H

Report of the Panel on DOE’s Integrated Gasification Combined Cycle Technology R&D Program

INTRODUCTION AND OBJECTIVE OF THE STUDY

Integrated gasification combined cycle (IGCC) is a technology that can use a variety of feedstocks to produce electricity, synthetic gas, and other by-products while minimizing the environmental impacts of doing so. The underlying coal gasification technology has been in commercial use since the beginning of the 20th century and has been demonstrated throughout the world to produce a variety of valuable end and intermediate products using a variety of configurations, technologies, and feedstocks. IGCC—that is, the coupling of gasification with a combustion turbine for electricity generation—has been in commercial development in the United States since the early 1980s. Various improvements to the gasifier and associated technologies in the IGCC system are under active investigation in programs funded by the private and public sectors.

The Panel on DOE’s IGCC Technology R&D Program was created by the NRC to apply the methodology developed in Phase One by NRC’s Committee on Prospective Benefits of DOE’s Energy Efficiency and Fossil Energy R&D Programs (NRC, 2005a) to assess the potential benefits of DOE’s R&D activities that are focused on IGCC.1 The panel consisted of experts with experience in coal-based electric power generation technologies and markets, combustion and gasification systems, environmental control technologies, and other relevant areas. Biographies of panel members are provided in Attachment A to this appendix.

The panel applied the committee’s methodology by (1) assessing the probability of success of meeting DOE’s time frame and targets for technology development, (2) considering alternative paths of development with and without DOE funding, (3) reviewing DOE estimates of the economic, environmental, and national security benefits of its program on IGCC technology, and (4) estimating the benefits under the alternative future states of the world (scenarios) specified by the committee.

The panel held two 2-day meetings and a conference call to complete its assessment. It was supported by a consultant and data and program information provided by DOE.

IGCC PROGRAM BASELINE AND GOALS

In IGCC technology, coal is gasified to produce a synthesis gas—principally carbon monoxide (CO) and hydrogen (H2)—which is cleaned to remove particulates and other contaminants (e.g., sulfur and mercury compounds), then burned in a gas turbine to generate electricity. Heat is recovered from the combustion gases to generate additional electricity. The DOE research activities that are key to the success of IGCC as a technology are the advanced IGCC subprogram and the advanced turbine subprogram. There are DOE coal programs in fuel cells and carbon sequestration that have some relationship to the ultimate implementation of the IGCC technology, but the panel confined itself to analyzing the goals of these two main subelements and their potential benefits. A key goal of the DOE program is to develop IGCC systems capable of separating carbon dioxide (CO2) for subsequent sequestration. This has a bearing on the performance of various components of the IGCC system other than the gasifier, principally the CO2 separation system and the gas turbine itself, which must be modified to operate on a hydrogen-rich fuel gas (i.e., after CO2 separation). During the meeting with the panel on October 5 and 6, 2005, representatives of DOE made presentations on the performance goals of the advanced IGCC subprogram2 and

TABLE H-1 Baseline and 2010 Goals for Total IGCC System as Given in DOE’s Advanced IGCC Research

|

Baseline/Goal |

Efficiency (%) |

Capital Costa($/kW) |

O&M ($/year) |

COE ($/MWh) |

Availability (%) |

|

Goal set by DOE advanced gasification program |

Increase of 2% to 4% |

5% decrease |

Decrease of $1 million |

|

Increase of 5% |

|

Baseline assuming entrained gasifier |

39.8 |

1,517 |

|

49.3 |

85 |

|

Goal assuming compact gasifier |

43.1 |

1,297 |

|

40.2 |

94 |

|

Baseline in DOE systems analysis |

37.5 |

1,300 |

|

47.0 |

75 |

|

2010 goal in DOE systems analysis |

48.0 |

1,000 |

|

32.0 |

85 |

|

Baseline input to NEMS cases |

41.1 |

1,400 |

|

|

|

|

2010 goal input to NEMS cases |

50.0 |

1,000 |

|

|

|

|

aOvernight costs in 2003 dollars. SOURCE: Gary Stiegel, Gasification Technology Manager, DOE, National Energy Technology Laboratory, “Gasification Overview: Prospective Benefits Study,” Presentation to the panel, October 5, 2005; and Julianne Klara, Senior Analyst, DOE, National Energy Technology Laboratory, “NEMS-based benefits of FE gasification R&D,” Presentation to the panel, October 5, 2005. |

|||||

the advanced turbines subprogram3 and on how DOE uses the Energy Information Administration’s (EIA’s) National Energy Modeling System (NEMS) to assess the economic benefits of the gasification program.4 Based on the presentations, there are quantitative goals, generally expressed in terms of the total IGCC system, for six principal criteria:

-

Thermal efficiency,

-

Capital cost,

-

Operation and maintenance (O&M) cost,

-

Cost of electricity (COE),

-

Availability (the fraction of time during which the plant is generating electricity), and

-

Emissions.

The principal research activities in the gasification program that are intended to provide the technology to meet the performance goals are these:

-

Warm gas cleanup,

-

Instrumentation (e.g., temperature measurement),

-

Materials (e.g., refractory),

-

Air separation by means of, for example, ion transport membrane (ITM),

-

Dry coal feeding (e.g., Stamet pump), and

-

Advanced gasifiers (transport gasifier, Rocketdyne gasifier).

In conducting the benefits analysis of the program, it became clear to the panel that there was some inconsistency in the goals and their timing as depicted in the DOE presentations. Furthermore, it was not clear from the information presented how much each of the major research activities listed above was expected to contribute, quantitatively, to reaching the goals. Therefore, the panel asked DOE to fill out a spreadsheet specifically for the gasification element of the program to clarify the program goals and improvements expected if the major program activities are successful.

Table H-1 was prepared by the panel based on information in the DOE presentations. Taken together, the baselines and goals indicate that the DOE program is seeking improvements of 5 to 10 percentage points in thermal efficiency (up to about 50 percent overall), $200 to $500 per kilowatt (/kW) in overnight capital cost (down to $1,000/kW), and 5 to 10 percentage points in availability (up to 90 percent).

Tables H-2, H-3, and H-4 show the data and reference notes DOE provided on the improvements its R&D is expected to make in IGCC system performance. The committee distinguished three categories of improvements:

-

Evolutionary improvements. These research activities are part of the DOE program but also likely to be developed to some extent by non-DOE efforts. The panel added two activities under the heading “non-DOE or non-gasification program advancements” to help quantify the improvement one might expect absent the DOE program (see Table H-2).

-

Evolutionary improvements—major DOE programs. These project activities are principally within the DOE program. The panel added a line for the goals of the complementary DOE turbines program (see Table H-3).

-

Revolutionary or long-term improvements. The panel concluded that these project activities of the DOE program would need to be successful, in addition to the activities that achieve “evolutionary” improvements, to achieve the more aggressive goals of the DOE program (e.g., 48 percent thermal efficiency). The panel added a line to Table H-4 for potential improvements to thermal efficiency resulting from gasifier research being done outside the United States, principally in China and Japan. It noted that advances in gasification-related technologies being developed in the

