3

Air-Breathing Propulsion

INTRODUCTION

Future U.S. armed forces must address an array of challenges that far surpass those faced in the past. Numerous security studies have described the evolving the U.S. security environment and its demand for transformational solutions. The security environment requires the United States to field propulsion systems that cover the entire Mach number range, up to Mach 16. This range of propulsion systems is greater than all the systems the U.S. has produced since World War II. Budget constraints mean that the Department of Defense (DoD) must use derivatives of existing engines to satisfy most new requirements, aggressively work on improving components to save money to pay for sustainment and fuel for existing engines, and increase propulsion science and technology (S&T) funding to meet the wide range of threats. In response to the challenges described in Box 3-1, aircraft propulsion systems must evolve more rapidly than ever before.

|

Box 3-1 Four Kinds of Challenges The kinds of challenges are traditional, irregular, catastrophic, and disruptive.

SOURCE: Adapted from Ron Sega, DDR&E, DoD propulsion science and technology, Presentation to the committee on May 24, 2005. |

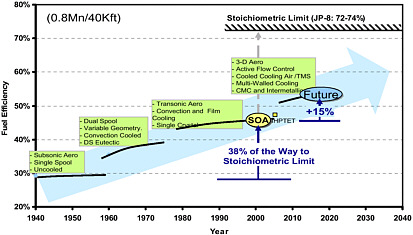

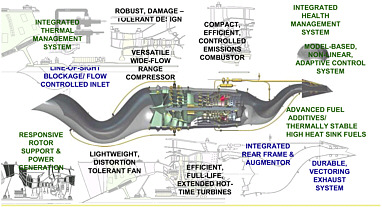

Gas turbine engines (GTEs) for aircraft GTE have undergone continual evolution and improvement since their introduction during World War II. As shown in Figure 3-1, fundamental engine performance parameters have been significantly advanced. However, there remains substantial potential for improvement beyond the current state of the art for fielded military engines, which must undergo further technological development to boost efficiency by increasing compressor inlet temperature (T3) and turbine inlet temperature (T4). For example, as shown in Figure 3-1, for large turbofan engines, fuel efficiency has improved only to the extent of closing 38 percent of the gap between the first jet engines and the theoretical Brayton cycle limit. An additional 15 percent fuel efficiency is expected to be realized in large gas turbines between now and the end of 2020 (planning horizon). Similarly, the specific horsepower of small turboshaft, turbojet, and expendable engines has increased, but only to 33 percent of the theoretical Brayton cycle limit. It is foreseen that between now and the end of the 2020 planning horizon, small gas turbine efficiency will be further improved by 30 percent. The committee believes that five technologies are critical for obtaining the improvements: (1) high-temperature compressor disk materials, (2) high-temperature turbine blade materials, (3) thermal management systems utilizing high-temperature, high-heat-sink fuels, (4) lightweight hot structures, and (5) signature controls.

FIGURE 3-1 Progress in turbine engine fuel efficiency. Note: The green boxes in the figure suggest some of many ways in which efficiency could be (or actually was) improved. SOURCE: AFRL (2005a).

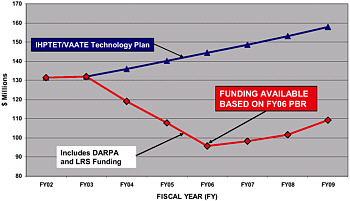

Three nearly simultaneous cutbacks to major gas turbine S&T programs have reduced total U.S. funding to between one-half and one-third of pre-FY00 levels. This total comprises funding for the versatile, affordable, advanced turbine engines (VAATE) program, the Integrated High Performance Turbine Engine Technology (IHPTET) program (see Figure 3-2), and the manufacturing technology (ManTech) program and takes into account the National Aeronautics and Space Administration’s (NASA’s) decision to drastically reduce aeronautics funding. (NASA traditionally invested approximately $100 million per year in gas turbine S&T.)

FIGURE 3-2 Engine technology funding. SOURCE: Larry Burns, “Current/future turbine engine technology investment plans and VAATE,” Presentation to the committee on April 5, 2005.

ManTech materials funding, which received between $70 million and $110 million annually until 1995, have fallen to levels averaging $50 million annually. The FY05 amended program objective memorandum (APOM) and beyond projects levels slightly below $40 million. The net result of these three reductions is that total annual funding has been reduced from approximately $300 million to approximately $100 million. At this reduced level, new technologies will be demonstrated at the systems level every 5 to 7 years instead of the 2- to 3-year demonstration cycles before FY00. In addition, the current VAATE program does not allow for the manufacture of two engines in each propulsion class, and the ManTech funding does not allow building a base for the repetitive manufacture of the new materials required for advanced engines. These funding levels will not allow the United States to maintain its dominance of the battlefield air space.

Finding 3-1. Gas turbine engines will continue to play a dominant role in propulsion in future warfare. Gas turbines have the potential for achieving the significant improvement necessary to meet a wide range of future warfighter needs. Proper funding of gas turbine technology during the planning horizon can improve gas turbine performance by 15 to 30 percent. The FY06 Presidential Budget Request (PBR) funding for gas turbine S&T is one-half to one-third pre-FY00 levels. This level of funding will not produce engine technology that allows U.S. aircraft to dominate future air wars.

Recommendation 3-1. To accelerate the development of new engine technologies, DoD and the Air Force should increase funding for Air Force gas turbine S&T funding significantly, from approximately $100 million annually to a level that reflects the buying power that prevailed when the F-15 and F-16 engines were being developed. First priority should be given to overcoming the technology barriers that will have the largest impact on future weapons systems:

-

Compressor discharge temperature reduction,

-

Turbine inlet temperature reduction,

-

High temperature and high-heat-sink fuels for thermal management,

-

Lightweight structures, and

-

Signature control.

Some of these solutions apply as well to ramjet and scramjet systems.

LARGE GAS TURBINE ENGINE PROGRAMS

Engine Development Programs

Large GTEs are the backbone of the military aviation force that guards U.S. interests at home and abroad, and they play an enormous role in establishing U.S. air dominance at the battlefront. Due to technological superiority gained from programs such as IHPTET, current turbine engines have enabled U.S. forces to achieve dominance of the air in all recent conflicts. To maintain this edge, however, the United States must respond to the increasing demand by the armed forces for more efficient, survivable, and lethal weapons systems. At the same time, the military needs to make those systems more affordable to minimize their impact on the federal budget. This can only be done through continual R&D in the turbine engine field.

A new generation of aircraft and propulsion systems technology enters warfighter operation roughly every 25 years. Today the United States is fielding state-of-the-art large gas turbines in engines for the F-22 and the F-35. Propulsion technologies in these engines are the result of roughly two decades of technology development from the IHPTET program,1 the ManTech program,2 other DoD programs, and NASA aeronautics. In the committee’s view, these propulsion systems are technically approximately 10 years ahead of competing systems such as the Eurofighter. That is, the technology level of the Eurofighter’s engines does not allow the Euro Fighter to supercruise or have thrust vectoring or stealth features. Rather, the Eurofighter technology level is roughly equivalent to the levels in the most advanced F-15 engines (F100-PW-229 and F110-GE-129). This technology advantage has degraded relative to that which existed in the 1970s, when the F-15 and F-16 were launched. At that time, the technology advantage could be characterized as being 20 years ahead of the rest of the world. Current gas turbine DoD S&T funding has been greatly reduced relative to the 1990s level, and if it is not increased the United States probably will lose its gas turbine technical advantage, as happened in civil aviation as well.

Fighter Engines

The F119-PW-100 engine developed for the new F-22 fighter aircraft represents a culmination of technologies developed over the past 20 years. The requirements for this engine include reduced radar signature to improve survivability and stealth and thrust vectoring capability.

Another key requirement was that the engines provide enough thrust to allow supercruise above Mach 1, improving range beyond that of the current generation of fighter aircraft. A low-bypass afterburning turbofan cycle was selected to provide the high thrust requirement in the supersonic mode. Dual-channel, full-authority digital electronic controls and pitch vectoring nozzles were developed in time to be incorporated into the engine demonstrator program. After passing through the Mach 1 drag rise, the high turbine inlet temperature allows the F-22 to shut down the afterburner in the supersonic cruise mode for increased fuel efficiency and range. The IHPTET program played a key role in the development of the F119 engine beginning with the prototype PW 5000 demonstrator.

