attack (such as hot corrosion) interact at these conditions to greatly affect component durability. In addition, the use of CCA would exacerbate the thermal gradients and, accordingly, the material challenge.

Materials limitations have also impacted the development of rocket propulsion systems, though in somewhat different ways. High turbine-inlet temperatures are not required in pump-fed rocket engines, and conventional nickel base superalloys are generally adequate for turbopumps. However, combustor temperatures, heat fluxes, and pressures are all much higher than in gas turbines, requiring either highly conductive, actively cooled structures for high-thrust engines or exotic Pt/Ir alloys running at very high temperatures for in-space engines. Other materials issues of significance include bearing materials, ablative materials, and lightweight, high-strength materials for solid rocket motor cases and ducts.

The problem of material erosion is a generic one that also affects key components in GTEs, such as compressor and turbine blades as well as rocket throats. To be sure, the solution will be different, but the need for a fundamental understanding of erosion mechanisms would be a shared need. The investigative tools developed for nanotechnology can be applied to greatly extend our understanding of erosion mechanisms and, more broadly, surface science and tribology.

The propulsion industry today, air-breathing and rocket, is taking advantage of materials and processing investments spurred by the Manufacturing Technology (ManTech) program (DSB, 2005). In retrospect, funding by the Services and DoD/ Defense Advanced Research Projects Agency (DARPA) has spawned the entire aerospace materials supply chain that exists today. As we look to a future with very limited and restricted ManTech funding, such investments are being driven by commercial engine needs, with DoD tagging along. More of the advanced work will migrate offshore. For instance, SiC fiber used

in highest temperature CMCs is supplied from Japan, and TiAl processing is rapidly advancing in Europe. Since the DoD production base is not high, these new material technologies become economical only if there are commercial applications. So there is an opportunity for realistic planning of ManTech programs that will provide baseline manufacturing technology for high-performance defense systems and will also leverage requirements of the nondefense aerospace sector.

Recommendation 6-2. The Air Force should fund ManTech at a level sufficient to enable future advances in materials for propulsion technology.

High-Temperature Structural Materials

Advances in materials for turbine engines over the past 60 years have lead to higher operating temperatures that, in turn, have produced higher efficiency. However, engine technology for air-breathing engines is now pushing physical limits in both materials and design.

Current engines rely on nickel base superalloys for reusable engines and carbon/carbon composites for expendable engines. Over the past 40 years, the time between engine overhauls has increased from 500 hours to more than 10,000 hours. Metals are used for critical structural applications because of their ductility, toughness, and fracture resistance. Ceramics, although capable of significantly higher operating temperatures than metals, are too brittle for structural applications where damage tolerance is required.2 A flaw the size of a human hair can degrade the strength of a ceramic by 10- to 100-fold, whereas the toughness of metals tolerates imperfections of up to a millimeter or even more. This flaw size is readily detectable by standard nondestructive test techniques: The maximum allowable flaws in ceramics are not readily detectable.

Unfortunately, most metal oxides and metal sulfides are much more stable than the metals themselves. As a result, high-temperature metals are alloyed, metallized, and coated with ceramics to improve durability. Aluminum and chromium are the principle alloying elements that produce a protective oxide scale on the metal surface. Aluminum, chromium, and platinum are the principle metallizing layers, while ceramic coatings are deposited by various methods. Nickel-base alloys containing large amounts of aluminum and chromium are the most widely used high-temperature structural materials in air-breathing engines today.

At temperatures exceeding eight-tenths of the melting temperature, or 0.8 Tmelt,3 all materials, even ceramics, lose their long-term strength. This phenomenon whereby a material will slowly change shape at elevated temperatures, is called creep. Current nickel base alloys, which melt at 2450F (2900 Rankine) and operate at 2000F (2460 Rankine), are already operating at 0.85 Tmelt. Thus, the workhorse engine material is pushing above its practical temperature limit.