TABLE H-2 Evolutionary Improvements Due to DOE Advanced IGCC Research

|

|

Change in Cost and Performance of IGCC System Attributable to R&D |

|||||

|

Research Activity |

Increase in Efficiency (%) |

Capital Cost Reduction ($/kW) |

O&M Reduction ($/year) |

Reduction in COE ($/MWh) |

Availability Improvement (%) |

Emissions |

|

DOE gasification programa |

|

|

|

|

|

|

|

Warm gas cleanup |

1 to 2 |

70 to 100 |

Minimal |

1.8 |

0 |

500 ppb sulfurb |

|

Instrumentation (temperature measurements)c |

0.5 to 1 |

0 |

Minimal |

Minimal |

1 to 2 |

— |

|

Materials (refractory)d |

0 |

0 |

2 million |

0.5 |

4 to 6 |

— |

|

Non-DOE or nongasification program |

|

|

|

|

|

|

|

Heat recovery |

3 |

|

|

|

|

|

|

Industry learning and evolution |

1 to 2 |

|

|

|

|

|

|

NOTE: COE, cost of electricity; kW, kilowatt; MWh, megawatt-hour; ppb, parts per billion; ppm, parts per million. aData courtesy of Gary Stiegel, DOE, National Energy Technology Laboratory. bReference case is 10 ppm sulfur. cEfficiency gain through high carbon conversion. dAssuming one turnaround per year. |

||||||

TABLE H-3 Evolutionary Improvements Due to DOE Advanced Gasification Research

|

|

Change in Cost and Performance of IGCC System Attributable to R&D |

||||

|

Research Activity |

Increase in Efficiency (%) |

Capital Cost Reduction ($/kW) |

O&M Reduction ($/kWh) |

Reduction in COE ($/MWh) |

Availability Improvement (%) |

|

DOE gasification program |

|

|

|

|

|

|

Ion transport membrane air separation |

1 |

75 Minimal |

1.4 |

0 |

|

|

Stamet pump |

0.5 |

40 to 100 |

Minimal |

1.4 to 1.8 |

0 |

|

Non-DOE or nongasification programs |

|

|

|

|

|

|

DOE turbine programa |

2 to 3 (for combined cycle power island) |

60 to 100 |

|

|

|

|

NOTE: COE, cost of electricity; O&M, operation and maintenance, kW, kilowatt; kWh, kilowatt-hour; and MWh, megawatt-hour. aThe DOE turbine program is considered complementary to its advanced IGCC subprogram. SOURCE: Gary Stiegel, DOE, National Energy Technology Laboratory. |

|||||

TABLE H-4 Revolutionary or Long-Term Improvements Due to DOE Advanced Gasification Research

|

|

Change in Cost and Performance of IGCC System Attributable to R&D |

||||

|

Research Activity |

Increase in Efficiency (%) |

Capital Cost Reduction ($/kW) |

O&M Reduction (c/kWh) |

Reduction in COE ($/MWh) |

Availability Improvement (%) |

|

DOE gasification programa |

|

|

|

|

|

|

Transport gasifier |

1 to 2 |

|

|

|

|

|

Rocketdyne gasifierb |

1 to 2 |

50 |

Minimal |

1 |

2 to 5 |

|

Chemical looping |

2.5 |

130 |

0.2 |

3 |

0 |

|

Non-DOE or nongasification program |

|

|

|

|

|

|

Non-U.S. gasifiers |

2 to 3 |

|

|

|

|

|

NOTE: COE, cost of electricity; O&M, operation and maintenance; c/KWh, cents per kilowatt-hour; kW, kilowatt; kWh, kilowatt-hour; and MWh, megawatt-hour. Improvements in the parameters in this table are deemed necessary in order to achieve 45-48 percent efficiency for the IGCC plant. aData courtesy of Gary Stiegel, DOE, National Energy Technology Laboratory. bPerformance is relative to slurry-fed quench gasifier. |

|||||

-

United States and other countries were not likely to be additive because they represent distinctly different technologies, and therefore separated the transport and Rocketdyne gasifier targets. The panel also concluded, based on a follow-up conversation with DOE, that the chemical-looping program, although funded out of the gasification budget, was separate from and further out in time than the core gasification program (see Table H-4).

The panel used this categorization of improvements and the estimated outcomes from each improvement as the basis for evaluating the potential outcomes of DOE’s program in terms of thermal efficiency, capital cost, and availability for the IGCC plant and for estimating the probabilities of the various outcomes. For example, if the DOE program were to achieve all its goals for capital cost reduction through the projects in warm gas cleanup, ITM air separation, the Stamet pump, and turbines, and if all of these were additive, the net improvement would be $245-$375/kW.

GENERAL OBSERVATIONS ON DOE IGCC GOALS

In conducting this analysis, the panel identified two issues that affected its ability to quantify the benefits of potential success of the DOE program.

First, DOE considers that its goals will have been achieved when the research has been completed that will lead to the claimed improvements and when the technology has been demonstrated and commercially deployed through operation of the nth plant. While this reflects the reality of the DOE R&D budget, which funds research separately from demonstrations and does not address deployment at all, it does create some possible confusion about the time at which the expected benefits of the R&D program can be realized. In its analysis as discussed below, the panel made an estimate of the time to demonstrate and commercially deploy the advanced IGCC technologies being developed by the DOE research. Clearly, the accuracy of this time-to-commercialization estimate has a significant impact on the discounted value of the research program.

Second, the panel observed that many of the research projects were expected to result in improvements under more than one performance criterion, so that the effects of failure or success of a single project could be amplified in the overall outcome. Also, success of some of the projects would not be additive (i.e., the success of the transport gasifier would not confer an additive benefit to the success of the Rocketdyne gasifier), and some of the technologies were not equally beneficial for all possible coal feeds (bituminous, subbituminous, lignite). Therefore, there was some question about how to combine probabilities of success for different elements of the program, and about their corresponding benefits. The panel attempted to do this through the decision tree analysis.

ASSESSMENT OF DOE IGCC PROGRAMS

Technical Risks

Overview

DOE has focused its R&D program for IGCC on achieving substantial reductions in plant capital cost, plant thermal efficiency, and improvements in operating reliability. Meeting these goals would make this technology competitive with or superior to other forms of coal-fired power generation.

The R&D program was formulated based in large part on the results of a series of workshops with key stakeholders, who identified and prioritized R&D needs. Progress in meeting cost and performance goals is evaluated periodically both in-house, by DOE’s National Energy Technology Laboratory (NETL), and by independent contractors. It should be noted that many of these projects deliver both cost and performance improvements. Failure to achieve the goals of any single project means that it may not be possible to achieve either cost or performance improvements. Some projects have synergies with others. As a result, simply adding up the improvements achieved by individual projects might not accurately represent the cumulative value of multiple projects.

Rocketdyne Gasifier

United Technology/Boeing has proposed the development of a compact gasifier that incorporates a number of innovative concepts based in part on rocket engine technology. If successful, this effort would reduce the estimated capital cost of an IGCC plant by about 15 percent and increase its efficiency by about 3 percent. The concept involves utilizing mechanical devices to pressurize the coal (dry feeders), feeding the pressurized coal into a compact reactor through multiple nozzles (rapid mix injectors), and removing heat from the reactor through membrane panels cooled by circulating water to prevent the reactor vessel from overheating (actively cooled wall liner).

A series of individual development activities have been formulated to test the feed system, the injectors, and actively cooled wall systems. If these three programs are successful, it has been proposed that an integrated pilot plant be built, followed by a full-scale demonstration. The technical risks are as follows:

-

One or more of the component development activities (feed system, injector system, actively cooled wall) might fail.

-

The promised cost and efficiency savings might disappear as the development program identifies unanticipated problems.

Transport Gasifier

The transport gasifier system has been developed with major sponsorship from DOE and technical leadership from the Southern Company. The program has been in operation since 1995 at a nominal 50 tons of coal per day (T/D) scale, demonstrating the concept of both air- and oxygen-blown gasification of a number of coals, including bituminous and subbituminous coals and lignite. The facility has also been used as a test bed for slipstream tests of various DOE-developed components and subsystems.

A 285-megawatt (MW) commercial-scale plant to be located at an Orlando Utilities Commission site in Florida is being designed by the Southern Company and its team under the DOE Clean Coal Power Initiative (CCPI) program. This plant will operate in an air-blown mode with Powder River Basin subbituminous coal. It is scheduled to begin operation in 2010. The technical risks are as follows:

-

One or more of the design concepts based on the experience obtained at the Power Systems Development Facility (PSDF) might not scale up as anticipated, and redesign or replacement of equipment might be required.

-

The coal feed injector (into the reaction zone) concept might require further development.

-

Some of the solids circulation systems might not work as initially designed.

ITM Air Separation

Production of oxygen of 95 percent or greater purity from air by current liquefaction technology requires about 10 percent of the gross power output of the plant and accounts for about 15 percent of an IGCC plant’s capital cost. This technology is very mature and has few unexploited areas that could promise further improvement.

DOE has been sponsoring work with Air Products and Chemicals, Inc. (APCI) on the ITM method of separating oxygen from air at high temperature by transporting oxygen ions through a high-temperature ceramic membrane. The source of the air is a bleed stream from the gas turbine compressor. Because the air must be heated to approximately 1000 F for transport through the membrane and the 99.99 percent pure product oxygen must be cooled and compressed prior to feeding to the gasification reactor, integration with the gas turbine cycle must be carefully optimized.