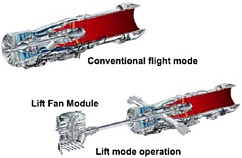

The F135 engine is a derivative of the F119 using the same core with modifications for the F-35 Joint Strike Fighter. This short-takeoff and vertical landing (STOVL) aircraft (Figure 3-3) was created to replace the AV-8V used by the Marine Corps. A novel configuration using a lift fan driven by the engine through a clutch and gearbox was developed to provide the required margin in the lift mode. This lift fan moves a larger volume of air at lower velocity, increasing propulsive efficiency and lift margin over the direct lift systems used in the AV-8V. During the maximum lift mode, the exhaust nozzle is vectored downward, and roll stability is controlled by the outboard compressor bleed nozzles. The power to drive the lift fan required a hotter high-pressure turbine and the addition of another low-pressure turbine stage (beyond what is contained in the F119 engine).

|

1 |

See, for example, the IHPTET Website at http://www.pr.afrl.af.mil/divisions/prt/ihptet/ihptet.html. Last accessed on March 27, 2006. |

|

2 |

See, for example, the ManTech Web site at https://www.dodmantech.com/. Last accessed on March 27, 2006. |

FIGURE 3-3 The F135-PW-600 STOVL propulsion system for the F-35 Joint Strike Fighter. SOURCE: Koff (2004).

An alternative engine for the F-35 aircraft, the GE F136, is being developed jointly by General Electric and Rolls Royce, in a 60/40 respective work split. This engine, a derivative of the GE F120 for the F/A-22 competition, features a conventional mixed-flow, augmented-turbofan configuration. This tri-Service configuration fits directly into the F-35 and is completely interchangeable with the Pratt & Whitney F135 engine. The degree of interchangeability of the F135 and F136 engines on the F-35 is by far the greatest of any fighter program to date.

The F119, F135, and F136 family of engines represents the state of the art in GTEs for fighter aircraft. The committee believes this technology is currently about 10 years ahead of the competing Russian and European engines.

Commercial and Transport Engines

The GE 90-115B is the world’s newest and largest turbofan engine. It was certified in 2003 at 115,000+ lb of thrust at sea level. This engine is a growth derivative of the GE 90-94B, which has a 123-in. diameter fan and a bypass ratio of 8.4. The GE 90-94B is a two-spool engine with 22 turbomachinery stages, which is the same as the Rolls-Royce three-spool Trent 800.

Normally, a three-spool turbofan has fewer stages since each stage can operate close to the optimum aerodynamic loading. This was made possible since the GE 90 10-stage compressor has a pressure ratio of more than 20:1, which is the world’s highest for aeronautical engines. The compressor technology was developed for the NASA GE E3 engine in the late 1970s and was ready for the B-777 competition in 1990. The composite fan blade technology was developed at GE over the past 45 years. In 1970, a composite first stage of the TF-39 fan was designed, manufactured, and tested. Then, although the rotor blades failed in a bird-strike test with 16 starlings, the technology effort was carried forward until success was realized.

Notable features include a 128-in. diameter (5 in. larger than the 90-94B) composite fan blade (an industry first) combining rearward sweep at the midspan and forward sweep at the tip. To drive this larger fan, which has 11 percent more flow than the GE 90-94B, the last stage was dropped from the compressor to increase the core flow and power. Increasing the core compressor exit flow is the same design strategy that was used to develop the higher thrust CF-50 engine from the TF-39/CF6 engine family. The overall pressure ratio of the GE 90-115 is more than 41 at sea level, which is among the highest for GTEs. Increasing GE 90-115B core power by removing a stage from the rear of the GE 90 compressor decreased the cruise bypass ratio from 8.4 to 7.1. State-of-the-art component efficiencies have been achieved using extensive three-dimensional analysis—computational fluid dynamics (CFD). The GE 90-115B is presently the most advanced commercial GTE in the world.

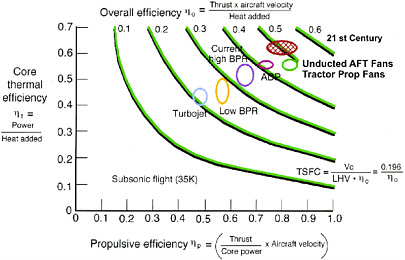

Figure 3-4 demonstrates the technology improvement path for GTEs that power subsonic aircraft. The potential increase in core thermal efficiency requires technologies that raise the limit for compressor discharge temperature barrier. Corresponding to the increase in compressor exit temperature technologies, for increases in turbine inlet temperature is also raised. Propulsive efficiency (ηp) increases are obtained by enabling the engine to accelerate an ever-increasing volume (mass) of air to speeds moderately higher than the aircraft forward speed. That is, propulsion efficiency is increased by increasing the engine bypass ratio (the volume of air that flows through the fan relative to that flowing through the engine core). Technologies that allow increased bypass ratio are lightweight structures, low-drag nacelles, and fan-driven gear systems.

FIGURE 3-4 Overall engine efficiency is a product of thermal and propulsive efficiencies. SOURCE: Koff (2004).

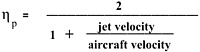

The approximate expression of propulsive efficiency is as follows:

This relationship shows that decreasing the ratio of engine jet velocity to aircraft flight speed increases the propulsive efficiency. A high-bypass turbofan engine has lower thrust per pound (air flow) but much lower jet velocity than turbojets or low-bypass turbofans. The increase in propulsive efficiency for these large, high-bypass turbofans is provided by a higher-airflow, low-velocity fan stream relative to the high-velocity exhaust from the core engine. Propeller aircraft engines still have bypass ratios that are five times greater than those of turbofans. In 1992, Pratt & Whitney tested a geared turbofan demonstrator with a bypass ratio of 12, achieving the world's lowest specific fuel consumption (SFC) for turbofan configurations.

Today’s state-of-the-art engines have an overall engine efficiency of no more than 40 percent. The hatched region of Figure 3-4 has core thermal efficiencies of 65 percent and propulsive efficiencies of 85 percent. The overall efficiency of an engine with these individual efficiencies would be 54 percent,

approximately 35 percent greater than today’s state-of-the-art engines. Engines that power fighters or supersonic aircraft require the same technologies to increase the core thermal efficiencies.

Recommendation 3-2. The Air Force and DoD should execute a total system engineering process starting with a preliminary design to establish project feasibility when undertaking any new propulsion development program.

IHPTET and VAATE Demonstrator and Research Programs

Since turbine engines are so critical to the capabilities of military aircraft, DoD has pioneered many advances through demonstrator and research programs such as the preeminent turbine engine research programs IHPTET and VAATE. The IHPTET program, begun in 1987, reached its conclusion in 2005. VAATE, begun in 1999, extends to 2017.

Because IHPTET pervades the turbine engine S&T community, the committee examined its origin, organization, goals, products, and lessons learned to gain insight into structure of VAATE and the latter’s likelihood of success.

IHPTET Program

IHPTET concluded in 2005 after having made major progress toward the program goals. Table 3-1 summarizes the goals and progress for the IHPTET turbofan and turbojet class. Demonstration of a 70 percent improvement in T/W and a 60°F improvement in combustor inlet temperature is expected. Materials and cooling technology advancements enabling a 200°F improvement in T3 were analytically shown but not actually demonstrated during the program. The goals of decreasing production and maintenance costs by 20 percent (Phase II) and 35 percent (Phase III) was essentially met.

The committee’s assessment of IHPTET was based on its own analysis as well as the consensus from industry and user community representatives. The primary strengths of IHPTET include the involvement of all pertinent parties from government and industry, the consistent focus on specific technical goals, and the continual refinement of a technology plan, governed by a rigorous and methodical process to trace investment to goal accomplishment. IHPTET embraced a robust engine demonstration program that enabled continual transition of high-TRL technologies to both fielded and developmental engines.

Even after the advances of IHPTET, there remains significant room for improvement in turbine engine cost, performance, and durability. In particular, over the VAATE timeframe, a 25 percent improvement in fuel efficiency appears achievable. Such improvement, applicable to civil as well as military aircraft, would have enormous impacts on vehicle size, range, payload, and support cost.

Although relatively stable, IHPTET funding was lower than required to execute the program as originally envisioned. The reduced funding level was inadequate to allow demonstration of all IHPTET goals, in particular, the combustor inlet temperature goal T3. Admirable progress was made on the other IHPTET goals given the funding realities. Materials technologies were inadequately advanced under IHPTET and will remain a significant challenge to achieving VAATE goals.