As shown in Figures 6-5 and 6-6, refractory metals (e.g., molybdenum, niobium, tantalum, and tungsten) have much higher melting temperatures and creep strength than nickel and have been effectively added to nickel-base superalloys to improve high-temperature mechanical properties. Considerable effort has been and is being made to qualify these metals for high-temperature, long-term structural use in air. Unfortunately, the chemical bonding that gives them superior melting temperatures is the same chemical bond that has an extremely strong affinity for oxygen, sulfur, and carbon. These materials must be coated and the coatings must be perfect; if they are not, even minute imperfections in the coating can cause loss of protection and catastrophic oxidation of the airfoil.

|

2 |

Although resistive to oxidative attack, ceramics are still subject to environmental degradation. For instance, silicon-containing materials undergo surface recession in combustion environments due to chemical reaction of the silica scale with water vapor (Si hydroxides, such as Si(OH)4, are formed through a hydrolysis reaction whereby SiO2 reacts with H2O to form volatile Si hydroxides. Thus, these materials must be protected with an environmental barrier coating for extended use at high temperature (see http://www.grc.nasa.gov/WWW/RT2002/5000/5160lee.html). Also, many ceramic materials undergo allotropic phase transformations, with associated changes in dimensions, physical, and mechanical properties that make them difficult to use in high-temperature structural applications, especially those that are subjected to thermal gradients. |

|

3 |

Tmelt must be calculated on an absolute temperature scale, such as Kelvin or Rankine, rather than Celsius or Fahrenheit. |

FIGURE 6-5 Advances in turbine blade alloys. SOURCE: Hardwick (2005).

FIGURE 6-6 Strengths of advanced metallic materials. SOURCE: Hardwick (2005).

As the temperature increases, the number of metal systems available for use decreases. As technology edges toward the melting temperature of the nickel base superalloys, future improvements will require combinations of refractory metals coated with multiple layers of oxidation-resistant metals and ceramics to achieve the balance of high-temperature strength, damage tolerance, and oxidation resistance that nickel alloys have provided up to 2300F. A quantum jump in the operating temperature of turbine blades will require a new base material other than nickel, yet only platinum has the balance of properties

required for operation at higher temperatures. The refractory metals will require new coating technologies to make them suitable for use in air-breathing engines. Ceramics will require structural support from metals to provide damage tolerance.

Intermetallics have been studied extensively for more than three decades and now show some promise as high-temperature disk materials. Titanium alloys replaced aluminum as the skin material for aircraft at high Mach numbers. But development of higher-temperature, lightweight skins will become more critical as speed and flight duration both increase.

The much higher temperature capability and high wear resistance of ceramics foretells their expanded use in the future as thermal barrier coatings, in the combustor, and in engine bearings. Only ceramics and CMC materials have the high-temperature strength for the hottest sections of engines for Mach numbers above 4 or 5. Owing to the low damage tolerance of the ceramics, these materials will require backup support from metals with lower temperature capabilities. These support metals will require active cooling and designs that permit substantial thermal expansion differences. As the materials requirements become more demanding, the designs become more complex, which escalates the cost of the system. One way to control costs is to focus on smaller-scale engine applications. Development of high-Mach-number, high-payload, man-rated applications could be delayed until the materials are proven in smaller, non-man-rated, high-Mach-number applications.

Fortunately, most of the most demanding temperatures will occur in engines that do not require long-term service and are not man-rated. Carbon/carbon composites and ceramics will find increasing use in systems that do not require safety and reliability levels deemed appropriate for humans. Knowledge gained from these short-term engines will eventually be transferred to long-term man-rated engine designs.

Combustion and Thermal Management

Augmentor Combustion Instability

Augmentor stability problems can be grouped into two areas: static stability and dynamic stability. Static stability is loosely defined as the ability to light the augmentor and ignition and to maintain the flame at lean blowout. Dynamic stability is the coupling between heat release and pressure fluctuations. One technical challenge is to develop a physics-based (rather than empirical) understanding of augmentor combustion instability. Computational fluid dynamics (CFD) and advanced diagnostic capability can be key to meeting this challenge.

Augmentor combustion is sensitive to fuel/air ratio, spray dynamics, atomization, and evaporation. Another parameter is vortex shedding. The time-dependent nature of vortex shedding and its effect on the time-dependent nature of the fuel and air at the flame are poorly understood. Currently, a transfer function for the feedback mechanism between heat release and pressure fluctuations is calibrated from rig or engine data. These calibrated models do not fare well when extrapolated outside the range where they were validated.