Currently, a 5-T/D pilot plant is in operation at an APCI facility in Sparrows Point, Maryland. Scale-up to 150 T/D has been proposed as the next step. The technical risks are these:

-

The production cost goals for ITM modules might not be achieved.

-

It might not be possible to scale up the technology successfully with integrated operation of multiple ITM units with one or two large gas turbines.

-

Some of the currently available gas turbines that use air for airfoil cooling (typical F series) might not provide sufficient air to the ITM unit; those turbines that use steam for airfoil cooling (typical advanced G and H series) could, however, provide the needed air.

Stamet Dry Coal Pump

Gasification processes that feed coal to the gasifier as a dry, fine powder (as, for example, in the Shell process) or as a dry, crushed solid (as in the KBR Transport reactor) utilize a series of lock hoppers and a transport gas, usually nitrogen, to inject the coal into the reactor. These lock hopper systems are expensive, require extensive maintenance, and require energy to compress the pressurization gas.

DOE has been sponsoring work by Stamet to develop a single-stage mechanical device or pump capable of pressurizing the reduced-size coal to a level that will allow it to then be transported and injected into the gasification reactor. Stamet has already developed and commercialized solids feeders that are successfully used by industry to pressure solids to low differential pressures. Laboratory work at Stamet facilities to date has successfully demonstrated that coal can be injected into a vessel operating at 500 psi. An initial test at the PSDF facility in Wilsonville, Alabama was successful, and further testing is planned. The technical risks are these:

-

There could be excessive mechanical wear of the Stamet rotating components.

-

It might not be possible to disperse the pressurized coal within the delivery vessel for transport to the gasification reactor.

Warm Gas Cleanup

Cooling product gas prior to sulfur removal is thermodynamically inefficient; the lower the temperature, the greater the inefficiency. Current cleaning technology requires cooling the gasifier effluent gas to between 0 F and 100 F prior to sulfur removal depending on the absorption solvent that is used for sulfur removal. DOE is attempting to increase efficiency by developing technology that is effective at higher temperatures.

Experiments are being conducted in a slipstream unit at the Eastman Chemical coal gasification plant in Kingsport, Tennessee, at a scale equivalent to 0.5 to 1 MW. The system utilizes a finely divided, zinc-based solid sorbent to capture sulfur compounds in the form of hydrogen sulfide (H2S) and carbon oxysulfide (COS) in the product gas. This work is being carried out in a two-vessel transport reactor system operating at about 600 pounds per square inch gauge (psig), with the absorber operating at 800 F and the regenerator at 1050 F. Recent results have shown that clean gas with a total sulfur content of 100 parts per billion (ppb) can be

obtained. The sorbent has also demonstrated an ability to remove arsenic from the gas without any deleterious impact on the sorbent. This attrition resistance of the sorbent has been adequate in limited experiments to date.

Successful development of this technology would eliminate a number of current IGCC plant equipment items, including a number of high-temperature heat exchangers, the COS hydrolysis unit to convert COS to H2S, the Selexol or other solvent unit to remove H2S, and the Claus/SCOT units for elemental sulfur production and tail gas cleanup. DOE has proposed scaling up this system to 50 MW, before it qualifies as a commercial offering. The technical challenges or “risks” include these:

-

Maintaining sorbent performance at desired levels while achieving sorbent consumption rates (due to activity loss and attrition) at economically attractive levels; and

-

Reducing the regenerator temperature to 700 F or lower to maximize efficiency.

Instrumentation (Primarily Temperature Measurement)

Improved instrumentation for use directly in gasifiers and in gasifier supporting systems has the potential to improve overall system efficiency and minimize operation and maintenance (O&M) expenses. The areas of need include direct gasifier temperature measurement, in situ measurement of slag viscosity, on-line (i.e., during operation) measurement of refractory wear, and real-time measurement of feed coal properties.

Perhaps the most important of these at the moment is the direct measurement of actual gasifier operating temperatures. Currently available gasifier instrumentation such as thermocouples have a very short life in commercial-scale coal gasifiers that operate at 2500 F-3000 F. As a result, peak temperatures in the gasification zone are inferred from the composition of the product gas. While these results are approximately correct, the result is the gasifiers are run at lower than optimum temperatures for carbon conversion to avoid excessive damage to refractories. This results in inefficiency.

DOE is sponsoring work at several locations: GE Energy; Albany Research Center in Oregon; Virginia Tech (with ConocoPhillips); Entertechnix; and the Gas Technology Institute (GTI). The work is focused on the development of temperature measuring systems based on direct observations of the flame in the gasification reactor and on processing the data from those observations to accurately and reliably infer temperature. The technical risks are as follows:

-

It might not be possible to keep the sighting ports open and/or clean enough for long enough periods.

-

The algorithms to process the data might not be accurate.

-

The materials used in the systems might fail due to long-term exposure at high temperature.

Refractory Materials for Gasifier Walls

Current coal gasifiers (those of GE and E-Gas for example) that utilize an internal refractory to protect the metal walls of the vessel from exposure to high temperatures would benefit from this research, while gasifiers using a cooled membrane wall (those of Shell) would not. The chromium oxide-based refractory used in these high temperature gasifiers is attacked by the molten slag (derived from the mineral matter in the coal) that flows down their walls during gasification operations. Variations in operating temperature and slag composition result in different rates of attack. Typical intervals for planned refractory replacement, which require 3-4 weeks of unit downtime, are from 6 to 18 months. Unplanned outages are also required from time to time for minor refractory repairs. Increasing the replacement interval for an unspared gasifier from 18 months to 36 months, the target of the DOE program, would increase availability by 2.5 percent. Elimination of 50 percent of unplanned outages would also increase availability.

DOE has sponsored work at the Albany (Oregon) Research Center that resulted in new refractory formulations based on phosphate additions that are being tested in two currently operating commercial IGCC plants. Initial results are promising. The risks that must be faced are these:

-

The refractions might not achieve their service life objectives.

-

It might be too expensive to manufacture them in commercial quantities.

-

They might be susceptible to premature failure when used with specific coals.

Hydrogen-Fired Gas Turbines

Most gas turbines were developed for use with methane as the primary fuel. Older models that operate at lower firing temperatures (1500 F-2000 F) were able to fire hydrogenrich gases (up to 90 percent hydrogen) without downrating. However, newer models that operate at much higher firing temperatures (2300 F-2600 F) on methane must be fired at 200 F-300 F lower firing temperatures on hydrogen-rich fuels.

DOE has embarked on a major effort to develop gas turbines that can operate at the same high temperatures as methane-fired turbines and so achieve the same efficiency, with NOx emissions of 2 ppm. The technical risks are as follows:

-

It might not be possible to achieve the efficiency and NOx emissions goals simultaneously.

-

The combustor system required to achieve those goals simultaneously might be significantly more expensive.

Chemical Looping

Chemical looping involves a reactor system with two fluidized beds. This system can be utilized to achieve either total combustion or total gasification. Solid particles containing metal oxides are supplied to the reactor used for combustion or gasification to supply the oxygen. When the oxygen in those solids is utilized for combustion, the oxides are reduced to metals. The metals are circulated to a second reactor, where they are reconverted to oxides by reacting them with air. The CO2-rich gas exiting the combustion reactor is diluted primarily with water, which can be removed by condensation, leaving an essentially pure CO2 stream, which can then be captured.

DOE has funded experimental work on chemical looping in pilot plants at Alstom and GE. The oxides that have been tested for use in this cycle include both supported and unsupported materials. The solid oxide materials evaluated include calcium carbonate (CaCO3), calcium sulfate (CaSO4), and iron oxide (Fe2O3). Supported oxide materials included copper oxide (CuO), Fe2O3, manganese oxide (MnO2), and nickel oxide (NiO) on various inert supports, including aluminum oxide (Al2O3), sepiolite, silicon oxide (SiO2), titanium dioxide (TiO2), and zirconium oxide (ZrO2). The technical risks are as follows:

-

The cycle efficiency might not be competitive;

-

The capital costs might not be competitive;

-

Gas cleanup to meet emission requirements (NOx, hazardous air pollutants, etc.) might be difficult to achieve; and

-

A solid that has appropriate chemical reactivity, chemical stability, and attrition resistance might not be available at the required cost level.