TABLE 3-1 Goals and Results of IHPTET at Program Conclusion

|

|

Turbofan/Turbojet Goals |

|||

|

Metric |

Phase I |

Phase II |

Phase III |

Resultsa |

|

Thrust/weight ratio |

+30% |

+60% |

+100% |

+70% |

|

Combustor inlet temperature |

+100°F |

+200°F |

+400°F |

+60°F |

|

Production costs |

N/A |

−20% |

−35% |

−32% |

|

Maintenance costs |

N/A |

−20% |

−35% |

−31% |

|

aAt TRL 6. |

||||

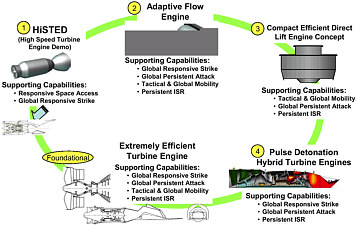

VAATE Program

Building on the success and lessons of IHPTET, VAATE is addressing not only classic turbine engine component improvements but also the changing requirements of propulsion systems—specifically, higher altitude, higher Mach, and long-endurance applications.3 The VAATE program addresses all military and commercial aviation engine types, including turbofan and turbojet engines, turboshaft and turboprop engines, engines for unmanned air vehicles, and expendable missile engines.

VAATE has been structured to take advantage of the features that made IHPTET successful. These include coordination between DoD, NASA, academia, industry, the Federal Aviation Administration (FAA), and the Department of Energy (DOE), allowing the program to coordinate the strategy for gas turbine technology development at a national level while leveraging funding of the constituent organizations. VAATE has, appropriately, a broader scope than IHPTET in order to optimize the integrated propulsion system at the weapons-system level rather than just at the level of the engine turbomachinery itself. Toward this end, the main aircraft manufacturers are full partners on the VAATE industry team.

VAATE’s focus on (1) optimization of the propulsion system at the level of the air vehicle system, (2) an affordable capability goal,4 including both performance and cost metrics, and (3) planned synergy and dual-use with civil aeronautics requirements goes beyond the IHPTET approach in a manner that is appropriate for the future. VAATE funding, however, is inadequate to accomplish the program as envisioned, particularly in regard to the critical TRL 6 engine demonstrations.

The evolving demands placed on the military will dictate a force structure that is leaner and less expensive but also more versatile, lethal, and survivable. Reflecting these requirements, the VAATE program aims by 2017 to improve the affordable capability of turbine engine propulsion systems 10-fold relative to the baseline year 2000 state-of-the-art systems. Capability in this context is technical performance, including thrust, weight, and fuel consumption. Cost is the total cost of ownership and includes development, procurement, and life-cycle maintenance cost (excluding fuel). The overall VAATE goal, the capability to cost index (CCI), is defined as the T/W ratio / specific fuel consumption (SFC) ratio / cost ratio.

The CCI approach has two key strengths. First, to promote optimization at the level of air vehicle system, VAATE, unlike IHPTET, allows CCI to capture the effects of advanced technology on airframe-mounted components of the propulsion system, such as the engine inlet or power and thermal management subsystems, as well as effects of traditional engine turbomachinery. (Consideration of airframe-mounted propulsion and power components were excluded from IHPTET.) VAATE might thus promote investment in a technology that actually increases engine flange-to-flange weight if that technology resulted in an overall improvement of installed propulsion system weight. For example, a variable- or adaptive-cycle engine installed in a Mach 2.5 cruise vehicle would weigh more than a fixed-cycle baseline engine but might allow far greater system-level weight reduction by eliminating variable geometry from the inlet. A second strength of the CCI approach is that each VAATE contractor is allowed to vary goal factors and thus tailor exactly how the overall CCI goal is achieved. As with

|

3 |

See, for example, the VAATE Web site at http://www.pr.afrl.af.mil/divisions/prt/vaate/vaate.htm. Last accessed on March 27, 2006. |

|

4 |

“Affordable capability” is the ratio of propulsion system capability to cost. |

IHPTET goals, the VAATE CCI goal is expressed incrementally across three phases of the program. Table 3-2 summarizes VAATE’s goals for large turbofan and turbojet engines.

Rather than being organized by engine component, VAATE is organized into three broad focus areas: (1) versatile core, (2) intelligent engine, and (3) durability. For each area, detailed technology roadmaps have been developed that, taken together, lead to achieving the 10-fold improvement goal of the program. The core is the heaviest, most complex, and most expensive component of the propulsion system.

TABLE 3-2 Target Date for Achieving the CCI Goal for Large Turbofan and Turboshaft Engines

|

VAATE |

|

|

|

Phase |

Year |

CCI Goal |

|

I |

2009 |

4X |

|

II |

2013 |

6X |

|

III |

2017 |

10X |

In the core, engine pressure, temperature, and rotational speed reach maximum value. Thus, the core is where technology advancement has the greatest payoff. The intelligent engine area concerns achieving the maximum utility from the engine through improved engine control systems, advanced prognostics and health maintenance, and system–level integration of the engine, airframe, and power management subsystems. The durability area reduces engine maintenance and part replacement costs by doubling component life while providing a significant increase in hot-time capability.

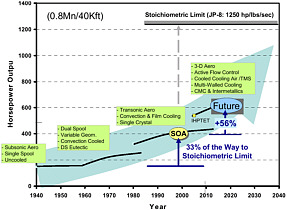

VAATE technology advancement culminates in demonstrations of the core and of the full propulsion system. The IHPTET program included a series of successful engine demonstrations as part of the joint turbine advanced gas generator (JTAGG) advanced development program, a joint Army, Navy, and Air Force effort managed by the Army Aviation Applied Technology Directorate. Demonstration of advanced VAATE technology is accomplished in 50- to 100-hr core and engine tests, leading to TRLs of 6 to prove out transition capability. The range of engine and airframe technologies of interest under VAATE is illustrated in Figure 3-5.

VAATE will continue to seek incremental improvements of key turbine engine metrics as well as to integrate advanced technologies. The ideal cycle based on stoichiometric (optimum) combustion properties can be used as an indicator of how current technology lags behind the theoretical limits in two key technology metrics—fuel efficiency and specific horsepower. Each of these metrics has a direct impact on propulsion system size, weight, and performance.

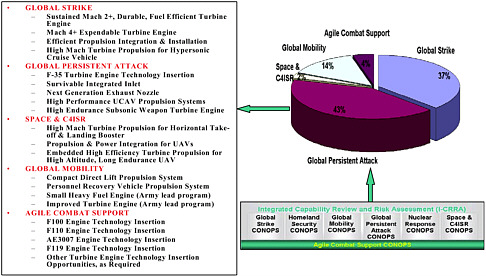

FIGURE 3-5 Total propulsion system advanced technologies. SOURCE: Burns (2005).

Each new improvement in turbine engine fuel efficiency since the 1940s has allowed stepwise increases in overall pressure ratio and turbine inlet temperature, resulting in improved fuel efficiency across a diverse range of engine applications. However, Figure 3-1 shows that current turbine engine fuel efficiency is only about 38 percent of the theoretical limits. It is expected that VAATE will achieve an additional 15 percent improvement in basic engine fuel efficiency. When combined with the other technologies in the VAATE program such as cooled air, liquid-vapor thermal management systems, and intermetallic materials, a 25 percent improvement in fuel efficiency is anticipated.

Specific horsepower is a similar measure of the level of turbine engine technology level. As shown in Figure 3-6, as with fuel efficiency, state-of-the-art specific horsepower improvements have closed only 33 percent of the gap between 1940s-era engines and theoretical limits. Under VAATE, technologies such as three-dimensional aerodynamics modeling, ceramic matrix composites, and intermetallic materials, active flow control, and cooled cooling air (CCA) will be matured to increase this capability another 56 percent.

FIGURE 3-6 Progress in turbine engine horsepower output. The boxes suggest some of many ways in which horsepower could be improved or was actually improved. SOURCE: AFRL (2005a).

Gas turbine engine propulsion S&T is a foundational requirement for maintaining U.S. military supremacy. Various studies have shown that advances in propulsion technology can have an enormous impact on the construct, capability, and cost of future military air power. Future scenarios envision a responsive, lethal, survivable force involving diverse platform requirements, such as global strike, uninhabited air vehicles, advanced stealth combat, high Mach cruise, low cost access to space, and STOVL. VAATE will provide increased range, a smaller logistics footprint, increased readiness, improved noise, emissions, and observability (stealth), and high-speed endurance. In addition, it might provide the Air Force with truly transformational capabilities, which would affordably maintain U.S. military air superiority through extremely efficient turbine engines that will double range or halve aircraft size (see Figure 3-7).