Fuel Injection and Mixing

Future high-performance combustors will employ supercritical injection of endothermically cracked fuel products of JP-8. Thus, rapid innovative mixing methods using CFD-large-eddy simulation modeling tools, improved endothermic models, and new fuel deposition and thermal breakdown mechanisms must be developed. Also, the compressor, combustor, and turbine interaction needs to be studied as a system.

Reactive-Film Cooling Studies

The demand for greater engine efficiency is driving future aircraft engines toward higher total temperature and higher fuel-air ratio. The radiative heat transfer to the combustor wall represents over 60 percent of the total heat flux, leading to the need for a radiation barrier coating on the combustor liner.

Such high-performance engines are facing additional durability issues related to heat release through the turbine as energetic species emitted from the combustor are further oxidized. The problem needs to be addressed for design and control of reactive cooling techniques employing endothermically cracking JP-8 fuel.

Combustor Structure and Durability

There is a need to develop a set of acceptance criteria for combustor liner life measurements, instantaneous thermal and transient loading of CMC combustors and turbine vanes, and modeling and simulation of CMC life and crack predictions.

Advanced Laser-Based Instrumentation for Diagnostics and Control

Advanced instrumentation is a key enabler for active control schemes, engine health monitoring, condition-based maintenance, and intelligent engines. Advanced instrumentation and control need to be developed for high-pressure, high-temperature combustion processes. Advanced laser instrumentation capable of operating above 10 atm and 500°C is required. Improving performance, reducing pollutant emissions, tailoring military signature, and enhancing reliability, maintainability, and affordability all demand a complete and predictive understanding of the chemistry and physics that drive gas-turbine combustors, augmentors, pulsed detonation engines (PDEs), scramjets, and other current and next-generation systems.

Future Innovative Concepts

Figure 6-7 shows the desired combustor attributes of future designs. Two innovative combustor concepts are being pursued: constant volume combustor (CVC) and the ultracompact combustor (UCC). Another combustor attribute, not included in Figure 6-7, is a SiC/SiC combustor liner that shows much greater temperature capability than a metal liner.

CVC technology shows the potential to benefit military and commercial turbofan engines and industrial power generation gas turbines. Analytical proof-of-concept studies have claimed for aircraft up to 20 percent fuel savings, a 70 percent NOx reduction, and a 25 percent engine weight savings. CVC offers features superior to PDEs, and the substantial pressure gain across the combustion system improves SFC by 5 percent or more (Akbari et al., 2004). A wave rotor eliminates valve losses and places pulsed combustion within the device’s channels to isolate pressure waves from perturbing either the compressor or the turbine. Also, use of a wave rotor simplifies the fueling and ignition systems. Finally, since the combustion charge remains at high temperature, but only for a short duration, NOx formation is significantly reduced.

The UCC concept combines a combustor with compressor exit guide vanes and turbine inlet guide vanes, leading to a compact engine core (Sturgess et al., 2005). This UCC concept is too immature to permit any realistic comparisons of its emissions characteristics with those of other engines.

FIGURE 6-7 Desired combustor attributes. SOURCE: Arana (2005).

Air Vehicle/Engine Thermal Management

The vehicle heat loads shown in Figure 6-8 represent the power needs of directed-energy weapons and short takeoff and vertical landing lift equipment where applicable; avionics and health monitoring systems; more electric aircraft (engine start, flight controls etc.); composite airframes (with nonconvective surfaces); reduced vehicle size (UAS, microUAS); bearing/lubricant systems; and environmental subsystem cooling.

FIGURE 6-8 Air vehicle heat loads. SOURCE: Burkhard (2003).

Also, the air vehicle mission profiles bound thermal management options. For example, a long-range supersonic aircraft cruising at 50,000 ft with Mach greater than 2 has a high heat load but also a high fuel heat sink capacity, whereas a loitering unmanned combat air vehicle has a high heat load but a low (available) fuel heat sink. The engine trends affecting thermal management are higher turbine inlet temperatures, higher performance, and high-heat-sink fuels. To meet these thermal demands requires the following:

-

Integrated cooling schemes (CCAs),

-

High-heat-sink fuels,

-

Reduced waste heat generation,

-

High-temperature materials,

-

Novel cooling strategies (endothermic, phase-change materials), and

-

A systems analysis thermal management approach based on warfighter needs.