Market Risks

Market risks must be considered for the time frame associated with demonstration and commercialization of the IGCC technology developed by this program as well as by other, non-DOE programs. Following completion of R&D sponsored by the DOE in 2010, the panel estimates nominal requirements of 9 and 5 years, respectively, for demonstration and commercialization, which would mean a grid-ready plant in circa 2024.

Significant market risk factors can be broadly classified as follows: fuel prices, the regulatory environment, and competing technologies. Of these factors, that associated with the relative price of competing fuels is believed to carry the greatest risk. If the cost of natural gas were to drop below approximately $5 (in 2005 dollars) per million British thermal units (MMBtu), an IGCC power plant, even one resulting from achievement of the DOE program goals, could not compete with a natural gas combined cycle (NGCC) plant in terms of the levelized COE. For an IGCC plant to be cost competitive, today and in the future, the ratio of fuel costs (natural gas to coal) should exceed 3:1. Much will depend on growth of the nation’s marginal needs for natural gas, the extent to which a liquefied natural gas (LNG) infrastructure is established to meet those needs, and global competition for natural gas supplies among net consumers.

Another significant risk would be the early implementation of an aggressive, mandatory CO2 emission reduction regulation. Such a regulatory measure, in combination with low to moderate gas prices, would favor natural gas. Conversely, a more restrained approach to regulating CO2 emissions, combined with high natural gas prices, would favor the commercialization of IGCC plants, which benefit from efficient means of CO2 separation. However, if adequate (large-scale) CO2 sequestration options fail to materialize, IGCC plants will lose the advantage afforded by efficient separation.

Competing technologies include ultra supercritical steampulverized coal (USC-PC) and circulating fluidized bed (CFB) combustion systems, nuclear power, fuel cells, and alternative/renewable sources such as wind, solar, and biomass. Advancements in the combustion (USC-PC and CFB) technologies, particularly if accompanied by cost-efficient means of carbon capture, represent the biggest technology threat to commercialization of IGCC plants. Table H-5 shows the significant differences between present costs and efficiencies for a range of coal-based and natural-gas-based power generation technologies and the DOE goals for IGCC. IGCC, utilizing a spare gasifier to bring its capacity factor up to 85 percent, has higher total plant costs and COE than alternative clean coal technologies. The total plant cost for NGCC is low, but the COE is high due to the high natural gas price and the resulting low capacity factor.5

Of the other technologies for generating electricity, nuclear power is encumbered by large capital costs, an extensive regulatory environment, and safety issues associated with radioactive waste disposal. Moreover, even with an eventual return to the construction of nuclear power plants, it is difficult to imagine any scenario other than one in which nuclear and coal options are concurrently developed. While fuel cells may one day provide a significant source of distributed power, progress will be slowed by related hydrogen supply and infrastructure requirements. However, sustained advancements in high-temperature (e.g., solid oxide) fuel cells may, in fact, enhance prospects for commercializing IGCCs by enabling hybrid systems with efficiencies exceeding 50 percent. Power generation from renewable forms of energy will continue to increase, particularly with the recent commitment of large corporations to the development and

TABLE H-5 Costs for 500-MW Power Plants Using a Range of Technologies Without Carbon Capture and Storage

implementation of related technologies, the growing application of renewable portfolio standards,6 and the emergence of social values as a significant driver of national energy policies. However, the impact of these trends is likely to be small relative to the need for electricity associated with sustained economic growth.

Other risk factors are those associated with weak economic growth (reducing the need for new plants), constraints on the transmission system (the electricity grid), and insufficient human capital (i.e., engineers) to derive maximum benefits from available opportunities. However, these factors apply to all options, not just to IGCCs. There is also a risk associated with inadequate development of the transportation infrastructure for coal, which would affect USC-PC and CFB as well as IGCC systems.

In summary, the biggest market risks for IGCC commercialization are associated with reemergence of low to moderate costs for natural gas and with premature imposition of an aggressive CO2 control regulation. Conversely, commercialization would benefit from high costs for natural gas and the gradual imposition of carbon constraints, as well as from opportunities for significant increases in efficiency and reductions in cost afforded by an immature technology such as IGCC.

RESULTS AND DISCUSSION

Overview

The committee’s methodology asks that the panel evaluate the benefits of IGCC under each of three global scenarios representing three different possible future states of the world. It also suggests that the evaluation should explicitly consider the role of DOE funding; should present the technical risks and market risks that can affect the outcome and the value of the program’s activities in a decision-tree format; and should include the net economic, environmental, and security benefits that will result from the portfolio. The panel considered each of these suggestions in its evaluation.

Consideration of Global Scenarios

The panel felt that the probability of technical success would not be influenced by the global scenarios, but that the probability of market success would be. As discussed above, two of the primary market risk factors are the cost of natural gas and the imposition of a carbon emissions restriction. The three global scenarios were defined specifically to consider the impact of changes in fuel prices and in the treatment of carbon emissions. These impacts are reflected in the probability estimates for market success, described below.

The Carbon Constrained global scenario was defined by the prospective benefits committee as a scenario wherein a $100/ton carbon tax is assumed to be in place in 2012. While the panel believes IGCC technologies could benefit significantly under this scenario, the benefits would depend critically on the success of research in carbon sequestration. Both IGCC R&D and sequestration R&D must make significant advancements for IGCC with sequestration to be a viable market choice; the panel does not believe it is possible to separate the benefits of IGCC R&D from the benefits of carbon sequestration R&D in this scenario. Thus, it did not evaluate the benefits of IGCC R&D in the Carbon Constrained scenario. The panel notes that another panel is using this methodology to evaluate DOE’s carbon sequestration R&D and is focusing exclusively on Carbon Constrained scenarios.

Decision Tree and Probability Assessments

Role of DOE Funding

In defining the various levels of technical and market success described below, the panel considered the specific information provided by DOE about its program, as well as panel members’ knowledge of the current performance of IGCC plants and of ongoing IGCC-related research that is being conducted independently of DOE’s program, including research being carried out overseas. The panel assessed the probability of achieving various levels of technical performance and market success for IGCC technologies, first assuming the DOE R&D program is funded and then assuming the program is not funded.

Technical Success

As noted above, the panel considered the specific activities being funded by DOE and the potential impact of that research on both the capital cost and efficiency of IGCC plants. Based on that consideration, the panel identified four levels of technical success in terms of IGCC plant efficiency and capital costs. A secondary type of technical success was defined in terms of plant availability.

The four levels of technical success were defined by the estimated capital costs and efficiency for the nth plant, assuming R&D completed in 2012 and at least 80 percent plant availability:

-

Low success. Efficiency of 38 to 40 percent on a higher heating value (HHV) basis at a capital cost of $1,400/kW, or approximately what is achievable with today’s technology.

-

Moderate success. Efficiency of 42 percent (HHV) at a capital cost of $1,265/kW.

-

High success. Efficiency of 45 percent (HHV) at a capital cost of $1,135/kW.

-

Very high success. Efficiency of 48 percent (HHV) at a capital cost of $1,040/kW. This level is approximately equal to DOE’s stated goals for the IGCC program.

The panel then estimated the probability of achieving the specified levels of technical success, first assuming DOE’s program is carried out and then assuming it is not.

Three levels of plant availability were also defined, and the panel estimated the probability of reaching each of these levels of availability both with and without DOE’s R&D program. The estimated availability depended in part on the capital costs and efficiency for the plant.

-

80 percent availability,

-

85 percent availability, and

-

90 percent availability.

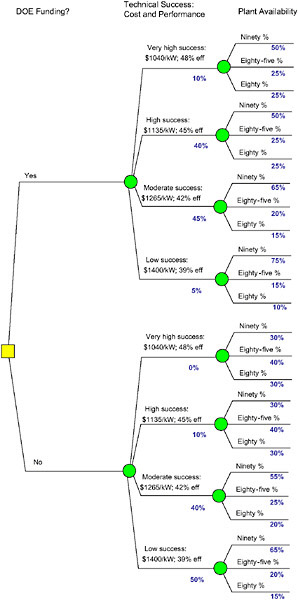

The panelists developed their probability estimates as a group during the second panel meeting. The consensus probabilities are shown in the decision tree in Figure H-1. Each path through the decision tree represents a level of overall technical success.