FIGURE 3-7 Turbine engine game-changing transformational concepts. SOURCE: Stricker (2005).

Key technologies include these:

-

High-speed, expendable turbine engines can be carried by all bomber and fighter aircraft in the fleet. They provide tremendous standoff capability yet are capable of striking targets at more than four times the speed of sound. They also serve as the basis for responsive systems that will one day propel human beings into space.

-

Adaptive-cycle engines optimize performance across the aircraft flight envelope. In essence, this propulsion capability will have variable features that allow both responsive supersonic strike and persistent subsonic loiter in a single air vehicle. Benefits for power generation and thermal management are an integral part of this propulsion concept.

-

Compact, efficient, direct-lift engines enable short takeoff and landing (STOL) and STOVL capabilities on future large transports. This will result in long-range, high-subsonic cruise, and short/vertical take-off operations capability for future multimission mobility.

-

Innovative concepts such as pulse detonation hybrid turbine engines could have dramatic impact on both performance and cost.

Technologies developed under all three VAATE focus areas will have a direct commercial impact. Versatile core will allow greater hardware commonality between military and commercial applications, thereby reducing cost through economies of scale. Prognostics and health maintenance concepts, developed in the focus area of intelligent engines, and many products from the focus area of durability will directly benefit almost all commercial applications. Conversely, VAATE will pull from the commercial sector to leverage NASA work on noise and emissions so that DoD assets will be able to operate all over the world without exceeding the environmental and noise limitations set by certain regulations. VAATE will also have similar spinoff benefits for turbine engines for marine, ground transportation, and power generation applications.

The original VAATE program, which would have allowed robust technology development, demonstration, and transition capability, was scheduled to be funded at the level of $145 million for FY06 and $149 million for FY07. Turbine engine S&T funding has been drastically reduced, however, to just under $90 million in the FY06 PBR, a reduction of $48 million from FY03. The FY07 budget is planned to remain stagnant at $90 million. At the current level of planned funding, it will be difficult to demonstrate and transition turbine engine technology.

Figure 3-8 shows the turbine engine technologies needed to meet the Air Force CONOPS vision. There is a clear disjunct between the Air Force S&T funding (burdened) required for these technologies to reach TRL 6 and the amounts planned for Air Force turbine engine S&T for the 5-year defense plan. This bow wave of shortfalls will cascade into the future, eroding the U.S. lead in turbine technology and undermining U.S. military superiority.

FIGURE 3-8 Turbine engine technologies needed to support the CONOPS vision. SOURCE: AFRL (2005b).

Finding 3-3. The IHPTET program demonstrated several marked strengths that form a foundation for continued success in VAATE. IHPTET transitioned performance, durability, and cost reduction technologies for both fielded and developmental engines—in particular, the F119 engine for the F/A-22 and the F135 and F136 engines for the F-35 Joint Strike Fighter. The VAATE focus on (1) optimization of the propulsion system at the level of the air vehicle system, (2) an “affordable capability” goal, including both performance and cost metrics, and (3) planned synergy and dual-use with civil aeronautics requirements goes beyond the IHPTET approach in a manner that would seem to be appropriate for the demanding yet uncertain requirements of the future.

On a very positive note, each VAATE contractor reviewed by the committee appeared to have a portfolio of advanced technologies planned for development and transition by the VAATE program. So far, the VAATE goals for improvement in fuel efficiency have been greater than the discontinuous improvements observed in other generations of turbine engine advances. VAATE’s payoffs are designed to be realized both in the long term, for new air systems now on the drawing board, and in the near term, for systems currently fielded (e.g., the F-16 and F-18), in production (e.g., the F/A–22), or still in development (e.g., the F-35 Joint Strike Fighter).

Recommendation 3-3. DoD should restore gas turbine S&T funding under the VAATE program to the original planned level. VAATE should address the primary risk areas necessary to advance jet engine technology, which includes a robust engine demonstrator program and key producibility challenges.

Component Improvement Programs

All of the military services are faced with huge and growing sustainment costs for the current fleet of aircraft. Over 60 percent of the expected 2020 warfighter’s fleet of aircraft are in existence or under development today. Near term, GTE technologies could be incorporated into this fleet to significantly reduce the cost of sustainment and decrease the amount of fuel burned.

The committee saw many examples where component improvement programs (CIPs), derivative engine programs, and engine capability enhancement programs (ECEPs) could yield sizable reductions in fuel burned, significantly improve performance, and greatly improve the time between shop visits.5

History has shown that CIPs decrease Class A mishaps, increase time on the wing, decrease fuel burn, and extend service life. In most instances, it can be readily shown that the cost of incorporating existing technologies into the legacy fleet are rapidly recouped. In fact, historically, programs of this type have returned $8 to $10 in the form of savings on sustainment and fuel burn dollars for existing engines per dollar invested. However, the current structure of the DoD budget makes it difficult to properly attribute these savings.

The F119-PW-100 engine is a low-bypass, augmented turbofan engine currently in production to power the F/A-22 Raptor. The F119 engine, after more than a decade of engineering and manufacturing development, has achieved a much higher level of design maturity than fighter engines in previous development programs. By incorporating revolutionary technologies, robust principles of systems engineering, integrated product development, and improved modular design, the F119 is uniquely positioned to cost effectively perform far better than legacy fighter engine systems. The F119 benefited from low levels of CIP funding before achieving initial operational capability (IOC), but greater investment is required to accelerate the rate of maturation. Also, discoveries in accelerated mission testing, F-22 flight test, and initial operational test and evaluation have revealed unique challenges for the F119 engine, such as integrally bladed rotor (IBR) repairs, unique low observable (LO) parts repair and retention, augmenter and nozzle durability, and engine control complexity. CIP investments to date have not allowed the F119 program to achieve the validation and verification test goals needed to rapidly mature proposed fixes and repairs. On average, it takes 2 to 4 years to complete a CIP task. Only 193 repairs of 850 distress modes for the F119 have been carried out under CIP. At the present rate of repair, the capabilities for making repairs will not have been developed. 100 percent depot repair capability of known problems will not be achieved until FY17. Because the F/A-22 fleet will be much smaller than legacy fleets it replaces, the F/A-22 will require much greater system reliability and mission-capable rate than previous fighter systems to achieve its mission. Since the number of F119 engines scheduled to be returned to depots for maintenance will increase dramatically by FY10, shortfalls in repair capability will drive the need for additional expensive spare parts (IBRs and major low observable cases) and may impact the readiness of the F/A-22 aircraft. The F119 program could save significant life cycle costs with relatively small investments of CIP funds early in production and close to the IOC and would help ensure mission success for the F/A-22 Raptor fleet.

Finding 3-4a. The cost of fueling and the cost of sustaining the legacy fleet are the two largest items in DoD’s annual propulsion budget.

Finding 3-4b. The component improvement program (CIP), set up for each engine type, model, and series by engine manufacturer, focuses on the improvement of individual hardware, controls, and accessories. The improved hardware or accessories are demonstrated on test engines either at the original equipment manufacturer (OEM) or at the Arnold Engineering Development Center with OEM oversight. The tests are conducted periodically and the engines are qualified for a particular mission. Such testing

would be appropriate as well for commercial engines used by the military and to which commercial components and technologies are applied to bring about improvement.

Recommendation 3-4. DoD should sustain the funding for the CIP to ensure solutions to operational problems and safety issues and the development of future upgrades.

Derivative Engine Programs

DoD aircraft systems are continually modernized to remain viable and responsive to the warfighter’s need. These modernization upgrades address identified performance deficiencies or provide new mission capabilities. The growth of aircraft capability typically results in increased weight, drag, and electrical and mechanical power loads, which translate into increased demands on the aircraft propulsion system. To accommodate these increased demands, the propulsion system must become more capable.

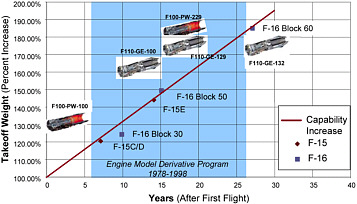

A proven, cost-effective and efficient approach to providing increased propulsion capability is the development of derivative versions of existing engines. As illustrated in Figure 3-9, derivative engines are the result of transitioning newer technology into existing legacy propulsion systems to improve performance and power capability.

FIGURE 3-9 History of derivative engines. SOURCE: Personal communication between Mark Amos, Agile Combat Support Wing, Wright Patterson Air Force Base, and National Research Council staff member Carter Ford on July 7, 2006. Approved for public release by ASC Public Affairs. Disposition Date: 7/6/2006. Document Number ASC 06-0271.