Thermal management involves air/air, fuel/air, air/oil, and fuel/oil heat exchange. The candidate thermal sinks are the external environment, fan/compressor discharge air, unburned fuel, and CCA. Future warfighter design needs will include mitigating techniques such as self-cooling components, on-demand pumping, and multiple heat sinks to aggressively manage all heat generated.

Fuel is typically treated as the most desirable heat sink for aircraft and engine waste heat, but inadequate integration of the thermal management system can compromise aircraft operability. For example, aircraft have been fielded that are required to land with 500 lb of fuel in the tanks for thermal management, which directly reduces payload. In another aircraft, fuel must be chilled prior to being loaded onto the aircraft to allow sufficient ground hold time to perform equipment checks. This is logistically unacceptable. Future low-fuel-consumption engines with CCA and/or engine power generation for directed-energy weapons will dramatically increase the heat load to be rejected to the fuel (and the penalties for poor system integration). This is a system-level concern throughout an aircraft’s mission.

As for the fuel itself, the challenge lies not in achieving the high fuel temperatures but in preventing any fuel system deposit formation (coking) from crippling the operation of the engine and limiting its life. Additives and fuel deoxygenation have been demonstrated to increase fuel system life by greater than an order of magnitude at temperatures above 500°F. Pratt & Whitney has successfully run a JT15D engine with JP-8 fuel at 600°F for more than 50 hours using a prototype fuel stabilization unit. In the past, such engine conditions would have required an expensive specialty fuel like JP-7.

Fuel flows and heat loads vary throughout an aircraft’s time in the air (and on the ground). This thermal management challenge is exacerbated at higher Mach numbers, where fuel temperatures can exceed 900°F at Mach 4 and 1300°F at Mach 7 (hypersonic). AFRL is leading an industry consortium in the development and application of open-architecture thermal management system modeling tools to better identify air vehicle thermal management problems in the design phase. The key advance here is cooperative use of the modeling tools by the manufacturers of the airframes (Lockheed, Boeing, and Northrop Grumman), the engines (Pratt & Whitney, GE, and Allison), and the subsystems (Honeywell and Hamilton Sundstrand). An integrated approach to warfighter requirements reduces fuel usage and takeoff gross weight and provides significant heat rejection to fuel on landing. Figure 6-9 shows other benefits.

FIGURE 6-9 Benefits to the warfighter of an integrated design approach. SOURCE: Burkhard (2003).

REFERENCES

Published

Akbari, Pezhman, Razi Nalim, and Norbert Müller. 2004. A Review of Wave Rotor Technology and Its Applications. International Mechanical Engineering Congress. American Society of Mechanical Engineers. Anaheim, California. November.

Burkhard, Alan. 2003. Total Vehicle Thermal Integration Presentation to the von Ohain Fuels and Combustion Center Workshop on Thermal Management of Aerospace Vehicle. Dayton, Ohio, November.

DSB (Defense Science Board). 2005. The Manufacturing Technology Program: A Key to Affordably Equipping the Future Force. Office of the Under Secretary of Defense (Acquisition, Technology, and Logistics). February. Available online at http://www.acq.osd.mil/dsb/reports/2006-02_Mantech_Final.pdf. Last accessed on August 21, 2006.

Edwards, Tim. 2003. Liquid fuels and propellants for aerospace propulsion: 1903-2003. Journal of Propulsion and Power 19:1089-1107.

Sturgess, G.J., Joseph Zelina, Dale Shouse, and W.M. Roquemore. 2005. Emissions reduction technologies for military gas turbine engines. Journal of Propulsion and Power 21(2): 193-217.

Unpublished

Carlos Arana, Air Force Research Laboratory. “Combustion systems science and technology,” Presentation to the committee on April 5, 2005.

Tim Edwards, Air Force Research Laboratory. “Aerospace fuels/thermal management,” Presentation to the committee on April 5, 2005.

Dallis Hardwick, Air Force Research Laboratory. “Gas turbine engine materials,” Presentation to the committee on April 5, 2005.