Market Success

As described above, the panel identified the key factors affecting the market success of IGCC technologies as fuel prices, the regulatory environment, and competing technologies. The impact of changes in fuel prices is captured by the High Oil and Gas Prices global scenario.

The primary factor that determines how many IGCC plants are built is how those plants compete with other technologies in terms of the COE. The panel identified the primary competing technologies as natural gas plants (if gas prices are low) and advanced coal combustion technologies (USC-PC and CFB). Other competing technologies include nuclear, advanced fuel cells, and renewables.

The panel also considered the results of DOE’s FY04 benefits analysis when it identified the primary competing technologies. That analysis identified PC plants, natural-gasfired turbines, fuel cells, and renewables (DOE, 2004, Figure 6.17) which is consistent with the panel’s assessment.

Quantification of Benefits

Introduction

The economic, environmental, and security benefits of improvements in IGCC technologies depend on the degree of technical improvement and the resulting reduction in the COE from IGCC plants, the amount of IGCC capacity added, the technologies that would have been implemented absent IGCC, and the relative costs of electricity with those nextbest alternatives.

The economic benefits that would be expected through technology advancements in IGCC technology include these:

-

The reduction in capital cost of IGCC plants that would be realized by R&D.

-

The increase in efficiency in IGCC plants that would be realized by R&D.

-

The quantifiable impact on environmental benefits of IGCC plants that would be realized by R&D.

-

The lower projected cost for removing CO2 emissions compared with the cost of using currently available technology for other coal technologies.

-

The impact on COE compared with the impacts of other options. COE is highly dependent on variables other than plant performance.

FIGURE H-1 Decision tree representing the panel’s assessment of the likely technical outcomes of IGCC R&D.

The panel estimated the economic benefits by focusing on the COE for IGCC plants relative to other options. The economic benefit in any one year is the product of the amount of IGCC-generated electricity produced and the difference between the COE with IGCC generation and the COE with the alternative technology. The total benefits are calculated as the net present value of the annual benefits stream assuming a 20-year plant life. To implement this method of estimating benefits, the panel developed two models: one for estimating the COE from different generation technologies and one for estimating the amount of IGCC capacity that would be built.

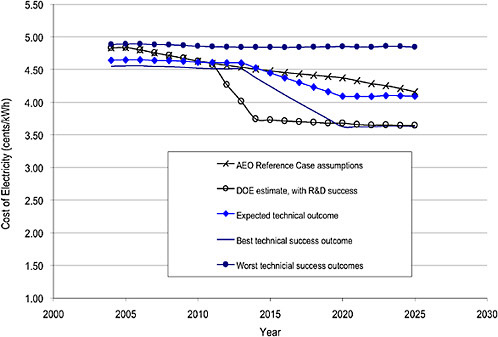

FIGURE H-2 Estimated COE for IGCC under different technical success assumptions for the AEO Reference Case global scenario.

Estimating the Cost of Electricity

The panel developed a simplified model for estimating the COE (i.e., the busbar costs) for IGCC and other technologies based on capital costs, plant efficiencies, operating and maintenance costs, and fuel costs.

The COEs for PC and NGCC plants—the presumed competitors to IGCC—were estimated based on plant characteristics taken directly from Assumptions to the Annual Energy Outlook: Electricity Market Module (EIA, 2005).7

The decision trees created by the panel specify a range of possible technical outcomes of IGCC research in terms of future capital costs, plant efficiencies, and plant availabilities, as described previously. For each of the 12 combinations of possible technical outcomes, a COE for IGCC plants can be calculated. Figure H-2 shows the range of the estimated COE over time for these different technical outcomes. The solid lines represent the COE for IGCC given the highest and lowest cost and performance outcomes from the panel’s decision tree assessments. The COE projections for all 12 of the technical success scenarios lie between these two lines, and the line with the diamond markers represents the COE over time based on the probability-weighted average of all 12 outcomes. This “average” performance would correspond to a hypothetical IGCC plant with capital costs of $1,197/kW, efficiency of 43.65 percent, and availability of 87 percent. The figure also shows the estimated COE for an IGCC plant based on the costs and efficiency assumptions in the AEO 2005 reference case, and the estimated COE for a “DOE success” case, assuming the IGCC research meets the goals set out by DOE over time. Note that the panel estimated it would take much longer for those costs and efficiencies to be achieved through widespread commercial deployment than DOE estimated in its analyses.

To the extent that IGCC reduces the impact of fuel price fluctuations by reducing the need for electric power plants that use natural gas (e.g., NGCC), this will be captured as a security benefit.

Estimating the Amount of IGCC Capacity Built

The amount of IGCC built in any year is a function of the COE for IGCC and for competing technologies, as well as other macroeconomic factors. DOE uses NEMS to make annual forecasts of the amount of electricity generation that will be added in the nation between now and 2025. The panel decided to use these NEMS new-generation build forecasts as a starting point for estimating IGCC capacity additions. DOE’s Office of Fossil Energy produces three build forecasts for IGCC based on different assumptions about the outcome of its R&D programs. There are forecasts for three cases:

-

A no-R&D case, which applies the AEO Reference Case assumptions to all technologies, including IGCC.

-

A case wherein the IGCC program is assumed to meet the technical goals established by DOE (e.g., $1,000/kW capital costs and 50 percent efficiency in 2014, increasing to 60 percent efficiency by 2024). This forecast for the case also assumes the success of all other DOE FE R&D programs, so that the IGCC technologies compete against conventional and other advanced technologies for market share.

-

A case wherein all FE R&D programs except the gasification R&D are assumed to succeed.

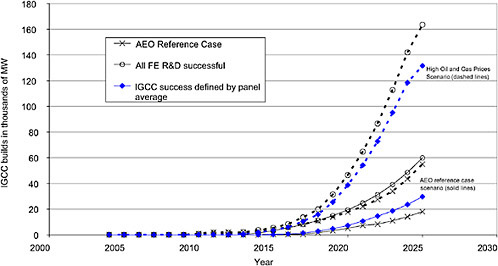

To estimate the amount of IGCC that would be built under any one of the technical success scenarios defined by the panel, a scaling function was employed based on the relative COEs for the three cases: for IGCC in the technical success scenario, for IGCC based on meeting DOE goals, and for competing technologies, including both PC and advanced natural gas plants. Figure H-3 illustrates the capacity of IGCC built in each year under the AEO Reference Case and the High Oil and Gas Prices global scenario, assuming IGCC performs at a level reflecting the average of the panel’s assessment of technical success. The figure also shows the quantities built in DOE’s analyses with and without DOE’s R&D programs.

The final step in estimating the benefit of IGCC advances is to establish what the next-best alternative technology would be; that is, to establish what type of generation will be built if IGCC is not cost-competitive. Based on the panel’s assessment of market risks, IGCC technologies will compete with both NGCC plants and other advanced coal technologies.

Based on a review of DOE’s FY04 benefits analysis and information presented by DOE to the panel, it appears that successful IGCC technologies compete with PC plants in some circumstances and with NGCC plants in others. Specifically, it appears that the success of other DOE FE research—for example, in distributed generation (DG)—affects what the next-best alternative to IGCC is: If DOE’s FE programs on other power systems are assumed to succeed, NGCC is the next-best technology, and if those programs do not succeed, PC is the next-best technology.

FIGURE H-3 Cumulative amount of IGCC built under three different technical success assumptions and two different global scenarios.

The panel also notes that other advanced coal technologies are currently under development (e.g., USC-PC) that could compete with IGCC. While assumptions about the success of DOE’s other FE R&D programs or other advanced coal technologies have a significant impact on the benefits calculation, it is outside the scope of the panel’s task to evaluate the chance of success. The panel’s benefit estimates are therefore based on the assumption that IGCC becomes the most cost-effective coal-based technology. To the degree that other coal-based technologies turn out to be more promising than IGCC, the benefits estimated here would be reduced. To address the issue of what technologies successful IGCC would compete with, the panel estimated benefits two ways: once assuming (conventional) PC is the next-best technology, and a second time assuming NGCC is the next-best technology.