There is currently no active programmatic vehicle for increasing the performance of legacy propulsion systems to replace the engine model derivative program (EMDP), which was canceled in 1998. Its cancellation has resulted in two significant gaps in the DoD engine development process. The first gap is the inability to conduct timely propulsion system enhancement studies and to develop technology transition roadmaps to support and complement aircraft modernization and capability growth studies prior to acquisition milestone A. The second gap is the lack of a process to demonstrate propulsion technology and thereby allow it to proceed from TRL 6 (demonstration in a relevant system) to TRL 7 (demonstration through initial flight test). This gap makes it more difficult to incorporate new technology into the propulsion system past acquisition milestone B.

EMDPs were a cost-effective way to improve capabilities and decrease the cost of supportability. For example, the derivative F100-PW-229 engine developed for the F-15E increased the capability of the aircraft and reduced the cost per flying hour by reducing the frequency of unscheduled and scheduled shop visits and reducing the incidence of Class A mishaps. Similarly, the F101, F110, and F108 common

core design has been a very cost-effective derivative engine that is providing power for a large range of aircraft.

DoD’s new capability assessment process specifies weapon system requirements using the initial capability document and analysis of alternatives. However, requirements for propulsion system capabilities are derived from aeronautical performance requirements for weapons systems and from subsystem functional interface requirements. The systems engineering process may not generate quantitative propulsion system requirements until the weapon system enters system design and development. This time delay, coupled with the lack of a funded EMDP, is limiting the benefit that DoD could achieve from derivatives of existing engines.

Funded EMDPs would ensure that the propulsion capability requirements are met in a timely and cost effective way. New centerline engine developments cost billions of dollars and require more than 10 years to complete. Derivative engines often cost only hundreds of millions of dollars and require only 3 to 5 years to complete. This reduced cost and more timely approach mitigates the significant cost and schedule risks of weapon system development.

Several existing and emerging weapon systems would benefit from an active EMDP study. The maximum operating altitudes of A-10 and B-1B aircraft are limited by increases in aircraft weight and drag. The range and mission effectiveness of the B-52 and KC-135 could benefit from an upgrade of their existing propulsion systems or by reengineering with a newer class of high-bypass-ratio engines. Future weapon systems like J-UCAS and the next-generation, long-range-strike Phase II will require propulsion systems that can satisfy conflicting requirements for engine volume and cruise efficiency. These emerging weapon systems are also constrained by scarce resources and time, providing further incentive to pursue the more cost-effective and timely approach: the derivative engine.

Finding 3-5. The process of identifying, developing, demonstrating, and fielding a new technological capability needs to be revitalized and reinvigorated through a reinstated EMDP. The cycle time to accomplish the demonstration to fielding of technology can be reduced by 50 percent to take advantage of the emerging technologies to enhance reliability and eliminate obsolescence. Oftentimes, a technology has been demonstrated using laboratory funding to a TRL of 5 or 6 but requires a TRL of 7 or 8 to become a fielded application. If no OEM investment is made, or there is no government program office with technology maturation funding, the technology may languish, with potentially significant savings to the customer left on the table.

Besides reducing the cycle time for transitioning technology, technology, especially materials technology, is not shared between OEM’s, except on rare occasions. Even though the technology has been through the development and maturation process and has been qualified and fielded, it is a difficult and grueling, if not impossible task for government engineers to get OEM technical buy-in and confidence.

Recommendation 3-5. DoD should reinstate an engine model derivative program (EMDP) to speed the transition of technology to the legacy fleet to improve safety, reliability and affordable readiness. An earlier EMDP demonstrated its usefulness and value for the current fleet of engines, most of which were developed spirally through it or similar programs in the commercial sector.

SMALL GAS TURBINE ENGINE PROGRAMS

This section reflects the views of the committee on the status, requirements, and anticipated plans for small (power range between 500 shaft horsepower (SHP) and 15,000 SHP) gas turbine engines intended for use by DoD from now to 2020. The comments apply to propulsion systems for UASs, helicopters, and compound helicopter/tilt-rotors. Turboshaft engines have broad applicability to a wide variety of systems used by (or anticipated to be used by) the services.

The anticipated extensive use of military helicopters, tilt-rotors, and UASs in the future is well described by the roadmap prepared by the Office of the Secretary of Defense (OSD, 2005). Additionally, Joint Vision 2010 and Joint Vision 2020 summarize the military’s plan for full-spectrum dominance in an

extremely lethal battlespace (CJCS, 1996; 2000). These requirements drive significant increases in speed, from today’s 160 kt (184 mph) up to 350 kt (403 mph), and significant increases in endurance and range (at least double that of today’s systems).

Engine Requirements and Development

All of the helicopter and UAS turboshaft engines in use by DoD were designed and built in the 1960s and 1970s. Since that time, few of the technologies developed by the JTAGG, IHPTET, or other programs in materials, electronics, software, computational design tools, and network-centric warfare have found their way into turboshaft propulsion systems.

Because of their size and usage, these military turboshaft engines have cooling, manufacturing, installation (they are often buried), and operational (sand, dust, ice) requirements very different from those of their commercial counterparts. While DoD can incorporate some improvements from the commercial sector, it must develop many of its own technologies and engines to satisfy military-unique requirements.

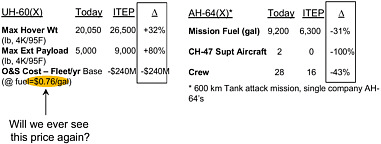

A major finding of the committee is that DoD could immediately benefit from work that has been done on technology over the last 30 years by developing a new 3,000-SHP class turboshaft engine and a new 10,000-SHP class engine. A modern 3,000-SHP class turboshaft engine would be applicable to the Air Force’s planned personnel recovery vehicle (PRV) system, the Army’s Apache AH-64 Block III and Blackhawk UH-60M helicopters, the Navy’s SH-60 Sea Hawk, and the Marine Corps’s UH-1Y and AH-1Z vehicles (specifications for the Apache and the Black Hawk are shown in Figure 3-10). Additionally, a modern 10,000-15,000-SHP class turboshaft engine would have an enormous positive impact on the design, performance, and cost of the emerging Joint Heavy Lift (JHL) vehicle and on the Marine Corps’s improved CH-53X helicopter capable of performing well at high altitudes and temperatures.

While the Army plans to increase its warfighting capability from development of the new 3,000-SHP class engine, the Air Force is looking toward propulsion improvements to increase helicopter capability. Currently, no PRV candidates can meet the combat radius key performance parameter of 325 nautical miles (nm) while maintaining payload and loiter. Propulsion improvements would greatly increase PRV range. A dramatic decrease in SFC (25 percent from current T700/CT7 family) would decrease fuel and weight and increase hover. A 3,000-SHP class engine would dramatically improve the capability and combat radius of the Air Force and DoD medium-lift rotary-wing fleet. Fuel savings will be greatly multiplied by savings in vehicle weight and cost as well as support structure (DSB, 2001).

FIGURE 3-10 Derivative aircraft provide improved capability. SOURCE: Butler (2000).

These two new engines are consistent with the 2020 requirements of all military services. Important elements of the anticipated aviation modernization plan relating to turboshaft engines for each of the services are summarized below. Most of these needs will represent those of rotary-wing manned helicopters and uninhabited air vehicles (UASs). Successful, affordable, and enduring war-fighting performance for U.S. Army aviation systems necessitates modern turboshaft engines to satisfy the

requirements of attack, reconnaissance, utility, and medium-cargo missions. All of these aviation systems will incorporate engines that will be 50 to 60 years old in 2020 unless proactive steps are taken today.

The planned development of a JHL vehicle capable of supporting the deployment of the Future Combat Systems (FCS) is not covered in this review of the Army’s needs. It is anticipated that FCS will require a vehicle capable of extended vertical takeoff and landing (VTOL) and the ability to lift a 20-ton payload, to cruise efficiently at about 250 kt, and to encompass a radius of action of at least 500 nm at 4,000 ft altitude on a hot (95°F) day.6 The resulting system is likely to have a gross weight of about 150,000 lb and to require a total installed power as high as 36,000 SHP. The Army is currently taking the lead in studying this important system. The resulting gross weight and cost of this vehicle will greatly depend on the level of technology introduced into its propulsion system (Scully, 2000).

The Marine Corps anticipates future requirements for an MV-22 tilt-rotor transport, a UH-1Y utility, an AH-1Z attack, and a heavy lift rotorcraft (either a CH-53X or a new JHL vehicle). All of these systems, as well as the fixed-wing KC-130, would benefit from development of the new class of turboshaft engines.

Component Improvement Programs

Industry has difficulty justifying repairs on many low-cost small parts for small gas turbine engines. GE reports that most complex repairs on the much-used T700/CT7 engines are for frames, essentially due to the higher cost of this type of repair, and that blisk7 repairs generally include the clipping and blending repairs.

The general feeling is that the advent of larger turboshaft engines, such as that for the JHL helicopter, will justify increased attention to the matter of maintenance. This would permit companies to leverage commercial repair development and to develop new and affordable repair procedures specific to the planned heavy lift engine. Finally, the community generally agrees that new repair procedures must be developed concurrently with the new product.

The advent of network-centric warfare and logistics suggests opportunities for propulsion system logistics and maintenance support never before possible. There is general consensus in the turboshaft engine industry that these technologies have potential merit, especially where data on engine and accessory health and the usage experienced are transmitted in real time by satellite, using a relatively high-bandwidth communication system, to the relevant logisticians, engineers, and suppliers. This information may provide useful diagnostic and prognostic information, thereby significantly impacting spares management, system availability, root cause failure analysis, and, certainly, direct operating costs.

Derivative Engine Programs

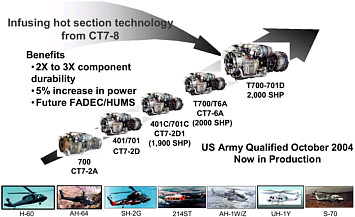

Companies continue to infuse technology enhancements into fielded DoD small gas turbines, and plans exist for the development of derivative engines largely intended to increase available power and to some extent improve component durability. An example is the application of advanced coatings to improve compressor erosion resistance in a severe sand- and dust-rich environment. These changes do not generally improve engine fuel consumption.

A typical example of this approach to derivative engine development is provided in Figure 3-11, which also illustrates how the hot-end technology and fully automated digital electronic control (FADEC) systems, originally developed for the commercial S-92 helicopter, are being infused into the T700 military product line. In this case, the technology originated in a commercial variant of the T700 turboshaft family and is now being retrofitted in the military product line.

|

6 |

For more information on the JHL rotorcraft, see http://www.defense-aerospace.com/cgibin/client/modele.pl?prod=62950&session=dae.15810530.1127168887.Qy87d8Oa9dUAADpX@2s&modele=release; and on the JHL concept design and an analysis, see http://www.globalsecurity.org/military/systems/aircraft/jhl-cda.htm. Last accessed on June 4, 2006. |

|

7 |

Bladed disk. |

Another example of a derivative turboshaft engine under development is the GE CT7-8C, currently in test development. This series, intended for use in the S-92, US101, and MH-60 helicopters, is an example of growth through technology infusion. Specifically, use of an advanced durable-hot-section, three-dimensional aerocompressor, and a 25 percent air flow growth (Wa) together with flying object damage (FOD)-resistant blades and a dual digital full authority electronic control allowed the CT7-8 to be certified in the 2,500-SHP class in 2000. The incorporation of a new three-stage power turbine has allowed the engine to enter the 3,000+ SHP class.

FIGURE 3-11 T700/CT7 1,500-2,000 SHP engines. HUMS, health and usage monitoring system. SOURCE: Personal communication from Tim Higgins, General Electric Aviation, to NRC staff member Carter Ford on September 19, 2006.

Once again, this kind of growth, while addressing immediate service needs, has not allowed the application of the technology necessary to improve SFC 25-35 percent. Application of this advanced technology is addressed in the Army’s currently unfunded Improved Turbine Engine Program (ITEP), which will be discussed next.

A further example of a derivative program under serious consideration is the 8,000-SHP class GE38-3 engine. State-of-the-art, yet mature, technology was applied to engines whose roots go back 30 or 40 years to achieve a dramatic increase in reliability and maintainability and lower the operation and service cost. While the payoff is considerable, no formal commitment has been made to develop this engine.

Engine Demonstration Programs

Past science and technology programs have significantly advanced the capabilities of turboshaft engines. Specific improvements are expected to lead to smaller, lighter, and more affordable rotorcraft and UAS designs. The resulting systems will cost less to operate and sustain. It is clear that stepwise improvement in capabilities could be realized today and that continued investment is justified.

One of the last elements in the IHPTET program was to be the JTAGG III demonstrator being designed and built jointly by Honeywell and GE. The technologies demonstrated were planned to directly support the affordable advanced turbine engine (AATE) and ITEP. The differential payoff for implementing JTAGG technology rather than just that available with a simple derivative engine is large. An SFC improvement of 30 percent is shown for the relatively large turboshaft engine required to power the JHL aircraft.

The small heavy fuel engine (SHFE) program is funded and has been awarded to Honeywell. Its goal is a 700-SHP engine demonstrator. The demonstrator engine is targeted to run in 2006 with the program

continuing into 2007. Industry and the government are also planning for the AATE program, funding for which is expected to start in 2008. Included in the plans for AATE are advance turbine technologies, including an uncooled power turbine that would require deployment of either ceramic matrix composites (CMCs) or monolithic ceramic vanes and blades. It is anticipated that the GE 1800 engine will greatly surpass the incumbent T700 class engine. The engine size originally targeted here was about 1,800 SHP. However, consideration is being given to increasing the AATE to about 3,000 SHP.

Finding 3-6. Two new small military gas turbine engines are needed to meet mission requirements in all of the services. The U.S. military has not developed a new centerline engine in the small and expendable class since 1972. The technology level of the U.S. military gas turbine engines in these classes is roughly on par with that of the competition. This equivalence, however, is not driven by available technology but by the fact that no new military engines in these power classes have been fielded anywhere in the world since the early 1970s. Not only is there a need to field new 3,000- and 10,000-SHP class gas turbines for helicopter and UAS missions, but the technology to do so exists as well.

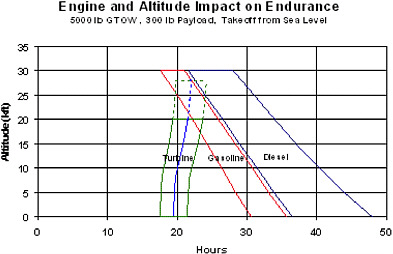

While gas turbines have very high thrust (or horsepower) per unit weight, their disadvantage is that their efficiency decreases when they are operated at suboptimal conditions. UASs, which operate in a broad range of conditions, including loitering, may benefit from a different type of engine. As shown in Figure 3-12, a turbocharged diesel, and quite possibly a turbo-compounded diesel, are alternatives for future long-endurance UASs (Bobula et al., 1986). Clearly, the historical advantages enjoyed by gas turbines due to their superb power to weight ratio might be eroded by the diesel or some other novel cycle with vastly superior SFC provided the mission is long enough. While the power to weight ratio achieved by these alternative concepts may never approach the ratio possible with the gas turbine, the SFC possibilities are very compelling. The challenge here is the incorporation of modern aerospace materials and the application of advanced turbomachinery elements and materials to these advanced engine concepts.

FIGURE 3-12 Impact of engine and altitude on endurance. SOURCE: DARPA (Undated).

Recommendation 3-6a. The Army should consider combining its Affordable, Advanced Turbine Engine (AATE) demonstration program and its unfunded improved turbine engine demonstration program, also targeted at 3,000 shaft horsepower (SHP).

Recommendation 3-6b. The Army should ensure that the size of the Future Affordable Turbine Engine (FATE) program, which remains undecided, is suitable for the demonstration of a 10,000-SHP class small gas turbine. The FATE demonstration could then form the basis for a new engine for a future heavy-lift helicopter mission or the Joint Unmanned Combat Air System mission.

Recommendation 3-6c. In addition to developing two new small gas turbines, DoD should carefully investigate innovative ways to integrate advanced engines and advanced vehicle propulsion systems. Examples here include novel inlets, exhausts, IR suppression systems, particle separators, integrated flight/engine controls, and systems to manage component health.