Economic Benefits Analysis Results

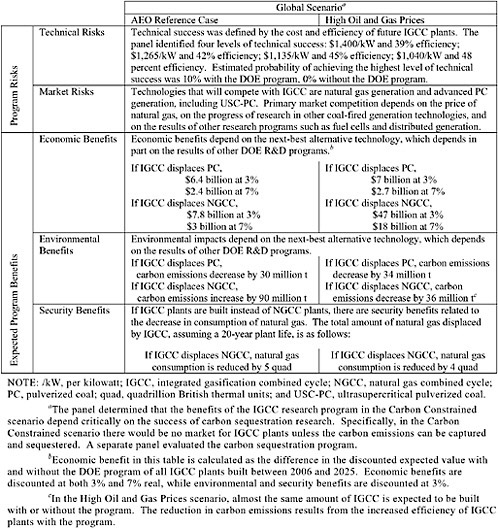

Using the simple models described above, it is possible to estimate the benefits of IGCC associated with each of the 12 technical success scenarios defined by the panel’s decision tree. For the lowest level of technical success the benefits are zero—no IGCC is built because the technology is not competitive. For the highest level of technical success, the net present value of the benefits is $30 to $33 billion8 for the AEO Reference Case global scenario, depending on whether IGCC is assumed to displace PC or NGCC.

Each of those technical success scenarios has two probabilities assigned to it by the panel: the probability of achieving that level of technical success without the DOE research program, and the probability of achieving that level of success with the DOE research program. The expected value of the IGCC improvements with or without DOE research is simply the probability-weighted average of the NPV for each technical success scenario using the appropriate probabilities. The value of the DOE research program is the difference between the expected value of IGCC research without the program and the expected value with the program.

Figure H-4 illustrates the expected economic benefits of the IGCC R&D, as well as the uncertainty surrounding those benefits assuming AEO Reference Case prices and that PC is the next-best alternative technology. The figure shows a cumulative distribution of net economic benefits with and without DOE support. The vertical lines represent the expected value of the benefits calculated as the probability-weighted average. The expected value of DOE’s IGCC research program in this scenario is $6.4 billion, the difference between the expected value with the program ($8.6 billion) and the expected value without the program ($2.2 billion).

The expected benefits of the DOE program differ from one global scenario to another and from one next-best technology to the other. For the AEO Reference Case scenario but assuming NGCC is the next-best technology, the expected value of the benefits increases to $7.8 billion.

Under the High Oil and Gas Prices scenario, there is much larger difference in expected benefits based on what is assumed about the next-best technology: If IGCC replaces PC, the benefits of the program are $7 billion, if it replaces NGCC, the benefits are $47 billion.

Environmental Benefits Analysis

The environmental benefits that could be attributable to technology advances in IGCC include these:

-

Reduction in regulated emissions, including sulfur oxides (SOx), nitrogen oxides (NOx), fine particulate matter (PM2.5), and mercury.

-

Reduction in CO2 emissions due to higher efficiency than other coal technologies.

-

Reduction in the amount of waste by-products compared to other coal-based technologies.

-

Reduction in water consumption compared to other coal-based technologies.

As suggested by the full committee, emissions of criteria pollutants (mercury and so forth) are assumed to occur at the regulated level for all fossil-fuel-based technologies. If reaching those limits is less costly for IGCC than for PC, that benefit is captured as an economic one rather than an environmental one.

There will be quantifiable differences in carbon emissions if IGCC is deployed instead of either of the next-best alternatives. When IGCC plants are assumed to displace conventional PC plants, carbon emissions will be reduced because the former are more efficient. When IGCC plants are assumed to displace NGCC plants, carbon emissions will be higher. Using the build quantities estimated for IGCC as described above and emissions factors for different power plants from the Annual Energy Outlook 2005 (EIA, 2005b), the panel was able to estimate the net change in carbon emissions attributable to the DOE’s IGCC research program. If IGCC replaces PC, the net reduction in carbon emissions is 30 million tons (discounted at 3 percent) over the full 20-year life of all plants built between 2006 and 2025 in the AEO Reference Case scenario and 34 million tons in the High Oil and Gas Prices scenario. If IGCC replaces NGCC, there will be a net increase in carbon emissions of 90 million tons (discounted at 3 percent) in the AEO Reference Case scenario. However, in the High Oil and Gas Prices scenario, large quantities of IGCC are expected to be built with or without the DOE R&D program. The higher efficiencies of

IGCC plants attained with the R&D program would decrease emissions by 36 million tons. Note that if IGCC plants were to replace USC-PC plants, the differences in carbon emissions would be negligible, because their thermal efficiencies are approximately the same.

Energy Security Benefits Analysis

The energy security benefits that could be seen through technology advancements in gasification technology because of the DOE IGCC program include the following:

-

Increased use of domestic coal rather than imported natural gas for power generation.

-

The ability to produce synthetic natural gas from coal.

-

The ability to produce liquid fuels from coal.

-

The ability to use coal rather than natural gas as a feedstock for the petrochemical industry.

-

Maintaining the nation’s technology leadership for both domestic and export applications as opposed to relying on importing technology from overseas.

If IGCC plants are built instead of natural gas plants, there are security benefits from the reduced usage of natural gas, especially to the degree that the reduced usage decreases the need for imports. Assuming IGCC plants replace NGCC plants, the net reduction in natural gas usage attributable to DOE’s research is 4 to 5 quads. The reduction in the demand for natural gas for electricity generation also helps to reduce the cost and increase the availability of natural gas for other purposes, such as chemical manufacture and residential and commercial use.

Results Matrix

Figure H-5 summarizes the results of the panel’s estimation of the benefits of DOE’s IGCC R&D program. Benefits are calculated as described in Chapter 3 for two scenarios: the AEO Reference Case and the High Oil and Gas Prices scenario.

SUMMARY AND RECOMMENDATIONS

Summary

Coal gasification and the rigorous cleanup of the product syngas have made the use of coal in gas turbines possible, opening the way to efficient and environmentally clean coalbased power generation in combinations of gas turbines and steam turbines.

While its capital cost is presently higher than that of a comparable size pulverized coal supercritical (SC/PC) steam plant, IGCC lends itself more favorably to retrofit with capture and compression of CO2 for sequestration. Success of DOE’s advanced gasification research is a prerequisite for IGCC’s timely commercialization.

Based on discussions with representatives of DOE, the panel extended the principal goals of the IGCC R&D program—efficiency and capital cost—to include availability, emissions, and COE. The panel evaluated the contributions of the major research projects under DOE’s Advanced Gasification Research. The evaluation included projects that promise to improve IGCC availability, such as Durable Refractory for Gasifier Lining, and Gasifier Instrumentation and Diagnostics, and others that promise to reduce capital cost and increase efficiency—for example, Ion Transport Membrane Air Separation, Dry Coal Feeding, and Warm Gas Cleanup. Projects such as the Rocketdyne Gasifier, the Transport Gasifier, and Chemical Looping, which represent stepwise advances in gasification technology and can be expected to reduce costs and improve efficiency in the longer term, were also evaluated.

Technical risks for the individual projects have been identified; these are generally associated with the possibility that the researchers might not reach their goal, the results might not be scalable, or the capital cost and/or the parasitic energy requirement might be excessive. The panel quantified the technical risks and posited 12 future technical outcomes of IGCC research both with and without the impact of the DOE program. The 12 outcomes were defined in terms of capital costs, plant efficiencies, and plant availabilities. The prospects for cost and efficiency have been assessed as follows:

-

5 percent chance of achieving only minor improvements over today’s technologies (39 percent efficiency and an nth plant capital cost of $1,400/kW) with the DOE program and a 50 percent chance of achieving only these minor improvements without it.

-

45 percent chance achieving η = 42 percent (HHV) efficiency and an nth plant capital cost of $1,265/kW with the DOE program and 40 percent without it.

-

40 percent chance of achieving η = 45 percent and an nth plant capital cost of $1,135/kW with the DOE program and 10 percent without it.

-

10 percent chance of achieving η = 48 percent and an nth plant capital cost of capital cost of $1,040/kW with the DOE program and 0 percent without it.9

For each of the above four cost and efficiency levels, plant availability was assessed at three levels—80, 85, and 90 percent. These comprise the 12 technical success scenarios.