EXPENDABLE TURBINE ENGINE S&T PROGRAMS

Expendable gas turbine engines are the prime propulsion systems for many cruise missile systems and some unmanned vehicle aircraft. The current main requirements for expendable GTEs are long-term storability, operability over a wide range of Mach numbers, and good fuel economy. They are also subject to severe volume restrictions and severe thrust-to-weight restrictions, In the committee’s expert opinion, expendable engines used by DoD are as good as or better than those of known competitors. Over the past two decades IHPTET has been developing technology for expendable engines. Some of these technologies have been incorporated in the derivative engines that will power the planned joint air to surface standoff missile (JASSM). The increased fuel economy of the expendable engine powering the JASSM is an important contributor to the missile’s increased range. However, irregular and catastrophic threats require a great increase in the Mach number range over which expendable engines must be able to operate. Standoff cruise missiles operating at Mach 4.0 will be required for warfighter missions in 2020. IHPTET has been developing many of the technologies required for these high Mach operations. However, IHPTET was unable to produce a demonstration engine with Mach 4.25 capability. The VAATE program, in partnership with DARPA, plans to demonstrate engines that can power missiles to Mach 4.25. These demonstrations will occur around 2008. After reviewing the programs to demonstrate high Mach number engines, the committee believes the demonstrations are well planned. However, given the criticality of high Mach number missiles for the 2020 warfighter, the committee suggests two more items that DoD might do well to consider. The first is a need for ManTech funding for the high-temperature materials necessary for GTEs to operate at Mach 4.25. Such funding would ensure consistent material properties and that the United States is able to supply these materials. This need is not unique to expendable GTEs but extends to all types of GTEs. The committee also notes that the high Mach demonstration program is success-oriented; that is, the program assumes success at all milestones, with little or no allowance for problems that might arise.

Finding 3-7. High Mach number cruise missiles are critical to the 2020 warfighter. The VAATE and DARPA programs have plans to demonstrate a Mach 4.25 expendable engine in 2008.

Recommendation 3-7. Given the criticality of the high Mach number cruise missile, DoD should support the goals of these demonstration programs by funding work to ensure the availability of high-temperature materials.

OTHER TECHNOLOGY PROGRAMS

There is a general misperception that aerospace propulsion is a mature plateau technology. To refute that notion, this section looks at several nascent and compelling aerospace propulsion alternatives.

Beyond conventional rocket and GTE aerospace propulsion in both concept and time scale lies an array of emerging alternative propulsion cycles, including hybrids and in situ reheat; fuels and energy sources; and propulsors applicable to in-atmosphere cruise and in some cases to Earth-to-orbit (ETO) and in-space propulsion. These frontier concepts are described in the NRC report Materials Research to Meet 21st Century Defense Needs: “In this case, the most important contribution of the panel may have been to

identify opportunities that are not being pursued aggressively due to limited budgets and a current focus on immediate needs and near–term payoff” (NRC, 2003, p. 58). These alternatives satisfy in various ways the DoD needs of 2018, which include increased range, loiter, timeliness, reliability, small system performance, and flight envelope, and lower observables and cost.

Alternative propulsion concepts are at various levels of maturity and application. The pulse detonation engine (PDE) approach is in the laboratory and exploratory stage. Variants of electric propulsion are currently being applied to a subset of small air vehicles, with the aim of increasing vehicle size and performance. Also applicable are “back-to-the future” possibilities for major improvements in internal combustion engines, such as free-piston devices and highly refined Wankel approaches.

Finally, there is a plethora of advanced aero-technologies and hybridization approaches for optimizing aerospace propulsion. As an example of a hybrid cycle, wave rotor devices could replace the combustor and portions of the critical turbine and compressor stages in GTEs. The following subsections briefly describe the physics, benefits, applications, overall state of the art, and associated recommendations for each of these alternative approaches.

Ramjet and Scramjet Engine Programs

Scramjet propulsion is crucial for standoff strike of time-critical and hardened targets, boost-phase intercept, and flexible access to space using airplanelike operations (NRC, 1998, 2004). Although the first patent on ramjet propulsion was awarded in 1913 (Lorin) and scramjet research started nearly 50 years ago, research flight tests have occurred mainly in the last 15 years. Serious application efforts are under way in various countries.

For the same vehicle volume, air-breathing power systems have inherently greater combat range than conventional rocket (solid or liquid) power systems, since air-breathers carry only the fuel, not the fuel and oxidizer. Air-breathing gas turbine propulsion operates below Mach 4. However, between now and 2020, the warfighter will need to operate at up to Mach 12. Scramjets are the only alternative air-breathing power system above Mach 4.0 on the planning horizon.

Scramjet propulsion systems are applicable to missiles, strike, reconnaissance, and ETO applications. Scramjets can fly up to Mach 8 using hydrocarbon fuels and can far exceed Mach 8 using hydrogen fuels. They can fly twice as far as missiles of the same volume/weight/length that use existing rocket technology. Scramjets offer (1) global reach (anywhere on the globe in approximately 2 hours), (2) time-critical strike (they reach targets hundreds of miles away in minutes), (3) sufficient kinetic energy to penetrate hardened targets, and (4) flexible access to space using airplanelike operations.

The competitors of air-breathing hypersonic propulsion are (1) rocket engines with high-energy-density materials as propellants; (2) low-cost autonomous attack systems, which can “be there” rather than having to “get there fast”; (3) microrockets; and (d) hypersonic boost-glide.

The current challenges in air-breathing hypersonic propulsion include (1) combined cycle transition, (2) system thermal management (engine/vehicle), (3) high-temperature/lightweight materials, (4) flow/combustion numerical simulation and design sensitivity, (5) cooled leading edge for Mach numbers larger than 7, (6) control and fuel system miniaturization, and (7) dual-mode scramjet flow path development. Additional challenges include integration of the propulsion into both turbine-based and rocket-based combined-cycle systems.

Two programs are currently developing scramjet propulsion systems based on liquid hydrocarbon fuels: the HyTech single engine demonstrator (SED), sponsored by the Air Force and DARPA, and HyFly, sponsored by the Navy and DARPA.8 The near-term application of the Air Force scramjet is a long-range hypersonic cruise missile, while the far-term one is a strike-and-reconnaissance Mach 8 aircraft and affordable, on-demand access to space with aircraft-like operations. The objective of the Navy scramjet program is to demonstrate the hypersonic propulsion and vehicle characteristics of a solid-

motor-boosted, hypersonic long-range strike missile that uses a dual-combustor ramjet (DCR) with an engine expected to accelerate the demonstrator to Mach 6 with a range of 600 nm. The DCR employs two air inlet systems. One feeds a subsonic gas generator in which a fuel-rich gas is generated. The gas is then coaxially mixed with supersonic air from the second inlet system. The diverging combustor section permits thermally choked operation as a ramjet but allows for transition to a supersonic combustion ramjet (scramjet).

The Force Application and Launch from Continental United States (FALCON) program is sponsored by the Air Force and DARPA (DARPA, 2004). Its goal is to develop and validate in-flight technologies that will enable both a near-term and far-term capability to execute time-critical, global-reach missions as well as to demonstrate affordable and responsive spacelift. The vision is to develop a hypersonic cruise vehicle (HCV) by 2025. The HCV will be a reusable autonomous aircraft capable of taking off from a conventional military runway and striking targets 9,000 nm away in less than 2 hours. The HCV will carry a 12,000-lb payload and will have a top speed of Mach 12. To achieve this speed, it will use scramjet engines burning liquid hydrogen. The FALCON program develops the systems required by the DoD for assured access to space.

To address the new threats, which include a hypersonic glide vehicle, a hypersonic powered vehicle, and a container-launched cruise missile, the Army is currently developing Mach 12 interceptor hypersonic projectiles in the Scramfire program. Scramfire is a 120-mm powered munition “that accelerates throughout flight to the target and offers increased velocity at the target for direct fire weapons or increased range for indirect fire” (NRC, 2004, p. 113). These systems are capable of variable velocity operation, are maneuverable, and can serve as an accelerator and/or a cruiser. The propulsion system is a scramjet engine that uses hydrogen fuels. Extensive experimental and numerical simulations are under way. The committee’s opinion is that this project is properly funded to achieve the project goals by 2009-2010.

The Mach 10 scramjet program HyCAUSE (hypersonic collaboration between Australia and United States experiment) is currently sponsored by DARPA and the Australian Hypersonics Initiative. The program involves the research, design, testing, and manufacture of all components involved in preparation for flight-testing a scramjet engine. A two-stage rocket booster will take the scramjet payload to an altitude of 315 km, and the experiment will be completed during the near-vertical reentry phase of the trajectory. The HyCAUSE objective is to conduct a controlled scramjet experiment at Mach 10.

In the last 2 years ramjet and scramjet technologies have matured at an accelerating pace. Single-digit-Mach-number free flights using a variety of fuels have demonstrated robust integrated engine and vehicle designs. For example, in 2004, NASA’s hydrogen-fueled X-43A flew successfully at Mach 7 and Mach 10. DARPA/ONR’s HyFly free-flight atmospheric scramjet test technique vehicle flew successfully at Mach 5.5 using liquid hydrocarbon fuel. DARPA’s ScramFire, a gun-launched, scramjet-powered projectile, flew at Mach 6 and Mach 8 using gaseous ethylene fuel. These three free flights have demonstrated completely successful applications of hypersonic technologies on experimental UAS, missile, and munitions platforms.