The target date of 2010 given for the above goals is the time when the research will have been completed. This stage is to be followed by demonstration and commercial deployment—the latter to occur through operation of the nth

FIGURE H-5 Results matrix of the Panel on DOE’s Integrated Gasification Combined Cycle Technology R&D Program.

plant. The panel believes a grid-ready plant with the claimed improvements will be available by around 2024.

Market risks to the IGCC program are represented by reduced priced natural gas, competing technologies, and an unfavorable regulatory environment. IGCC deployment would benefit from the gradual imposition of carbon constraints, but the reemergence of moderate natural gas prices (<$5.00/MMBtu), combined with premature imposition of an aggressive mandatory control on CO2, is considered to be the greatest risk to IGCC’s market penetration.

Advancements in USC/PC and CFB combustion technologies in the near term—and, if accompanied by cost-effective oxy-combustion for CO2 sequestration, also in the longer term—represent the biggest technology threats to IGCC deployment and commercialization.

The IGCC R&D program’s benefits also come in the

economic, environmental, and energy security categories. IGCC is a technology that allows coal, an indigenous energy source, to be used cleanly, in compliance with environmental expectations. It is the route to zero-emissions power generation, to hybrid power plants with fuel cells, and to the economic capture and sequestration of CO2. Its successful implementation will favorably affect public health, national security, the balance of payments, the competitiveness of energy-intensive industries, and jobs in the sector.

Conclusions

-

IGCC has a favorable cost and efficiency outlook, but successful market penetration requires more operational experience to be gained in the near term while IGCC is still more expensive and is perceived to have lower availability than alternative coal technologies. Speeding up the research on topics that improve IGCC plant availability—such as durable refractory, dry coal feed, instrumentation and diagnostics, and improved availability of the syngas-fired gas turbine—would hasten implementation of IGCC technology.

-

Efficiency is an important goal of the IGCC program. Increased efficiency saves fuel and also reduces emissions, but it can also result in a more complicated plant and, hence, reduced availability. When there is a conflict between efficiency and availability, as in the case of extensive subsystems integration, it is recommended that, at least for the near term, availability should be favored over efficiency increases.

-

The date in DOE’s program goals is the time when the research will have been completed to enable the construction of a demonstration plant. The claimed improvements would then be realized only after experience with the demonstration plant and the subsequent operation of commercial plants. A clearer definition of the timeline of this process would help in assessment of the time at which the benefits of the research can be expected to accrue.

ATTACHMENT A

PANEL MEMBERS’ BIOGRAPHIES

Jack S. Siegel, Chair, is a principal with the consulting firm Energy Resources International, Inc., and president of its Technology and Markets Group. While at the U.S. Department of Energy (DOE), he held various positions of leadership, including deputy assistant secretary for coal technology and acting assistant secretary for fossil energy. Prior to DOE, he was at the U.S. Environmental Protection Agency and led efforts to regulate and enforce the Clean Air Act of 1970. Mr. Siegel has broad and extensive experience on energy and environmental issues and has recently been involved in studies on markets and barriers to clean coal technologies; conventional and advanced turbines; renewable energy systems; distributed power systems; the impact of electric power restructuring on fuel and technology choices in the energy sector; options for reductions of greenhouse gases; and energy and environmental analysis in support of a number of foreign countries, the World Bank, and the Global Environment Facility. He served as a member of the NRC Committee on Challenges, Opportunities, and Possibilities for Cooperation in the Energy Futures of China and the United States and was a member of the Committee on Benefits of DOE’s R&D on Energy Efficiency and Fossil Energy and the Phase One committee. He has received the Presidential Award for Superior Achievement (1992) and the Secretary of Energy’s Gold Medal for Outstanding Performance (1994). He has a B.S. in chemical engineering from Worcester Polytechnic Institute.

Rakesh Agrawal (NAE) is Winthrop Stone Distinguished Professor of Chemical Engineering at Purdue University, where he has worked since 2004. From 1980 until 2004, he was employed at Air Products and Chemicals, most recently as an Air Products fellow. His research interests include basic and applied research in gas separations, process development, synthesis of distillation column configurations, adsorption and membrane separation processes, novel separation processes, gas liquefaction processes, cryogenics, and thermodynamics. Dr. Agrawal has broad experience in hydrogen production and purification technologies. His current interest is in energy production issues especially from renewable sources such as solar. He holds 116 U.S. patents and more then 300 foreign patents. He has authored 64 technical papers and given many lectures and presentations. He chaired the Separations Division and the Chemical Technology Operating Council of the American Institute of Chemical Engineers and also a Gordon Research Conference on separations. He was a member of the NRC Committee on Alternatives and Strategies for Future Hydrogen Production and Use. Dr. Agrawal received a B.Tech. from the Indian Institute of Technology, in Kanpur, India; an M.Ch.E. from the University of Delaware; and an Sc.D. in chemical engineering from the Massachusetts Institute of Technology.

Janos Beer is currently professor emeritus of chemical and fuel engineering at the Massachusetts Institute of Technology. He is also a member of the National Coal Council, which provides guidance to the U.S. Secretary of Energy. Dr. Beer’s current research interests include clean fossil energy electric power generation; turbulent combustion of gaseous, liquid, and solid fuels; and reduction of pollutant emissions from combustion processes. He has headed divisions of several prestigious research facilities, including the Combustion Section at the Budapest Heat Research Institute and The Netherlands Research Station of the International Flame Research Foundation. He served as dean of engineering from 1973 to 1976 at the University of Sheffield, England, and as director of the MIT Combustion Research Facility from 1976 to 1993. Dr. Beer earned his economics and engineering degrees at the Jozsef Nador University of

Technical and Economic Science in Budapest in the 1940s. He achieved his Ph.D. in 1960 and D.Sc. (Tech.) in 1968 at the University of Sheffield, England.

Francis P. Burke is vice president, research and development, CONSOL, Inc. Dr. Burke has been with CONSOL since 1975, engaging in a wide variety of coal-related R&D, including the development of technology for coal conversion and emissions control. His research activities have related to trace elements in coal and coal utilization processes; coal liquefaction process development; control technology development for oxides of sulfur and nitrogen; coal-related wasted management and utilization; and methanol reforming and synthesis. He has been involved in numerous national and international workshops and symposia on coal-related R&D needs. He has a B.S. in chemistry from Gonzaga University, a Ph.D. in physical chemistry from Iowa State University, and an executive education from the Darden School of Business, University of Virginia.

Linda R. Cohen is a professor of economics at the University of California, Irvine. She was previously chair of the Department of Economics, University of California, Irvine, where she taught in various capacities with increasing responsibility since 1987. Previously, Dr. Cohen was an economist associate at the Rand Corporation, a research associate for economics with the Brookings Institution, a senior economist at the California Institute of Technology’s Environmental Quality Laboratory, and an assistant professor of public policy at Harvard University’s Kennedy School of Government. She has been the Gilbert White Visiting Fellow at Resources for the Future, the Olin Visiting Professor in Law and Economics at the University of Southern California Law School in 1993 and 1998, a fellow of the California Council for Science and Technology in 1998, and a research fellow at the Brookings Institution in 1977. Dr. Cohen has written many articles and coauthored a book on federal research and technology policy. She is currently a member of the editorial board of Public Choice and a member of the California Energy Commission’s Advisory Panel for the Public Interest Energy Research Program. She has served on a variety of panels and committees and was a member of the NRC Committee on Benefits of DOE’s R&D on Energy Efficiency and Fossil Energy and of the Phase One committee. She has an A.B. degree in mathematics from the University of California at Berkeley and received her Ph.D. in social sciences from the California Institute of Technology.

Frank P. Incropera (NAE) is McCloskey Dean of Engineering and Brosey Professor of Mechanical Engineering, University of Notre Dame. His previous positions included head, School of Mechanical Engineering, Purdue University; visiting scholar, Mechanical Engineering Department, University of California, Berkeley; professor, School of Mechanical Engineering, Purdue University; and others. He has been a visiting scholar at a number of universities. He has been the recipient of numerous awards, including fellow, American Society of Mechanical Engineering (ASME); Senior United States Scientist Award of the Alexander von Humboldt Foundation (Bonn); Heat Transfer Memorial Award of the ASME; Worcester Reed Warner Award of the ASME; and has been named as one of the world’s 100 most highly cited researchers in all fields of engineering. He has served on the NRC’s Department of Energy Panel on Integrated Manufacturing and the Panel on Engineering, Applied Sciences, and Applied Mathematics. His expertise spans a wide range of heat transfer research, including all forms of convection, boiling, and two-phase flow, radiative transfer, and engineering applications, as well as manufacturing processes and materials engineering. He has an S.B. in mechanical engineering from the Massachusetts Institute of Technology and an M.S. and a Ph.D. in mechanical engineering from Stanford University.