Major and difficult thermal management issues have been resolved. For example, in a follow-on activity to the AFRL robust scramjet program, an affordable, regeneratively cooled ramjet engine has been ground tested in a closed-loop system with the same hydrocarbon fuel stream used to both cool the engine walls and burn in the combustor. This milestone was achieved in 2005, at the NASA Langley Research Center test facility. The lightweight, circular-cross-section combustor sustained over 20 minutes of direct-connect test time at Mach 5 while remaining in pristine condition. This test-proven combustor design uses a conventional metallic structure and is readily manufactured (it progressed from conceptual design to test hardware in 7 months). In 2006, the same engine was tested over the Mach number range from 3.7 to 5.3 and showed robust performance at all simulated altitudes. This proven design will form the basis for an affordable approach that could quickly turn the challenge of a regeneratively cooled ramjet concept into a flight-ready engine.

Whereas previous flight activities were rocket-boosted or gun-launched to the ramjet/scramjet takeover condition, combined-cycle (turbine/ramjet) systems have been designed to achieve takeoff to hypersonic speeds in a single stage. A program for a turbine-based combined-cycle experimental aircraft

(the NASA X-43C) was well under way when it was cancelled in 2006 to free up funds for manned spaceflight initiatives. The X-43C utilized an integrated GTE with the ramjet/scramjet engine cycle. The gas turbine would have been used for takeoff to high supersonic speeds (above Mach 2.5). The X-43C program was designed and planned to test variable-geometry inlet architectures and nozzle arrangements and to examine their performance both analytically and experimentally. Mass injection precompressor cooling technologies were ground tested on an F100 jet engine, allowing it to easily operate at Mach 3.4, which is 35 per cent higher than its rated speed. This performance would have provided significant overlap of the turbine’s higher speeds with the ramjet’s lower speeds.

While aircraft applications of hypersonic flight have received more press, missile applications have been equally significant. Boost-to-cruise experiments using rockets to reach takeover speed have been successfully launched at Wallops Island Test Range. These sounding-rocket-class launches not only demonstrated scramjets they also paved the way to low-cost flight testing of hypersonic systems.9

Finding 3-8. Consistent with the National Aerospace Initiative (NAI), DoD has active scramjet technology development efforts. In the committee’s opinion, the level of U.S. technology is on a par with or ahead of the competition. It is also the committee’s opinion, however, that a more synergistic effort among DoD’s several scramjet efforts would allow DoD to meet the country’s needs more economically and quickly.

The existing DoD scramjet programs are well focused and address the DoD S&T strategy. NASA scramjet propulsion programs are being replanned. There is a need for a government–sponsored, focused program like IHPTET/IHPRPT to maintain the U.S. technology base for scramjets.

Recommendation 3-8. DoD should develop a strategy to exploit the synergies between the hypersonics programs in each of the services for the benefit of DoD as a whole and to achieve a common technology and cost savings. There are alternative solutions for both time-critical and hardened targets and flexible space warfare that should also be studied and compared with the scramjet solution.

Pulse Detonation Engine Programs

PDEs are devices in which the combustion process is accomplished in an unsteady way by a supersonic detonation wave. In its simplest form, a PDE combustion chamber is a straight tube filled with a fuel-air mixture. As the detonation wave occurs, the pressure changes with time at a given location and varies along the tube at a given time. This is in contrast to a gas turbine engine, in which the combustion process is nominally steady and constant through the combustion chamber.

The combustion cycle of a PDE has three different phases. In the initial phase, the fuel-air mixture enters the tube and is ignited. In the second phase, a detonation wave starts and propagates down the tube, moving supersonically with respect to the fluid downstream. (Valving is needed to support the propagation.) In the third phase, the hot combustion products in the tube exit at the downstream end, and the resulting low-pressure region causes a new charge of fuel and air to enter the tube so the cycle can start again.

Heiser and Pratt (2003) carried out instructive analyses of the theoretical performance potential for PDEs and compared it to Brayton cycle engines (the cycle for turbines, ramjets, and scramjets). They also assessed the decrease in performance for both cycles in the presence of representative component losses.

Though some progress has been made, many issues need to be resolved to transform PDEs into operational systems (Schauer and Stutrud, 2001; Dean, 2003; Santoro et al., 2003). Some of the issues have to do with the losses in the unsteady processes, including unsteady compression system exhaust effects, entrance valve losses (sudden expansion), detonation initiation without O2, internal combustor losses (wall friction, heat transfer, protuberance drag), combustor exhaust valve losses, and unsteady, nonuniform expansion system entrance effects. There is also concern about the power density that can be achieved (i.e., the power per volume).

The committee feels that PDEs could turn out to be a niche application in the spectrum of DoD propulsion systems rather than a broad-based application that will change the landscape. The technology needs to progress from TRL 3 or 4 to TRL 6 before it can be applied. These engines may offer greatest potential in low-cost missiles for Mach numbers less than 4 rather than as a replacement for gas turbine engines or for high-speed Brayton cycle engines.

High-Thrust Electric Propulsion

Factors driving interest in electric propulsion as an alternative to GTEs and piston engines include the potential to eliminate CO2 and nitrogen oxide (NOx) emissions; up to a twofold increase in thermodynamic efficiency; potential improvements in cost, reliability, maintenance, and safety; reduced noise and thermal signature; efficiency at high altitudes; and the opportunity for distributed propulsion (utilization of propulsion for flow and vehicle control and drag reduction). High-thrust electric aerospace propulsion is at an early stage, with initial applications confined to small aeronautical vehicles. However, high-thrust electric aerospace propulsion is being increasingly applied to satisfy a number of DoD aeronautical mission requirements. “Each of the services has a vision for an all-electric future…. The Air Force and Navy have promoted visions of the all-electric aircraft and the all-electric ship” (NRC, 2003, p. 75).

Electrical Energy Generation, Storage, and Supply

Foremost among the approaches to generating electrical energy for aerospace propulsion are fuel cells, which exhibit high efficiencies, are easily scaled, can be nonpolluting or closed cycle, and can be applied in a distributed fashion. Of the myriad of fuel cell approaches, solid oxide is the favorite, and proton exchange membrane is a possibility. Solid oxide can be enhanced with a bottoming cycle, whereby waste heat is regenerated using either a turbine-based cycle or direct thermal-to-electric conversion via, for example, thermal diodes. Fuel cell efficiency, in kilowatts per kilogram, is an order of magnitude less than required for large aircraft, but various advanced technologies are projected to be able to narrow that gap. Longer term, the application of multiwalled nanotubes to fuel cells is projected to improve their performance by up to an order of magnitude.

For less stressing applications, batteries and capacitors (i.e., electrical storage devices) are employed. The object of intense research, storage capacities are improving rapidly. For high altitudes and balloons with their large external surface area, hybrid cycles using solar photovoltaics are useful. Long-term alternative sources for electrical energy include carbon nanotube (CNT) flywheels, off-board beamed microwave energy internalized via recently improved “rectennas,” and superconducting magnetic energy storage with CNT magnets. The latter, from very preliminary analyses, may ultimately provide energy densities approaching or surpassing the energy densities of chemical sources.

Fuels

The fuel of choice to power fuel cells is hydrogen. Biotechnology is enabling direct production of H2 via photosynthesis. Nanotechnology is contributing options for producing hydrogen using solar energy. Materials research is providing extremely inexpensive (compared to silicon) photovoltaics, and recent efforts suggests that efficiencies up to twice that of silicon are possible. Commercial entities have begun to manufacture and market inexpensive photovoltaics incorporated in thin sheets and roofing shingles. The electricity produced could be used to produce hydrogen. In addition, there has been progress on the highly efficient photocatalysis of water using visible light for direct H2 production.

Perhaps the most important outstanding issue with electric aerospace propulsion is hydrogen storage. Aside from cryostorage, advanced, emerging, and, possibly, more efficient approaches to hydrogen storage include CNT pressure vessels and adsorption storage within lithium nitride, graphite nanofibers, and CNTs. Additional H2 storage options include densified, or slush, H2 and ammonia. Alternative fuels

or sources of hydrogen, which have innate drawbacks related to emissions, include reformed hydrocarbons and methane.

Propulsors