Mike Mudd has over 30 years experience in the utility industry, with most of his career having been focused on coal-fired generation. He has been involved in the design, construction, start-up, and operation of large coal-fired power plants, including American Electric Power’s 1,300-MW and 600MW coal-fired power plants. He was responsible for several clean coal technology demonstration projects, including as project manager for the 70-MW Tidd pressurized, fluidizedbed combustion (PFBC) demonstration plant, the first such power plant in North America, built with the cooperation of the DOE and the Ohio Coal Development Office. In 1996, Mr. Mudd moved to AEP Resources, where he was a developer in the nonregulated utility business, responsible for the development of cogeneration projects in the United States and Canada and independent power producer projects in Mexico. In 2002, he returned to the R&D arena with AEP, where in his current position he is responsible for corporate R&D associated with energy supply technologies, including coal, gas, nuclear, and renewable energy technologies. Mr. Mudd is currently on the FutureGen Alliance board of directors and is playing a key role in the development of AEP’s recently announced IGCC project. He is active in several industry associations, including participation in committees associated with the Coal Utilization Research Council, EPRI, and the National Coal Council. Mr. Mudd chaired a working group on a study for the National Coal Council on opportunities to expedite the construction of new coal-fired power plants that was published in 2005. He also serves on the IGCC Expert Working Group for the EPRI CoalFleet program. Mr. Mudd has a B.E. and postgraduate studies from Stevens Institute of Technology.

Ronald H. Wolk is principal, Wolk Integrated Technical Services. His previous positions include director, Advanced Fossil Power Systems Department, Electric Power Research Institute, and Associate Laboratory Director, Hydrocarbon Research, Inc. Mr. Wolk has extensive experience in as-

sessing, developing, and commercializing advanced power generation and fuel conversion technologies, including fuel cell, gas turbine, distributed power generation, and integrated gasification combined-cycle technology systems. He served on the NRC Committee on R&D Opportunities for Advanced Fossil-Fueled Energy Complexes. He has a B.S. and an M.S. in chemical engineering from the Polytechnic Institute of Brooklyn (now Polytechnic University).

ATTACHMENT B

ESTIMATION DETAILS

Introduction

The benefits of IGCC depend ultimately on how many such plants are placed into operation and on the subsequent cost of electricity, the environmental consequences of electricity production, and the security implications of the industry structure. Demand for IGCC and its benefits depend on costs of alternative technologies, fuel cost and availability, demand for electricity, and constraints on the electrical system such as the need for peak load plants. Because of the important feedbacks between demand and prices and the interactions between different technologies on prices, costs, and demand for each, estimating IGCC benefits is a complex undertaking. Sophisticated computer modeling, such as the NEMS model employed by DOE, necessarily plays a critical role in benefit assessments. At the same time, the NEMS model is resource-intensive in itself, and given the many options that this study considers, the long time horizon and related uncertainly about the trajectory of fuel prices, the state of alternative technologies, and economy-wide factors that affect electricity demand, the simplifications that are employed here provide a ballpark estimate that is probably within the range of estimates that more sophisticated modeling efforts would yield. The NEMS estimates made for the four scenarios and two R&D cases,10 which were used as a starting point for the panel’s analysis, were modified in the ways discussed below. Some additional NEMS estimates, discussed below, would be useful for refining and checking the panel’s estimates.

The analysis in this attachment is based on three sets of numbers from the NEMS output:

-

Estimates of costs of electricity from IGCC and alternative technologies and of relative capacities of the different technologies deployed, given no DOE R&D program.

-

Estimates of costs and deployment given successful—that is, programs attain all of the program goals related to cost, timing, and performance—DOE R&D for all FE components other than IGCC.

-

Estimates of costs and deployment given successful DOE R&D for all FE program components, including IGCC.

The panel modified the NEMS estimates to account for variations in cost, timing, and performance for IGCC. It also modified them to correspond to a set of assumptions necessary for appropriate consideration of the technologies displaced by IGCC. Each of these is discussed here.

Cost and Performance

The capital cost, availability, and efficiency assumptions on each branch of the decision tree (Figure H-1) yield a levelized COE given the relative contributions to cost in the AEO ascribed to each electricity generation technology. When the estimated cost is smaller than that given by the AEO Reference Case, IGCC should fare better and the alternative worse; when the estimated cost is larger, the reverse situation holds. A scaling procedure that rests on a locally linear demand relationship for the different technologies allows an estimate to be made of the quantity of IGCC (i.e., the capacity) under the revised cost conditions. Let XALT be the average cost of the alternative technology; XIGCC be the average cost of IGCC; b be the change in the average cost of IGCC; Q0IGCC be the original quantity of IGCC added during the year (the AEO estimate); Q1IGCC be the quantity of IGCC added given the change in average cost; and d be the difference in quantities in the two cases:

Then,

and

As is discussed above, the panel concluded that the DOE time goals for IGCC are optimistic. The panel thought a more likely time frame allowed completion of the R&D program in 2014, with prototypes and demonstration experience such that full competitive consideration of the technology would be possible in 2020. This time frame is in part reflected in the NEMS study, which allows only limited construction of IGCC in the years between 2012 and 2018 notwithstanding the formal completion of the R&D program. The panel’s assessment is thus only somewhat more limited than that given by the NEMS model, although it departs formally from the DOE goal.

The panel’s adjustment of the NEMS estimates of newly installed capacity relied on changing the capital cost estimates for IGCC, which was allowed to decline linearly from

$1,400/W in 2014—the current estimated capital cost—to the cost corresponding to the level of technical success achieved by 2020. This procedure allows a steady introduction of IGCC during the development and demonstration period, with full commercial credit given in 2020.

Competing Technologies

The NEMS runs made available to the panel by the Office of Fossil Energy provide an interesting illustration of the interaction among different DOE programs. According to the NEMS calculations, successful completion of other DOE program components leads to a large increase in baseload electricity generation in the United States. The amount of base (coal and NGCC) generation increases dramatically, the amount of distributed generation increases, and the contribution of gas turbines and diesel generators falls. These changes occur in both the Reference Case and the High Oil and Gas Prices scenario. According to the NEMS estimates, NGCC dominates additions to base capacity generation absent the DOE IGCC R&D program. With IGCC R&D, IGCC substitutes for an increasing share of NGCC capacity. Under the High Oil and Gas Prices scenario, it displaces NGCC in the later years. In the NEMS scenario, other coal technologies—in particular, advanced PC units—are dominated by both IGCC and NGCC given the reduction in gas prices that results from other DOE R&D activities.

In the absence of all DOE R&D, total baseload demand in the United States is much lower and natural gas prices relatively high. One consequence is that pulverized coal continues to compete with NGCC, but the combined demand for NGCC and PC is less than when DOE pursues R&D, either with or without an IGCC component. The panel did not have NEMS output for the case where only IGCC R&D is pursued. Given the other studies, however, it is possible to deduce that IGCC would further divide the baseload market between the coal and gas technologies. In this case, IGCC would compete initially with PC. In addition, if the cost of IGCC is low, it would also compete for some of the NGCC plants. The NEMS results imply that DOE’s R&D program has complementary components: Success in DG and other distributed energy resources (DER) programs increases demand for IGCC. Similarly, success in the sequestration program increases IGCC demand in Carbon Constrained scenarios. Thus the economic benefits from the IGCC program are larger when the entire DOE program is successful than when only components of it are pursued to completion. The security and environmental benefits of IGCC change with success in the larger DOE program. If the entire program is pursued, IGCC replaces substantial gas generation, with positive security benefits and negative environmental consequences. If the remaining program is not undertaken, the environmental benefits of IGCC may be substantial, depending on emissions from PC plants, but the security benefits are negligible.